Plunger-cylinder assembly

A component and piston technology, applied in non-mechanical drive clutches, fluid drive clutches, clutches, etc., can solve the problems of interference, troublesome construction of connecting parts of piston-cylinder components, etc., and achieve the effect of simple connection, reliable mechanical fixation and electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

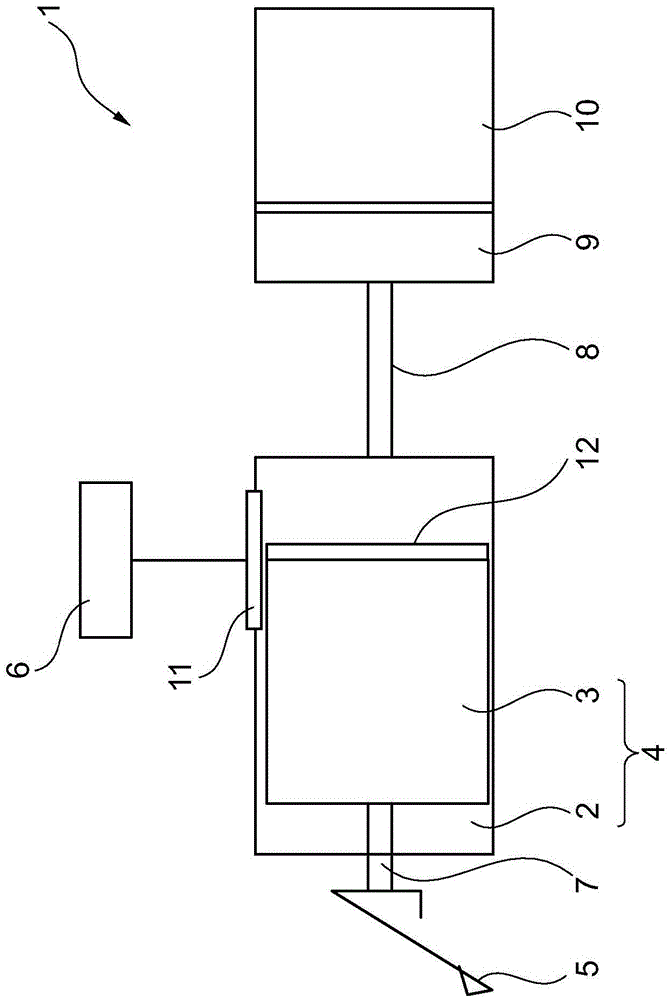

[0021] exist figure 1 A hydraulic clutch system 1 as it would be used in a motor vehicle is shown in . Such a clutch system 1 has a hydraulic actuation system in the form of a clutch master cylinder 4 , which comprises a cylinder designed as a housing 2 in which a piston 3 is mounted axially movable. The piston 3 is actuated by a clutch pedal 5 which acts on a piston rod 7 . The clutch master cylinder 4 is connected with the slave cylinder 9 for actuating the clutch 10 through a hydraulic line 8 . The adjustment of the position of the clutch 10 takes place on the basis of the actuation of the piston 3 via the clutch pedal 5 . In this case, clutch master cylinder 4 and clutch 10 with slave cylinder 9 are arranged spatially separated in the motor vehicle.

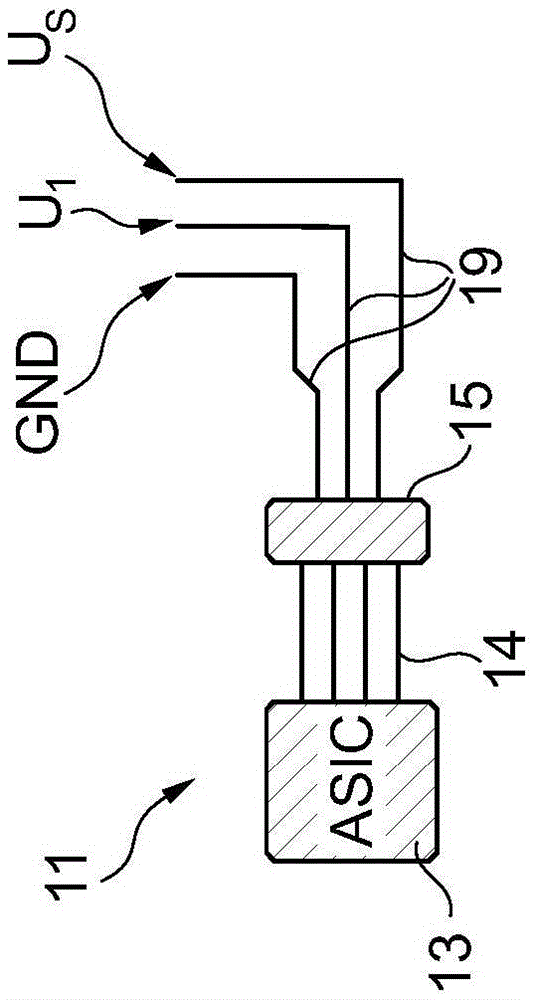

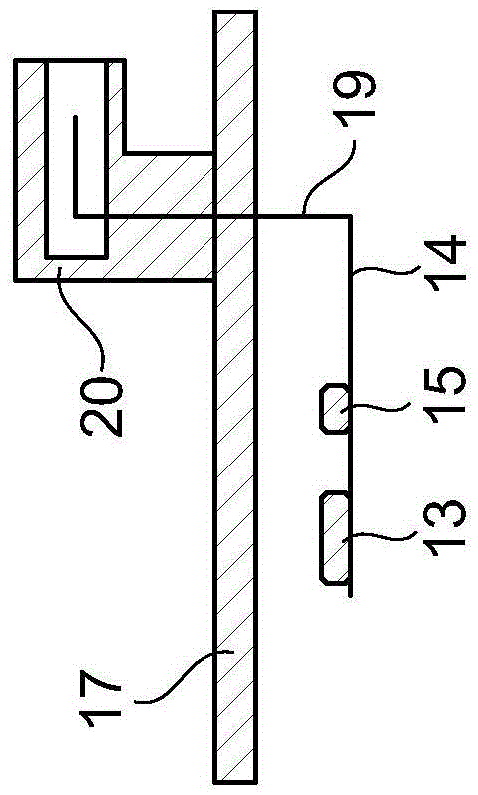

[0022] Arranged on the outside of the cylinder serving as housing 2 is an inductive sensor system 11 , opposite said inductive sensor system an electrically conductive target 12 fastened to the end face of piston 3 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com