Unsintered tape winding device

A technology of winding device and raw material tape, which is applied in the field of winding device for sealing materials, can solve the problems that it is difficult to ensure the winding quality of raw material tape, affect the quality of pipe fittings connection and installation, and the quality is uneven, so as to increase the comfort of use, There is no requirement for skills and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

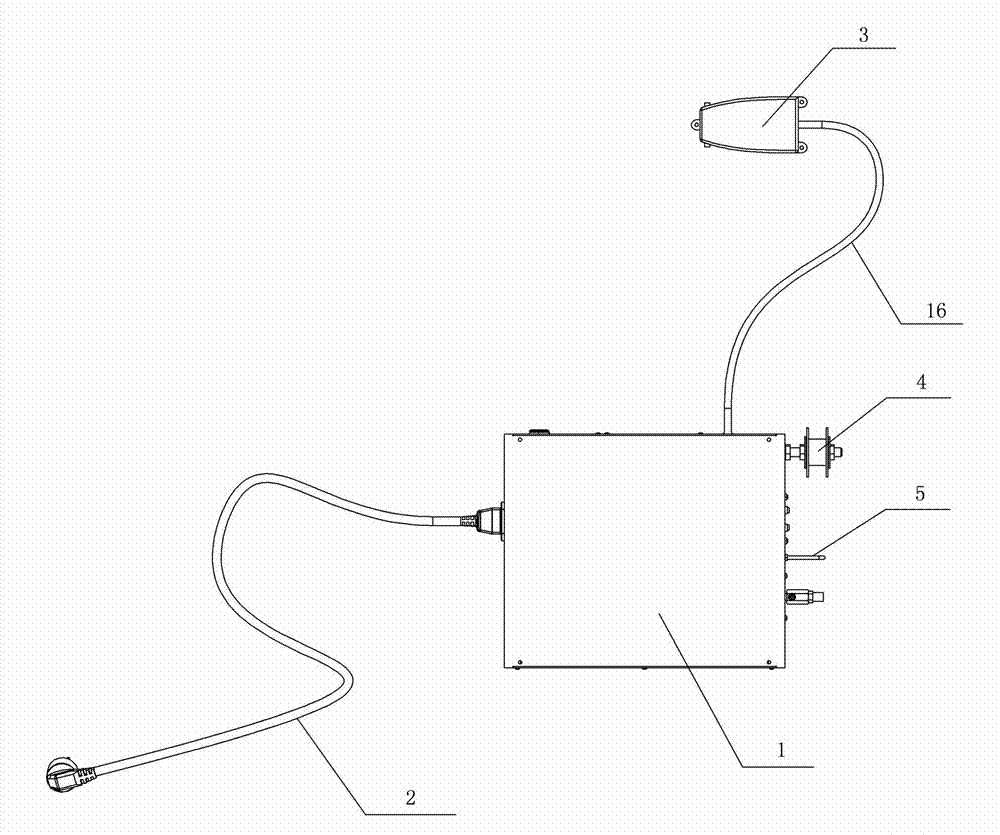

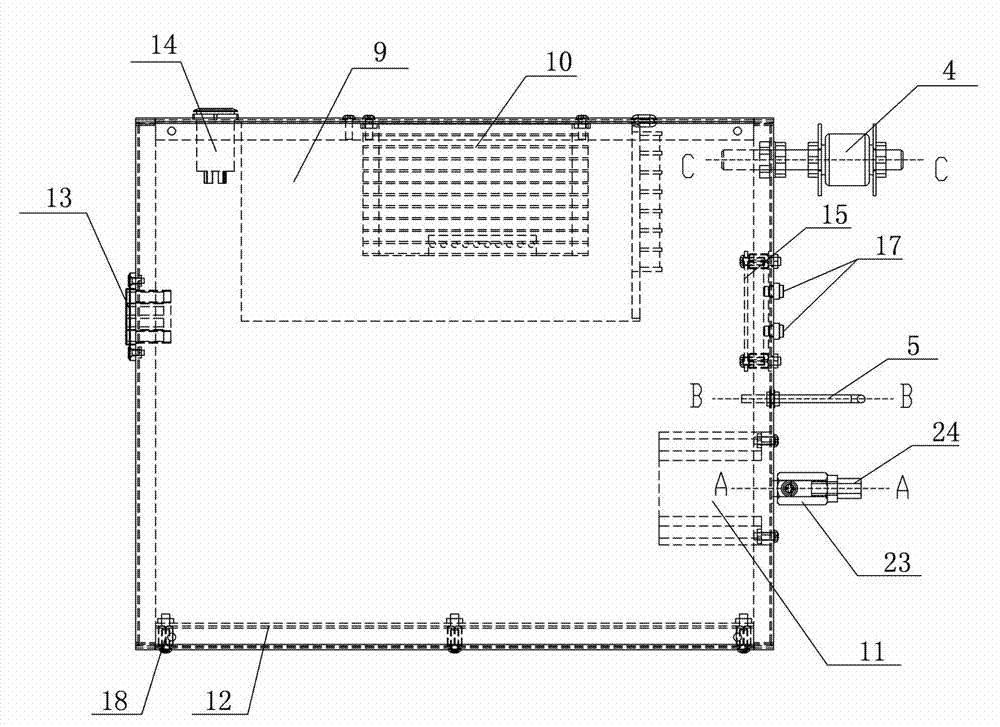

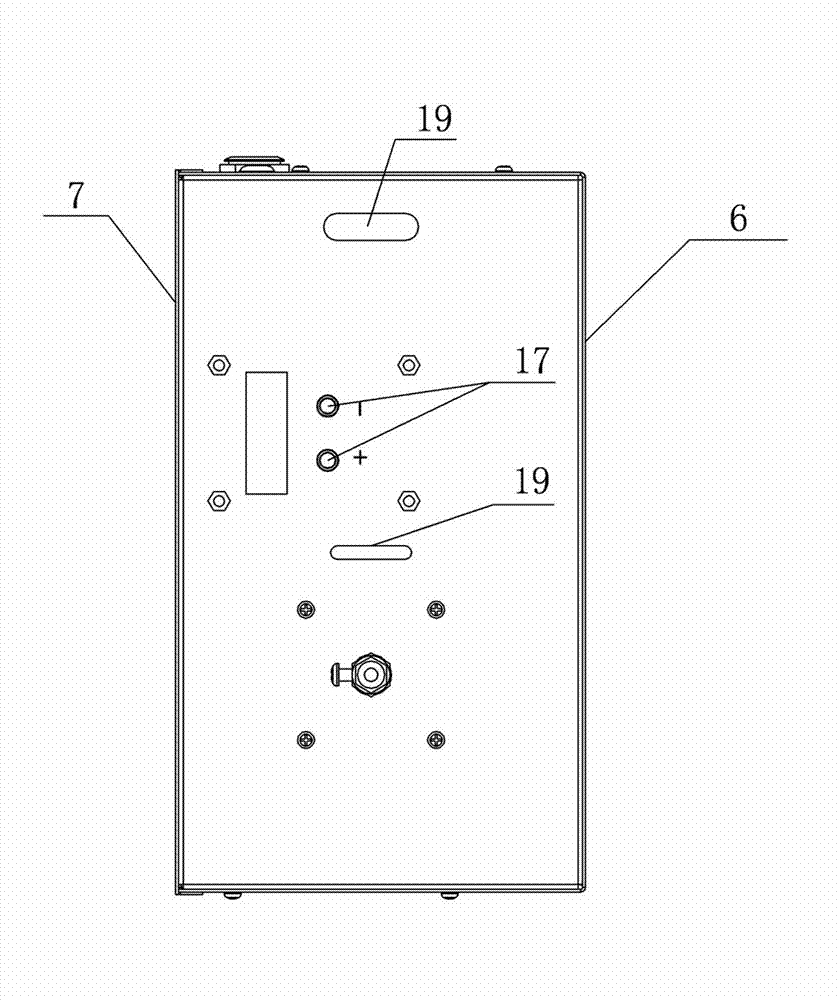

[0027] Embodiment one: see figure 1 , Figure 2a-Figure 2c , the raw material tape winding device of the present invention includes a power cord 2, a winding control device 1, and a control switch 3, and the winding control device mainly includes a switching power supply 9, a stepping motor driver 10, a stepping motor 11, and an industrial control board 12; The output end of the switching power supply is connected to the industrial control board one way, and the stepping motor driver is connected to the stepping motor driver through the control switch 3, and the output of the stepping motor driver is connected to the stepping motor. The switching power supply, the stepping motor driver, the stepping motor, and the industrial control board Installed inside a closed casing, the stepper motor is fixed on the inner wall of one end of the closed casing, the rotating shaft of the stepping motor protrudes from the inner wall of the end outside the closed casing, and a columnar clamp ...

Embodiment 2

[0028] Embodiment two: see figure 1 , Figure 2a-Figure 2c , The raw tape winding device of this embodiment is different from Embodiment 1 in that it further discloses a columnar clamp structure. see Figure 3a , one end of the columnar fixture is provided with a round hole matching the output end of the stepper motor shaft, a hole is opened on the side of the columnar fixture to communicate with the round hole vertically, and the columnar fixture is fastened to the stepper motor shaft through screws 8 , to ensure that the columnar clamp rotates with the stepping motor shaft; the other end of the columnar clamp is provided with an internally threaded hole, and the internal thread of the internally threaded hole matches the external thread of the joint 24 that adds the raw material belt.

Embodiment 3

[0029] Embodiment three: see figure 1 , Figure 2a-Figure 2c 1. The raw material belt winding device of this embodiment is different from the first or second embodiment in that a raw material belt pulley support device and a limit rod are arranged on the side wall of the closed casing and the columnar clamp; see Figure 4a , Figure 4b , the raw material pulley support device is composed of a support rod 20, a bolt 21, and a gasket 22. Wherein the supporting rod is made of nylon to reduce weight; the mating surface of the supporting rod and the pulley is made of frosted surface to increase friction and make the pulley rotate smoothly.

[0030] see Figure 3b , the limit rod 5 is an L-shaped screw rod, the bottom straight rod part is provided with a threaded section, the threaded section passes through the corresponding annular slotted hole on the wall of the closed shell, and passes through the inner and outer sides of the closed shell wall. The washer 22 and the nut 21 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com