Automatic horizontal winding machine

A horizontal winding machine, active technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem that the winding distance of the horizontal winding machine cannot be effectively adjusted, and the horizontal winding machine Poor winding effect, inconvenience of horizontal winding machine, etc., to achieve the effect of easy remote control, long life, and avoiding offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

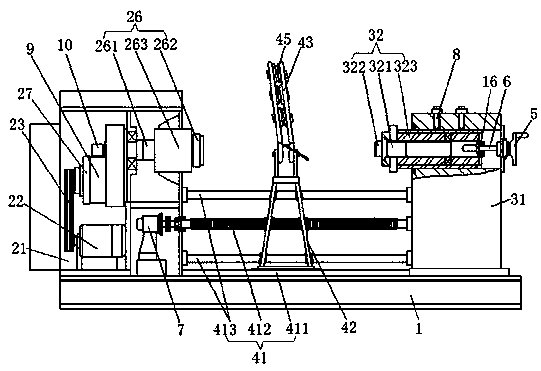

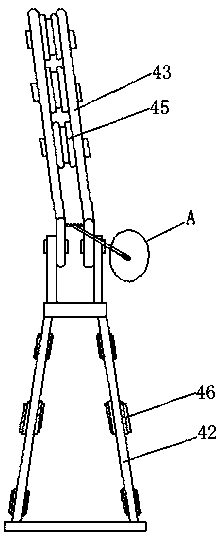

[0025] Such as Figure 1 to Figure 4 As shown, the automatic horizontal winding machine of the present invention includes a workbench 1, a main base 2 and a tailstock 3 symmetrically arranged on both sides of the workbench 1, and a movable set between the main base 2 and the tailstock 3. Wire mechanism 4;

[0026] Described main frame 2 comprises main frame 21, and the reduction motor 22 that is fixed in the main frame 21, and the transmission shaft 24 that is connected with reduction motor 22 through belt 23 transmission, and with transmission shaft 24 through transmission gear set 25 transmission connection connection. Active support 26; the active support 26 includes a transmission main shaft 261, and a main chuck 262 fixed on the end of the transmission main shaft 261; the transmission main shaft 261 is movably installed in the main chassis 21 through a main shaft sleeve 263;

[0027] The tailstock 3 includes a tailstock box 31, and an auxiliary support 32 that is movably...

Embodiment 2

[0036] Such as Figure 5 As shown, the structure of the automatic horizontal winding machine of the present invention is basically the same as that of Embodiment 1, wherein the auxiliary support 32 is fixed in the tailstock box 31 through the positioning assembly 11; the locking assembly 11 includes two-way Screw rod 111, and two bidirectional nuts 112 threadedly connected with bidirectional screw rod 111; a positioning wedge 113 is respectively welded and fixed above each of the bidirectional nuts 112; And it is movably attached to the auxiliary support member 32 ; one end of the two-way screw 111 is movably connected with the tailstock box 31 through the positioning bearing 15 , and the other end passes through the tailstock box 31 and is connected with the positioning hand wheel 12 in transmission.

Embodiment 3

[0038] Such as Figure 6 As shown, the structure of the automatic horizontal winding machine of the present invention is basically the same as that of Embodiment 1, wherein a guide rack 13 is also installed between the drive screw 412 and the guide rod 413 on the lower side; Both sides of the seat 42 are fixed with guide blocks 14 for inserting the guide racks 13; guide teeth run through the guide blocks 14;

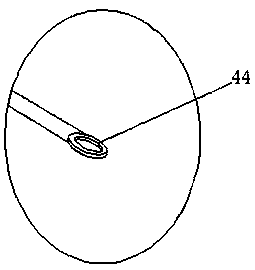

[0039] In the automatic horizontal winding machine of the present invention, during the winding operation, the workpiece to be wound is fixed between the main box and the tailstock through the main chuck and the auxiliary chuck, and then the wire is passed through the guide ring on the lead frame , and guided by the U-shaped grooved wheel to the workpiece, and fixedly bonded to the workpiece; start the deceleration motor and power motor, the deceleration motor drives the transmission shaft to rotate through the belt, and drives the transmission spindle connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com