Bifilar winding system for manufacture of nuclear fusion polar field superconducting magnets

A technology of superconducting magnets and poloidal fields, which is applied in the manufacture of inductors/transformers/magnets, thermonuclear fusion reactors, and coils. It can solve problems such as limited experience in production line design, and achieve high winding precision and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

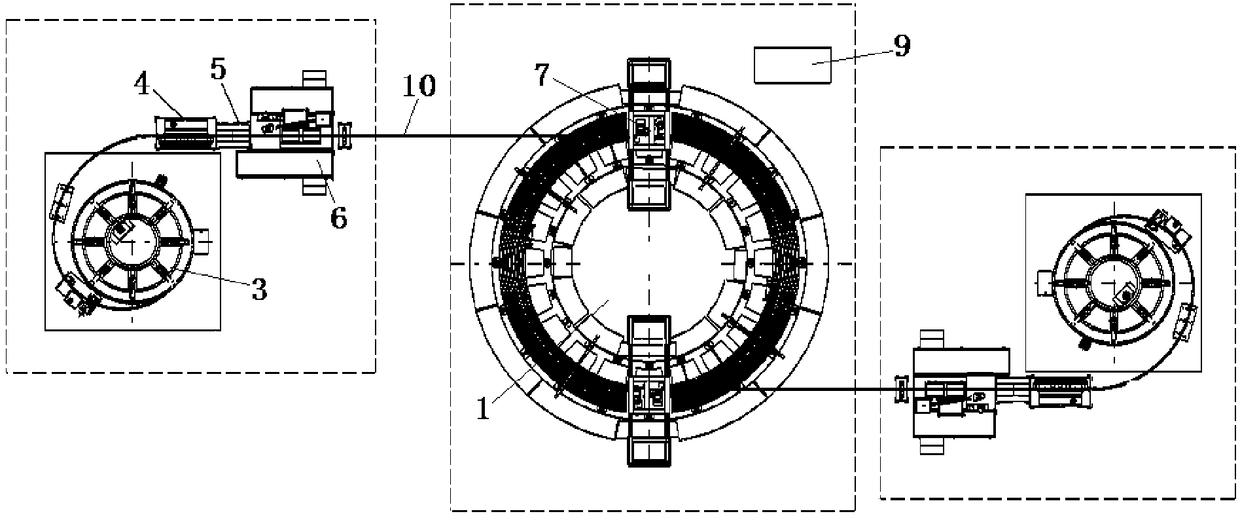

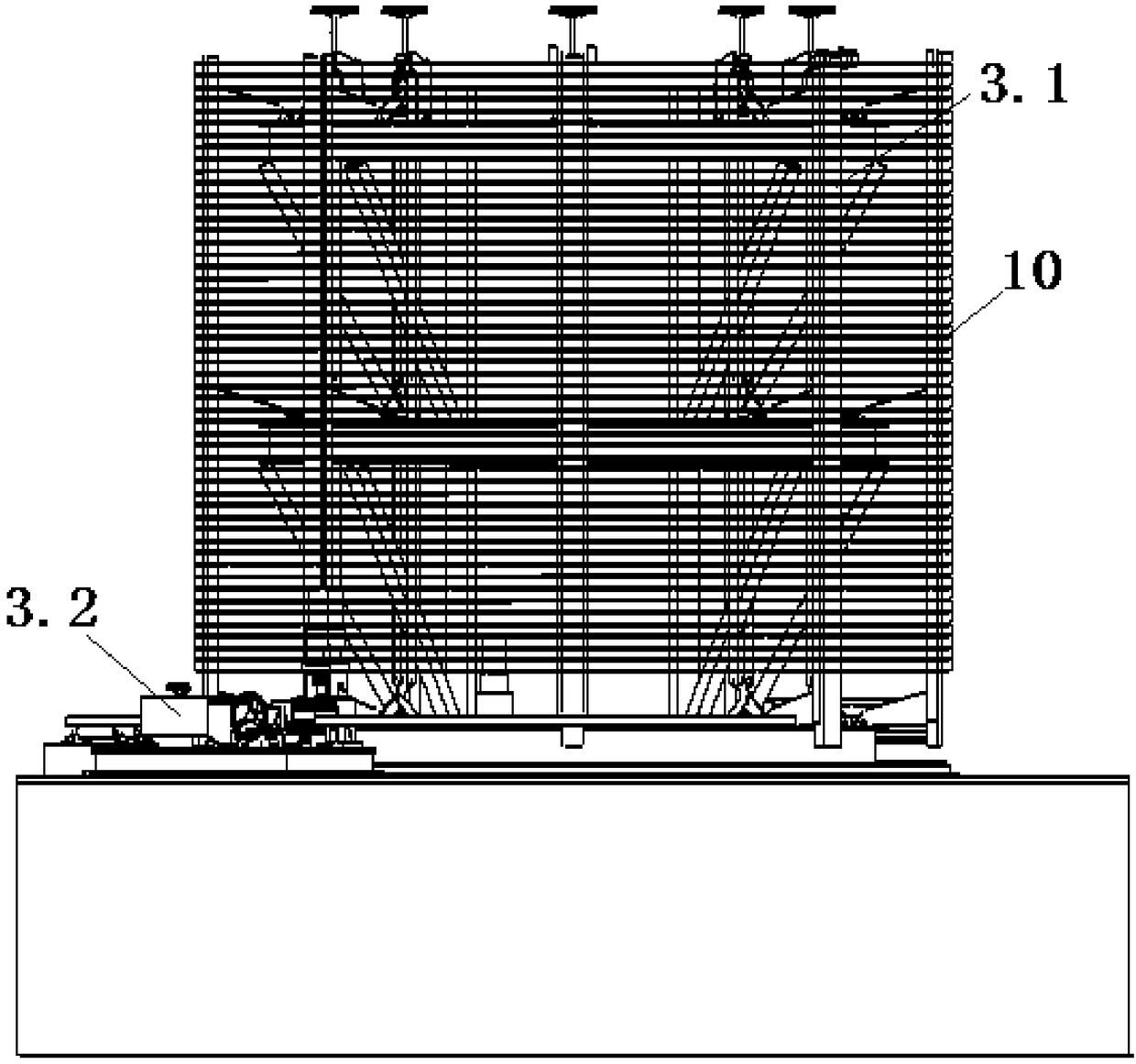

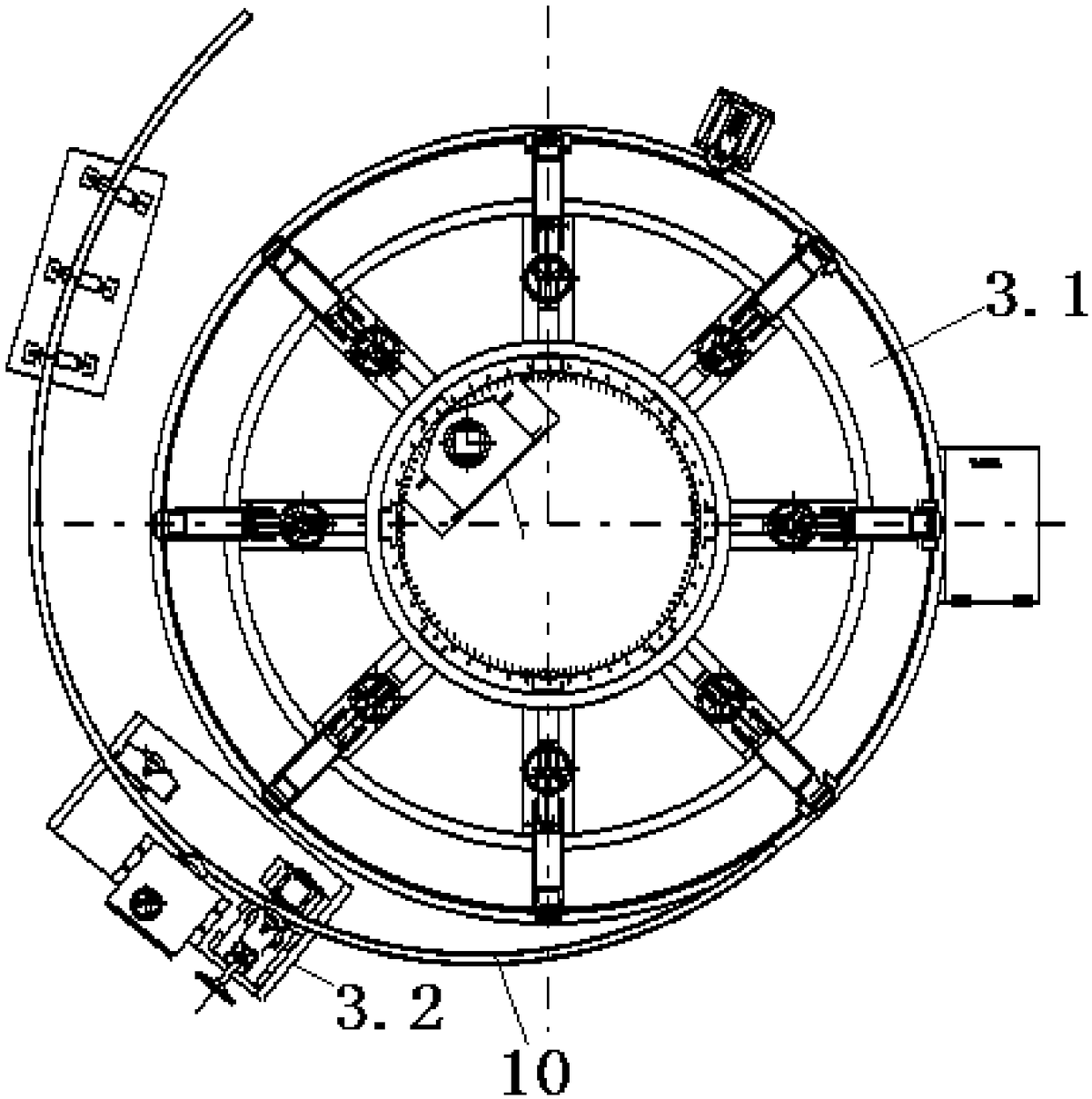

[0026] Such as figure 1 As shown, a double-wire parallel winding system for the manufacture of nuclear fusion poloidal field superconducting magnets includes two completely symmetrical superconducting coil winding production lines, as well as a rotary platform 1, a drop mold tooling 2 and a winding mold; Each superconducting coil winding production line is composed of conductor feeding equipment 3, straightening machine 4, ultrasonic cleaning machine 5, sand blasting cleaning machine 6, bending forming machine 7, and inter-turn insulation tape wrapping machine 8. The bending forming machine 7 and the inter-turn insulation tape wrapping machine 8 in the coil winding production line are respectively arranged on the rotary platform 1, and the die tooling 2 and the winding mold are also arranged on the rotary platform 1; during the coil winding process, each The conductor delivery equipment 3 in the superconducting coil winding production line releases the superconducting conducto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Straightness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com