Continuous fiber self-reinforcing gradient lamination board and preparation method thereof

A continuous fiber and gradient layer technology, applied in the field of continuous fiber self-reinforced gradient laminate and its preparation, can solve problems such as difficulty in realization and lack of research, and achieve the effects of improving winding accuracy, saving time, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Single-layer board preparation: 10 kinds of single-layer boards with different volume percentages ranging from 11% to 50% were prepared by using cotton yarn shaking blackboard according to the density of shaking yarn;

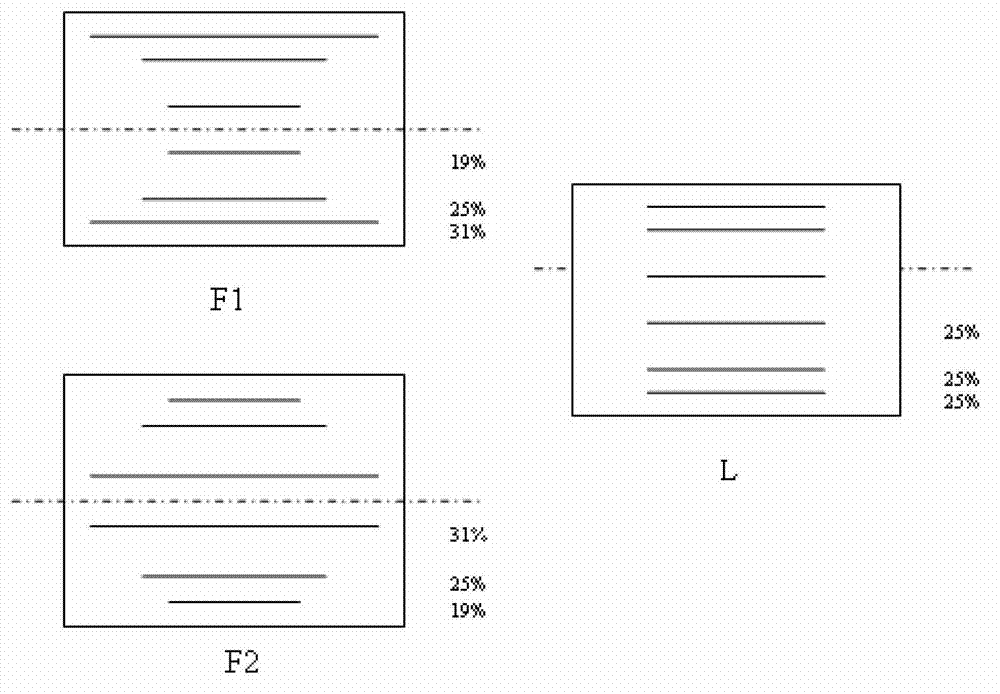

[0028] 2. After optimization analysis, the volume content of single layer is selected as: 19% (1#), 25% (2#), 31% (3#)

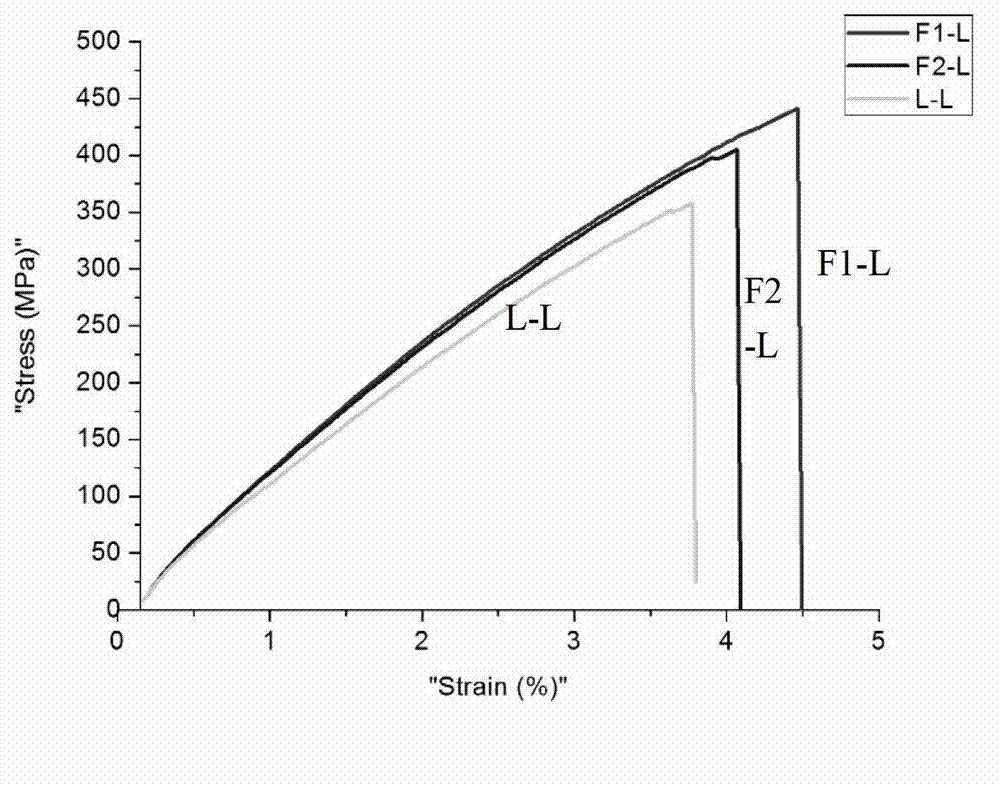

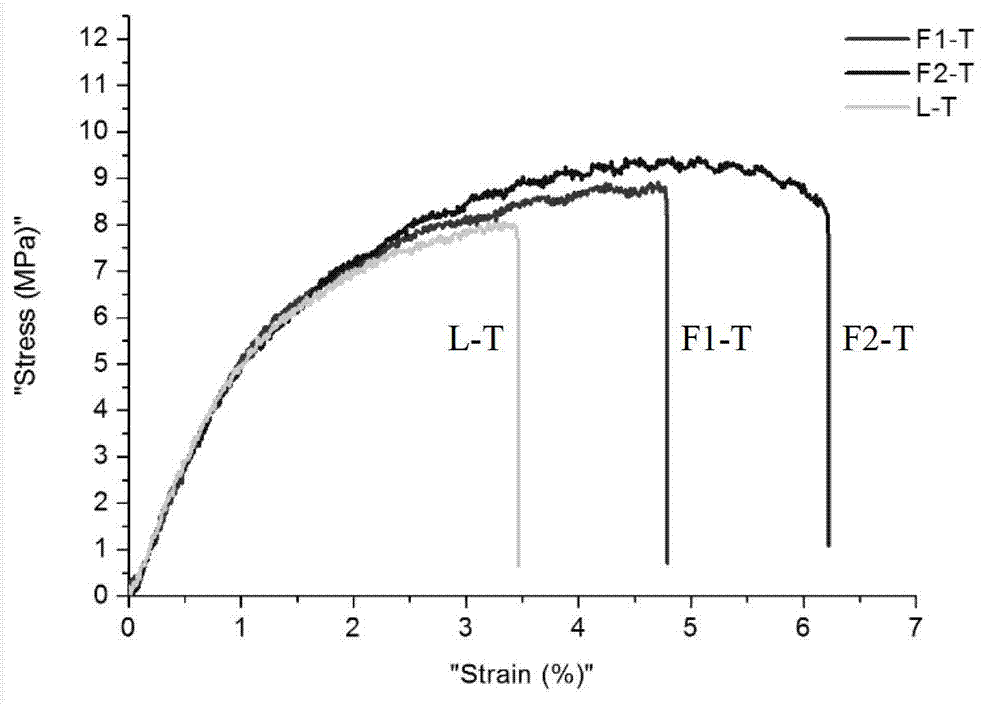

[0029] Gradient laminates with two gradient directions were prepared, F1: [3# / 2# / 1#] s and F2:[1# / 2# / 3#] s , and prepared a common laminate (L: [2#] 6s ) for comparative tests (see the diagram for the structure of the gradient laminate figure 1 ). Prepare 5 samples of each type, perform the mechanical test according to GB / T1447-2005, and take the average value of 5 experiments. Specific steps are as follows:

[0030] Step 1: Filament Winding

[0031] 1>Use the cotton yarn shaking blackboard machine to evenly wind the fibers on the 1-3mm thick steel plate;

[0032] 2> Change the fiber winding density by adjusting the spinning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com