Radial tire bead ring winding machine with six stations

A bead winding machine and radial tire technology, which are applied in tires, wire processing, and wire manufacturing loops, etc., can solve the problems of low space utilization, low winding efficiency, low production line efficiency, etc., to improve the utilization rate and use. efficiency, reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

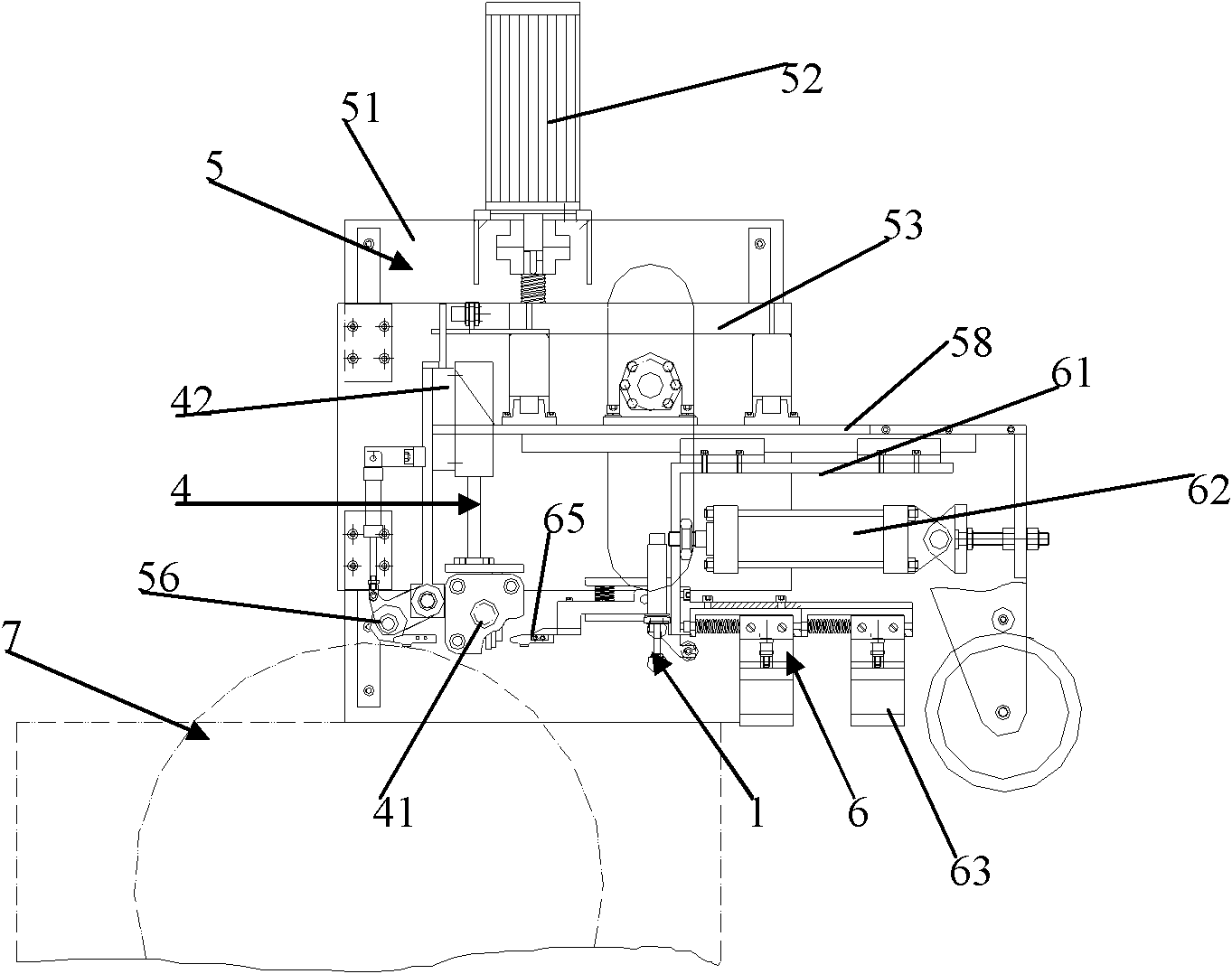

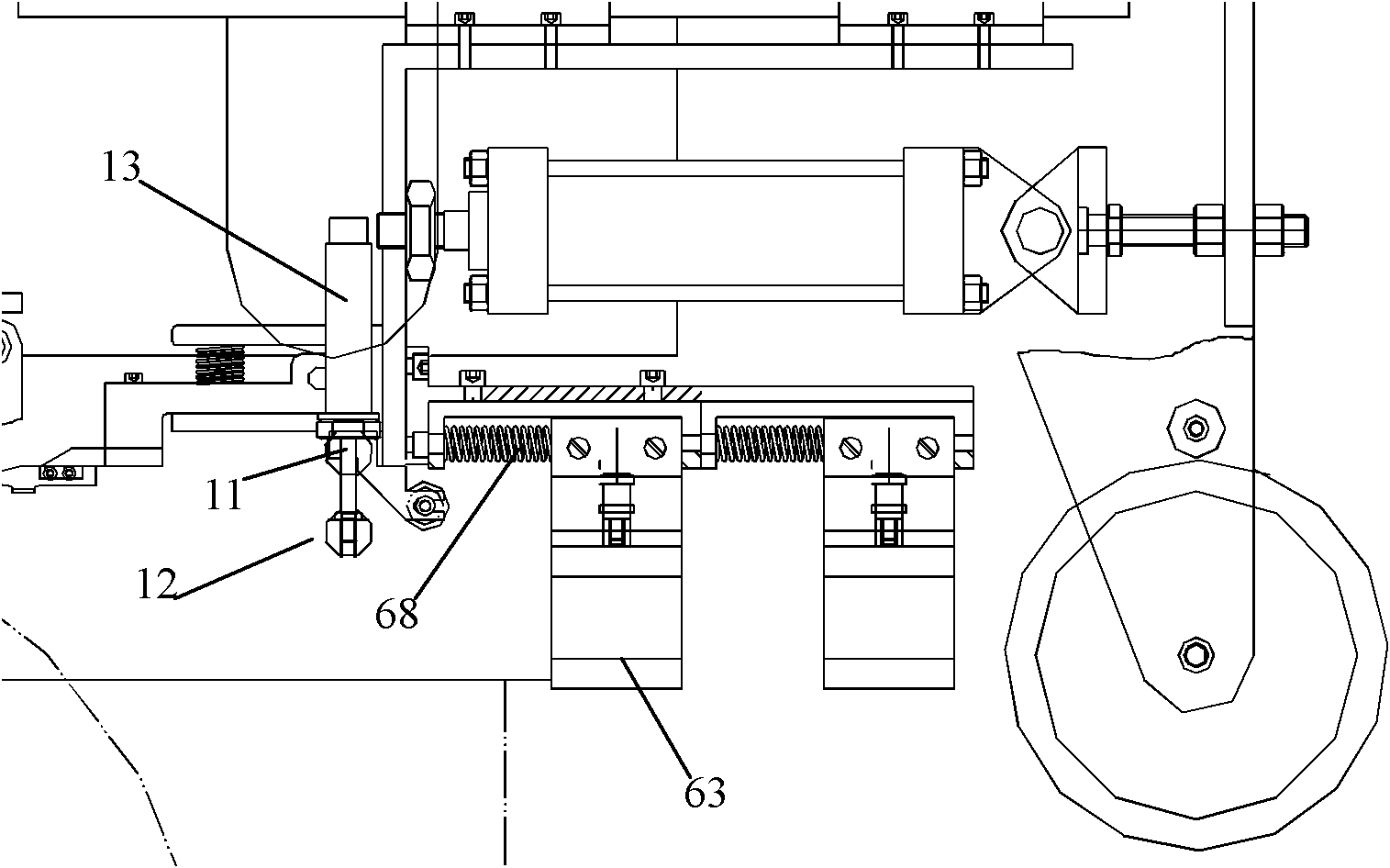

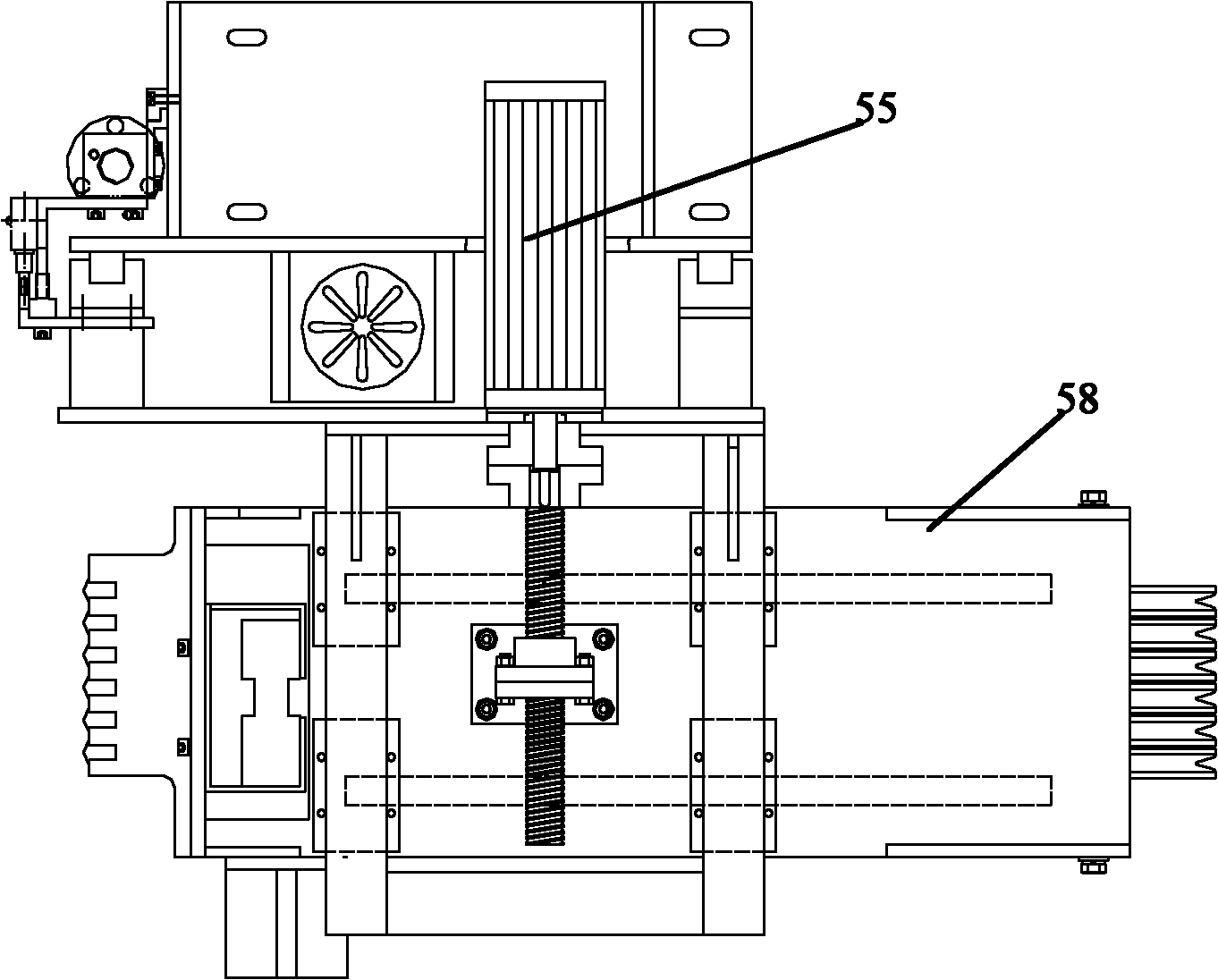

[0022] Such as Figure 1-3 As shown, the six-station radial tire bead winding machine of the present invention includes a wire discharge device 5, a wire feeding device 6, a wire cutting device 4 and a winding device 7, and the wire discharge device 5 includes a lifting bracket seat 51 and is fixed on The lifting motor 52 on the lifting bracket base 51 is provided with a linear guide rail structure between the lifting bracket plate 53 and the lifting bracket base 51 to realize that it can slide up and down and is fixed, and the lifting motor 52 and the lifting bracket plate 53 are respectively arranged There are matching ball screw and lead screw female support structure, so that under the effect of lifting motor 52, the vertical lift operation of lifting bracket plate 53 relative to lifting bracket base 51 is realized. A translational motor 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com