Full-automatic single-wheel numerical control circling welding machine and circling welding method thereof

A fully automatic, welding machine technology, applied in welding equipment, resistance welding equipment, other household appliances, etc., can solve the problems of affecting accuracy, cumbersome adjustment, affecting fastness, etc., achieving convenient structure and method, simplifying equipment structure, guaranteeing The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

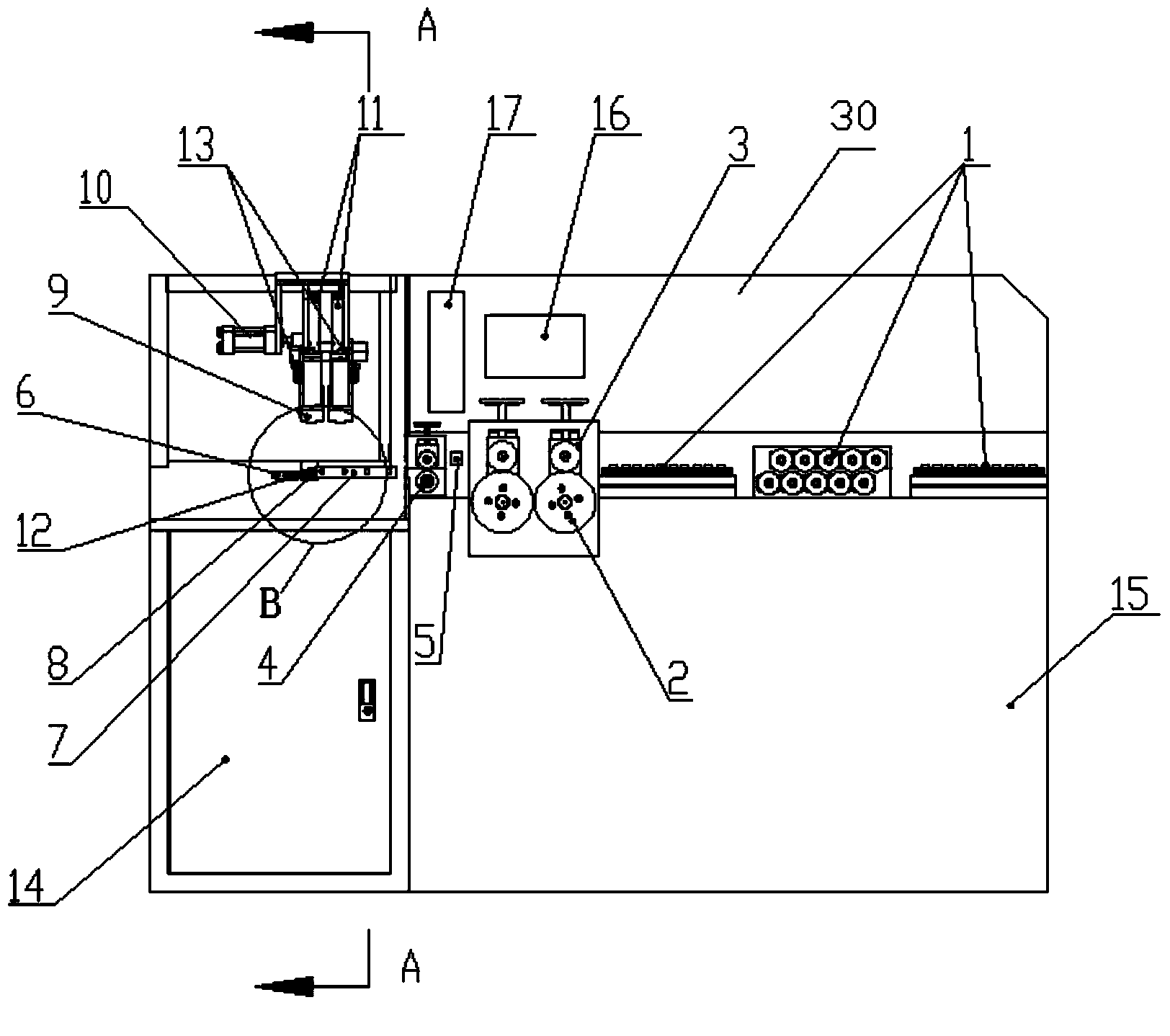

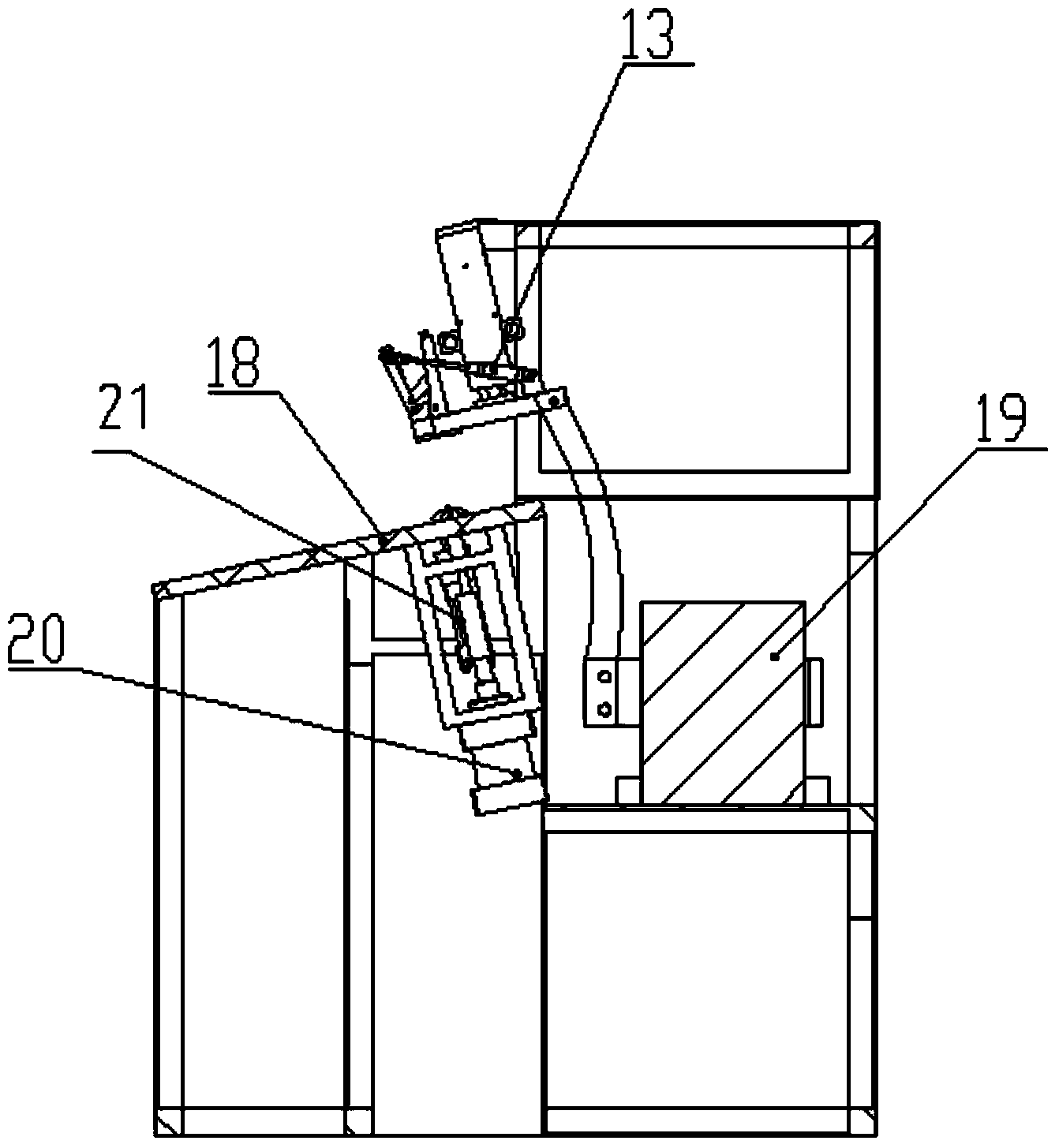

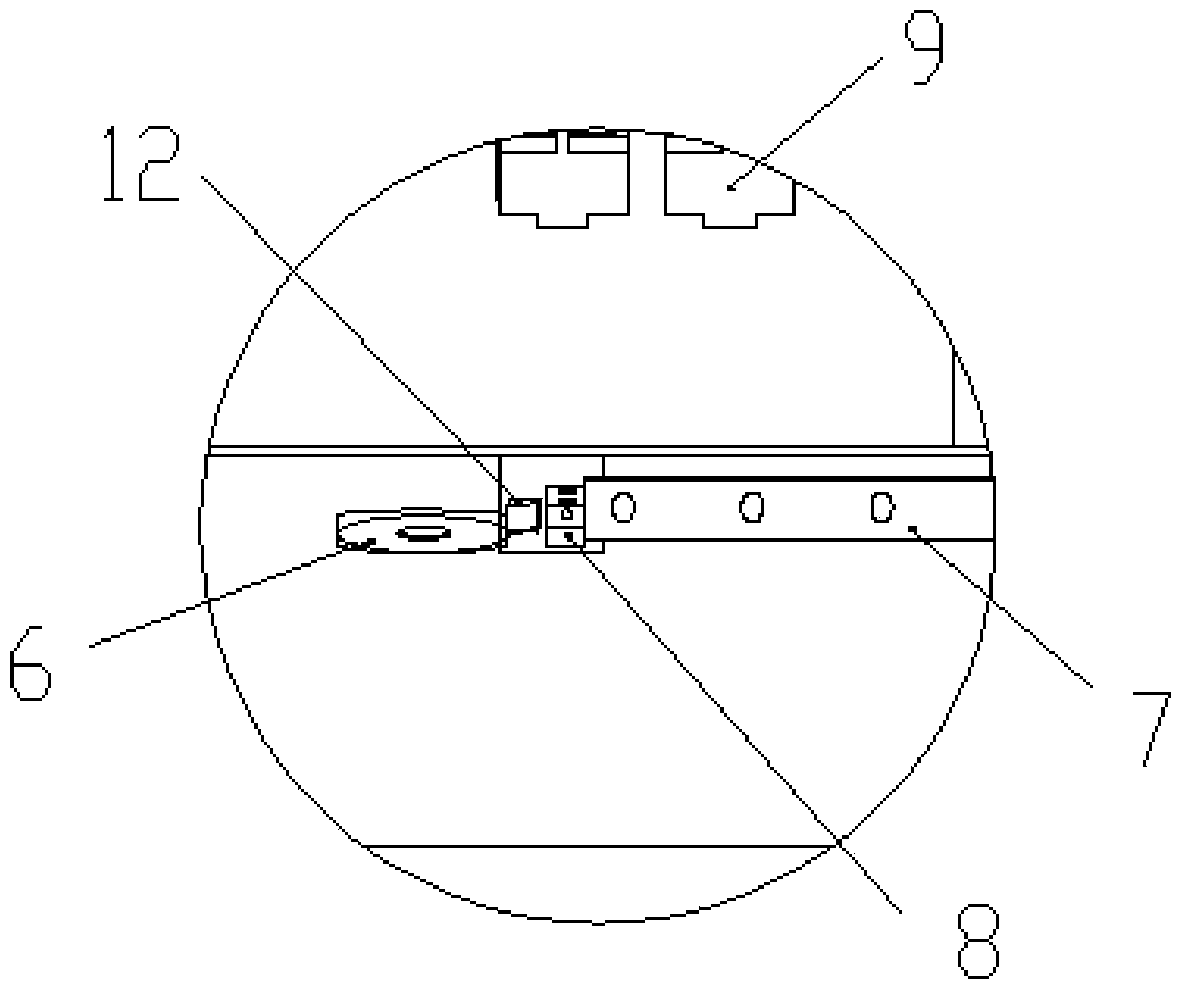

[0024] Such as Figure 1 to Figure 5 A fully automatic single-wheel numerically controlled circle welding machine, comprising a fuselage 30 and a working table 18, the fuselage 30 is sequentially provided with a straightening mechanism, a feeding mechanism, a lead plate, a cutting device, a single-wheel Forming mechanism and butt welding mechanism, the single-wheel forming mechanism includes a forming wheel 6 for forming and processing workpieces.

[0025] In order to further improve the above-mentioned technical solution, in order to ensure its processing accuracy, the single-wheel forming mechanism also includes: a sliding guide rail 22, a stepping motor 24 for adjusting the diameter of the workpiece, and a hydraulic cylinder 21 for lifting the forming wheel 6; The butt welding mechanism comprises a clamping manipulator, a manipulator clamping cylinder, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com