Gantry type annular container winding machine

A winding machine and gantry-type technology, which is applied in the production field of fiber winding products in annular containers, can solve the problems of grinding yarn and inaccurate positioning, and achieve the effects of high winding precision, precise control of the position of the wire nozzle, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

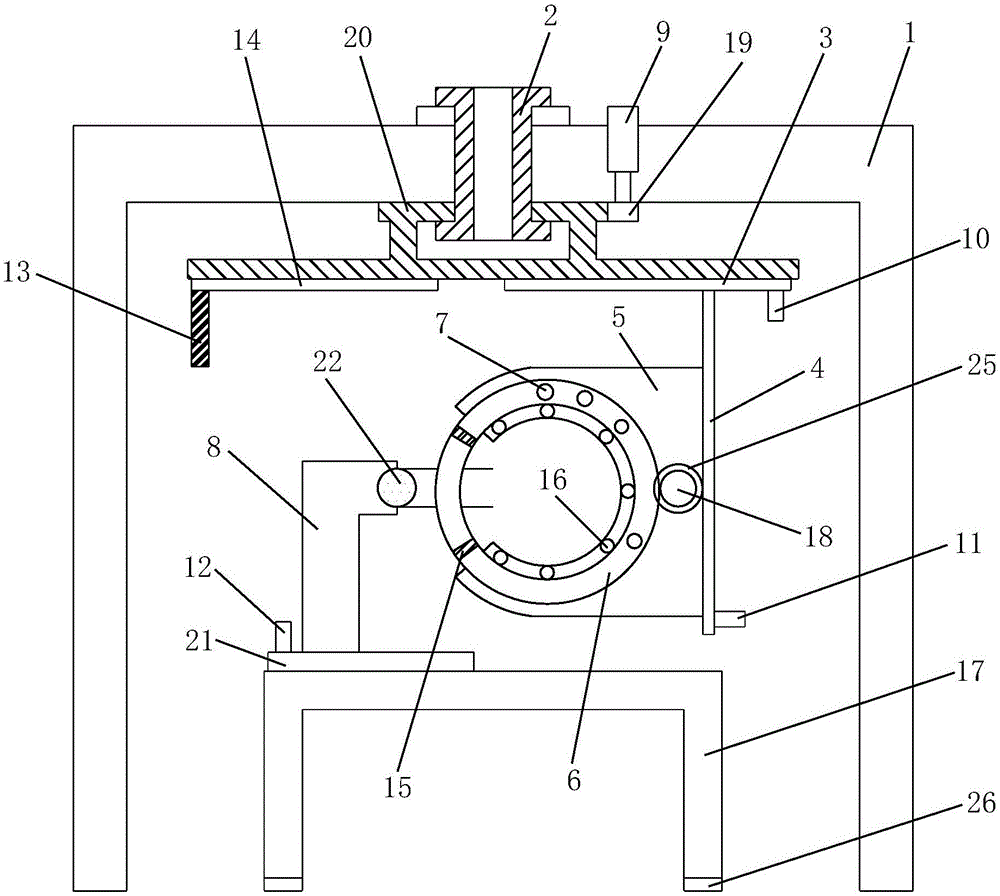

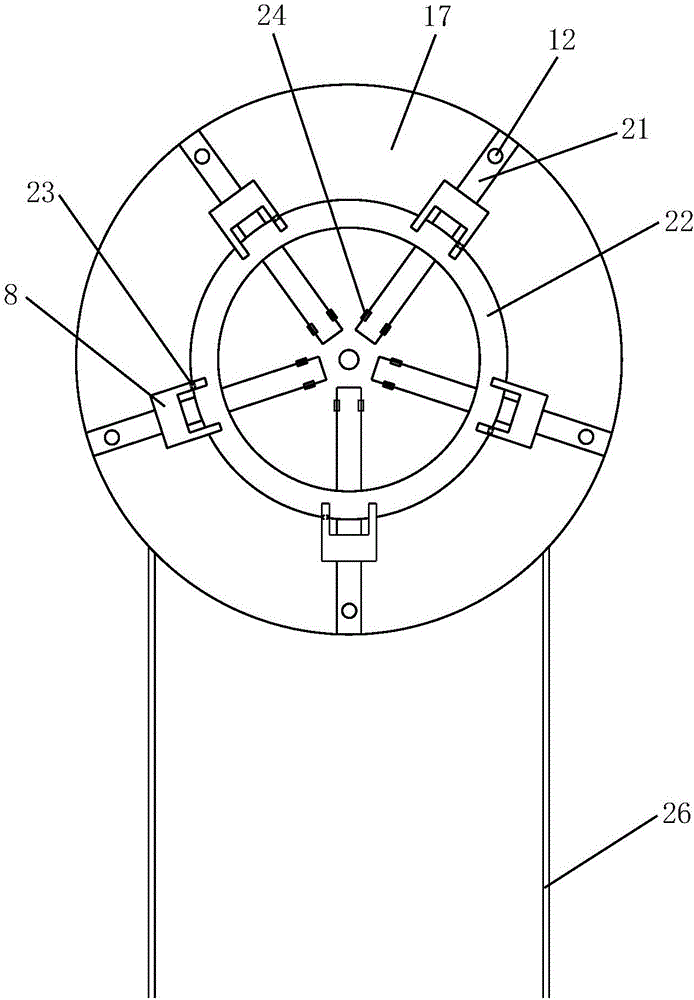

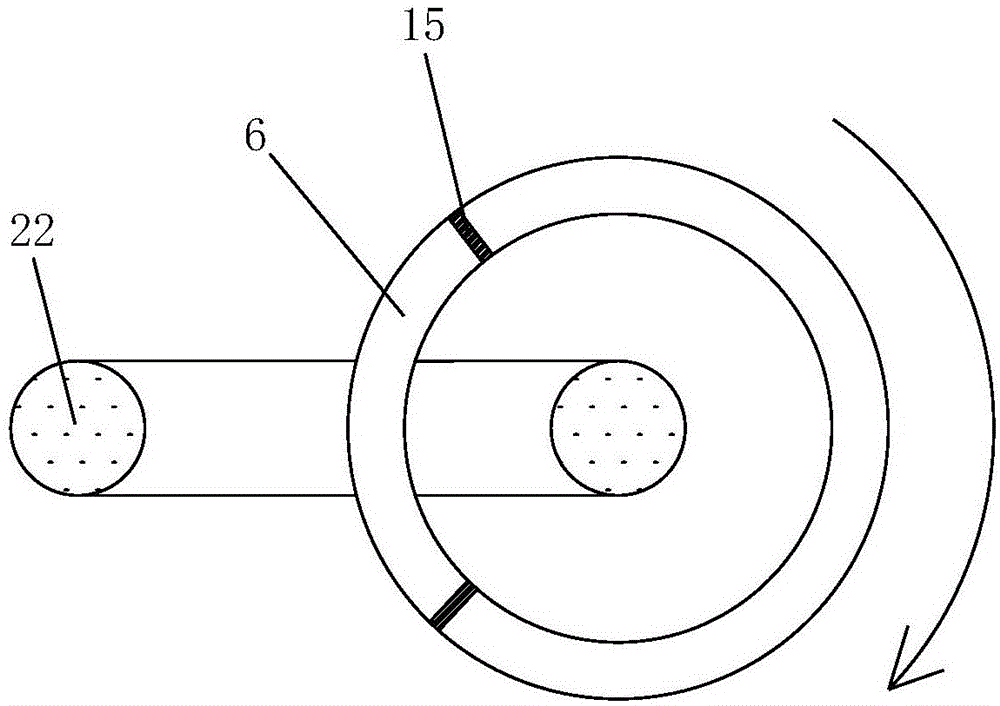

[0036] like figure 1 , image 3 and Figure 4 As shown, the present invention comprises gantry support 1, base 17 and wire mouth support 5, and described base 17 is arranged in gantry support 1, and described silk mouth support 5 is arranged on the top of base 17, and multiple A mandrel clamping device for fixing the annular mandrel 22, the top of the gantry support 1 is equipped with a silk mouth support rotating device for driving the silk mouth support 5 to rotate around the outer circumference of the annular mandrel 22, the silk mouth The support 5 is installed at the bottom of the rotating device of the thread nozzle support, the thread nozzle support 5 is equipped with an annular thread nozzle 6, and the thread nozzle support 5 is equipped with a ring for driving the annular thread nozzle 6 around the annular mandrel 22 cross section A drive mechanism for circumferential rotation, and a yarn guide wheel 7 is installed on the annular yarn nozzle 6 .

[0037] The gantry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com