Method and apparatus of manufacturing annular concentric stranded bead cord

A technology of stranded strands and beads, applied in the field of bead cords, can solve the problems of unstable rotation of the annular core 1, disturbance of the arrangement of side wires, etc., and achieve the effect of good formability and good winding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

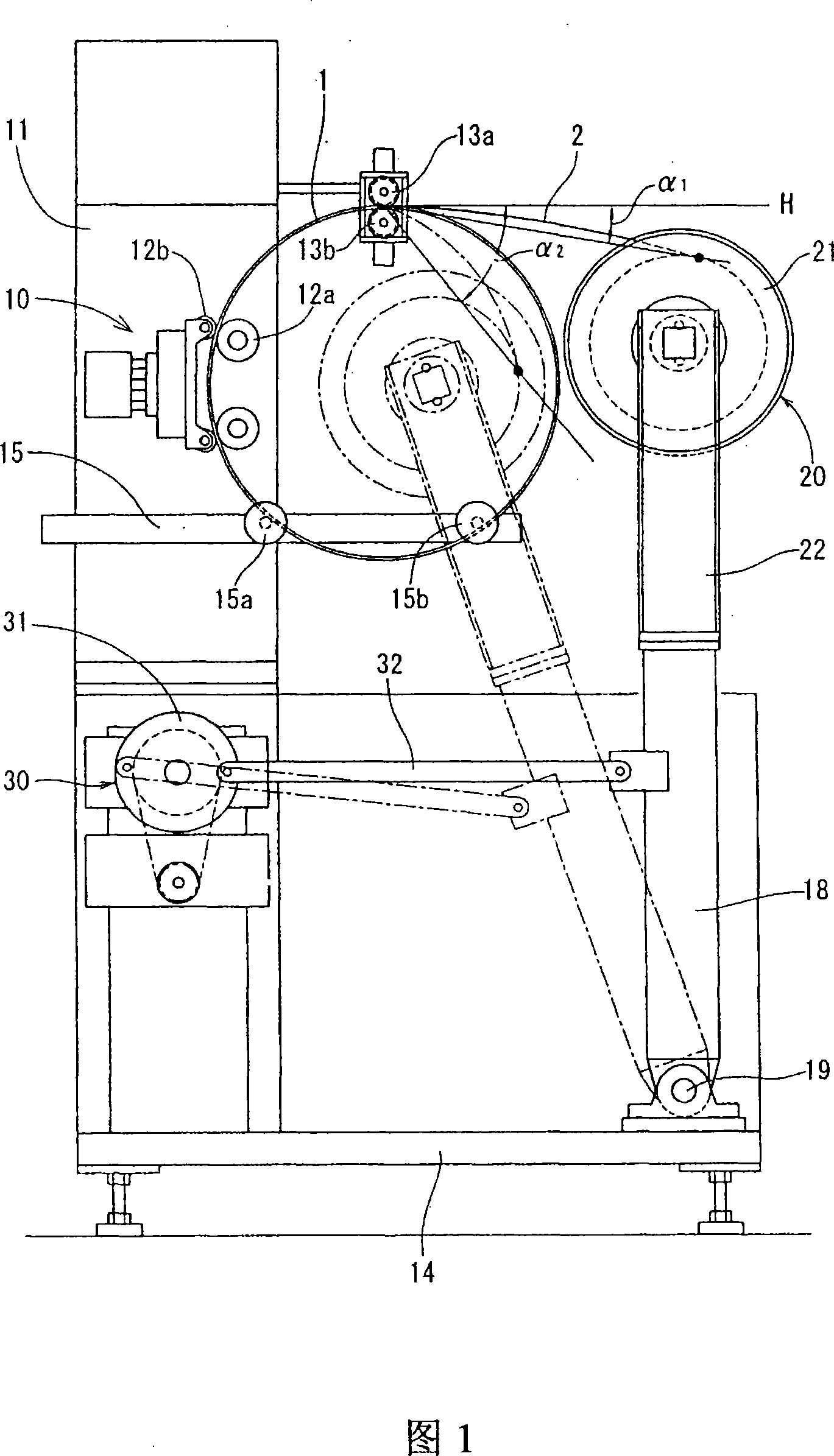

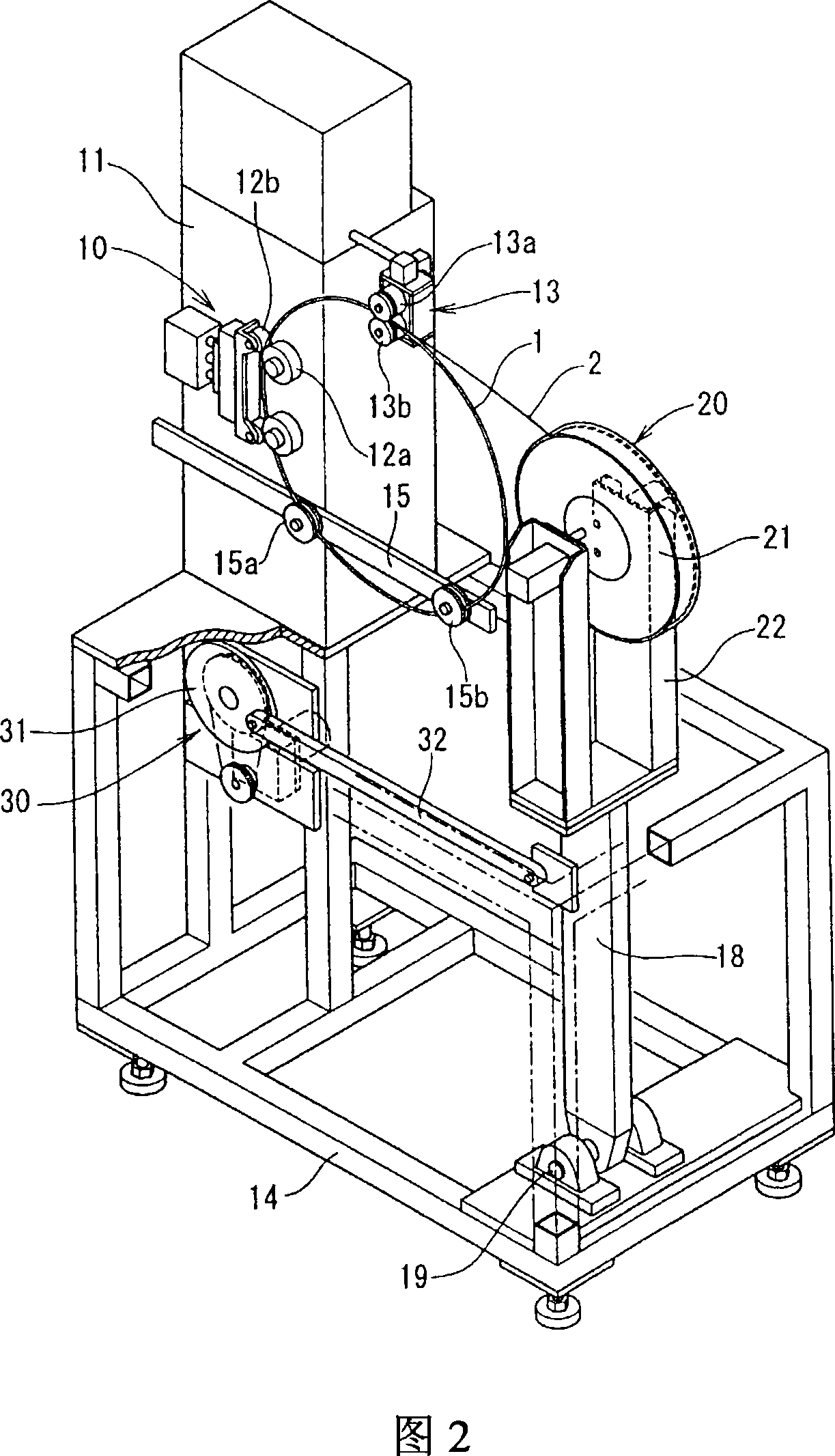

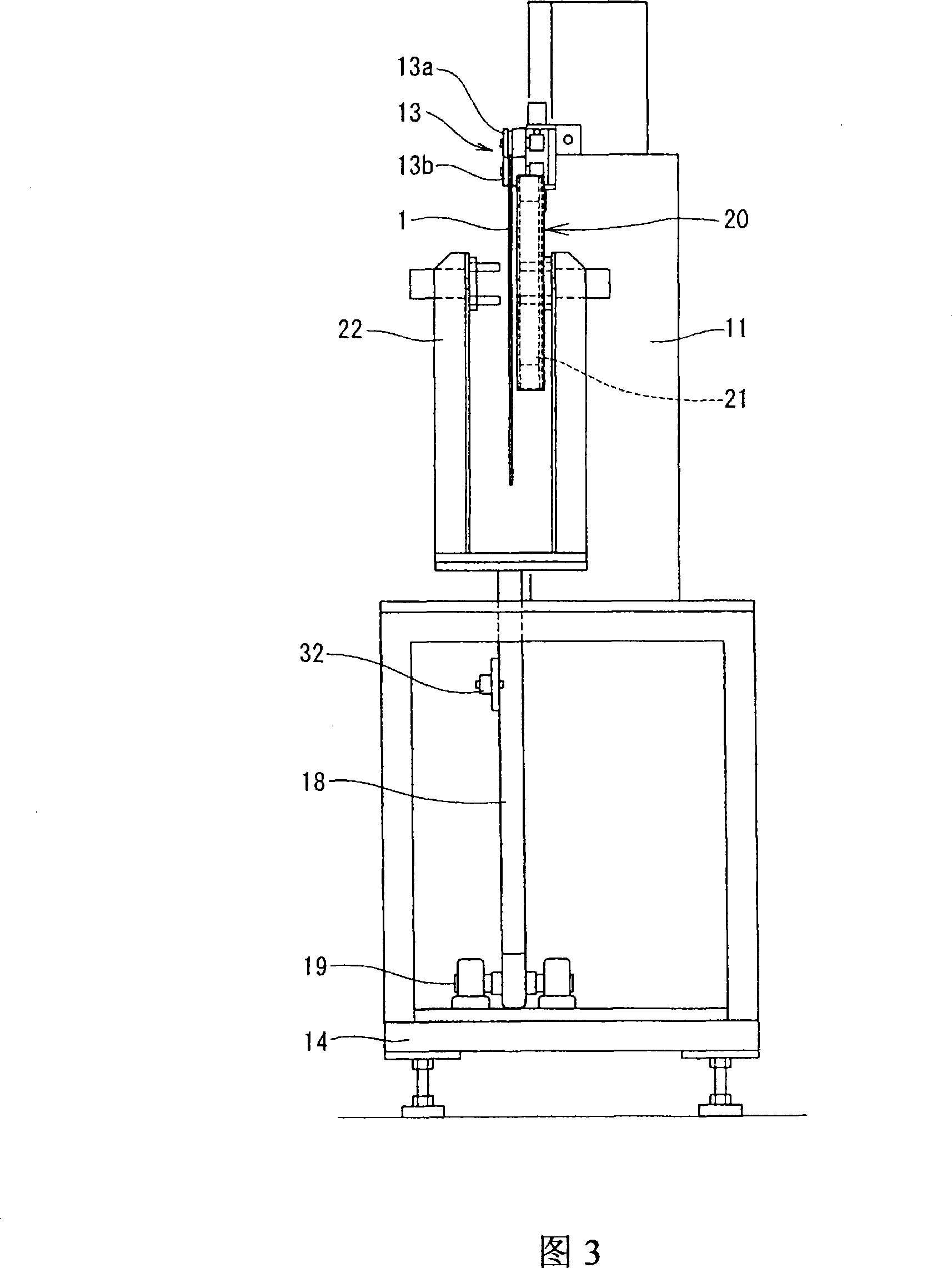

[0053] An apparatus for manufacturing an annular concentric stranded bead cord according to an embodiment of the present invention will be described below with reference to FIGS. 1 to 8 .

[0054] The manufacturing apparatus includes a drive unit 10 and a supply unit 20 . The drive unit 10 rotates the annular core 1 in the circumferential direction at a fixed position. The supply unit 20 supplies the side wire 2 wound on the drum 21 to the winding portion of the annular core 1 .

[0055] The drive unit 10 includes two pinch rollers 12a and 12b connected to a drive motor for rotating the annular core 1 in a circumferential direction in a vertical plane. Pinch rollers 12 a and 12 b are provided on the pillar 11 of the table 14 .

[0056] The clamping unit 13 surrounding the annular core 1 is provided on the support 11 so as to be arranged on the supply side of the side wire 2 in the direction opposite to the rotation direction of the annular core 1 . The clamping unit 13 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com