Lag angle control system in precise winding device

A technology of a winding device and a control system, which is applied in the field of lag angle control system, can solve the problems of high coil wiring precision, high labor intensity, and the wiring precision cannot meet the design requirements, etc., and achieves high winding precision and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

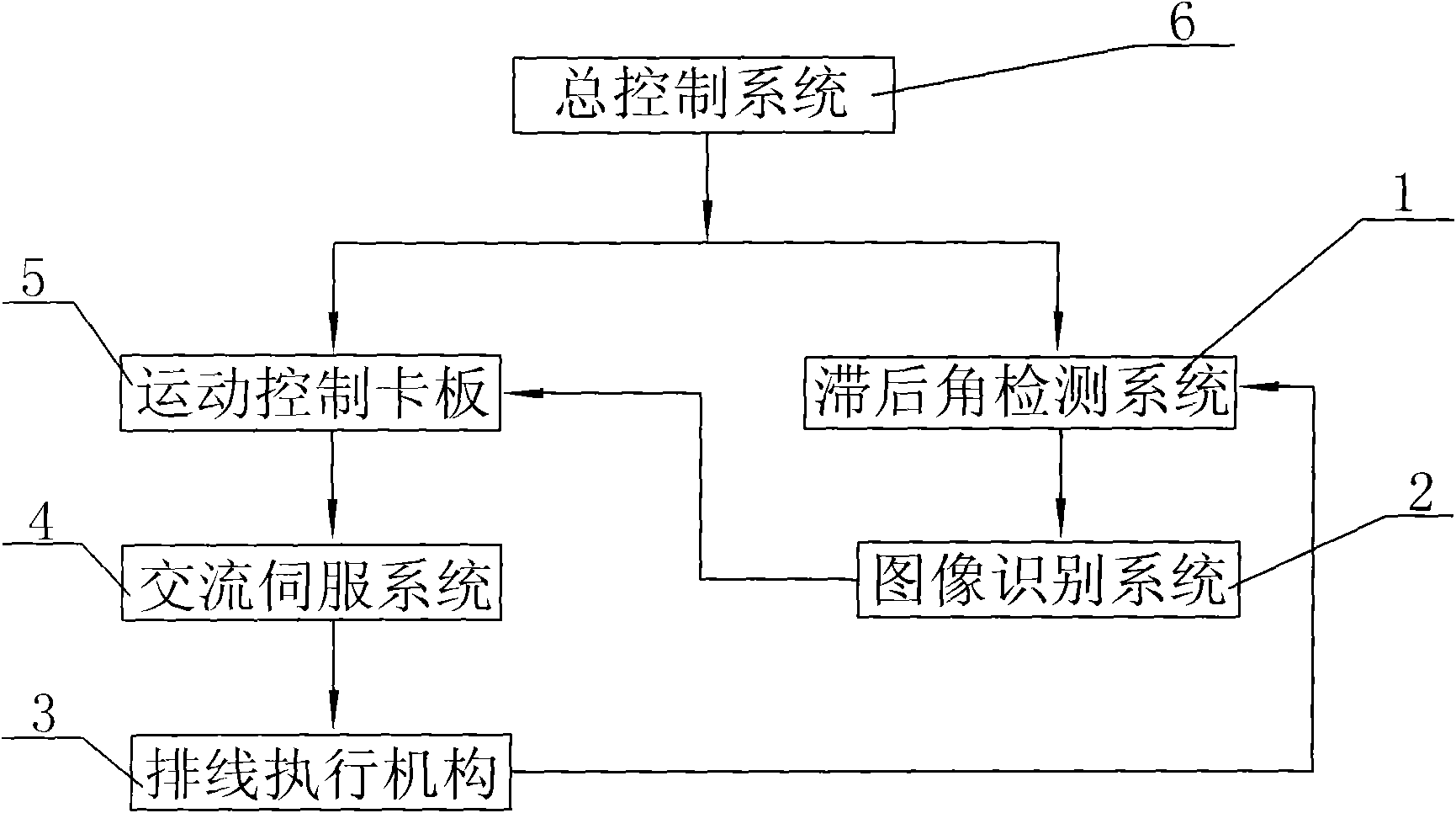

[0014] Such as figure 1 , a lag angle control system in a precision winding device of the present invention includes a precision camera device, a high-speed image processing system, and a precision cable arrangement system, wherein the precision camera device includes a lag angle detection system 1, and the high-speed image processing system Including an image recognition system 2, the precision cable system includes an AC servo system 4 and a cable actuator 3, and the cable actuator 3 is composed of a precision ball screw and a precision linear guide; the lag angle detection system 1 Connect the image recognition system 2 and the wiring actuator 3, and send the detection result to the image recognition system 2, which is then recognized by the image recognition system 2 and then controlled by the computer in the general control system 6. The wiring actuator 3 is connected to the AC servo system 4, and the precision ball screw is controlled by controlling the AC servo system 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com