Method of treatment installation with strip-shaped metal band and corresponding treatment installation

A metal belt and ring technology, applied in textiles and papermaking, calendering, papermaking, etc., can solve the problems of paper thickness characteristic defects, defective thickness and humidity characteristics, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

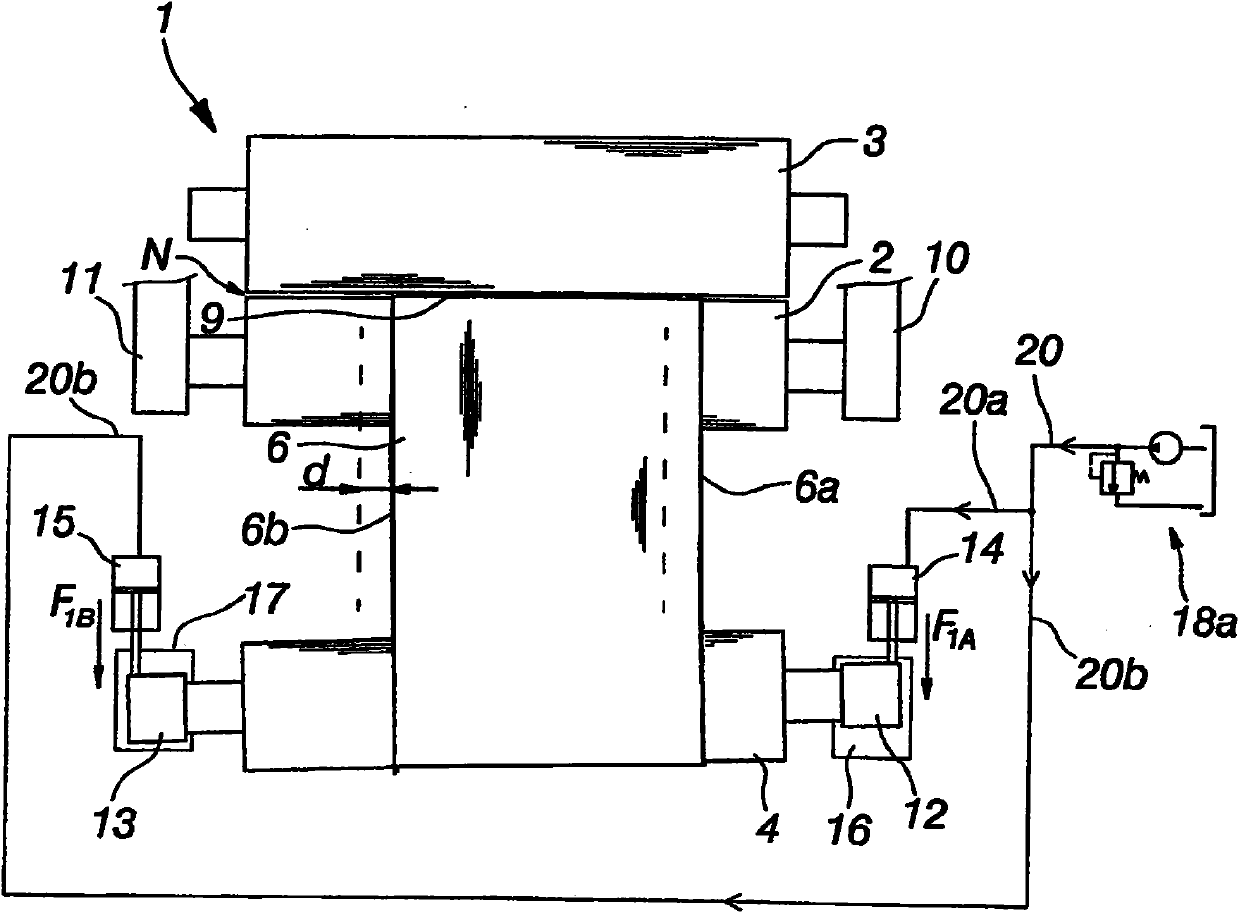

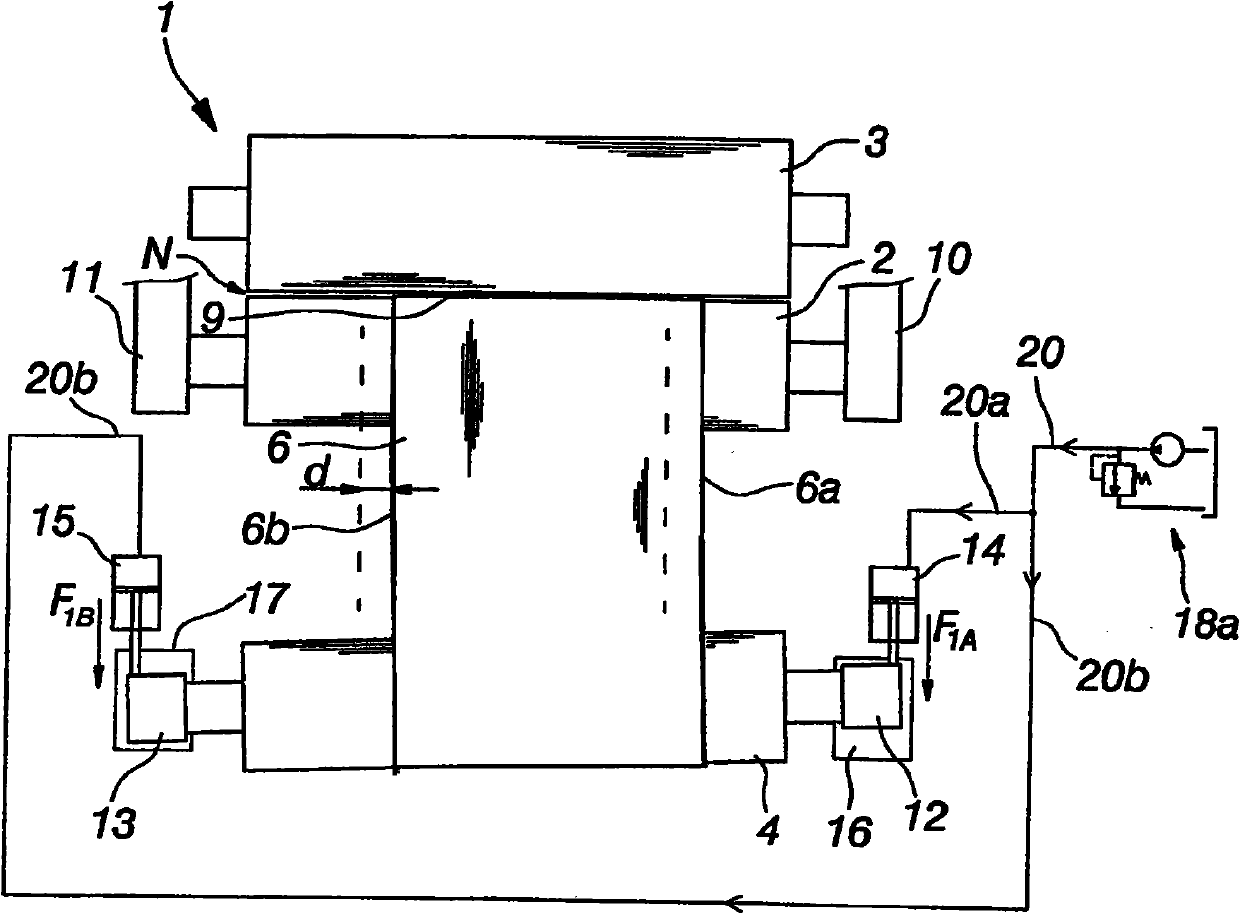

[0013] figure 1 An exemplary front view of a processing plant, embodied as a metal belt calender 1 , for applying the method according to the invention is shown. figure 1 Only the part of the metal belt calender important for the description of the invention is shown, for example with a polymer roll 2 with a soft surface, the shaft of which is supported on supports 10 and 11 on the bearing. The polymer roll 2 can have a fixed shaft or a shaft that rotates with the sleeve. Arranged axially parallel to polymer roll 2 in the vicinity of polymer roll 2 is guide roll 4 , which is supported via shaft ends on bearings 12 and 13 .

[0014] The roller can also be embodied as a roller supported centrally on the inside. An endless metal belt 6 is arranged around the polymer roll 2 and the sleeve of the guide roll 4 . The belt 6 travels with the rollers 2 and 4 and the roller sleeves along a closed, endless track at a position in the axial direction of the rollers. The belt calender ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com