Grouping method and grouping device

An item group, horizontal direction technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problem of large mass to be moved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

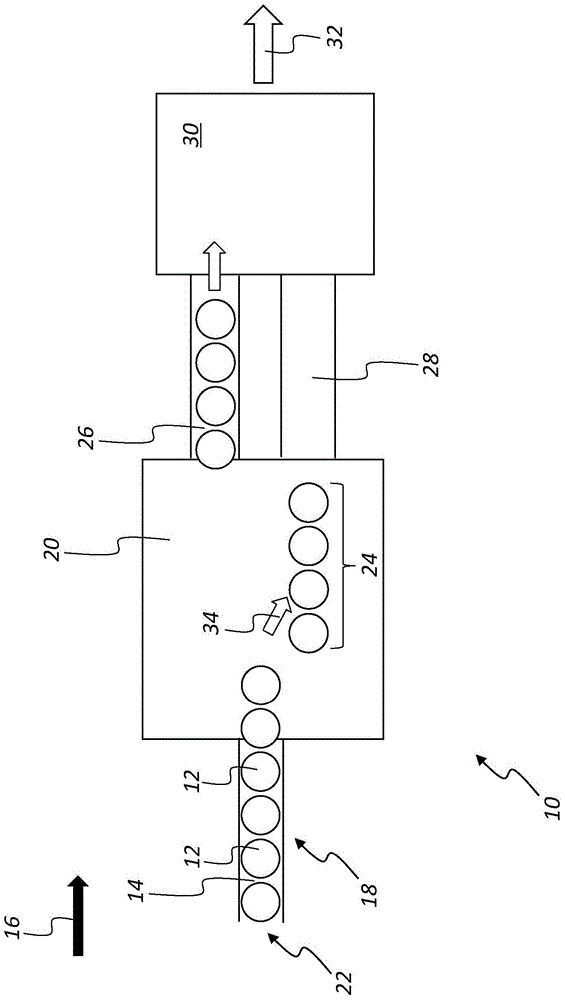

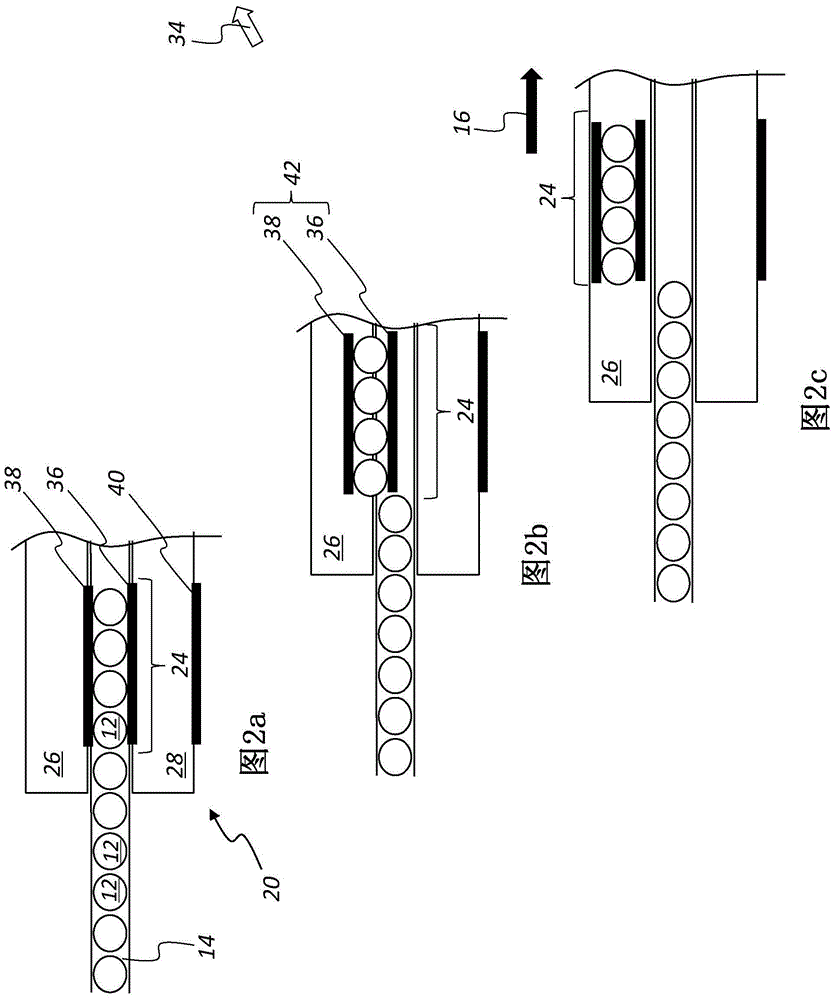

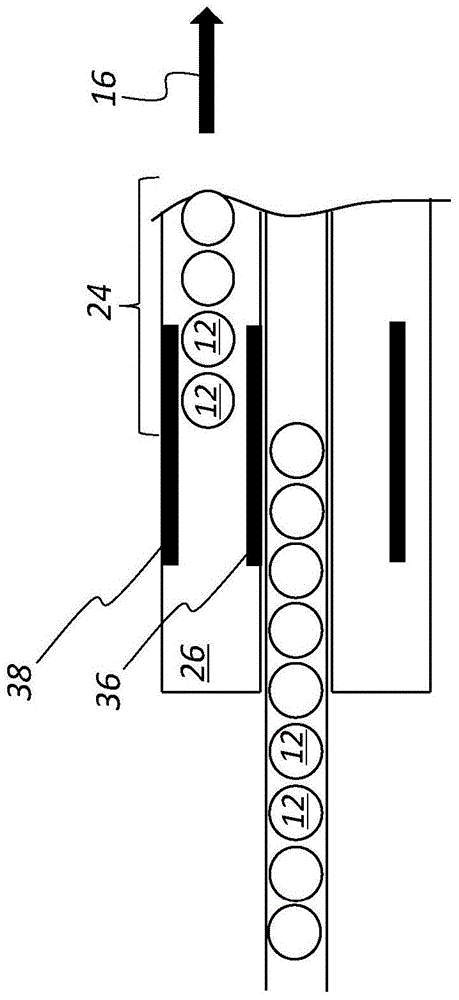

[0030] figure 1 The schematic illustration of shows the synergistic parts of the device 10 according to the invention for grouping objects 12, such as containers, bundles, individual goods or the like, which can be seen from the left by means of The infeed mechanism 14 is regularly and sequentially conveyed to the grouping mechanism 20 in the overall row 8 along the horizontal transport direction 16 . Within this grouping mechanism 20, the continuous conveying flow 22 of objects 12 defined by the input mechanism 14 is divided into a plurality of successive groups 24 each defining the number of objects and moved into two groups arranged in the conveying direction 16. In parallel transfer channels 26 (upper) and 28 (lower) downstream of mechanism 20 . The parallel conveying channels 26 and 28 in which the group 24 of a defined number of articles is conveyed further can for example lead to a grouping mechanism, a palletizing mechanism and / or other manually operated mechanism or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com