Shaping tooling for quenched check ring

A technology for tooling and retaining rings, applied to wire processing, manufacturing rings from wires, and other household appliances, can solve problems such as low processing efficiency, difficulty in feeding materials, and increased production costs, achieving good flatness, good shaping effects, The effect of easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

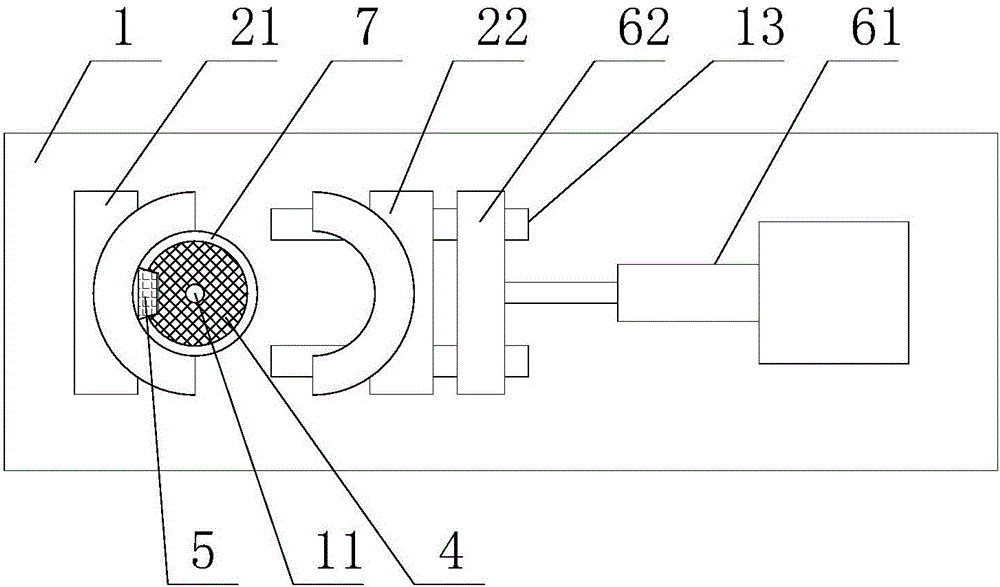

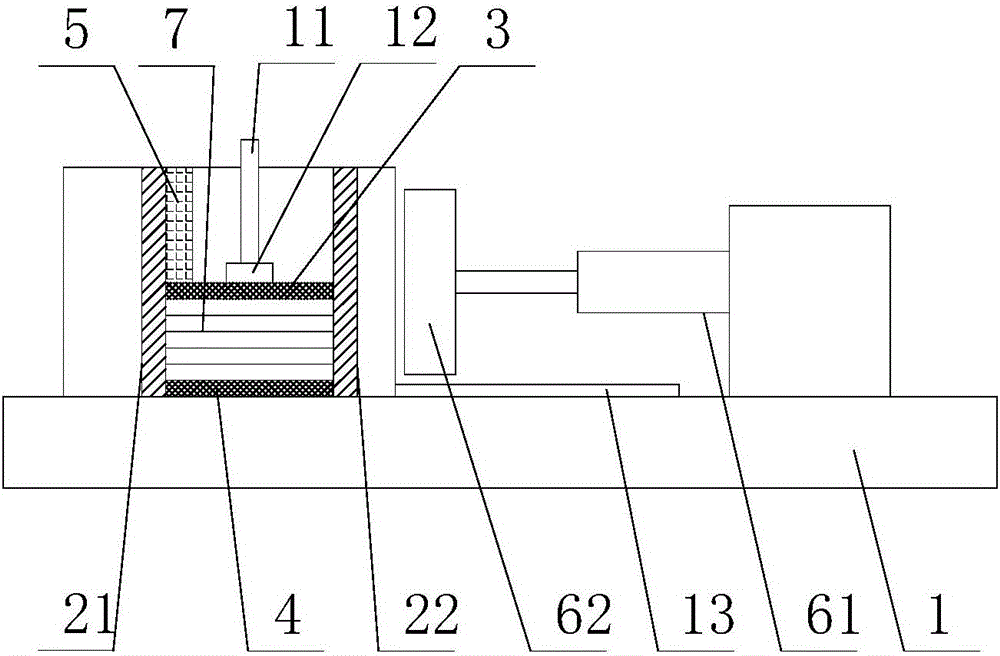

[0022] like figure 1 and 2 as shown, figure 1 It is a schematic diagram of the structure of a retaining ring after quenching and shaping tool proposed by the present invention, figure 2 It is a side view cross-sectional schematic diagram of a retaining ring quenched shaping tool proposed by the present invention.

[0023] refer to figure 1 and 2 , a kind of retaining ring shaping tool after quenching proposed by the present invention is used for shaping the retaining ring 7, the retaining ring 7 includes an annular base body, a central hole is formed in the middle of the annular base body, the annular base body has a predetermined thickness and has an opening, The base body is surrounded by two annular planes, an inner surface and an outer surface, the opening is formed between the two annular planes, and the shaping tool after quenching of the retaining ring includes: a base 1, a clamping mechanism, and a top backing plate 3. Bottom plate 4. Driving mechanism;

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com