Metal rubber gasket manufacture process

A manufacturing process, metal rubber technology, applied in the direction of manufacturing rings from wires, wire processing, and other household appliances, etc., can solve problems such as difficult to guarantee product quality, no manufacturing process, etc., achieve simple manufacturing process, improve service life, and durable sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

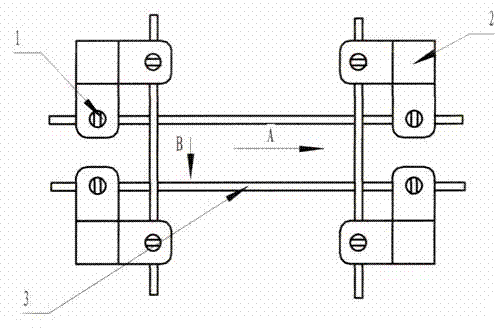

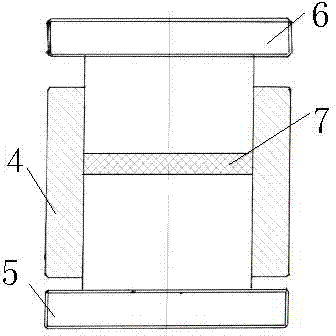

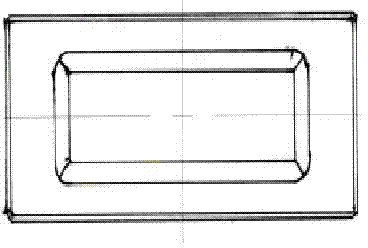

[0017] This embodiment provides a metal rubber gasket manufacturing process, which is characterized in that: the tools used in the metal rubber gasket manufacturing process include screws 1, fixing blocks 2, steel wires 3, precision pressing dies 4, lower dies 5, The upper mold 6; the four steel wires 3 are fastened on the four fixed blocks 2 by screws 1, and the steel wires 3 form a tight rectangular structure arrangement;

[0018] The manufacturing process is to adjust the position of the fixed block 2 according to the size of the blank of the part, and use the SMM-208 CNC winding machine to wind the 1Cr18Ni9Ti stainless steel wire with a diameter of 0.1 mm into a spiral coil with an outer diameter of 0.8~1.3 mm, and then weave , the weaving process is to wind the spiral on the steel wire 3, first wind one layer along the A direction, then wind one layer according to the B direction, and rotate the winding direction, repeat 2~3 times, after winding, disassemble it, and the bl...

Embodiment 2

[0024] This embodiment provides a metal rubber gasket manufacturing process, which is characterized in that: the tools used in the metal rubber gasket manufacturing process include screws 1, fixing blocks 2, steel wires 3, precision pressing dies 4, lower dies 5, The upper mold 6; the four steel wires 3 are fastened on the four fixed blocks 2 by screws 1, and the steel wires 3 form a tight rectangular structure arrangement;

[0025] The manufacturing process is to adjust the position of the fixed block 2 according to the size of the blank of the part, and use the SMM-208 CNC winding machine to wind the 1Cr18Ni9Ti stainless steel wire with a diameter of 0.1 mm into a spiral coil with an outer diameter of 0.8~1.3 mm, and then weave , the weaving process is to wind the spiral on the steel wire 3, first wind one layer along the A direction, then wind one layer according to the B direction, and rotate the winding direction, repeat 2~3 times, after winding, disassemble it, and the bl...

Embodiment 3

[0031] This embodiment provides a metal rubber gasket manufacturing process, which is characterized in that: the tools used in the metal rubber gasket manufacturing process include screws 1, fixing blocks 2, steel wires 3, precision pressing dies 4, lower dies 5, The upper mold 6; the four steel wires 3 are fastened on the four fixed blocks 2 by screws 1, and the steel wires 3 form a tight rectangular structure arrangement;

[0032] The manufacturing process is to adjust the position of the fixed block 2 according to the size of the blank of the part, and use the SMM-208 CNC winding machine to wind the 1Cr18Ni9Ti stainless steel wire with a diameter of 0.1 mm into a spiral coil with an outer diameter of 0.8~1.3 mm, and then weave , the weaving process is to wind the spiral on the steel wire 3, first wind one layer along the A direction, then wind one layer according to the B direction, and rotate the winding direction, repeat 2~3 times, after winding, disassemble it, and the bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com