Glass reinforced plastic winding equipment and glass reinforced plastic winding method

A glass fiber reinforced plastic and equipment technology, applied in the field of polymer material processing equipment, can solve the problems of high price, unable to meet the stability requirements, limited winding accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

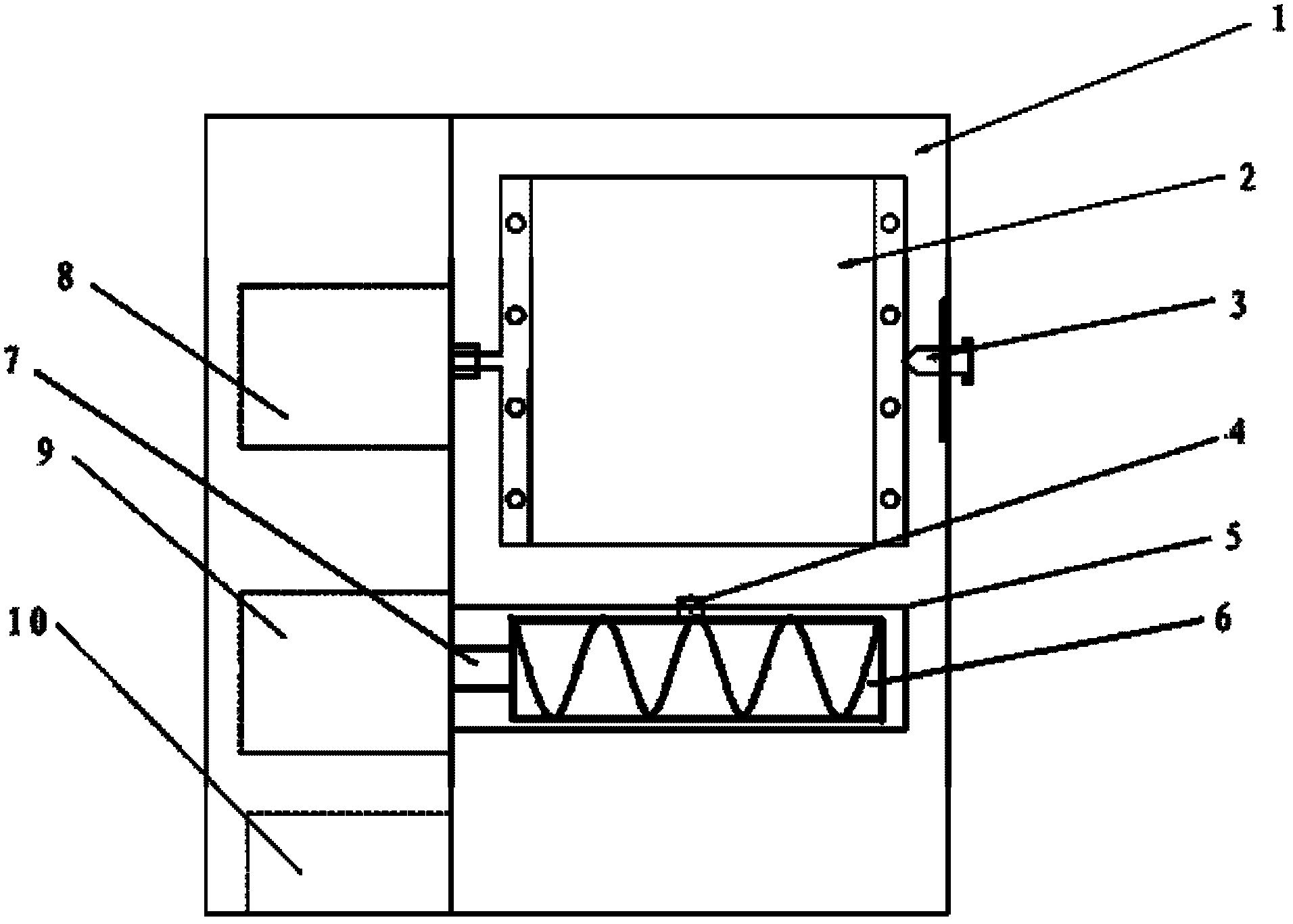

Method used

Image

Examples

Embodiment 2

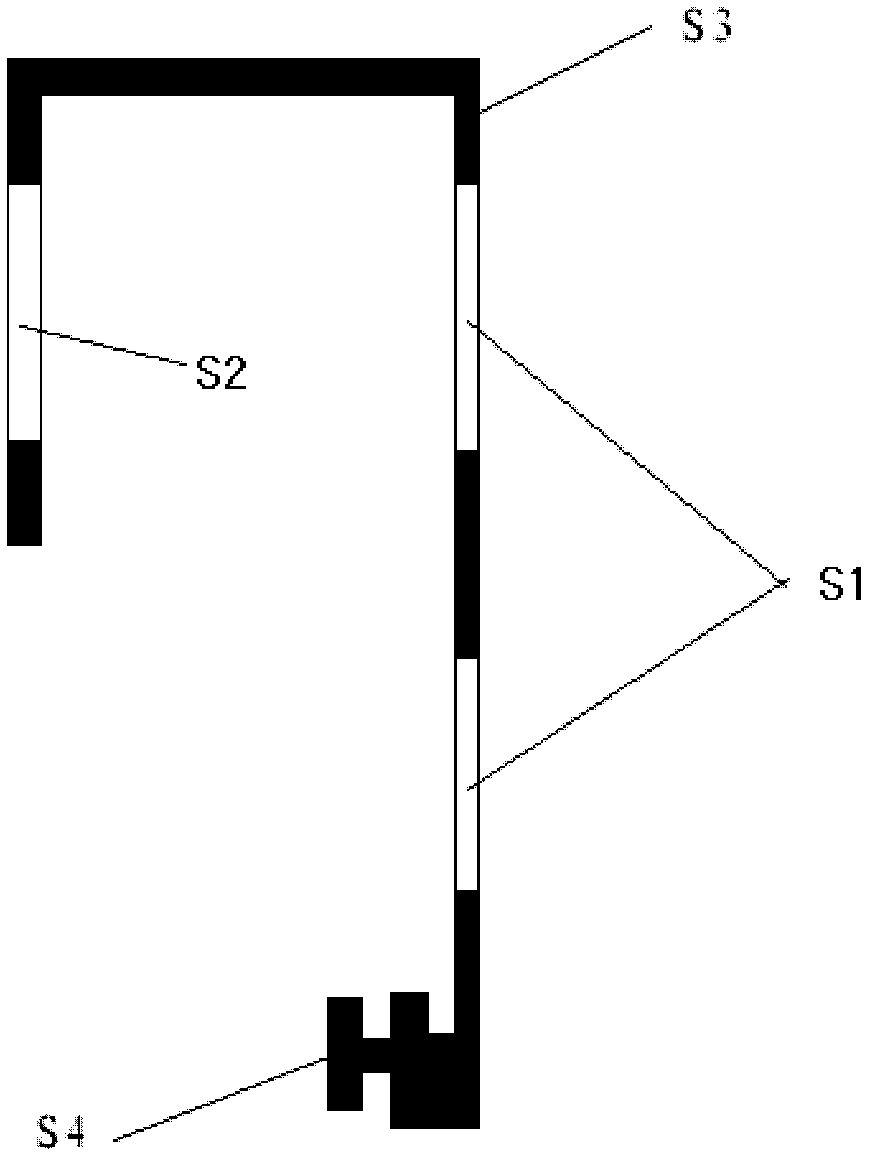

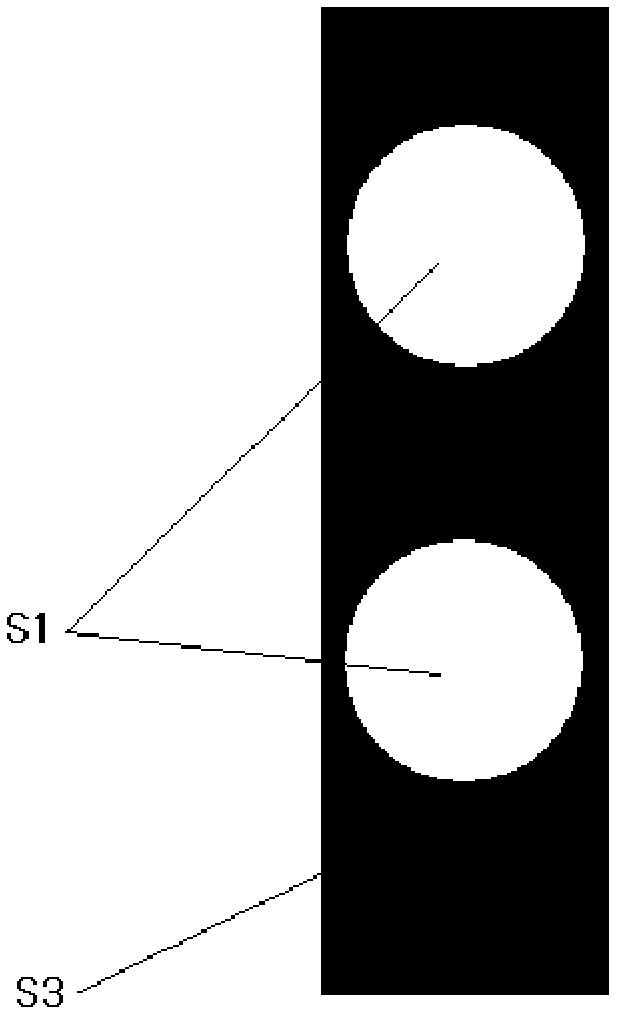

[0044] After unwinding the glass fiber yarn, pass through the dipping tank, and then pass through image 3 The through hole of the cable guide shown is fixed on the winding mold, turn on the cam motor to adjust the position of the cable guide to the edge of the mold, and pour a sufficient amount of unsaturated polyester resin into the dipping tank to completely impregnate the yarn in the resin , adjust the rotation speed ratio of the mold motor and the cam motor. It is desired to set the cable angle to 0.5° and the mold width to 200mm. According to the trigonometric formula, the horizontal displacement distance of the cable is 1.75mm. After setting up the machine, turn on the motor to start winding. The winding thickness is required to be 2mm. According to the yarn density and winding angle setting, the number of winding layers is calculated to be 3 layers. After winding, turn off the motor, close the mold, and release the mold after curing according to the curing method of th...

Embodiment 3

[0047] After unwinding the glass fiber yarn, pass through the dipping tank, and then pass through image 3 The through hole of the cable guide shown is fixed on the winding mold, turn on the cam motor to adjust the position of the cable guide to the edge of the mold, and pour a sufficient amount of unsaturated polyester resin into the dipping tank to completely impregnate the yarn in the resin , adjust the rotation speed ratio of the mold motor and the cam motor. It is desired to set the cable angle to 0.8° and the mold width to 200mm. According to the trigonometric formula, the lateral movement distance of the cable is 2.79mm. After setting up the machine, turn on the motor to start winding. The winding thickness is required to be 1.5mm. According to the yarn density and winding angle setting, the number of winding layers is calculated to be 3 layers. After winding, turn off the motor, close the mold, and release the mold after curing according to the curing method of the res...

Embodiment 4

[0050] After unwinding the glass fiber yarn, pass through the dipping tank, and then pass through image 3 The through hole of the cable guide shown is fixed on the winding mold, turn on the cam motor to adjust the position of the cable guide to the edge of the mold, and pour a sufficient amount of unsaturated polyester resin into the dipping tank to completely impregnate the yarn in the resin , adjust the rotation speed ratio of the mold motor and the cam motor. It is desired to set the cable angle to 2° and the mold width to 200mm. According to the trigonometric formula, the lateral movement distance of the cable is 6.98mm. After setting up the machine, turn on the motor to start winding. The winding thickness is required to be 2mm. According to the yarn density and winding angle setting, the number of winding layers is calculated to be 5 layers. After winding, turn off the motor, close the mold, and release the mold after curing according to the curing method of the resin m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com