Cereal-based edible tableware and making method thereof

A production method and grain technology, applied in the fields of application, baked food, food science, etc., can solve the problems of long material degradation cycle, difficult degradation of plastic tableware, high processing cost, etc., achieve uniform heating, good functional characteristics, and ensure edible sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

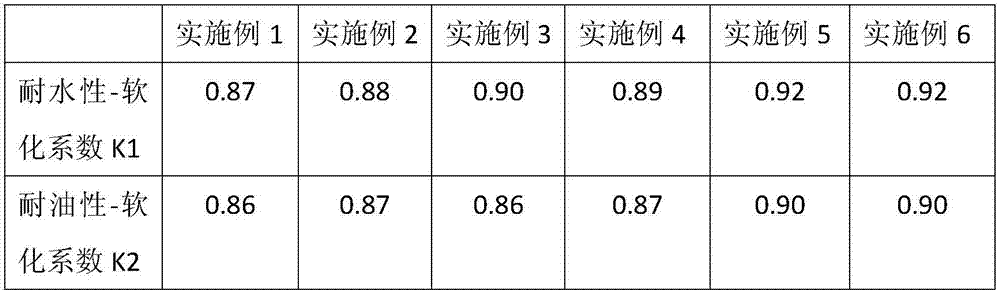

Examples

Embodiment 1

[0016] 60 parts of whole wheat flour, 20 parts of sorghum flour, 15 parts of rice flour, and 5 parts of millet flour were subjected to microwave-assisted treatment and roasting and pre-cooking treatment. The power of microwave-assisted treatment was 500W, the time was 120S, and the power of roasting and pre-cooking treatment was 900W. The time is 10 minutes; after the microwave-assisted treatment and roasting and pre-cooking treatment, 3 parts of grain flour and butter, 5 parts of sucrose and 30 parts of water are mixed evenly, and then added to the dough mixer, kneaded into dough, and kneaded into a ball; Divide the dough into several portions of appropriate size, press them into the mold, and heat them to shape. The heat preservation temperature is 85°C, and the heat preservation time is 5 minutes. Keep the temperature at 120°C, pressurize once during the period, and apply a pressure of 80N; use a brush to evenly coat the tableware with a concentration of 2% rice flour gelati...

Embodiment 2

[0018] 60 parts of whole wheat flour, 5 parts of sorghum flour, 15 parts of rice flour, 10 parts of millet flour, and 10 parts of purple potato flour were subjected to microwave-assisted treatment and roasting pre-cooking treatment. The power of microwave-assisted treatment was 800W, and the time was 30S. The curing treatment power is 1800W, and the time is 0.5min; 5 parts of grain powder and butter, 2 parts of green tea powder, 1 part of chili powder, 2 parts of table salt and 40 parts of water after microwave-assisted treatment and pre-cooking treatment are mixed. Add it to the dough mixer, knead the dough, and knead it into a ball; divide the kneaded dough into several portions of appropriate size, press them into the mold, and heat them to shape. The heat preservation temperature is 65°C, and the heat preservation time is 10 minutes; Take the tableware out of the mold, put it into the baking tray for intermittent pressure baking, keep the temperature at 120°C, pressurize on...

Embodiment 3

[0020] 80 parts of whole wheat flour, 5 parts of sorghum flour, and 15 parts of rice flour were subjected to microwave-assisted treatment and dry-heat pre-cooking treatment. The microwave-assisted treatment power was 500W, the time was 120S, and the dry-heat pre-cooking treatment temperature was 100°C, and the time was 30min; Mix 3 parts of grain powder and butter, 2 parts of green tea powder, 1 part of chili powder, 1 part of sucrose and 30 parts of water after microwave-assisted treatment and dry heat pre-cooking treatment, add them to the dough mixer, and knead into dough. Knead the dough into a circle; divide the reconciled dough into several portions of appropriate size, press them into the mold, and heat them to shape. The heat preservation temperature is 85°C, and the heat preservation time is 5 minutes; Intermittent pressurized roasting, the temperature is kept at 120°C, pressurized once during the period, and the applied pressure is 80N; the tableware baked to nine mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com