Patents

Literature

274results about "Wire rings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

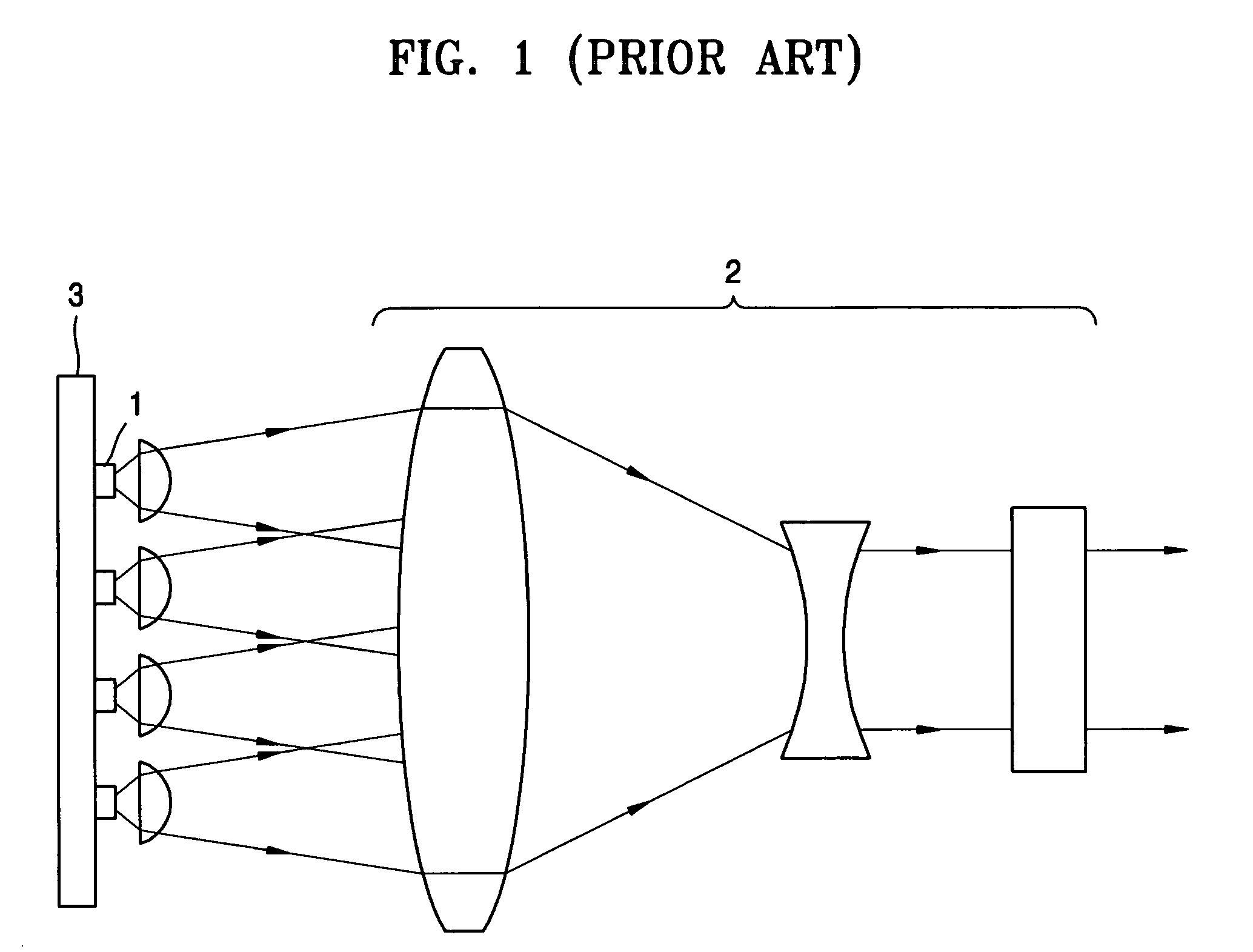

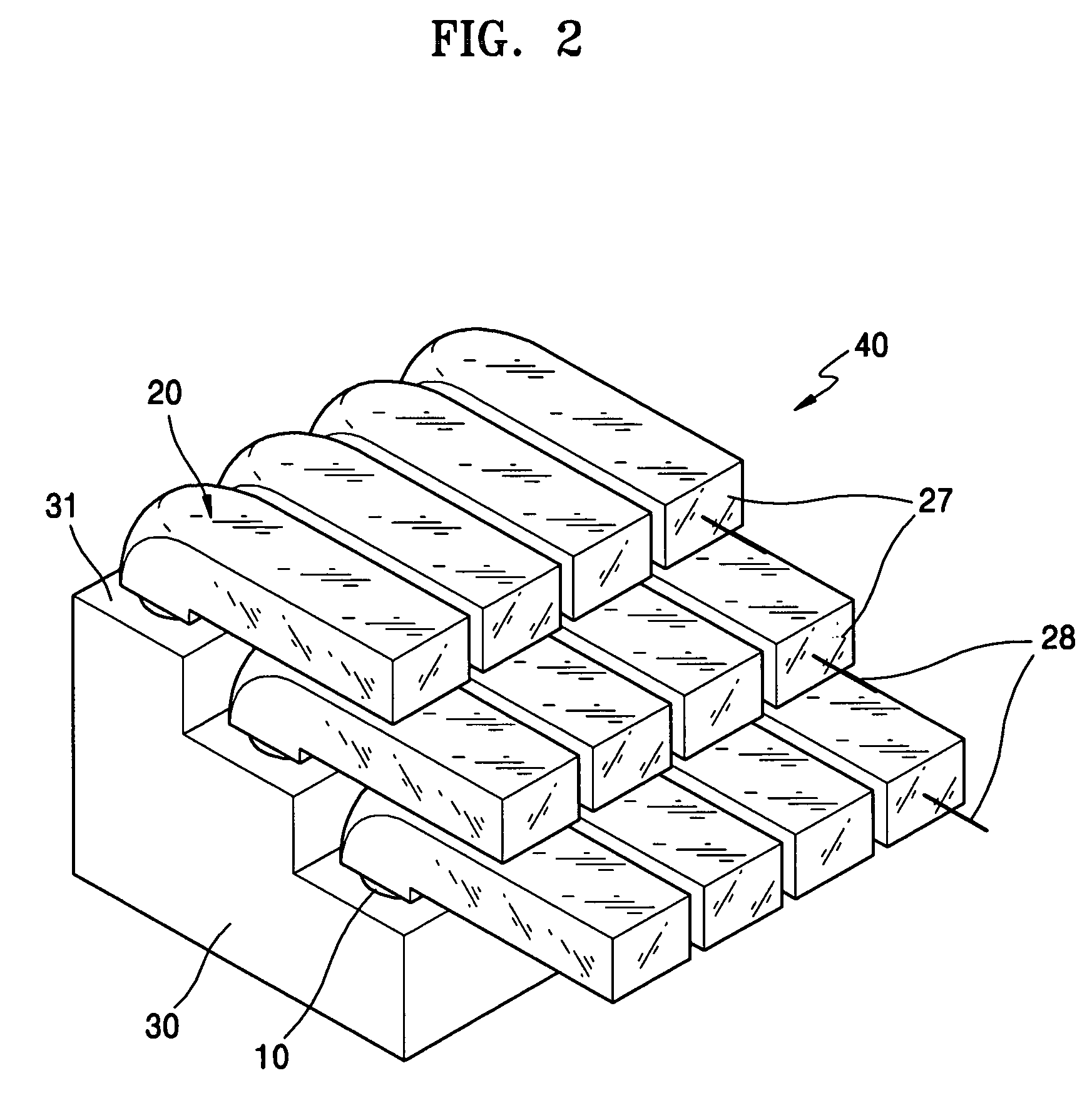

Illuminating unit and projection type image display apparatus using the same

InactiveUS20060203486A1Efficient dischargePoint-like light sourcePortable electric lightingLight guideLight beam

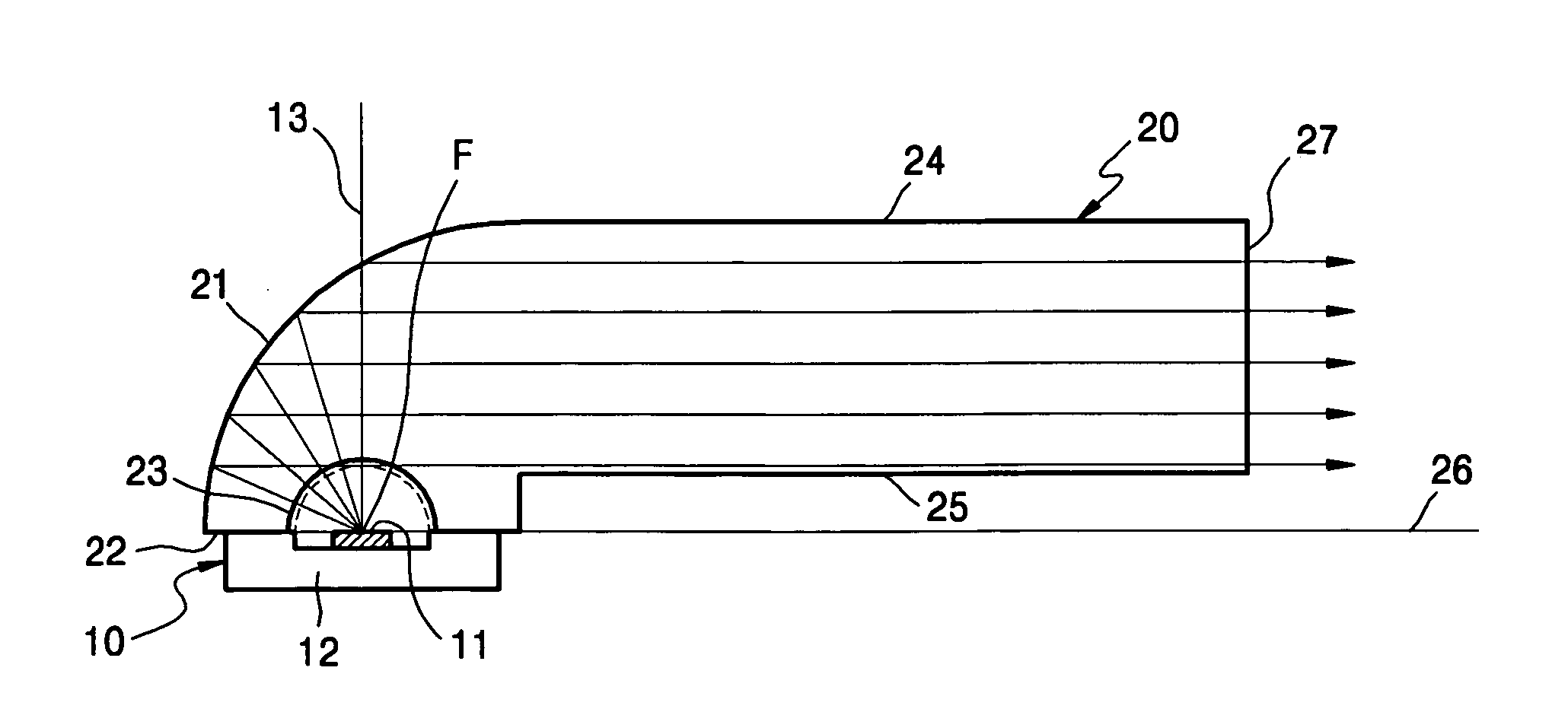

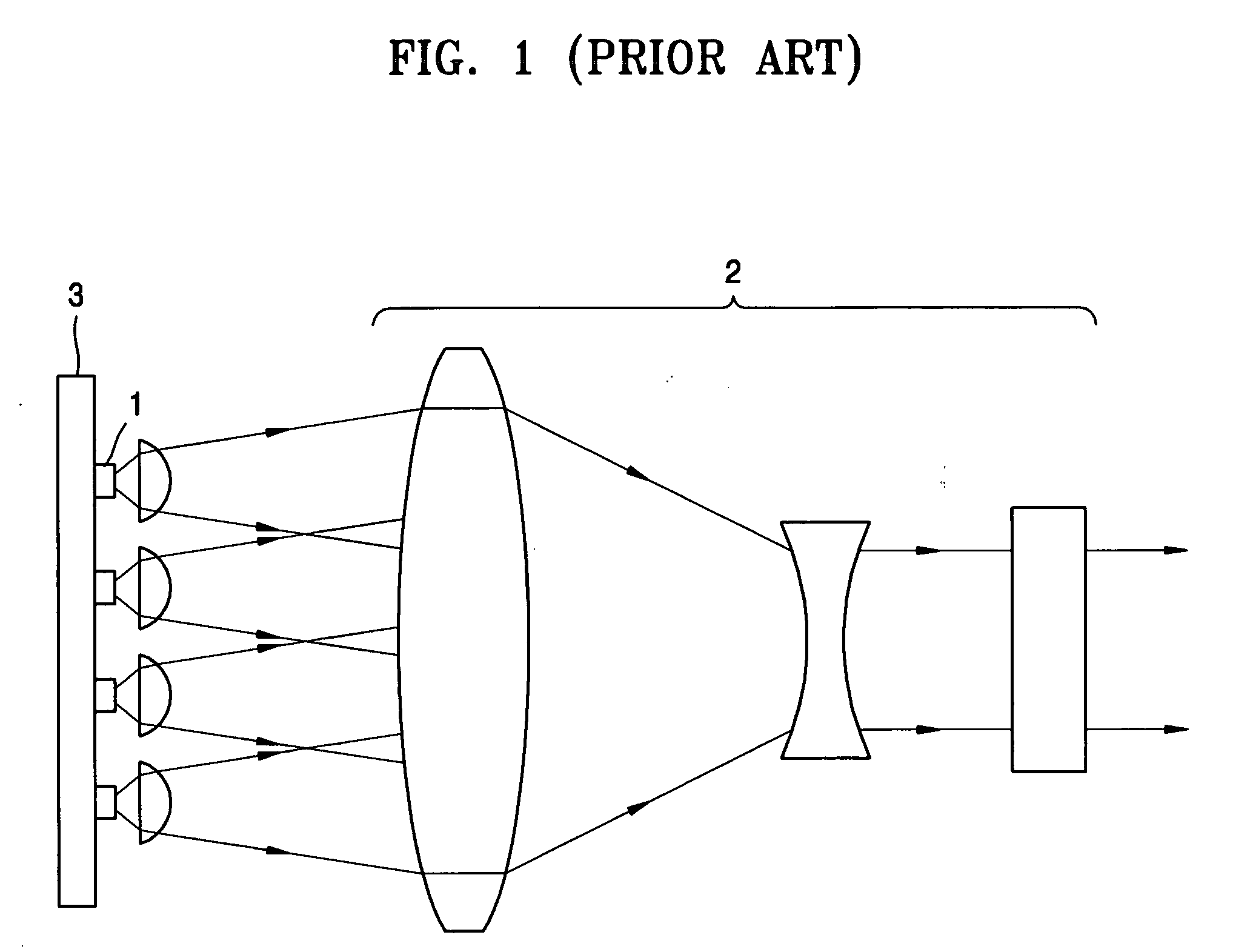

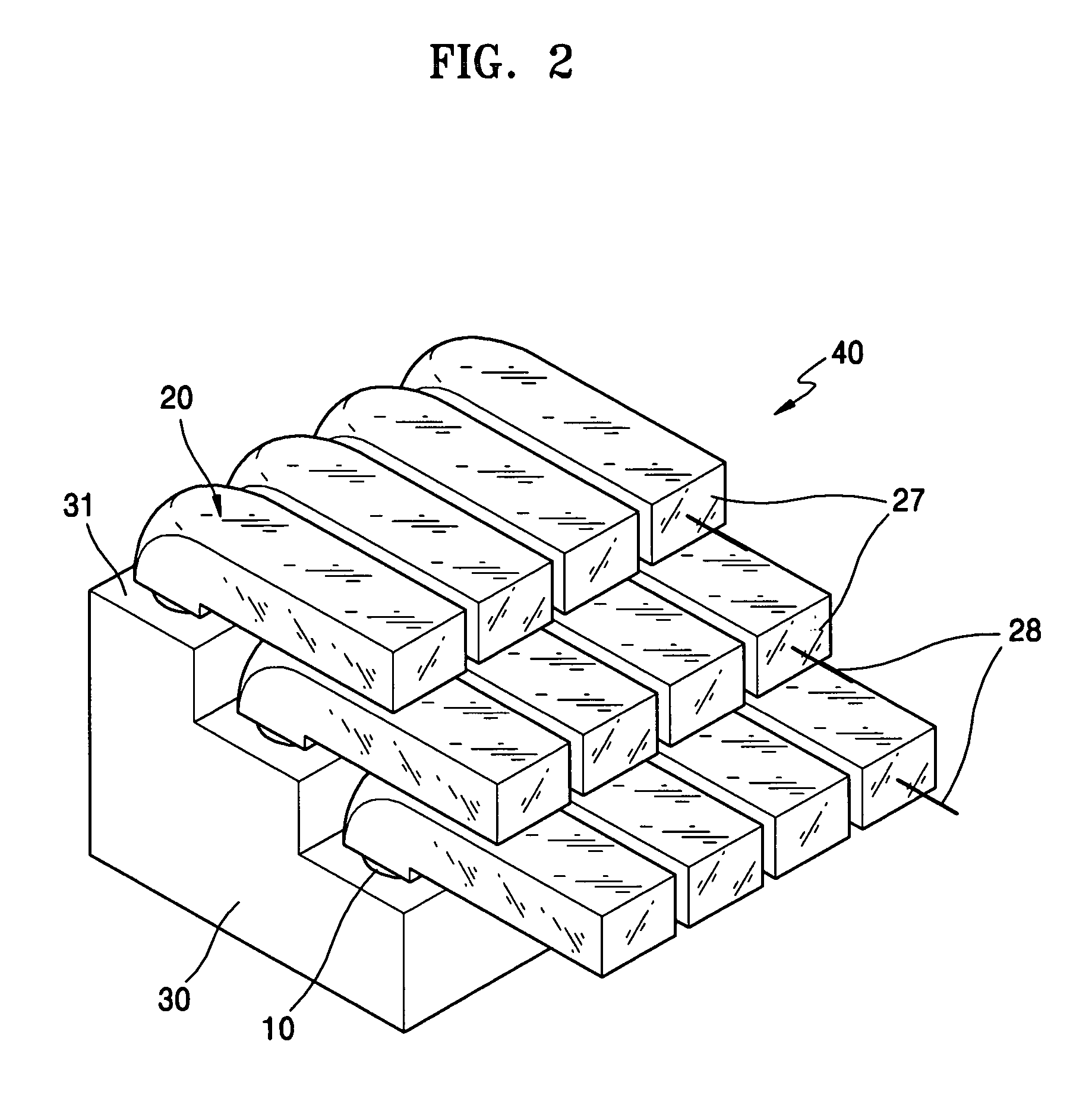

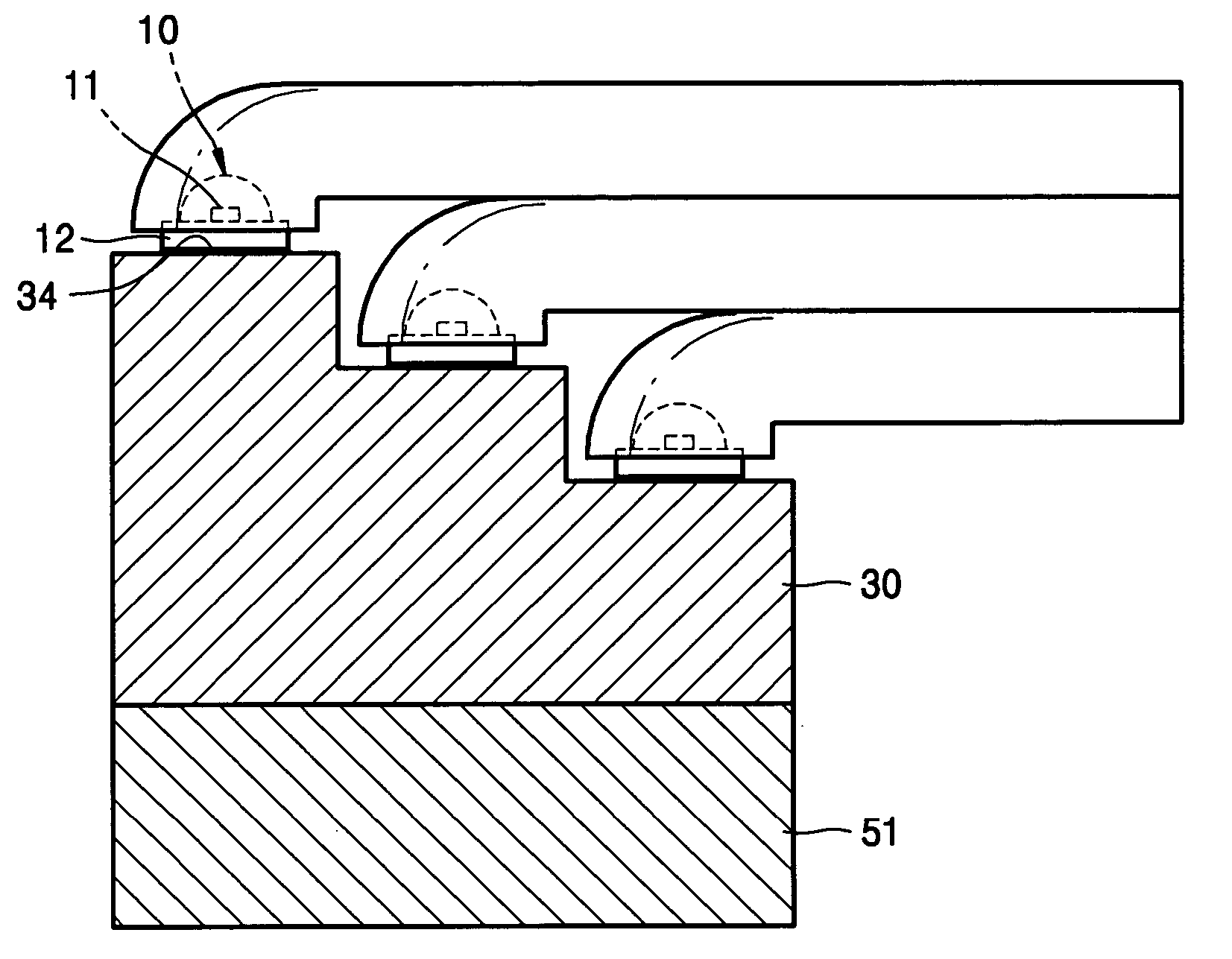

An illuminating unit having a plurality of light emitting devices and collimators and a projection type image display apparatus using the same are provided. The illuminating unit includes: a plurality of light emitting devices which output light beams of predetermined wavelengths; a plurality of collimators, each having a parabolic reflection surface for reflecting the light beam in a predetermined direction, a mounting section for locating the light emitting device at the focal point of the parabolic reflection surface, a light output surface opposite to the parabolic reflection surface, and a light guide section for guiding the light beam reflected from the parabolic reflection surface to the light output surface; and one or more fixing members having two or more steps for mounting the light emitting devices and the collimators on their top surface. A plurality of light emitting devices and collimators are efficiently arranged in a small space. Therefore, thermal concentration can be reduced and heat can be effectively discharged.

Owner:SAMSUNG ELECTRONICS CO LTD

Illuminating unit and projection type image display apparatus using the same

InactiveUS7331694B2Efficient dischargePoint-like light sourcePortable electric lightingLight guideLight beam

An illuminating unit having a plurality of light emitting devices and collimators and a projection type image display apparatus using the same are provided. The illuminating unit includes: a plurality of light emitting devices which output light beams of predetermined wavelengths; a plurality of collimators, each having a parabolic reflection surface for reflecting the light beam in a predetermined direction, a mounting section for locating the light emitting device at the focal point of the parabolic reflection surface, a light output surface opposite to the parabolic reflection surface, and a light guide section for guiding the light beam reflected from the parabolic reflection surface to the light output surface; and one or more fixing members having two or more steps for mounting the light emitting devices and the collimators on their top surface. A plurality of light emitting devices and collimators are efficiently arranged in a small space. Therefore, thermal concentration can be reduced and heat can be effectively discharged.

Owner:SAMSUNG ELECTRONICS CO LTD

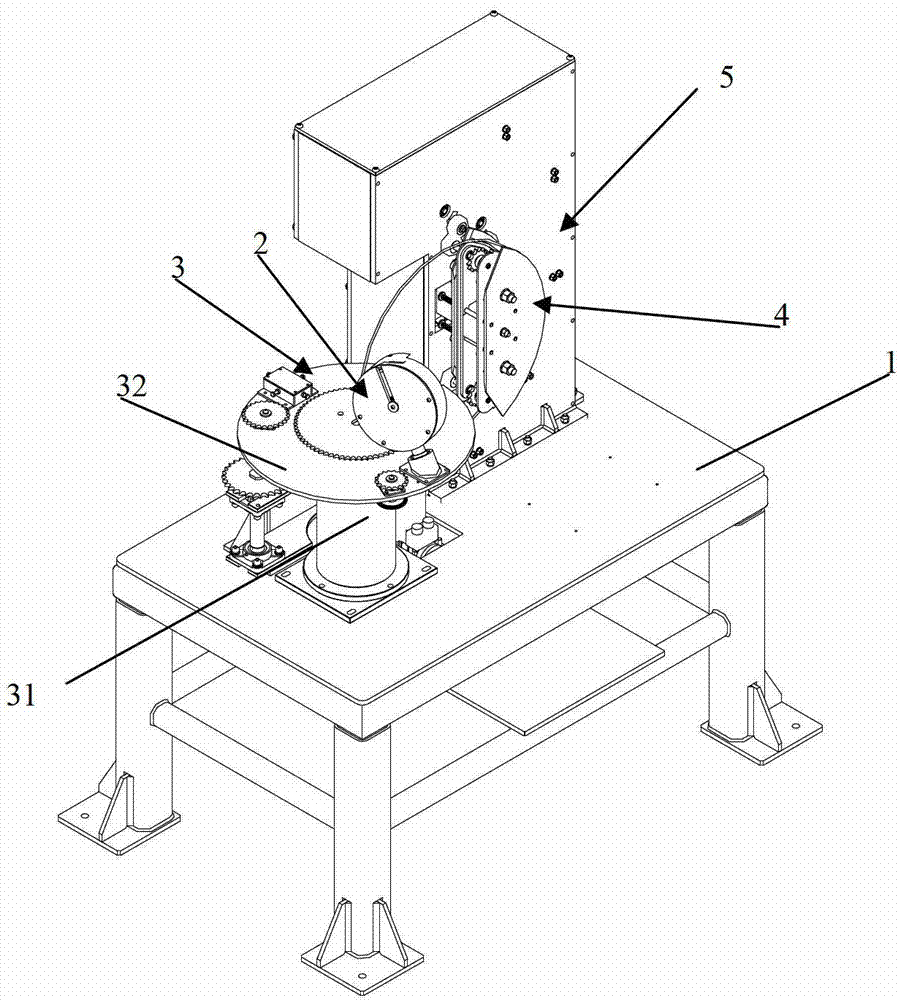

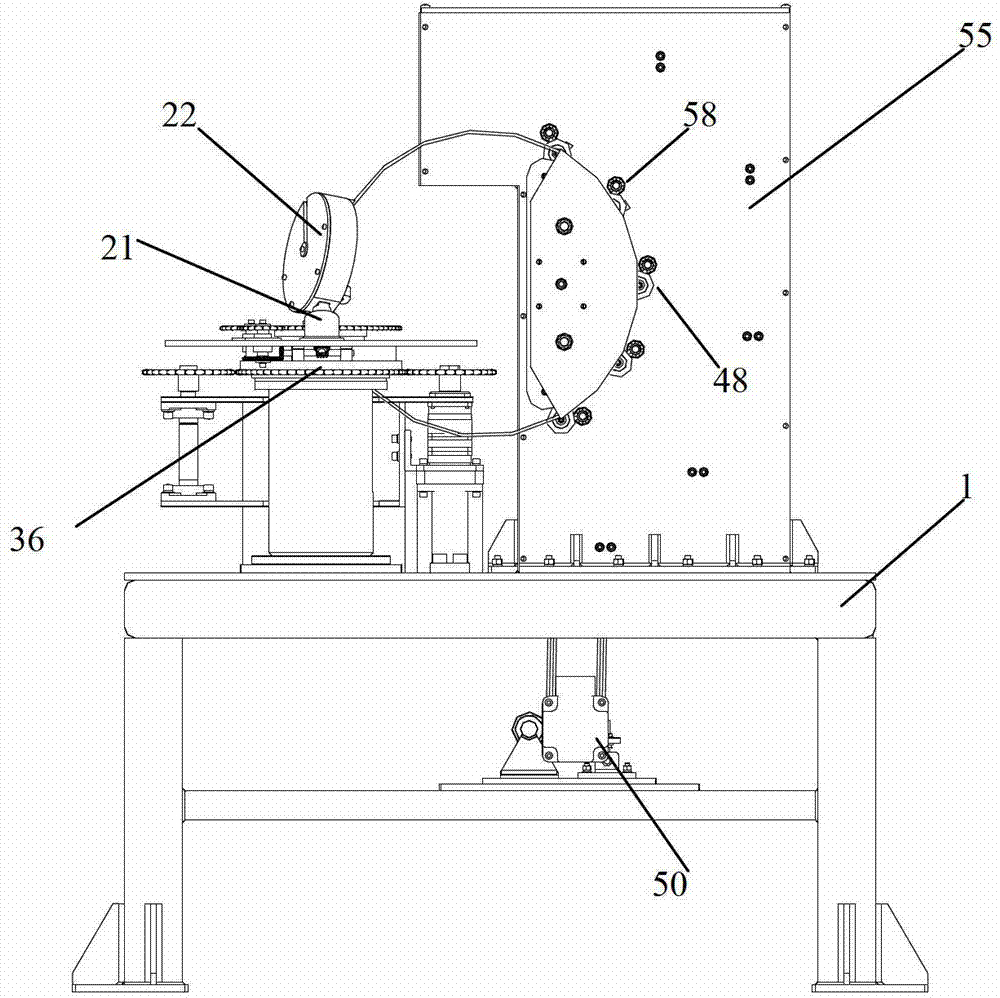

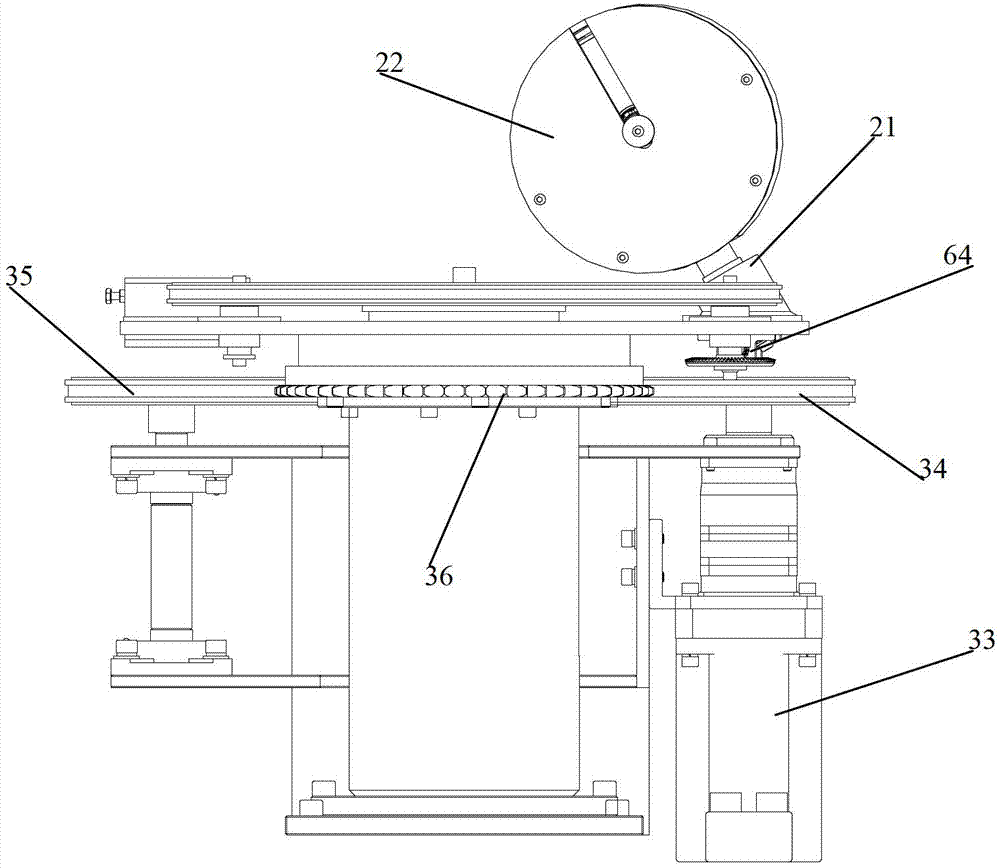

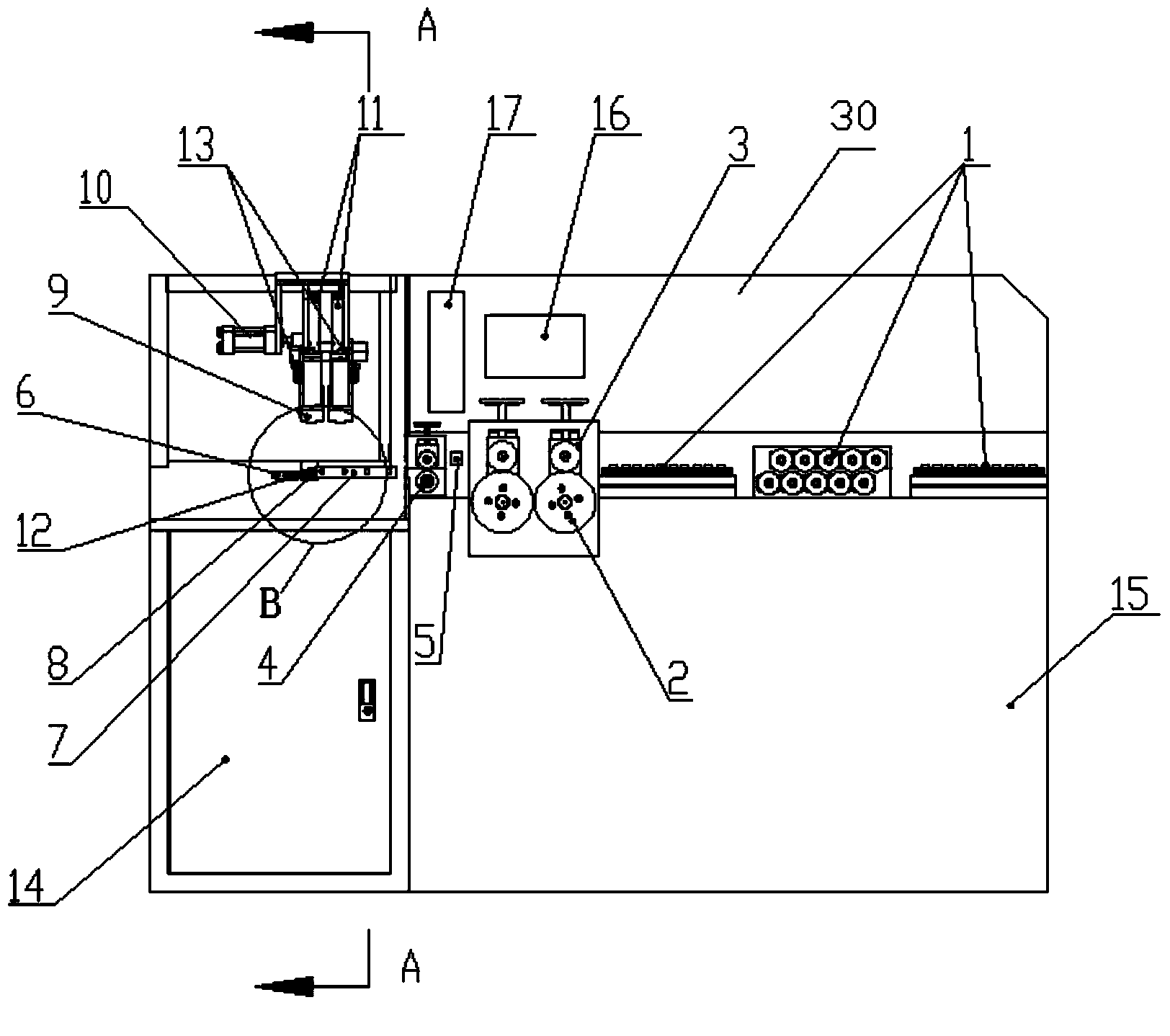

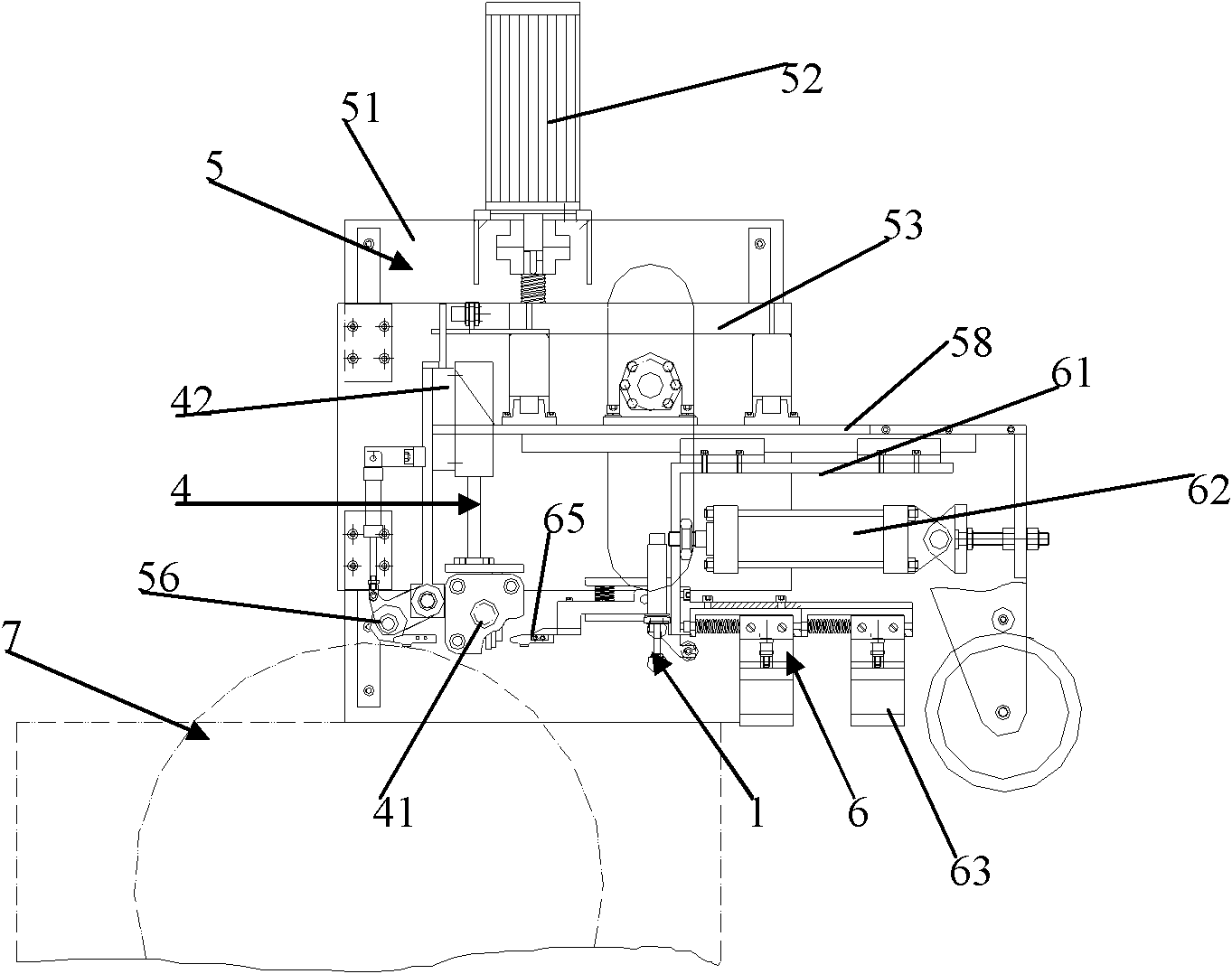

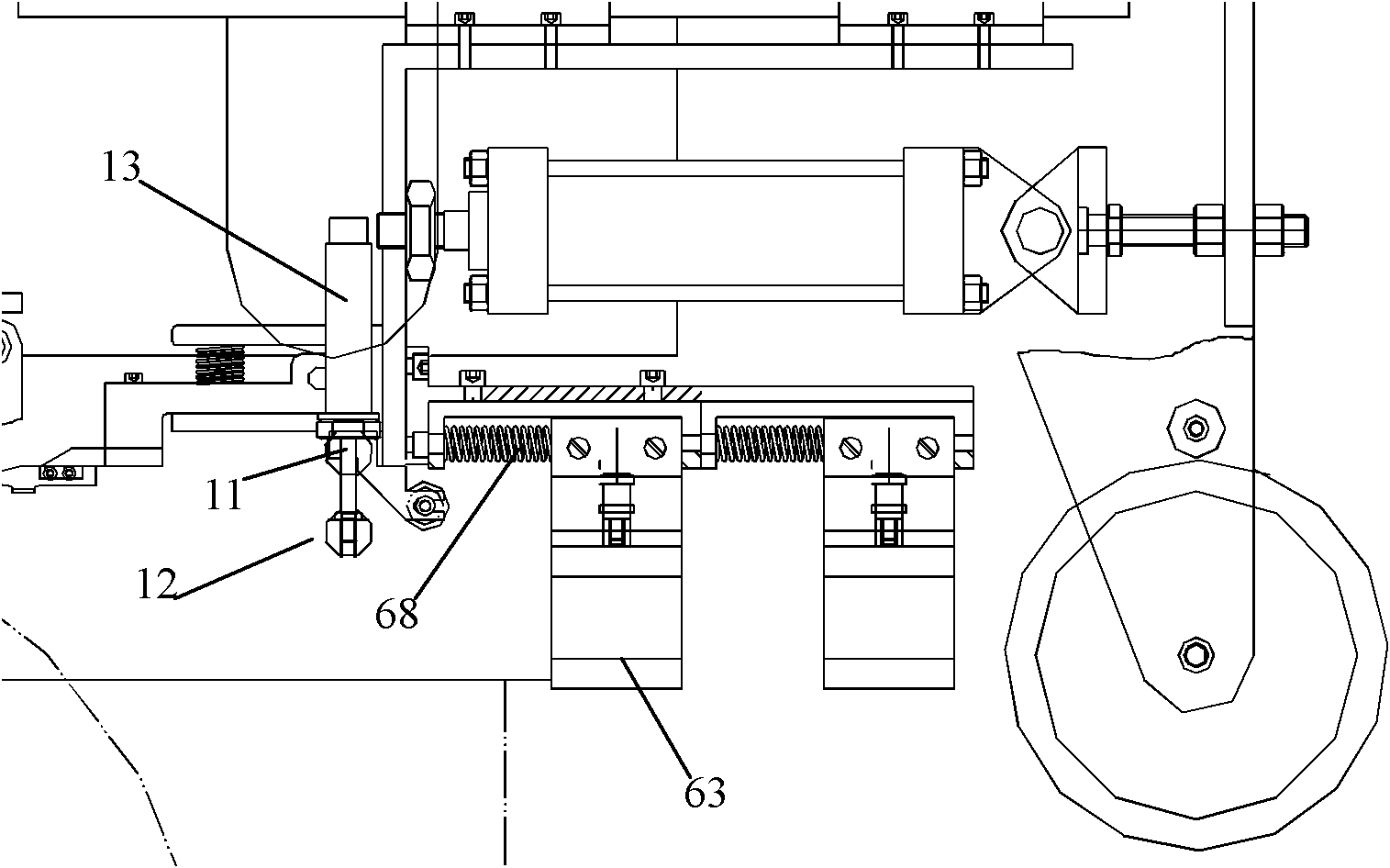

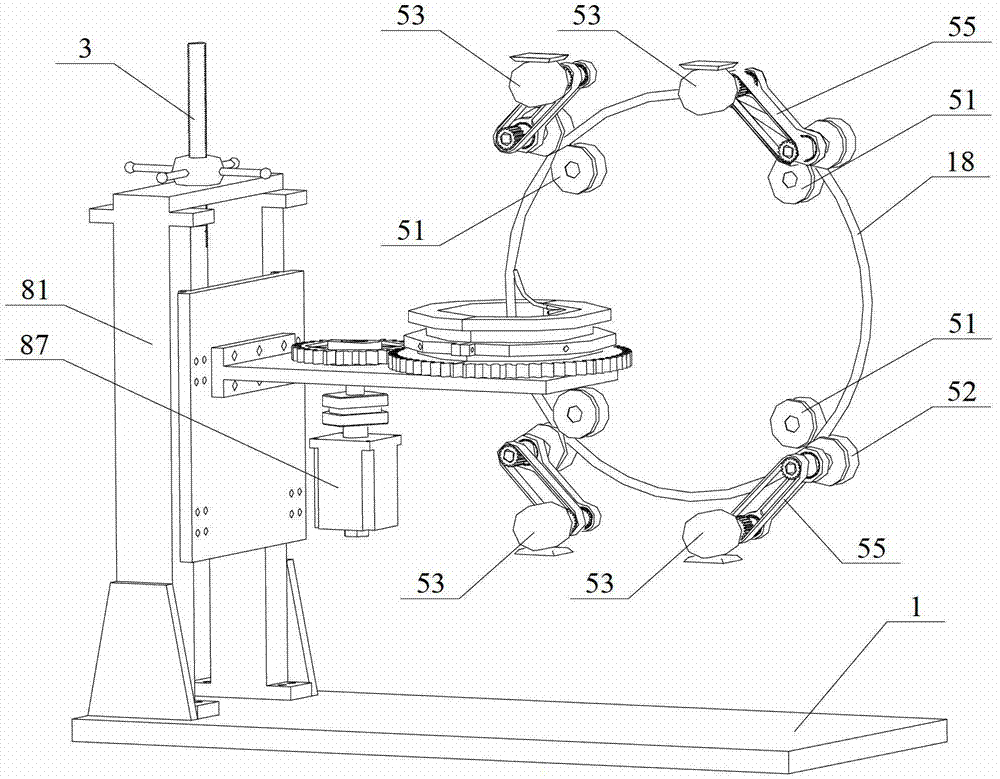

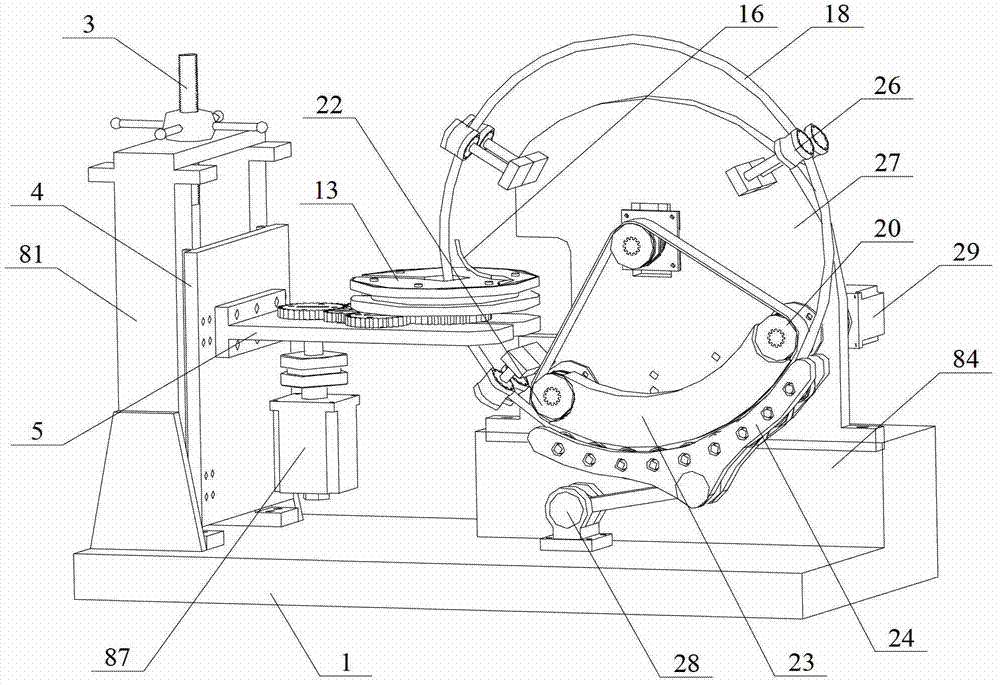

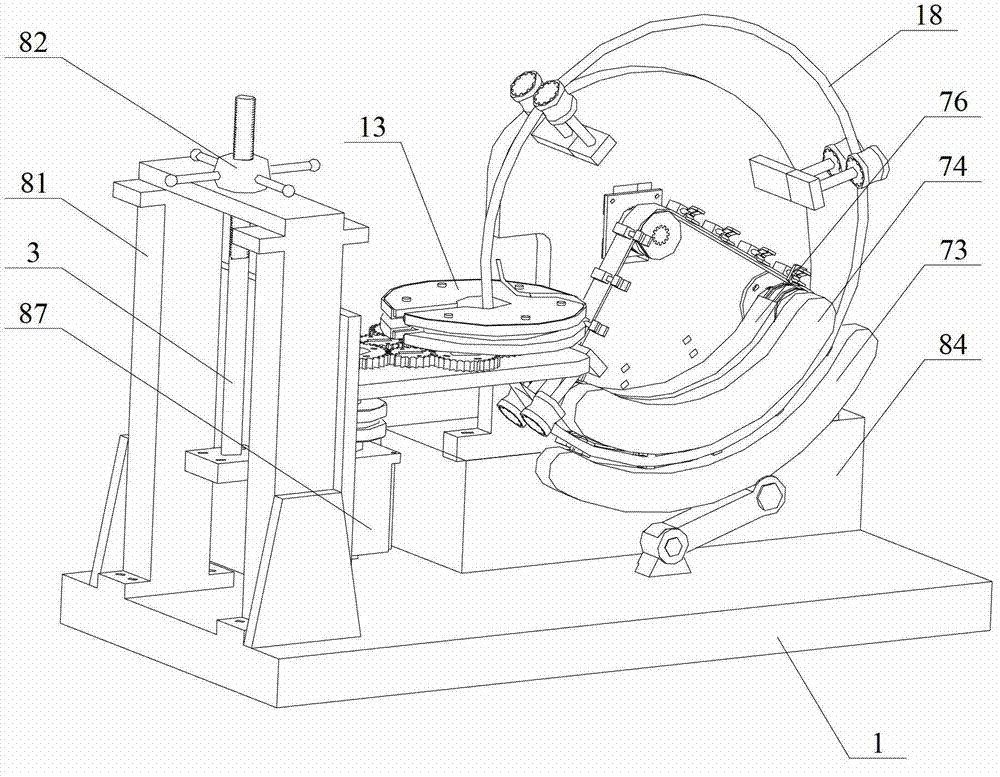

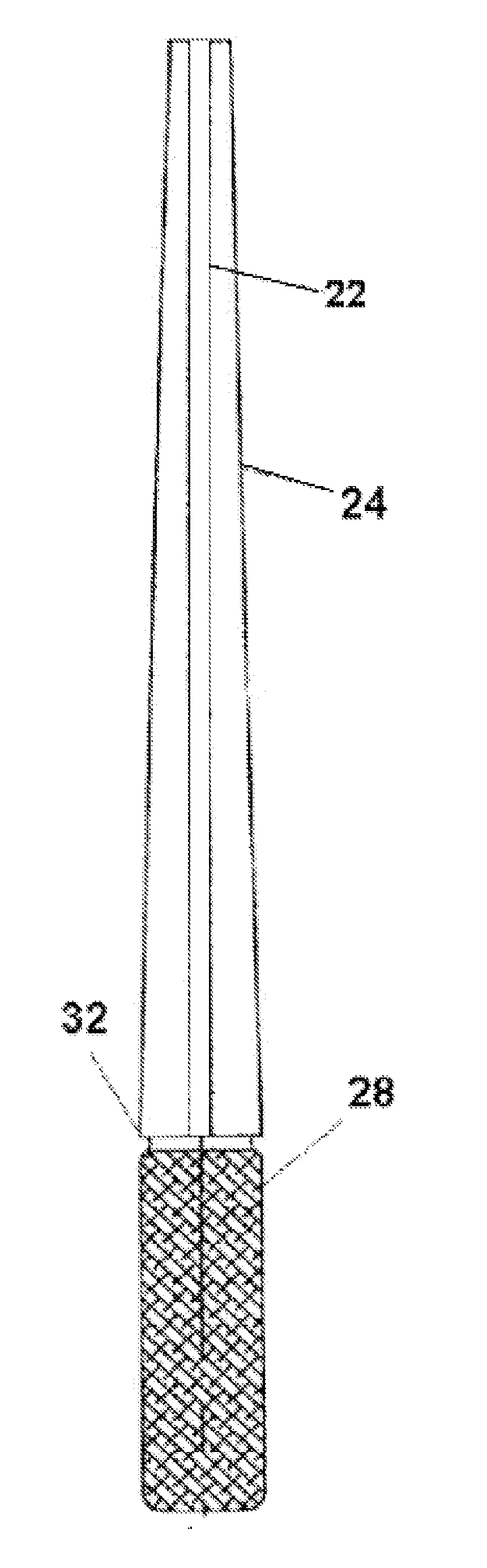

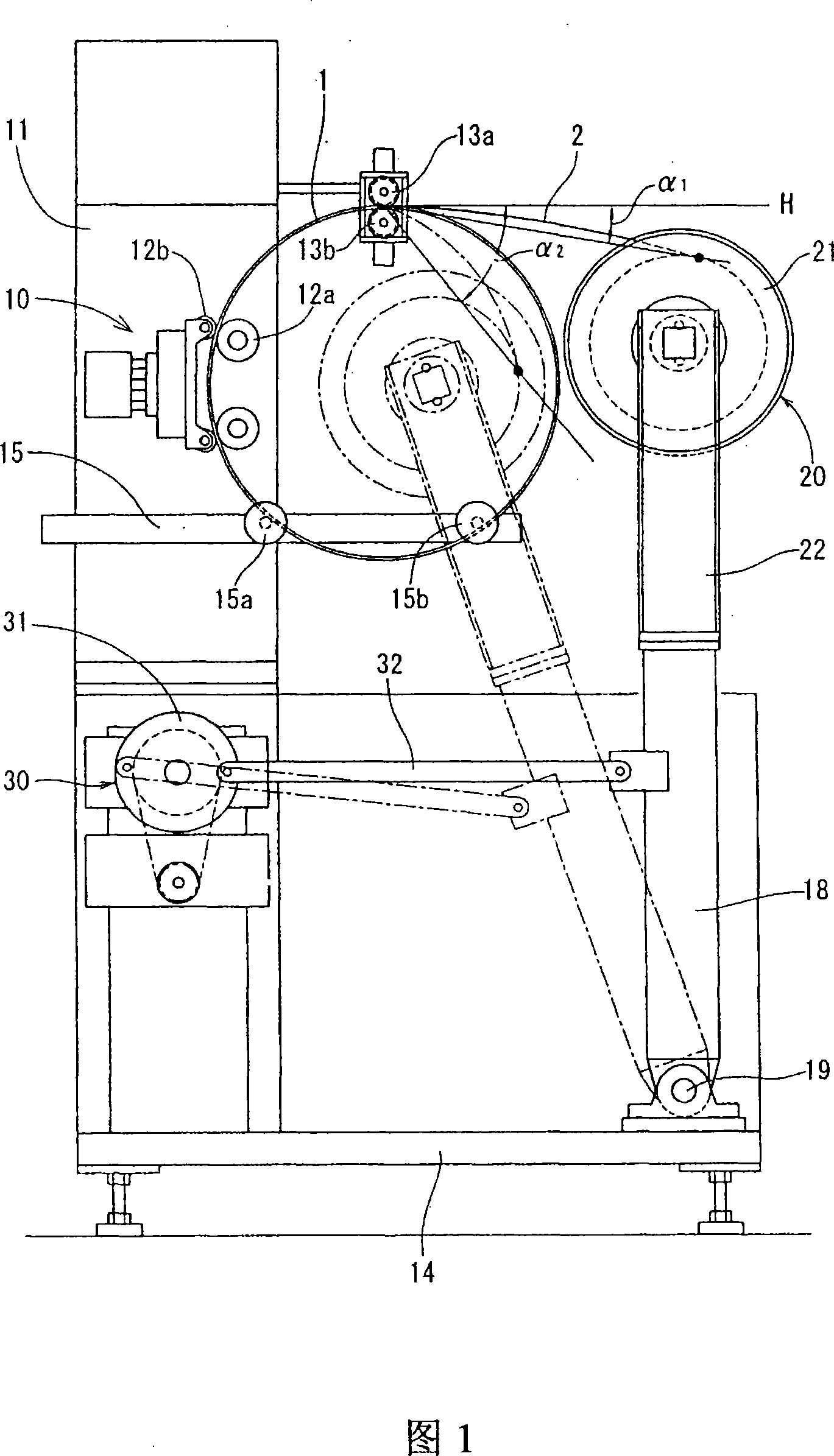

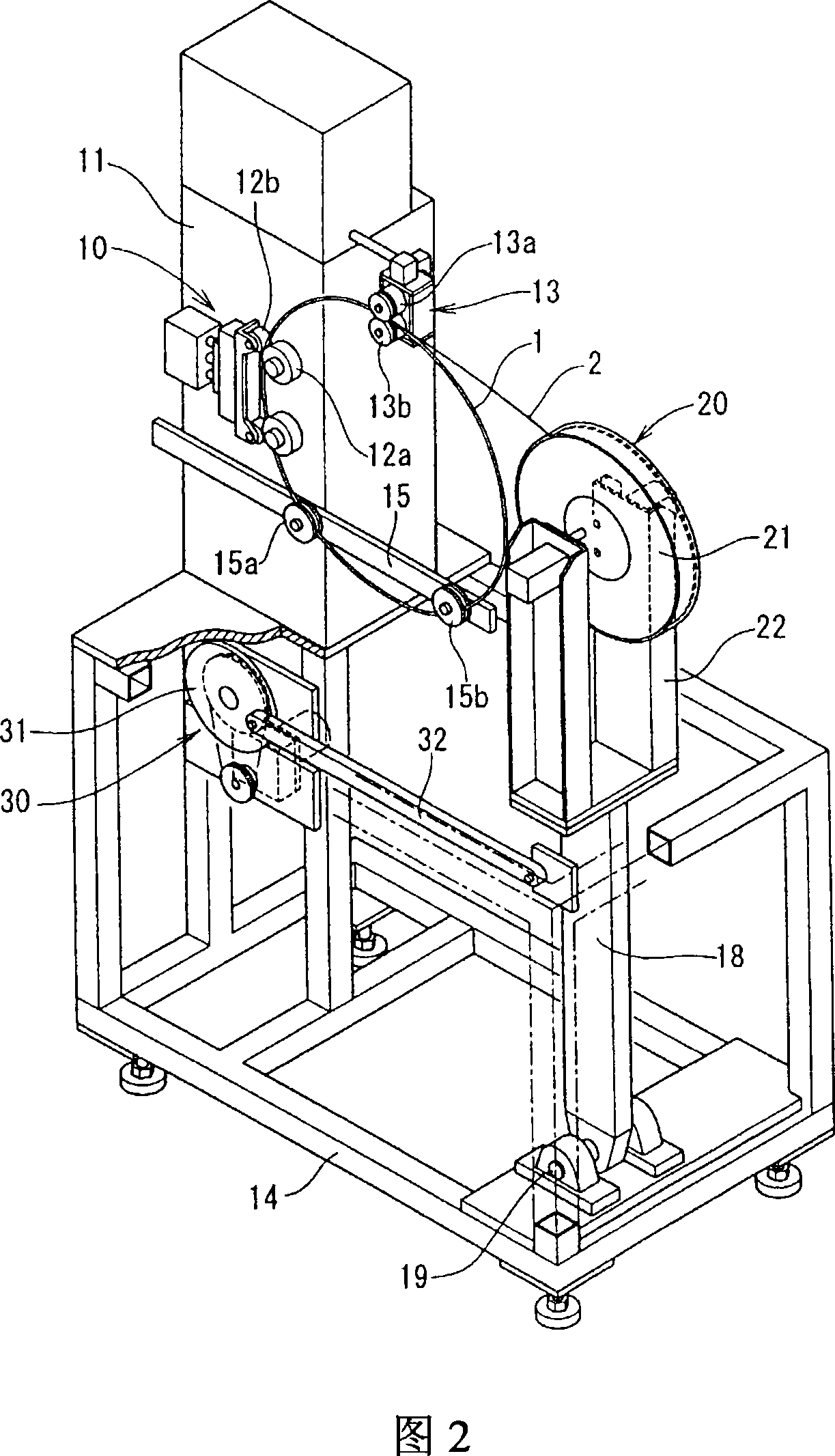

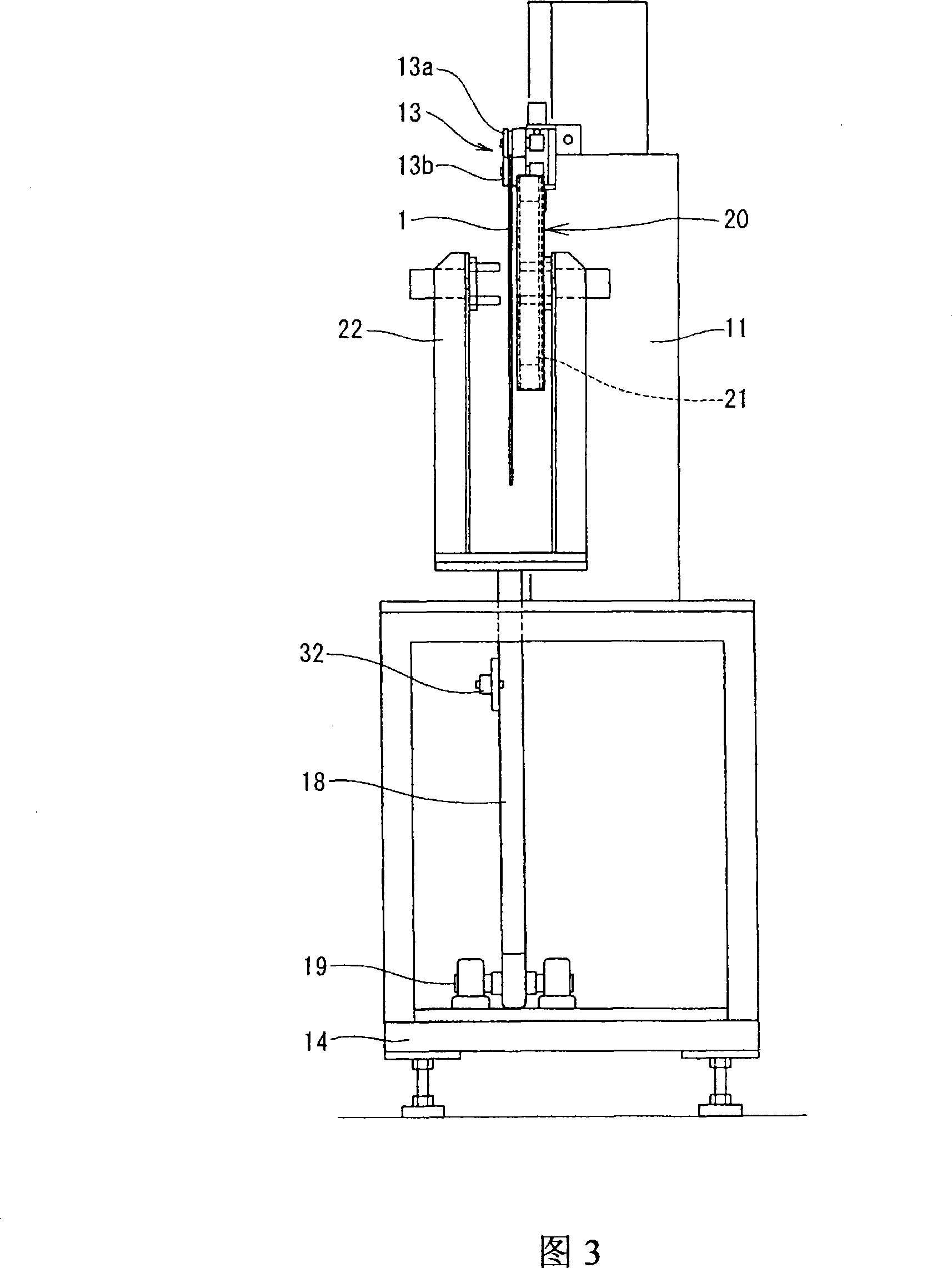

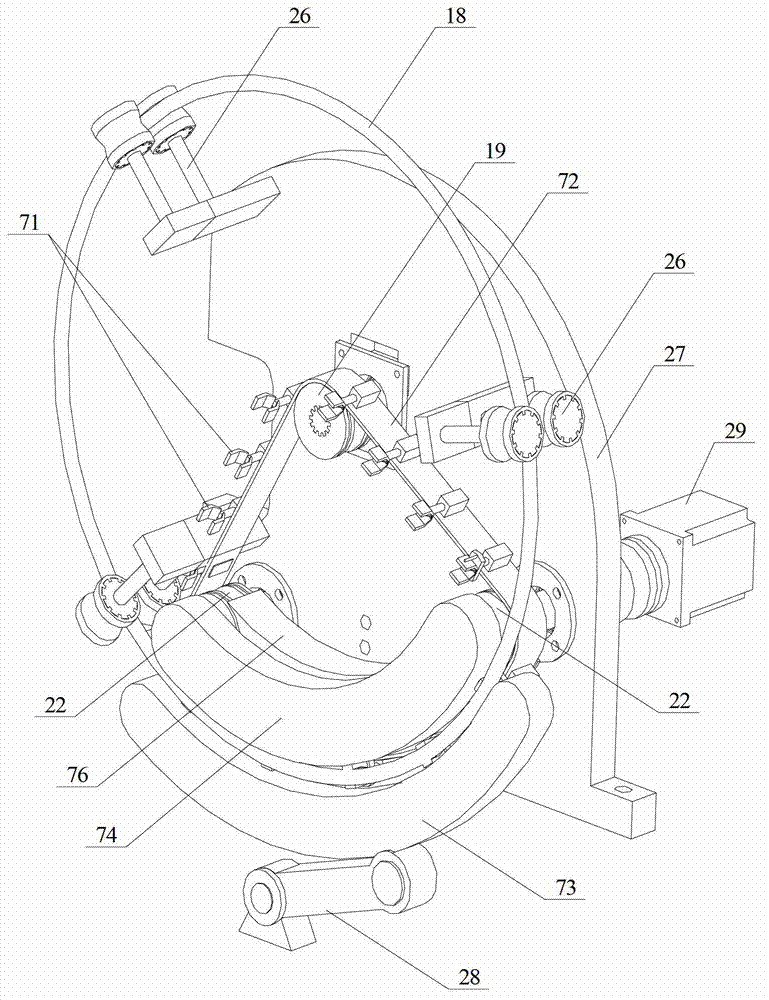

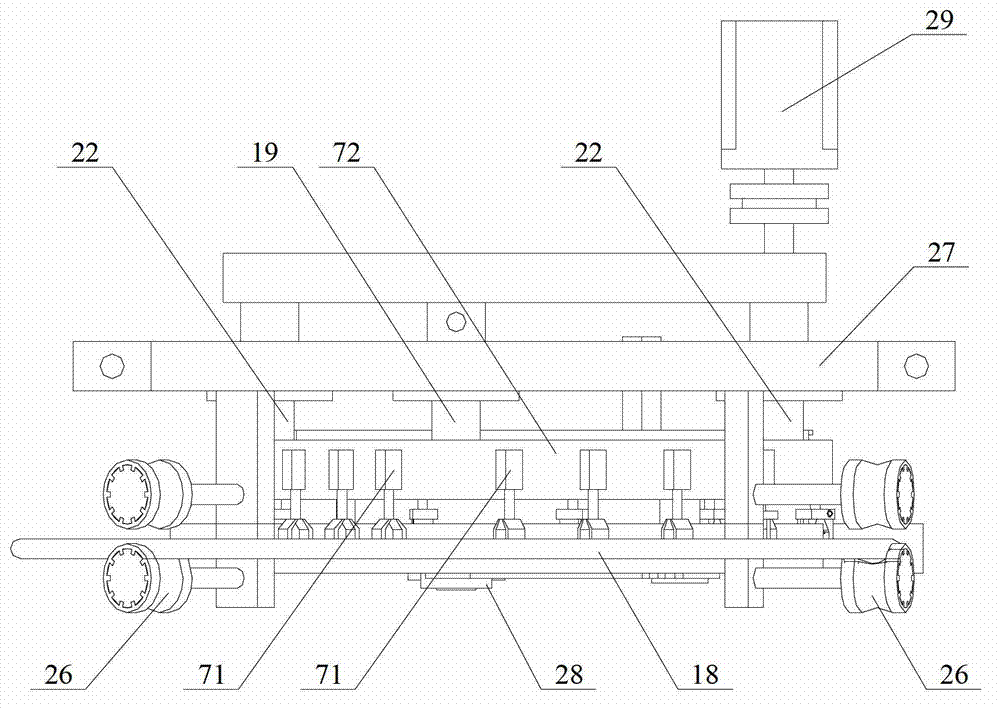

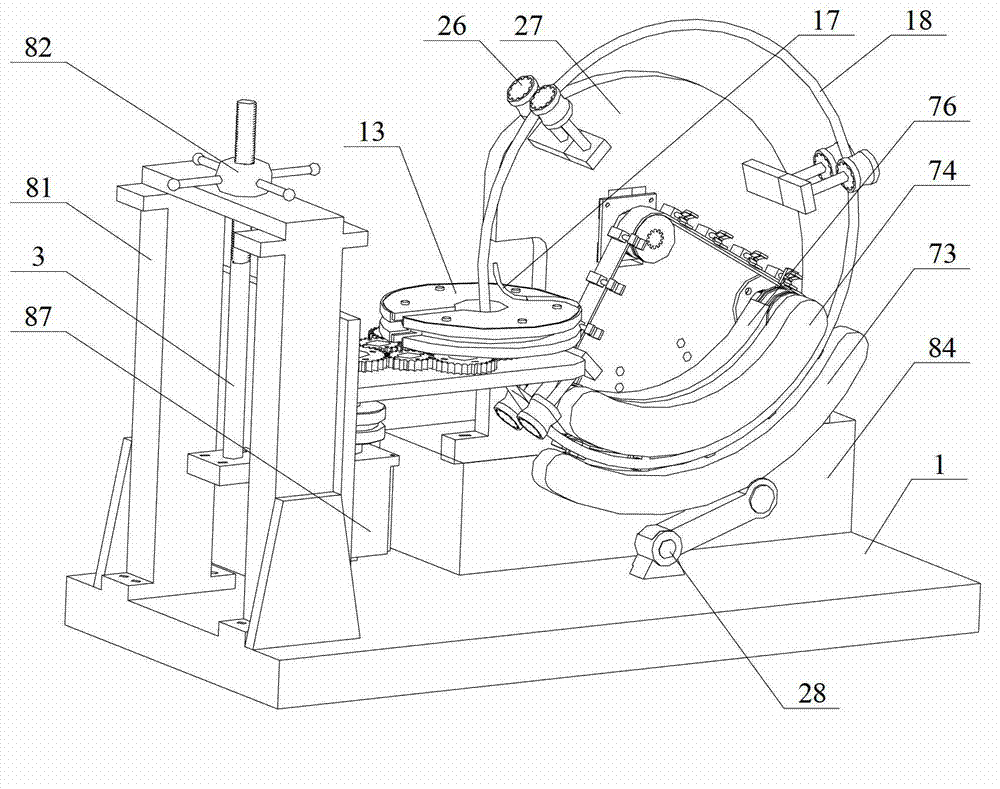

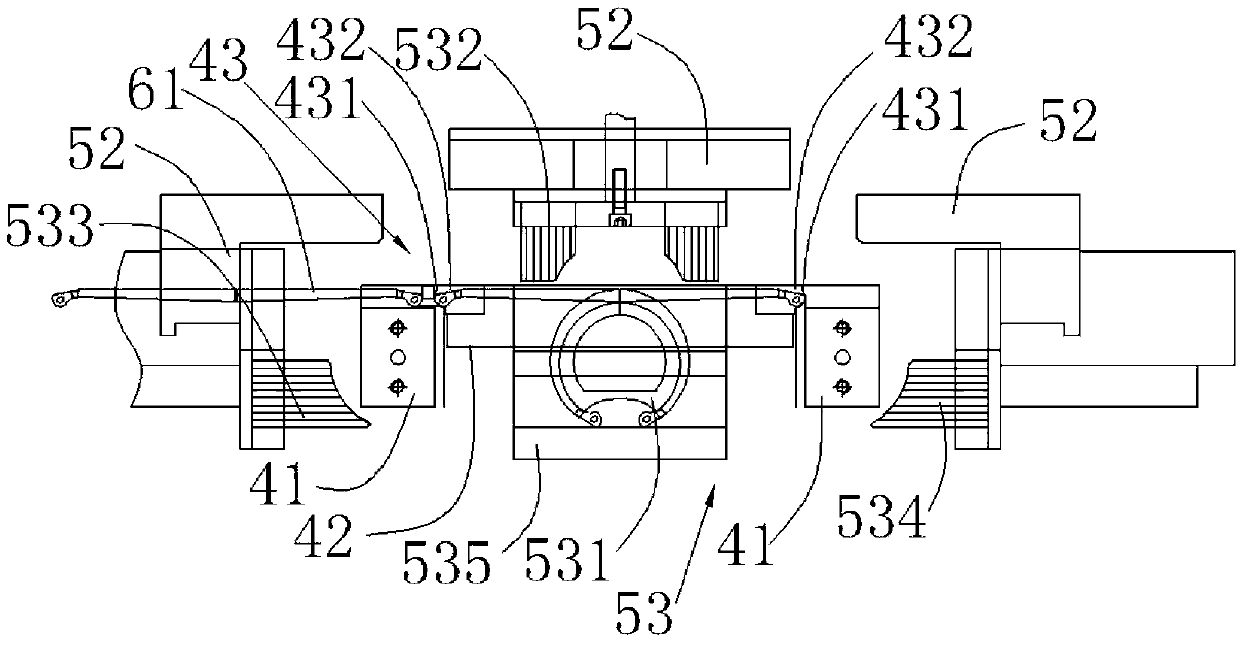

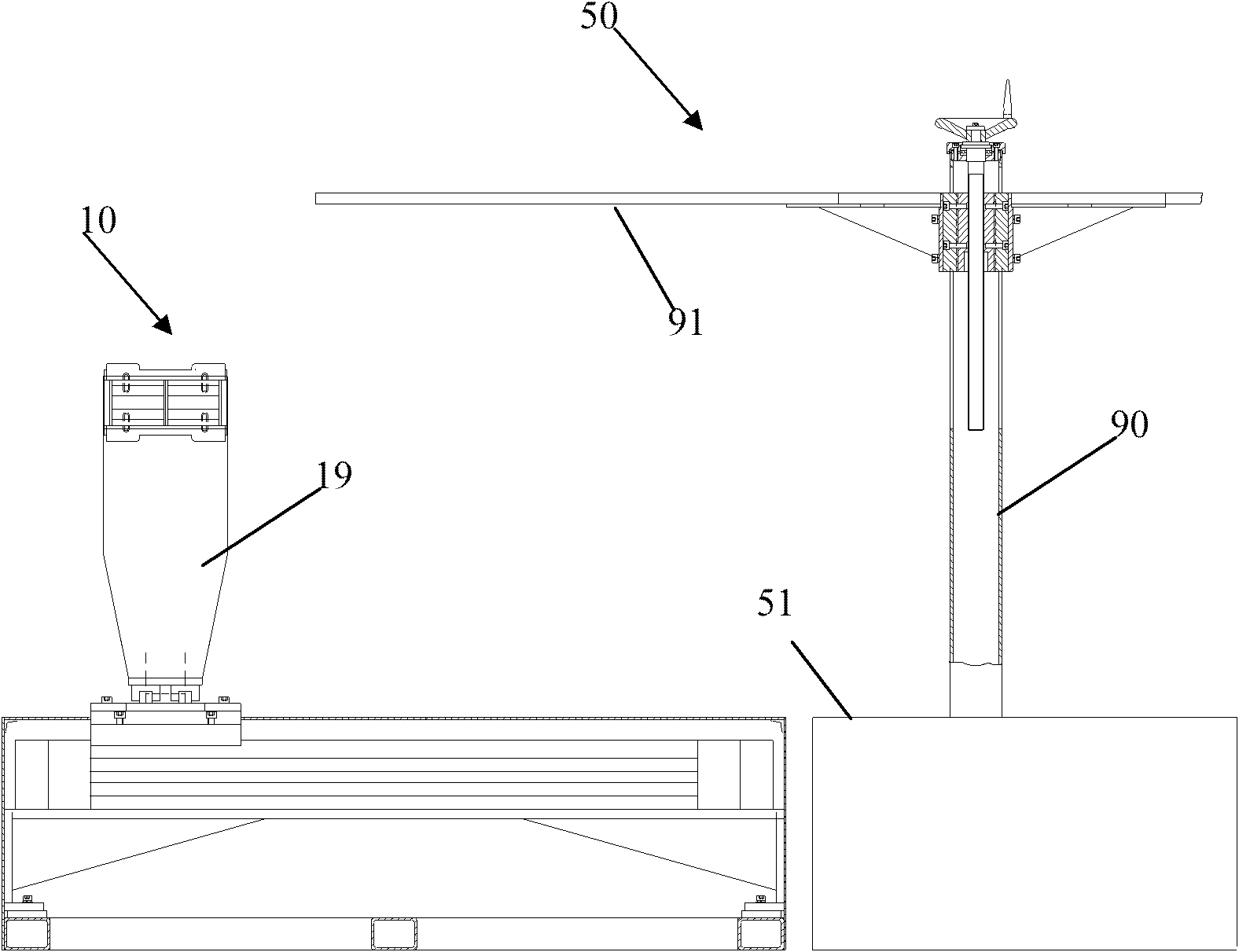

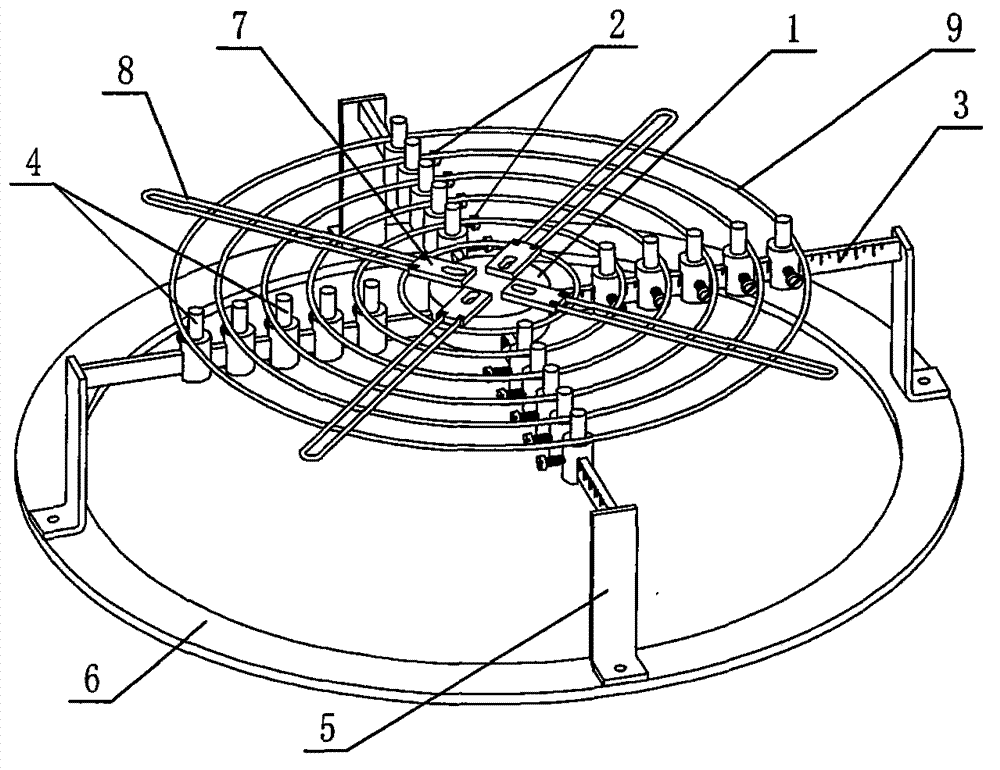

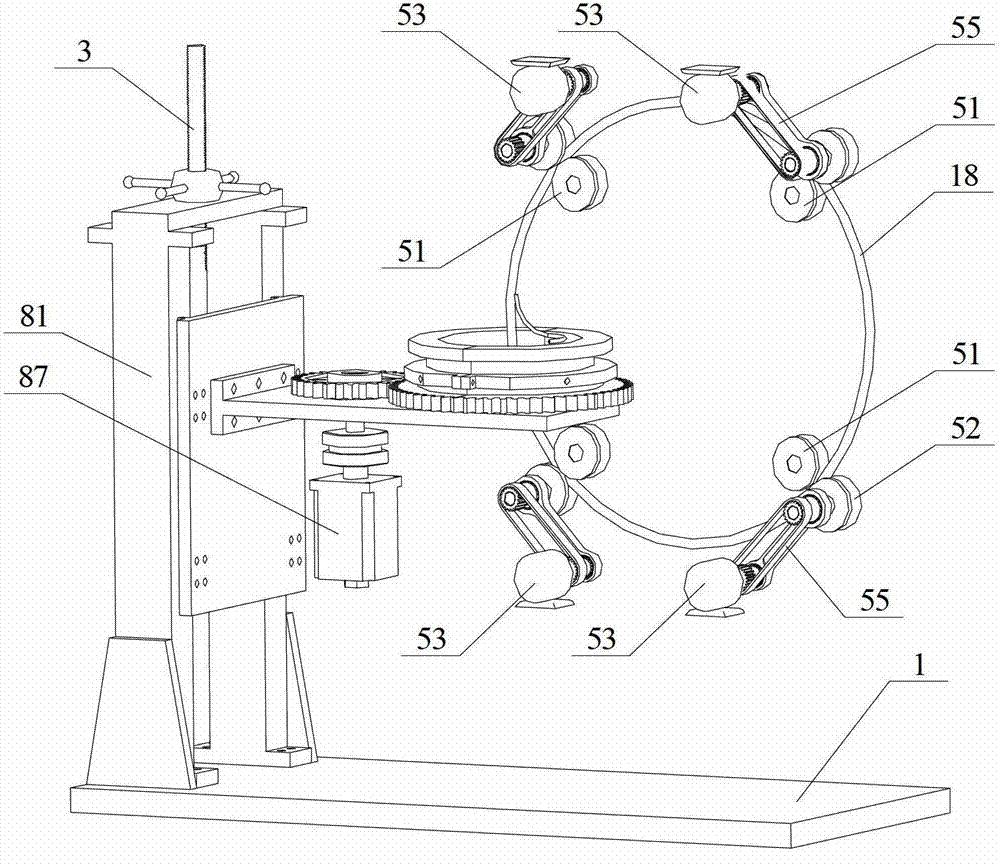

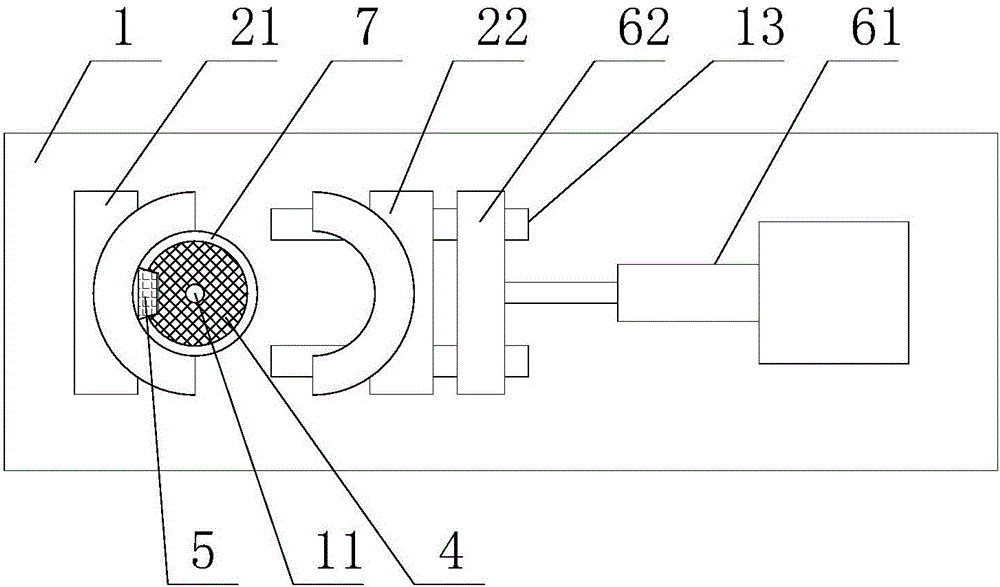

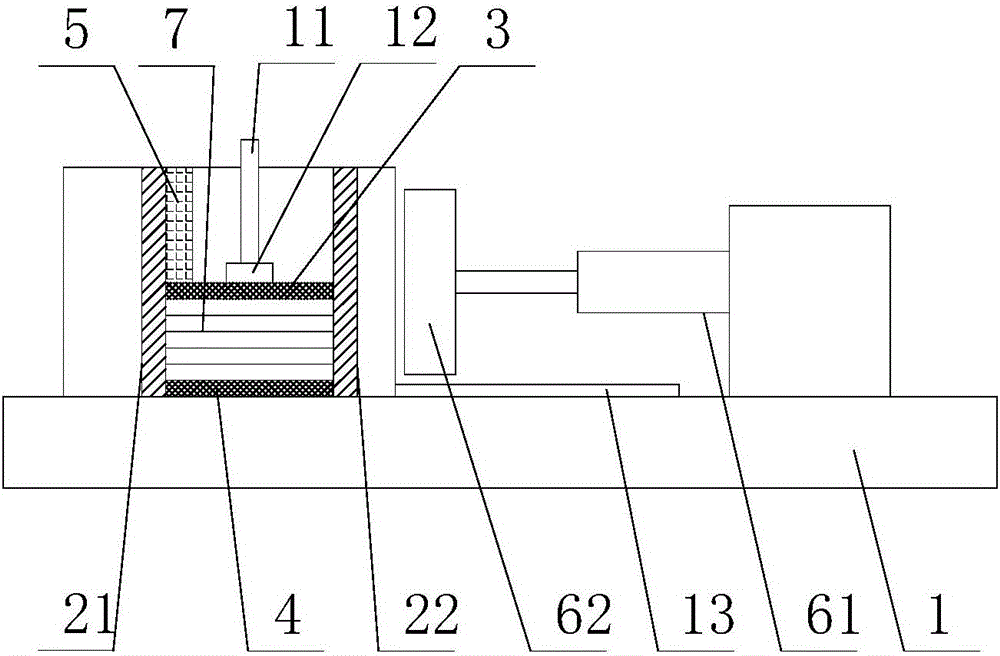

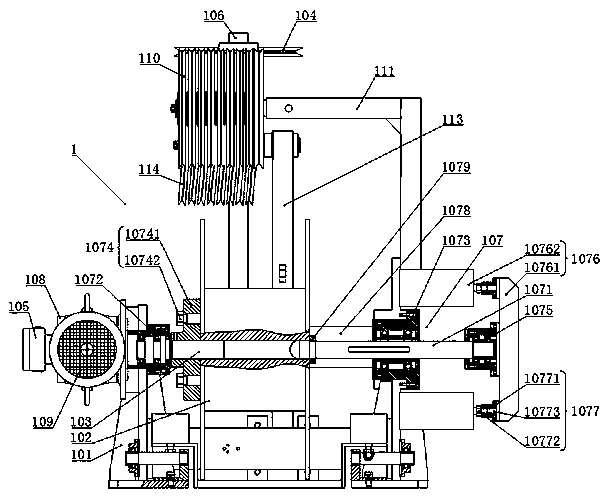

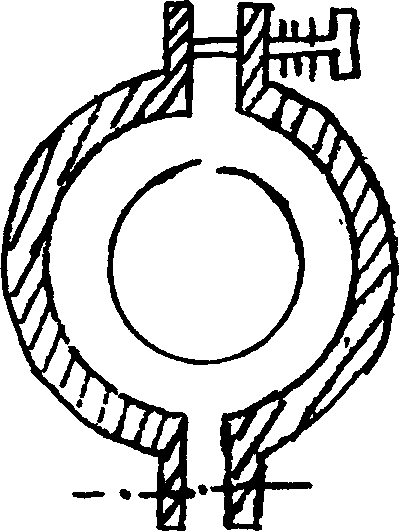

Winding apparatus of bead ring of circular section

The invention discloses a winding apparatus of a bead ring of a circular section. The winding apparatus of the bead ring of the circular section comprises a stander, a bead ring winding mechanism, a bead ring opening mechanism and a bead ring core clamping mechanism, wherein the bead ring winding mechanism comprises a vertical support post, a disc-shaped horizontal rotation platform which is rotatably arranged at the top of the support post and provided with a slot, and a servo motor capable of driving the horizontal rotation platform to rotate; the bead ring opening mechanism is arranged on the horizontal rotation platform; and the bead ring core clamping mechanism comprises two D-shaped outer support plates, two D-shaped inner clamp plates, a chain and sprocket assembly, the servo motor and a plurality sets of clamping assemblies. According to the winding apparatus of the bead ring provided by the invention, the structure is simple, the control is precise, the servo motor serves as motor input, the chain and the sprocket are taken as a transmission assembly, the bridging is simple, the space requirement is low, and the winding of the bead ring of the circular section can be effectively realized by the rotation of the bead ring core and the rotatable winding of a winding steel wire.

Owner:TIANJIN SAIXIANG TECH

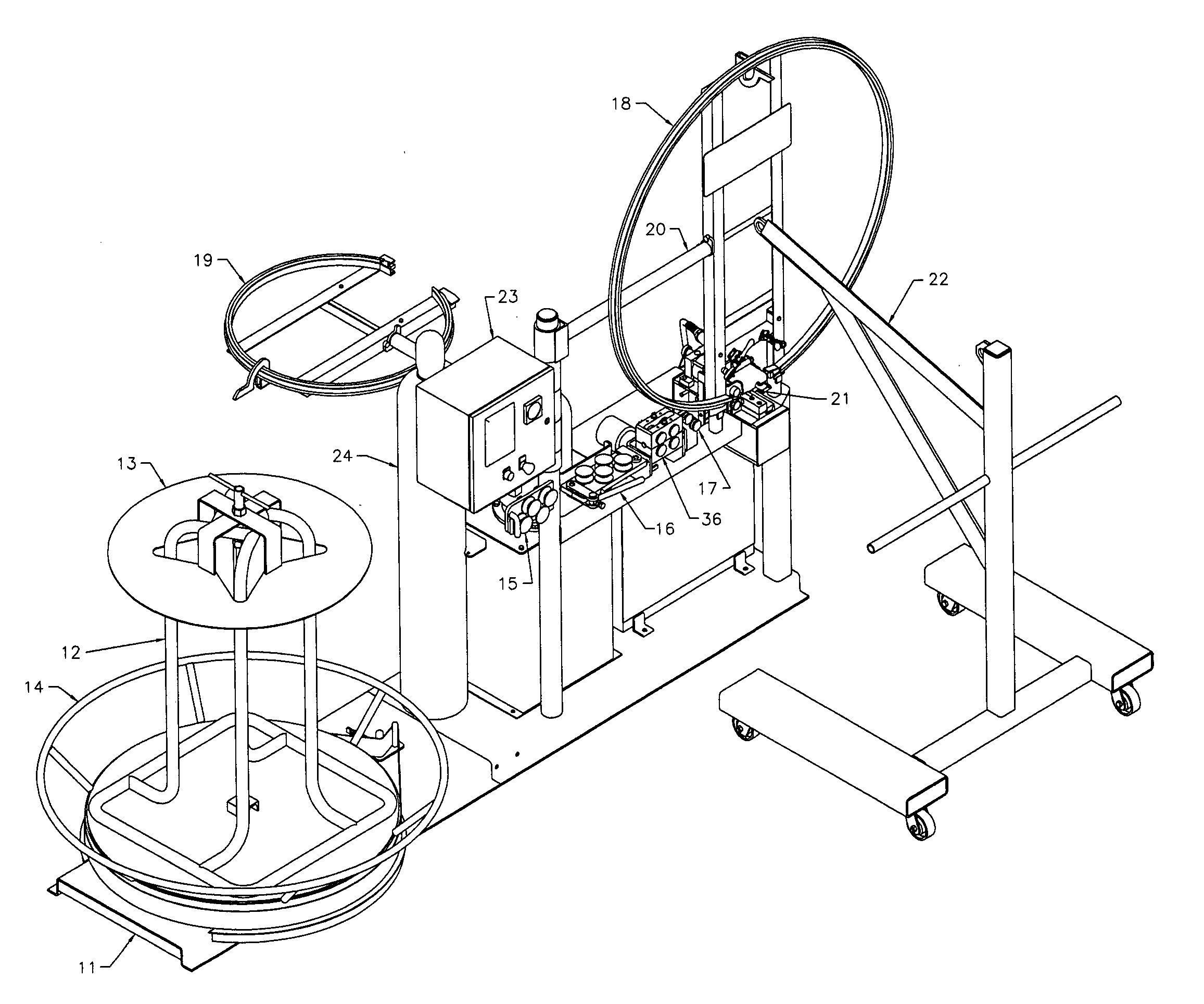

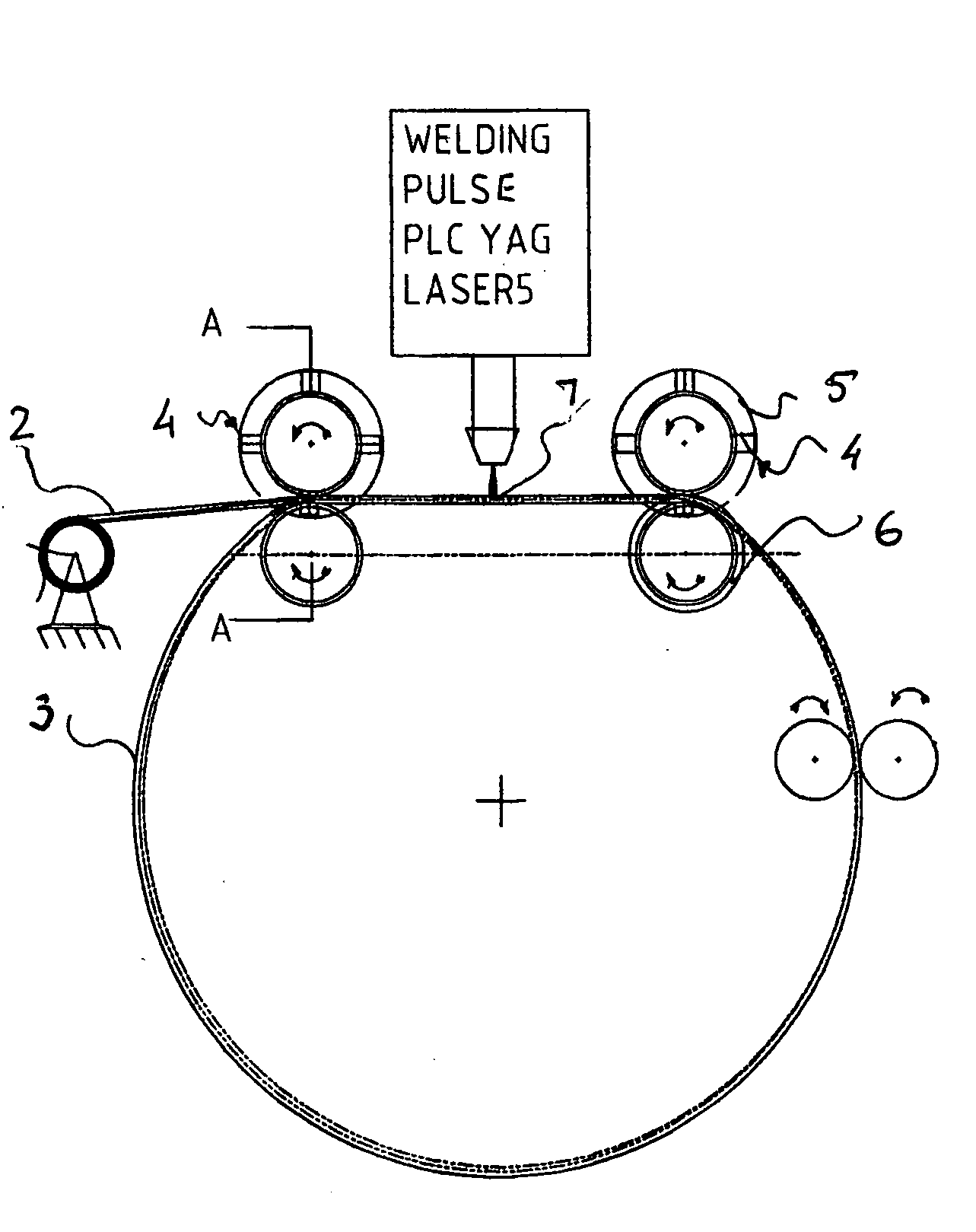

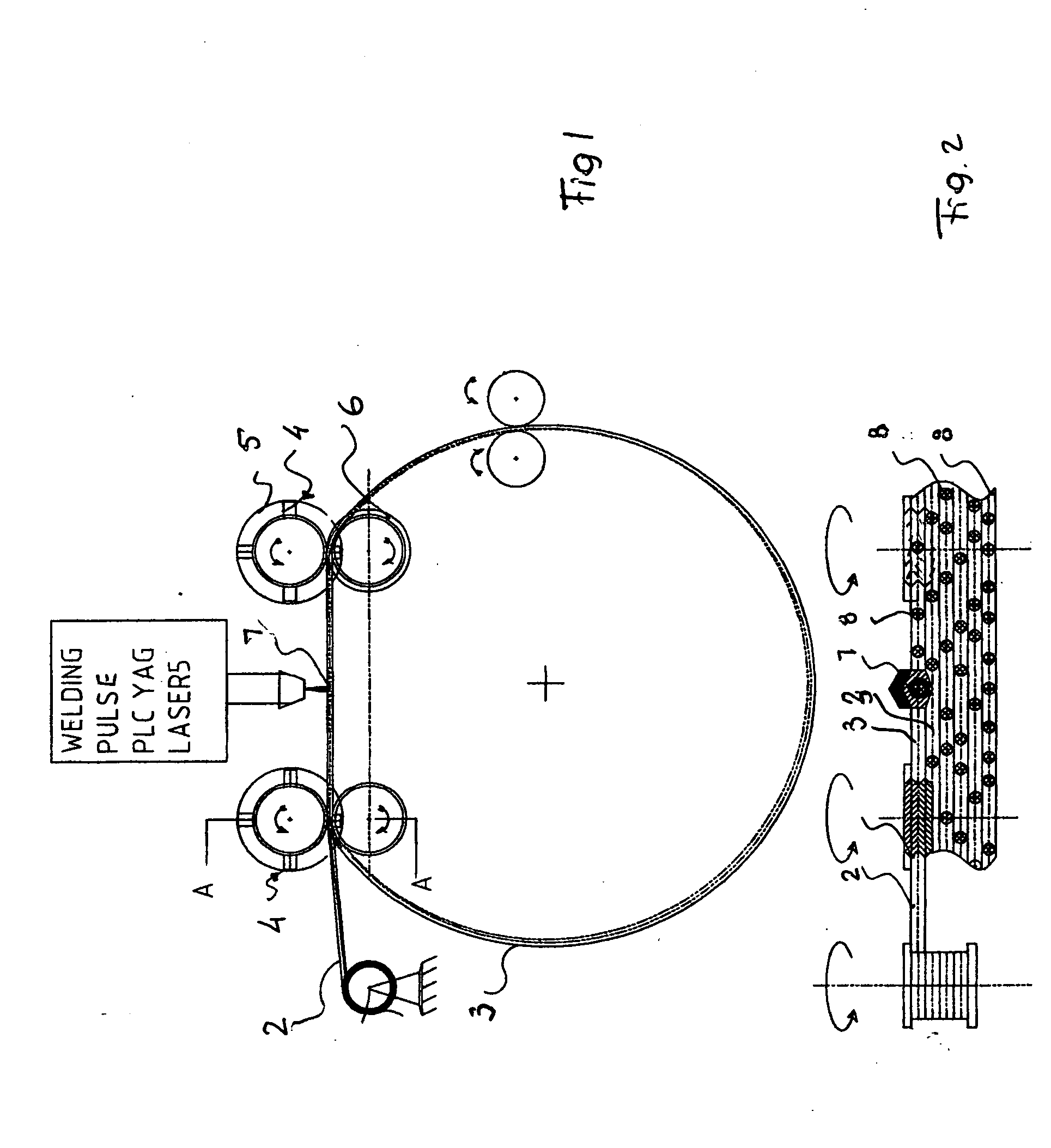

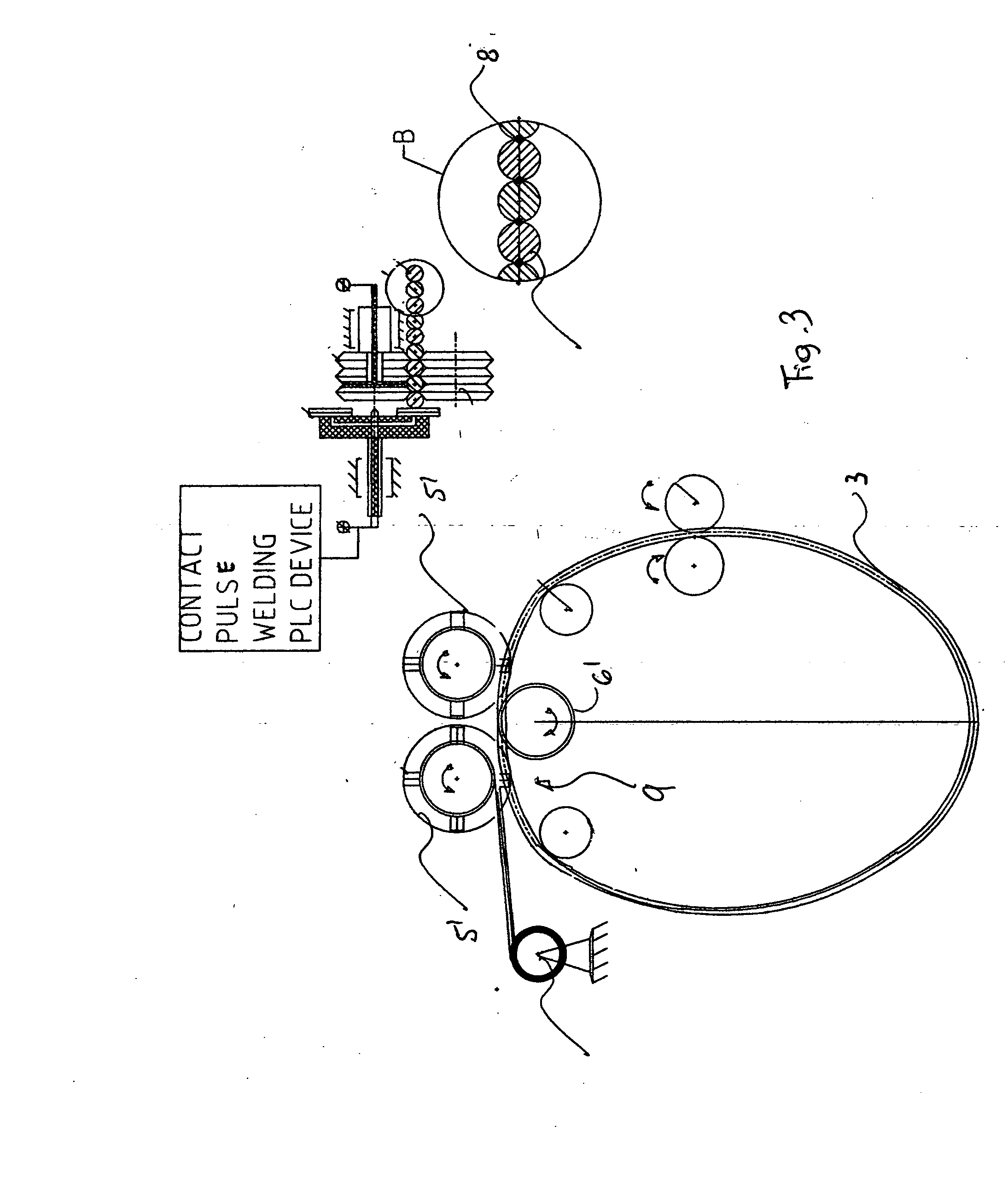

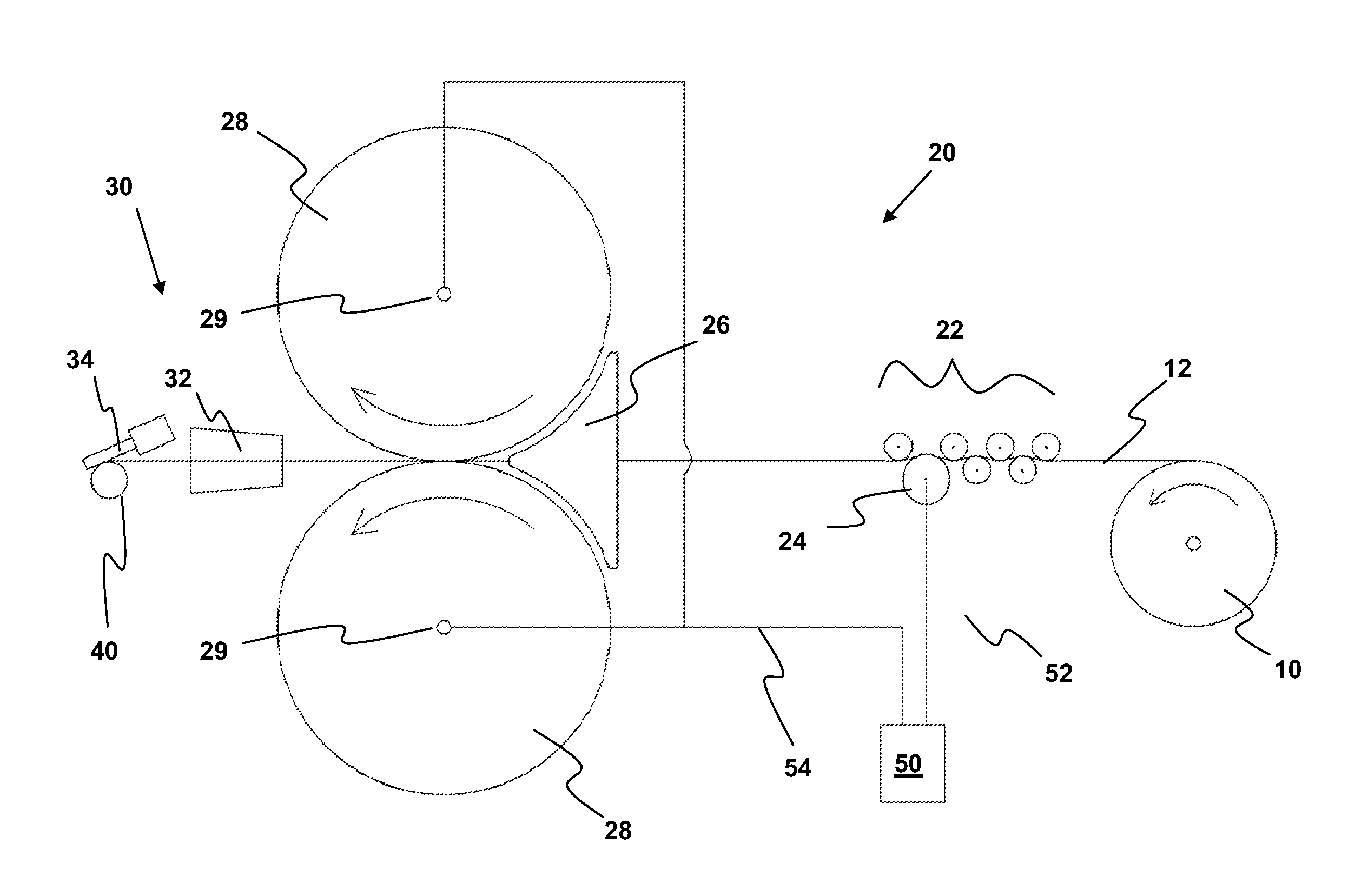

Machine for making steel hoop circumferential reinforcing elements

An automatic hoop forming machine comprising a wire decoiling and feeding element connected to a series of rollers designed to pull, take out some irregularities and partially impart a curve before said wire is fed on to a hoop guide roll of the desired diameter to form a hoop-shaped element. The ends are overlapped and welded prior to cutting. Any number of hoops may be formed automatically and are eminently useful as reinforcing members within cementitious materials used to make manholes, for example.

Owner:CLECO MFG

Full-automatic single-wheel numerical control circling welding machine and circling welding method thereof

InactiveCN103433408AEasy to adjustQuality assuranceWire ringsResistance welding apparatusNumerical controlMachine parts

The invention relates to a full-automatic single-wheel numerical control circling welding machine which comprises a machine body and a working table. The full-automatic single-wheel numerical control circling welding machine is characterized in that the machine body is sequentially provided with a straightening mechanism, a feeding mechanism, a guide line plate, a cut-off device, a single-wheel forming mechanism and a butt-weld mechanism according to the processing sequence, and the single-wheel forming mechanism comprises a forming wheel which conducts contour machining on workpieces. According to the full-automatic single-wheel numerical control circling welding machine, the single forming wheel is used for achieving contour machining, flexible adjusting of the specifications of machining parts is achieved, a starting point cutter device is used so that starting point cutting-off can be achieved in the machining process, errors caused by a cutter can be reduced, the butt-weld mechanism can effectively guarantee the welding precision and firmness, and therefore workpiece quality is guaranteed.

Owner:诸暨市振华液压科技有限公司

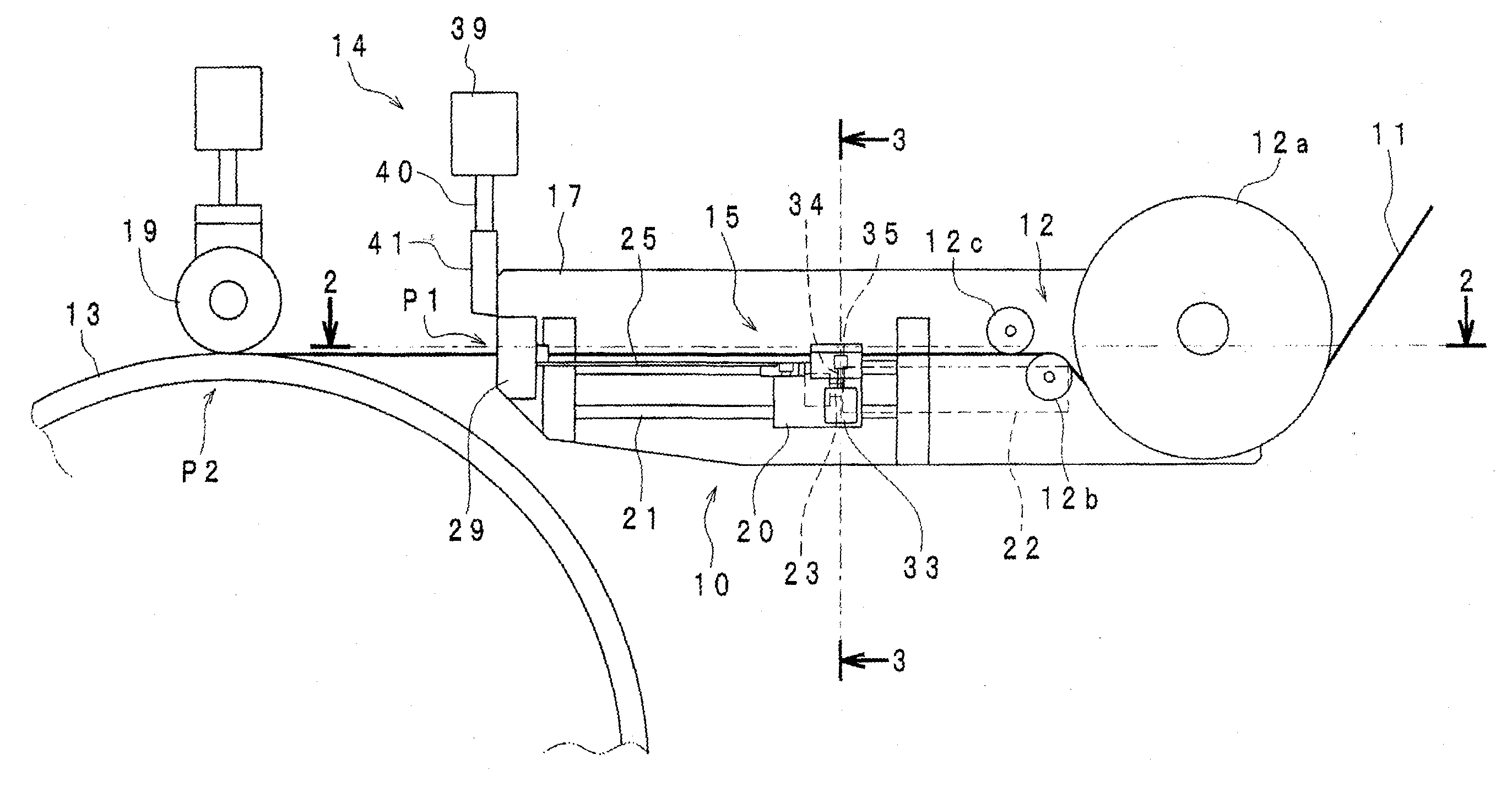

Bead wire winding and forming device

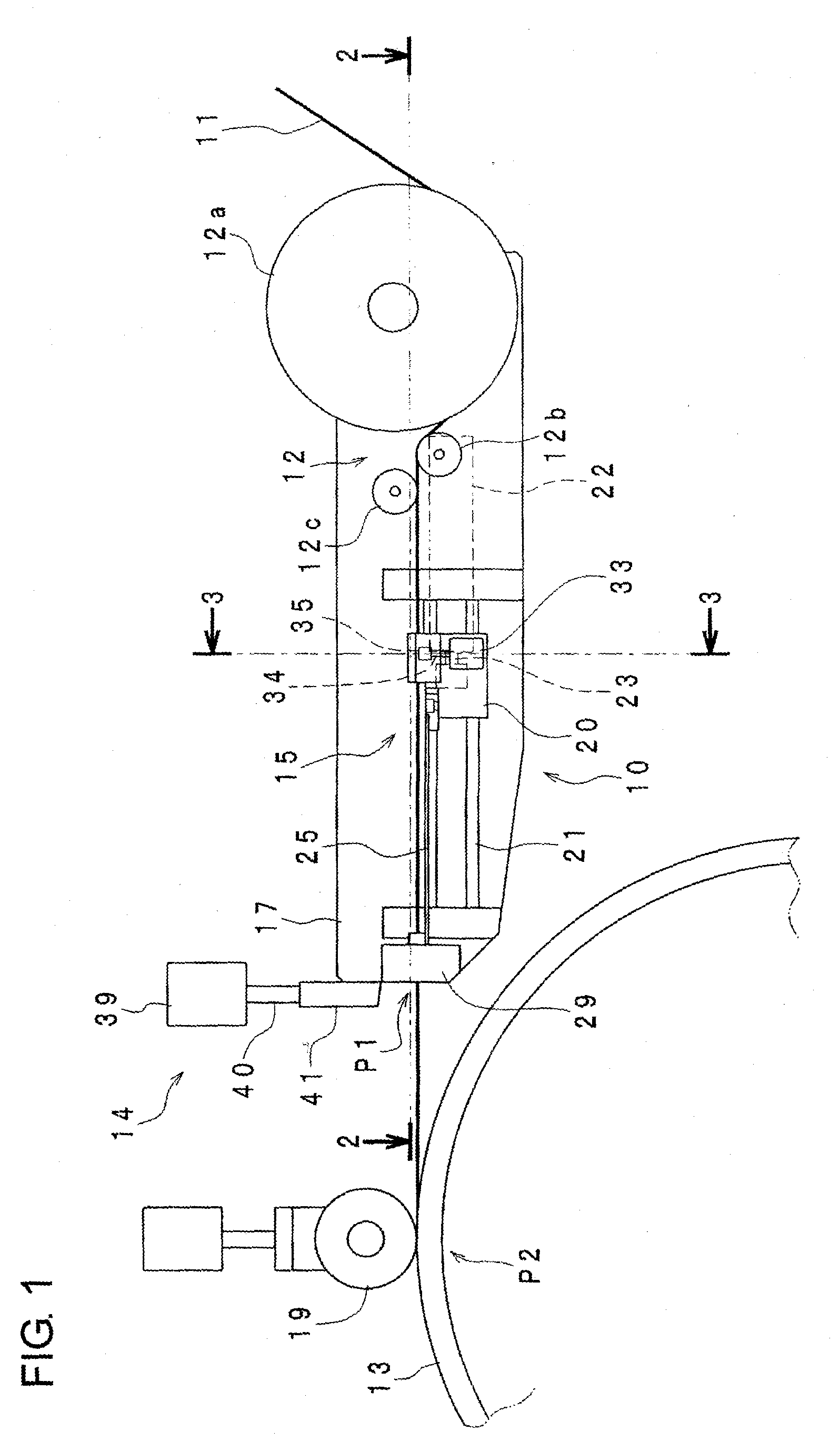

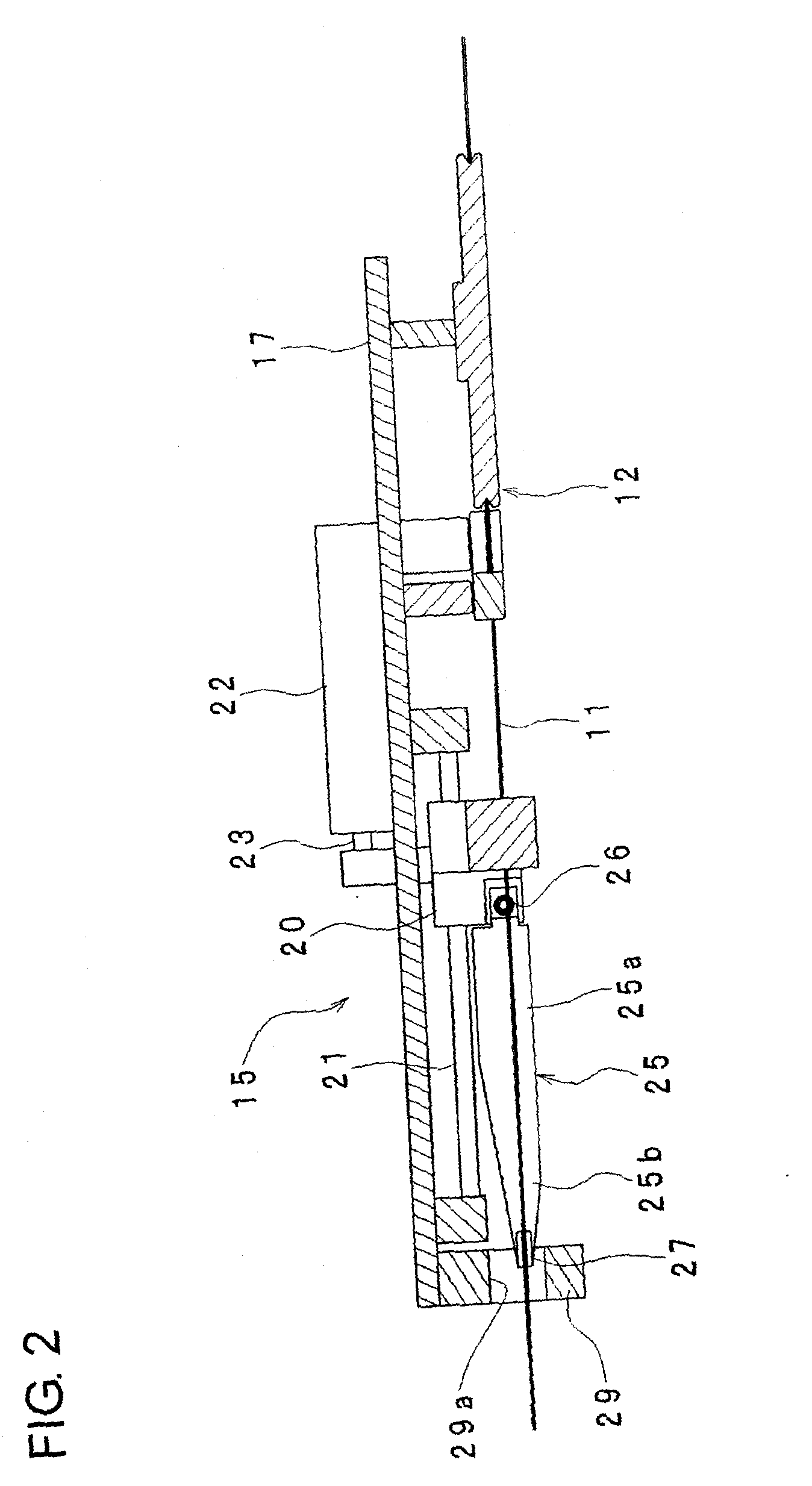

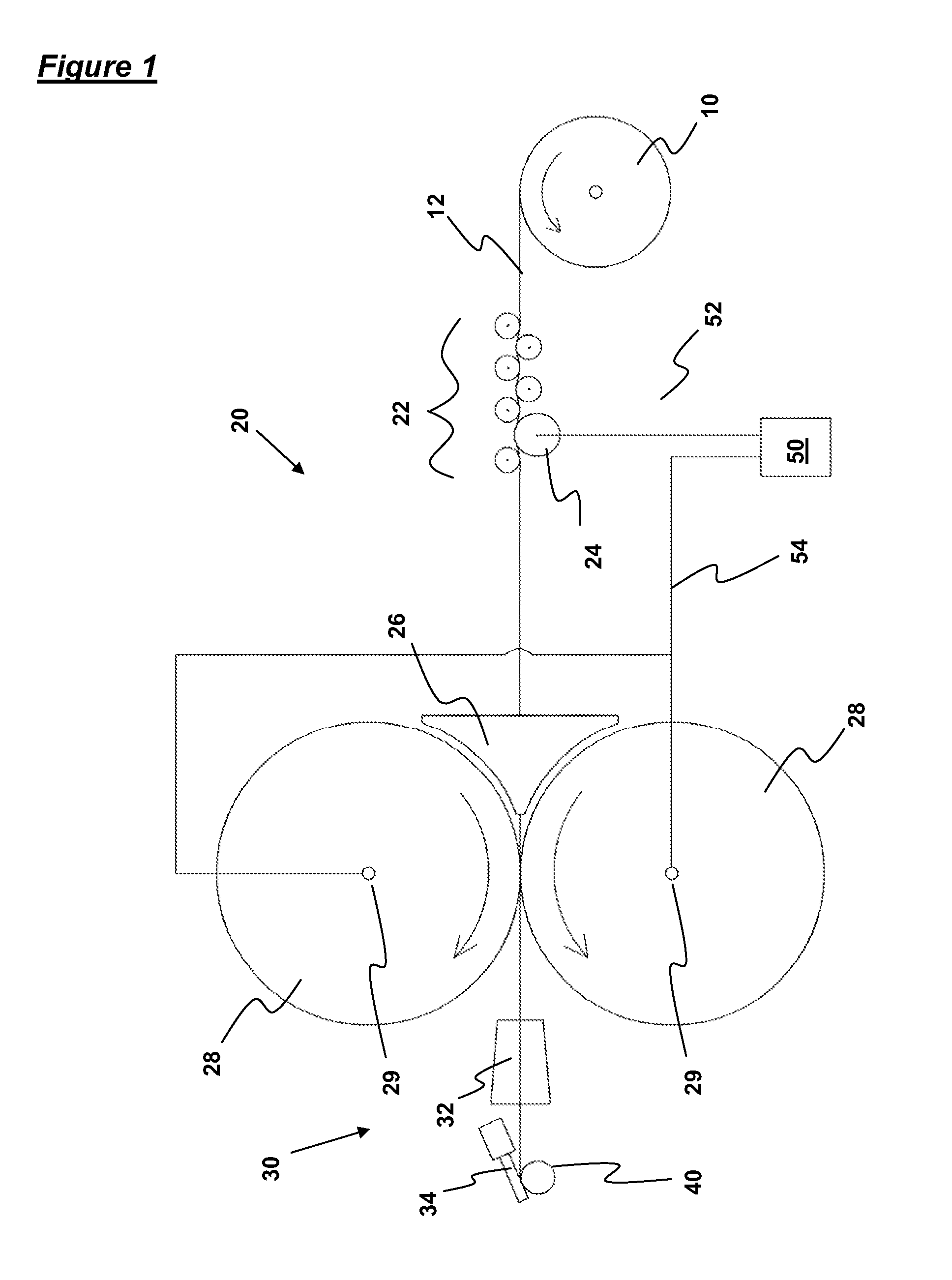

ActiveUS20110030835A1Winding and forming of the bead wire can be carried out reliably and accuratelyFreedom of movementFilament handlingTyresRotational axisEngineering

In a bead wire winding and forming device, a guide mechanism guiding a bead wire to a former is supported to be movable in a tangential direction of the former and includes a movable body capable of clamping and unclamping the bead wire, a guide body supported on the movable body to be swingable in a plane parallel to a rotational axis of the former and having a guide portion for guiding the bead wire in the tangential direction of the former, and a restriction member for allowing the swing motion of the guide body when the movable body is at a retracted position but for restricting the swing motion of the guide body when the movable body is at an advanced position.

Owner:THE YOKOHAMA RUBBER CO LTD

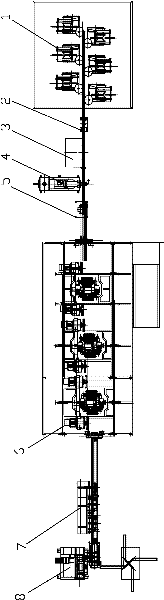

Radial tire bead ring winding machine with six stations

The invention discloses a radial tire bead ring winding machine with six stations, comprising a wire arraying device, a wire feeding device, a wire cutting device and a winding device, wherein the winding device comprises a stand, a sliding shaft driving motor, a sliding shaft, a main shaft, a main shaft driving motor and a speed reducer; a main connecting disk is installed on the main shaft; a plurality of fixed linear rails in an outward radiating form from the center are uniformly distributed on the end face of the main connecting disk; an umbrella stand seat is installed on a sliding block of the linear rail; a hexagonal pyramid-shaped movable umbrella stand is arranged fixedly at the end part of the sliding shaft; a winding module is detachably and fixedly arranged on the umbrella stand seat; and a plurality of wire winding grooves are uniformly distributed along the circumference direction of a cambered surface on the winding module. According to the radial tire bead ring winding machine with six stations disclosed by the invention, six wire winding grooves are arranged on the winding module, thus the bead rings can be wound in the six stations simultaneously, the production efficiency is improved by at least more than 50% compared with two-ring and four-ring winding, bead rings with different diameters can be effectively wound by controlling the positions of the movable umbrella stand and the umbrella stand seat, and the diameter range of the bead rings is 13-25cun.

Owner:TIANJIN SAIXIANG TECH

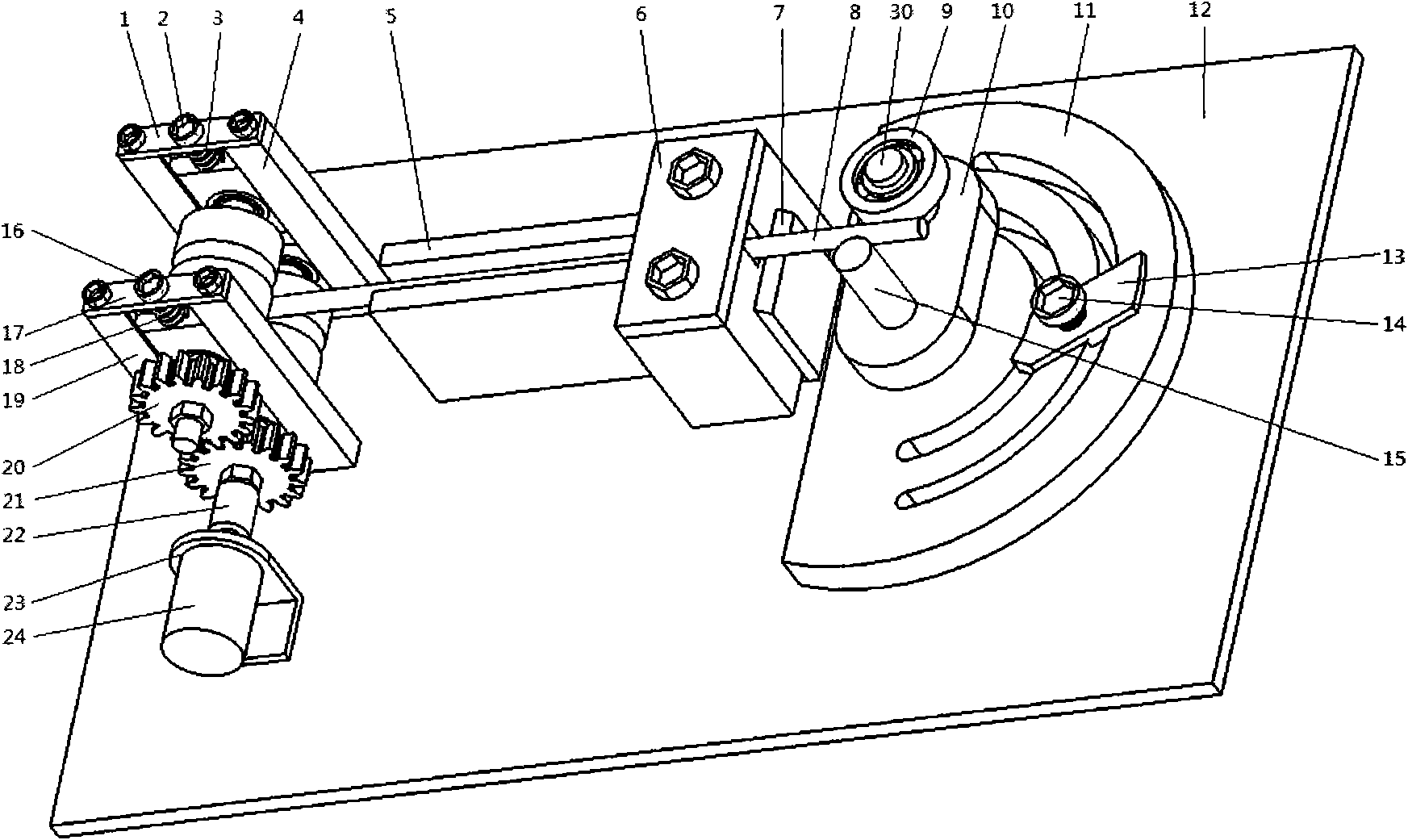

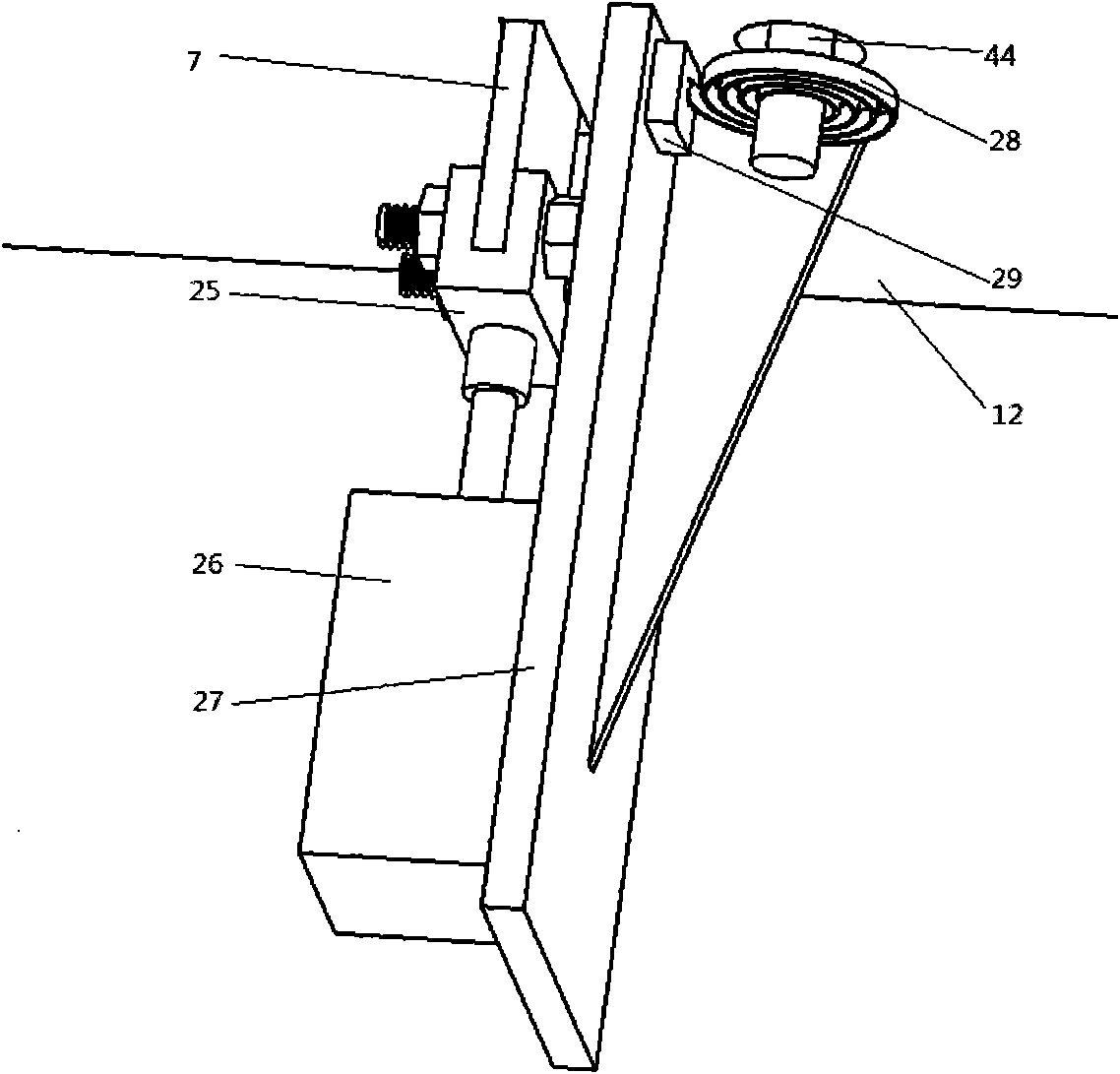

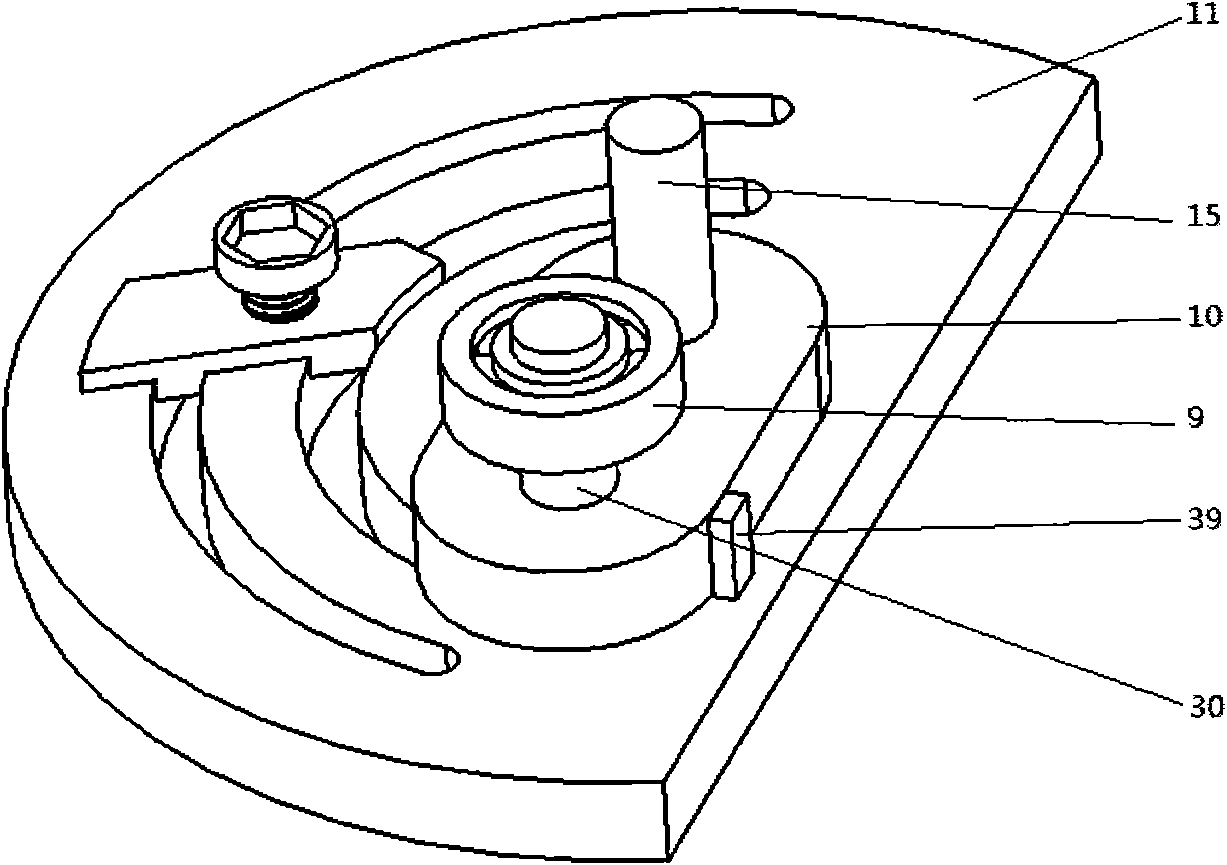

Metal ring machining device and using method thereof

InactiveCN102145367AEasy and intuitive to useReduce labor intensityWire ringsAutomatic controlEngineering

The invention discloses a metal ring machining device and a using method thereof. The metal ring machining device comprises a first pressing plate, a first adjusting bolt, a first hold-down bolt, a first U-shaped guide rail, a feeding guide rail, a fixed plate, a cutter, a metal wire to be machined, a bending roll wheel, a rotating block, a compass, a working platform, a pointer, a pointer fastening screw, a permanent roll wheel, a second adjusting bolt, a second pressing plate, a second hold-down spring, a second U-shaped guide rail, a driven gear, a driving gear and other parts. When the metal ring machining device is used, a corresponding radius numerical value is marked on the compass, and various annular metal rings or arc-shaped metal rings with different diameters can be automatically formed by only changing the position of the pointer, therefore, the metal ring machining device is more intuitive and feasible in use and operation during production. The metal ring machining device has the advantages of simple mechanical structure and control mechanism, high production efficiency and low working intensity of operators, ensures that automatic control and mechanical production can be realized easily, and meets the requirement for common production, and the product has a certain precision. The metal ring machine device has the advantages of simple structure, convenience for maintenance and low maintenance cost.

Owner:ZHEJIANG UNIV

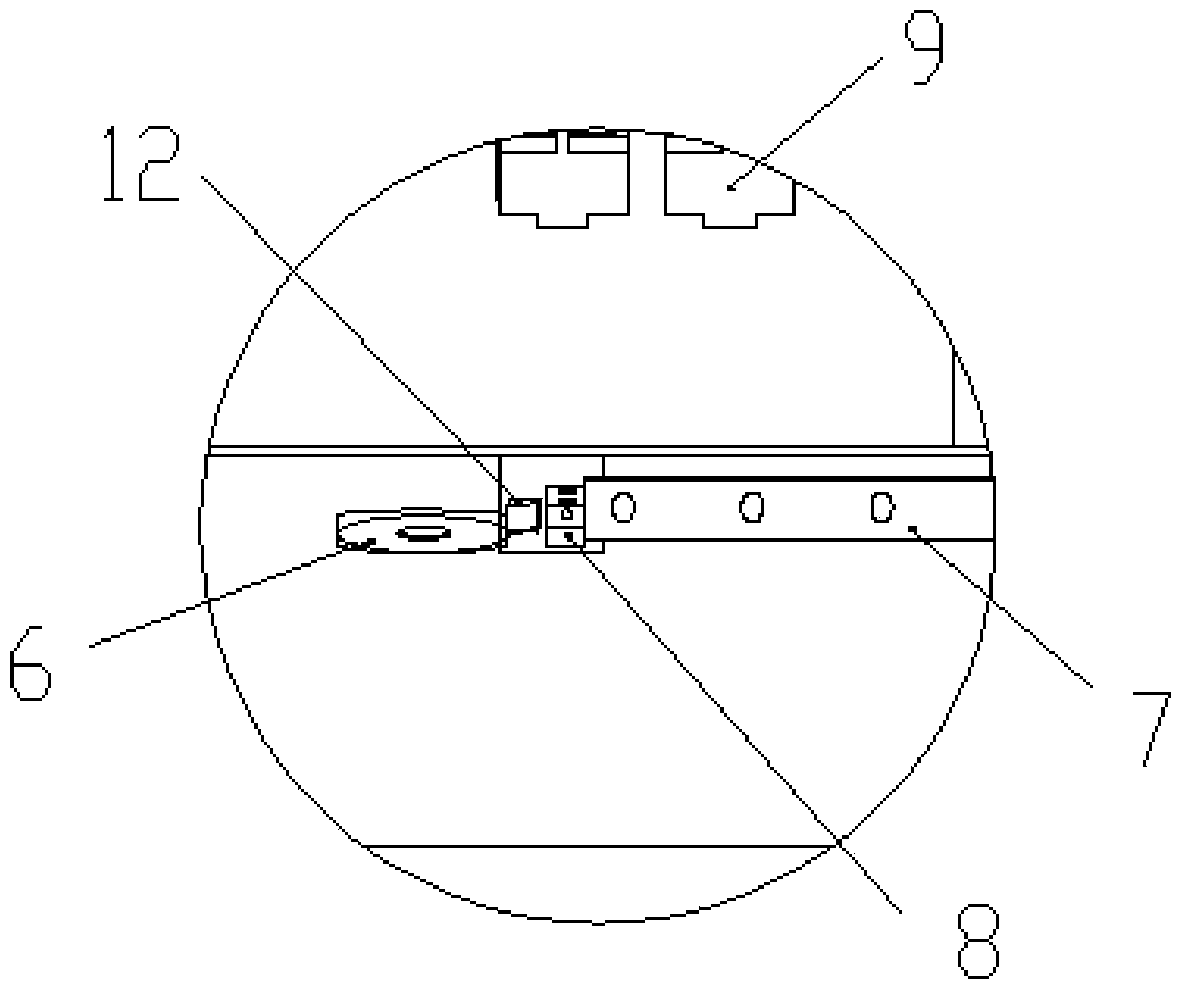

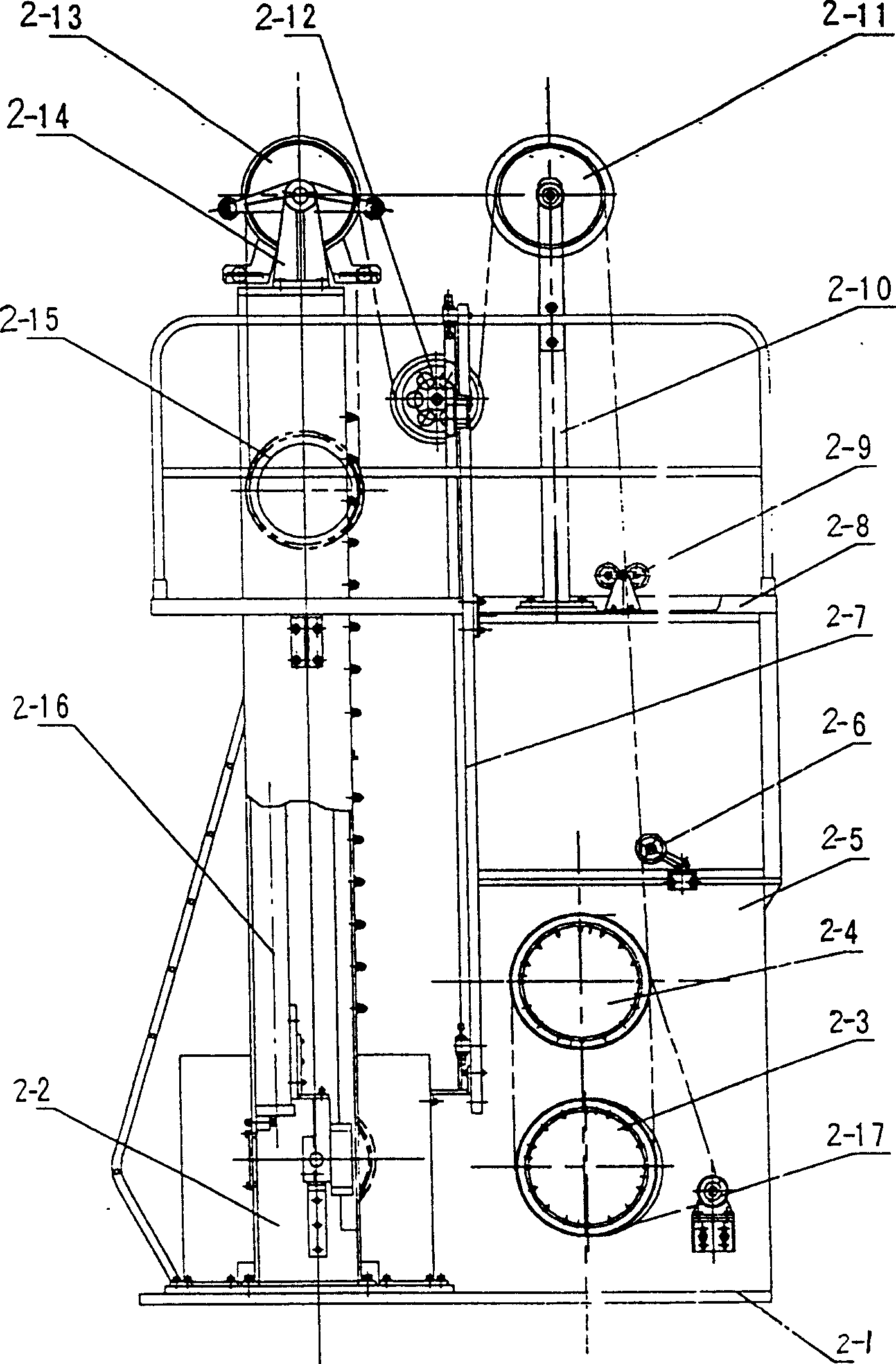

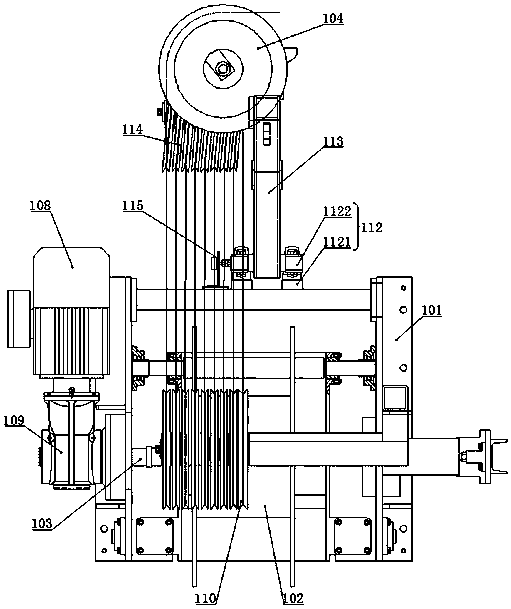

Steel wire ring winding machine

The invention discloses a steel wire ring winding machine, and belongs to the technical field of winding machines. A main transmission device is arranged on one side of a rack, a stored wire and steel wire tension controlling device is arranged on the upper portion of the main transmission device, and a steel wire positioning and clamping rotating device is arranged on the other side of the rack. The steel wire ring winding machine is simple in structure and easy to produce and manufacture. Rotating directions of an outer layer and an inner layer of the wound steel wires are opposite, the steel wire in one layer rotates leftwards, the steel wire in the other layer rotates rightwards, no rubber filling is required between the steel wires, and the steel wire ring winding machine can be directly used in manufacturing of tires. The tire produced by the steel wire rings manufactured by the steel sire ring winding machine is applicable to usage in high internal pressure, high load, large deformation and strong impact load. A tire bead portion of the tire is not easy to damage even if large yielding deformation is repeatedly generated, delaminating or cord thread breaking between the steel wire ring and a cord fabric surface is avoided, and durability of the tire is greatly improved.

Owner:哈尔滨工大宏图橡塑科技有限公司

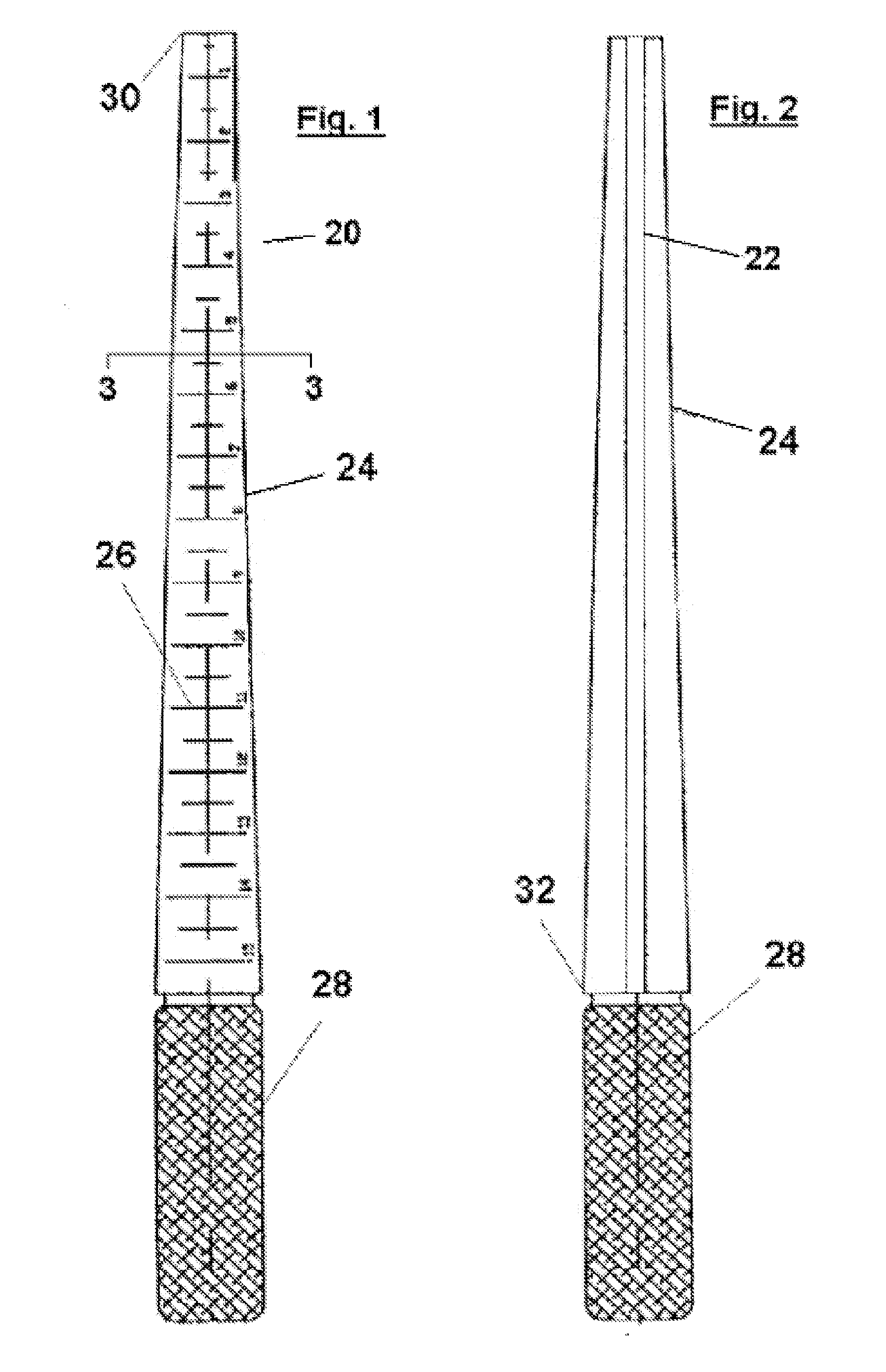

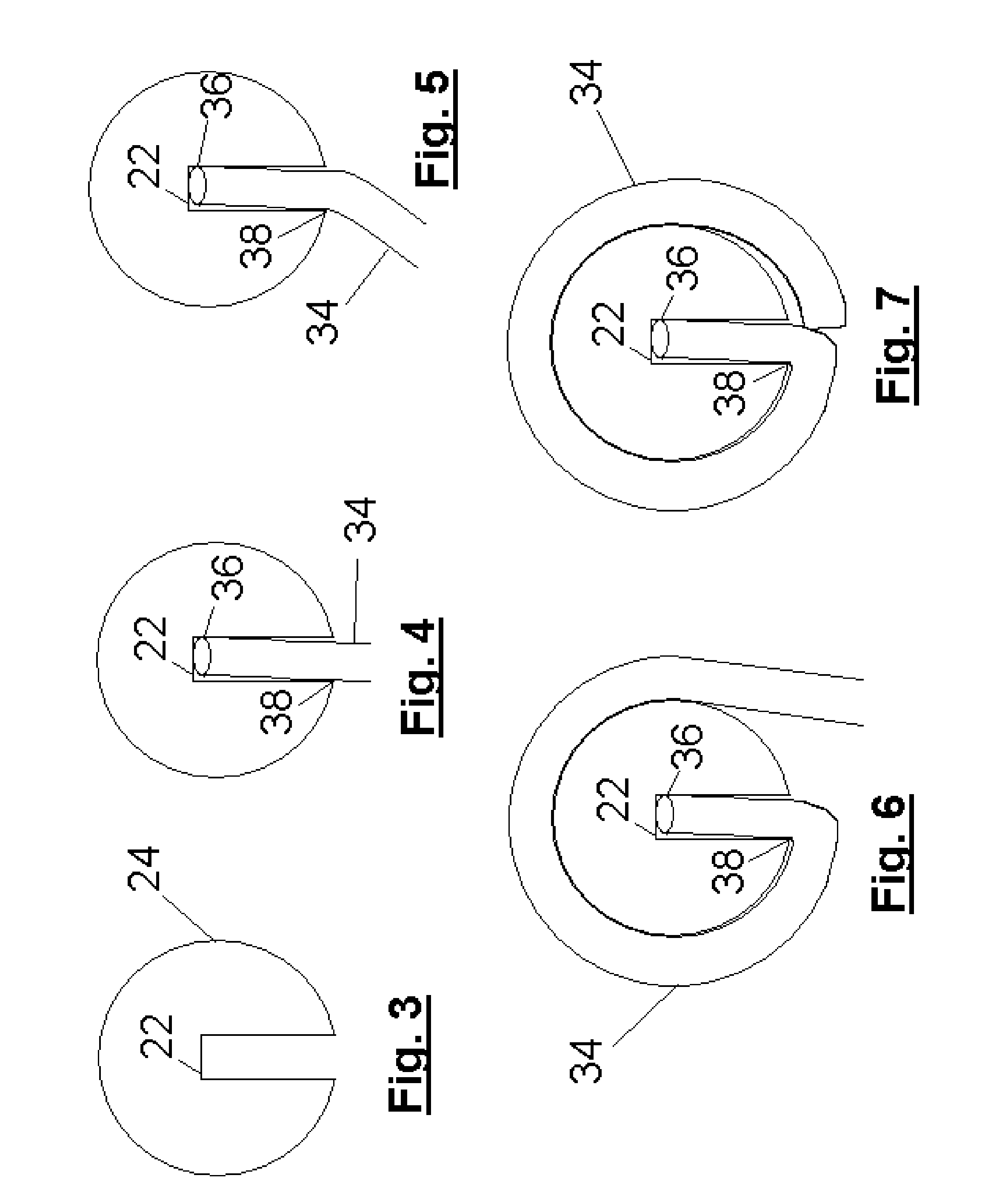

Jewelry Mandrel and Method of Using the Same

A jewelry mandrel having a tapered shaft with an axial groove in the surface of the shaft. The axial groove is capable of accepting one end of a metal wire at a pre-selected location and the depth and width of the groove are sized, such that the metal wire is not generally displaced axially from the pre-selected location as the wire is wound around the perimeter of a cross-section of the shaft.

Owner:TERESIAK MACIEJ A

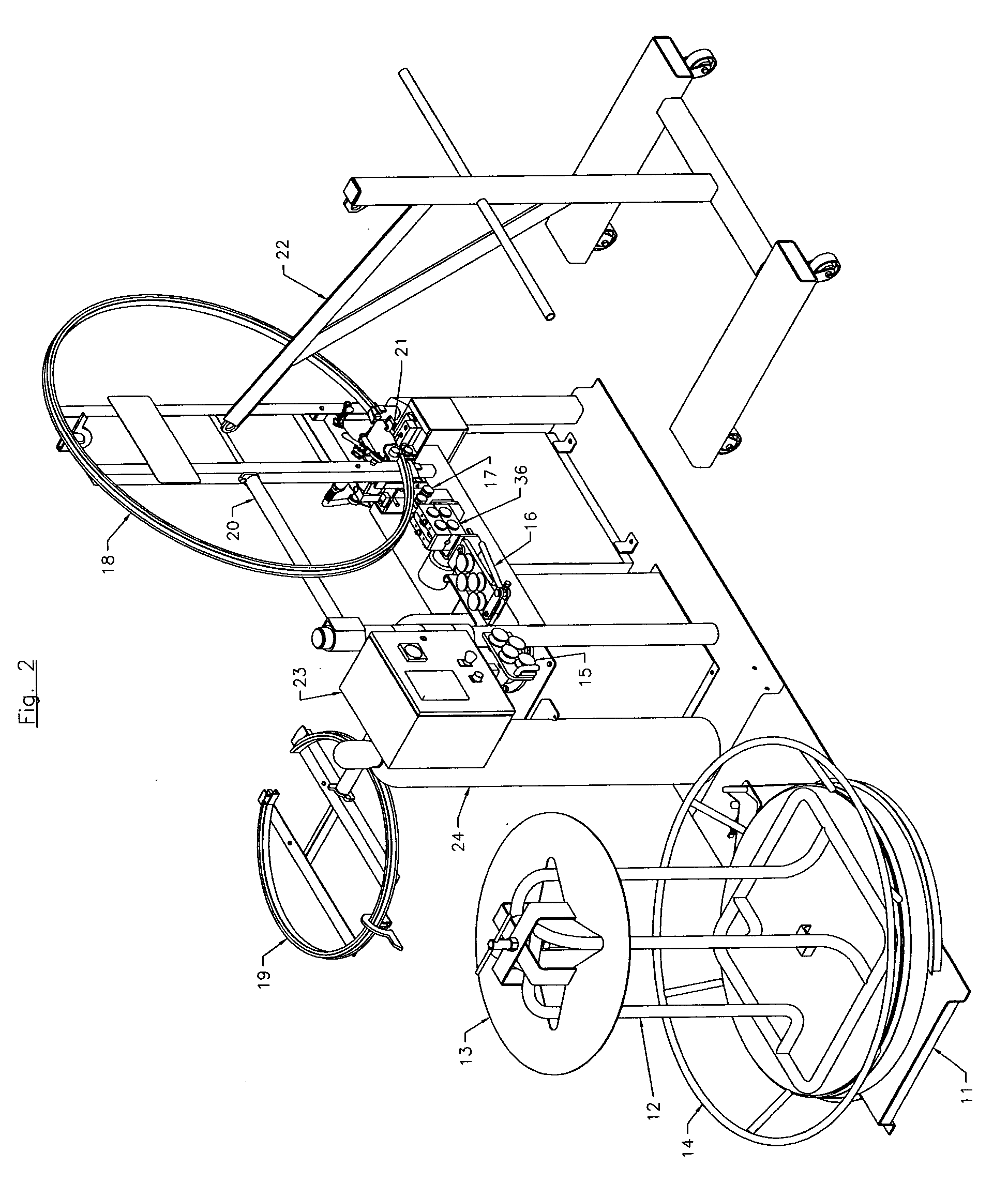

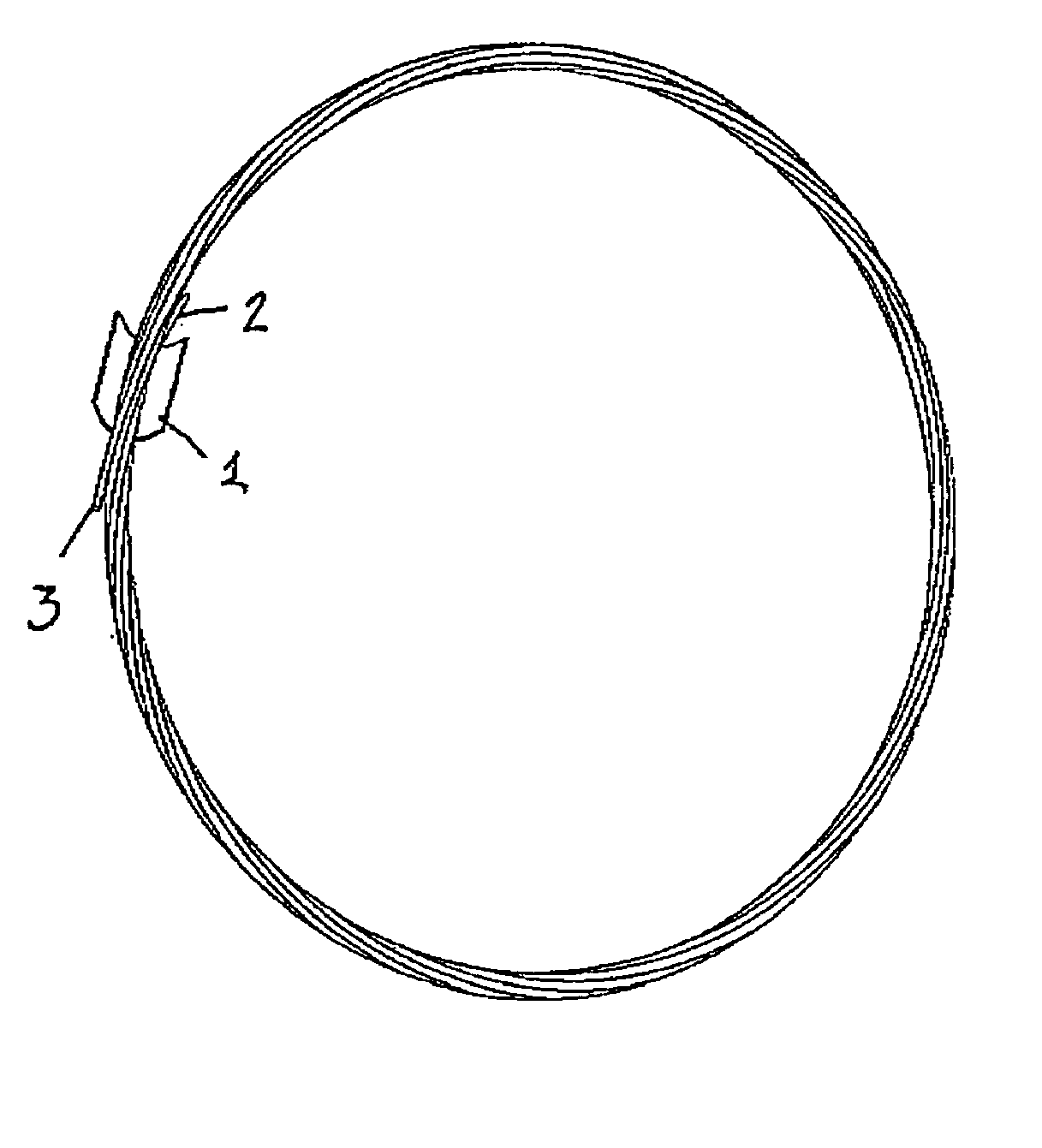

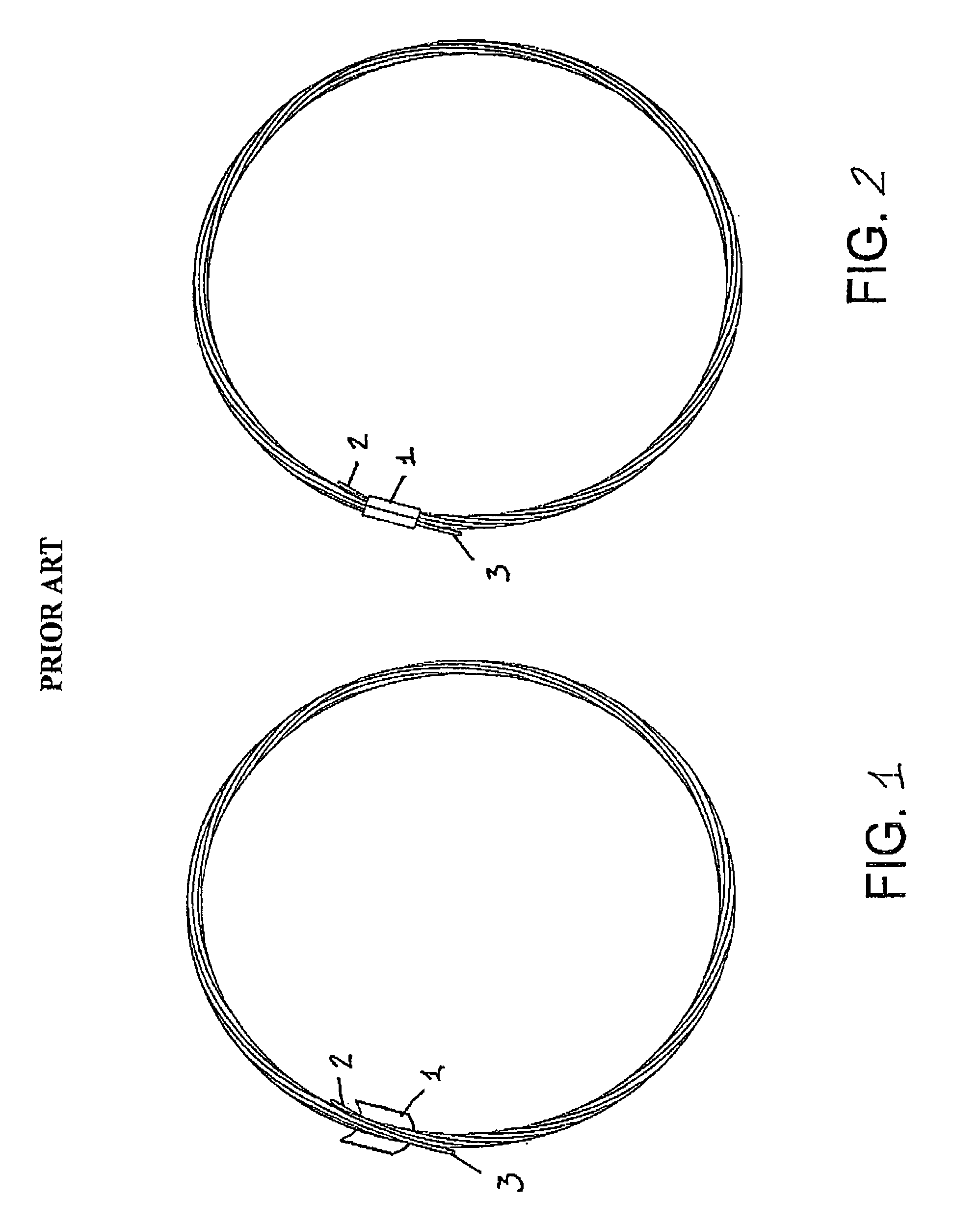

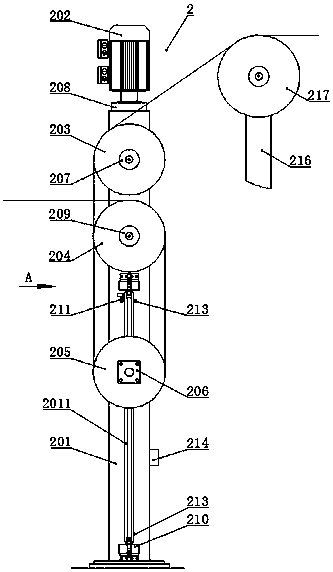

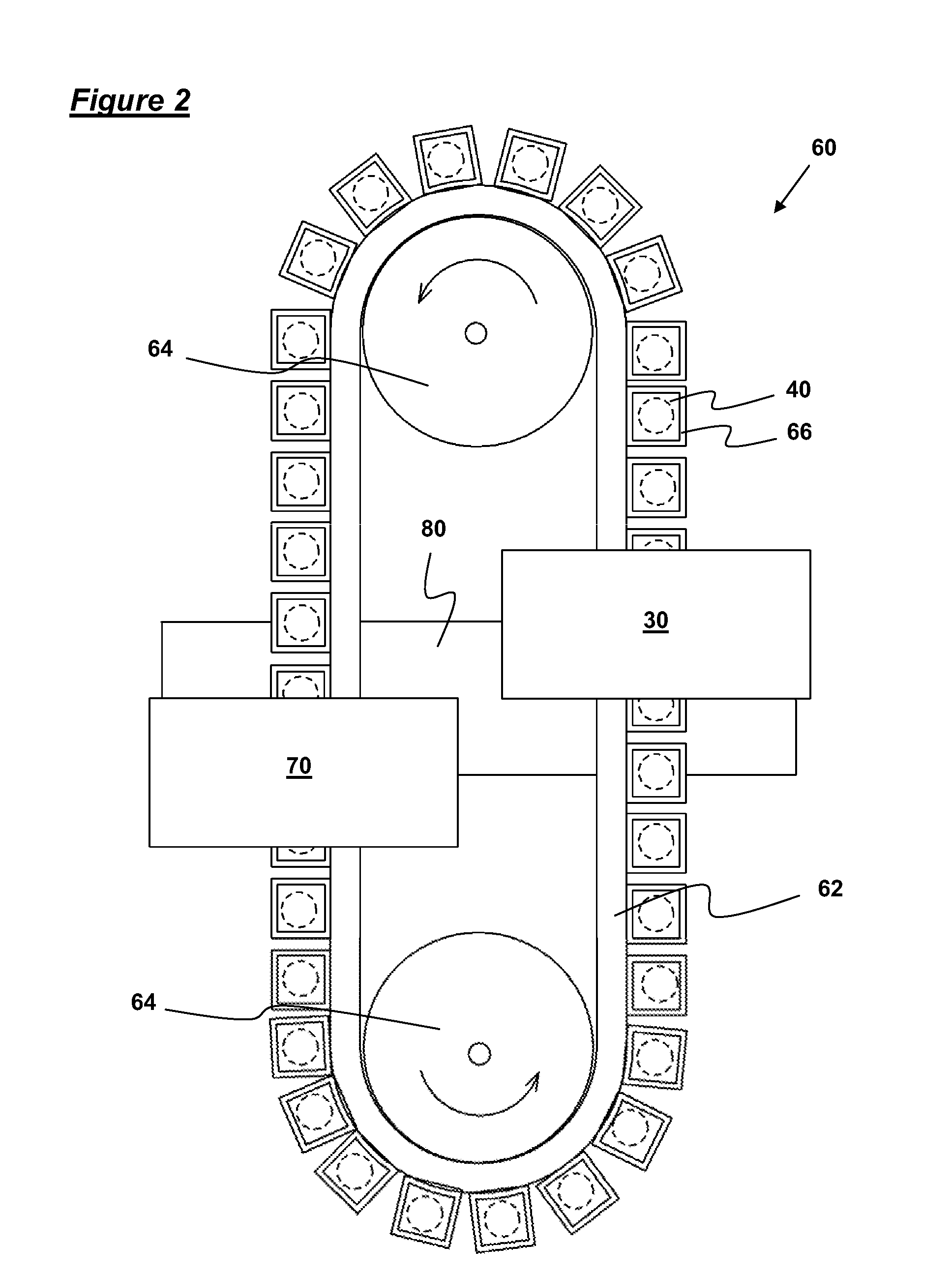

Method and apparatus of manufacturing annular concentric stranded bead cord

InactiveCN101200120AGood formabilityDo not disturb alignment stateTyresWire ringsEngineeringConductor Coil

A method of manufacturing an annular concentric stranded bead cord, wherein, while rotating an annular core at a fixed position in a peripheral direction, a reel, upon which a lateral wire is wound, repeatedly performs a pendulum swinging movement and a perpendicular movement with respect to the annular core, thereby spirally winding the lateral wire upon the annular core to form a sheath layer. When forming the sheath layer, a fulcrum of the pendulum swinging movement of the reel is determined so that, with reference to a tangential line of a circle of the annular core passing through a winding point where the lateral wire is wound upon the annular core, the lateral wire is wound upon the winding point of the annular core within 15 degrees at a position above the tangential line and within a range of 55 degrees at a position below the tangential line.

Owner:SUMITOMO (SEI) STEEL WIRE CORP +1

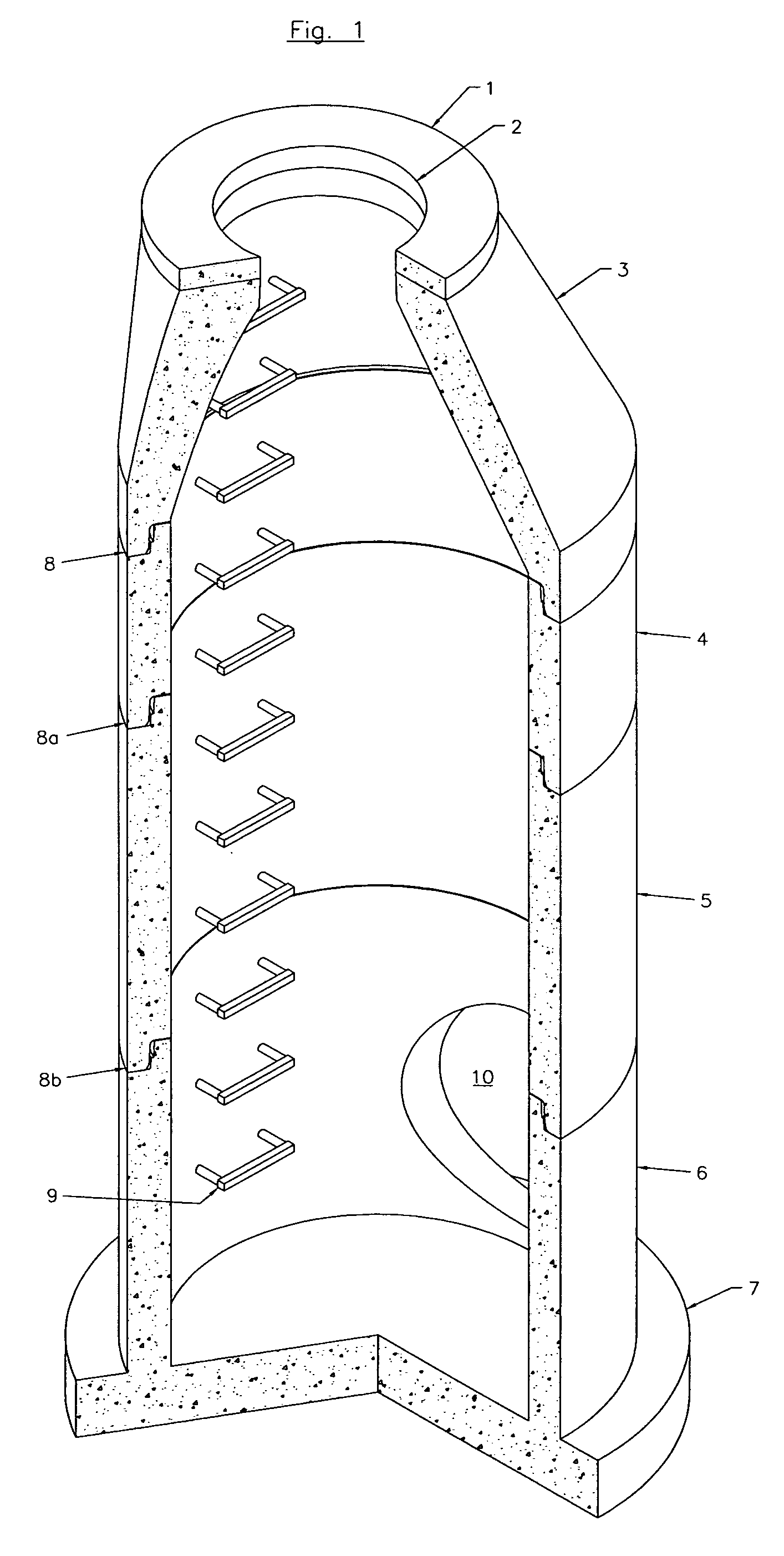

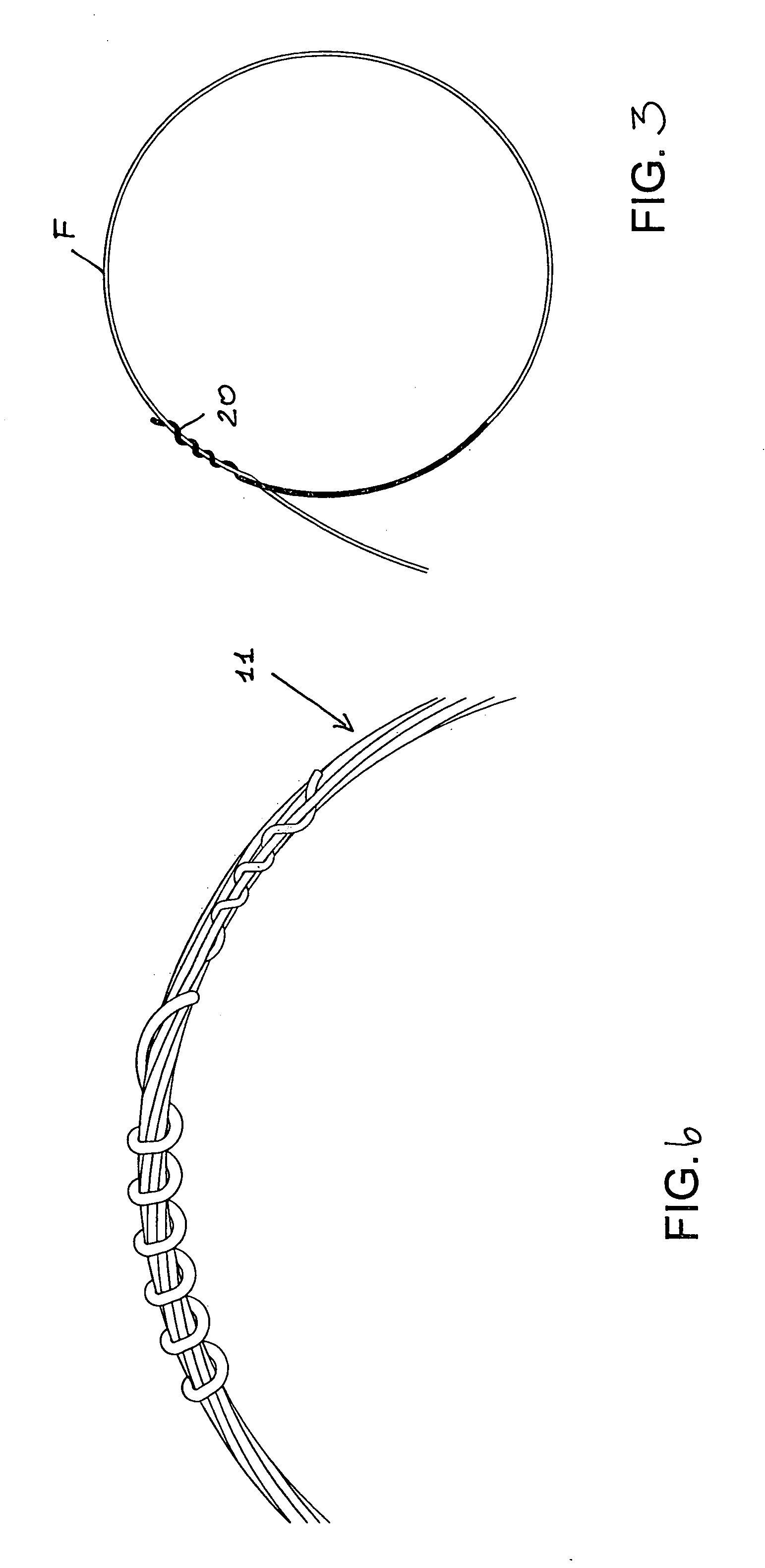

Wire ring net for rocky wall barriers and method for making it

InactiveUS7108233B2Optimum strength and constructional characteristicIncrease clamping forceMeshed-ring wire networkProtective constructionElectric wireEngineering

A wire ring net, particularly for providing barriers for rocky walls and the like comprises a plurality of braided wire rings, each wire ring comprising, at a starting end of its wire, a first curled portion wound about the wire of the first turn and, at the terminal, end of the wire, a second curled portion wound about the rope forming the wire ring.

Owner:IGOR

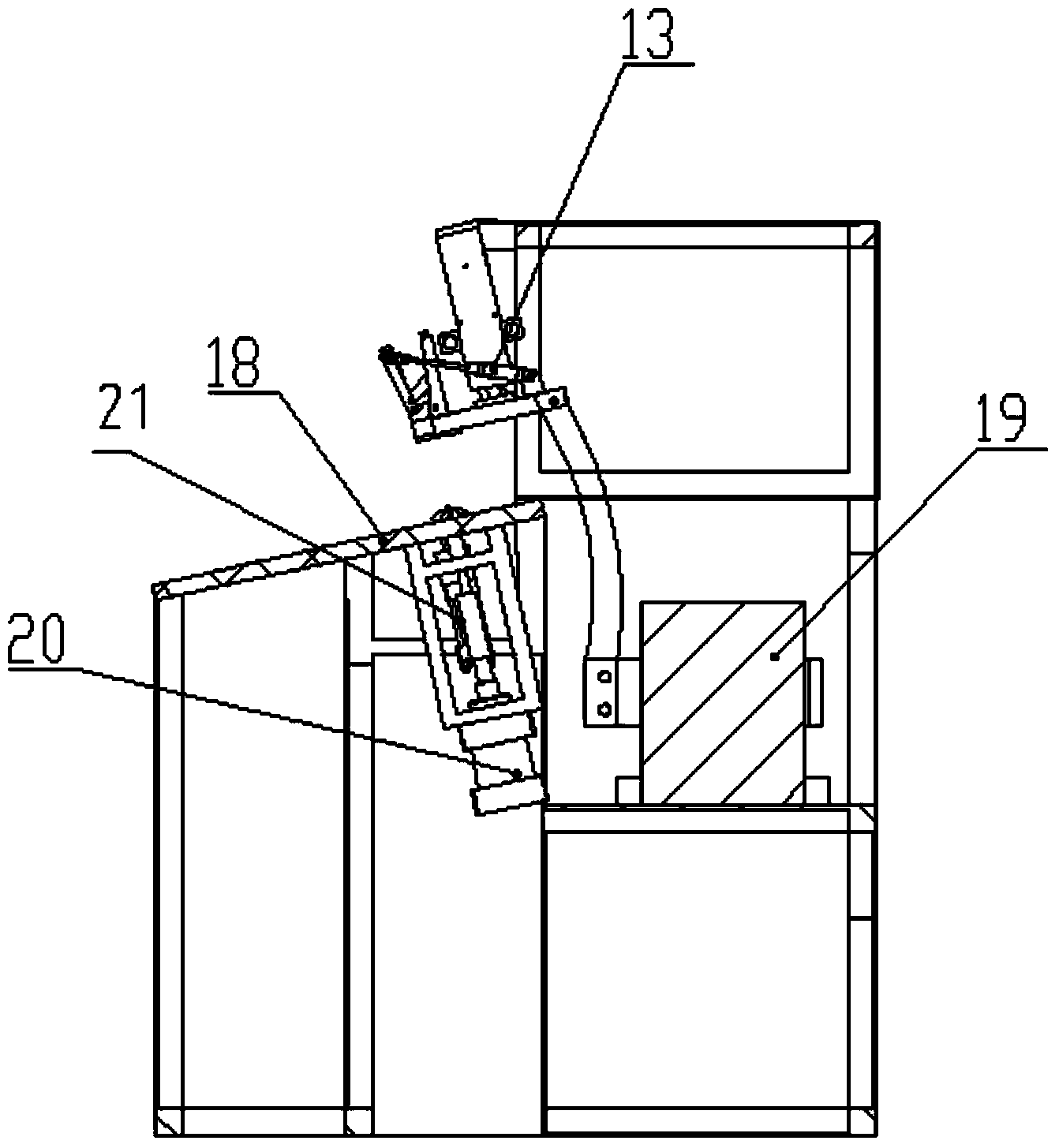

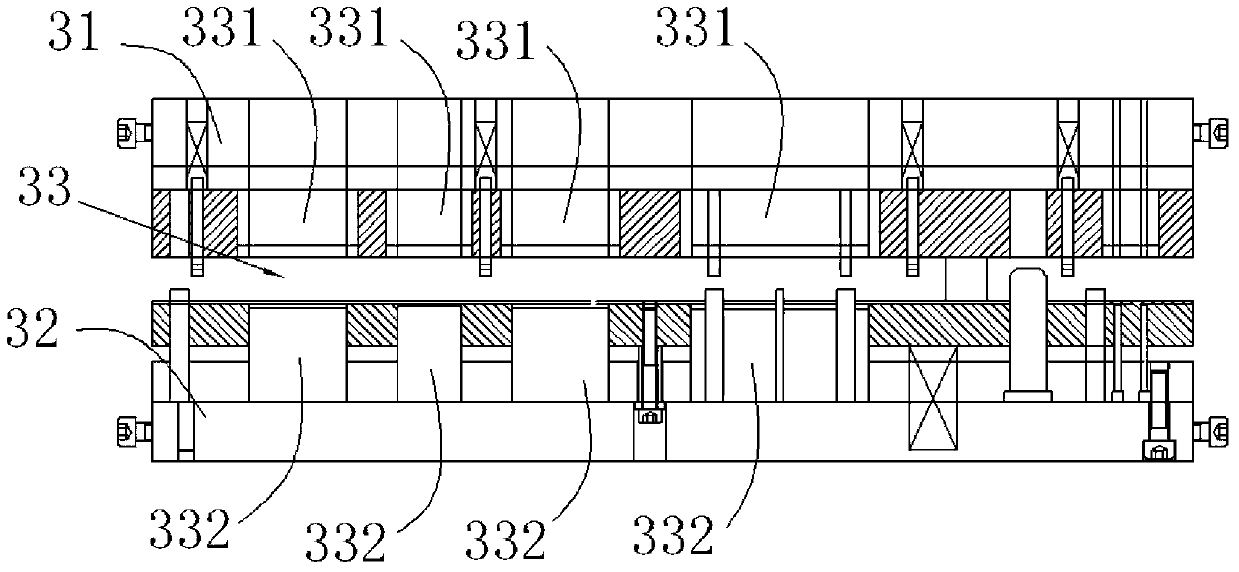

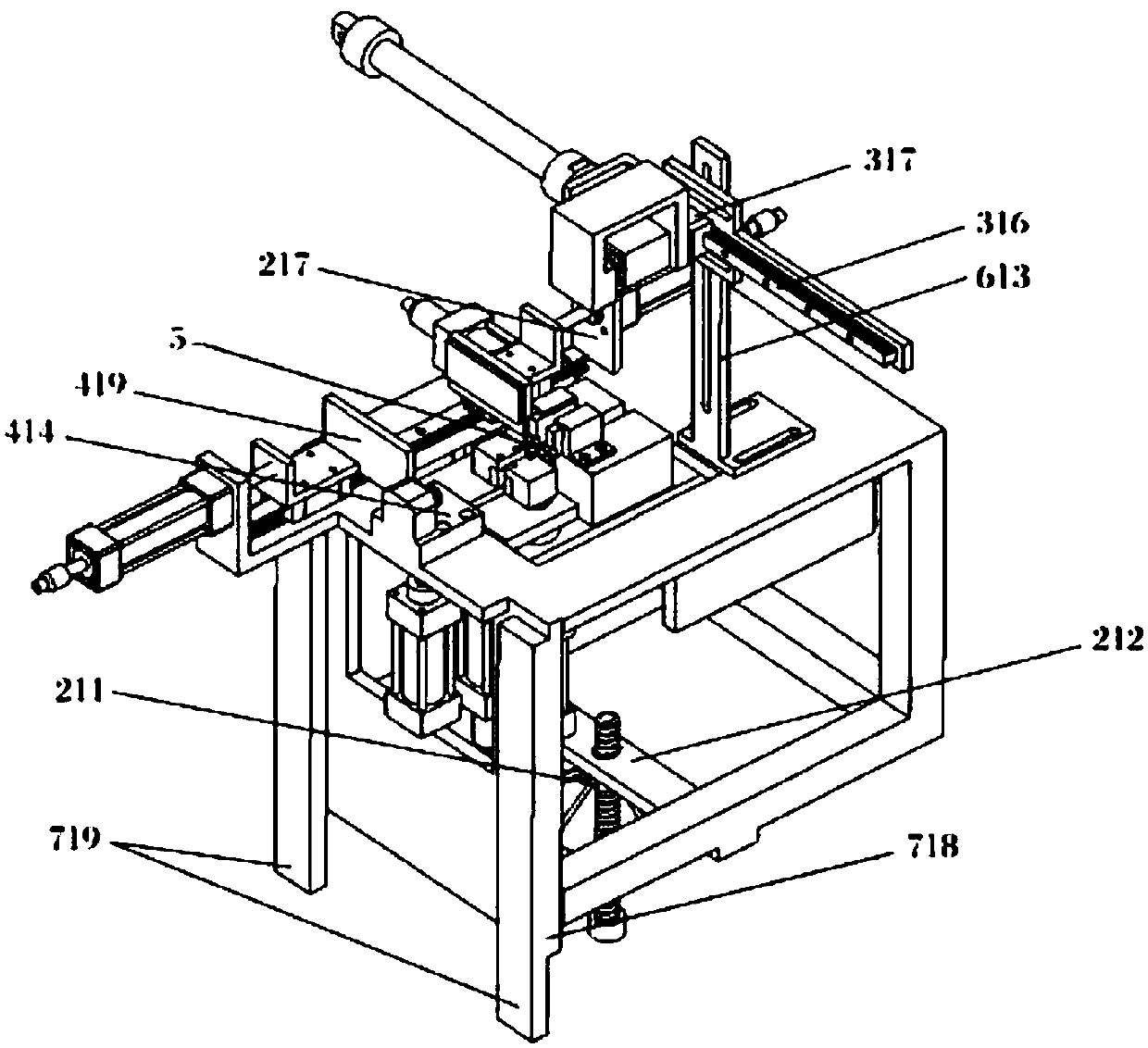

Steel wire ring positioning clamping rotating device of steel wire ring winding machine

The invention provides a steel wire ring positioning clamping rotating device of a steel wire ring winding machine and belongs to the technical field of rotating devices. The device is characterized in that three pairs of help rollers are arranged on a rear machine plate, a steel band is in transmission connection with a central roller and two transmission rollers respectively and provided with a manipulator, an upper-portion guide steel plate is fixed on a supporting steel plate, a lower-portion guide steel plate is arranged on the lower portion of the upper guide steel plate, and the lower end of the lower-portion guide steel plate is connected with a hydraulic cylinder. The steel wire ring positioning clamping rotating device is simple in structure and easy to produce and manufacture, rotating directions of steel wires between an inner layer and an outer layer of a wound steel wire ring, the steel wire on one layer rotates leftwards while the steel wire on the other layer rotates rightwards, filling of rubber between the steel wires is not needed, shearing force cannot be generated in any circumstances, and the steel wire ring positioning clamping rotating device can be directly used in manufacturing of tires. Tires produced by using steel wire rings manufactured by the steel wire ring positioning clamping rotating device of the steel wire ring winding machine is suitable for occasions with high internal pressure, high load, big deformation and quite strong impact load.

Owner:哈尔滨工大宏图橡塑科技有限公司

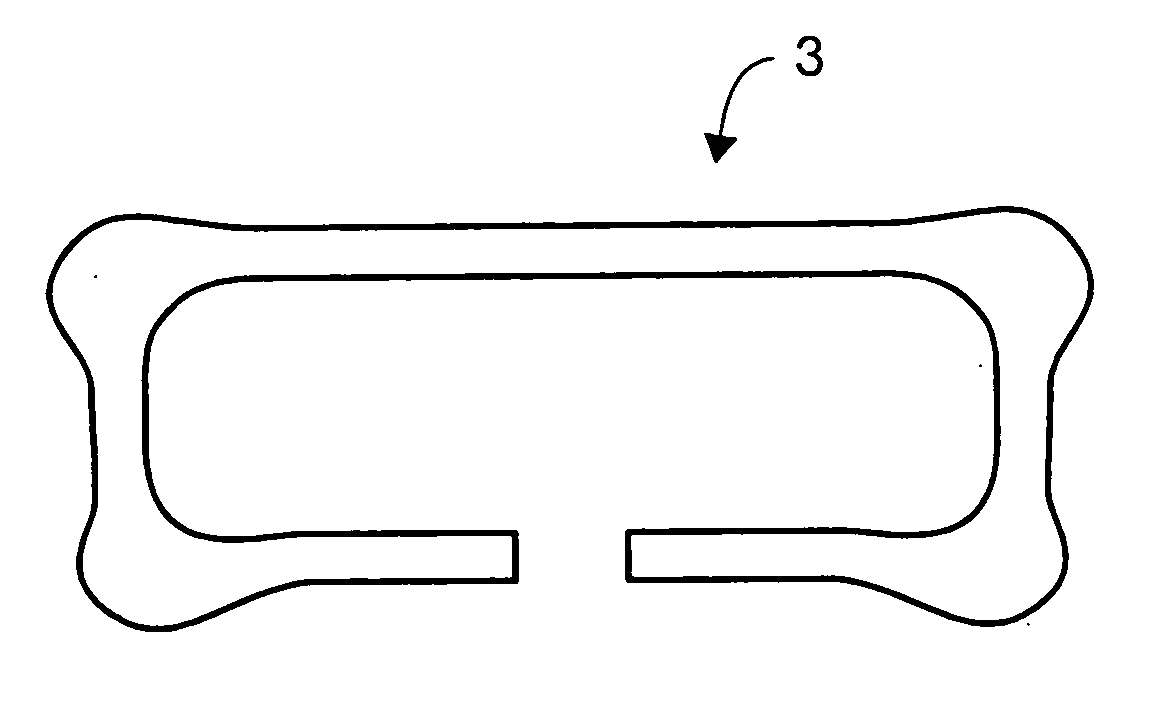

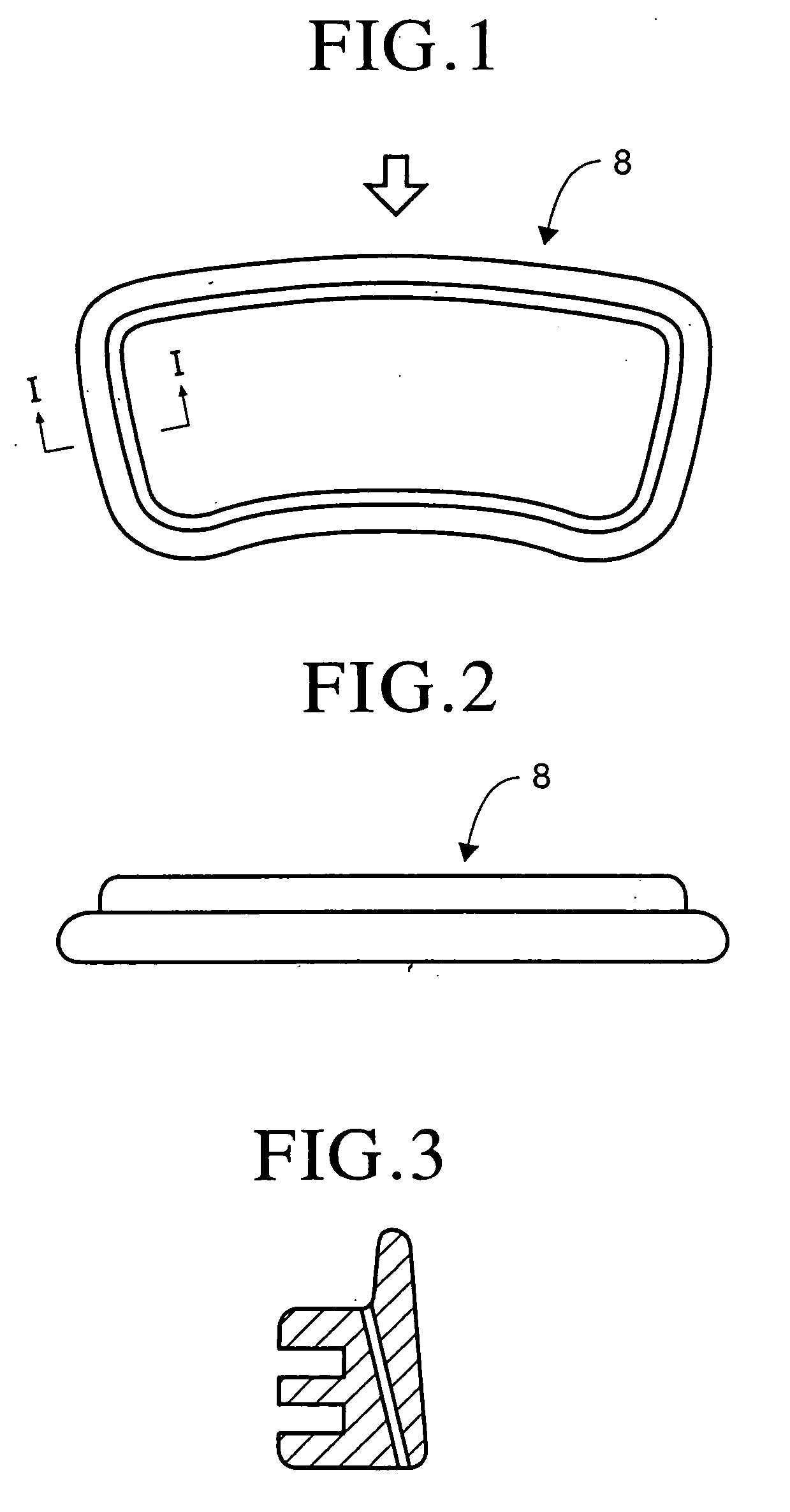

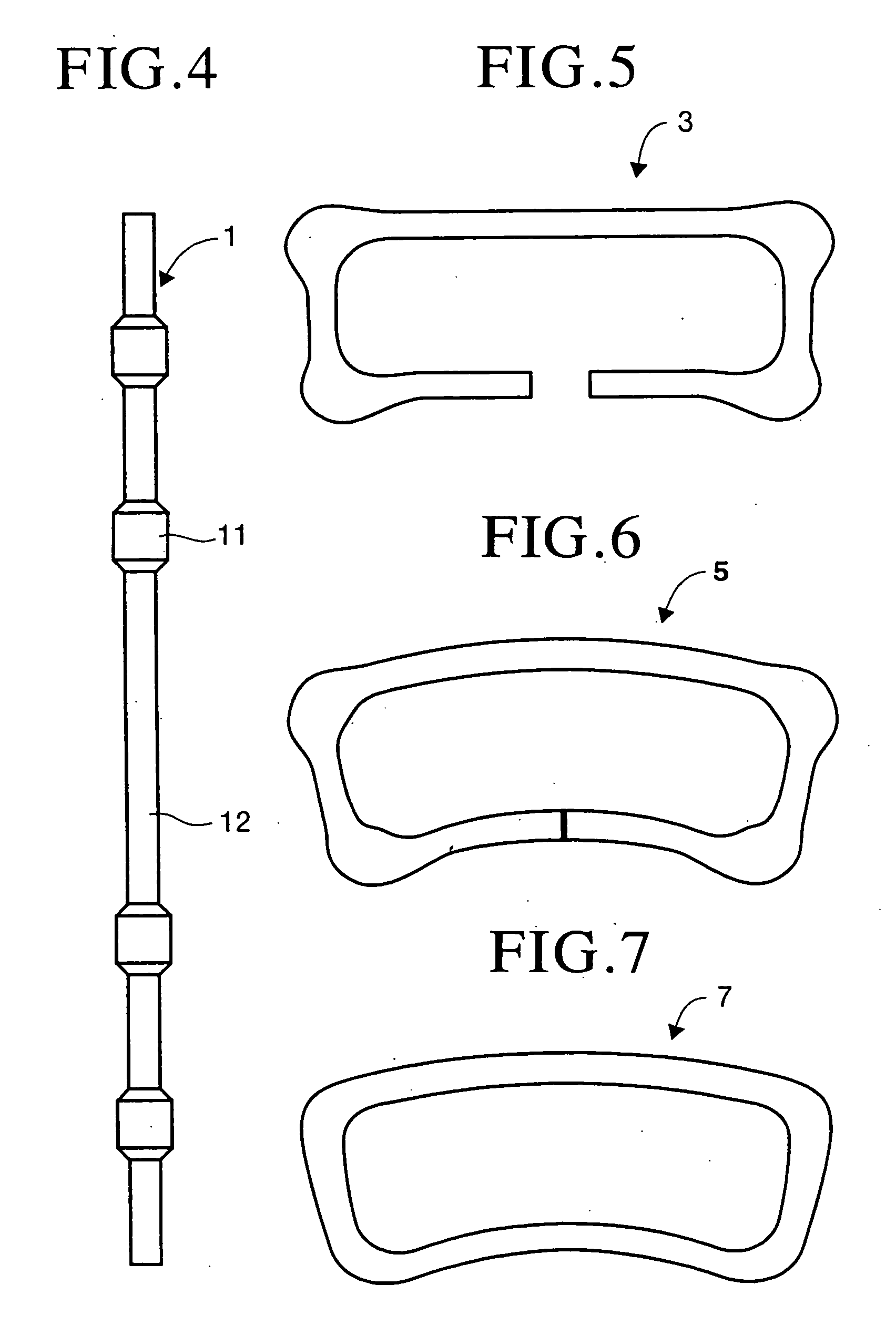

Method of producing polygonal ring-shaped machine parts having complex cross-section

Disclosed is a method of producing a polygonal, ring-shaped machine part having a complex cross-section starting from a metal rod with improved productivity and remarkably increased material yield. The method comprises the steps of: forging a rod to prepare a notched blank 1 having large diameter parts 11 and the remaining small diameter parts 12; bending the large diameter parts 11 to form a first intermediate 3 of polygonal, open ring-shape and a complex cross-section with confronting ends; butting and welding the confronting ends of the first intermediate 3 to form a second intermediate 5; die-forging the second intermediate 5 to form a ring-shaped product 7; and subjecting the product 7 to necessary finishing step such as machining to obtain the final product.

Owner:DAIDO STEEL CO LTD

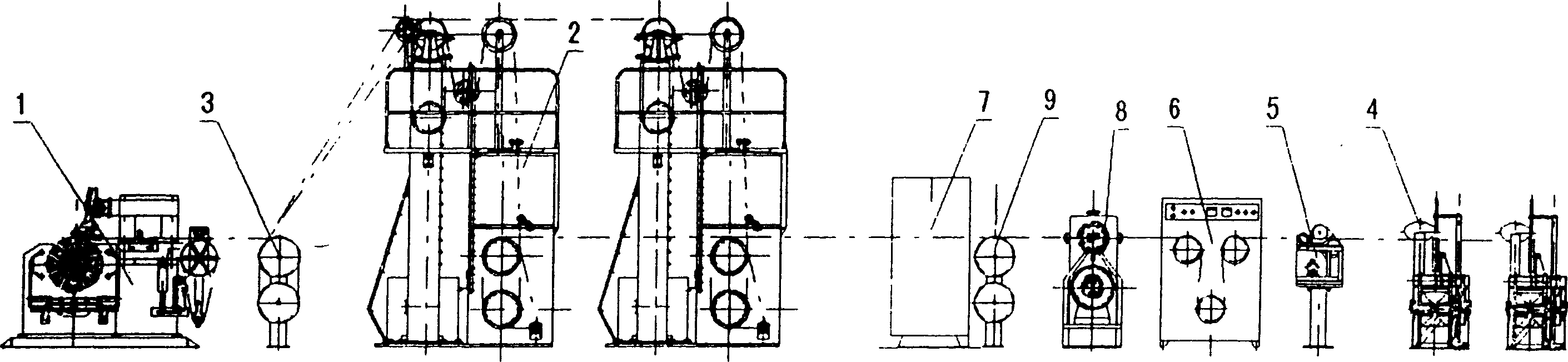

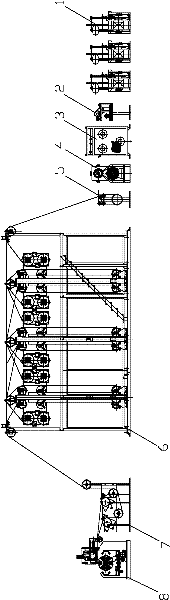

Double-pulling double-ring winding machine set of tyre multikind cross section steel wire ring

InactiveCN1559789AImprove continuous operation functionIncrease storage capacityTyresWire ringsWinding machineEngineering

A dual-turn winder set with double drawings for the steel wire with diferent cross-sections used for tyre is composed of steel wire pilot unit, steel wire cleaning unit, steel wire heater, the temp controller of extruder, rubber extruding out unit, steel wire extending unit, the storage unit with double working positions for ensurijng the continuous working of winding unit, steel wire gathering unit and steel wire winding unit.

Owner:TIANJIN PLASTIC RUBBER MACHINERY INST

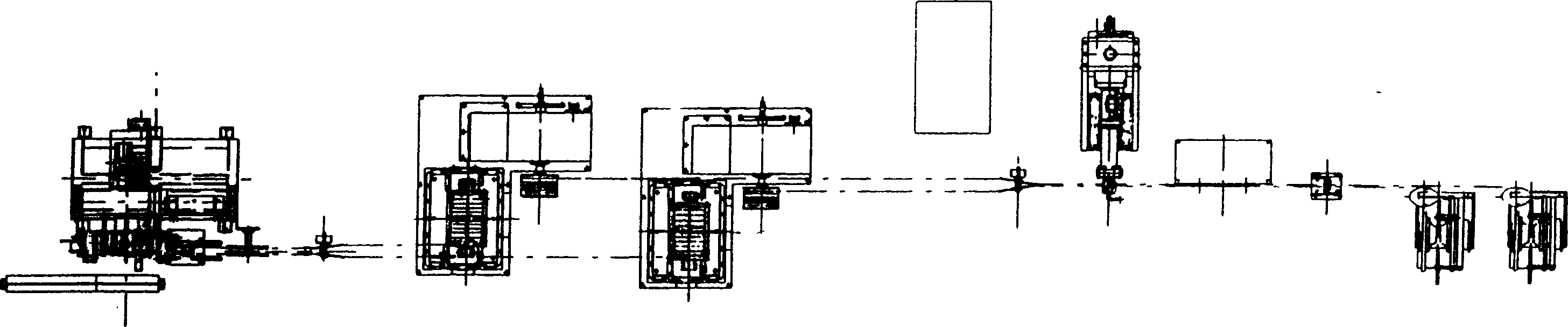

Six-station radial tyre steel wire ring production line

ActiveCN102189202AAchieving a constant angleIncrease productivityTyresWire ringsWinding machineElectric heating

The invention discloses a six-station radial tyre steel wire ring production line capable of effectively improving the winding efficiency. A steel wire unwinding device, a steel wire dirt removing device, a steel wire electric heating device, an extruder, a flaring wire guiding device, a storage device, a bending device and a winding machine are sequentially arranged at intervals in the production line. The winding module of the winding machine of the six-station radial tyre steel wire ring production line with the structure is provided with six wire winding grooves, the distance between two wire winding grooves is reduced by precise processing, the steel wire ring can be simultaneously wound on six stations by optimizing the positions of the parts under the condition that the volume of awinding die disc and the volume of other subsidiary machinery are not increased, the production efficiency is improved by at least over 50 percent compared with two-ring or four-ring winding, the utilization rate of the winding machine and the whole production line is improved, and the energy consumption is reduced.

Owner:TIANJIN SAIXIANG TECH

Machining process of TP (topaz) bead ring for spinning

ActiveCN103170561AGuaranteed growthEasy to processWire ringsSolid state diffusion coatingFriction reductionChemical plating

The invention discloses a machining process of a TP (topaz) bead ring for spinning. The machining process is characterized by comprising the steps of: 1, selecting materials: selecting an excellent-quality alloy steel wire containing elements of W, V, Ni and Co as a raw material; 2, flaking; 3, annealing; 4, forming; 5, quenching-tempering; 6, polishing; and 7, carrying out surface treatment: nickelling the surface of a bead ring matrix by adopting a chemical plating method, and adding a nano powder body in a plating solution to ensure that the nano powder body is co-deposited on the bead ring matrix; and 8, carrying out surface curing treatment: removing the stress and enhancing the hardness to ensure the surface of the bead ring is golden yellow. The TP bead ring machined by adopting the machining process has relatively good abrasion resistance, friction reduction and corrosion prevention properties, is capable of well meeting the requirement on the existing high-count, high-speed and high-efficiency spinning, is particularly suitable for compact spinning and common high-speed ring spinning, and has a good development prospect and a wide market popularization space.

Owner:CHONGQING JINMAO TEXTILE ACCESSORIES

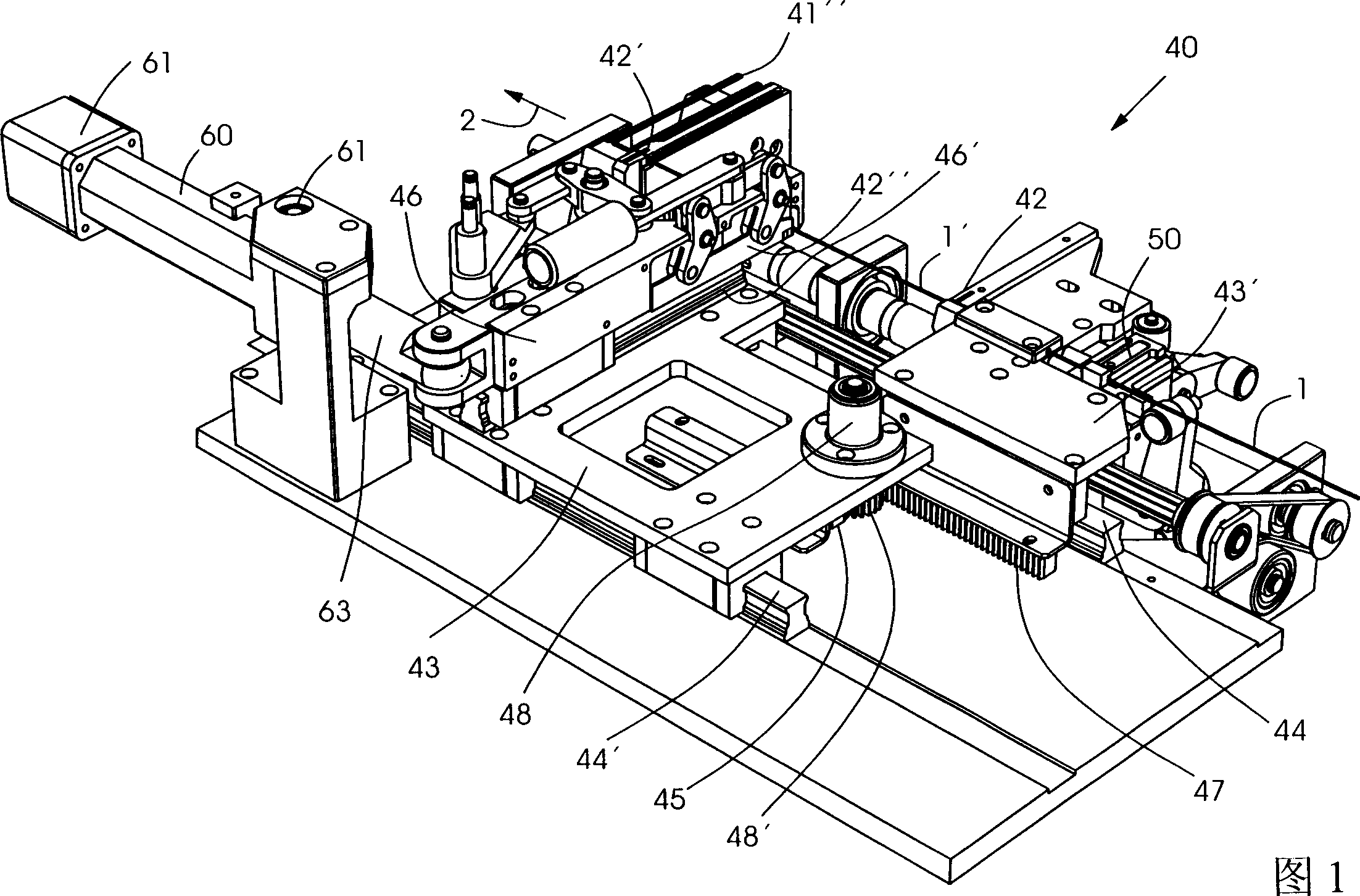

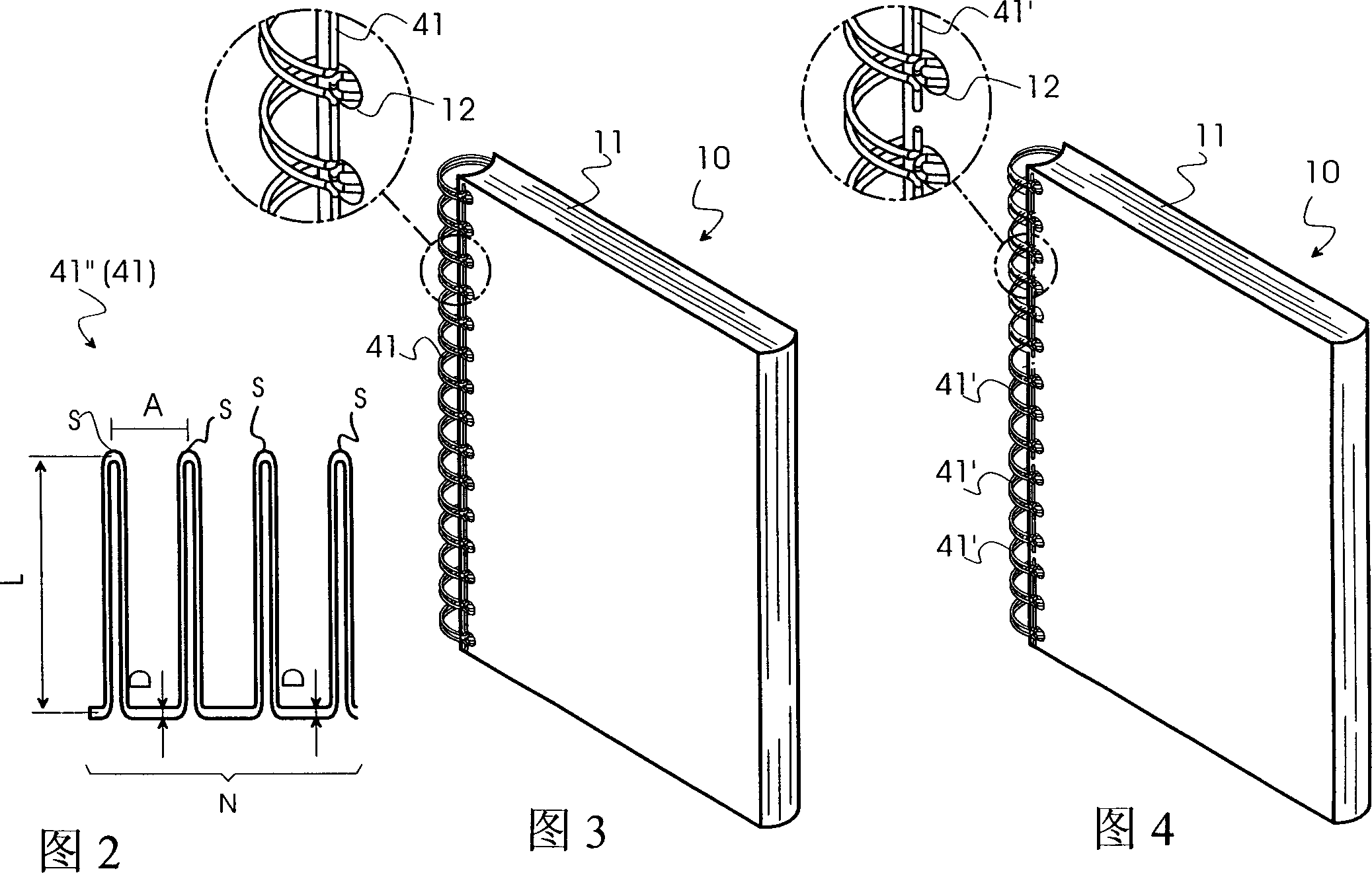

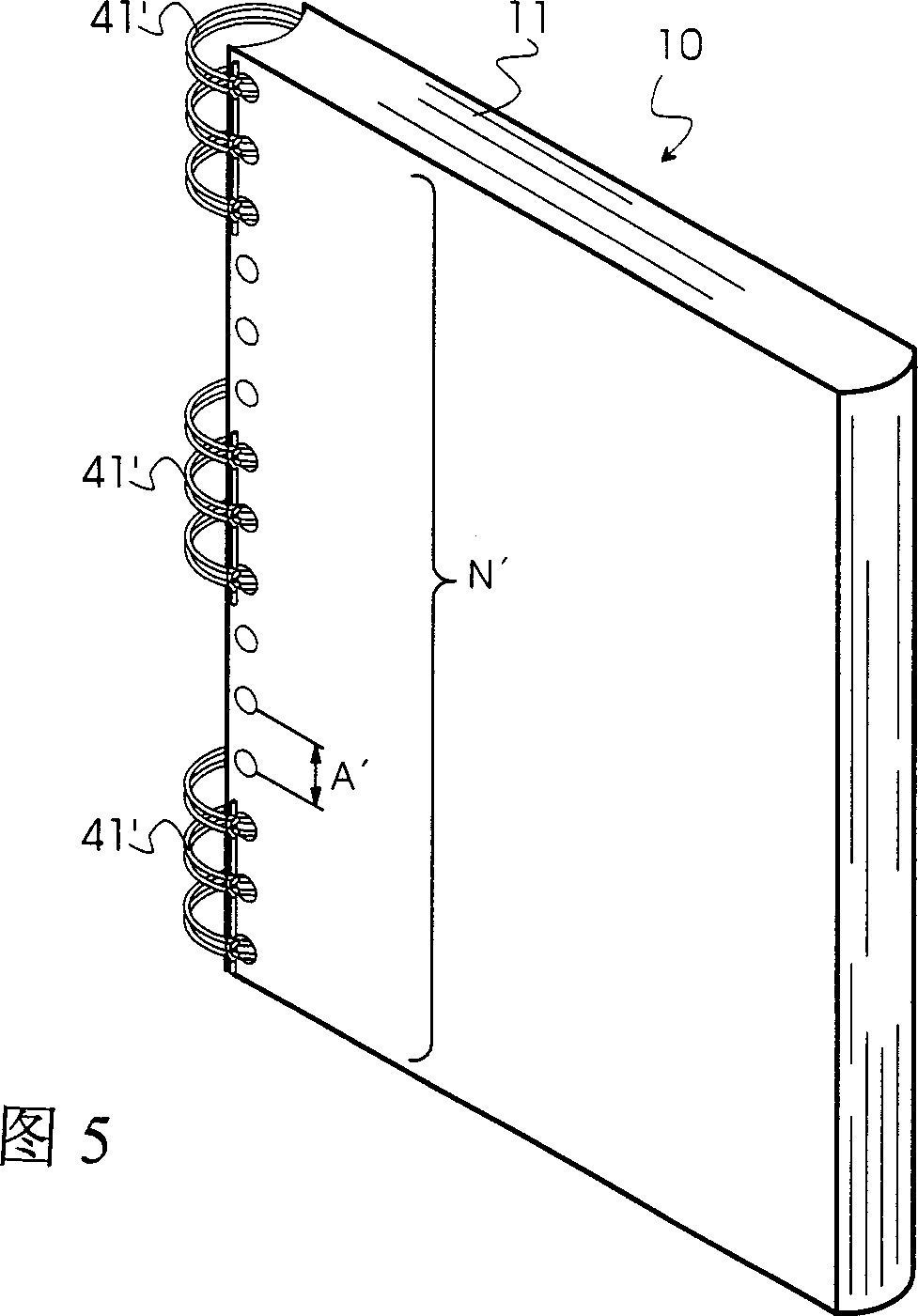

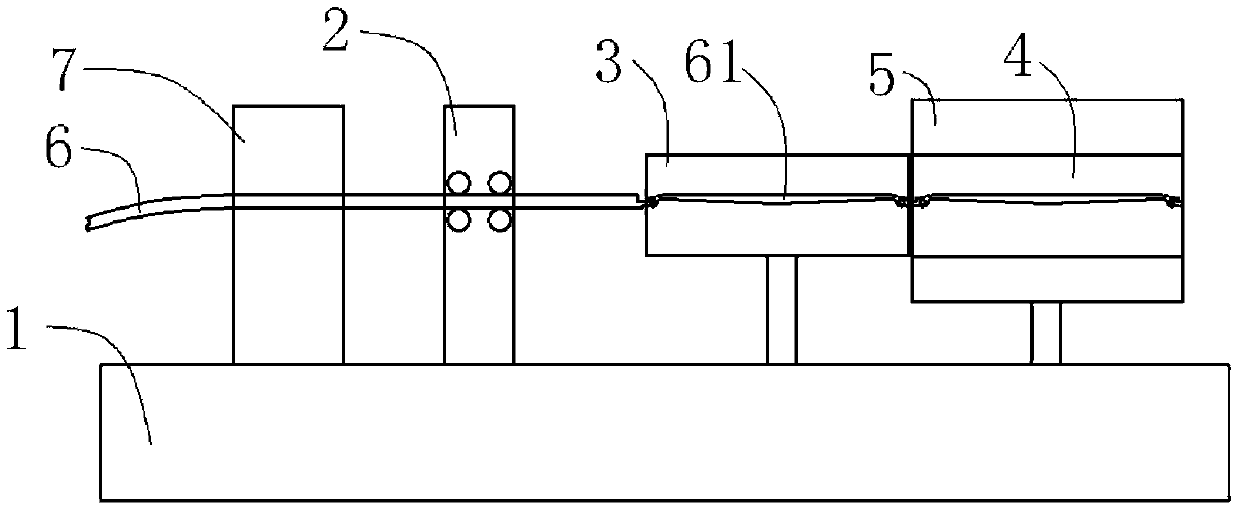

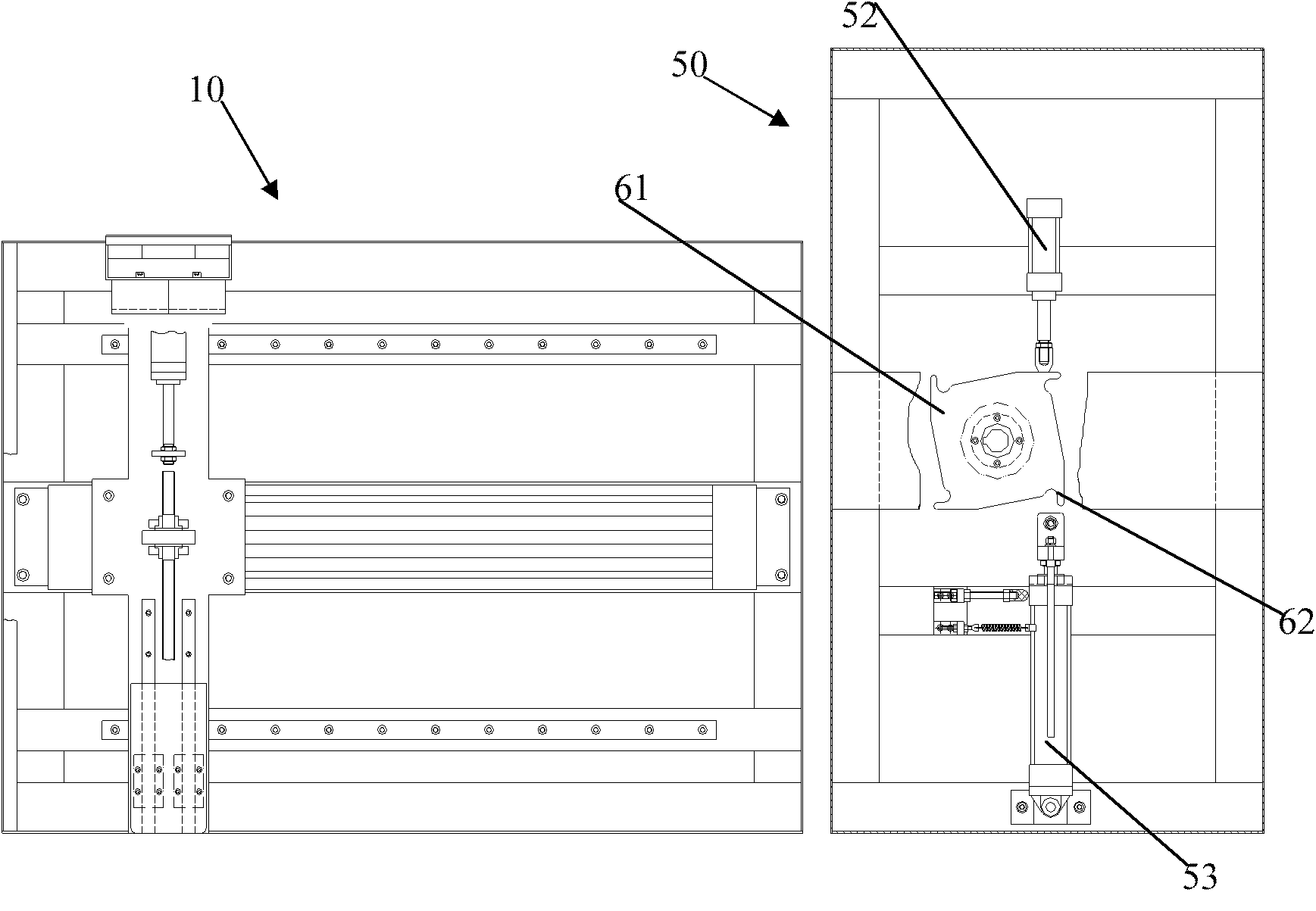

Apparatus for making metallic wire binding parts

InactiveCN1365897ASave materialFast bindingWire ringsFiling appliancesLoop lengthMechanical engineering

The flat loop-shaped wire binding element is bent into a C-shape in a segment fashion. Bending is carried out using a device (90) with two bending units (95, 95), each with at least one retaining part (91, 91), at least one support (92, 92) and at least one bending beam (93, 93), the two bending units being individually movable along the wire loops in a controlled manner. Two O-shaped dies (94, 94) are used to bend the C-shapes into O-shapes, which are used to hold brochure sheets together.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Machining technology and machining forming device of elastic collar

The invention provides a machining technology and a machining forming device of an elastic collar. According to the machining technology and the machining forming device of the elastic collar, a stepping feed technology, a grading stamping technology and a multidirectional bend forming technology are adopted to produce the elastic collar, a use ratio of raw materials is greatly improved, and product quality and production efficiency are improved. The machining forming device of the elastic collar comprises a rack, a straightener, a feed mechanism, a punching machine mechanism, a cutting-off mechanism and a forming mechanism, wherein the straightener, the feed mechanism, the punching machine mechanism, the cutting-off mechanism and the forming mechanism are installed on the rack in sequence. Raw material metal wires are firstly straightened by the straightener, and then enter the feed mechanism. The feed mechanism carries out stepping feed according to a fixed step length so as to enable most front ends of the metal wires to enter in sequence. The punching machine mechanism carries out blanking processing on the most front ends of the metal wires so as to form arc-shaped strip blanks with a certain curvature. The cutting-off mechanism carries out cutting-off processing on the formed arc-shaped strips which are processed by blanking, and blanks needed by the forming mechanism are isolated. The forming mechanism curls each arc-shaped strip which is cut off to form a circle with an opening.

Owner:吴成涛

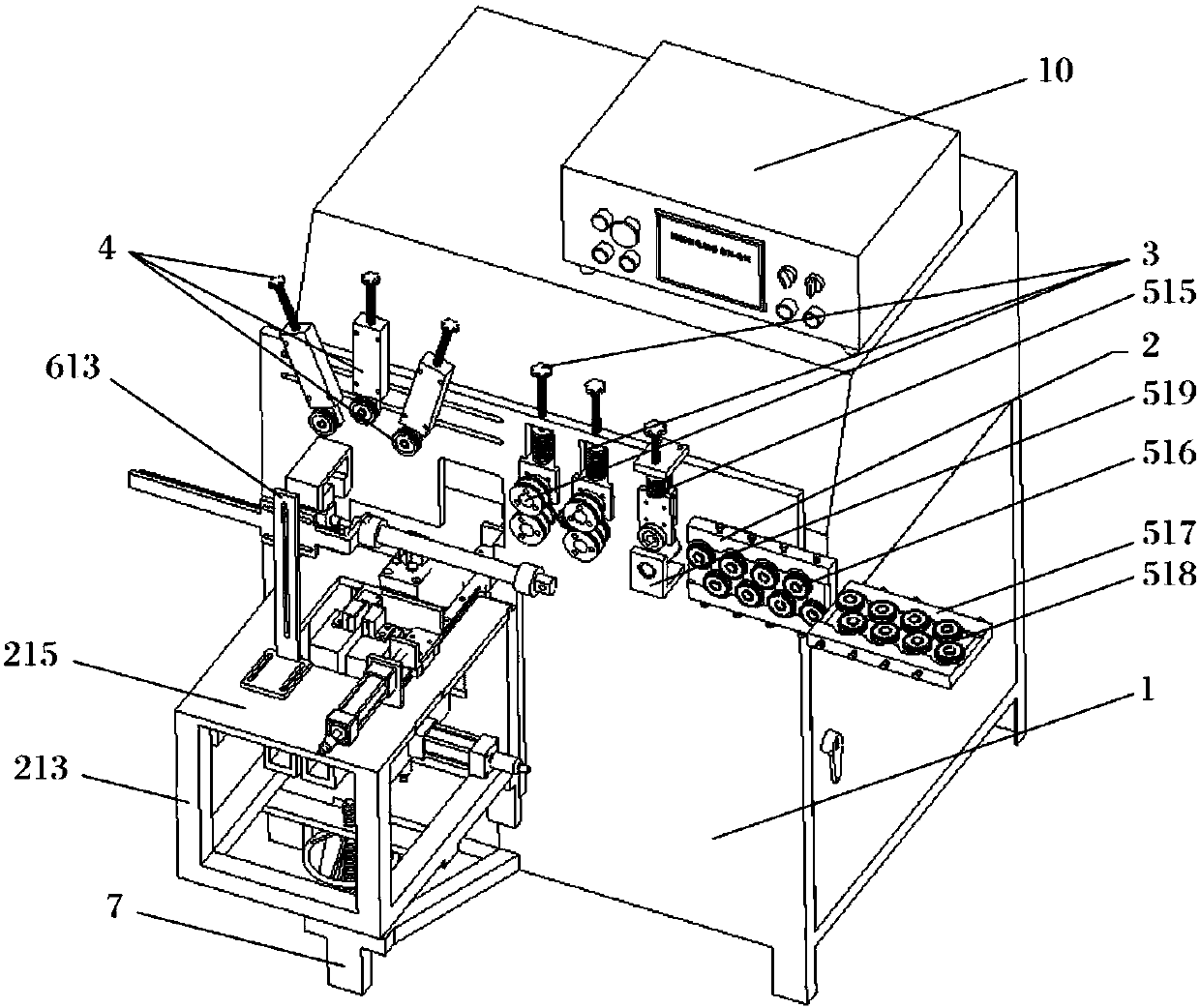

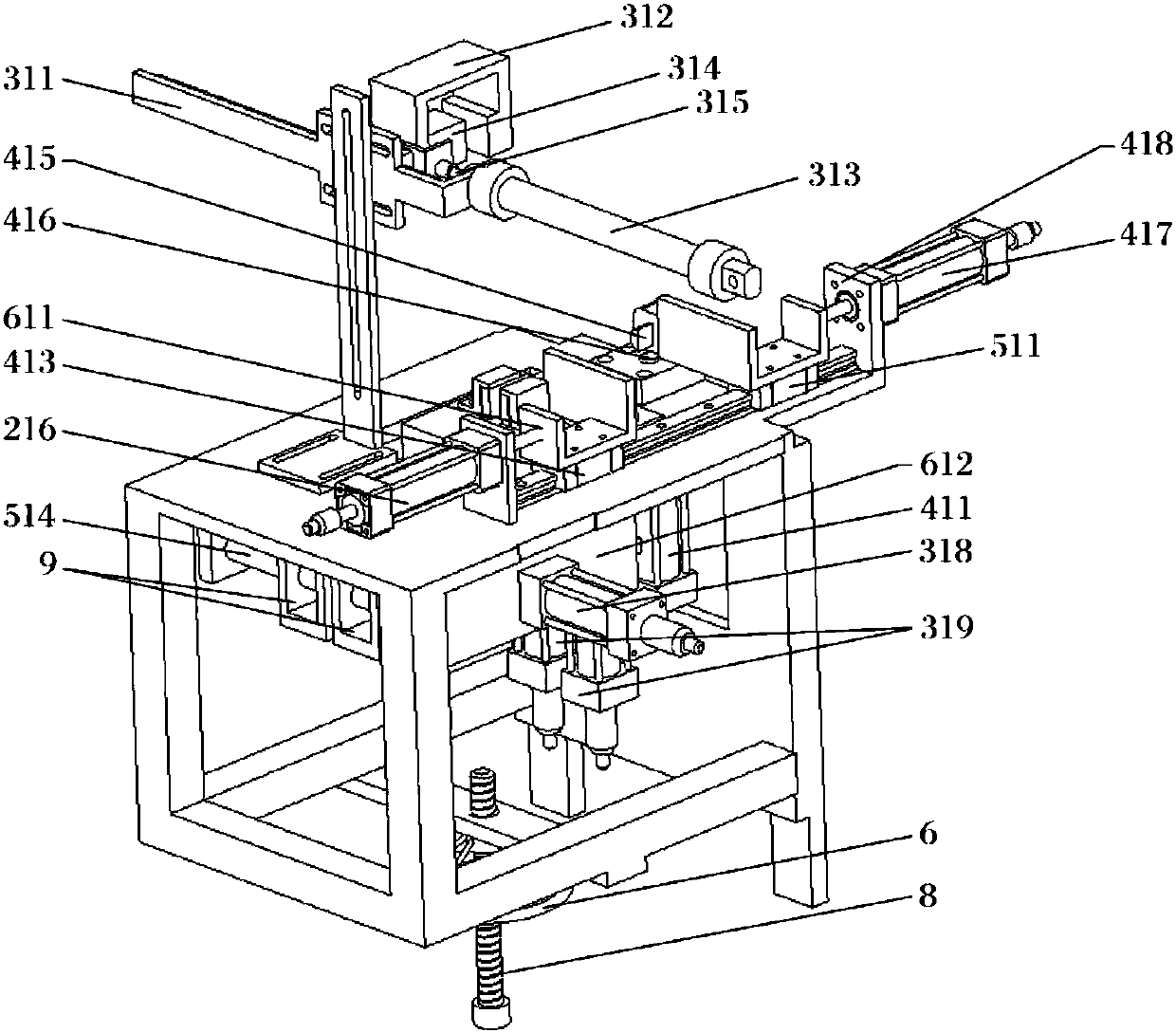

Full-automatic looping and butt-welding integrated machine

PendingCN107552693AEasy to fixNot easy to looseWire ringsOther manufacturing equipments/toolsButt weldingRelative motion

The invention discloses a full-automatic looping and butt-welding integrated machine. The full-automatic looping and butt-welding integrated machine comprises a welding platform, a ring clamping module, a ring conveying module, two iron ring clamping mechanism sliding blocks, two ring clamping upper molds, two ring clamping lower molds, an adjustment mechanism, welding electrodes and a circuit control module, wherein the ring clamping module is capable of moving back and forth and arranged on the welding platform, the ring conveying module is capable of moving back and forth and arranged on the welding platform in the form of being opposite to and matched with the ring clamping module, and the two iron ring clamping mechanism sliding blocks are capable of doing opposite motions in the left-right direction and oppositely arranged in parallel; the two ring clamping upper molds are fixedly connected with one iron ring clamping mechanism sliding block; the two ring clamping lower molds arematched with the ring clamping upper molds in an up-down opposite manner and are vertically and movably connected with one iron ring clamping mechanism; the adjustment mechanism is used for adjustingthe up-down motion stroke of the ring clamping lower molds and is connected with the ring clamping lower molds; the welding electrodes are arranged on the ring clamping upper molds and the ring clamping lower molds; and the circuit control module is electrically connected with the ring clamping module, the ring conveying module, the ring clamping upper molds, the ring clamping lower molds and thewelding electrodes. The full-automatic looping and butt-welding integrated machine is precise in welding, and welded junctions are uniform.

Owner:江门市新会区国正机电设备有限公司

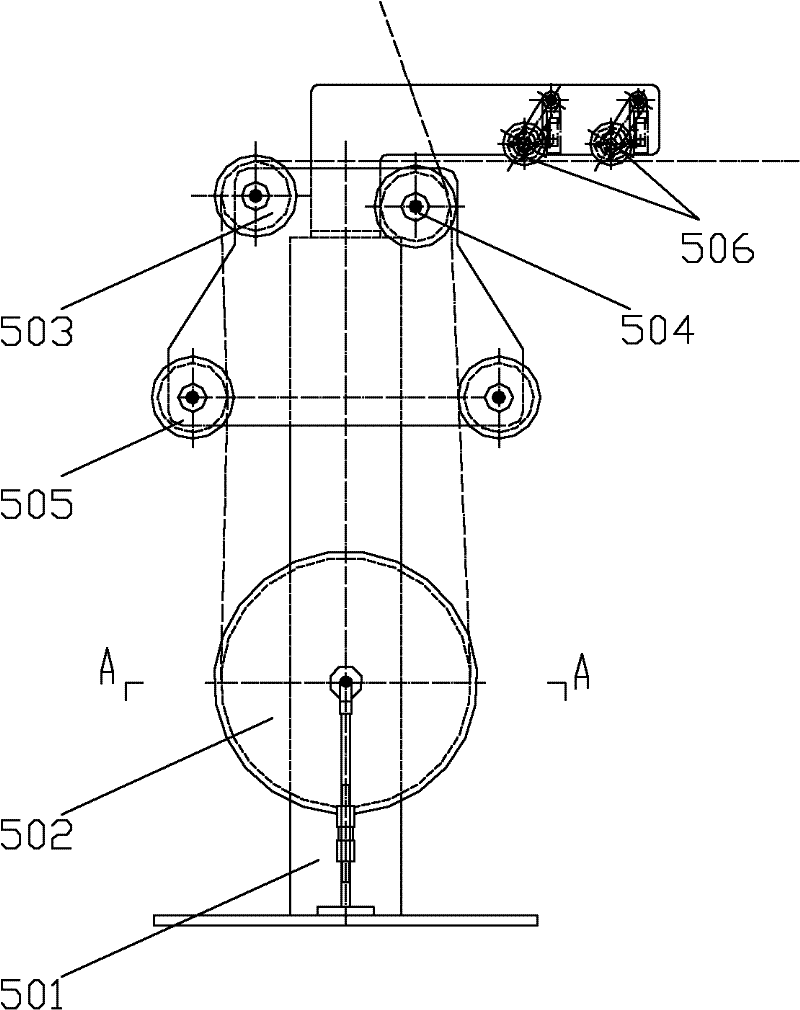

Steel wire ring disassembling device for winding machine

The invention discloses a steel wire ring disassembling device for a winding machine, which comprises a ring catching device and a ring receiving device, wherein the ring receiving device comprises an upright post which can be fixed on a bottom box body rotationally; a rotation driving device is arranged at the bottom of the upright post; and the end part of the upper part of the upright post is provided with at least two receiving arms. In the steel wire ring disassembling device, the ring receiving device with the plurality of receiving arms and the control of the ring catching device are combined to realize the sequential winding of a plurality of groups of steel wire rings on one receiving arm, the steel wire rings are sequentially placed at fixed intervals, the interference among thesteel wire rings is avoided, subsequent mechanical removal of the steel wire rings is facilitated, production efficiency is improved, and decrease in product quality due to the mutual influences of the steel wire rings is avoided.

Owner:TIANJIN SAIXIANG TECH

Metal rubber gasket manufacture process

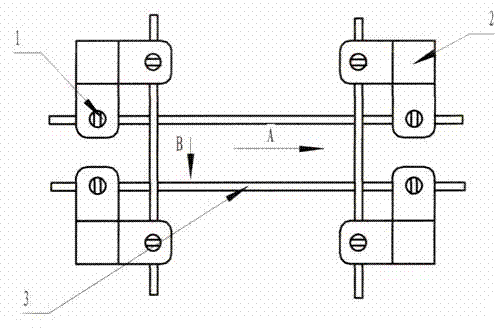

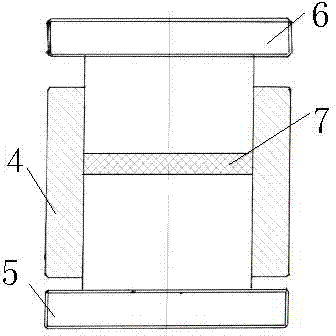

A metal rubber gasket manufacture process is characterized in that adopted tools include screws, four fixing blocks, four steel wires, a finishing die, a lower die and an upper die, and the four steel wires are fastened on the four fixing blocks through the screws and are arranged in a tight rectangular structure. The manufacture process includes: adjusting the positions of the fixing blocks according to the size of a part blank, winding stainless steel wires into spirals by the aid of a numerical control winding machine, weaving by placing the spirals on the steel wires, winding the spirals for one layer along the direction A and for another layer along the direction B, winding along the direction A and the direction B alternately, repeating 2-3 times, and detaching after winding so that blank winding is completed; and then, pressing the blank subjected to winding in a special die. The metal rubber gasket manufacture process has the advantages that the metal rubber gasket manufacture process is simple and is simple in required equipment and capable of guaranteeing the size and the density of a metal rubber gasket, meets the use requirements and can be widely applicable to the aviation field, the service life of an engine component is prolonged greatly, and durability of the gasket is improved remarkably.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

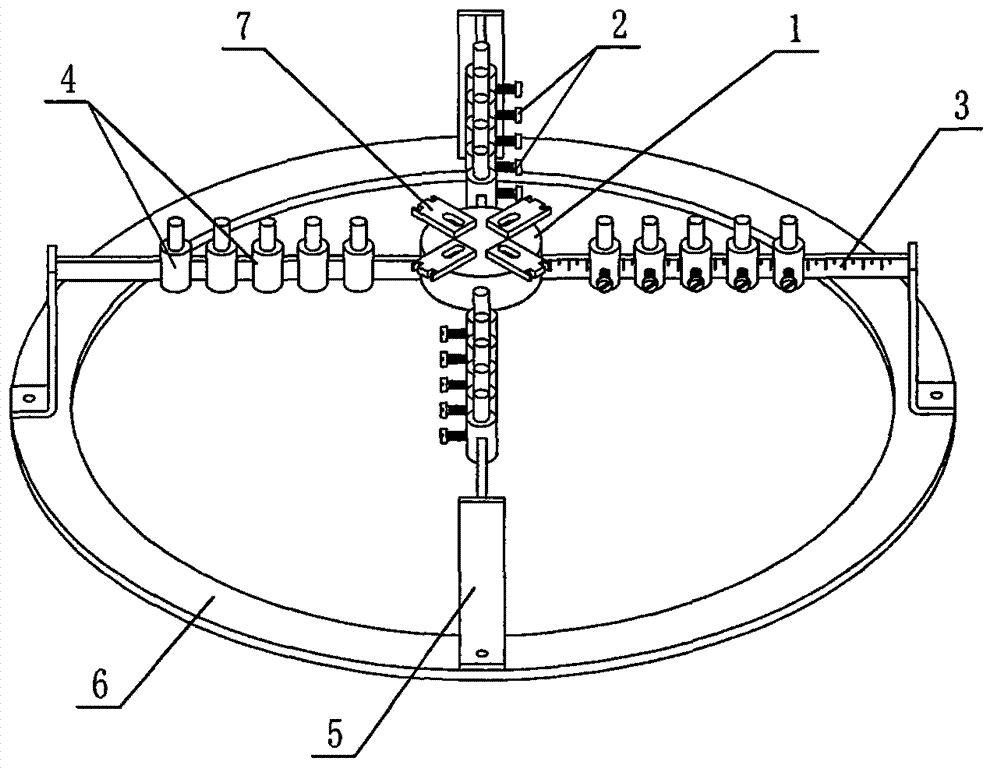

Circular ring manufacturing tool

InactiveCN103111783ASimple structureImprove labor efficiencyWelding/cutting auxillary devicesWire ringsManufacturing qualityRing mode

The invention discloses a circular ring manufacturing tool which comprises a fixed station. A plurality of limited blocks are distributed on the fixed station in a ring mode, and a planishing bar is inserted on each limited block. The fixed station is further fixedly provided with at least three radialized support arms, and the top faces of the support arms are lower than the planishing bars. Each support arm is provided with scales and a plurality of check blocks which are arranged at intervals in a sliding mode. Each check block is provided with a bolt which enables the check blocks to be locked on the support arms. The circular ring manufacturing tool further comprises an annular chassis. The outer end portion of each support arm is provided with a support plate which extends downwards, and a downward extending end of each support plate is fixedly installed on the chassis. The circular ring manufacturing tool is simple in structure, capable of being generally used for processing and manufacturing of annular rings with various specifications, and furthermore, labor efficiency is high and manufacturing quality is good.

Owner:GAOMI YIBANG GENERAL MACHINERY

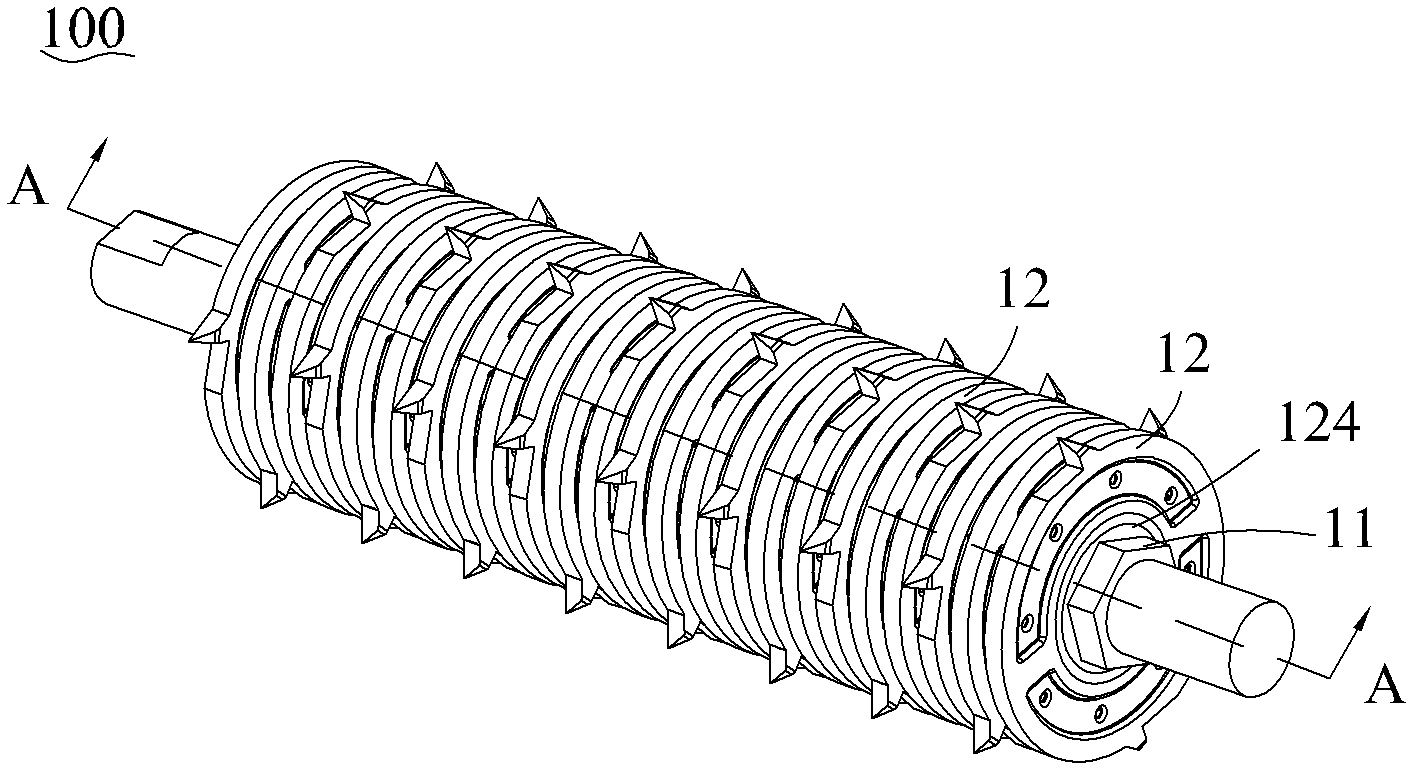

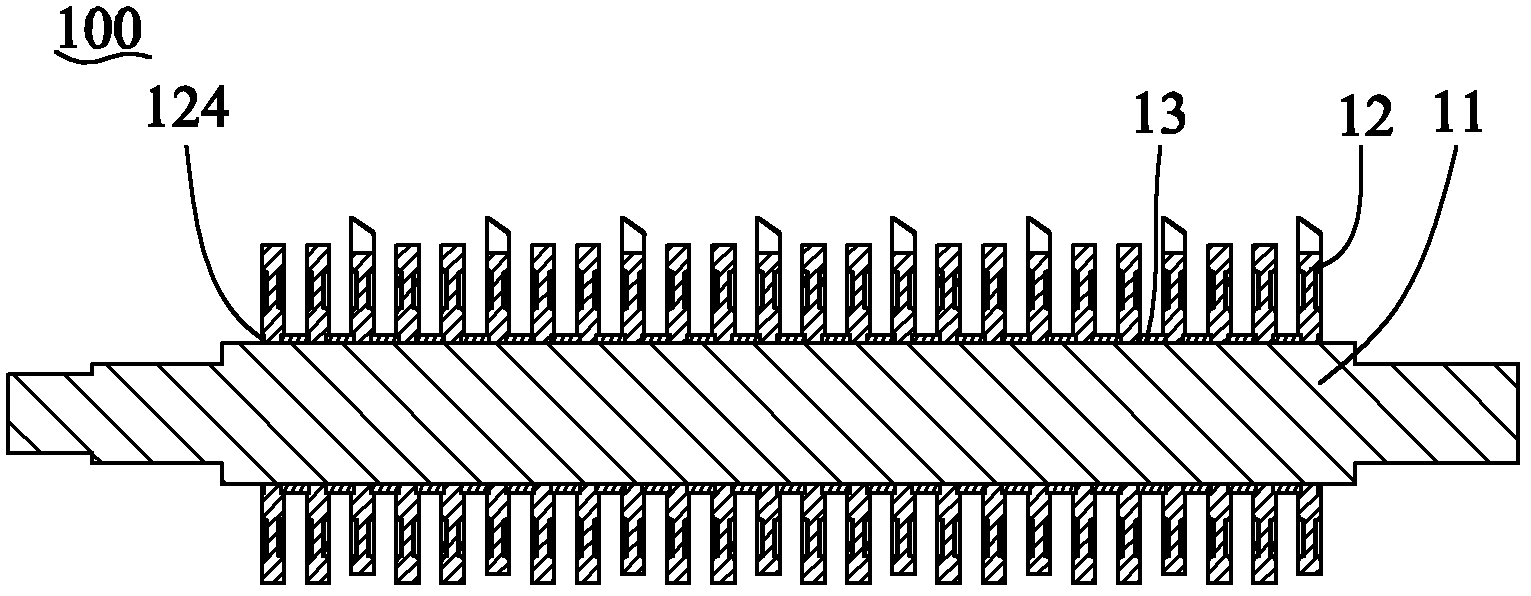

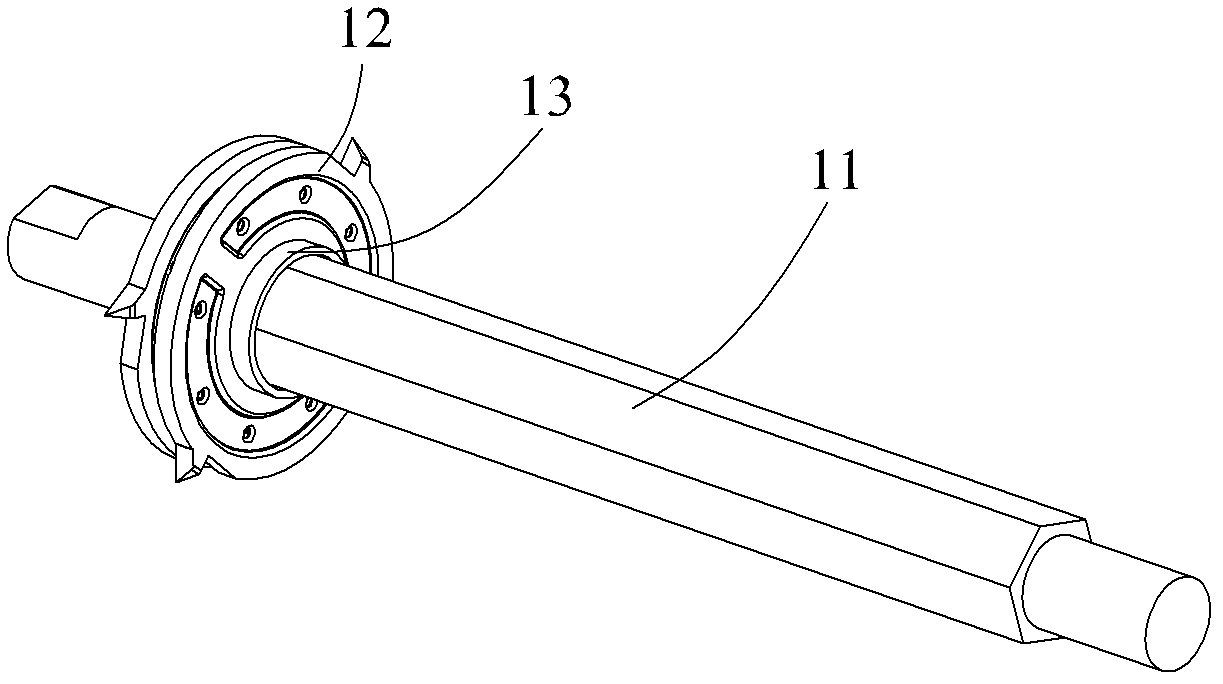

Paper shredder cutter and processing method thereof

ActiveCN102294290AImprove rigidityEqual distanceWire ringsGrain treatmentsKnife bladesWaste material

The invention discloses a cutting tool of a paper shredder. The cutting tool comprises a cutter shaft and blades, wherein the blades are arranged on the cutter shaft at certain intervals; the space between every two blades is provided with a metal spacing ring; and the metal spacing rings are formed by rolling and cutting metal strips. Compared with the prior art, the invention has the advantages that: on one hand, the metal spacing rings are arranged between every two blades at intervals, and the cutting tool has high rigidity and uniform thickness, so that the cutting tool of the paper shredder is firmer integrally and is difficult to deform; and on the other hand, the metal spacing rings are formed by rolling and cutting the metal strips, so that the cutting tool is easy to process, has low cost, small tolerance fluctuation and high consistency and does not generate waste materials during processing. The invention also discloses a corresponding processing method for the cutting tool of the paper shredder.

Owner:DONGGUAN ELITE ELECTRIC HARDWARE PRODUCT CO LTD

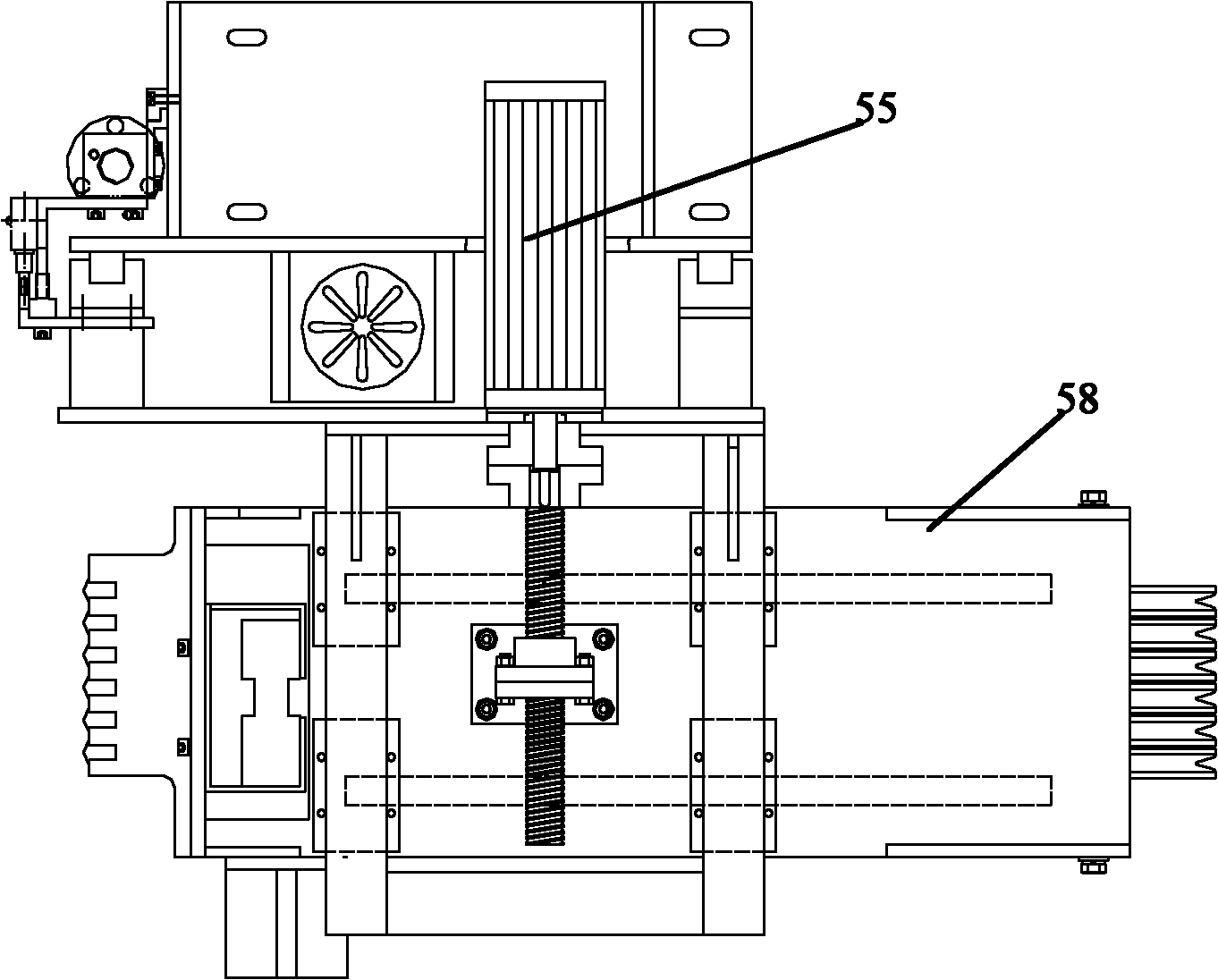

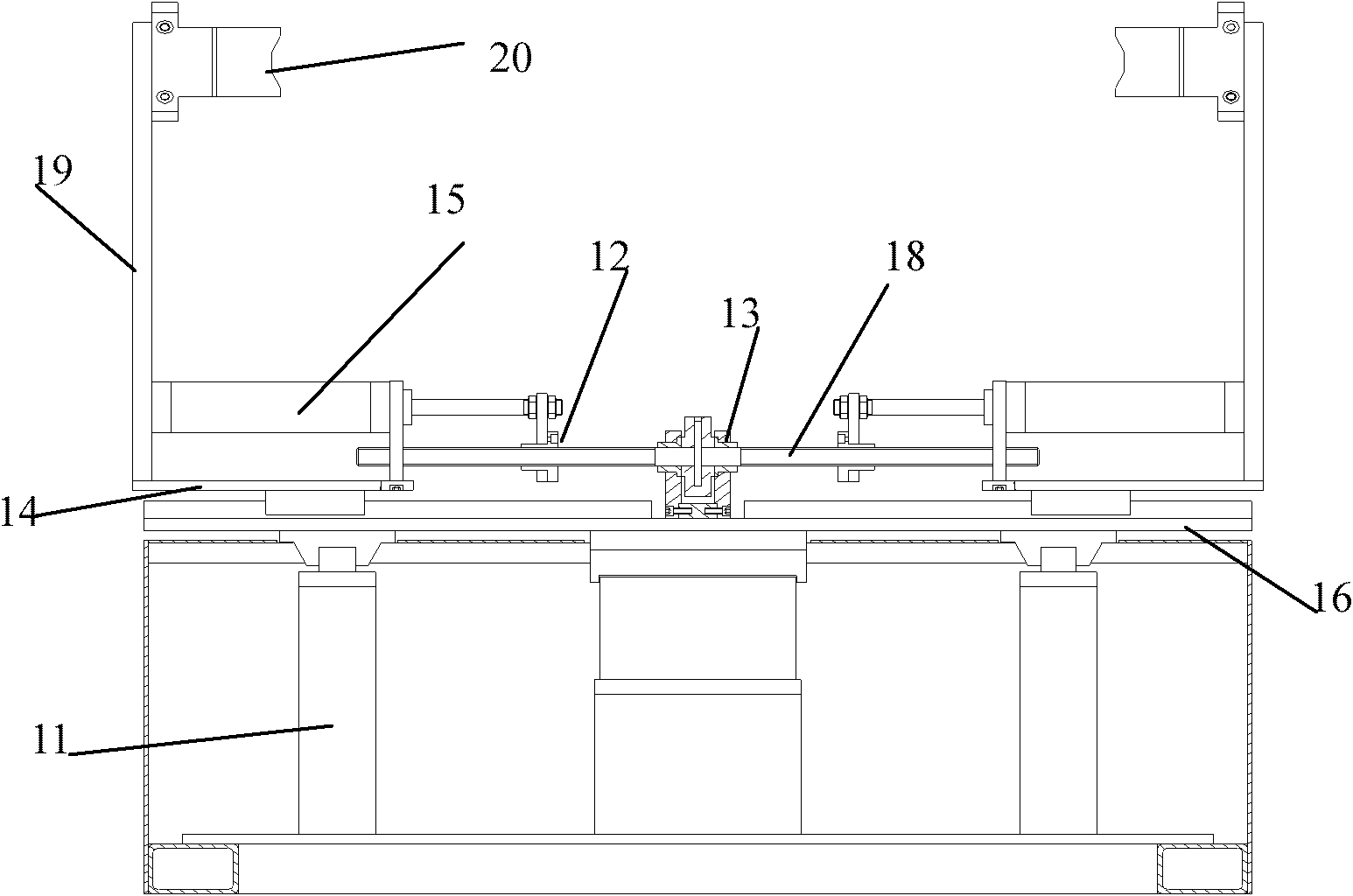

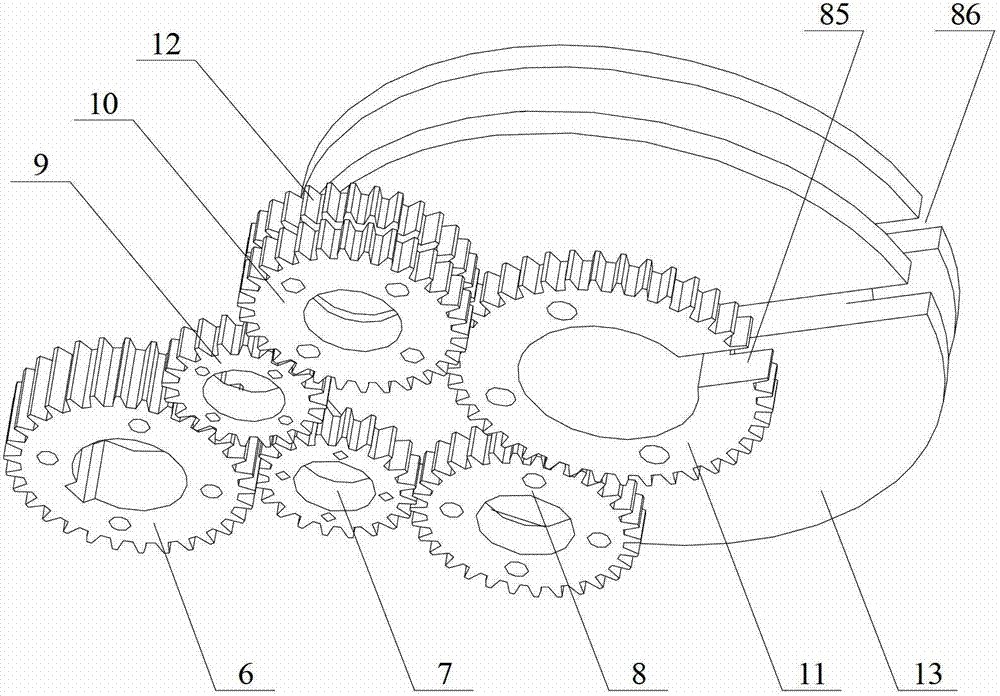

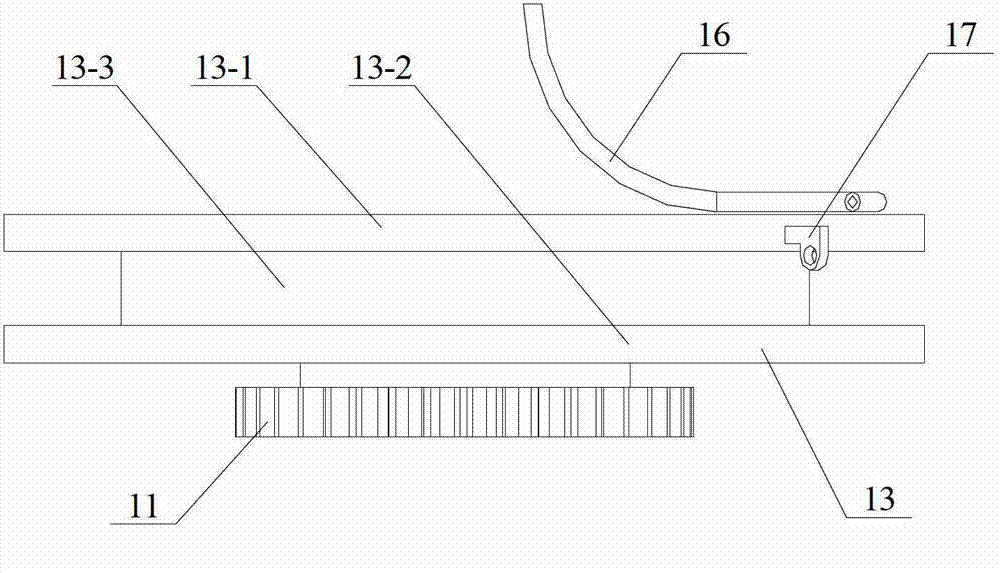

Main drive for bead ring winder

ActiveCN103115110AHigh winding precisionSimple structureToothed gearingsRope making machinesEngineeringMechanical engineering

Owner:哈尔滨工大宏图橡塑科技有限公司

Method of and a device for producing parts

InactiveUS20090189007A1Eliminate disadvantagesWelding/cutting auxillary devicesWire ringsConductor CoilMechanical engineering

Owner:COOPER ALEX +2

Shaping tooling for quenched check ring

The invention discloses a shaping tooling for a quenched check ring. An upright rod which is arranged vertically is arranged at the top of a base; a fixed block and a movable block are respectively positioned on the two sides of the upright post; clamping surfaces which are formed oppositely are formed on the fixed block and the movable block; when the quenched check ring is machined, a check ring is positioned between the fixed block and the movable block through a locating post on the fixed block; a top cushion plate is pressed on the check ring and is compressed through a limiting piece; a driving mechanism drives the movable block to move to the fixed block, so that the clamping surfaces of the fixed block and the movable block extrude and shape the outside diameter of the check ring; then, the limiting piece is continuously moved downwards, so that the check ring is further compressed by the top cushion plate; the outside diameter and the flatness of the check ring are shaped by extruding and compressing repeatedly. According to the shaping tooling for the quenched check ring disclosed by the invention, a material is loaded and unloaded easily and conveniently; a plurality of check rings can be shaped simultaneously at one time; the shaping effect is good; the flatness of the shaped check rings is good.

Owner:ANHUI NINGGUO DONGBO FASTENER

Feeding device for tire wire winding machine

The invention discloses a feeding device for a tire wire winding machine and aims to solve problems of poor steel wire friction quality, proneness to accumulation and instability of steel wire tensionin the prior art. Two ends of a spool are supported on a let-off supporting frame through a let-off rotating shaft and a clamping part, and one end of the spool is in detachable connection with one end of the let-off rotating shaft. A let-off frequency-variable motor is mounted on one side of the let-off supporting frame, and an output shaft of the let-off frequency-variable motor is in transmission connection with the other end of the let-off rotating shaft through a let-off speed-reduction diverter. A let-off fixed wheel set is rotationally supported on the let-off supporting frame througha fixing support arm, and a let-off moving wheel set is rotationally supported at an output end of the let-off supporting frame through a moving support arm. An angular displacement sensor between thelet-off supporting frame and a rotating connector is in electrical connection with a controller, and the controller is in electrical connection with the let-off frequency-variable motor through a frequency converter. The feeding device has advantages that friction of steel wires is avoided, high quality and tension stability of steel wires are realized, butt joints are less prone to breakage, stability in operating and braking of the spool is achieved, and less proneness to accumulation is realized.

Owner:PRINX CHENGSHAN (QINGDAO) IND RES & DESIGN CO LTD

Manufacture of coil springs

ActiveUS20110247383A1Reduce arcingEnhance resilienceMetal-working apparatusWire ringsPower flowCoil spring

An apparatus is disclosed for the manufacture of a coil spring from a wire. The apparatus comprises first and second tools for contacting the wire prior to, and / or during, deformation of the wire into a coil spring. The apparatus includes means for applying an electrical potential difference between the first and second tools such that an electric current is caused to flow through at least part of the wire during use.

Owner:SPRINGFORM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com