Double-pulling double-ring winding machine set of tyre multikind cross section steel wire ring

A bead ring and double traction technology, which is applied in the field of special machinery and equipment for rubber tire production parts manufacturing, can solve the problems of less storage of rubber-coated steel wires, affecting the production efficiency of the unit, and intermittent startup and speed increase, so as to improve the continuous operation function and reduce the The effect of frequently starting the acceleration phenomenon and reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

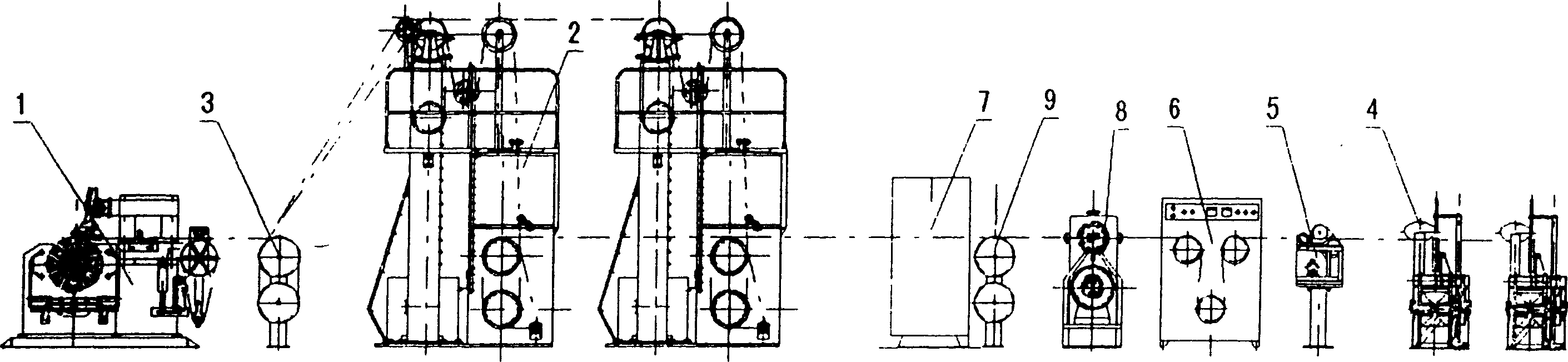

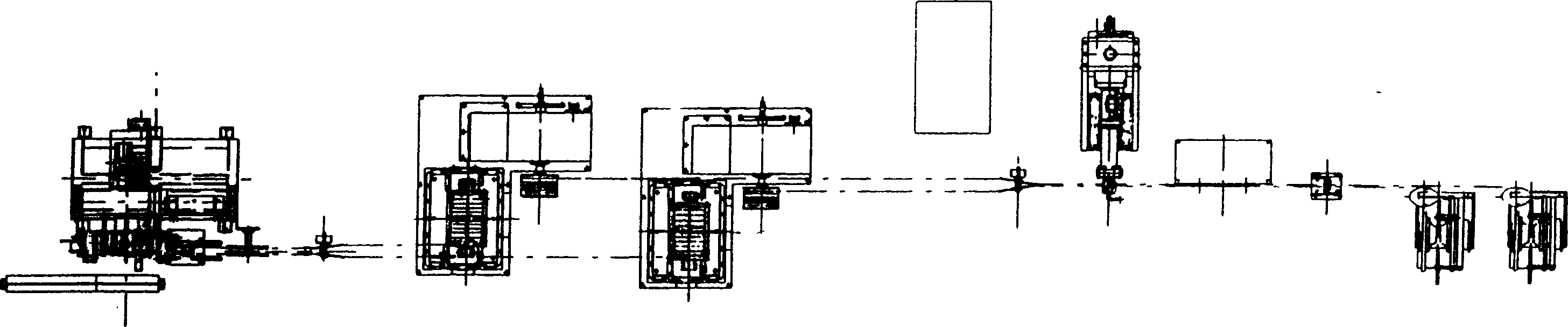

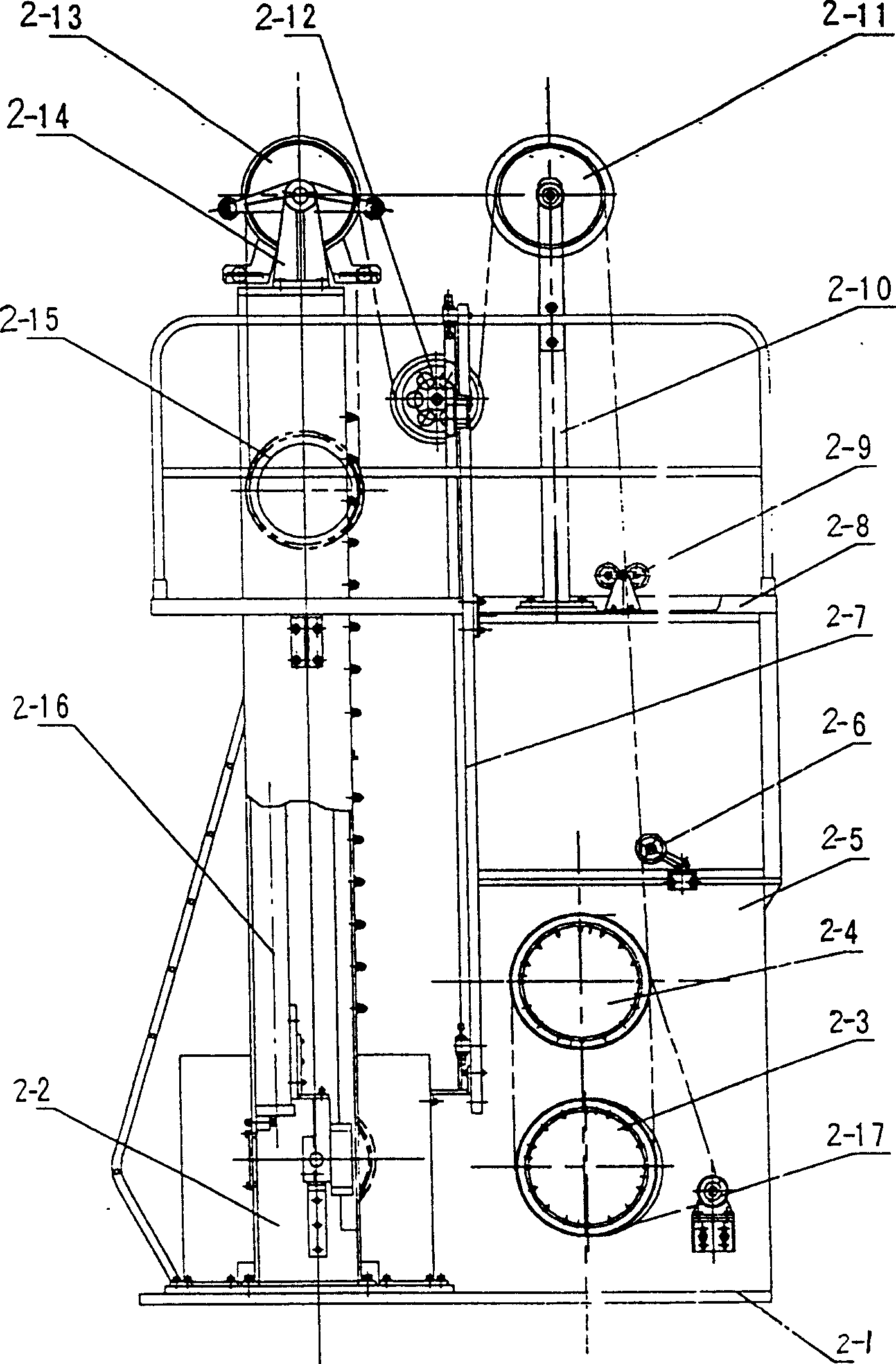

[0014] Embodiment: a kind of multiple-section steel traveler double-circle winding unit for double-traction tires (see figure 1 -ab), comprising a steel wire guide device 4, a steel wire decontamination device 5, a steel wire heating device 6, an extruder temperature control device 7, a rubber extruding mechanism 8, a steel wire expansion device 9, a storage mechanism, a steel wire shrinking device 3 and Steel wire winding mechanism 1, the above-mentioned mechanisms and devices constitute a tire traveler double-turn winding unit with multiple cross-sections, and the whole unit is installed on the same corresponding foundation plane, and its feature is that the said steel wire expansion device 9 and the steel wire shrinking device 3 The storage mechanism between is a double-traction structure 2, and said double-traction storage mechanism 2 is made of a double-station storage mechanism, and the double-station storage mechanism is a front-to-back dislocation arrangement (see figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com