Medium silicon molybdenum nodular cast iron and production method thereof

A technology of ductile cast iron and production method, which is applied in the field of ductile iron, can solve problems such as general nodularization effect, and achieve the effects of improving mechanical properties, reducing segregation, and eliminating whitening tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

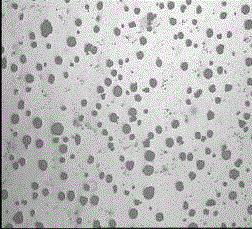

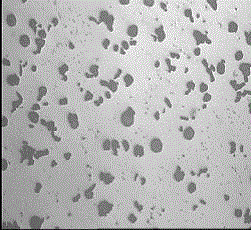

Image

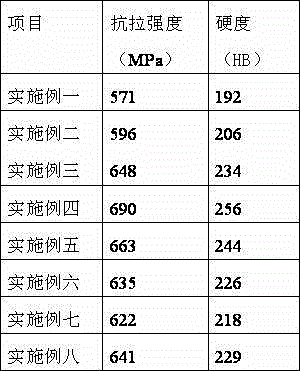

Examples

Embodiment 1

[0029] This embodiment provides a kind of medium-silicon-molybdenum ductile iron, the mass percentage of each component is: C: 3.15%, Si: 3.5%, Mn: 0.3%, P: 0.07%, S: 0.02%, Mo: 0.6%, Mg: 0.03, the balance is Fe and unavoidable trace elements.

[0030] The production method of above-mentioned silicon-molybdenum nodular cast iron comprises the steps:

[0031] 1) Place the proportioned pig iron, recycled material, scrap steel and ferromolybdenum in the medium frequency induction furnace for smelting. After the temperature of the molten iron reaches 1450-1480℃, slag making and slag removal are carried out to ensure the purity of the molten iron;

[0032] 2) Control the temperature of the molten iron out of the furnace at 1520-1540 °C, use an electronic crane scale to lift the ladle at the furnace mouth to tap the iron, and the iron weight is 490-510kg;

[0033] 3) Add a rare earth magnesium series nodulizer into the ladle for spheroidization treatment, and the added nodulizer is...

Embodiment 2

[0040] This embodiment provides a kind of medium-silicon-molybdenum ductile iron, the mass percentage of each component is: C: 3.18%, Si: 3.9%, Mn: 0.3%, P: 0.07%, S: 0.02%, Mo: 0.7%, Mg: 0.034, the balance is Fe and unavoidable trace elements.

[0041] The production method of above-mentioned silicon-molybdenum nodular cast iron comprises the steps:

[0042] 1) Place the proportioned pig iron, recycled material, scrap steel and ferromolybdenum in the medium frequency induction furnace for smelting. After the temperature of the molten iron reaches 1450-1480℃, slag making and slag removal are carried out to ensure the purity of the molten iron;

[0043] 2) Control the temperature of the molten iron out of the furnace at 1520-1540 °C, use an electronic crane scale to lift the ladle at the furnace mouth to tap the iron, and the iron weight is 490-510kg;

[0044] 3) Add a rare earth magnesium series nodulizer into the ladle for spheroidization treatment, and the added nodulizer i...

Embodiment 3

[0051] This embodiment provides a kind of medium-silicon-molybdenum ductile iron, the mass percentage of each component is: C: 3.22%, Si: 4.3%, Mn: 0.3%, P: 0.07%, S: 0.02%, Mo: 0.7%, Mg: 0.038, the balance is Fe and unavoidable trace elements.

[0052] The production method of above-mentioned silicon-molybdenum nodular cast iron comprises the steps:

[0053] 1) Place the proportioned pig iron, recycled material, scrap steel and ferromolybdenum in the medium frequency induction furnace for smelting. After the temperature of the molten iron reaches 1450-1480℃, slag making and slag removal are carried out to ensure the purity of the molten iron;

[0054] 2) Control the temperature of the molten iron out of the furnace at 1520-1540 °C, use an electronic crane scale to lift the ladle at the furnace mouth to tap the iron, and the iron weight is 490-510kg;

[0055] 3) Add a rare earth magnesium series nodulizer into the ladle for spheroidization treatment, and the added nodulizer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com