Fiber reinforced composite material ring test sample winding device

A composite material and fiber reinforced technology, which is applied in the field of fiber-reinforced composite material annular sample winding device, can solve the problems of high cost, high use cost, and reduced production efficiency of large-scale winding machines, and achieves stable and reliable winding process and high degree of mechanization. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

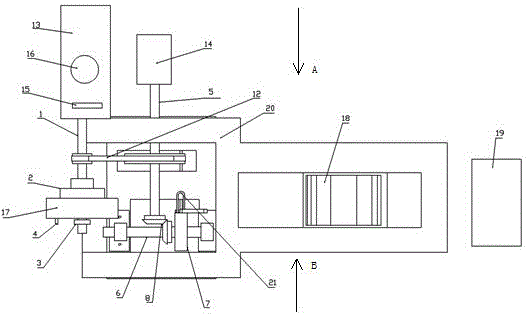

[0022] Embodiments Improve a fiber-reinforced composite ring sample winding device, which has the advantages of low production cost, easy operation, light weight and convenience, and can meet the requirements of winding high-performance ring samples of a certain size for testing. The device is suitable for the preparation of various fiber-reinforced composite material ring samples such as carbon fiber, glass fiber, and aramid fiber.

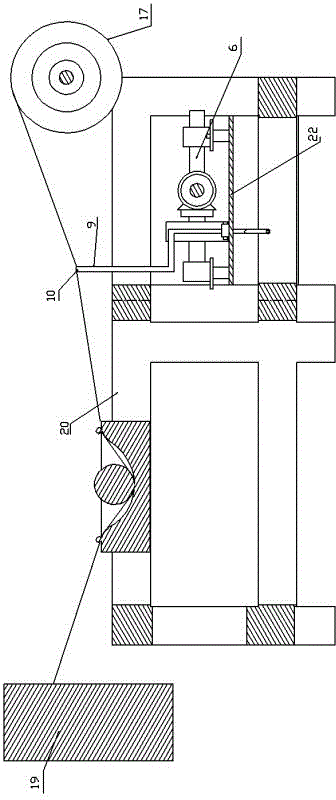

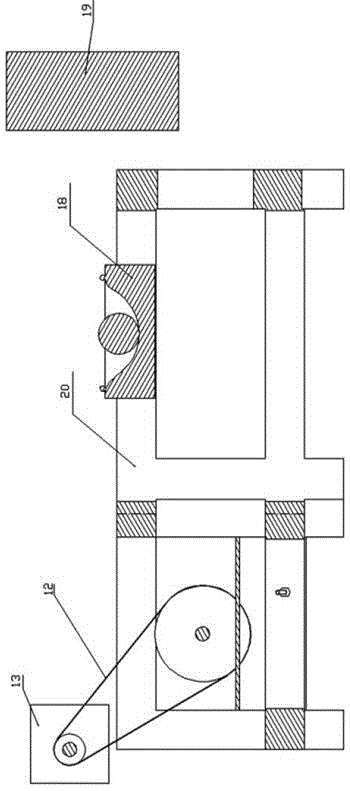

[0023] This fiber-reinforced composite ring sample winding device includes a mold 17 and a ring sample winding mechanism, the mold 17 is used for sample forming, and the ring sample winding mechanism includes a stepless variable speed motor 13, a main shaft 1, a mold positioning assembly, a transmission assembly, Yarn guide components such as figure 1 , figure 1 is the top view of the device. The positioning of the mold 17 is realized by the mold positioning assembly, and the rotation of the mold 17 is driven by the main shaft 1 , and the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com