Machine for making steel hoop circumferential reinforcing elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

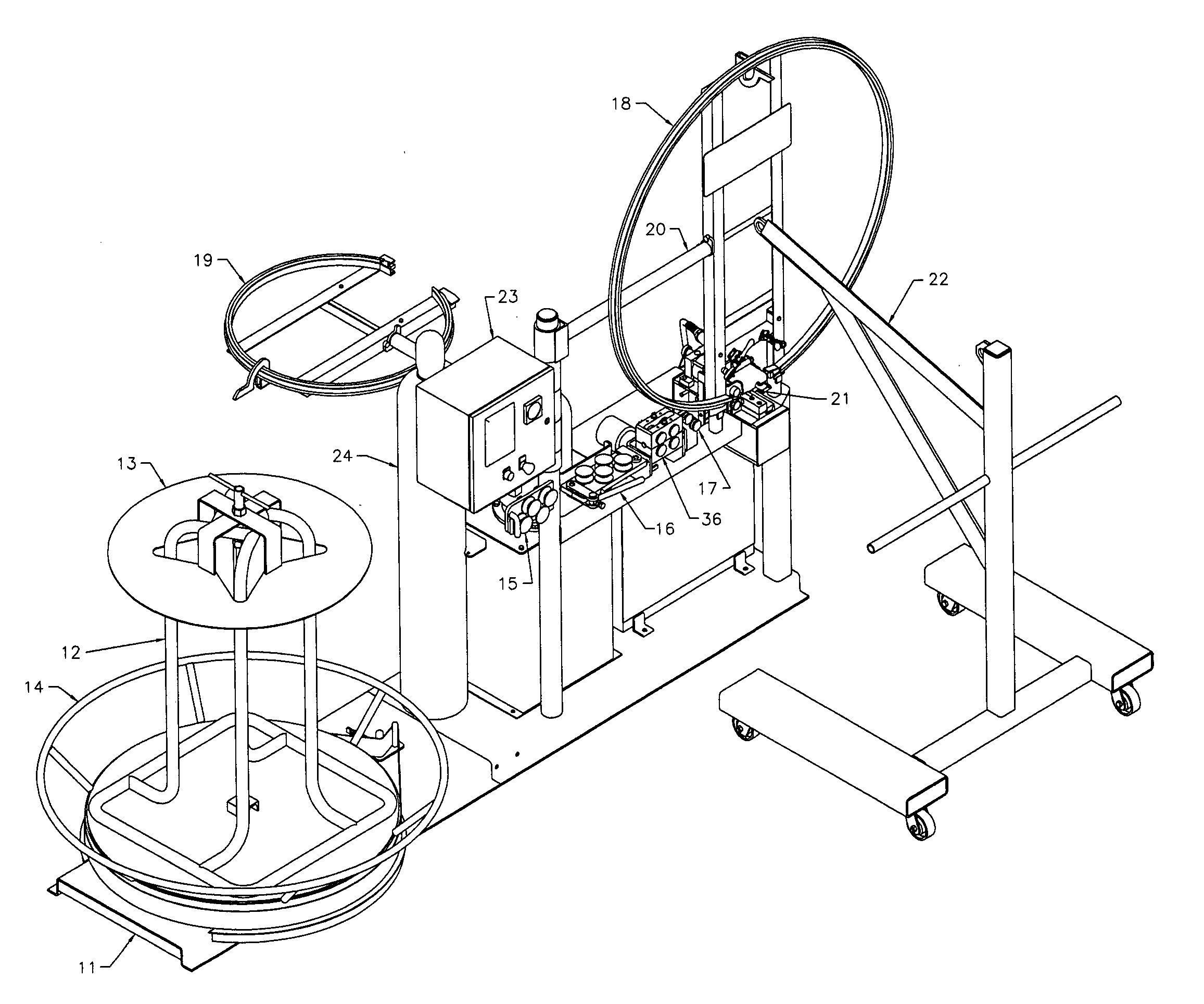

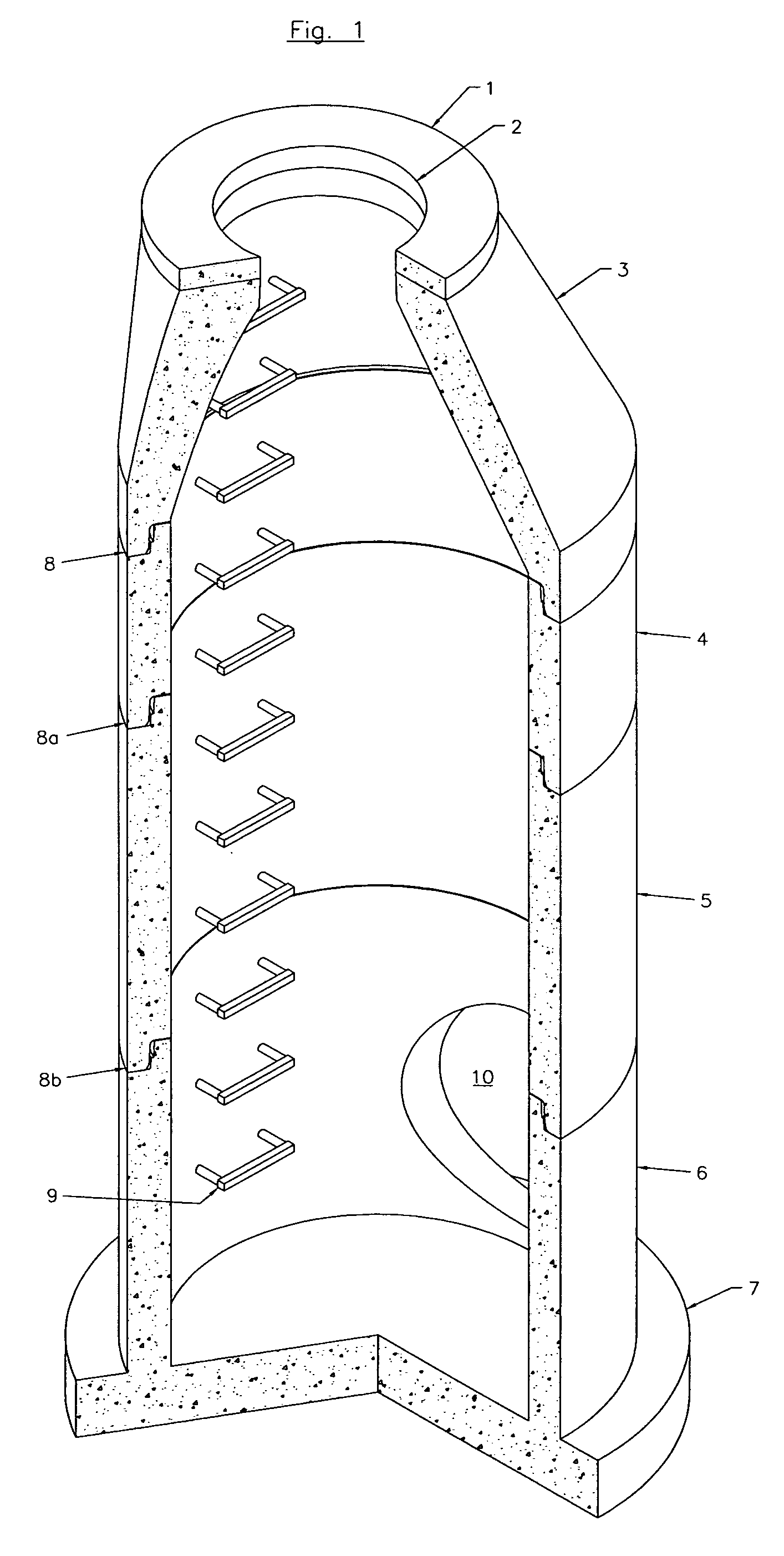

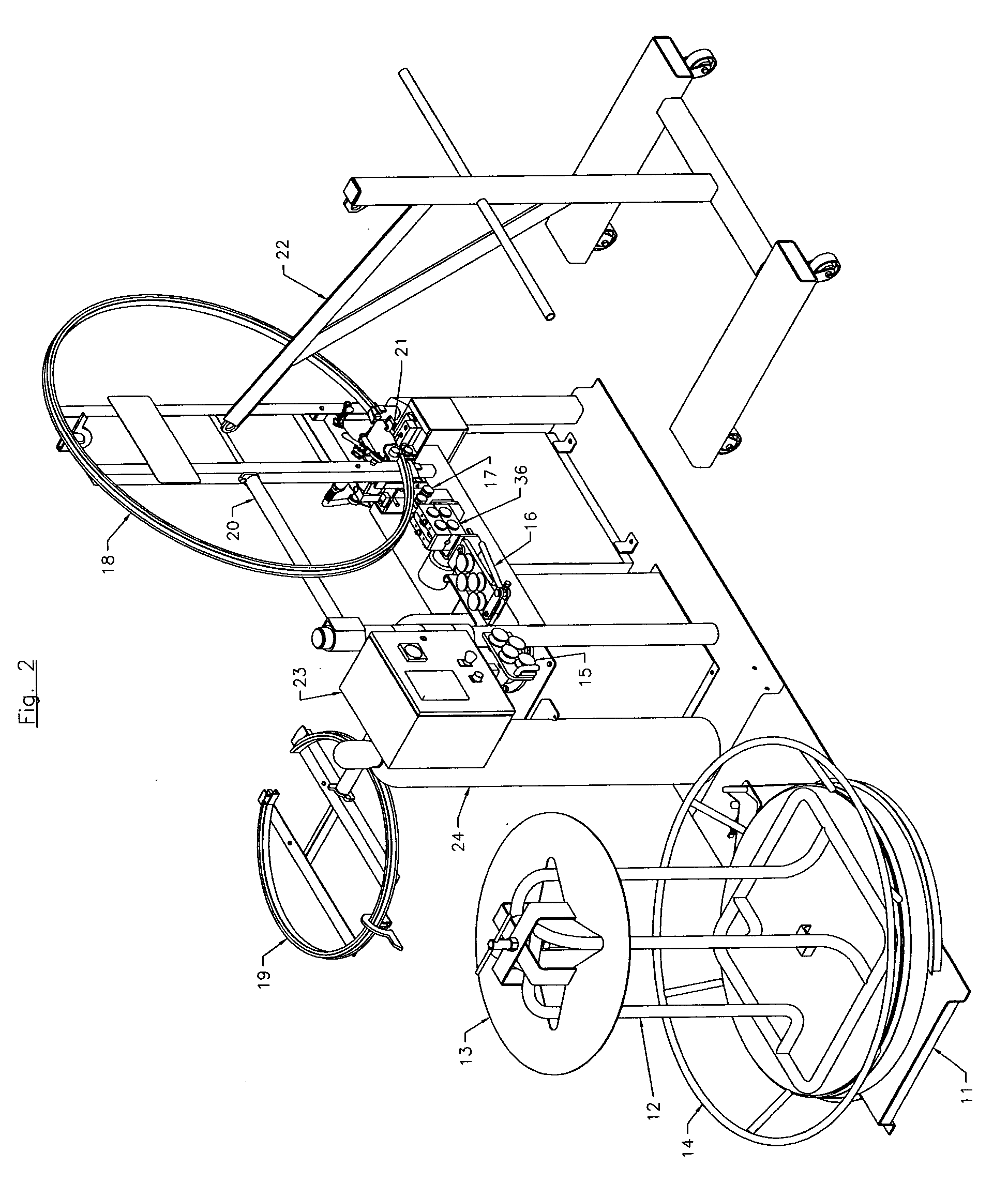

[0025] Looking now specifically at the drawings accompanying this invention, which show particularly preferred embodiments, but to which I am not limited, FIG. 1 is a cutaway view of a typical manhole the components of which may contain the reinforcing hoops of this invention. In this drawing, going from top to bottom, or from ground level to under ground level, I is the grade ring having an opening 2 through which one can enter the manhole. 3 is an eccentric cone top followed by two riser sections 4 and 5, which are shown as different lengths (2′ and 4′) in this drawing. 6 is a 4′ extended base section with a foot 7 to permit a firm footing under ground. The connection and mating elements of each section are shown as 8, 8a and 8b. A series of entry steps, one of which is shown as 9, permit easy entry into the manhole for servicing. One, of what may be a plurality of pipe openings, is shown as 10. The reinforcing hoop elements made by the teachings of this invention are useful in fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com