Robot filament winding work station

A robot and workstation technology, applied in the field of robot filament winding workstations, can solve the problems of disordered lines in the on-site control cabinet, inconvenient loading and unloading of core molds, and low production costs, achieving good axial mechanical properties, saving raw materials, and smooth and stable line shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

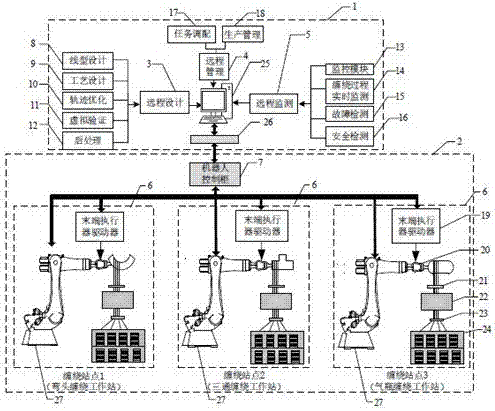

[0024] Attached below figure 1 The present invention is further described with specific embodiment:

[0025] A robotic fiber winding workstation, which consists of a remote control platform 1 and a fiber winding robot group 2, characterized in that the remote control platform 1 includes remote design 3, remote monitoring 5 and remote management 4, as well as a computer 25 and a switch 26 , the fiber winding robot group 2 includes at least one fiber winding robot 6 and a field control cabinet 7 of the fiber winding robot; between the remote control platform 1 and the field control cabinet 7 of the fiber winding robot, data is converted through a switch 26 and transmitted via Ethernet To transmit data; according to the needs of fiber winding, the remote control platform 1 sends control commands to the field control cabinet 7 through Ethernet, and the end effector driver 19 drives the end effector 20 with a three-jaw chuck to pick up the corresponding mandrel. Corresponding fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com