Machining technology and machining forming device of elastic collar

A kind of elastic retaining ring, processing and forming technology, applied in the direction of wire processing, wire manufacturing rings, other household appliances, etc., can solve the problems of high accident rate, high cost, easy fatigue of personnel, etc., to reduce production costs and improve production efficiency. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

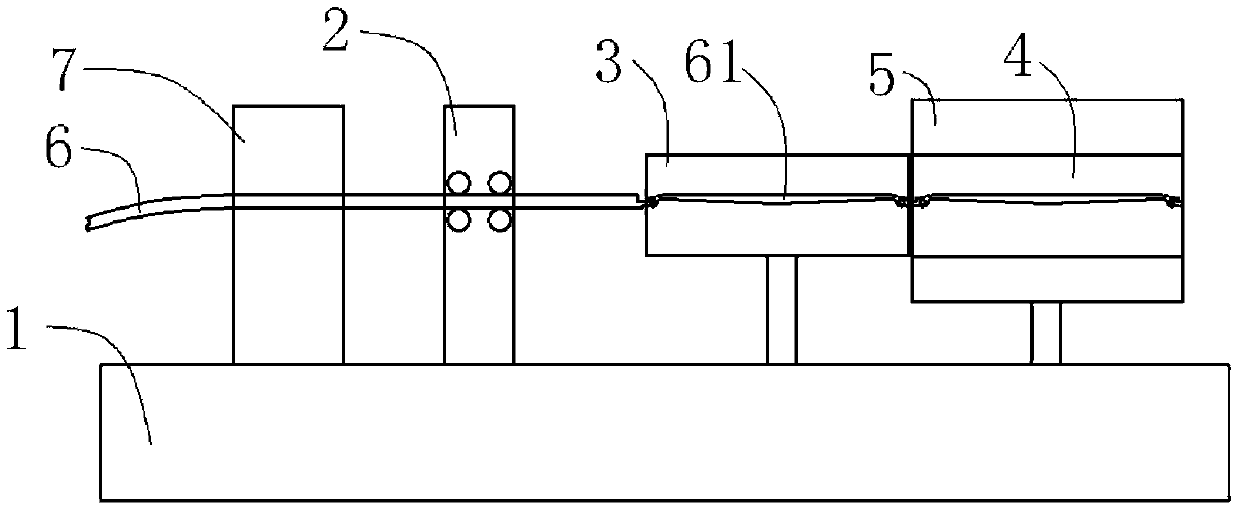

[0020] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

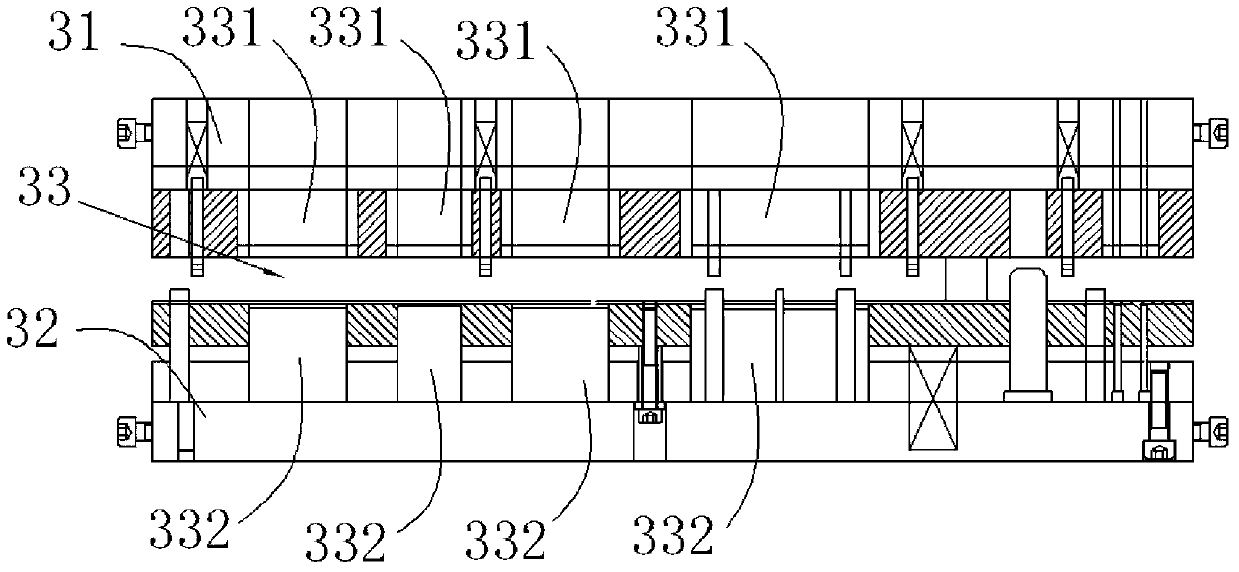

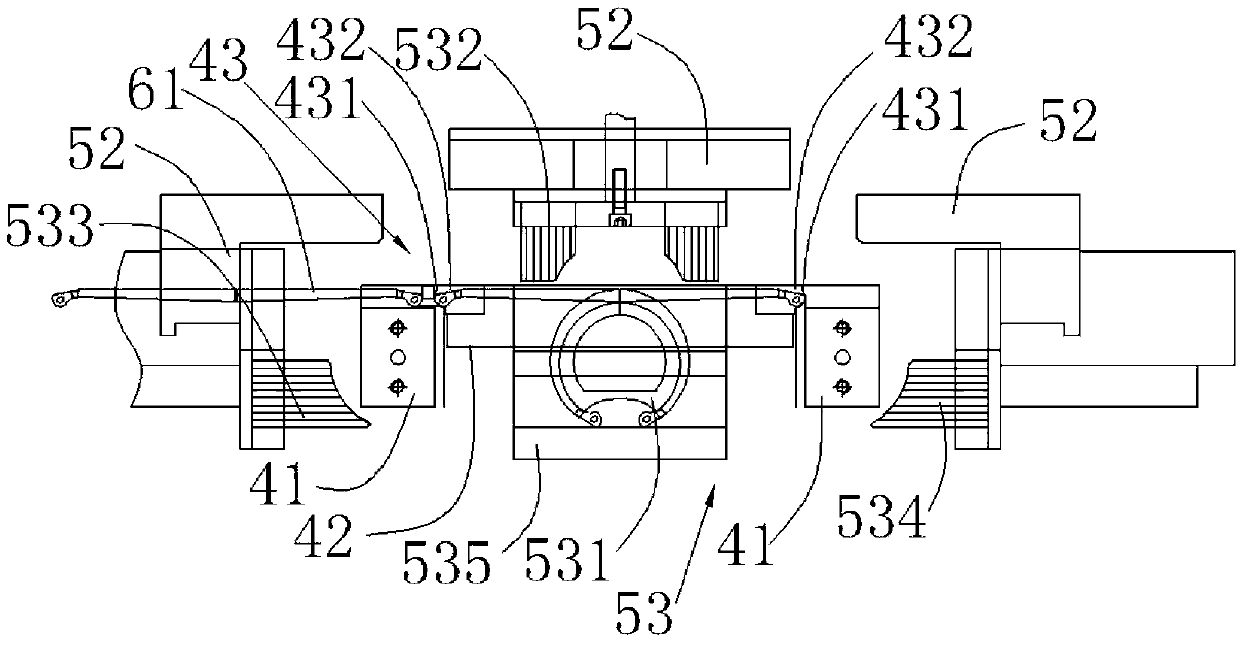

[0021] The processing technology of the elastic retaining ring of the present invention realizes the automatic forming process of the elastic retaining ring, reduces the production cost, improves the product quality, greatly improves the production efficiency, and has a remarkable effect in actual production. It is mainly divided into feeding part, stamping part, cutting part and forming part. Metal wire is used as raw material (or metal strip is pretreated to form metal wire). The raw material (metal wire) is firstly processed by the straightening part of the machine tool (frame). Straightening processing; then the clamping mechanism of the mechanical feeding part clamps the automatic feeding according to the adjusted feeding step length (fixed step size), and the material is sent into the stamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com