Patents

Literature

76results about How to "High winding precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

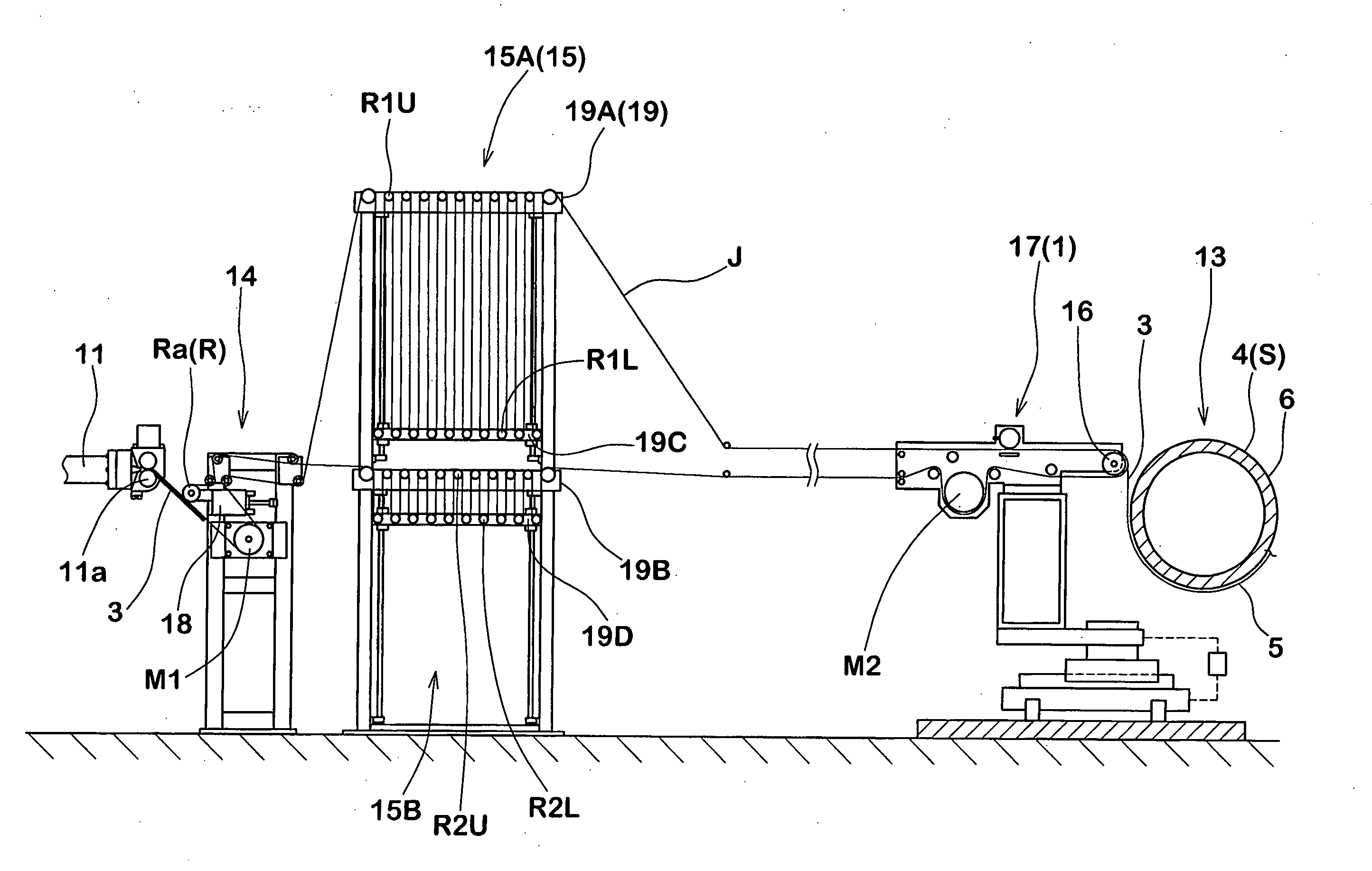

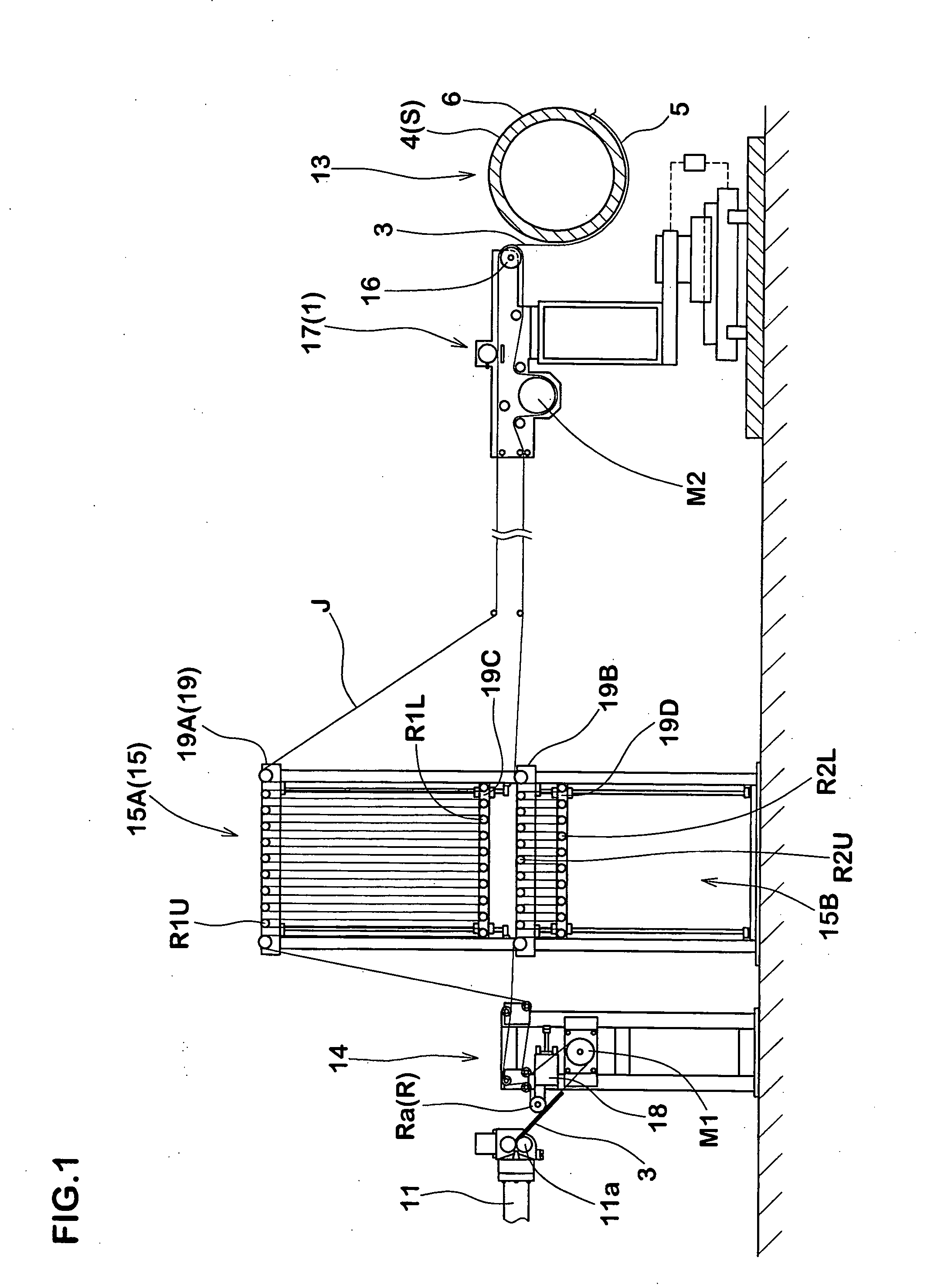

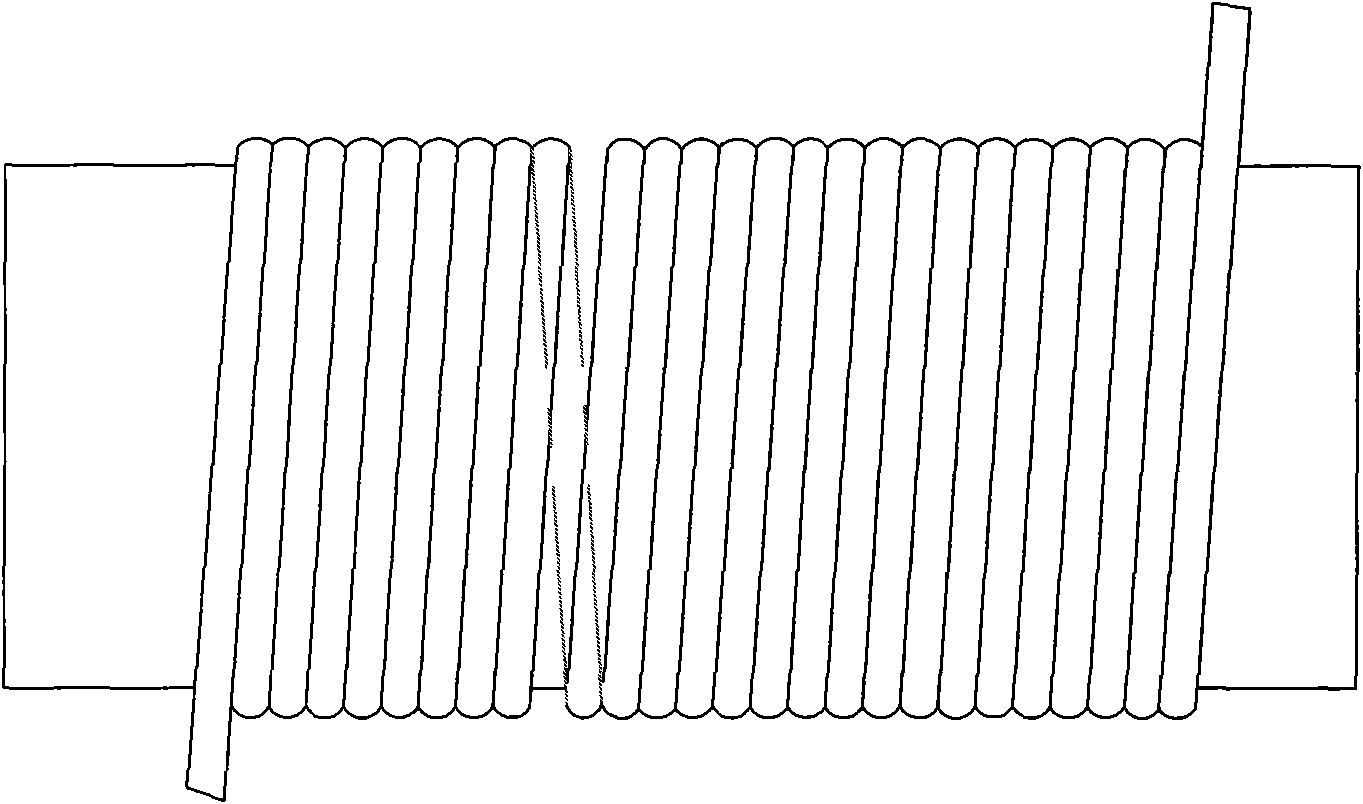

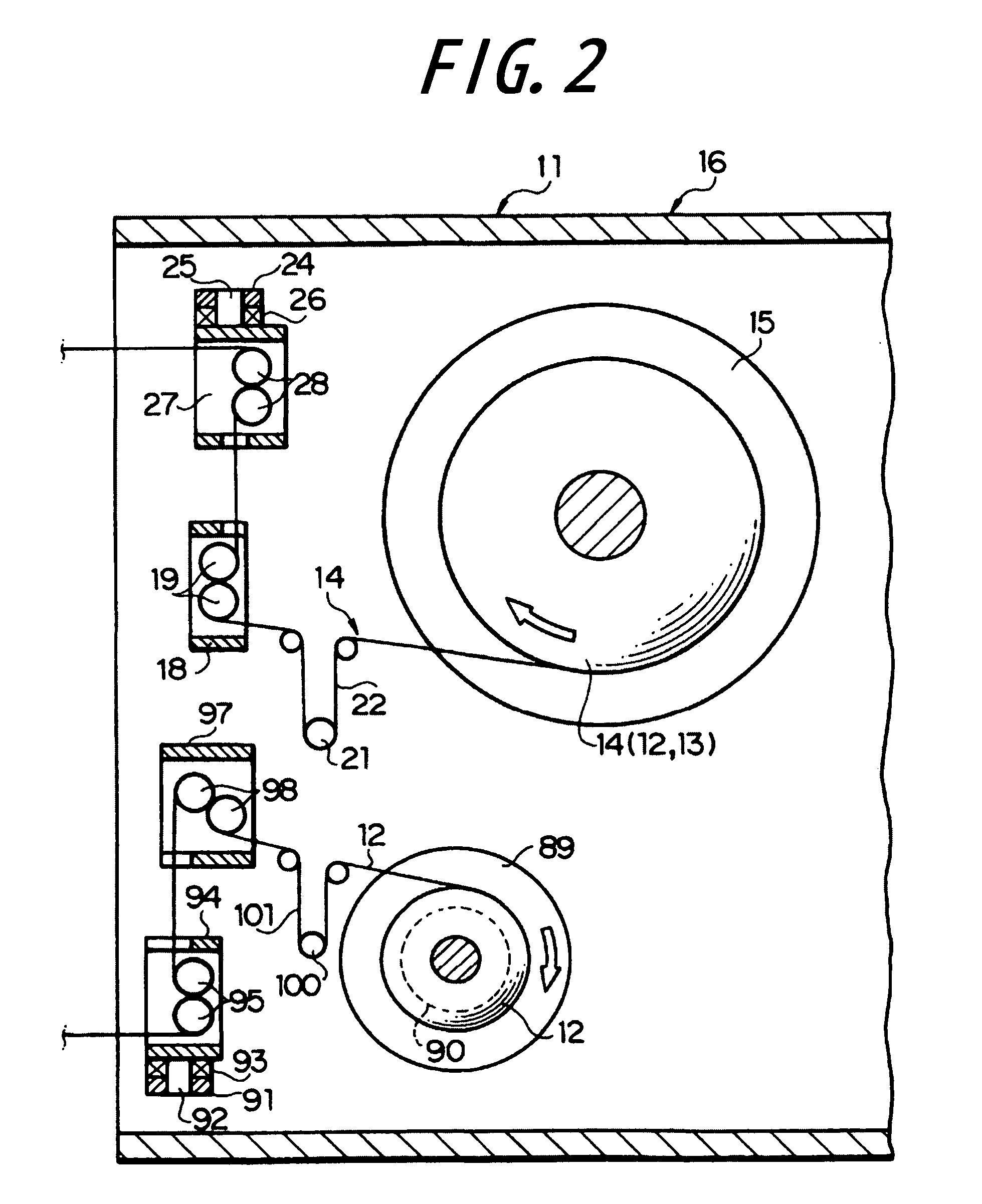

Producing method of rubber strip winding body, and rubber strip winding apparatus

InactiveUS20060081325A1Restraint torsionHigh winding precisionTyresEngineeringMechanical engineering

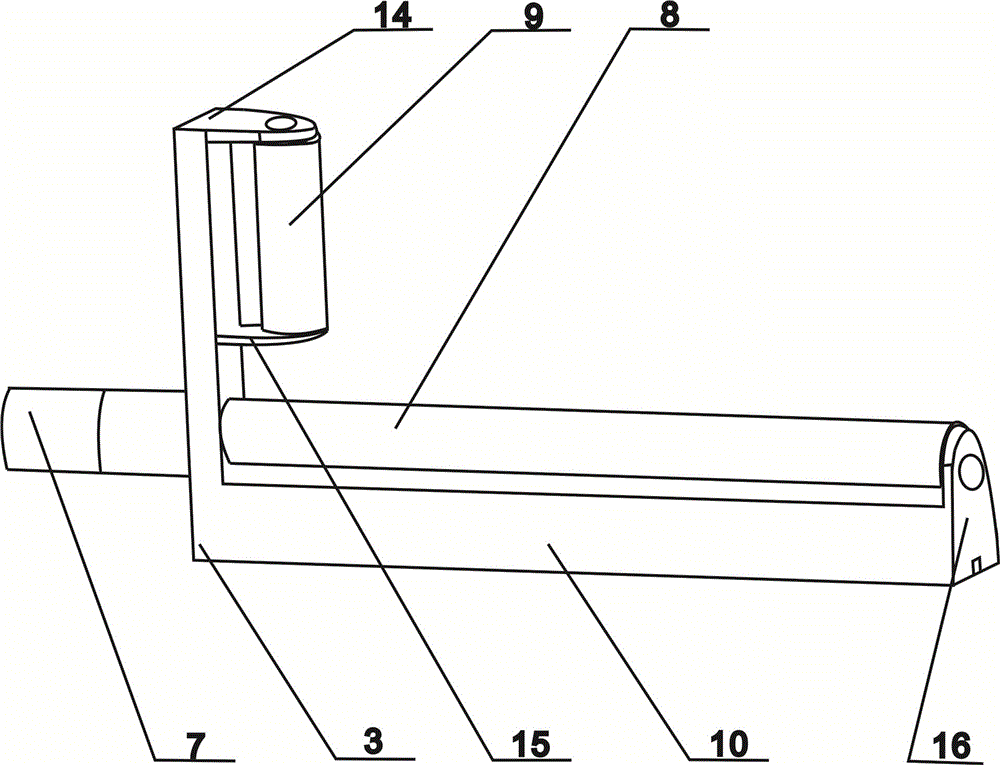

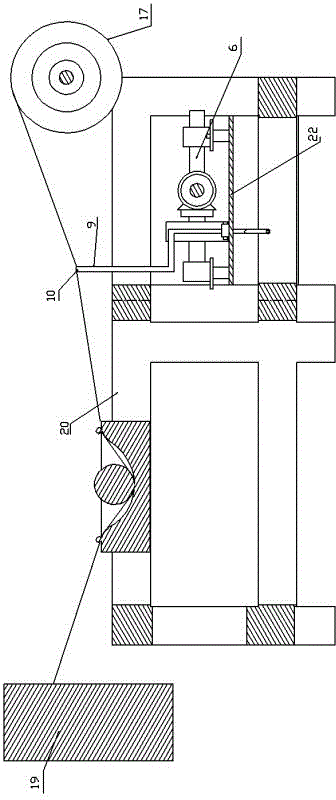

An unvulcanized rubber strip (3) is supplied to an outer peripheral surface of a rotating cylindrical body (4) from a sending-out roller (16) which laterally moves in an axial direction of the cylindrical body (4), thereby spirally winding the rubber strip (3) to form a winding body (5). In a tilting reference plane (29) defined as a plane which is in parallel to a plane (4S) passing through an axis (4i) of the cylindrical body (4) and which passes through an axis (16i) of the sending-out roller (16), the sending-out roller (16) is held such that the sending-out roller (16) can tilt positively and negatively within an inclination angle (α) of 0 to 45° with respect to a tilting reference line (N) which is parallel to the axis (4i) of the cylindrical body (4). The sending-out roller (16) is laterally moved while changing the inclination angle (α).

Owner:SUMITOMO RUBBER IND LTD

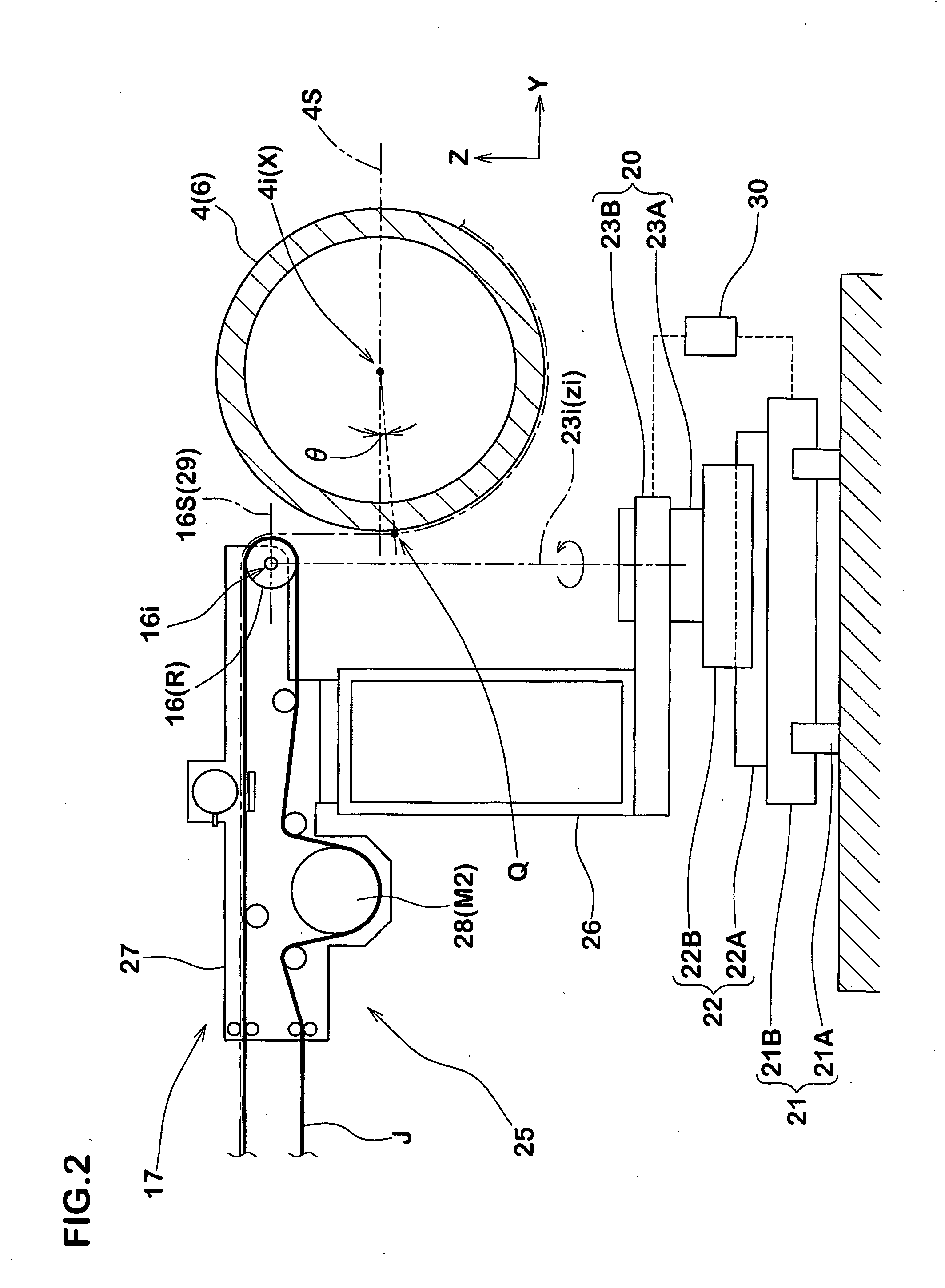

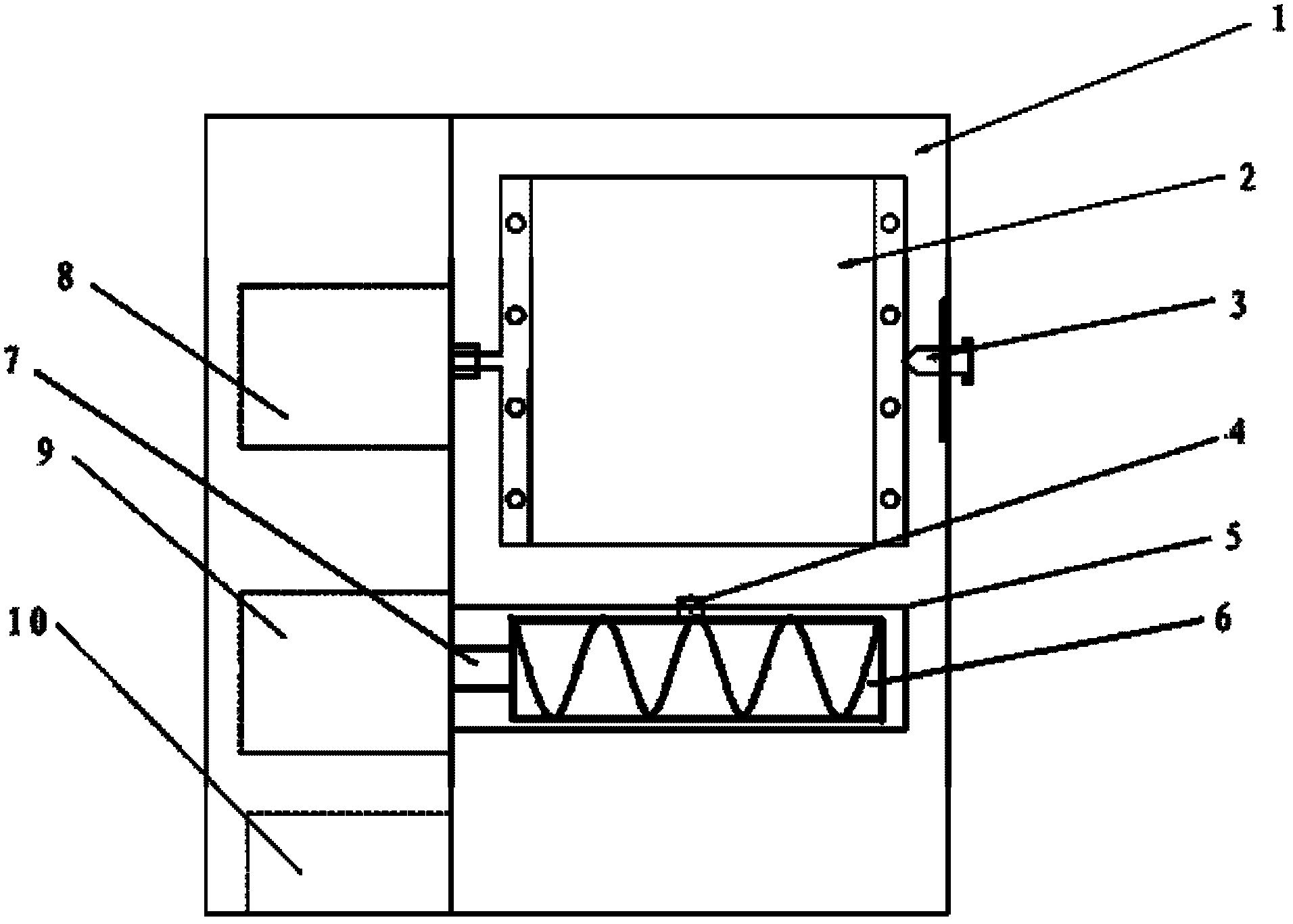

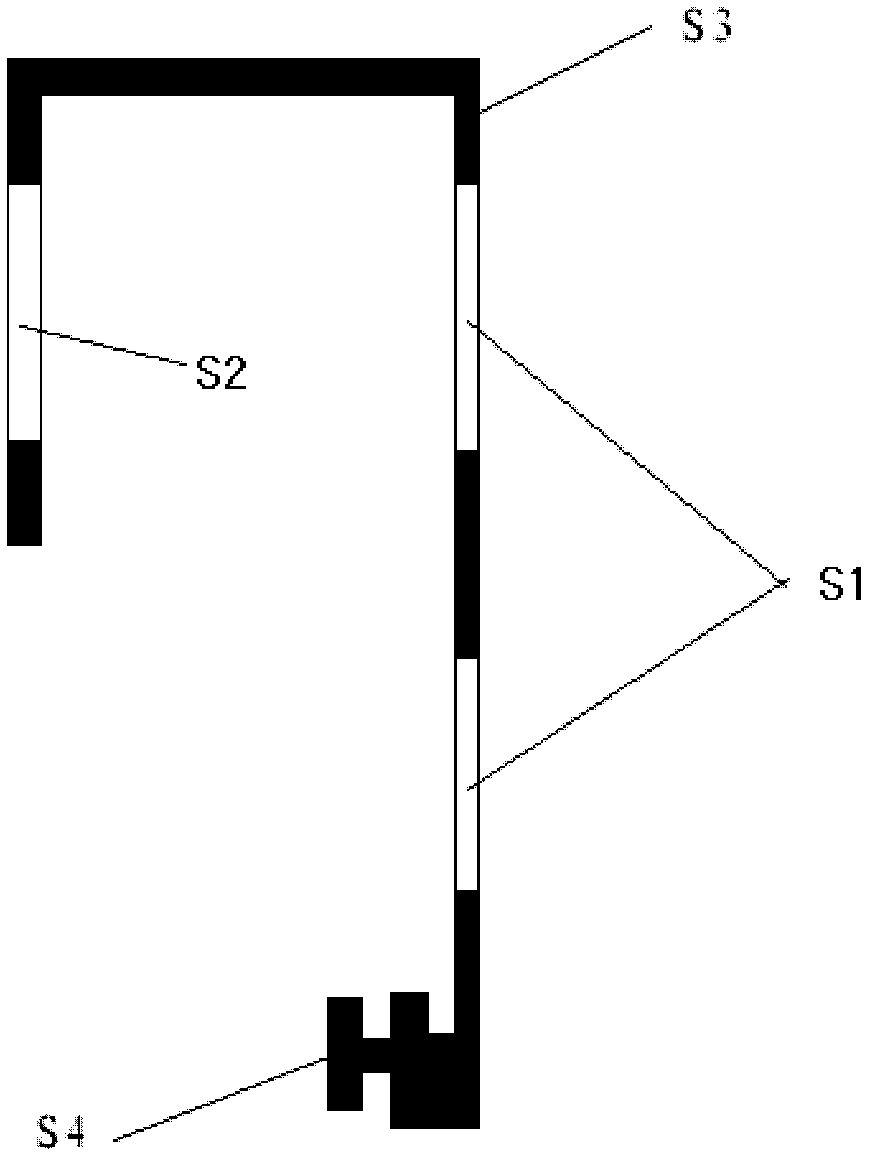

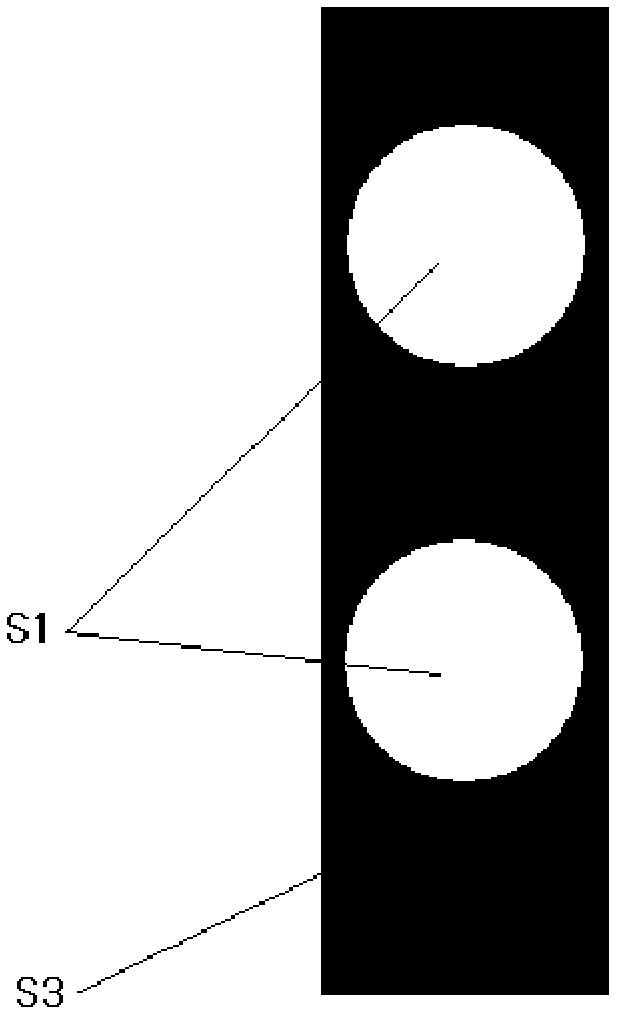

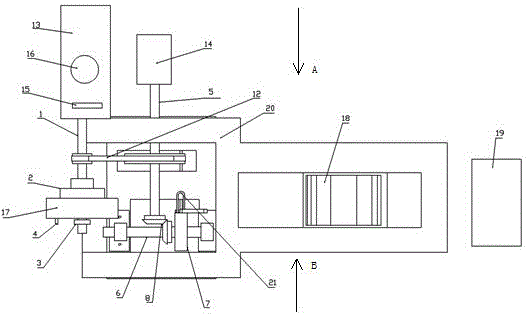

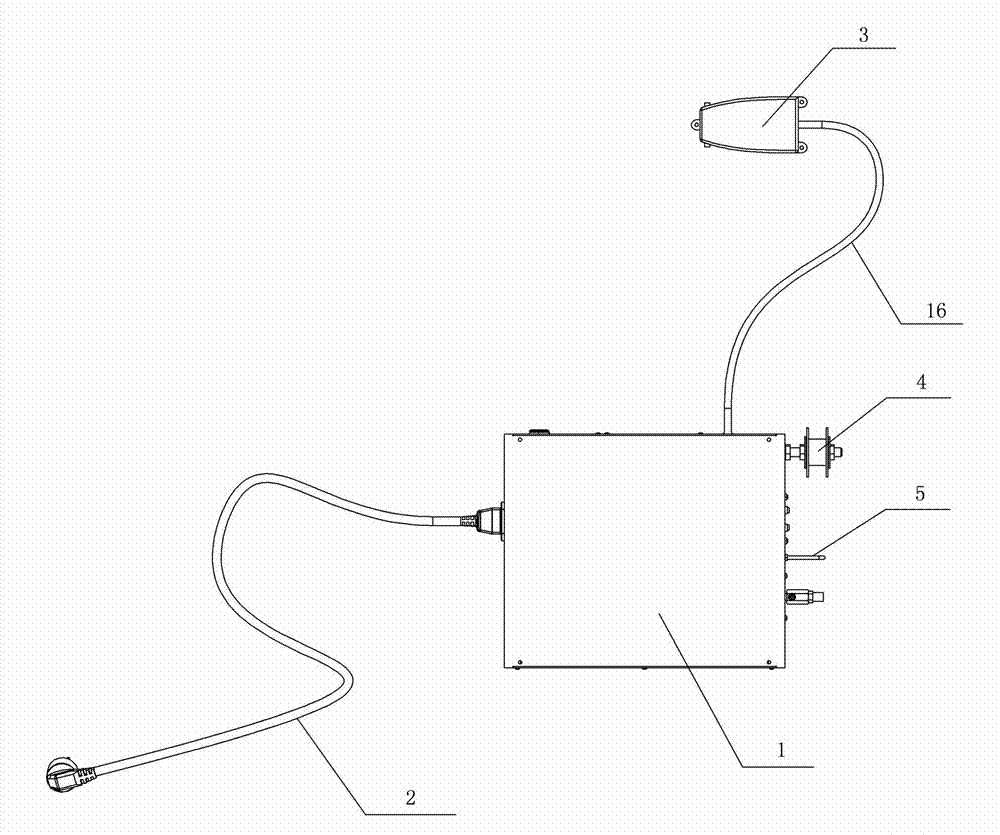

Lag angle control system in precise winding device

InactiveCN102053627AHigh winding precisionRealize closed-loop controlFilament handlingControl using feedbackAutomatic controlImaging processing

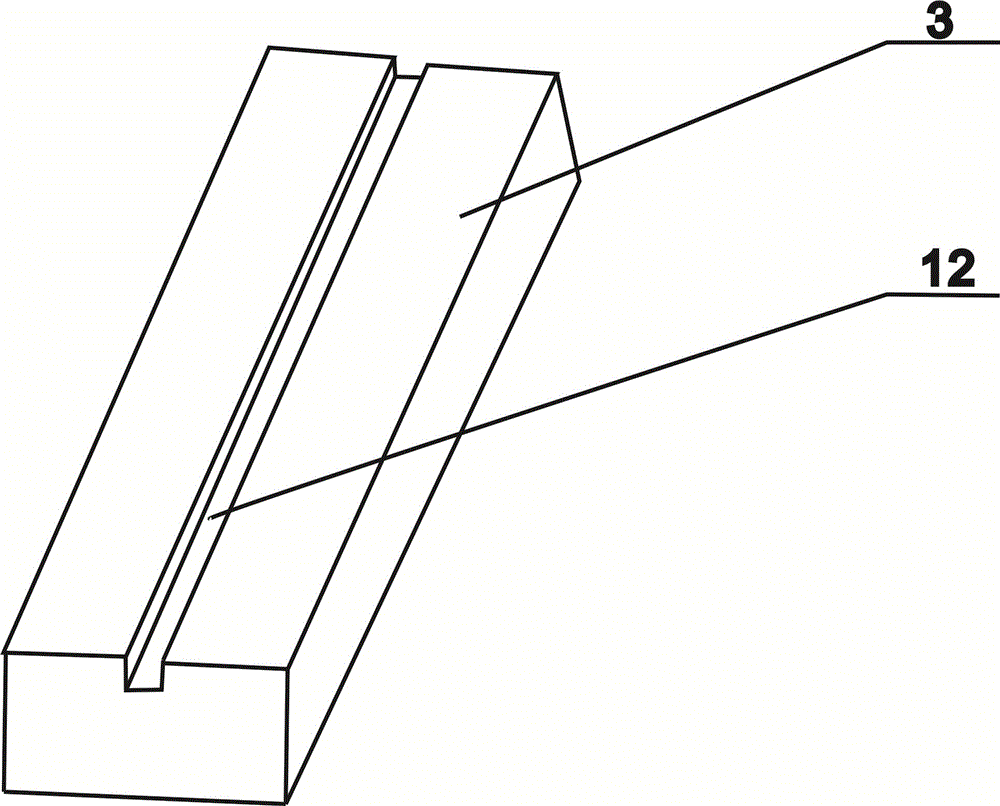

The invention relates to a lag angle control system in a precise winding device. The system comprises a precise camera shooting device, a high-speed image processing system and a precise wiring system, wherein the precise camera shooting device comprises a lag angle detection system; the high-speed image processing system comprises an image identification system; the precise wiring system comprises an alternating current servo system and a wiring execution mechanism, and the wiring execution mechanism consists of a precise ball screw and a precise linear guide rail; the lag angle detection system is connected with the image identification system and the wiring execution mechanism and used for sending a detection result to the image identification system, and after being identified by the image identification system, the detection result is controlled by a computer in a control system; the wiring execution mechanism is connected with the alternating current servo system and drives the precise ball screw to control the size of a wiring thread pitch through controlling the alternating current servo system; the alternating current servo system is also connected with a motion control card; and the motion control card is connected with the image identification system. The system has the advantages of high winding precision and small labor intensity and also realizes automatic control.

Owner:THE NORTHWEST MACHINE

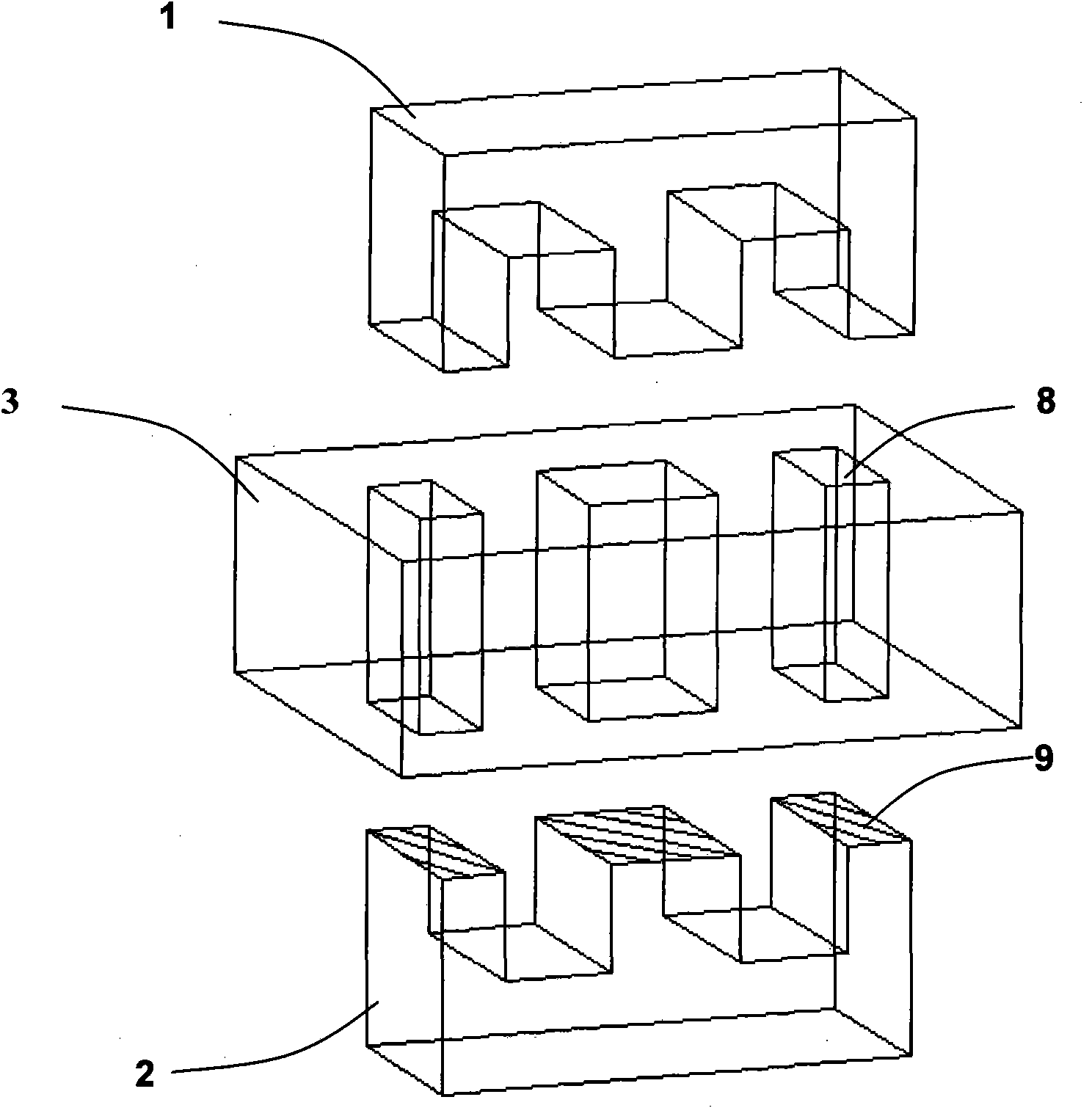

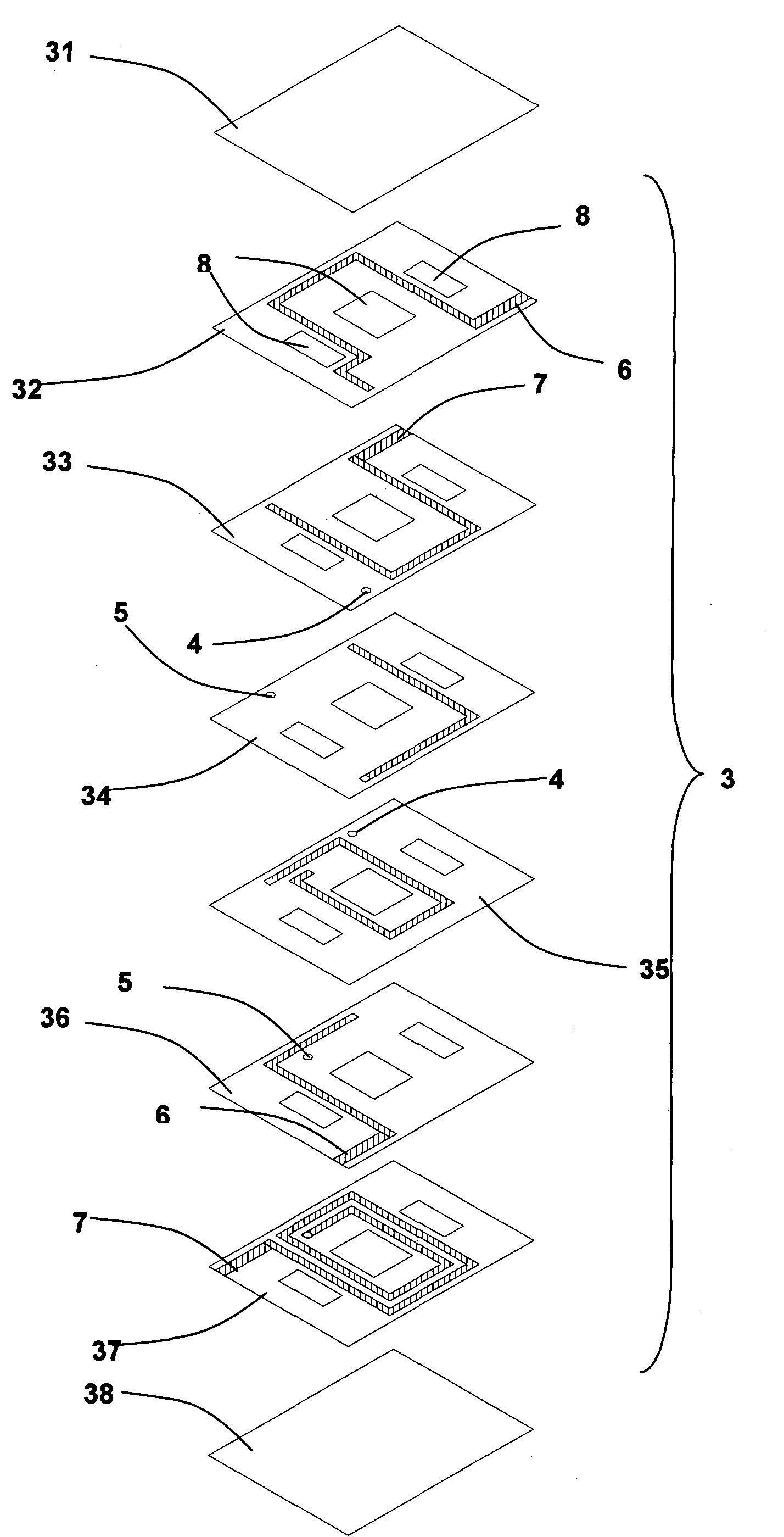

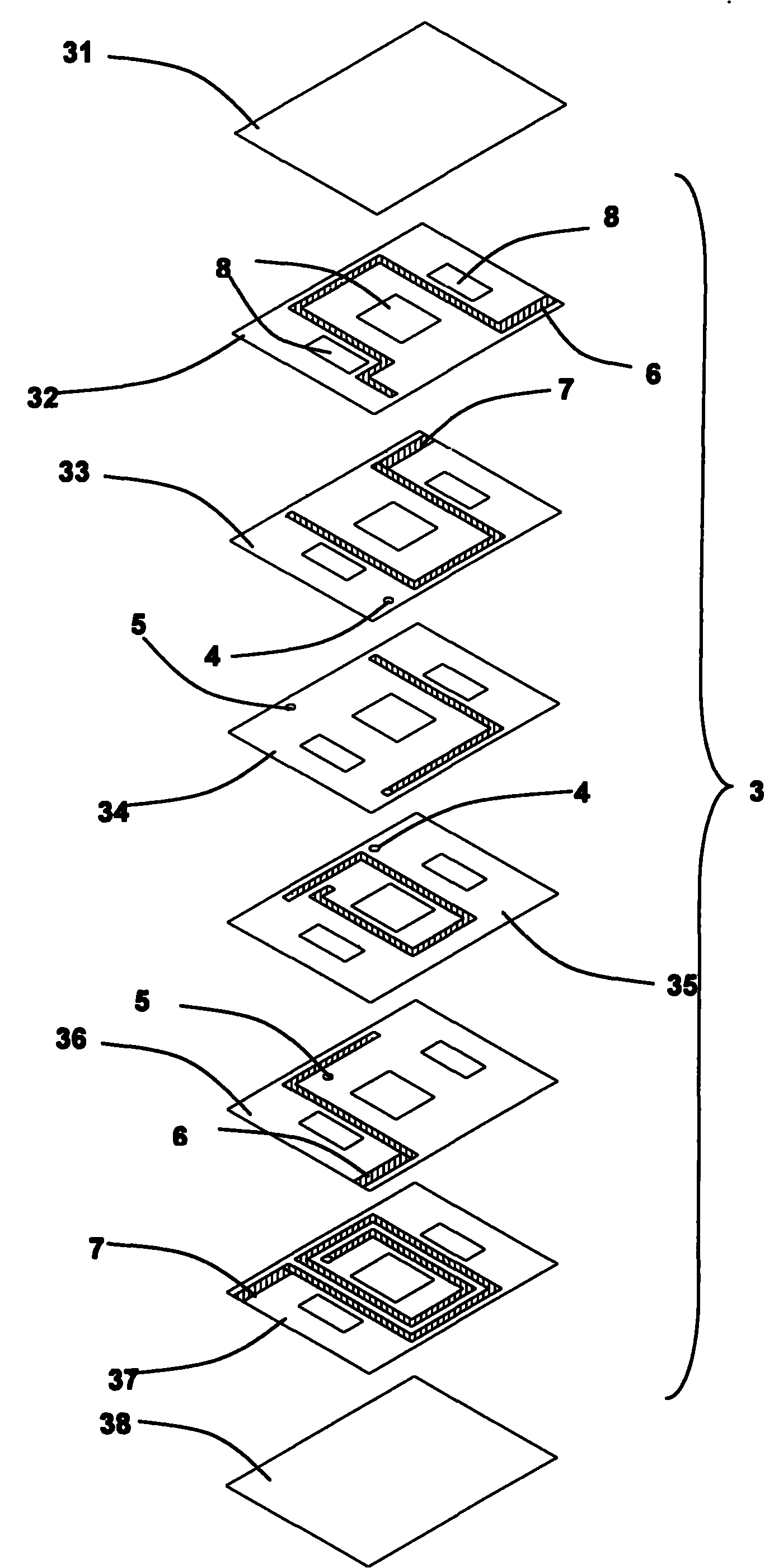

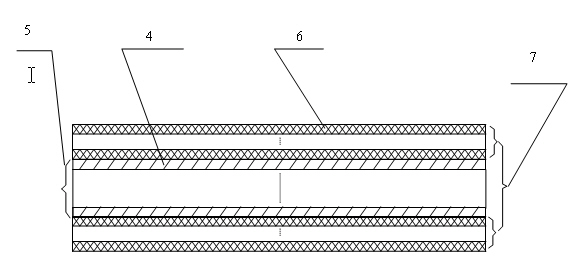

LTCC low temperature co-fired ceramic flat surface transformer

InactiveCN101789311AIncreasing the thicknessMiniaturizationTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresCapacitanceCoupling

The invention relates to an LTCC low temperature co-fired ceramic planar transformer. The transformer comprises a ferrite magnetic core composed of an upper magnetic core and a lower magnetic core. The transformer is characterized in that the transformer also comprises an LTCC planar transformer base plate provided with at least one group of planar coil component, each planar coil component comprises a primary coil with high coupling coefficient and a secondary coil; the LTCC planar transformer base plate is provided with one or three penetrating holes used for assembling the ferrite magnetic core; and the upper and lower magnetic cores separately penetrate the penetrating holes from the upper and lower sides of the LTCC planar transformer base plate and are butted and adhered together to form the ferrite magnetic core. Compared with the traditional planar transformer, the LTCC low temperature co-fired ceramic planar transformer of the invention has the following beneficial effects: the transformer of the invention has low direct current impedance, leakage inductance and distributed capacitance and can satisfy the design requirement of the resonance circuit; and as the magnetic core has good magnetic shielding, the transformer can inhibit the radio frequency interference.

Owner:SHENZHEN SUNLORD ELECTRONICS

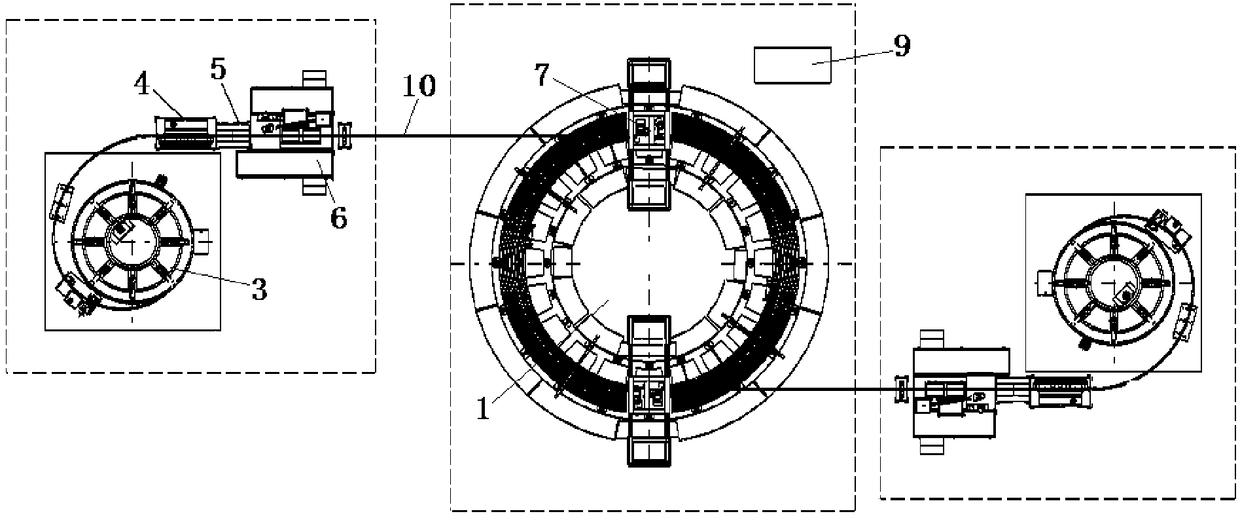

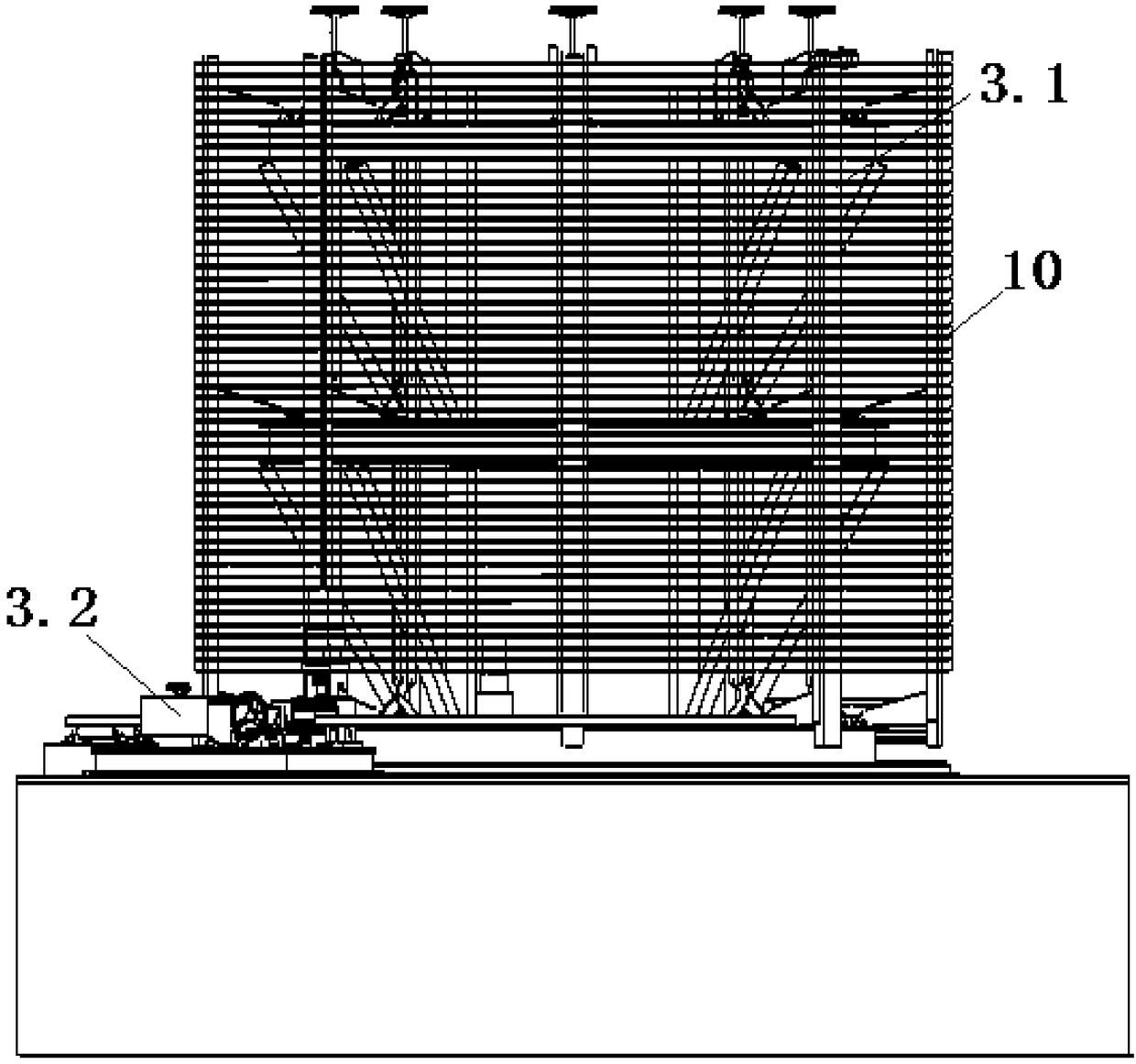

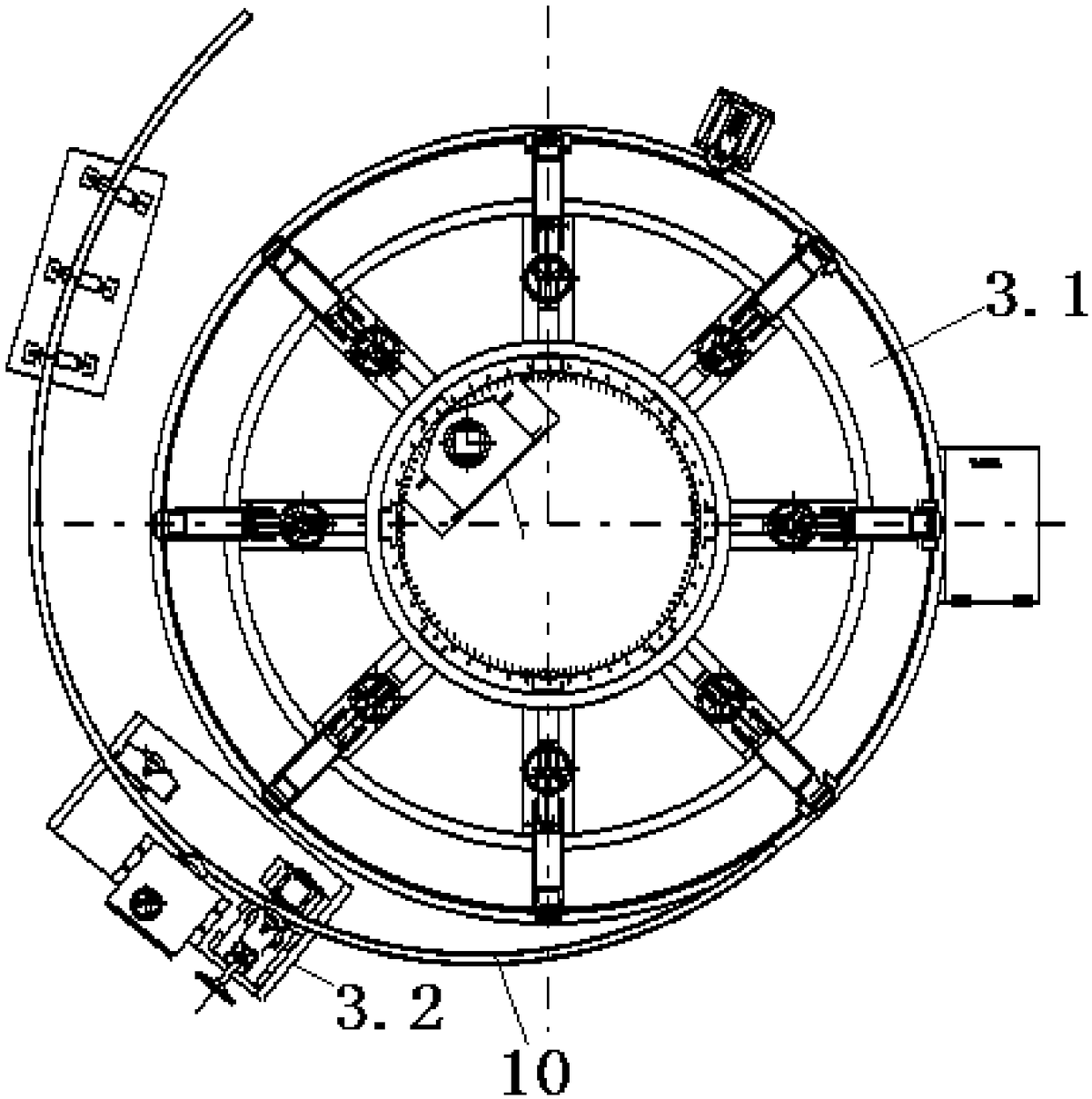

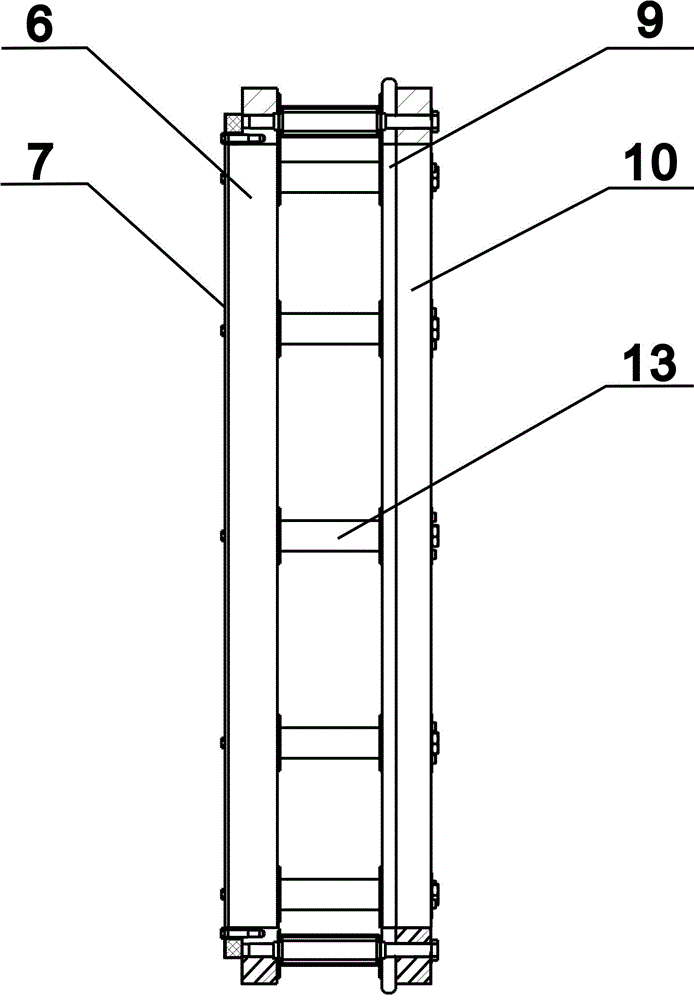

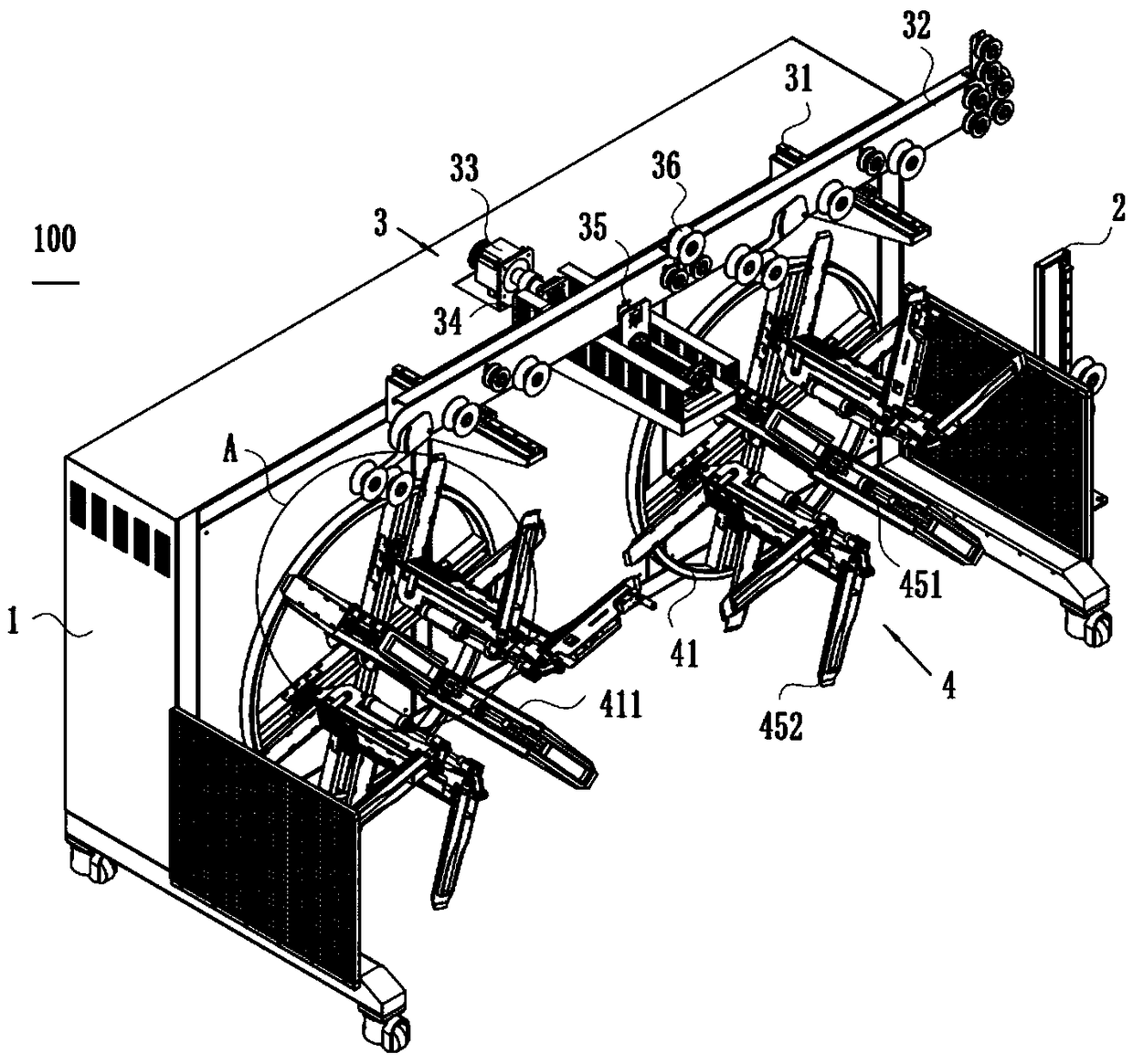

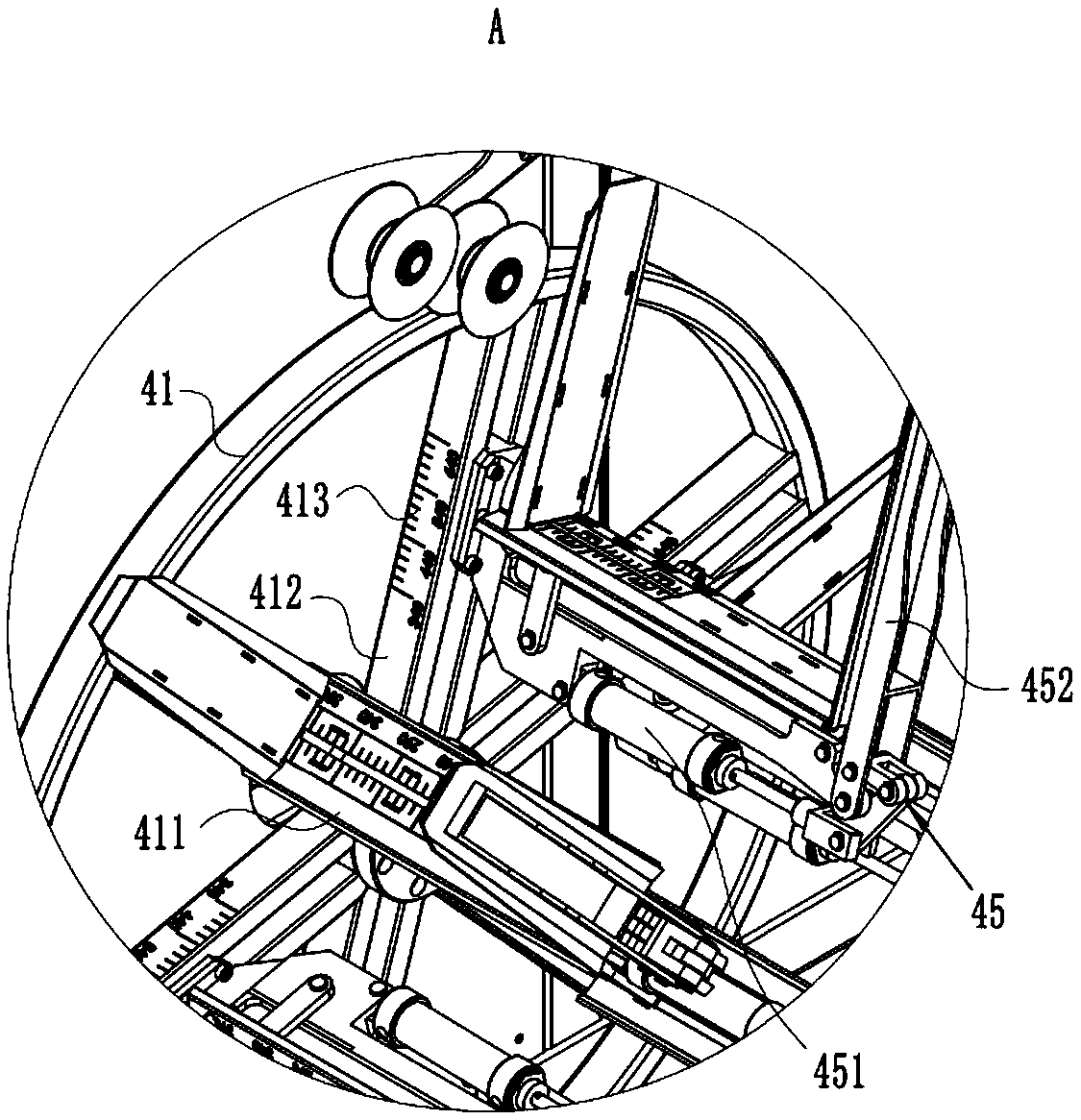

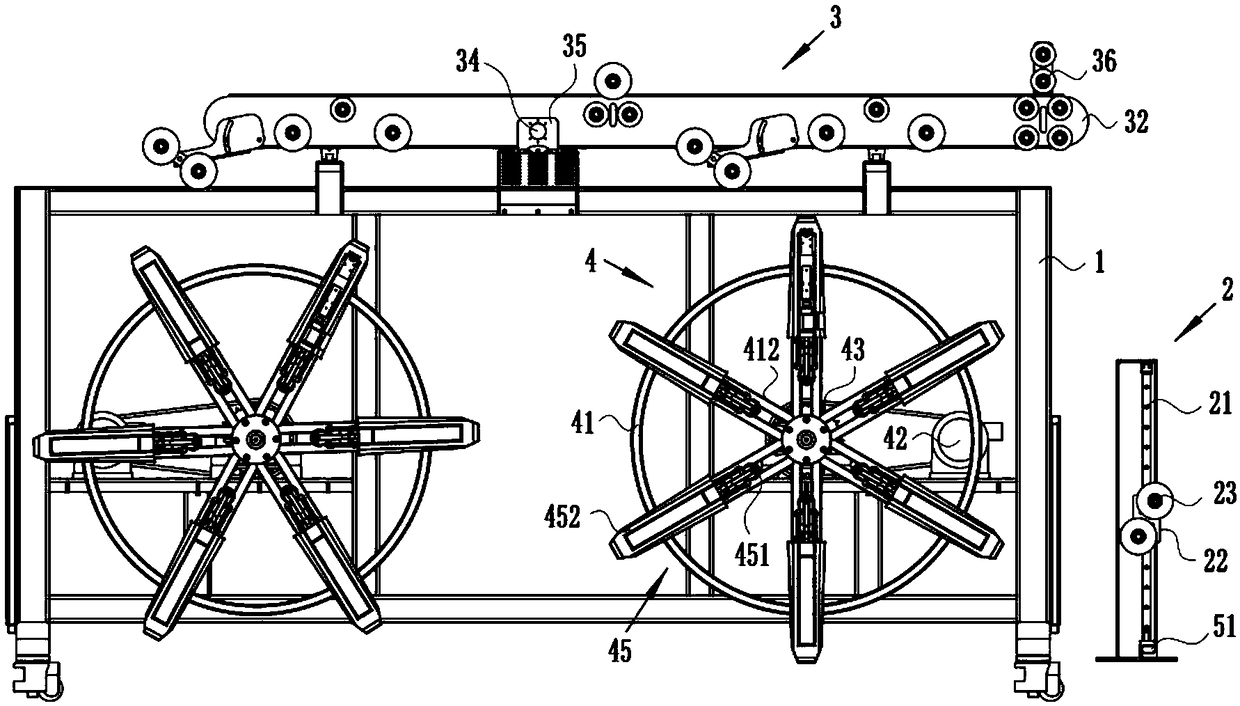

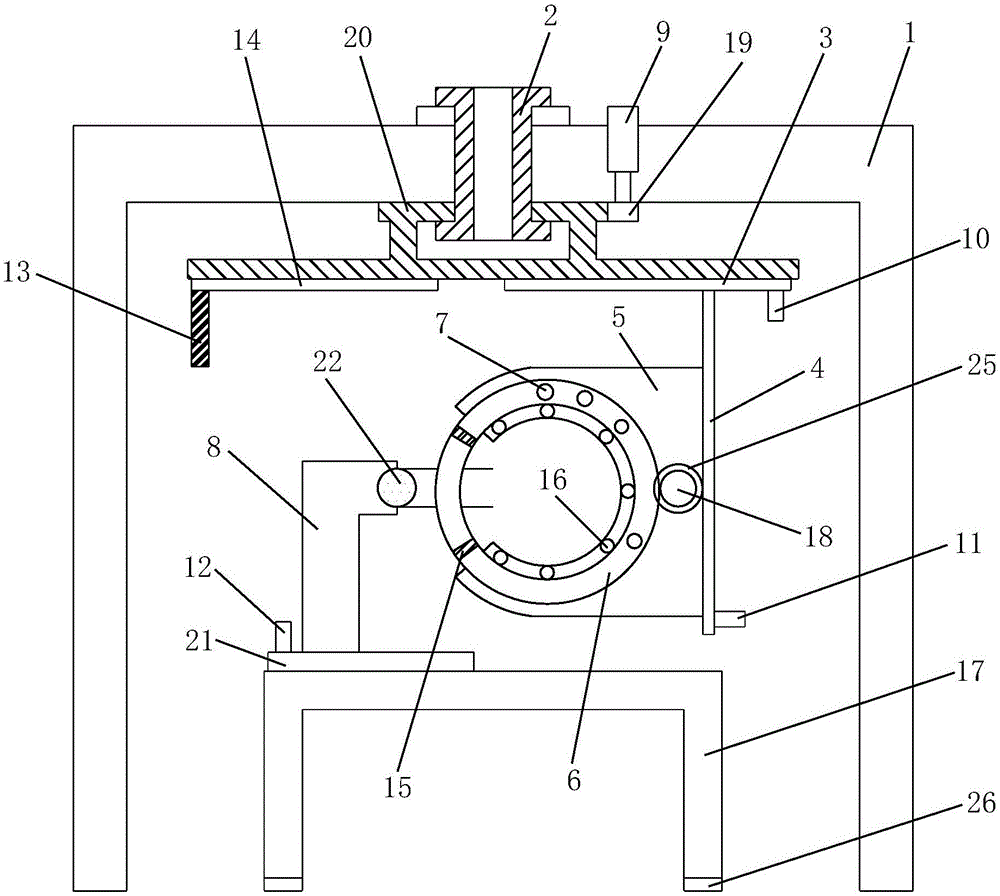

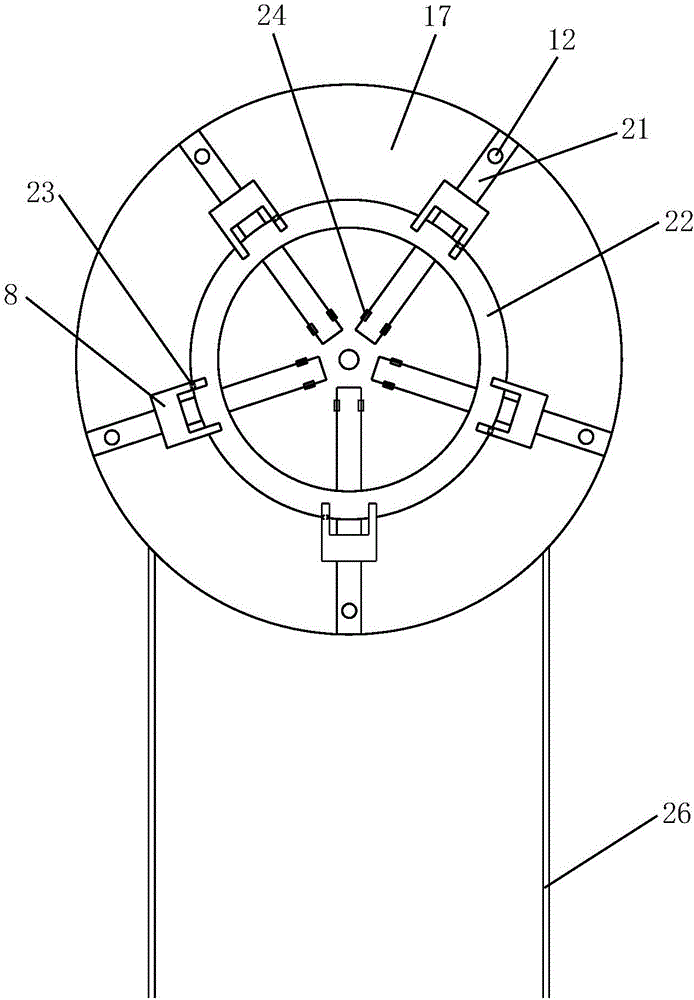

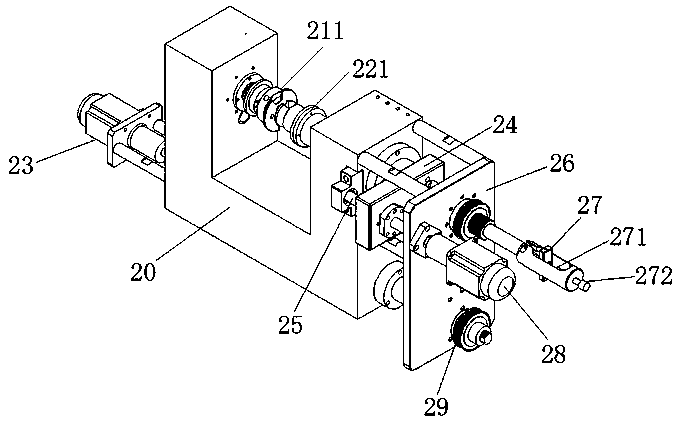

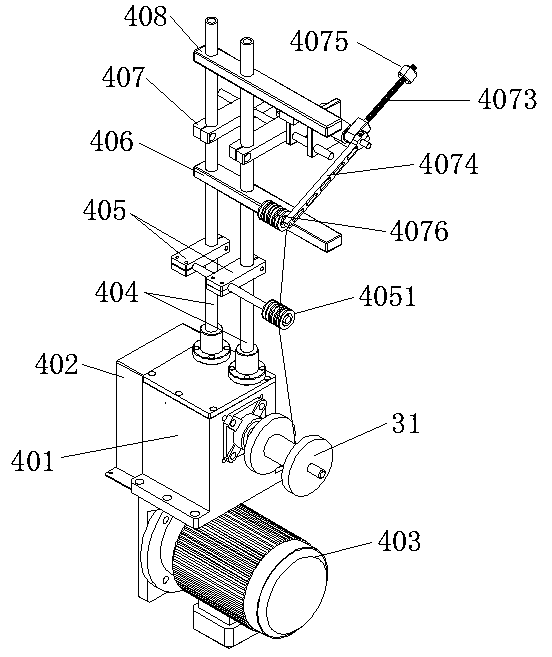

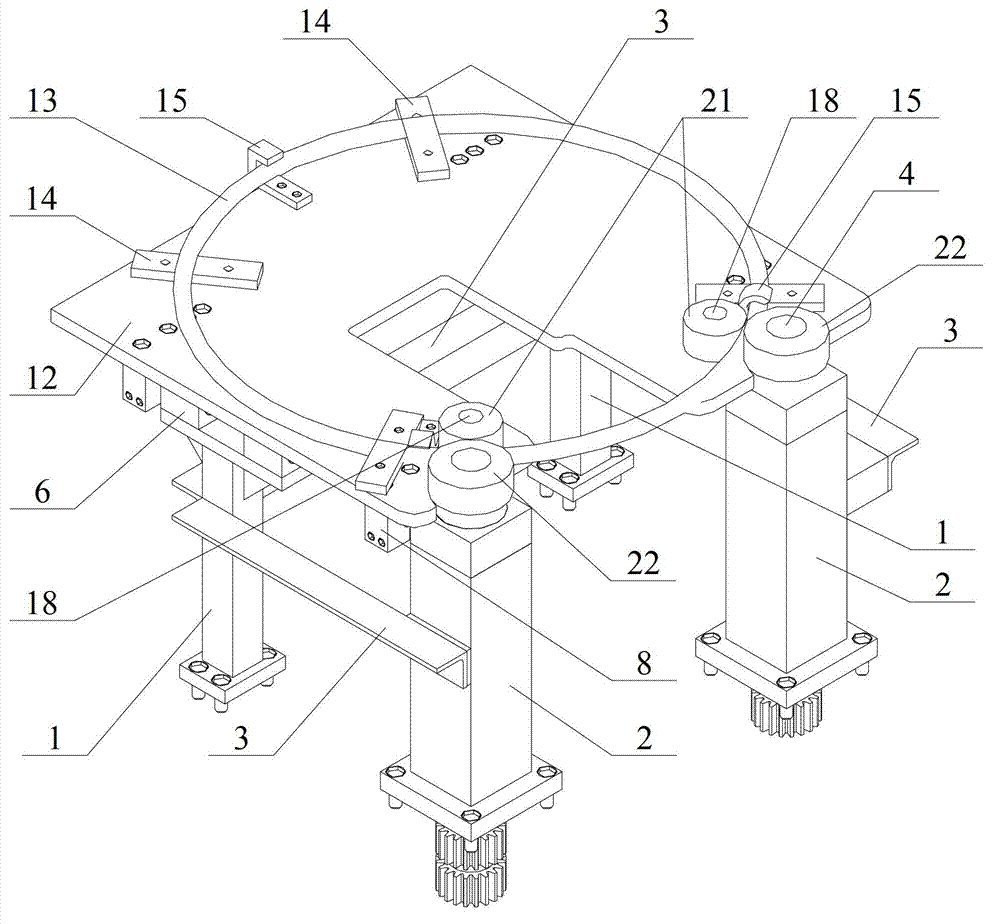

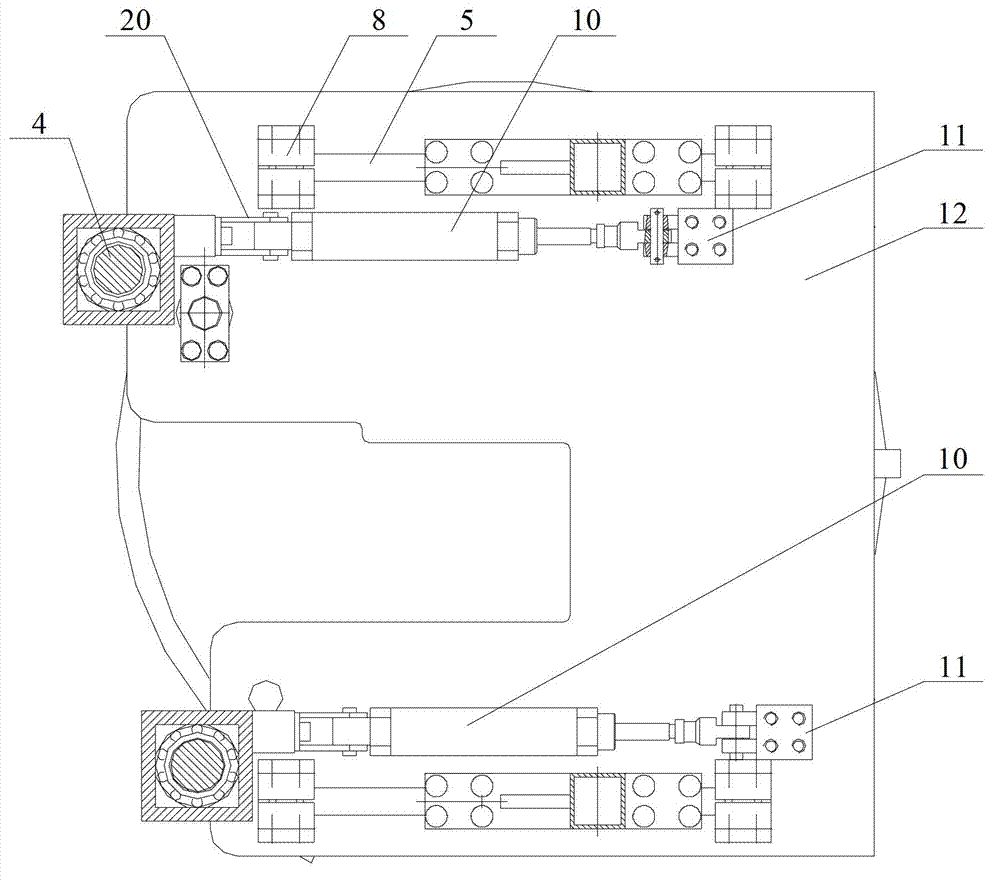

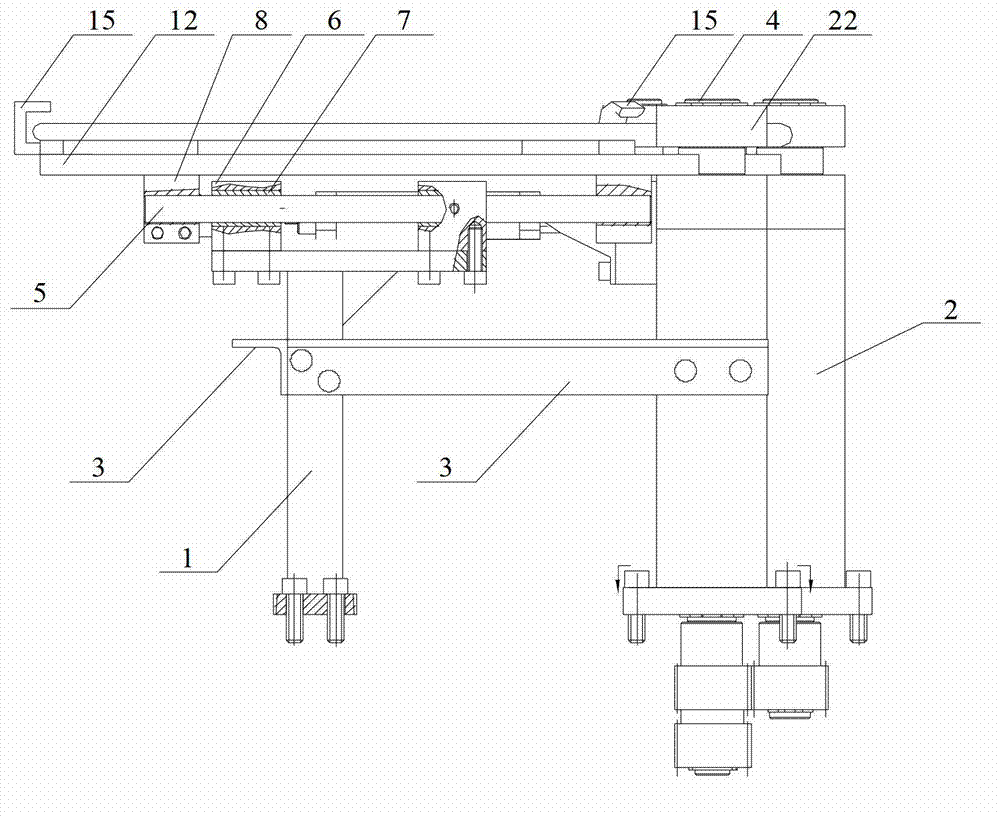

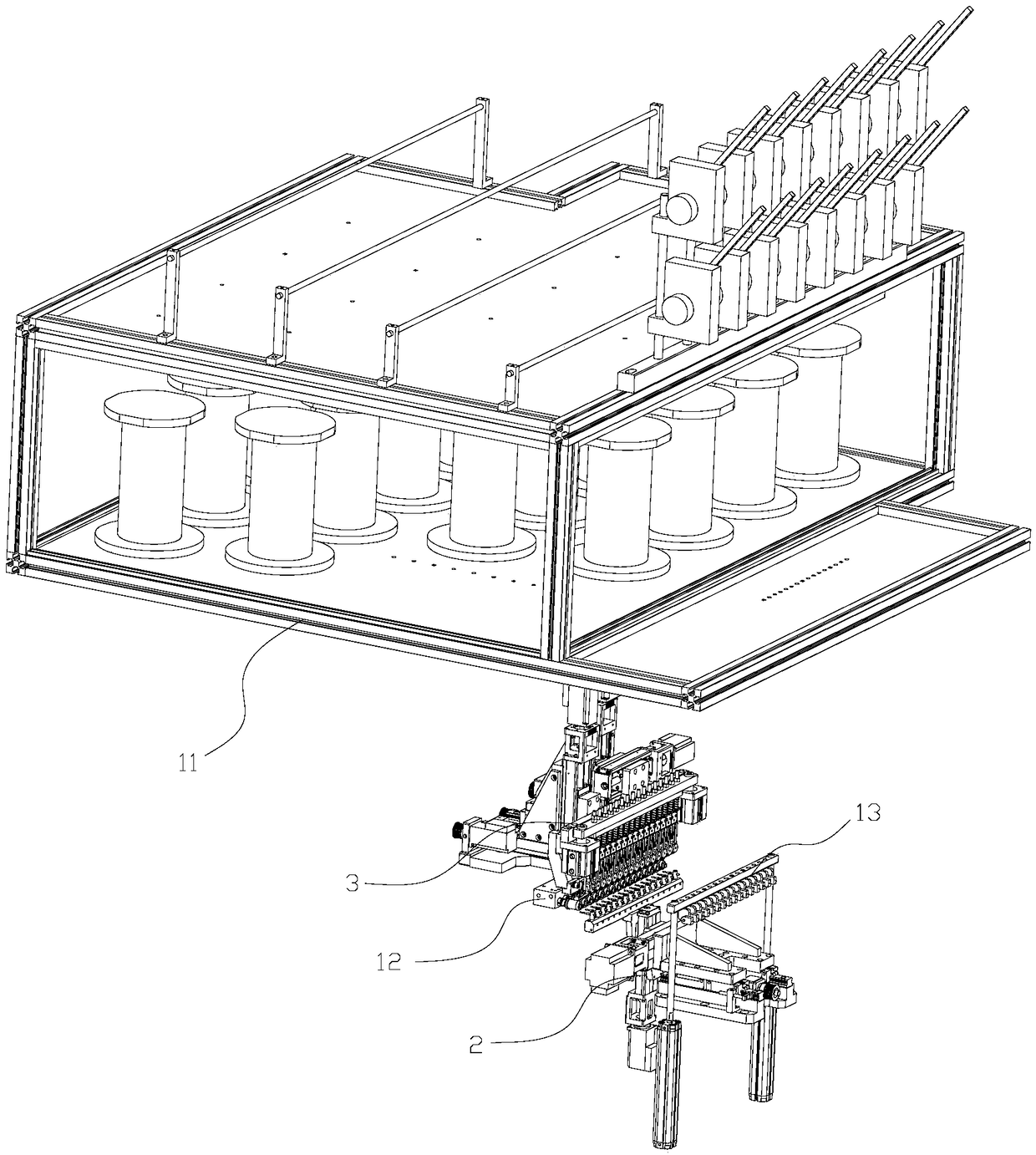

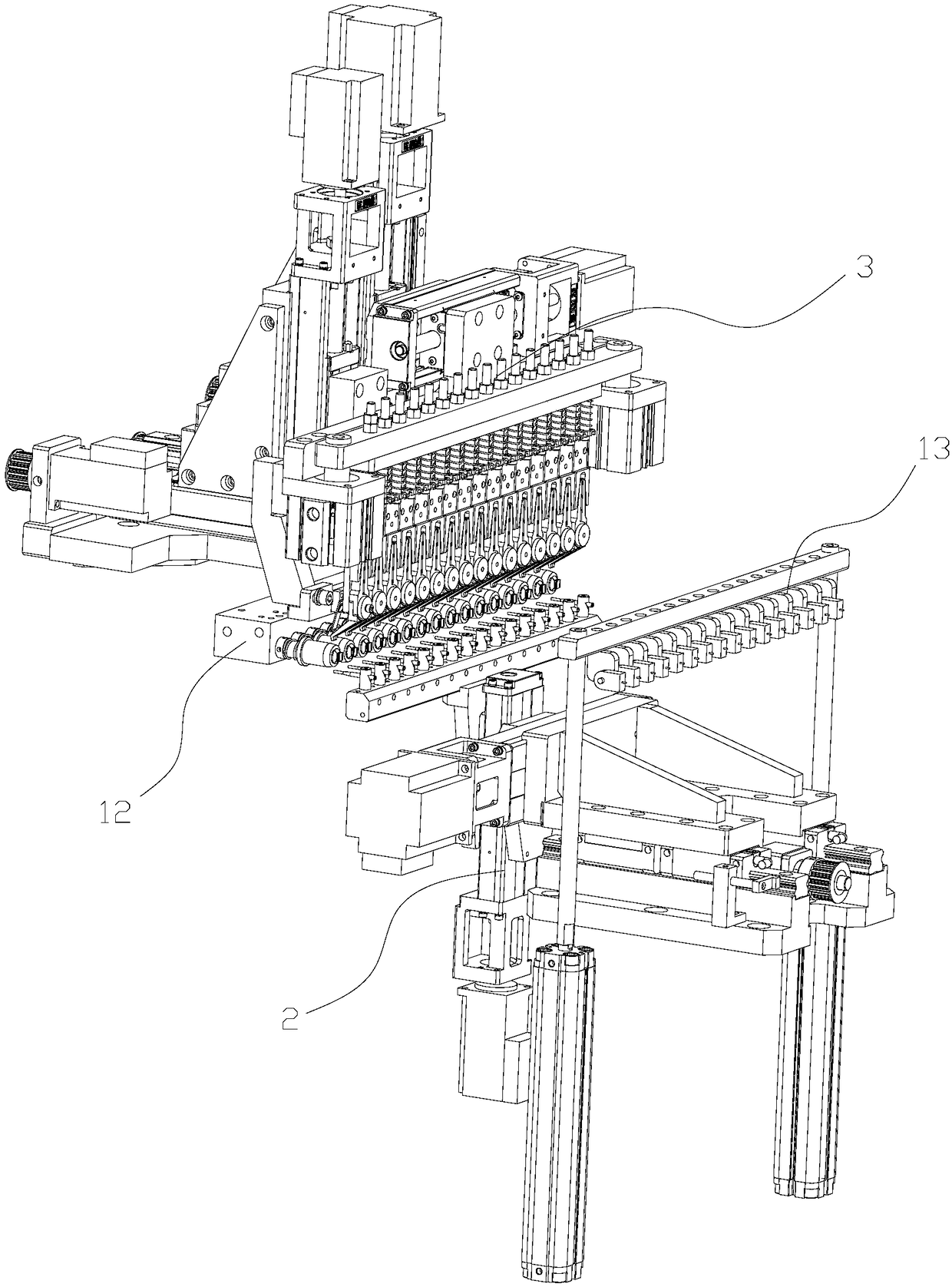

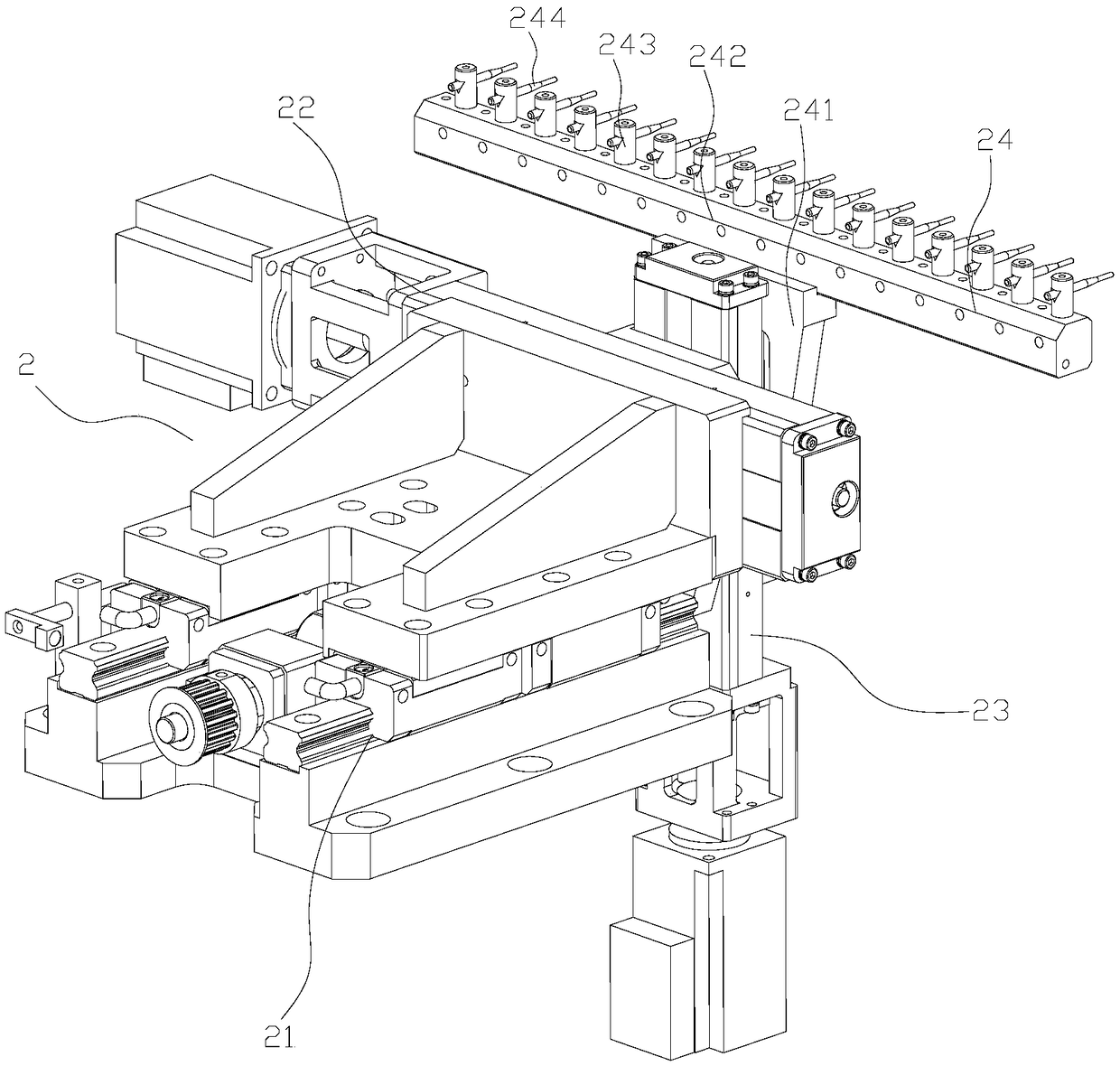

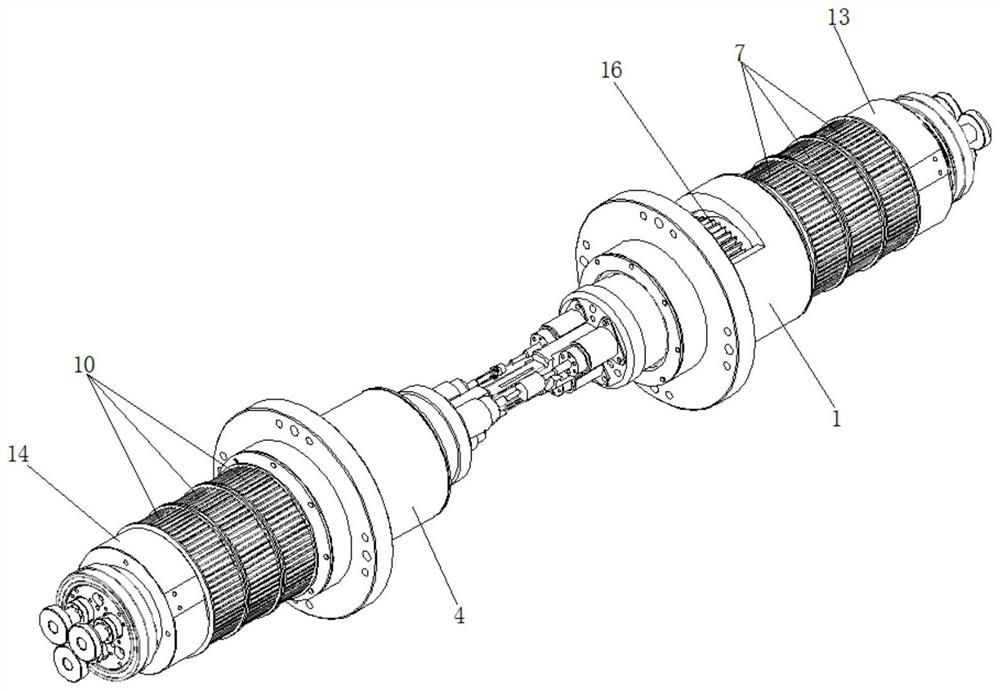

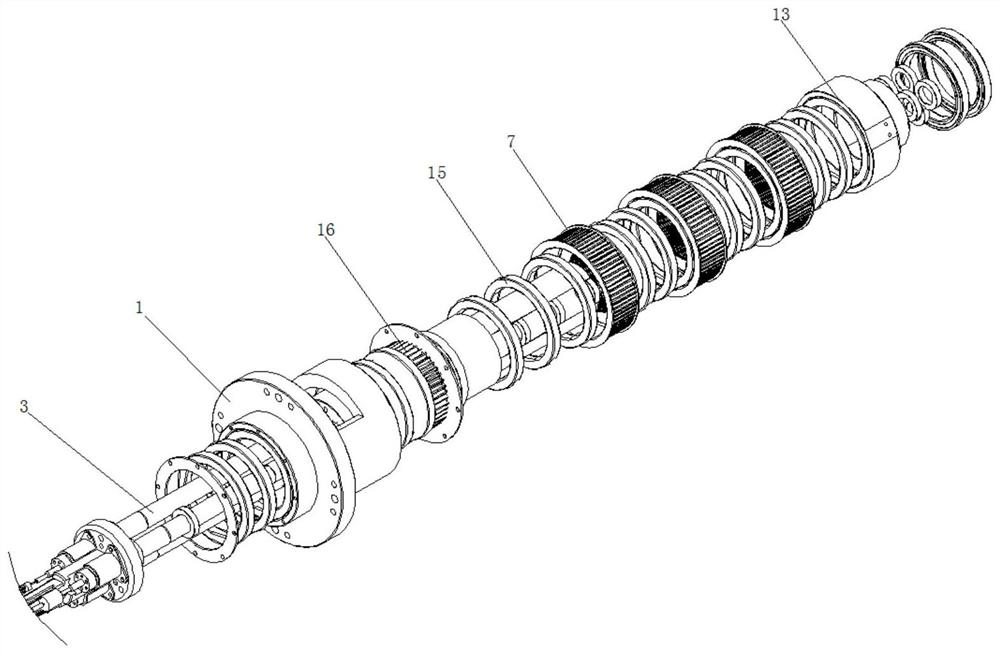

Bifilar winding system for manufacture of nuclear fusion polar field superconducting magnets

ActiveCN108597850AEasy to useHigh winding precisionNuclear energy generationCoils manufactureSuperconducting CoilsAutomatic control

The invention discloses a bifilar winding system for manufacture of nuclear fusion polar field superconducting magnets, comprising two totally symmetric superconducting coil winding production lines,as well as a drop-molding tool, a rotary platform and a winding mold, and an automatic control system, wherein each winding production line is respectively composed of conductor discharging equipment,a straightening machine, an ultrasonic cleaning machine, a sand blasting cleaning machine, a bending forming machine, an inter-turn insulation tape wrapping machine, etc.; in the coil winding process, the automatic control system discharges the superconducting conductor from the conductor discharging device, and then bends the conductor into a required radius after straightening, ultrasonic cleaning, sand blasting and cleaning, then completes the wrapping of the multi-layer insulating tape by the inter-turn insulating tape wrapping machine, and finally precisely fixes the conductor at the correct position in the contour of the mold on the rotary platform by the drop tooling until the bifilar winding coil is wound. Finally, the invention meets the requirements such as high-precision size and inter-turn insulation performance for manufacture of nuclear fusion polar field superconducting magnets.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

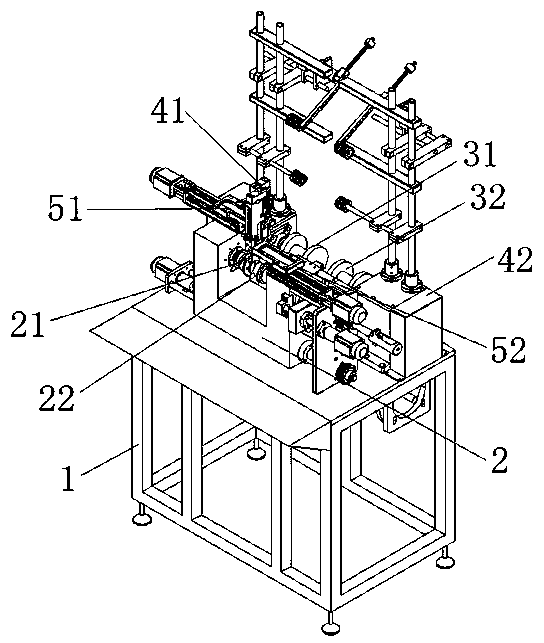

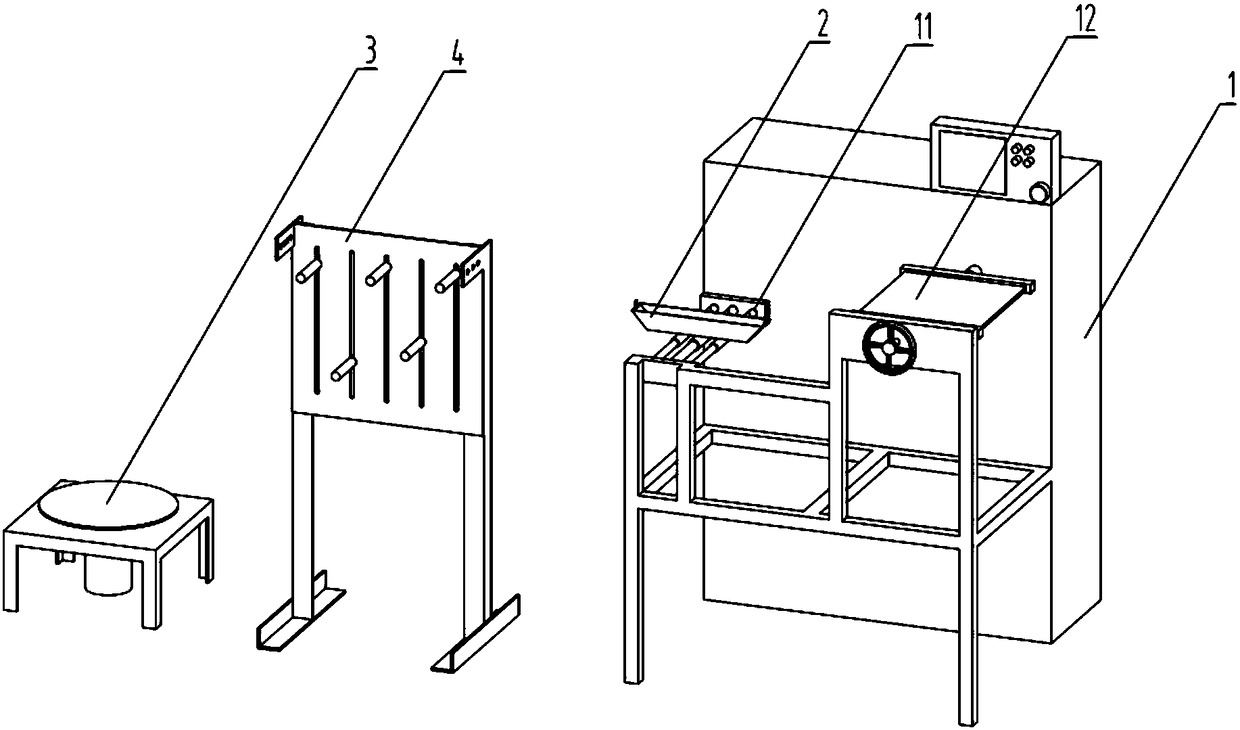

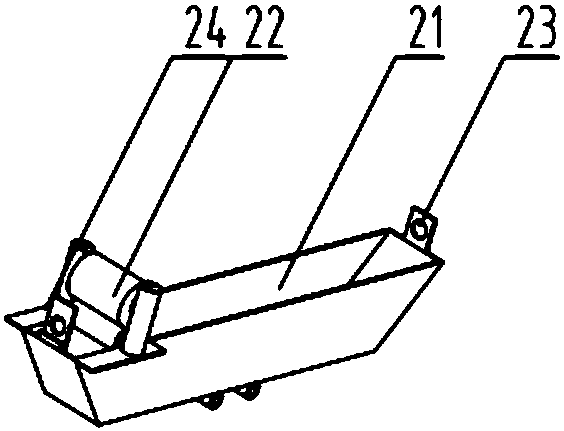

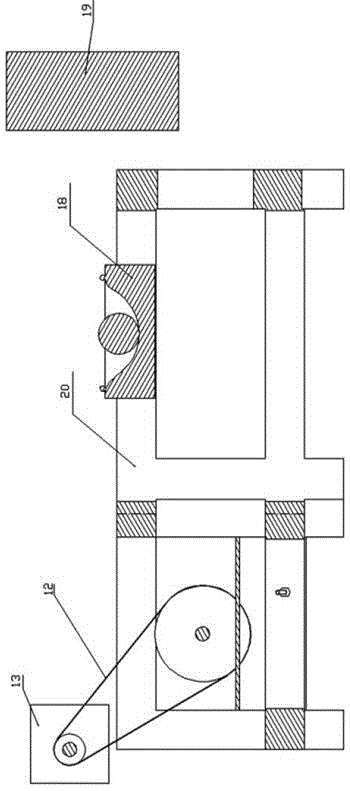

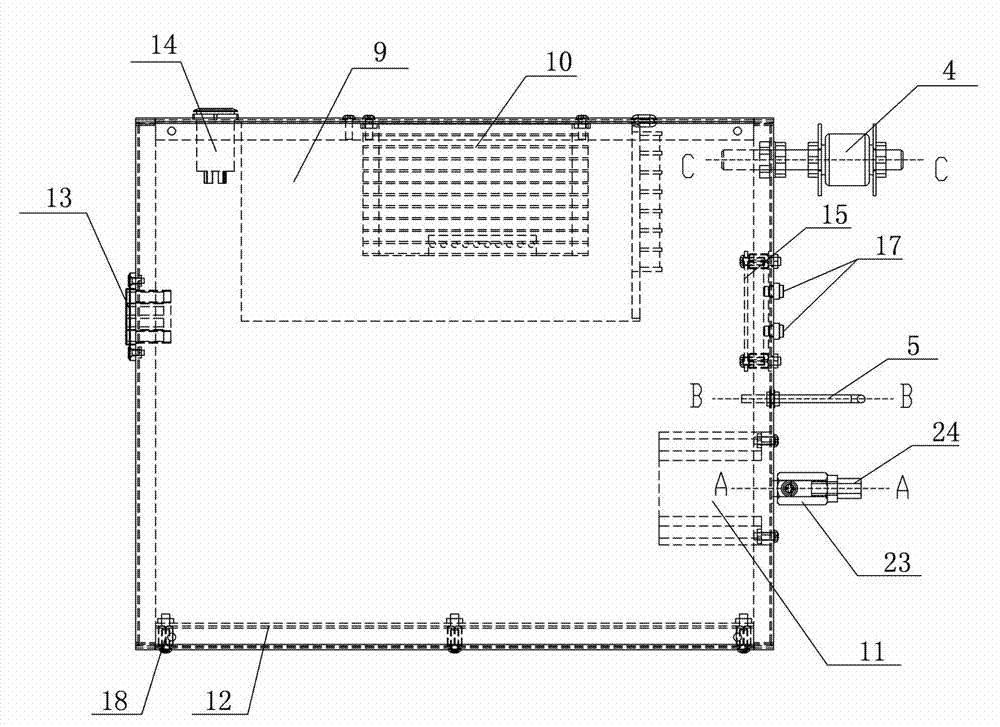

Glass reinforced plastic winding equipment and glass reinforced plastic winding method

The invention provides glass reinforced plastic winding equipment. The equipment comprises a frame, and a power system and a winding system which are arranged on the frame, wherein the winding system comprises a cam mechanism, a winding displacement mechanism and a mold; the winding displacement mechanism is arranged on the cam mechanism and is driven to do reciprocating motion through the cam mechanism; the mold and the winding displacement mechanism are arranged parallel to each other; and the mold and the cam mechanism are driven through the power system. The equipment provided by the invention has high winding accuracy and a small producing area. The invention also provides a glass reinforced plastic winding method.

Owner:CHONGQING POLYCOMP INT

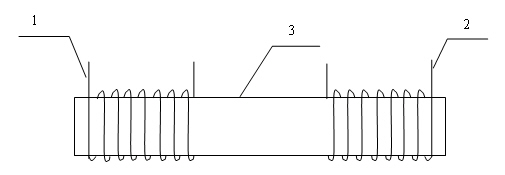

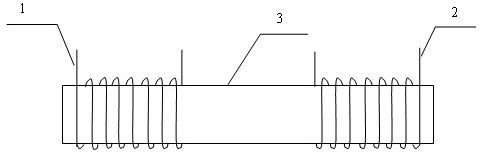

Fluxgate probe based on ferrous amorphous alloy magnetic core and method for making fluxgate probe

InactiveCN102147451AIncrease stiffnessOvercoming inevitable compositional segregationMagnitude/direction of magnetic fieldsSignal-to-noise ratio (imaging)Room temperature

The invention relates to a fluxgate probe based on a ferrous amorphous alloy magnetic core and a method for making the fluxgate probe. The probe comprises a magnetic core main shaft, and an excitation coil and a detection coil which are respectively wound at the two ends of the magnetic core main shaft, wherein the magnetic core main shaft comprises a magnetic core made of ferrous amorphous foil tapes and an external sleeve coated outside the magnetic core. The method for making the probe comprises the following steps of: 1, performing heat treatment on the ferrous amorphous foil tapes; 2, coating glue on the surface of one of the ferrous amorphous foil tapes to make the ferrous amorphous foil tape hard, or coating the glue on the plurality of ferrous amorphous foil tapes and then laminating and hardening the ferrous amorphous foil tapes to make the magnetic core after room temperature is reached by air cooling; 3, coating thin materials made of paper outside the magnetic core, and bonding and solidifying the thin materials made of paper by using the glue to form the external sleeve and then make the magnetic core main shaft; and 4, respectively and symmetrically winding the excitation coil and the detection coil at the two ends of the magnetic core main shaft to form the fluxgate probe. By the fluxgate probe provided by the invention, the signal-to-noise ratio and the sensitivity are improved. The method for making the probe is simple in operation and low in cost.

Owner:GUANGDONG UNIV OF TECH

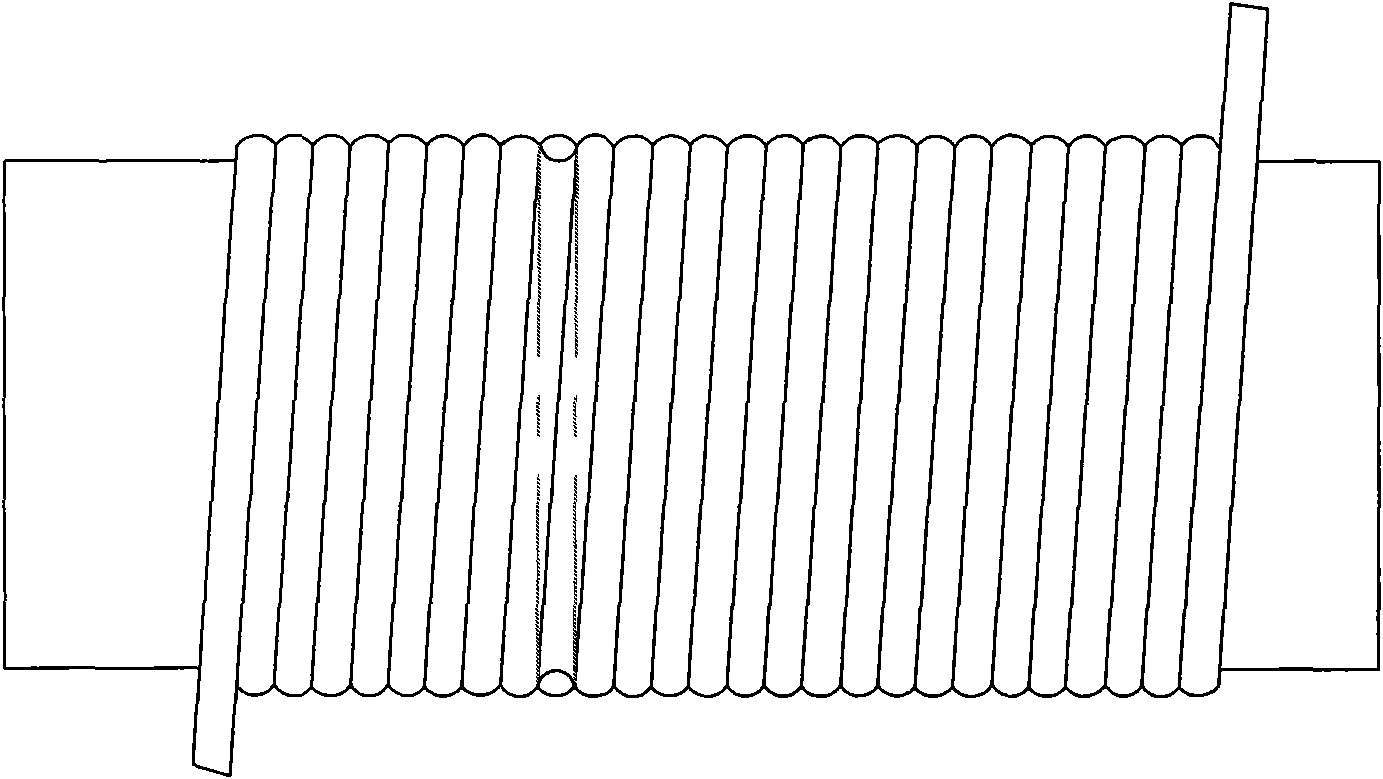

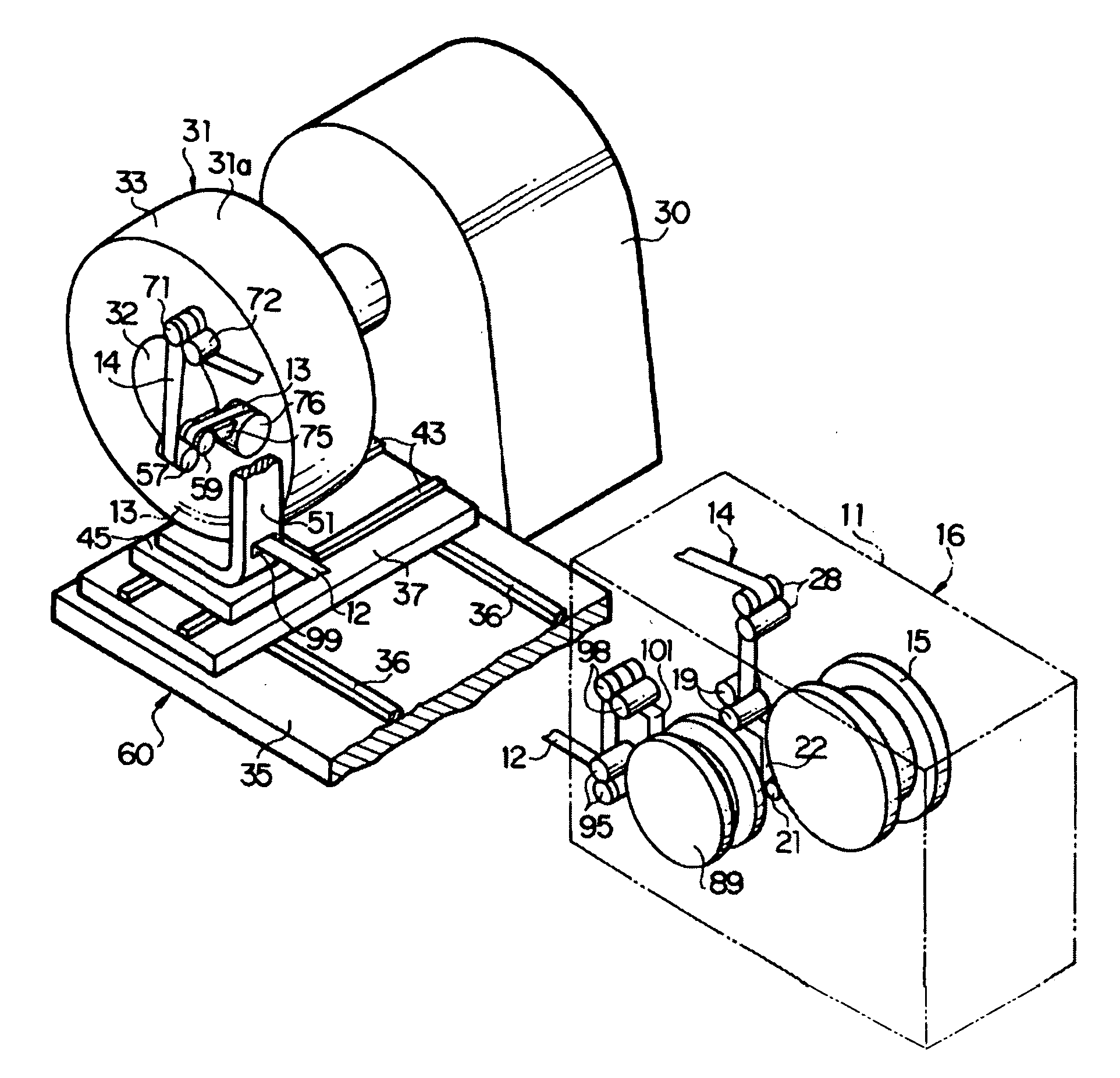

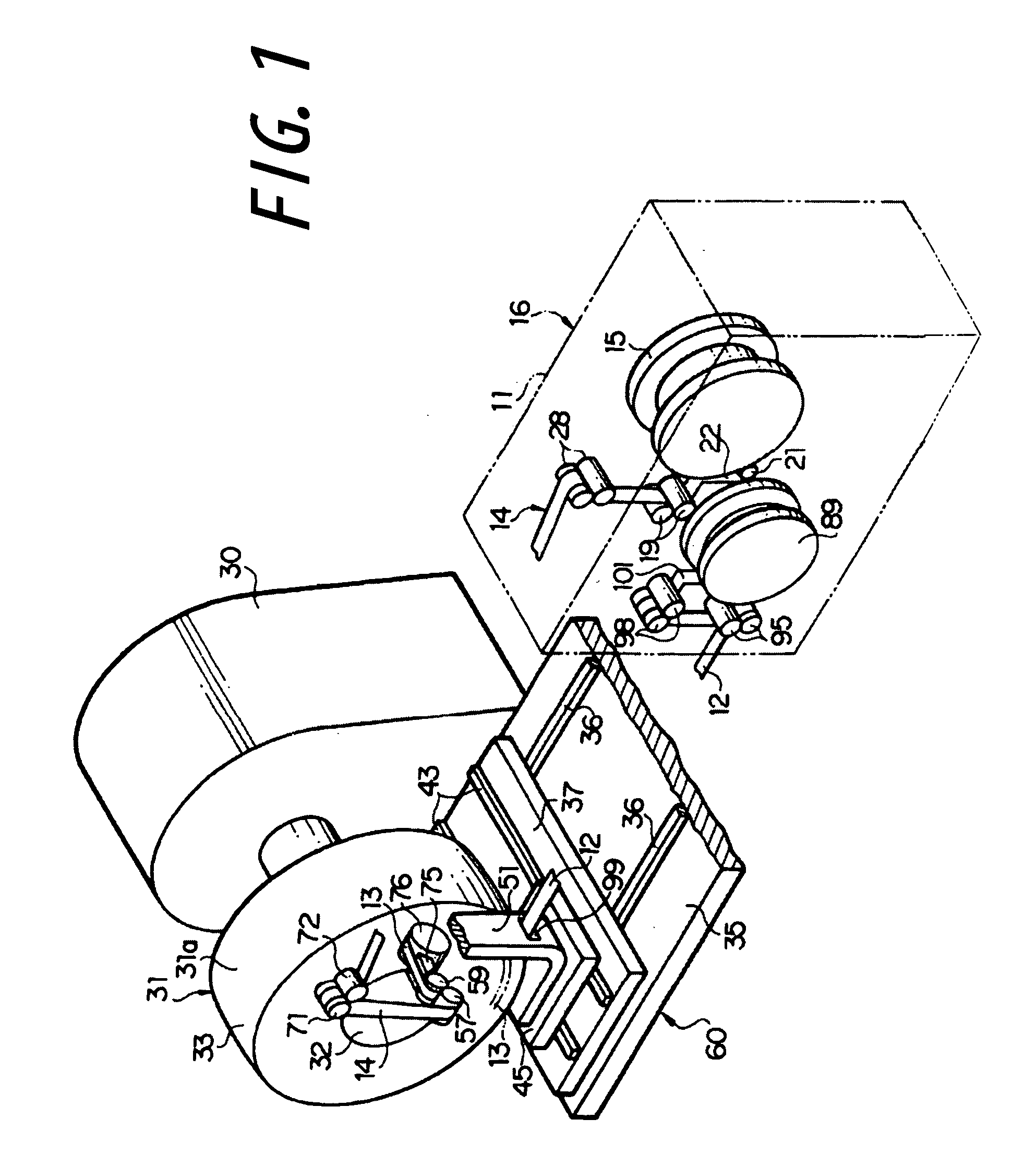

Method and apparatus for manufacturing unvulcanized tires

A ribbon-like element supplied from a supply source is wound on the rotating toroidal support member, when a first rotatable guide roller arranged spaced from the outer surface of the support member is moved in parallel with the meridian direction along the outer surface of the support member, and turned so that the direction of its rotational axis approaches a tangent relative to the outer surface of the winding member. A second guide roller is arranged on a straight line perpendicular to a plane containing the moving trajectory of the first guide roller and passing through the first guide roller, and has a rotational axis that extends in the widthwise direction of the ribbon-like body extending from the supply source toward the winding member. When the second guide roller is driven to achieve a parallel movement integrally with the first guide roller, the ribbon-like element contacts successively with the second and first guide rollers in this sequence, before it is supplied to the outer surface of the support member.

Owner:BRIDGESTONE CORP

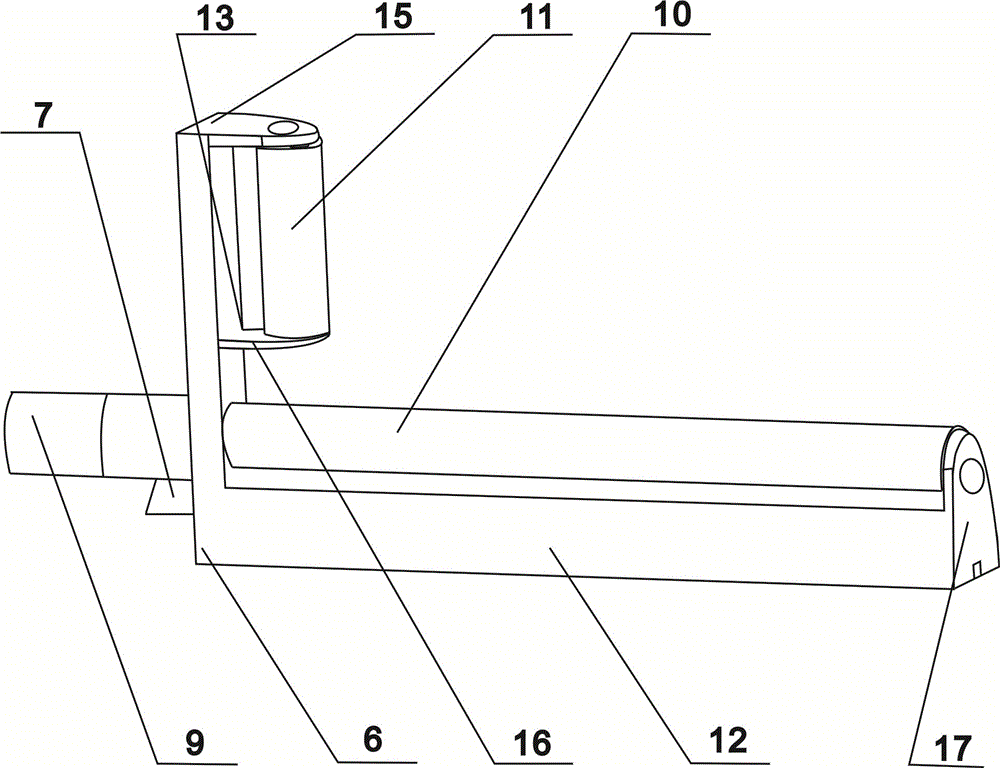

Bend winding device with three-section heating function

ActiveCN106182732AScientific and reasonable designSimple structureThermal shrinkageElectrical and Electronics engineering

The invention discloses a bend winding device with a three-section heating function. The bend winding device comprises a winding disc, a drive guide rail, a centering device, a winding disc temperature control device and outer flame heating devices. The winding disc is arranged at the middle position of the drive guide rail. The drive guide rail is arranged at the bottom position and is in a sector shape. The winding disc is arranged at the middle position of the drive guide rail and fixedly arranged on the drive guide rail. The centering device is arranged in the winding disc and fixedly arranged in the winding disc. The wining disc temperature control device is arranged on the inner side of a connecting plate and fixed to the connecting plate. The two outer flame heating devices are arranged, one outer flame heating device conducts preheating, the other outer flame heating device conducts tail end heating, the outer flame heating device for preheating is fixedly arranged at the left end of the drive guide rail, and the outer flame heating device for tail end heating is arranged at the right end of the drive guide rail. According to the bend winding device with the three-section heating function, the winding quality of an antiseptic thermal shrinkage rubber belt is greatly improved, the work efficiency is improved, the labor intensity is lowered, and the service life of a bend is prolonged.

Owner:HENAN XINKAIYUAN PETROCHEM PIPELINE

Pipe winding machine

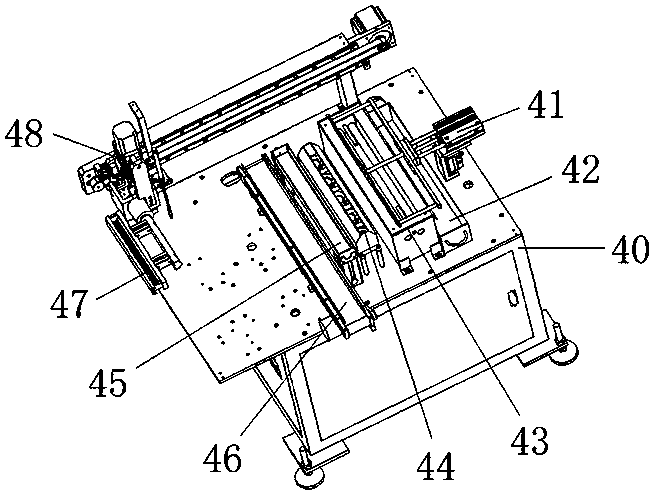

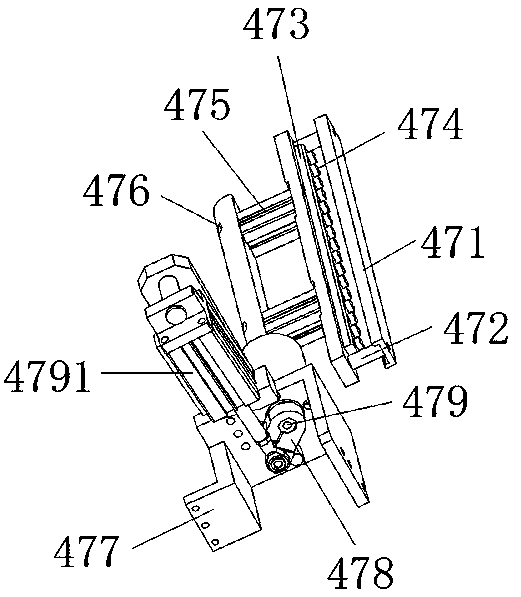

PendingCN109368399AHigh winding precisionReal-time adjustment of winding tensionFilament handlingWinding machineSprocket

The invention discloses a pipe winding machine, and belongs to the technical field of plastic pipe production equipment. The pipe winding machine aims to solve the problem that winding precision of anexisting pipe winding machine is not high. The pipe winding machine comprises a machine frame, a tension adjusting device, a pipe arranging device, at least one winding device and a control unit. Inthe pipe winding machine, the displacement information of a sliding block is detected through a pipe pulling sensor, then the size of the tension of a pipe in the winding process is detected, and thewinding tension of the pipe is adjusted in real time; the winding actions of winding discs are realized through the structures of meshing transmission of first chain wheels and second chain wheels, the rotation tooth number information of the first chain wheels is detected through photoelectric counters, then each time the winding discs rotate by the set tooth number, a pipe arranging rod can moveby the distance equal to the diameter of the current wound pipe, then it is guaranteed that when the pipe is wound around the winding discs, each time the winding discs rotate by one whole circle, pipe arranging can be started to be performed by the pipe arranging device, so that the winding precision of the pipe is higher.

Owner:常州金纬管道科技有限公司

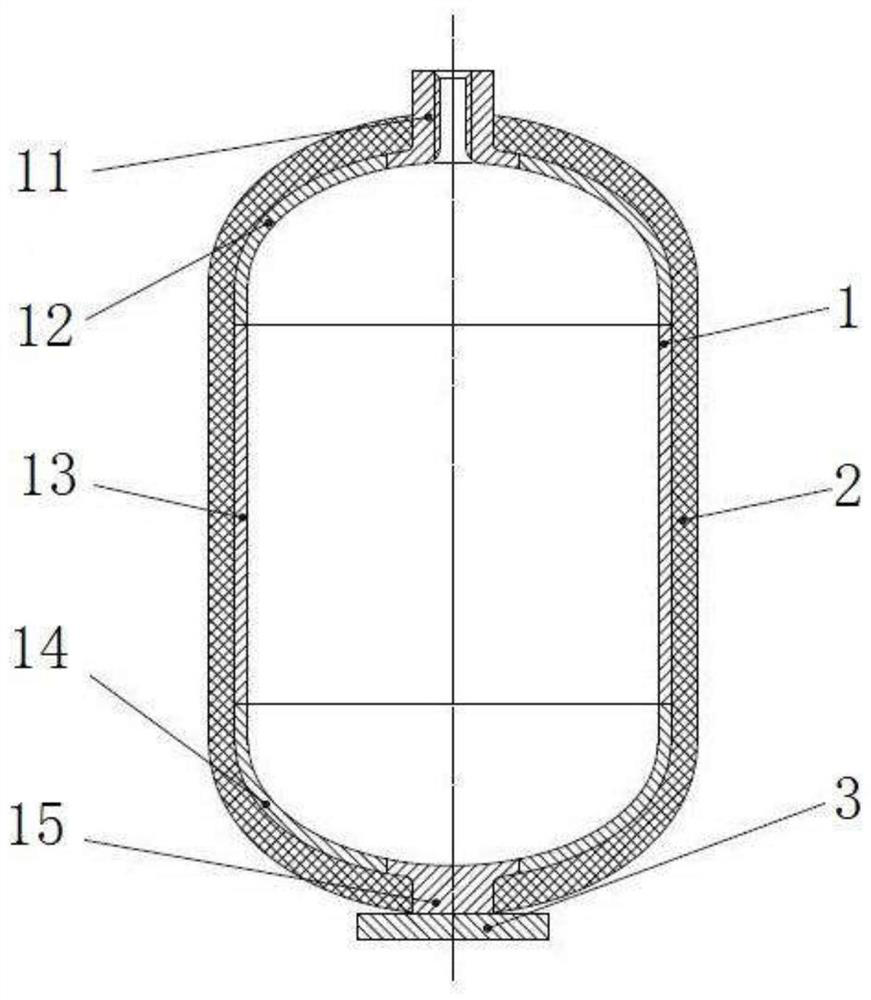

Metal lining carbon fiber winding composite material gas cylinder and manufacturing method thereof

PendingCN112963722AHigh winding precisionImprove stress-strain coordinationVessel mounting detailsVessel manufacturingEpoxyFiber

The invention relates to the technical field of composite material gas cylinders, in particular to a metal lining carbon fiber winding composite material gas cylinder and a manufacturing method thereof. The metal lining carbon fiber winding composite material gas cylinder comprises a nickel-base alloy lining, a carbon fiber / epoxy resin composite layer and a metal flange. The nickel-based alloy lining is formed by welding an air port joint, an air port end sealing head, a cylinder body, a sealing end sealing head and a sealing end joint. The carbon fiber / epoxy resin composite layer is wound on the outer surface of the nickel-based alloy lining. The metal flange is connected with the bottom of the sealing end sealing head. The metal lining carbon fiber winding composite material gas cylinder is simple in structure, high in reliability, high in safety, high in pressure bearing capacity, small in body mass, wide in medium storage range and high in high and low temperature environment resistance, the performance requirements for high performance factors and long fatigue life can be met at the same time, and the requirements for light high-strength composite gas cylinders in the fields of spaceflight, aviation, ships and the like are met.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

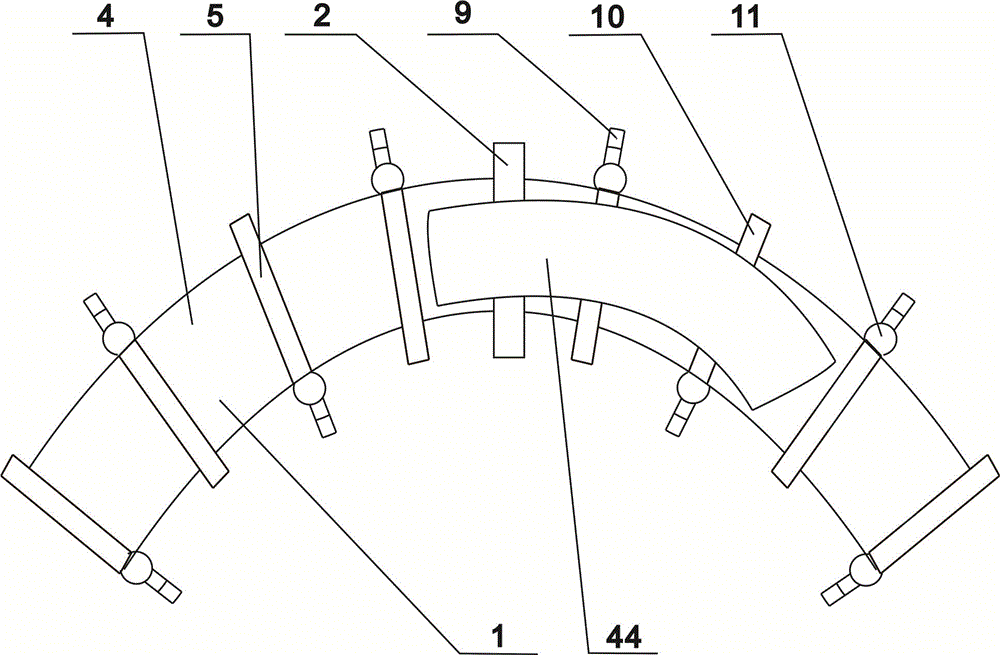

Winding disc for bent tube winding and wrapping

The invention discloses a winding disc for bent tube winding and wrapping. The winding disc for bent tube winding and wrapping comprises a winding disc, an aligning device and a drive guide rail, wherein the drive guide rail is arranged at a bottom position and is fan-shaped, the winding disc is arranged at the middle position of the drive guide rail and is fixedly installed on the drive guide rail, and the aligning device is arranged in the winding disc, and is fixedly installed in the winding disc; and the aligning device comprises a longitudinal aligning device and a transversal aligning device. According to the winding disc for bent tube winding and wrapping, the winding quality for winding an anticorrosive thermal-shrinkable adhesive tape is greatly improved, the labour intensity of manual winding is reduced, and overlapped side tilting, uneven and non-uniform overlapping, and skirts occurring during a winding process for the anticorrosive thermal-shrinkable adhesive tape are prevented; and meanwhile, the compactness of the anticorrosive thermal-shrinkable adhesive tape is improved, and the occurrence of a winding deflection phenomenon is avoided.

Owner:HENAN XINKAIYUAN PETROCHEM PIPELINE

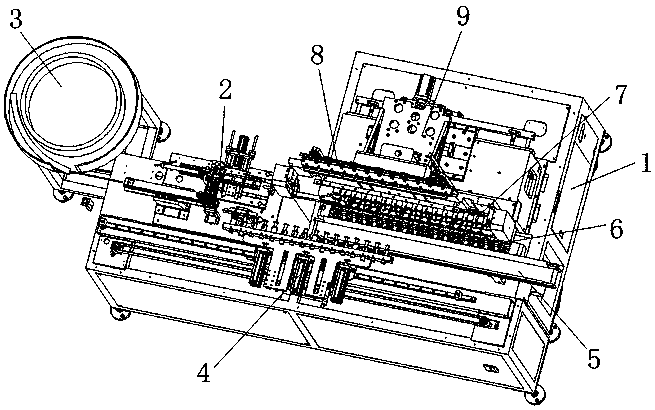

Full-automatic wire winding and tin soldering machine

ActiveCN108188528AMeet the requirements of mass productionIncrease productivityMetal working apparatusSoldering auxillary devicesWinding machineSoldering

The invention provides a full-automatic wire winding and tin soldering machine which comprises a machine case, a full-automatic feeding trolley transmission mechanism, a full-automatic feeding vibration disc, a full-automatic tin soldering machine, a main full-automatic wire winding machine, and a full-automatic wire winding and discharging mechanism. By adoption of the full-automatic wire windingand tin soldering machine provided by the invention, a workpiece can be subjected to a series of operations such as automatic feeding transmission, automatic material distribution, automatic materialreceiving, automatic wire winding positioning, automatic wire pay-off tightness adjustment, automatic wire winding, automatic waste wire breaking, automatic tin adhering, cooling after tin soldering,automatic flux adhering, automatic tin soldering, automatic tin scraping, and finished product discharging and recycling; the whole machining process can be fully automatically operated and no manualintervention is needed; the two different working procedures of wire-winding machining and tin-soldering machining can be combined together, and then the workpiece can be subjected to wire winding and tin soldering synchronously, thereby greatly improving the production efficiency and the productivity; and besides, the full-automatic wire winding and tin soldering machine is high in wire windingprecision and good in wire winding effect, is more convenient and rapid to use, and meets the large-scale batch production demand of an enterprise.

Owner:湖北省磁特科技有限公司

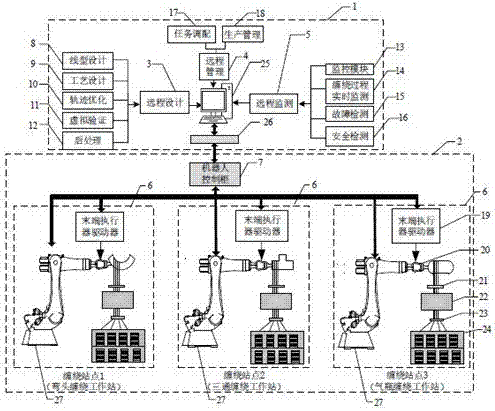

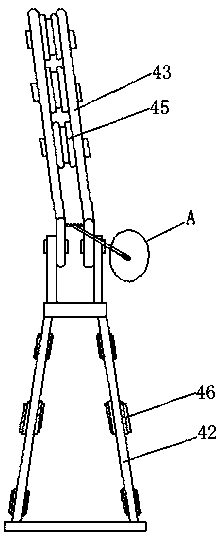

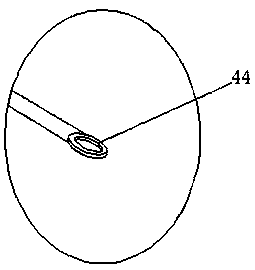

Robot filament winding work station

The invention discloses a robot filament winding work station. The robot filament winding work station comprises a remote control platform and a filament winding robot set. The remote control platform comprises remote designing, remote monitoring, remote managing, a computer and an interchanger, the filament winding robot set comprises at least one filament winding robot and a control cabinet of the filament winding robot, data conversion is conducted between the remote control platform and the field control cabinet of the filament winding robot through the interchanger, data transmission is conducted between the remote control platform and the field control cabinet of the filament winding robot through an ethernet network, and a remote monitoring control system sends a wireless control instruction to the field control cabinet to control a corresponding control positioner to conduct filament winding according to filament winding needs. According to the robot filament winding work station, the robot winding work station is modularized to improve the universality of the equipment, and the winding efficiency of the robot is improved and the energy consumption is reduced by establishing virtual verification to optimize a winding path; remote monitoring and managing are achieved based on the network technology to optimize task allocation of the work station, and automation of the technology in the overall process is achieved; and the robot filament winding work station can meet the winding requirements for various pipe fittings and containers, the winding pattern is accurate, operation is convenient and rapid, the labor is saved, and remote monitoring and control can be achieved.

Owner:HARBIN UNIV OF SCI & TECH

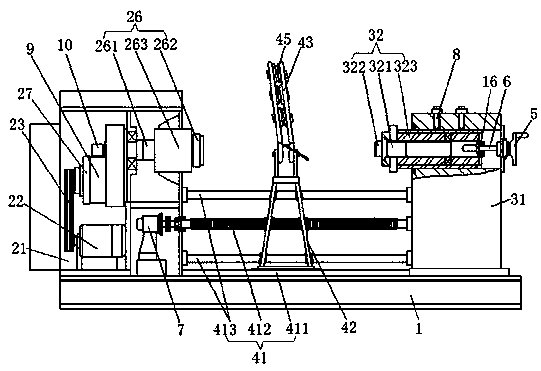

Automatic horizontal winding machine

The invention discloses an automatic horizontal winding machine which comprises a worktable, a main base and a tail base symmetrically arranged on two sides of the worktable and a wire guiding mechanism movably arranged between the main base and the tail base; the main base comprises a main case, a reducing motor fixed in the main case, a transmission shaft in transmission connection to the reducing motor through a belt and a driving supporting part in transmission connection to the transmission shaft through a transmission gear bank; the tail base comprises a tail base box and an auxiliary supporting part which is movably mounted on the upper part of the tail base box and is arranged aligned with the driving supporting part; the wire guiding mechanism comprises a guide rail assembly arranged between the main base and the tail base, a guide seat movably mounted on the guide rail assembly and a wire guiding rack fixed above the guide seat. The automatic horizontal winding machine disclosed by the invention can be suitable for clamping and positioning workpieces of different lengths, and the guide seat is more stable to move, so that the winding precision is improved.

Owner:JINAN KO YO ELECTRICAL TECH

Gantry type annular container winding machine

The invention discloses a gantry type annular container winding machine. The gantry type annular container winding machine comprises a gantry bracket, a base and a wire nozzle bracket, wherein the base is arranged in the gantry bracket, the wire nozzle bracket is arranged above the base, a plurality of core mold clamping devices for fixing an annular core mold are mounted on the base, a wire nozzle bracket rotating device for driving the wire nozzle bracket to rotate around the periphery of the outer side of the annular core mold is mounted on the top of the gantry bracket, the wire nozzle bracket is mounted in the bottom of the wire nozzle bracket rotating device, an annular wire nozzle is mounted on the wire nozzle bracket, a driving mechanism for driving the annular wire nozzle to rotate around the periphery of the cross section of the annular core mold, and yarn guiding wheels are mounted on the annular wire nozzle. According to the gantry type annular container winding machine disclosed by the invention, the annular core mold is immobilized by virtue of the core mold clamping devices, the annular wire nozzle rotates around the periphery of the outer side of the annular core mold and around the periphery of the cross section of the annular core mold, and a fiber is wound on the surface of the core mold by rotational synthesis, so that the problem of inaccurate locating and yarn grinding caused by a friction drive mode of the annular core mold is solved.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

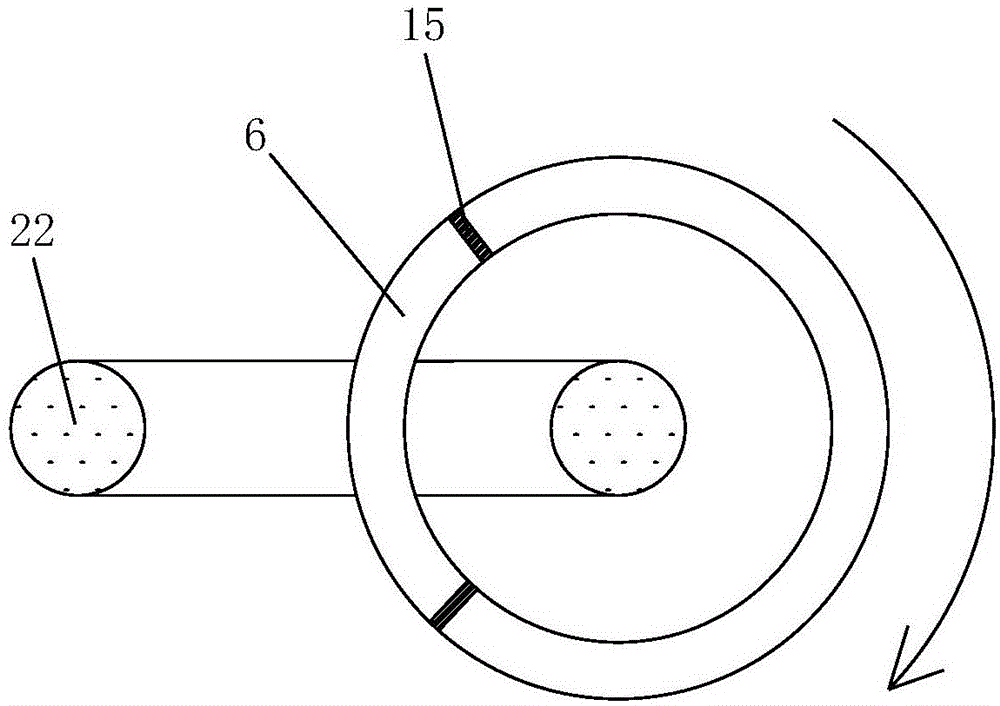

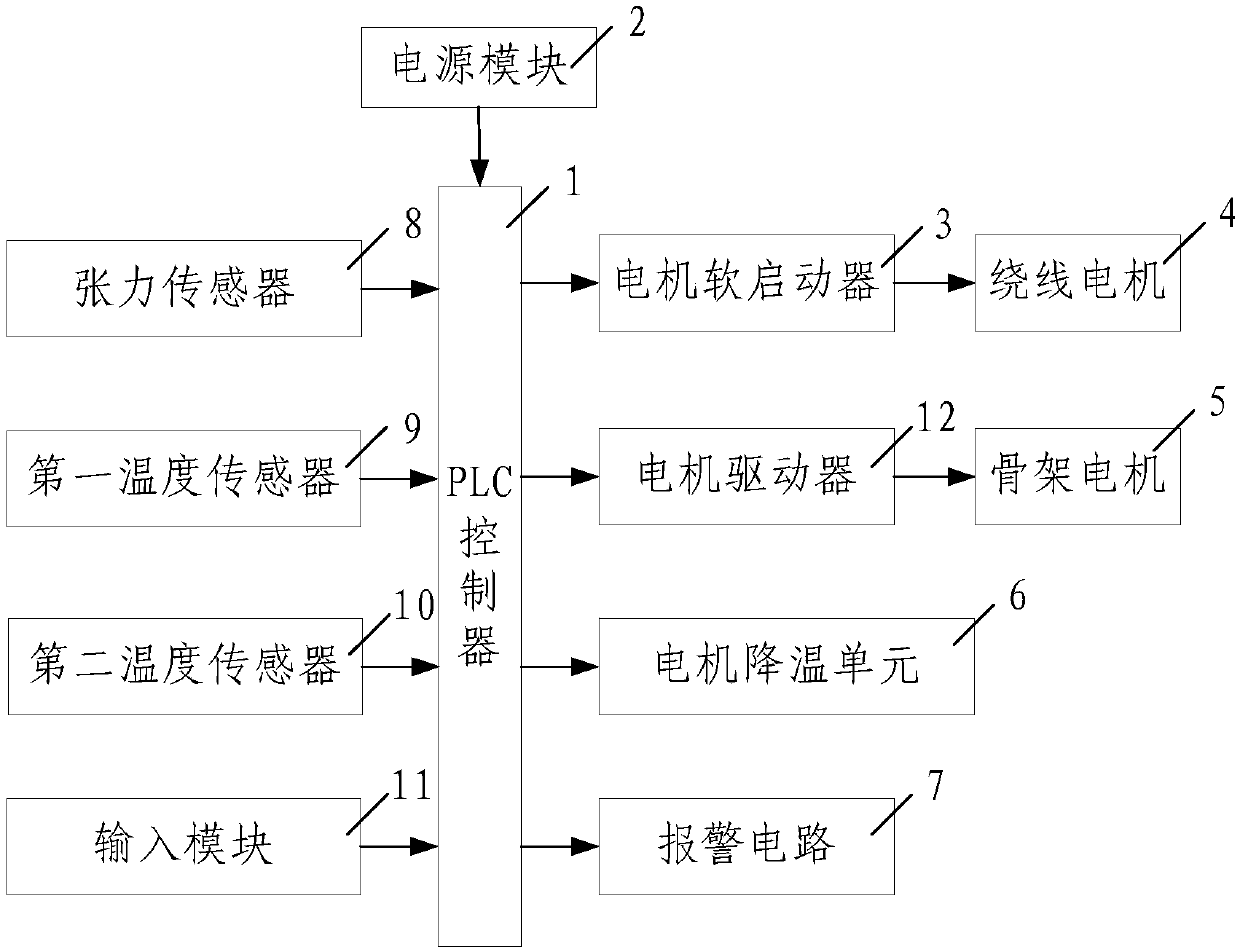

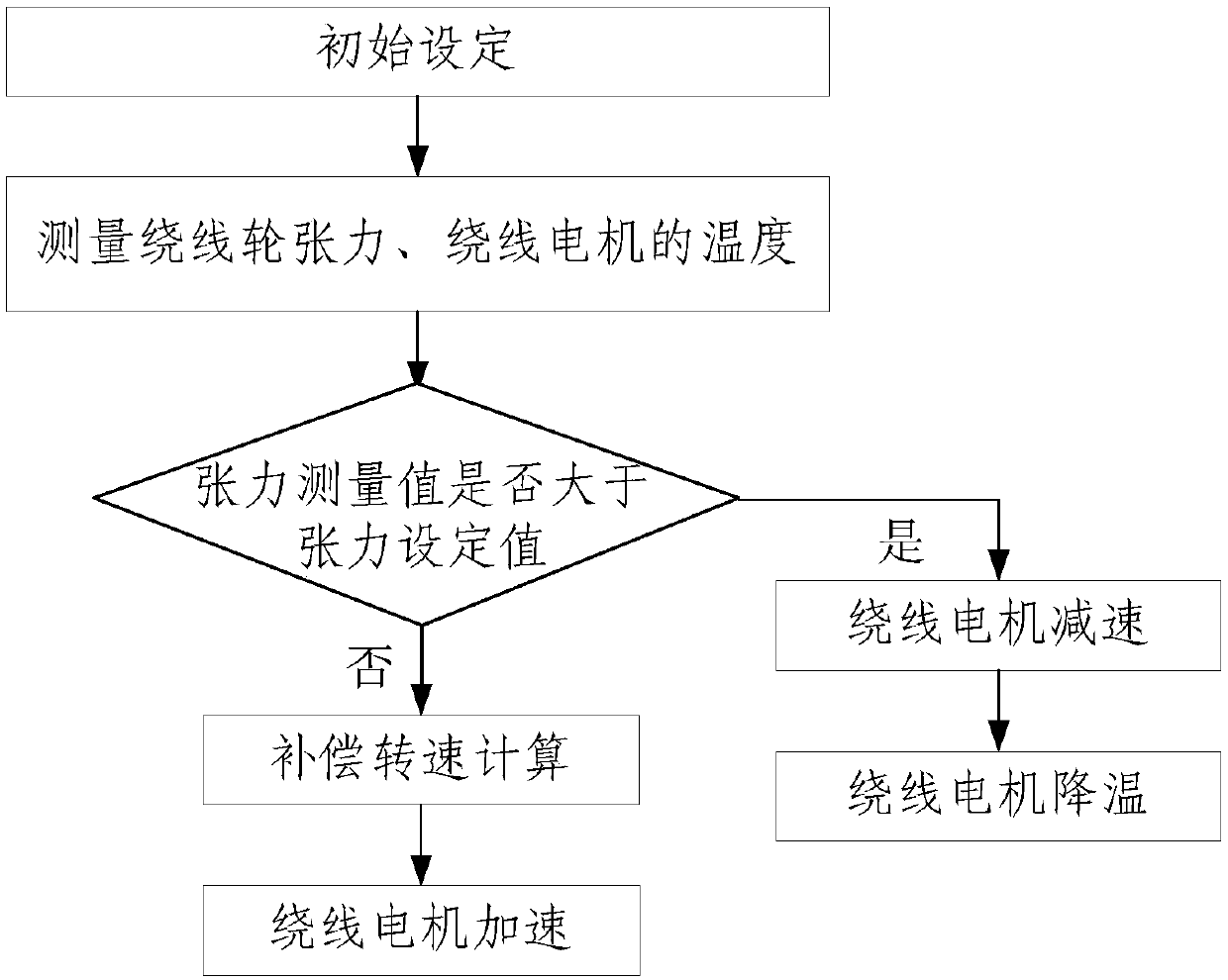

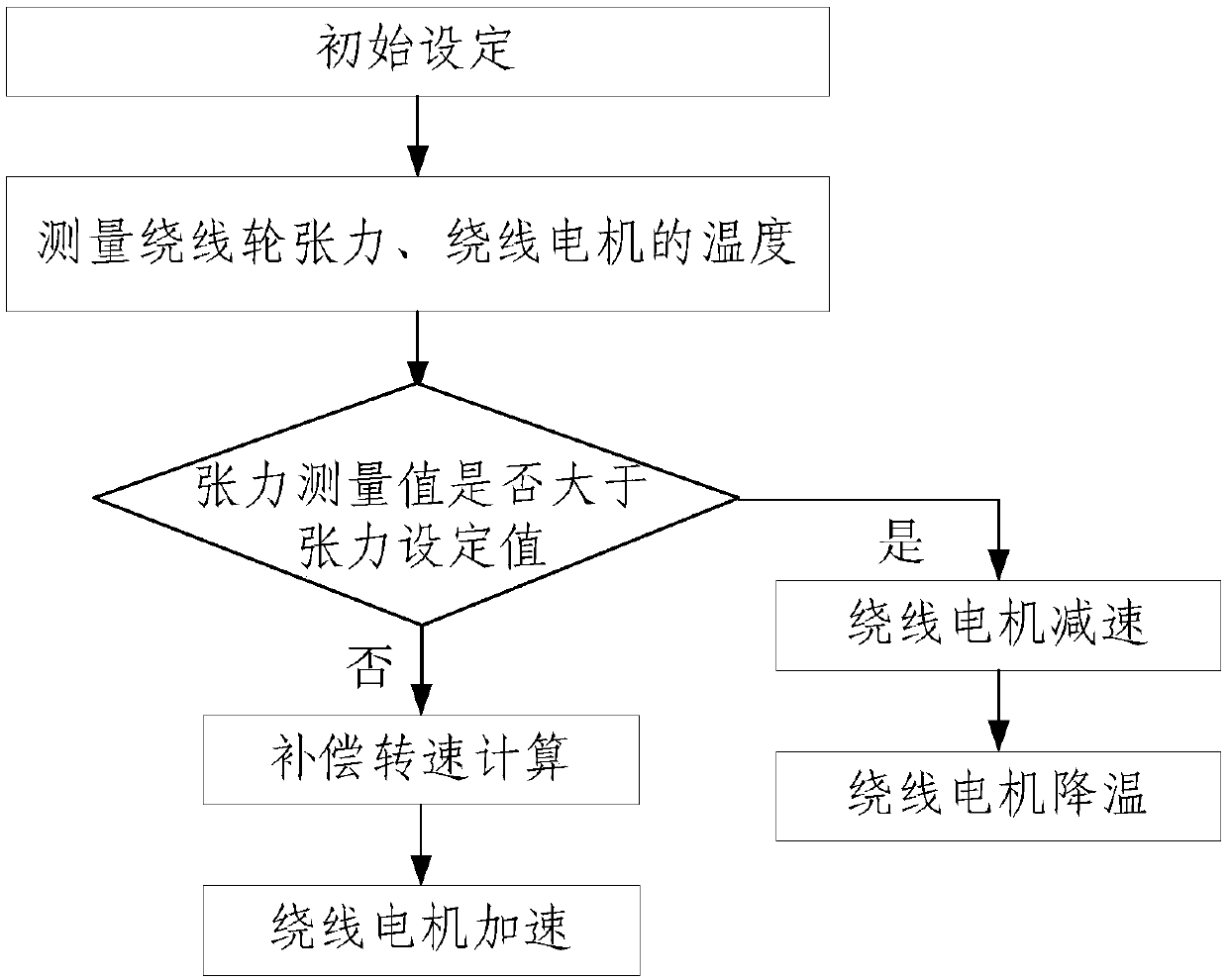

Winding device of inductor and winding compensation method

InactiveCN107068389ASimple structureReasonable designElectric motor controlInductances/transformers/magnets manufactureProgrammable logic controllerElectric machinery

The invention discloses a winding device of an inductor. The winding device comprises a rack, a winding wheel, a wire clamp, a framework motor, a winding motor, a programmable logic controller (PLC), a tension sensor, a first temperature sensor, an alarm circuit, a motor driver and a motor soft starter. The invention discloses a winding compensation method of the inductor. The winding compensation method comprises the steps of 1, initial setting; 2, measurement; 3, tension comparison; 4, acceleration compensation of the winding motor; and 5, speed reduction of the winding motor. The winding device is simple in structure and reasonable in design, a tension force of the winding wheel is detected by the tension sensor and is transferred to the PLC, the PLC is used for compensating a rotational speed of the winding motor according to a current rotor temperature of the winding motor, an effect of protecting the winding motor is achieved, and the winding device is high in automation, high in practicability and good in application effect, and is convenient to use and operate, and promotion and application are convenient.

Owner:DANFENG RONGYI ELECTRONICS

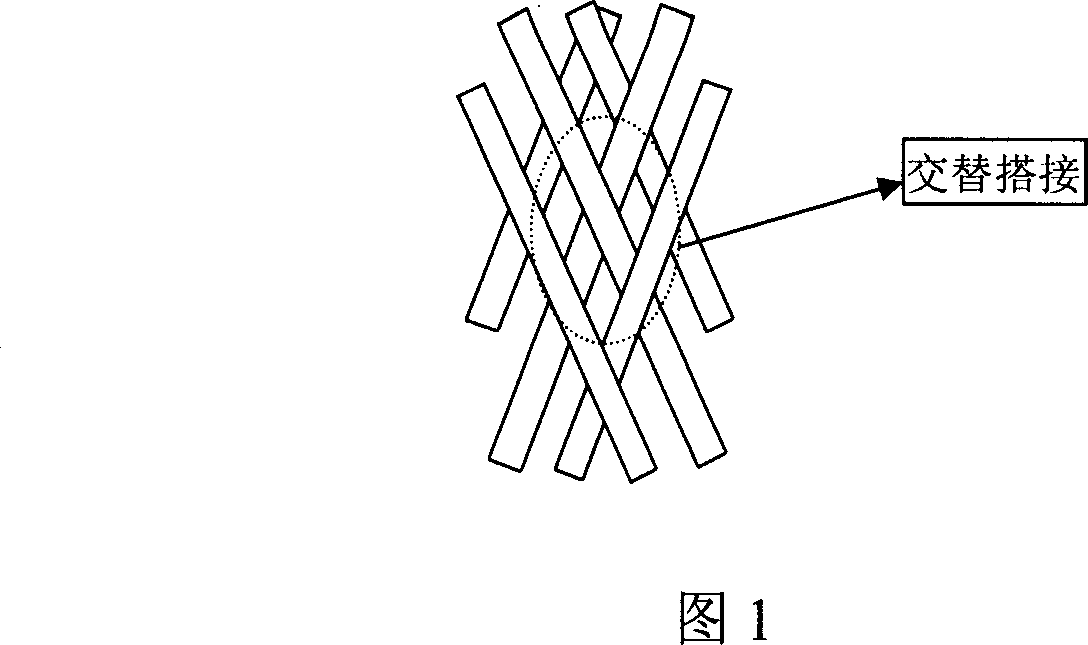

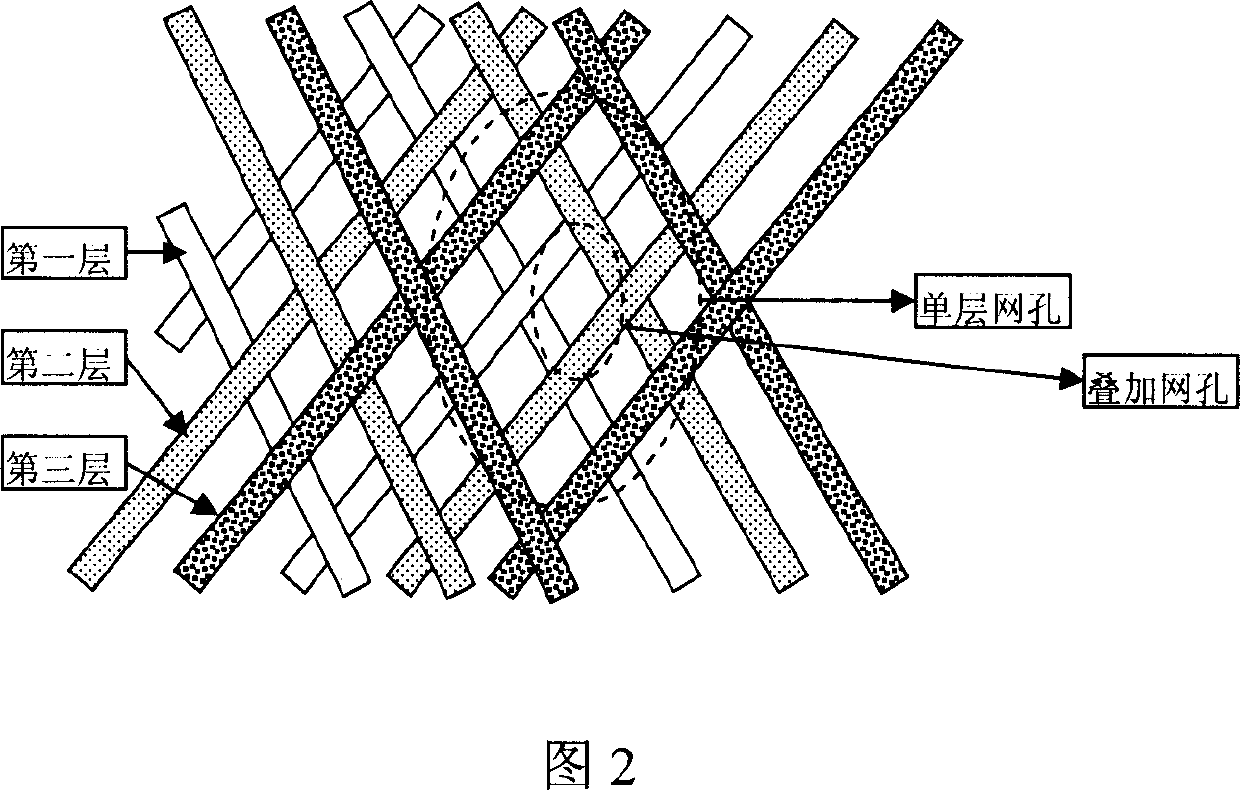

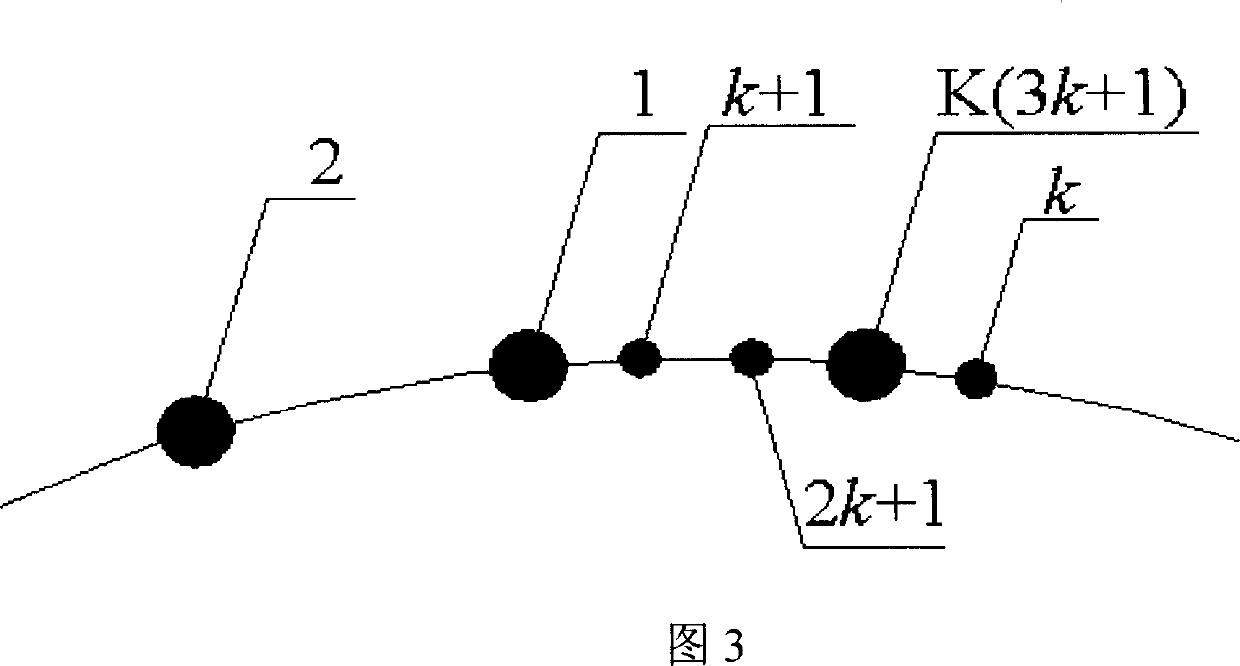

Metal oil-filter screen multiple-layer superimposing winding shaping method

The invention relates to a multilayer coiling shaping method of metal oil filter network. wherein, it comprises that designing post core mould; using d0cosalpha=3K(d1+d2) / 3K+1 to control HG-2 ejection large digit control fiber coiling machine, to calculate the coil control code; via multi-tangent-point multilayer metal wire alternative coiling method, coiling the post core mould; (3), sintering coiled metal oil filter network, removing core mould, shearing over section, coiling into metal oil filter network. The invention has better rigidity, multilayer coiling, uniform network, non stack at end, and high coiling accuracy.

Owner:HARBIN INST OF TECH

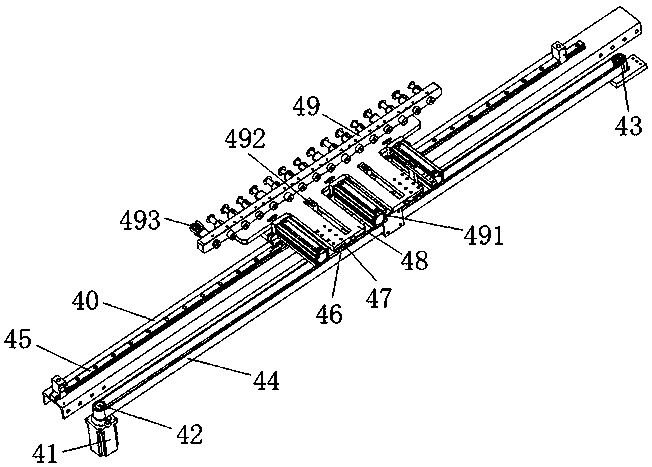

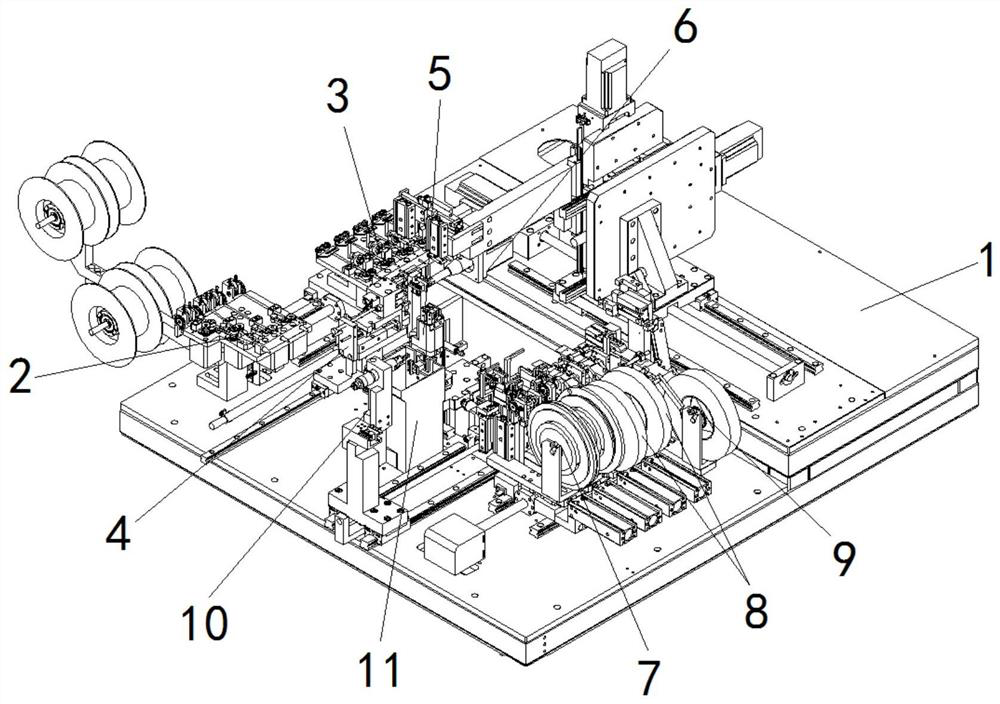

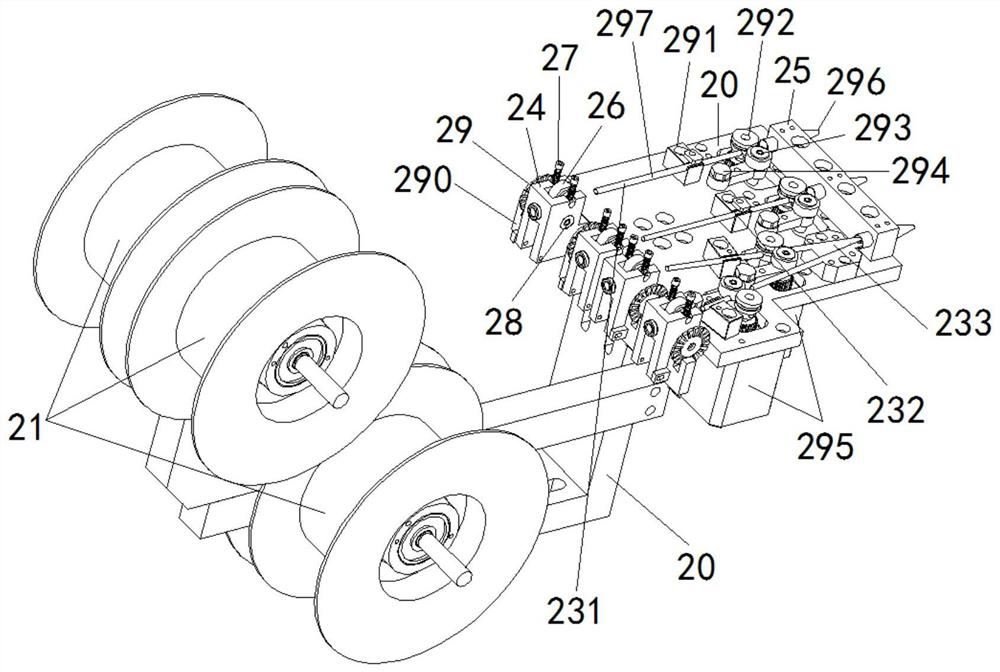

Gyroscope light ring constant-tension closed-loop unwinding and winding precise array winding machine and winding technology thereof

InactiveCN108792822AHigh accuracy of wiringImprove the wiring effectFilament handlingWinding machineGyroscope

The invention discloses a gyroscope light ring constant-tension closed-loop unwinding and winding precise array winding machine and a winding technology thereof. According to the gyroscope light ringconstant-tension closed-loop unwinding and winding precise array winding machine and the winding technology thereof, a left winding and unwinding tension constant device, a right winding and unwindingtension constant device, a left winding displacement and wire storing device and a right winding displacement and wire storing device are set to be closed-loop devices, wherein the left winding and unwinding tension constant device and the right winding and unwinding tension constant device can achieve reverse unwinding and reverse winding and can move and swing to a certain angle according to the production requirements for closed-loop lagged precise winding displacement, the same raw material wire is uncoiled from a left raw material coil and a right raw material coil, and it can be guaranteed that under the situation that the raw material wire does not need to be shorn, different layers of raw material wires and multiple layers of raw material wires can be wound around multiple different winding parts of products; and the same raw material wire can be controlled by the left winding displacement and wire storing device and the right winding displacement and wire storing device to becircularly, reversibly and precisely wound around the products in an array manner from each winding and unwinding tension constant device. According to the gyroscope light ring constant-tension closed-loop unwinding and winding precise array winding machine and the winding technology thereof, the winding precision is high, the winding efficiency is high, and operation stability is high.

Owner:DONGGUAN ZONGHENG ELECTROMECHANICAL SCI & TECH

Glass fiber composite material plate forming apparatus and method

The invention discloses a glass fiber composite material plate forming apparatus. The glass fiber composite material plate forming apparatus comprises an untwisting device, a tension control device, aglue dipping device and a winding device. The tension control device is arranged between the untwisting device and the winding device. The winding device comprises a guide rail mechanism, a wire arranging mechanism and a winding die. The guide rail mechanism comprises a lead screw pair. A rotary shaft of the winding die is parallel to a lead screw. The guide rail mechanism further comprises a guide rail parallel to the lead screw. The wire arranging mechanism is installed on a nut of the lead screw pair and is used in cooperation with the guide rail to carry out reciprocating rectilinear movement between limiters along the lead screw and the guide rail by being driven by a lead screw motor. The glass fiber composite material plate forming apparatus is compact in structure and small in floor space, and is stable in winding and high in accuracy through cooperation between the high-accuracy lead screw guide rail mechanism and the winding die. According to a glass fiber composite materialplate forming method, the glass fiber composite material plate forming apparatus is used for winding forming of a glass fiber composite material plate, an obtained winding product is uniform and reliable, and a finished product of the plate is good in test stability.

Owner:CHONGQING POLYCOMP INT

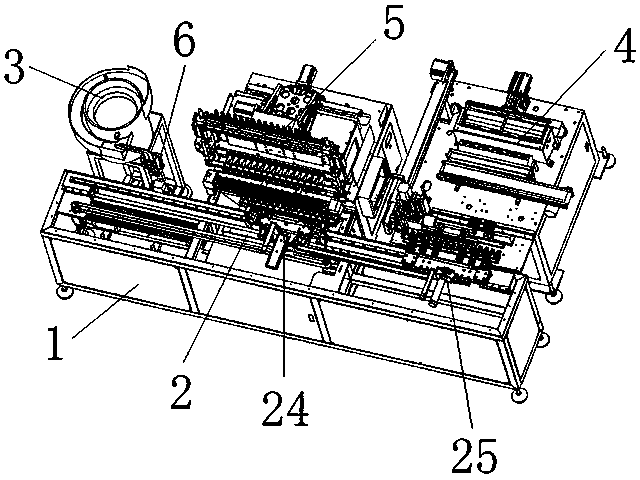

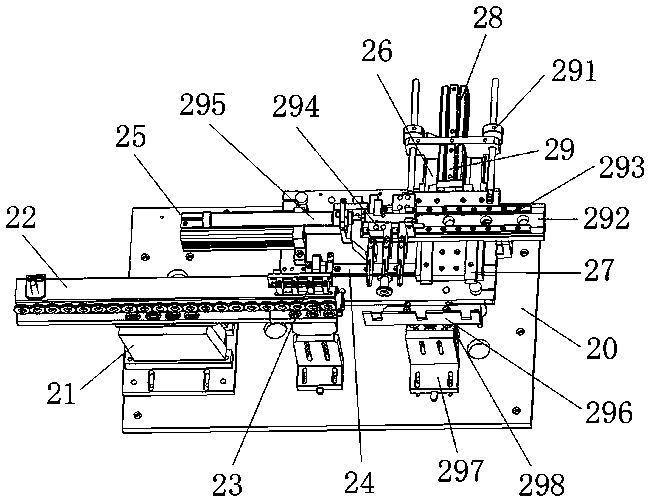

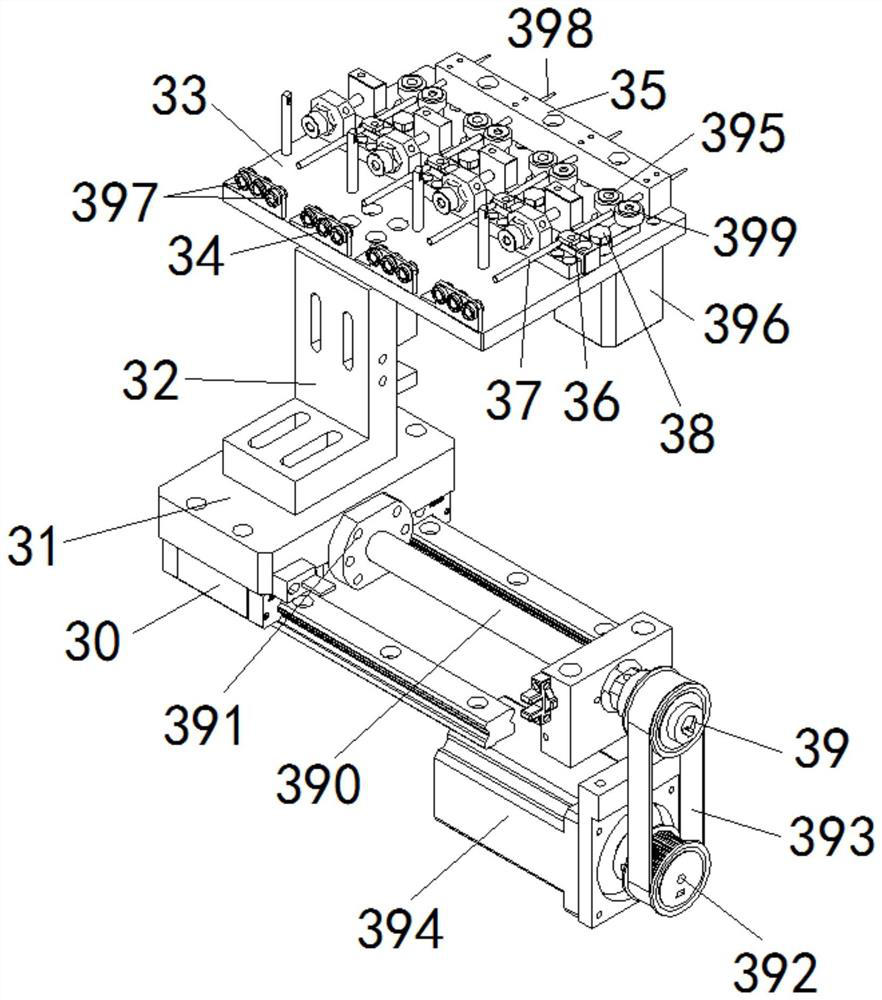

Automatic feeding winding machine for E-shaped coil bobbins

ActiveCN108281276AHigh winding precisionReduce labor intensityCoils manufactureWinding machineEngineering

The invention discloses an automatic feeding winding machine for E-shaped coil bobbins. The automatic feeding winding machine comprises a machine frame, an E-shaped coil feeding nail opening-closing mechanism, an E-shaped coil feeding vibrating disc, an E-shaped coil feeding carrier vehicle mechanism, an E-shaped coil discharging conveyor belt line mechanism, an E-shaped coil feeding residual wireclamp mechanism, a winding machine spindle, an E-shaped coil feeding tensioning mechanism and an E-shaped coil feeding three-axis positioning mechanism. The automatic feeding winding machine integrates a series of full-automatic operation including feeding, equidistant distribution conveying, three-axis positioning, winding, residual wire pinching-off and discharging recovery for workpieces and is also suitable for positioning workpieces with different sizes, so the winding machine spindle can carry out winding on workpieces with different sizes, and high winding precision of the winding machine spindle is ensured; the whole operation process is fully automatic, it is not needed to insert E-shaped coil bobbins manually or carry out winding manually, and thus the automatic feeding windingmachine is high in winding efficiency, good in winding effect, high in productivity and convenient and fast to use and greatly reduces the labor intensity of workers and the labor cost.

Owner:湖北省磁特科技有限公司

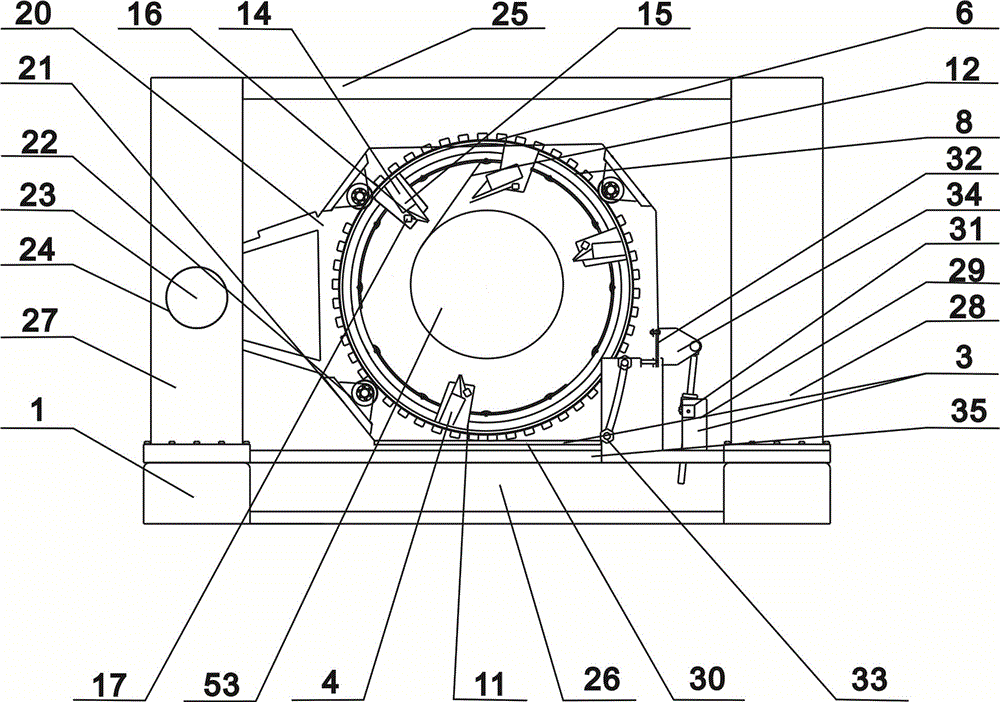

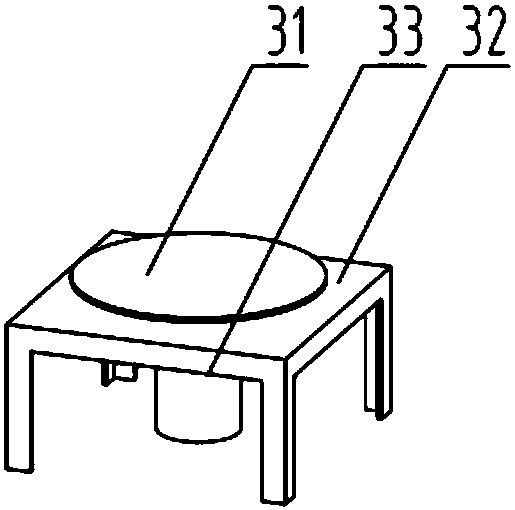

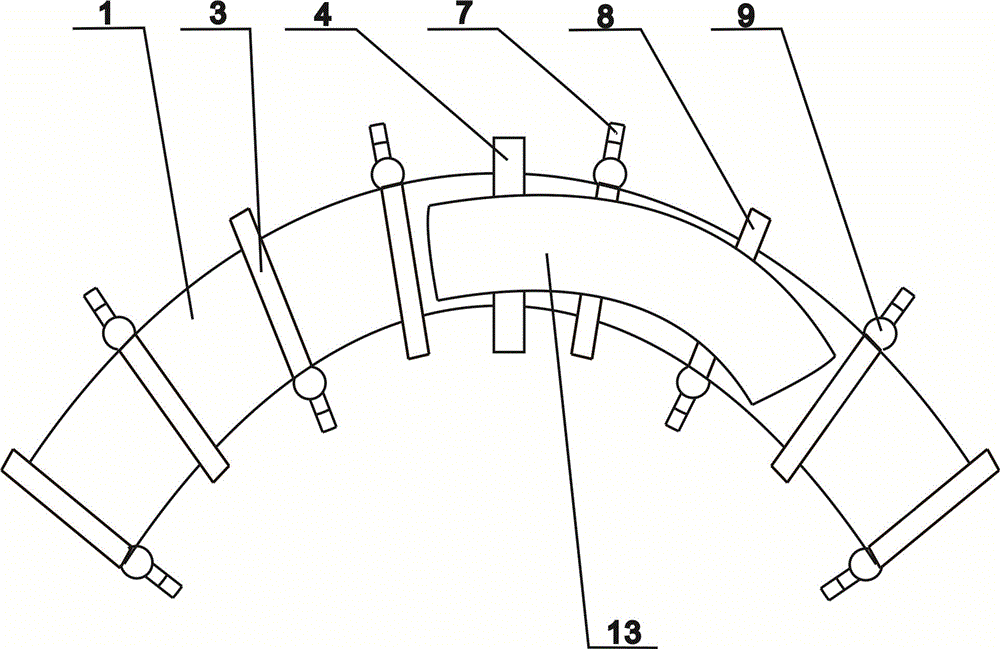

Bead positioning and clamping platform of bead winding machine

ActiveCN103203423AGuaranteed stiffnessLow installation and positioning accuracy requirementsWire ringsWinding machineDrive shaft

The invention provides a bead positioning and clamping platform of a bead winding machine. A pair of platform guide pillars and a pair of bead driving uprights are vertically fixed below an operating platform. Two ends of a fixed equilateral steel angle of the platform are connected to the platform guide pillars and the bead driving uprights respectively. Two platform guide sliders are fixed at the upper end of each platform guide pillar. A platform guide copper sleeve is inset in an inner hole of each platform guide slider. After gas is introduced into cylinders, the cylinders drive the operating platform to move through platform guides, so that a driven shaft roller sleeve, a bead core and a bead driving shaft roller sleeve are contacted with one another and compressed, the bead core is held, a bead driving shaft is driven, and the bead core is driven to rotate by friction between the driven shaft roller sleeve and the bead driving shaft roller sleeve. The requirement on bead fitting and positioning precision is low, a platform pad and a bead pressure block on the operating platform need not be demounted repeatedly, and accordingly clamping is easy, operating is simple and efficiency is higher.

Owner:哈尔滨工大宏图橡塑科技有限公司

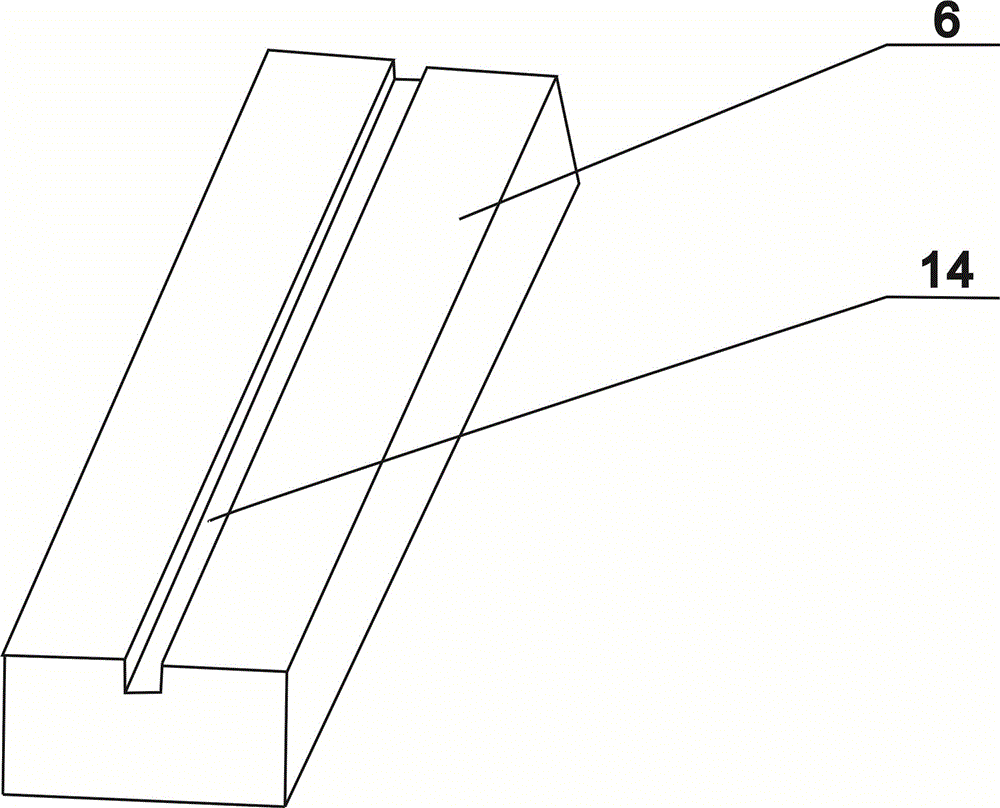

Elbow pipe winding guide rail

InactiveCN106144394AScientific and reasonable designSimple structureConveyorsRoller-waysAdhesiveEngineering

The invention discloses an elbow pipe winding guide rail, which comprises a base plate, a base plate sleeper and a drive unit. The base plate is arranged on the lower part of the base plate sleeper; the base plate sleeper is arranged on the upper part of the base plate and is fixedly connected with the base plate; the base plate is in a fan shape; the base plate sleeper is formed by an adjustment base plate and a slide block; the slide block is arranged on the upper part of the adjustment base plate, and is a raised cuboid; the drive unit is formed by a drive device, an idler wheel, a clamping wheel, an idler wheel support seat, a clamping wheel support seat, a sliding chute and a baffle plate; the drive device is arranged on the left side position; the idler wheel support seat is arranged on the right side of the drive device, and is in an L shape; and the shorter side of the idler wheel support seat is fixedly connected with the drive device. According to the elbow pipe winding guide rail provided by the invention, the work efficiency of a winding anticorrosion thermal shrinkage adhesive tape of automatic elbow pipe winding equipment is improved, the labor intensity is reduced, and meanwhile, the winding quality of the elbow pipe winding anticorrosion thermal shrinkage adhesive tape is greatly improved.

Owner:HENAN XINKAIYUAN PETROCHEM PIPELINE

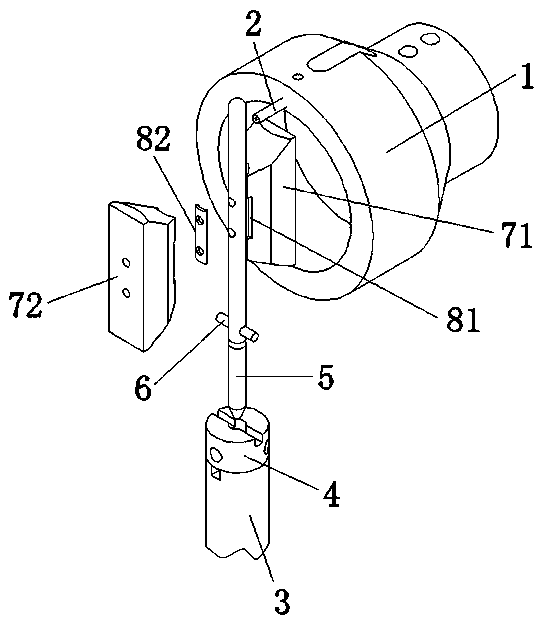

Laser galvanometer coil and winding process thereof

InactiveCN108766759AHigh winding precisionEasy to produceCoils manufactureWinding machineGalvanometer

The invention relates to a laser galvanometer coil and a winding process thereof. The laser galvanometer coil comprises a fork bowl, a wire needle, a rotating polar shaft, a spindle base, a spindle, alocating pin, a first wire block, a second wire block, a first mould core, a second mould core, a limiting groove, a spindle mounting hole and a rotary servo motor. According to the laser galvanometer coil provided by the invention, the coil can be molded in the process of winding the coil, thus the production process is simplified, the production efficiency and the productivity are improved, andthe coil is more convenient to manufacture; and the wound coil has the advantages of being good in molding effect, high in winding precision and high in yield, the winding of the coil is simpler, more convenient and faster, and the problems that the existing laser galvanometer coil and the winding process thereof need to be wound into a parallel coil by adopting a parallel winding machine, and then need to be pressed and formed by a mold, which results in complicated manufacturing process and complicated manufacturing process, low production efficiency and low qualification rate of finished products are solved.

Owner:东莞市台立电子机械有限公司

Fiber reinforced composite material ring test sample winding device

ActiveCN104527087APrecise windingHigh winding precisionPreparing sample for investigationYarnDrive shaft

The invention provides a fiber reinforced composite material ring test sample winding device comprising a die and a ring test sample winding mechanism. The ring test sample winding mechanism comprises a stepless variable-speed motor, a main shaft, a die locating assembly, a transmission assembly and a yarn guiding assembly. The die locating assembly comprises a locating disk, a screwing nut and a die locating bolt. The transmission assembly comprises a transmission shaft, an auxiliary shaft and a conveying belt. The yarn guiding assembly comprises an oval iron disk, a swing arm and an extensible spring. By the adoption of the fiber reinforced composite material ring test sample winding device, the winding precision of a rotating body is improved, the whole winding process is stable and reliable, mechanical degree is high, operation is convenient, high-quality ring test samples can be wound accurately, and cost is low.

Owner:HENGSHEN

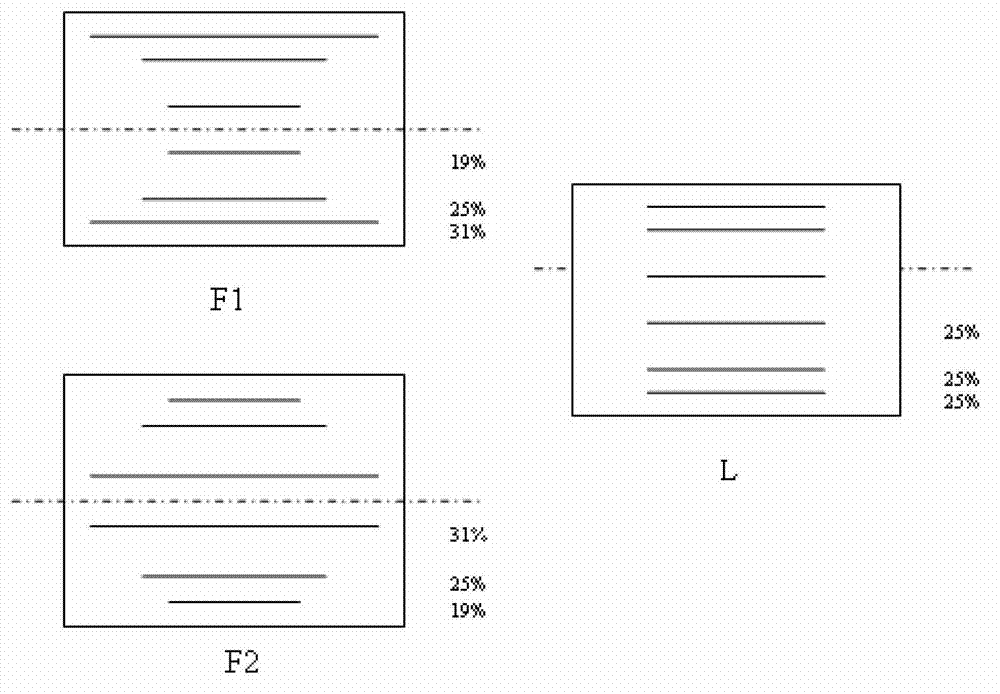

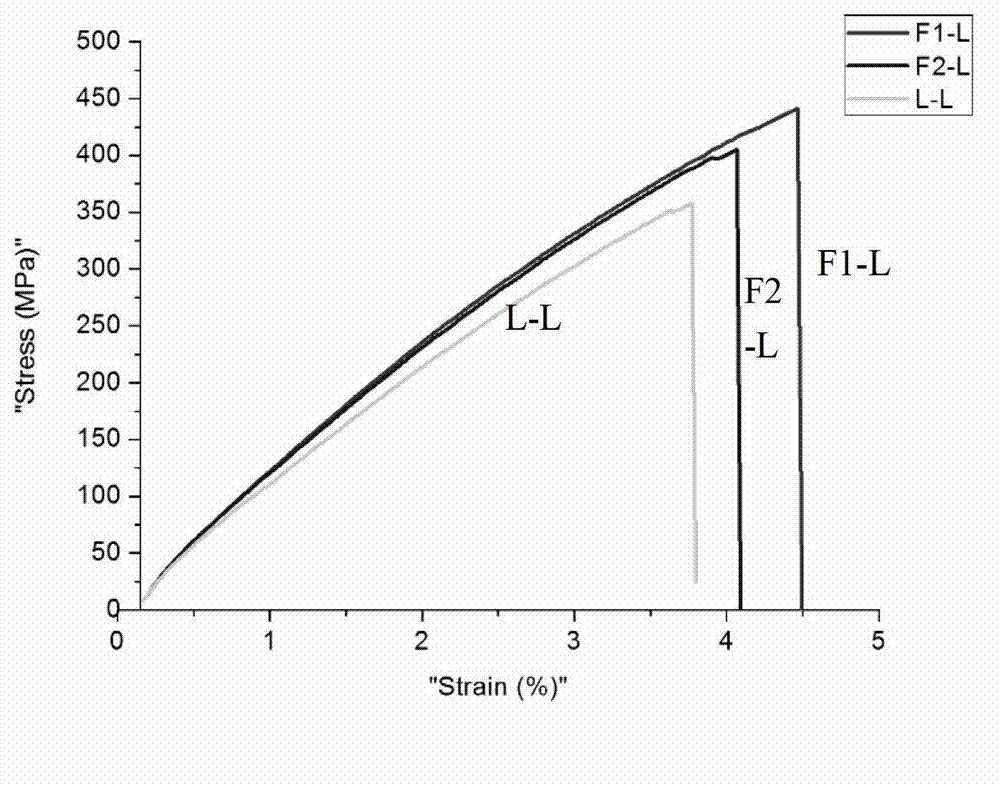

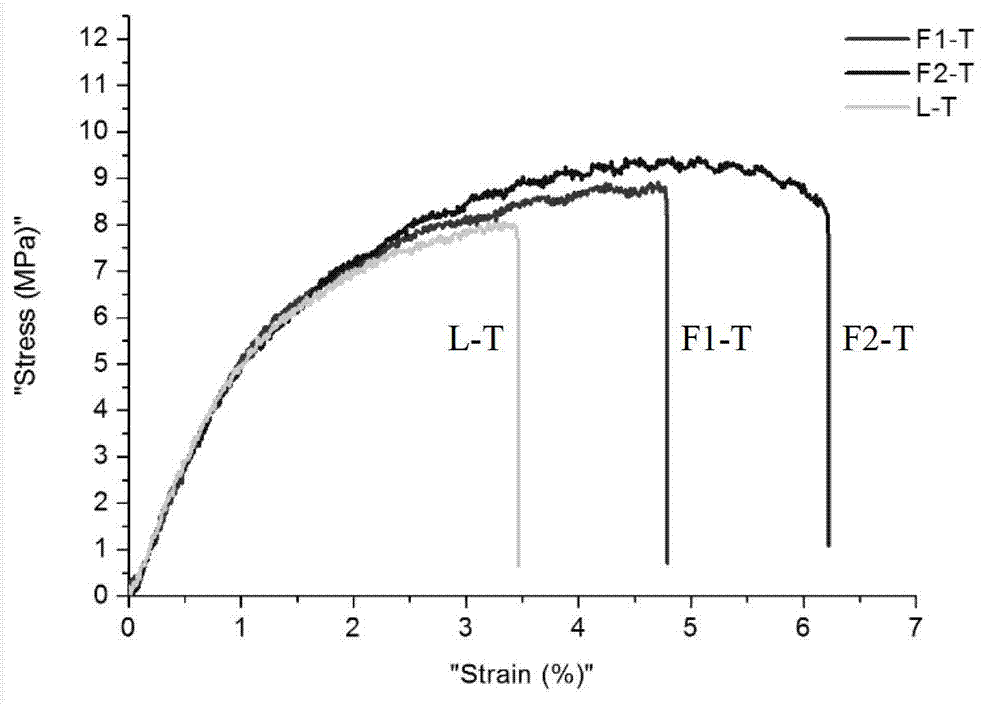

Continuous fiber self-reinforcing gradient lamination board and preparation method thereof

InactiveCN103112175AHigh winding precisionImprove efficiencyMetal layered productsYarnVolumetric Mass Density

The invention relates to a continuous fiber self-reinforcing gradient lamination board and a preparation method thereof. The fiber volume content and the material properties of the lamination board are in gradient distribution along the thickness direction of the lamination board, wherein the fiber volume content is changed from 10% to 60%; the volume content difference of all fiber layers is from 3% to 10%; and the lamination board is provided with 6 to 50 fiber layers. A yarn examining machine is utilized to wind the fibers; the fiber volume content is changed by changing the yarn reeling density; and the fibers are molten in a hot pressing manner to be molded into the lamination board. The obtained lamination board has various excellent mechanical properties, and especially the lateral tensile strength and the vertical and horizontal shearing strength can be enhanced by 10% to 20%. In addition, the preparation method is simple, low in energy consumption and easy in molding operation and can easily realize the mass production.

Owner:DONGHUA UNIV

Full-automatic inductor winding device

ActiveCN108717901AImprove work efficiencyImprove performanceInductances/transformers/magnets manufactureIncreasing energy efficiencyInductor windingsMulti axis

The invention discloses a full-automatic inductor winding device comprising a wire storage frame component, a three-axis winding device, a wire clamping and cutting device, a multi-axis spindle component and an anti-jumper component, wherein the wire storage frame component is used for storing an enameled wire and providing the enameled wire for the three-axis winding device after bypassing the anti-jumper component, the multi-axis spindle component is used for clamping a processed inductor, the three-axis winding device winds the enameled wire on the processed inductor, and the wire clampingand cutting device is used for clamping the end part of the enameled wire and cutting the enameled wire. The full-automatic inductor winding device has the advantages of high automation, high windingefficiency, high winding precision, good winding quality, and no damage to the magnetic core and the enameled wire, which are absent in the prior art.

Owner:SHENZHEN CENKER ENTERPRISE

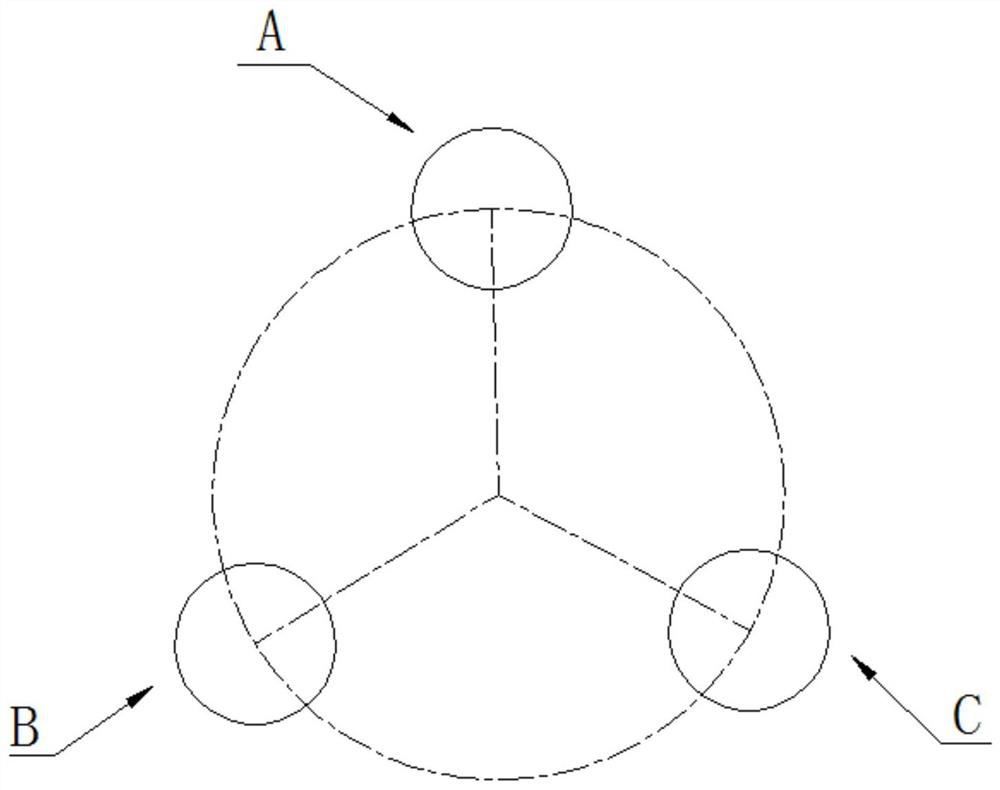

Ultra-small-distance winding needle structure of winding machine for lithium battery piece production

ActiveCN112928339AReduce center distanceReduce distanceAssembling battery machinesFinal product manufactureWinding machineGear wheel

The invention relates to an ultra-small-distance winding needle structure of a winding machine for lithium battery piece production. The ultra-small-distance winding needle structure comprises an inner rotating tower, an inner winding needle mounting shaft, inner winding needles, an outer rotating tower, an outer winding needle mounting shaft, outer winding needles, inner transmission wheels, a first inner gears, first outer gears, outer transmission wheels, second inner gears and second outer gears. According to the invention, three inner transmission wheels movably sleeve the rear part of the inner winding needle mounting shaft, one first inner gear is arranged behind each inner transmission wheel, three outer transmission wheels movably sleeve the rear portion of the outer winding needle mounting shaft, one second outer gear is arranged behind each outer transmission wheel, and the outer gears are arranged in the transmission wheels by arranging an inner meshing structure of the outer gears and the inner gears, so space is saved, and the center distance of three shafts of the winding needles is reduced; and the three first outer gears correspond to the three first inner gears in position, the three second outer gears correspond to the three second outer gears in position, the three pairs of the inner winding needles and the outer winding needles independently rotate without interference, and thus, winding precision is high, and high-precision winding of an ultra-small battery cell is achieved.

Owner:东莞泓宇智能装备有限公司

Winding method of heat-shrinkage adhesive tape used for bent pipe

ActiveCN106363901AConsistent service lifeSolve the entanglementTubular articlesWrinkle skinThree stage

The invention discloses a winding method of heat-shrinkage adhesive tape used for a bent pipe. Three-stage heating processes are adopted, and the three-stage heating temperatures are strictly controlled. A pipe body is preheated in the first-stage heating process; the double faces of the heat-shrinkage adhesive tape are heated in the second-stage heating process; the pipe body wound with the heat-shrinkage adhesive tape is heated in the third-stage heating process, a rolling and grinding process is comprehensively utilized for rolling and grinding the bent pipe in a winding mode, and the feeding size of the bent pipe and the overlapping size of the heat-shrinkage adhesive tape are strictly limited, so that the purposes that the winding precision is high, the surface of a coating layer is flat and smooth and free of wrinkles, warping edges and bubbles, the coating layer overlapping position is flat, excessive glue is sufficient and uniform, and the service life of the heat-shrinkage adhesive tape is consistent with that of the pipe are achieved; and meanwhile, the problems that the labor intensity of manual winding is high, the heat-shrinkage adhesive tape is prone to winding deviation, and winding is not firm are solved.

Owner:HENAN XINKAIYUAN PETROCHEM PIPELINE

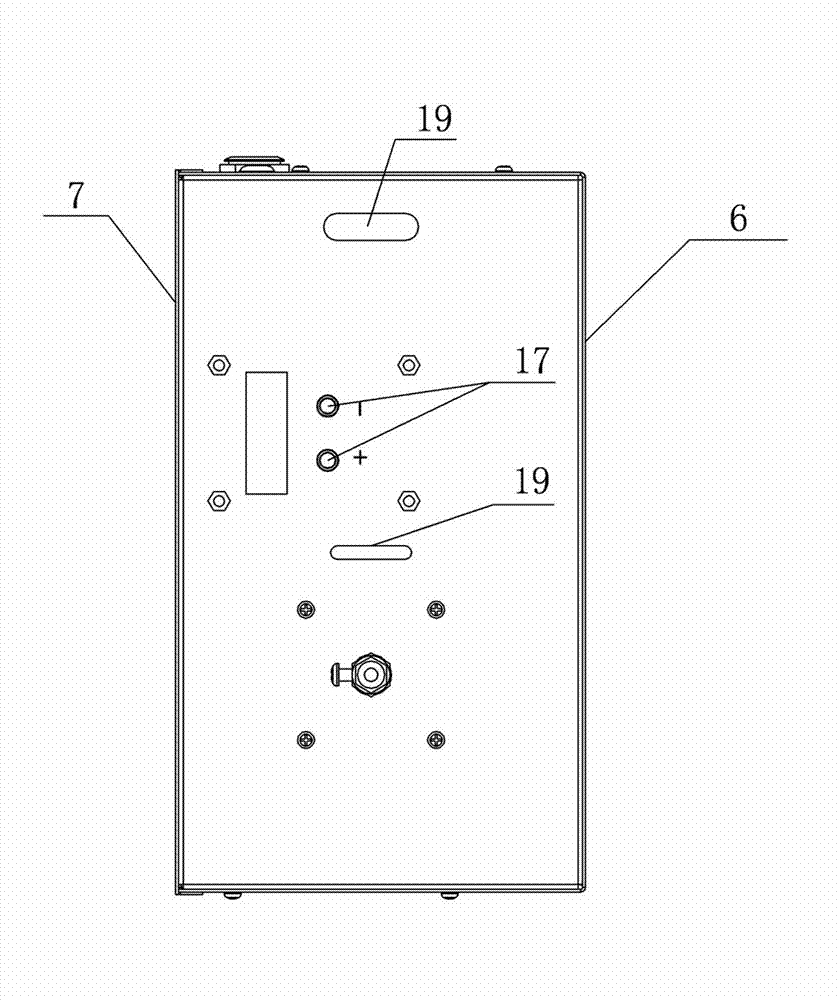

Unsintered tape winding device

The invention relates to a winding device of sealing materials, in particular to an automatic unsintered tape winding device. The automatic unsintered tape winding device comprises a winding control device and a control switch; the winding control device comprises a switching power supply, a stepping motor driver, a stepping motor and an industrial control board; one path of the output end of the switching power supply is connected with the industrial control board, and the other path of the output end of the switching power supply is connected with the stepping motor driver through the control switch; the output of the stepping motor driver is connected with the stepping motor; the switching power supply, the stepping motor driver, the stepping motor and the industrial control board are arranged inside a sealed shell; a rotating shaft of the stepping motor extends out of the sealed shell from the inner wall of the end, where the stepping motor is fixed, of the sealed shell; and a cylindrical clamp is arranged on the rotating shaft of the stepping motor. According to the unsintered tape winding device disclosed by the invention, in allusion to the problems of difficulty in control over force, easiness in loosening, low efficiency during batch winding and the like in the mode of manually winding unsintered tapes, the stepping controller is used for controlling the winding of the unsintered tapes; and the automatic winding device is mechanically-operated in working process, convenient and rapid to use, suitable for batch operation and greatly improved in production efficiency.

Owner:HENAN ZHONGFEN INSTR

Retaining wall encapsulation, adhesive tape reverse folding, winding and pipe sleeving all-in-one machine

InactiveCN111755239AHigh winding precisionImprove the winding effectCoils manufactureWinding machineWire rod

The invention discloses a retaining wall encapsulation, adhesive tape reverse folding, winding and pipe sleeving all-in-one machine, which comprises a multi-sleeve feeding mechanism, a multi-wire-diameter wire feeding mechanism, a sleeve storing and penetrating mechanism, a wire arranging mechanism, a winding mechanism, a retaining wall mechanism, an encapsulation mechanism, a reverse folding mechanism, a wire end trimming and shaping mechanism and a finished product discharging barrel. According to the invention, a plurality of different processes such as conveying and feeding of a pluralityof different sleeves, conveying and feeding of a plurality of wires with different specifications, threading of the wires into the sleeves, retaining wall adhesive tape encapsulation, winding, adhesive tape encapsulation, reverse folding adhesive tape gluing, trimming, shaping of wire ends and discharging of finished products can be automatically carried out on a framework coil on one set of equipment; there is no need of purchasing multiple sets of equipment or use a large area to place the equipment, the all-in-one machine has the advantages of being high in working efficiency, good in winding effect, good in encapsulation effect and low in production cost, and the problems that the working efficiency is low, the labor intensity of workers is high and the labor cost of enterprises is high due to the fact that the framework coil is machined in a manual operation mode traditionally are solved.

Owner:湖北省磁特科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com