Washing machine defoaming method

A washing machine and defoaming technology, which is applied to other washing machines, control devices of washing machines, washing devices, etc., can solve the problems such as the inability to increase the dehydration speed, the pollution of the residence environment, and the reduction of the dehydration rate, so as to improve the dehydration rate and the rinsing rate. The effect of protecting the residential environment and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

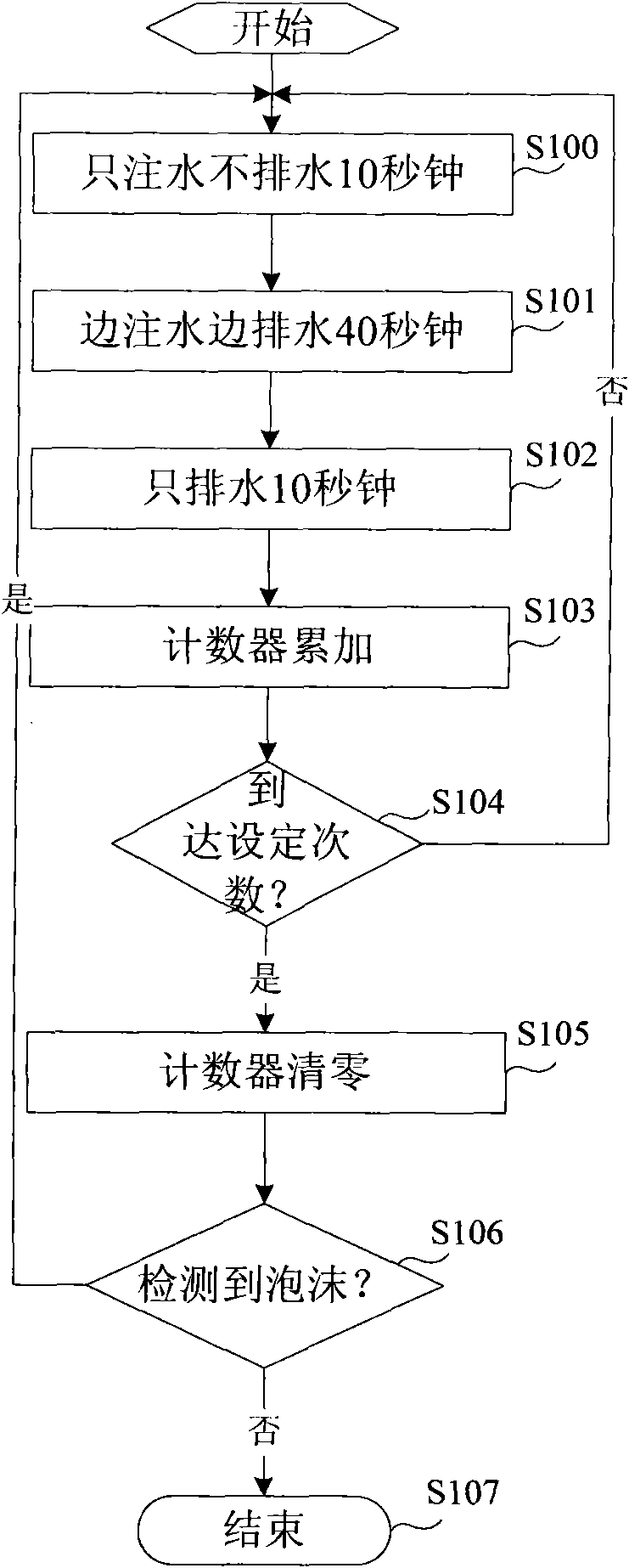

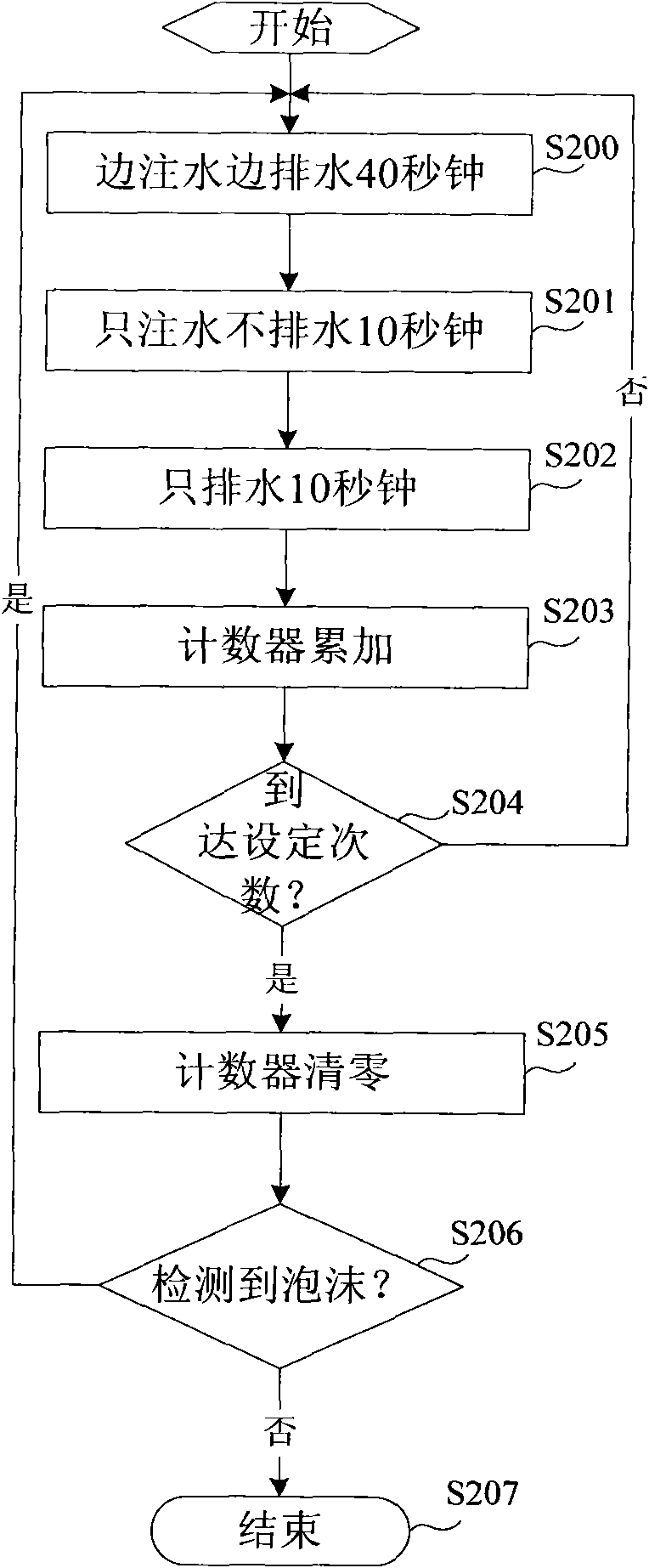

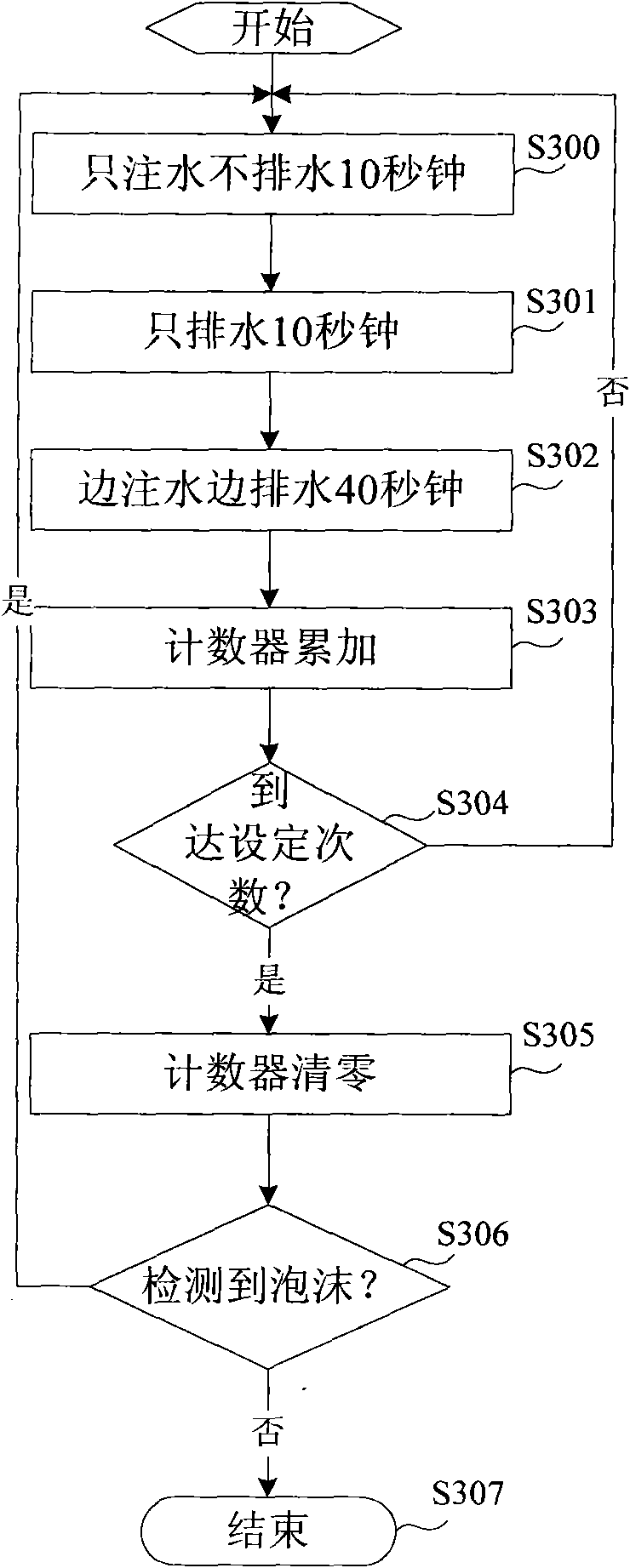

[0023] During the laundry process, if too much foam is detected during the distribution pulse process, defoaming treatment is required; the defoaming treatment here can be adopted figure 1 , figure 2 , image 3 Any one of the three embodiments shown will be described in detail below.

[0024] refer to figure 1 , illustrates a flow chart of a first embodiment of a method for defoaming a washing machine according to the present invention. As shown in the figure, the following steps are included:

[0025] Step S100, only injecting water without draining water for 10 seconds.

[0026] That is, at this moment, the water inlet valve is opened and the water outlet valve is closed for 10 seconds. Because in the washing process, generally there will be foam pouring into the water injection tank, and then it may further overflow to the outside of the barrel, thereby cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com