Method for controlling operations of shaker of computerized flat knitting machine

A technology of computerized flat knitting machine and control method, which is applied in the direction of electrical program control and digital control, etc. It can solve the problems of knitting clothes leaving defects, computerized flat knitting machine can not complete the pattern, and the shaking table is not accurate enough, so as to avoid the deviation of turning stitches , Solve the effect of unstable shaking table precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

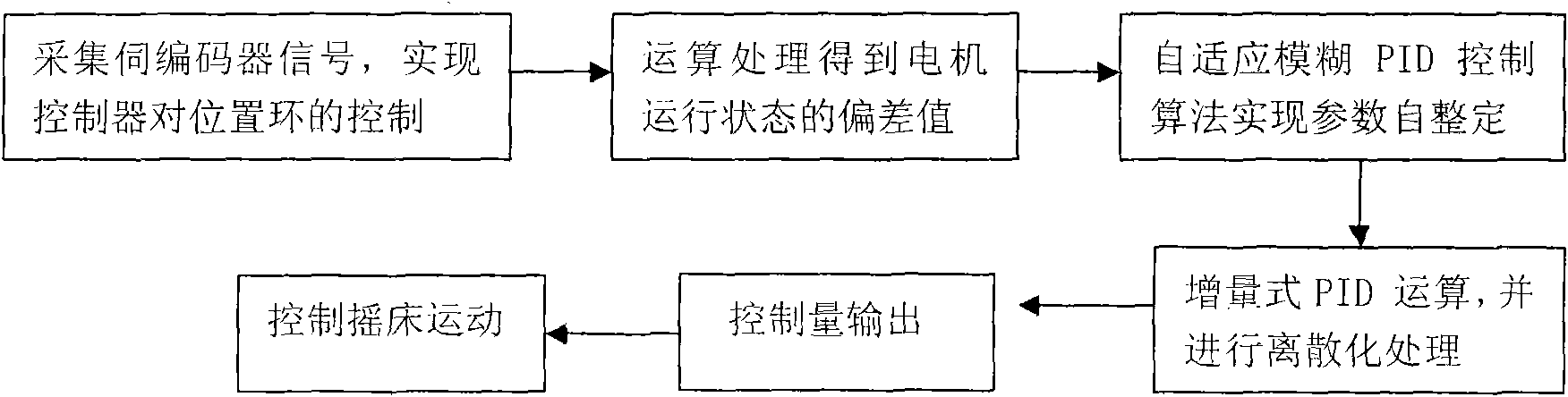

[0017] refer to figure 1 : the control method that computerized flat knitting machine shaker operation of the present invention comprises the following steps:

[0018] (1) Collect the information of the real-time operation of the servo motor; use the photoelectric encoder to monitor the actual displacement of the shaking table;

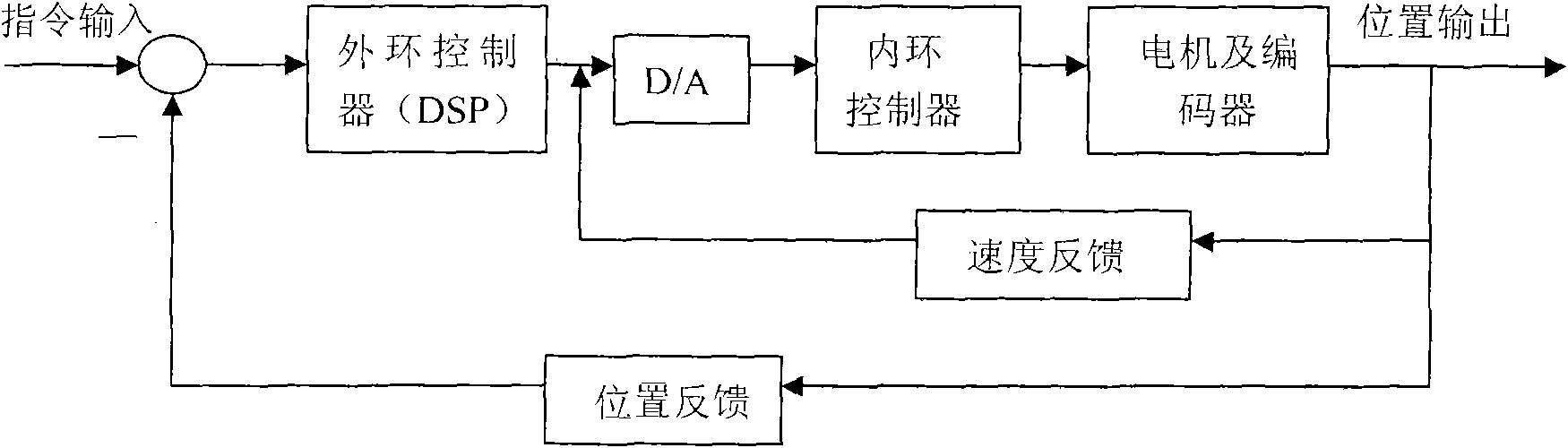

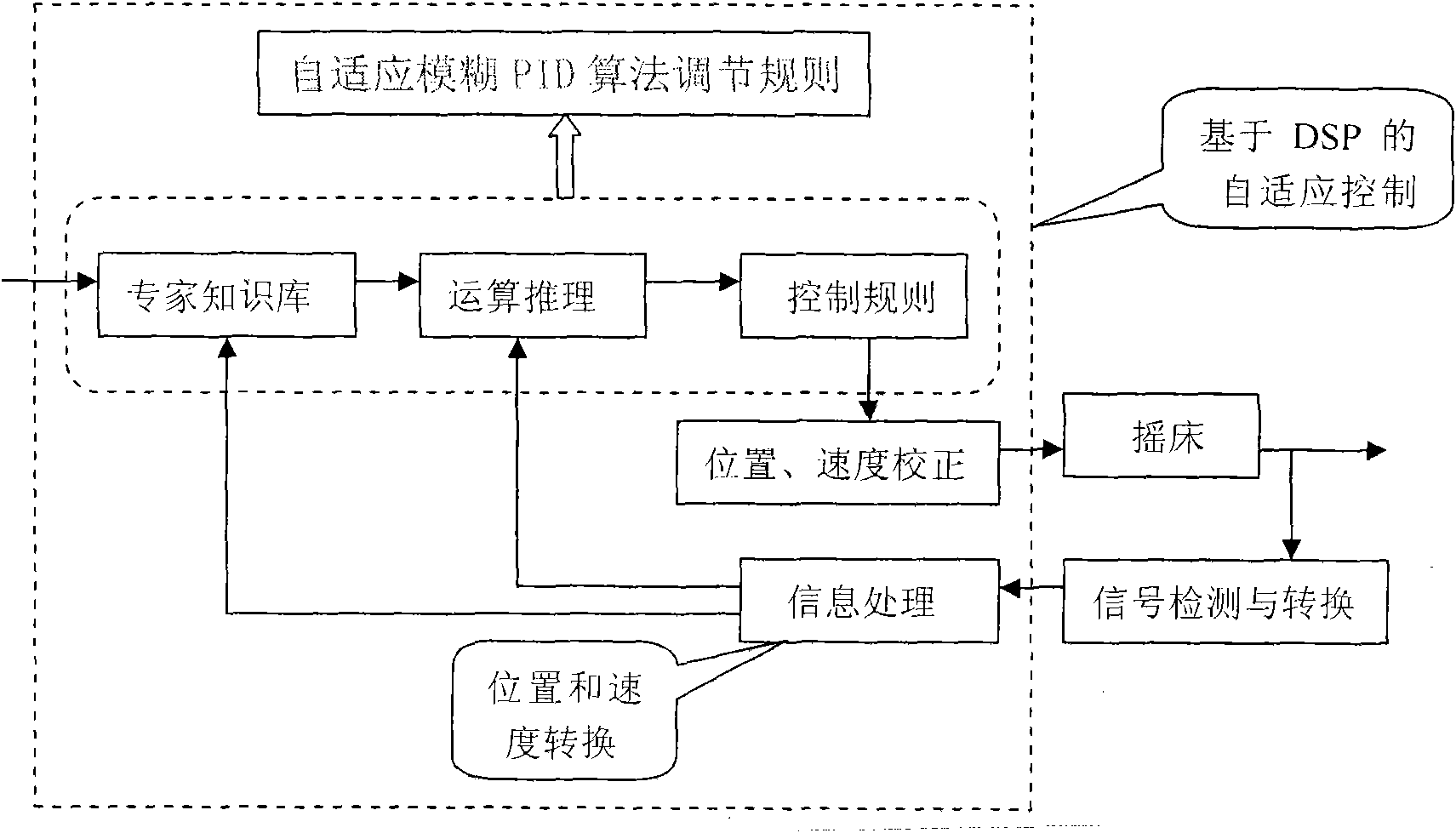

[0019] (2) Input the obtained servo motor operation information into the information processor for calculation and processing; send the actual displacement value of the shaking table movement to the DSP to compare with the given value to generate position deviation e and deviation change rate ec;

[0020] (3) Use the fuzzy PID control algorithm of the adaptive control method to calculate the deviation value in step (2), obtain the current correction data, and input the correction data into the program controller; adopt the method of fuzzy reasoning to realize the parameters Kp, Ki, Kd The online self-tuning of PID parameters, that is, the fuzzy self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com