Patents

Literature

34 results about "Fuzzy self tuning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

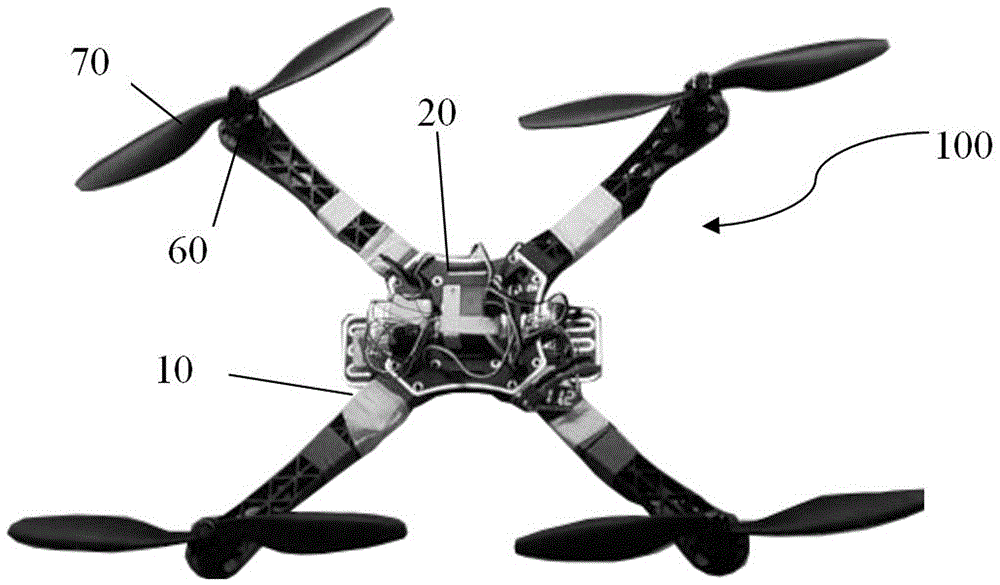

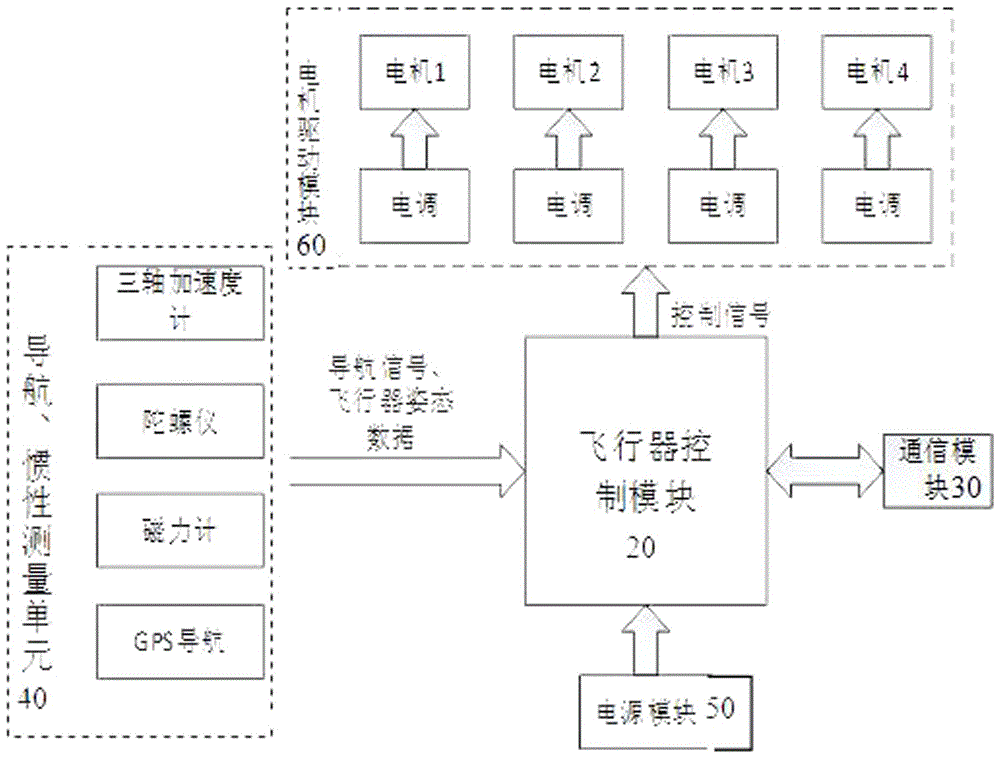

A quadrotor aircraft and a control method thereof

ActiveCN106094860AAchieve attitude controlRealize self-tuningAttitude controlPosition/course control in three dimensionsMotor driveFlight vehicle

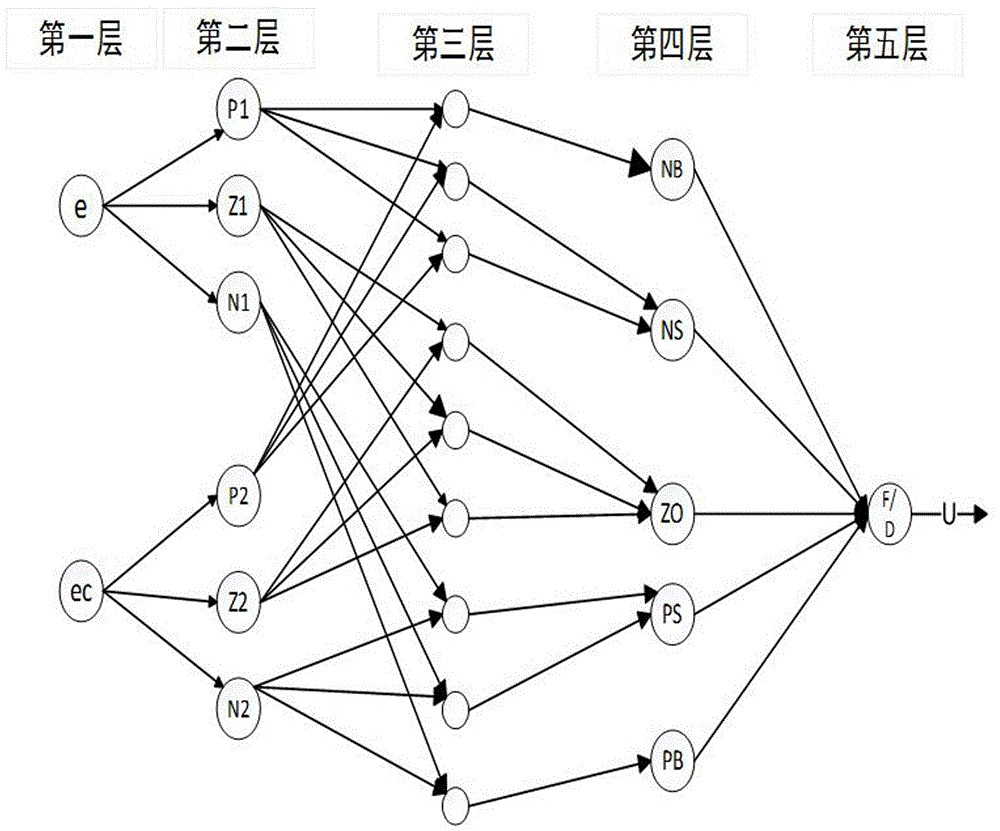

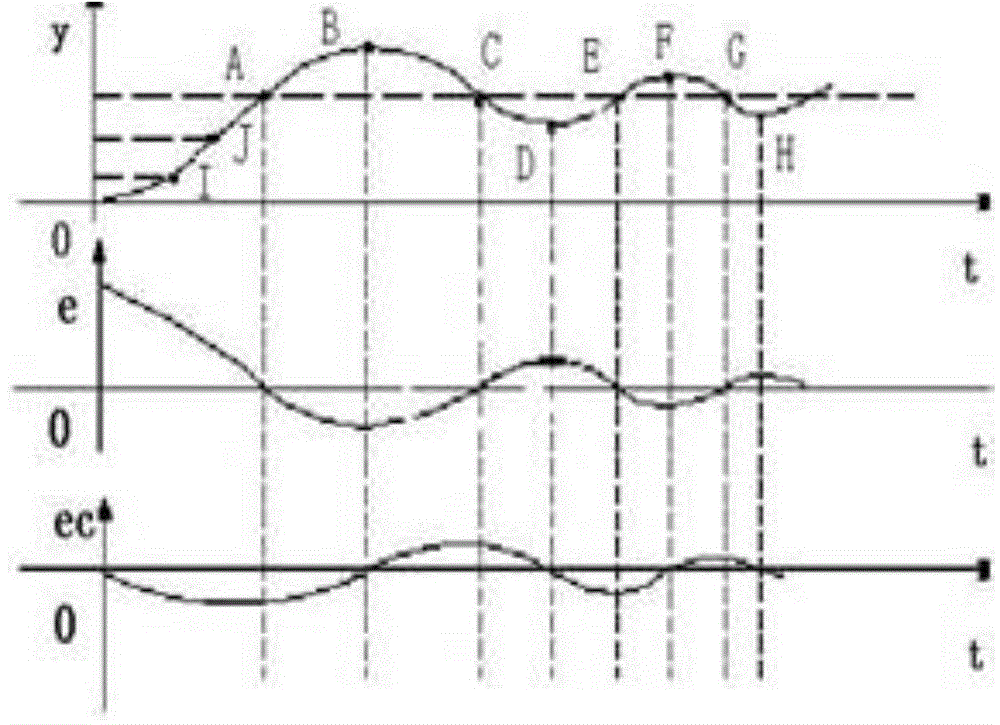

The invention provides a quadrotor aircraft and a control method thereof. The quadrotor aircraft includes a body and an aircraft control module, and a navigation and inertial measurement module, a power module, a communication module and a motor drive module separately connected with the aircraft control module. The main controller module performs synthesis calculation of real-time flight attitude information and control information of the communication module fed back by the navigation and inertia measurement module to output motor control signals to control the motor drive module. The quadrotor aircraft of the invention can automatically adapt to changes of the external environment to modulate flight parameters to reach a predetermined control effect. In the control method, the flight controller module adopts a nerve-based fuzzy self-tuning PID control scheme to calculate a practical output variable to improve robustness of flight of the aircraft.

Owner:GUANGXI NORMAL UNIV

Method and system for self-adjusting fuzzy PID (Proportion Integration Differentiation) parameters in furnace temperature control system

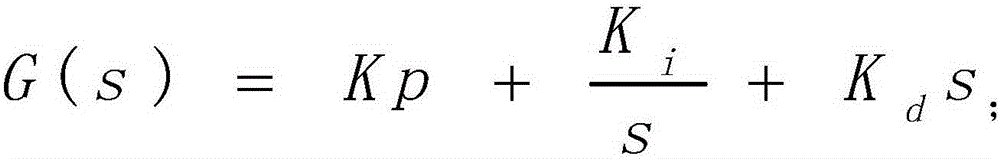

InactiveCN104808708AImprove qualityTemperatue controlAdaptive controlFurnace temperatureDifferential coefficient

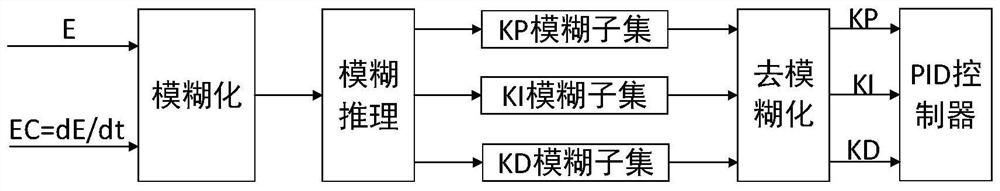

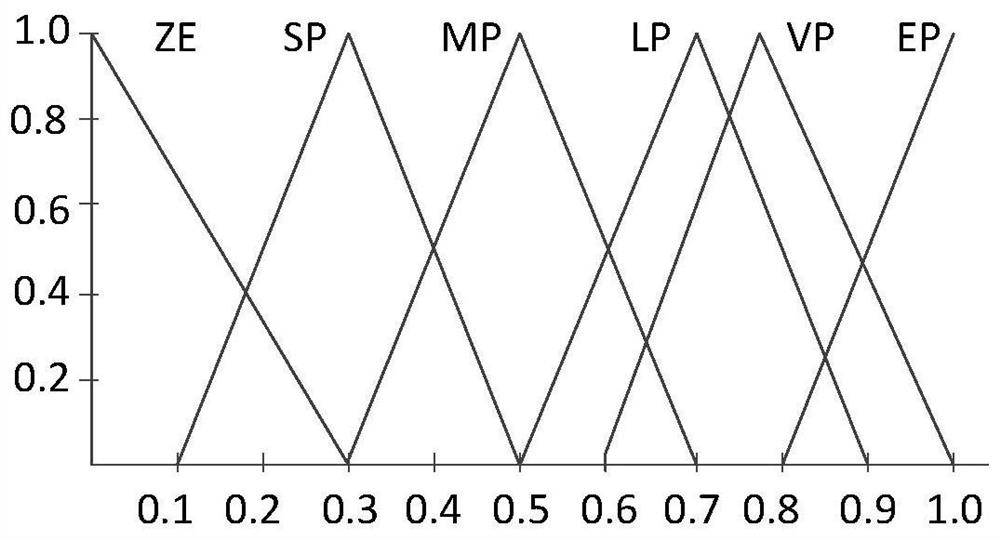

The invention provides a method and a system for self-adjusting fuzzy PID (Proportion Integration Differentiation) parameters in a furnace temperature control system. The method comprises the following steps: selecting and quantifying variables in a PID controller and finding out a fuzzy relation of three PID control parameters including a proportionality coefficient KP, an integral coefficient KI and a differential coefficient KD , and system deviation e and a deviation varying rate ec; establishing a fuzzy relation table; and carrying out online modification on the three parameters by a fuzzy control method. The system corresponds to the method. After PID parameter online fuzzy self-adjustment is carried out, a normal working state is automatically switched, and a PID parameter adjusting process is automatically started when system performances are changed and the readjusted PID parameters so that the system has the better control quality.

Owner:CHONGQING TECH & BUSINESS INST

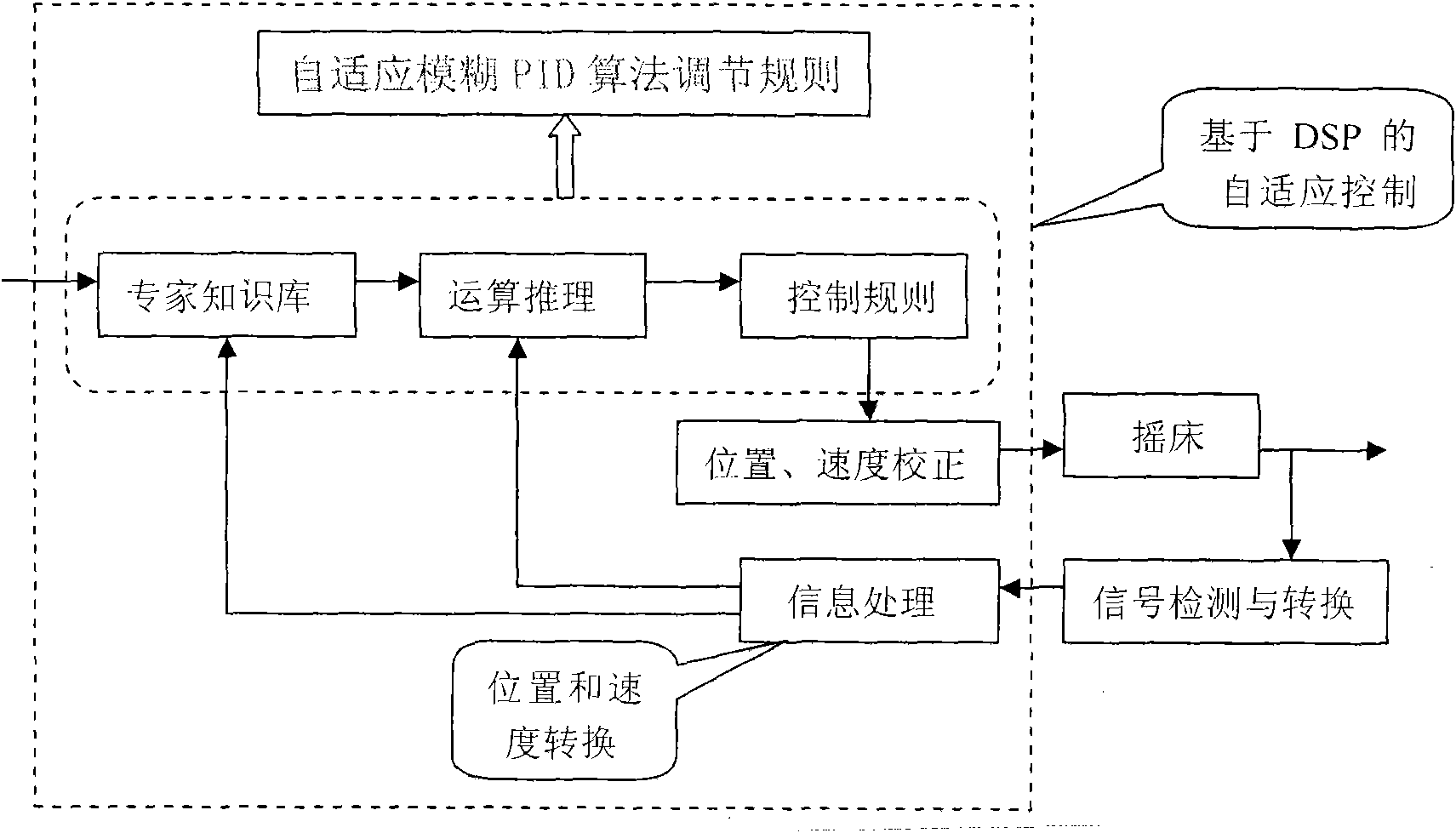

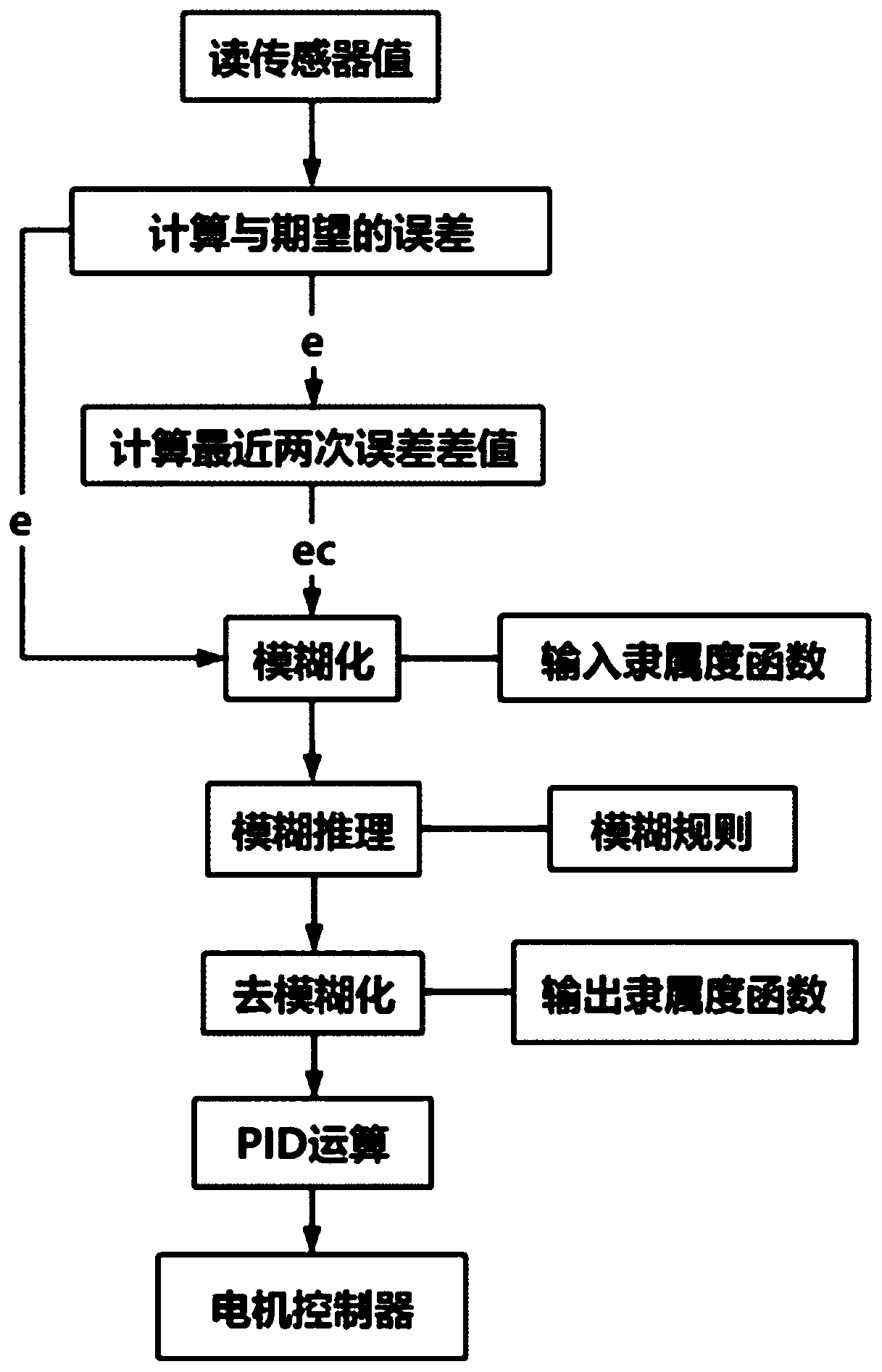

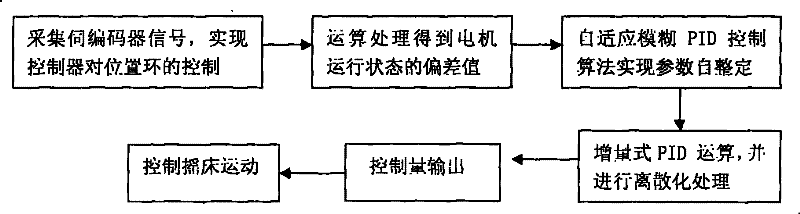

Method for controlling operations of shaker of computerized flat knitting machine

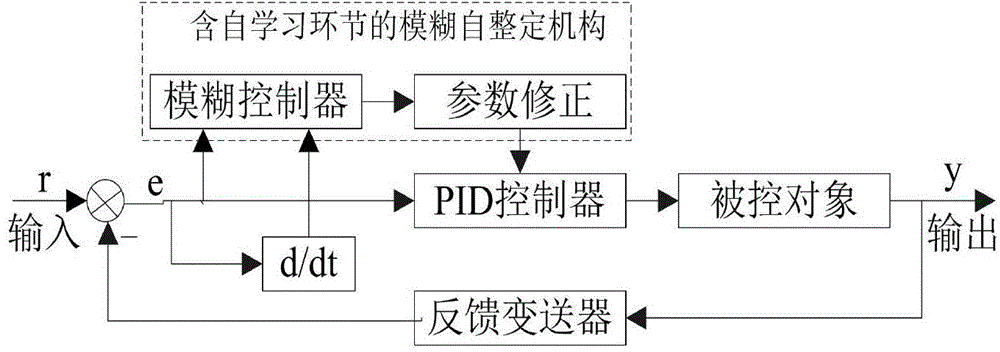

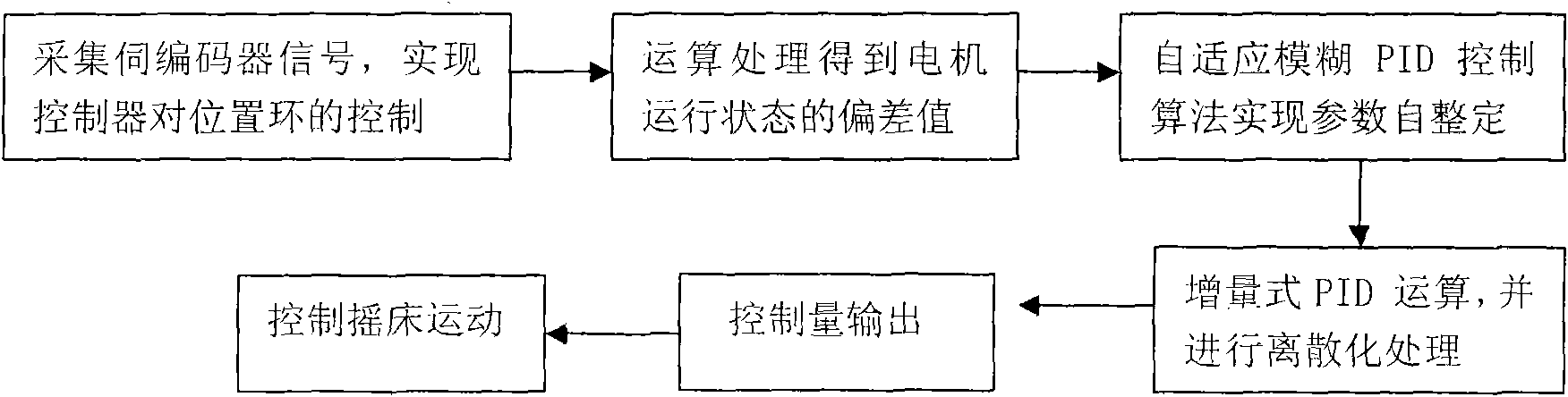

InactiveCN101655704AAutomatically correct running errorsRun accuratelyNumerical controlFuzzy pid controlPid control algorithm

The invention belongs to the technical field of computerized flat knitting machines, in particular to a method for controlling operations of a shaker of a computerized flat knitting machine. The method comprises the following steps: collecting real-time operation information of a servo motor; inputting the obtained operation information of the servo motor into an information processor to calculate; calculating an offset value in the step (2) by adopting an adaptive fuzzy PID control algorithm so as to obtain current revised data and then inputting the revised data into a program controller; calculating current Kp, Ki and Kd values by utilizing a fuzzy self-tuning rule and carrying out discretization processing through an incremental PID calculation; and outputting control signals to the servo motor by the program controller according to a control program to realize the automatic operation error correction and the precise operation control of the shaker. The invention can avoid needle transferring and connecting deviations and ensure that the computerized flat knitting machine works in an optimal state all the time, thereby solving the problem of unstable precision of the shaker inan operation process of the computerized flat knitting machine.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

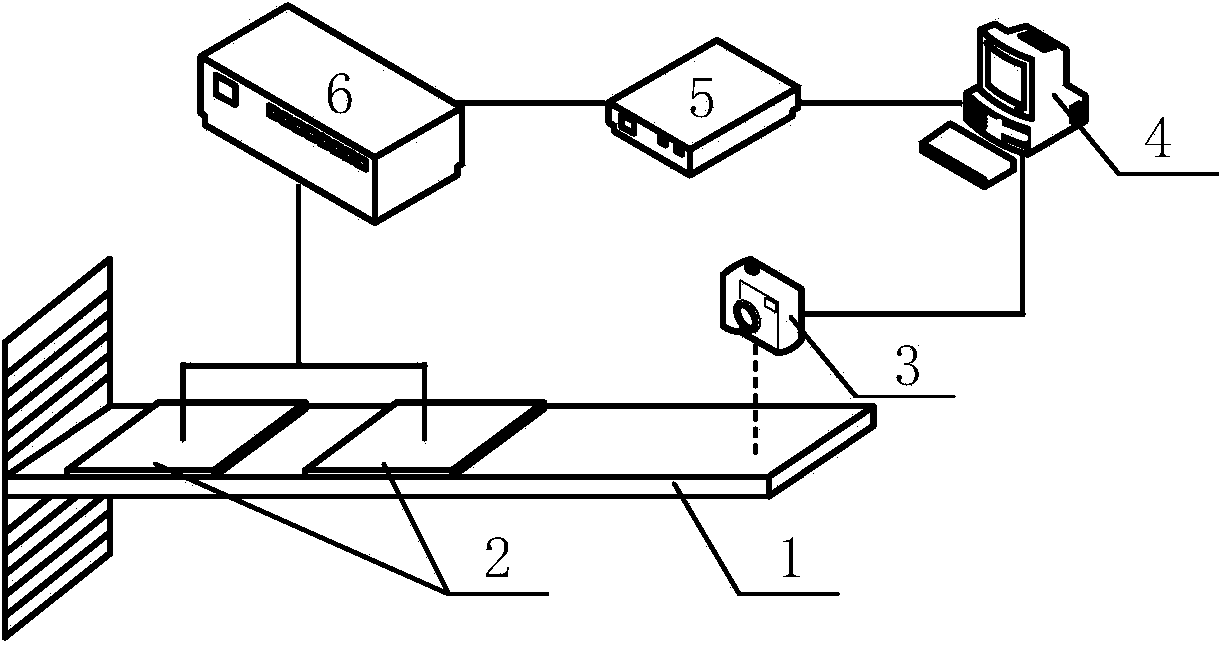

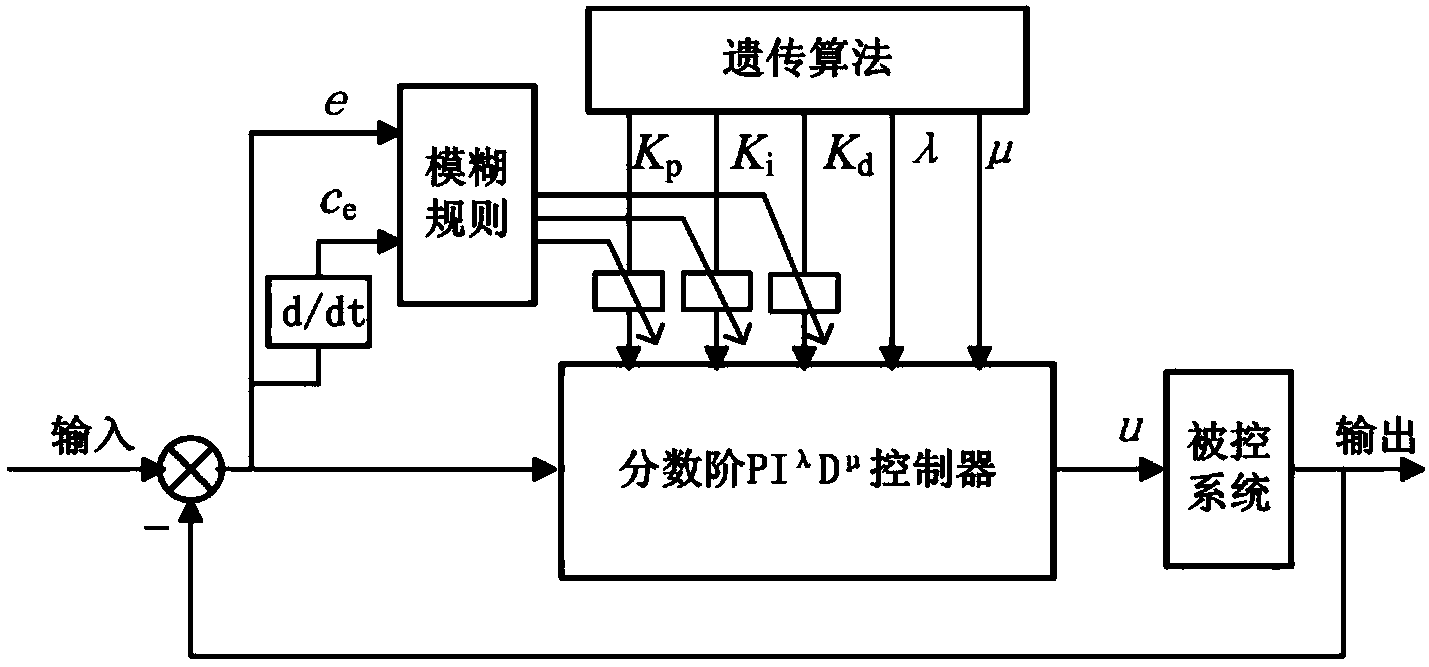

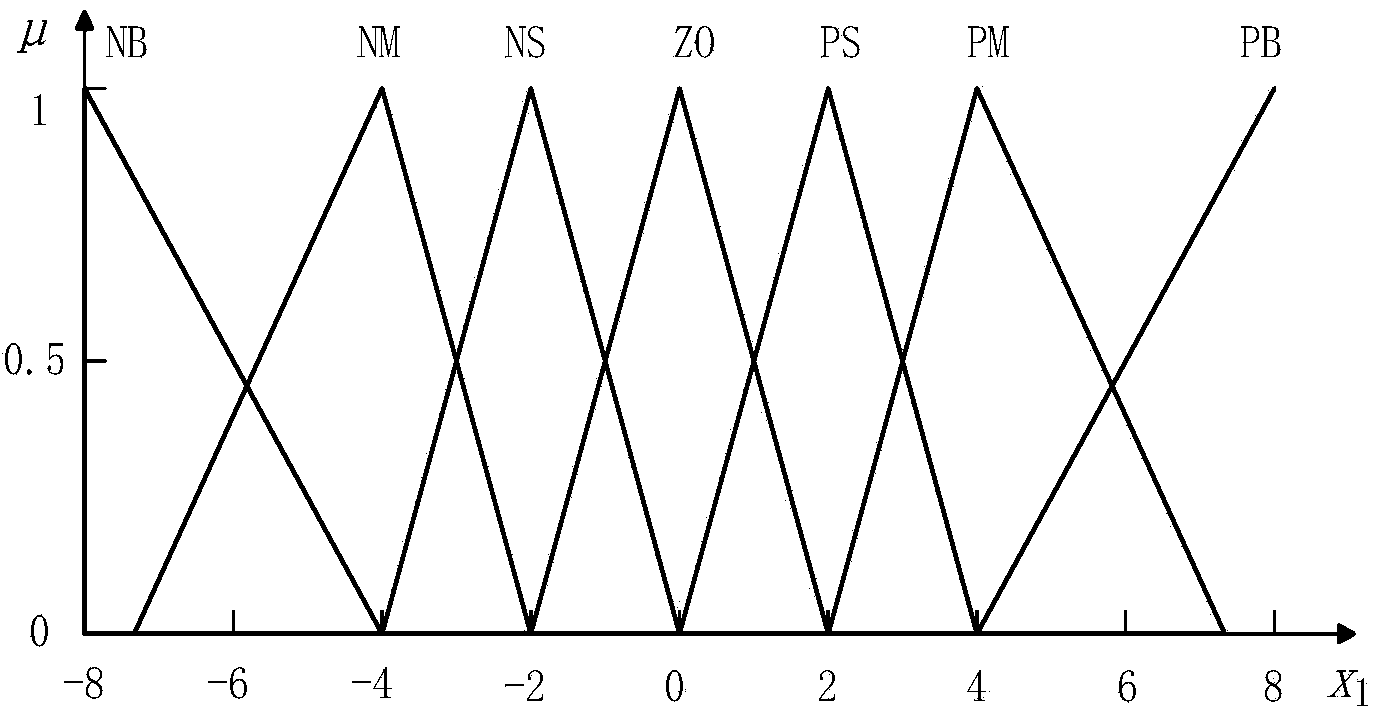

Active chattering control method for flexible cantilever beam structure

InactiveCN103869702AImprove flexibilityEasy to processGenetic modelsAdaptive controlGenetic algorithmFuzzy self tuning

The invention belongs to the field of active chattering control of a beam structure, and relates to an active chattering control method for a flexible cantilever beam structure. The active chattering control method comprises the following steps: establishing a fussy control rule according to a large quantity of simulation experiments and parameter adjusting rules; optimizing five parameters by using a fuzzy self-tuning fractional order PIlambdaDmu controller based on a genetic algorithm by means of the genetic algorithm; encoding the initial parameter of the fractional order PIlambdaDmu controller in a real number encoding way, and determining the value range of each parameter. A piezoelectric composite material is taken as an actuator, so that the actuator has high flexibility, machining performance and sensitivity, and can be applied to curved structures. The advantages of memory and accuracy of fractional order PIlambdaDmu control as well as the advantages of flexibility and robustness of fuzzy control are utilized fully, so that an optical control effect is achieved.

Owner:DALIAN UNIV OF TECH

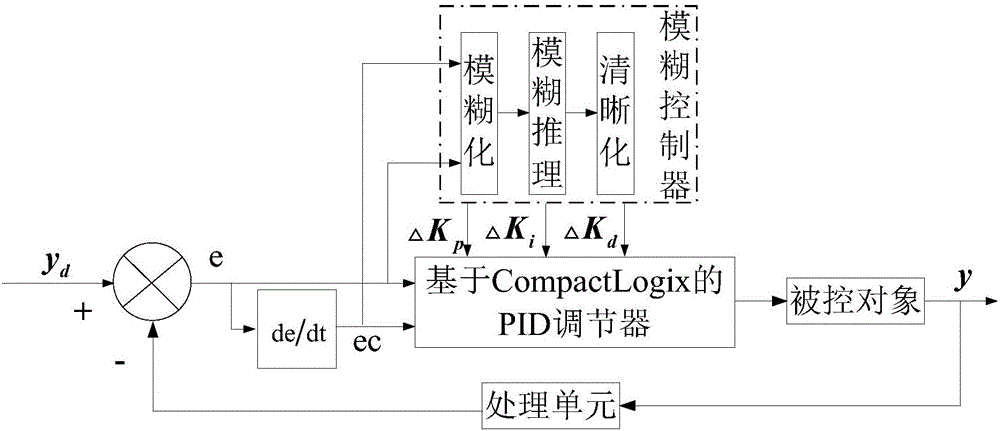

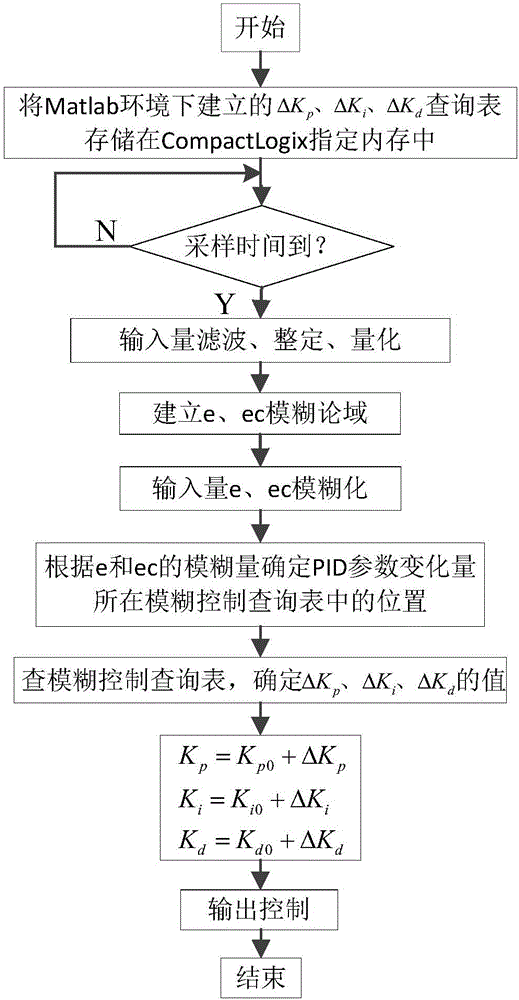

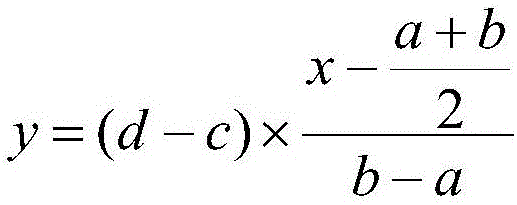

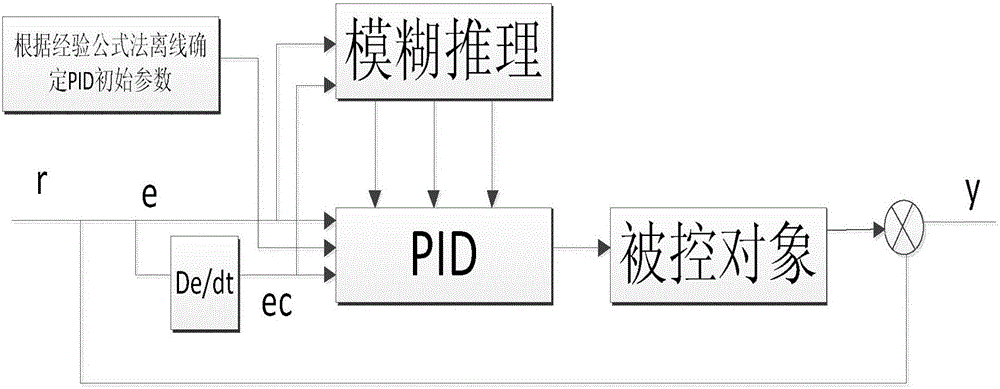

CompactLogix-based fuzzy self-tuning PID liquid level control method

InactiveCN106647832AEasy to set upControl liquid level with high precisionLevel controlValue setOptimal control

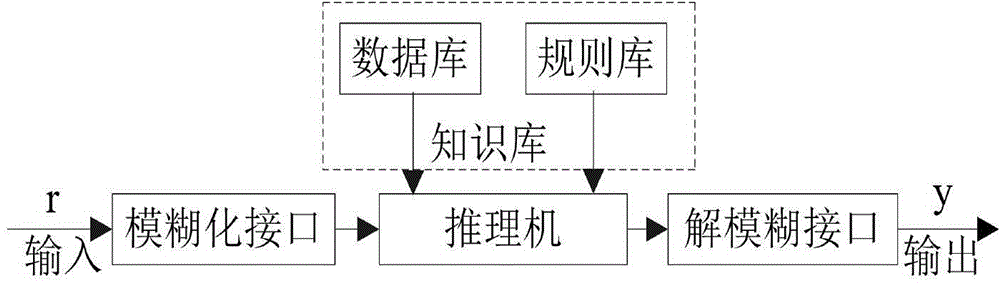

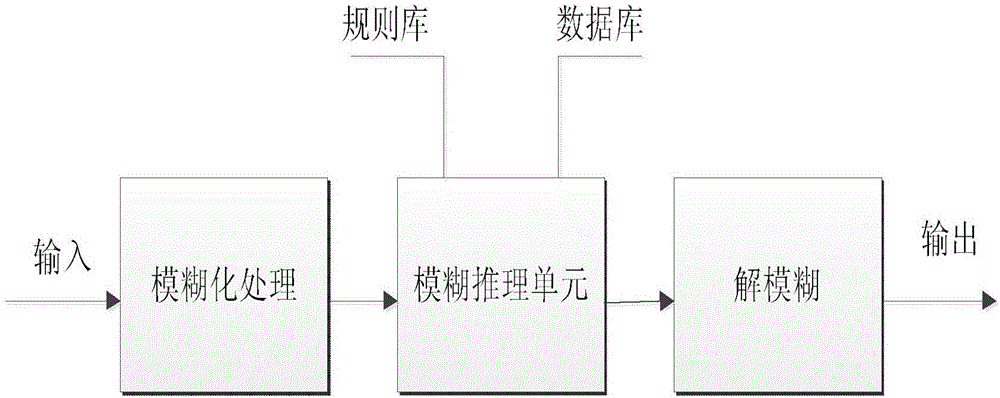

The invention discloses a CompactLogix-based fuzzy self-tuning PID liquid level control method which comprises the following steps: in step 1, actual liquid level signals y are subjected to sampling, filtering, tuning and quantifying operation; deviation e and a change rate ec of the deviation between the actual liquid level signals y and preset liquid level signals yd are calculated; in step 2, input quantities are subjected to fuzzification, fuzzy reasoning and deblurring operation; output quantities [delta]Kp, [delta]Ki and [delta]Kd of a fuzzy controller can be obtained finally; in step 3, based on an initial benchmark value set in a conventional PID controller, three parameters of a PID controller is obtained, and control output is calculated and is applied to an object being controlled. Via the control method, a problem that the conventional PID control parameter setting is high in difficulty and low in efficiency and difficult in realization of optimal control effects can be solved.

Owner:XIAN UNIV OF TECH

Fuzzy self-tuning PID control method used for denitration control system

The invention discloses a fuzzy self-tuning PID control method used for a denitration control system. The error of the output and the expected value of a controlled object and the change rate of the error are returned under the operation state of a coal-fired unit SCR denitration system, the parameters of the PID are adjusted online according to the fuzzy inference principle and the controlled object can be adjusted to the original state when the controlled object changes. The advantages of the fuzzy self-tuning PID control method used for the denitration control system are that the fuzzy self-tuning PID method does not need to know the exact mathematical model so that the difficulty in modeling can be avoided, the PID parameters can be adaptively modified in real time to be adaptive to the change of the condition and thus the method is intelligent, reduces the burden of operation personnel and the result is better than that of the conventional control.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

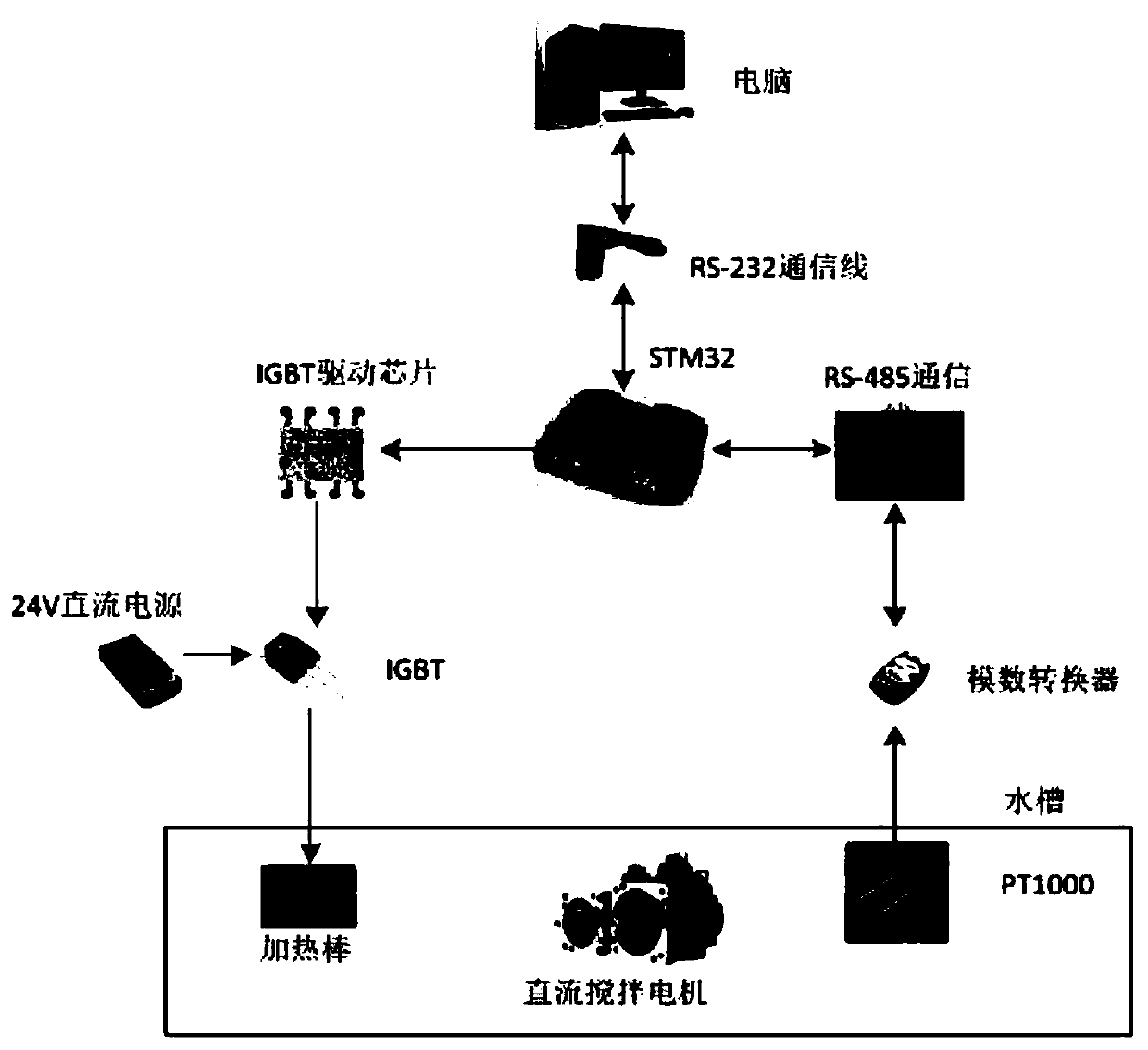

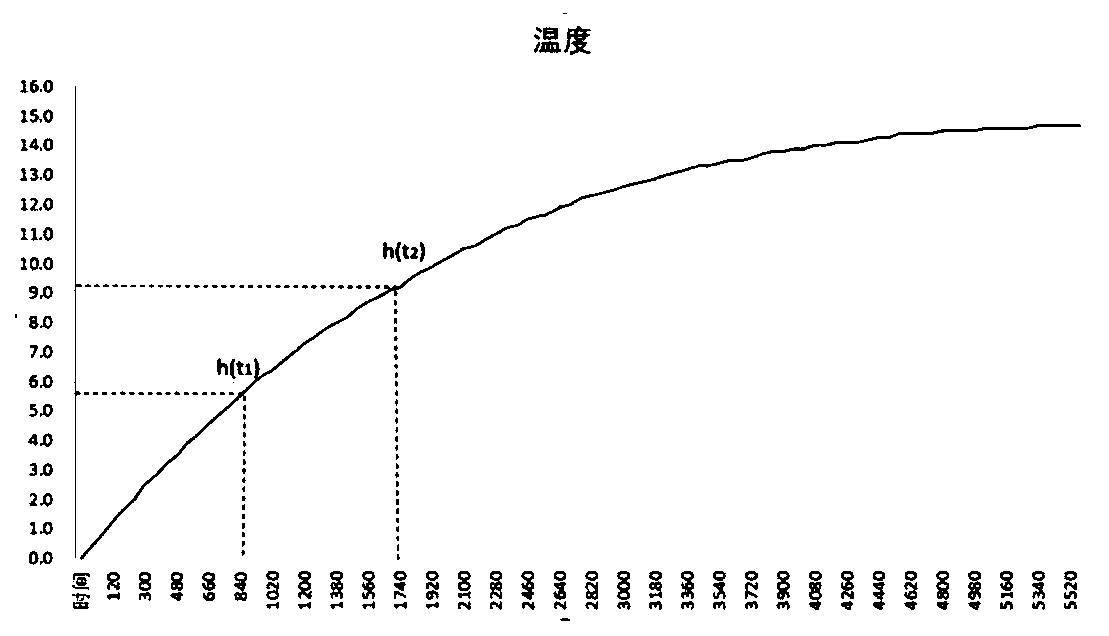

Constant-temperature water bath control method based on feedforward feedback fuzzy self-tuning PID control algorithm

InactiveCN111459212ATemperature controlRealize precise temperature controlAuxillary controllers with auxillary heating devicesWater bathsMathematical model

The invention provides a constant-temperature water bath control method based on a feedforward feedback fuzzy self-tuning PID control algorithm. The constant-temperature water bath control method comprises the following specific steps: 1) measuring a temperature step curve of a constant-temperature water bath; 2) establishing a thermostatic water bath temperature mathematical model; and 3) performing controlling by adopting a fuzzy PID control algorithm. According to the invention, the fuzzy PID control system is applied to the constant-temperature water bath monitoring system, and has great significance in improving the stability of the system, improving the dynamic performance of the system, enhancing the adjustment level of the system, improving the control efficiency, ensuring the measurement quality and saving energy.

Owner:JINLING INST OF TECH

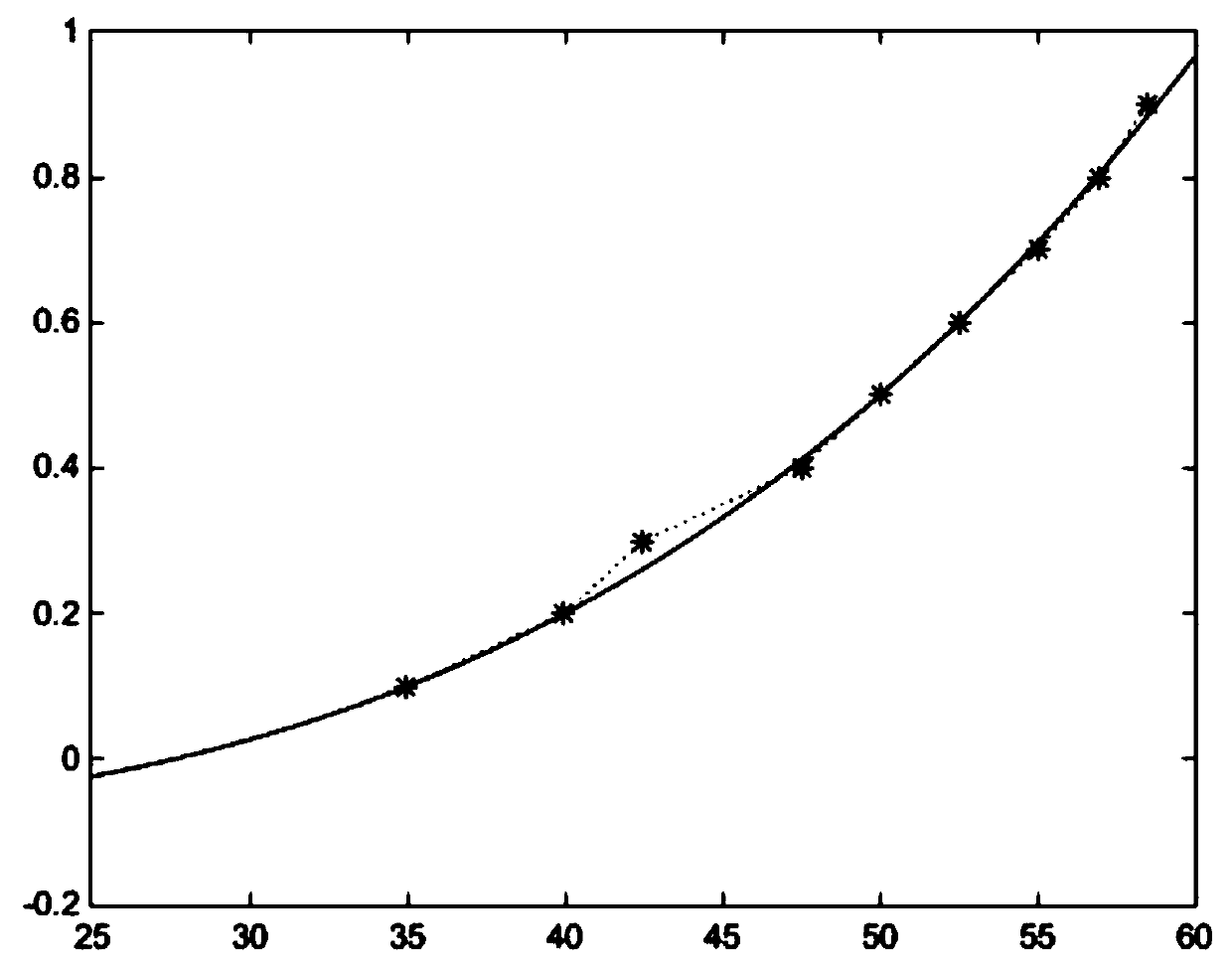

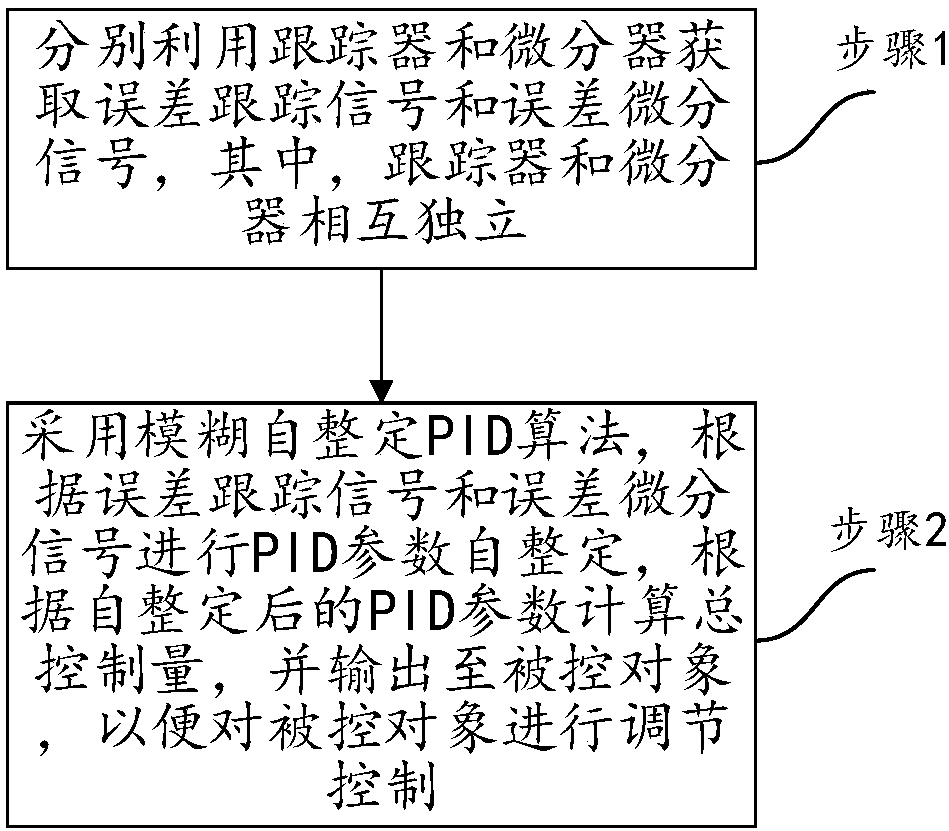

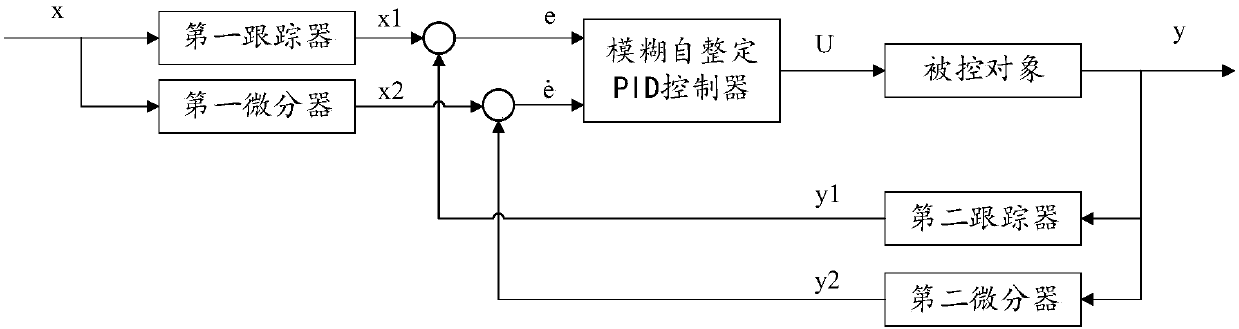

Fuzzy self-tuning PID control method and system

The invention discloses a fuzzy self-tuning PID control method comprising the steps that an error tracking signal and an error differential signal are acquired by using a tracker and a differentiator;the tracker and the differentiator are mutually independent; and PID parameter self-tuning is performed according to the error tracking signal and the error differential signal by using a fuzzy self-tuning PID algorithm, and the total control amount is calculated according to the PID parameters after self-tuning and outputted to the controlled object so that the controlled object is adjusted andcontrolled. The mutually independent tracker and the differentiator are adopted, and the error tracking signal and the error differential signal of great performance can be acquired by reasonably setting the relevant parameters of the tracker and the differentiator so that the contradiction between the problem of phase delay in case of signal tracking and the problem of noise amplification and waveform distortion in case of signal differentiation can be avoided and the overall control effect can be effectively enhanced. The invention also discloses a fuzzy self-tuning PID control system whichhas the beneficial effects.

Owner:GUANGDONG UNIV OF TECH

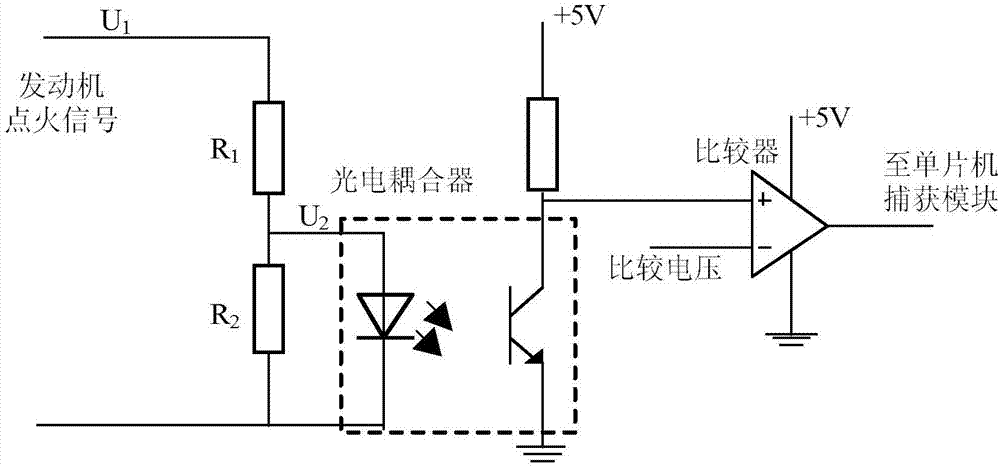

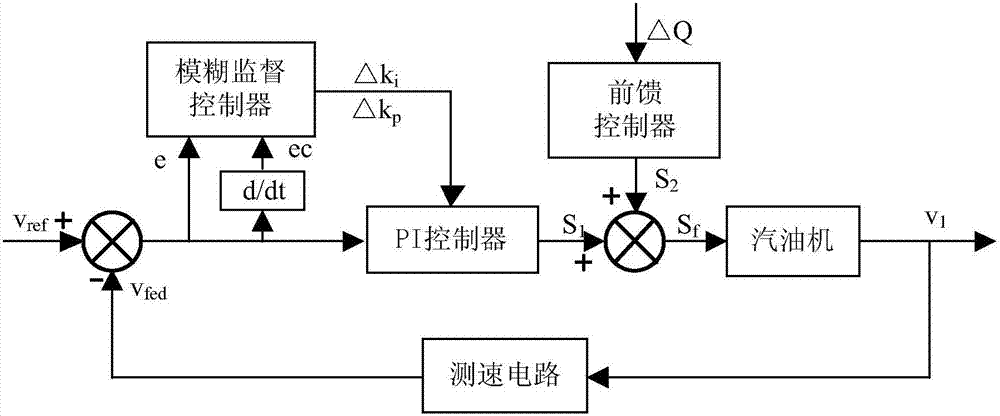

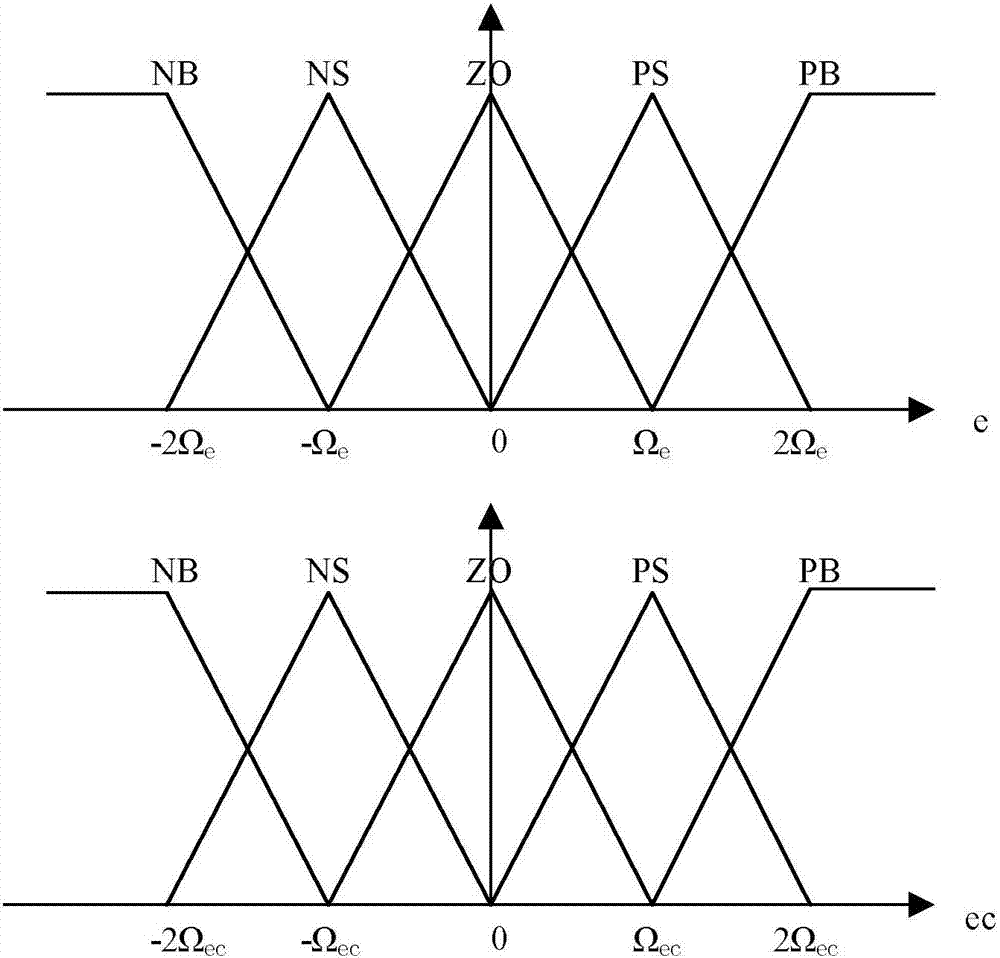

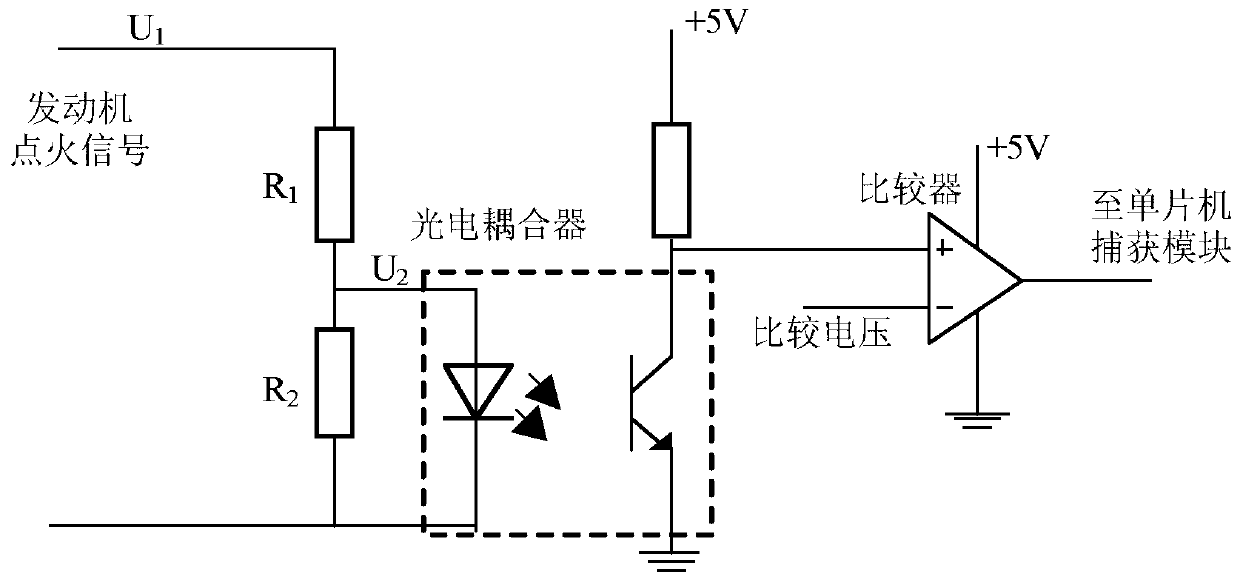

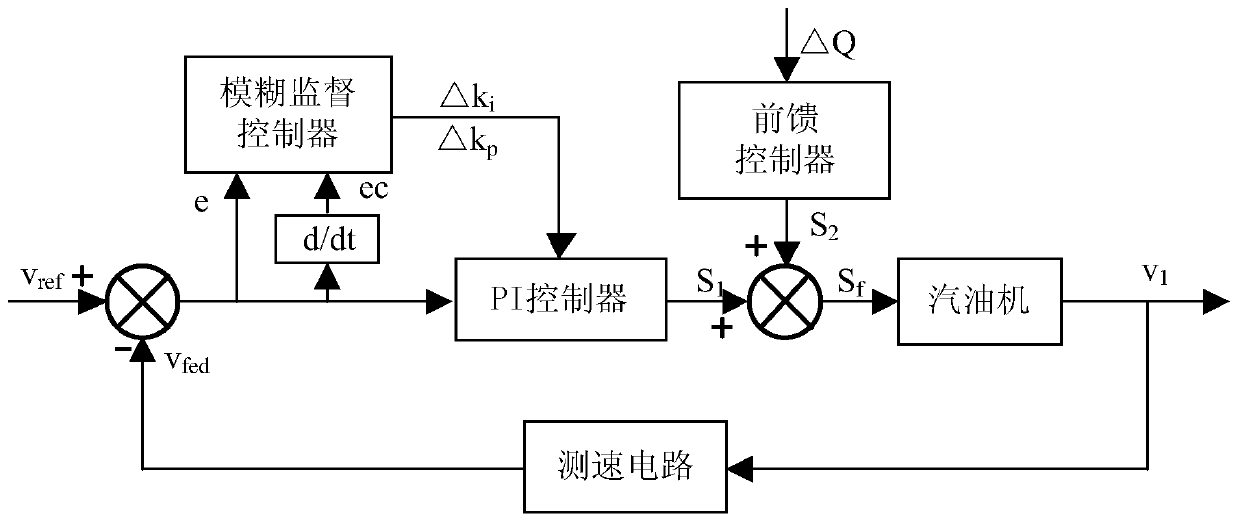

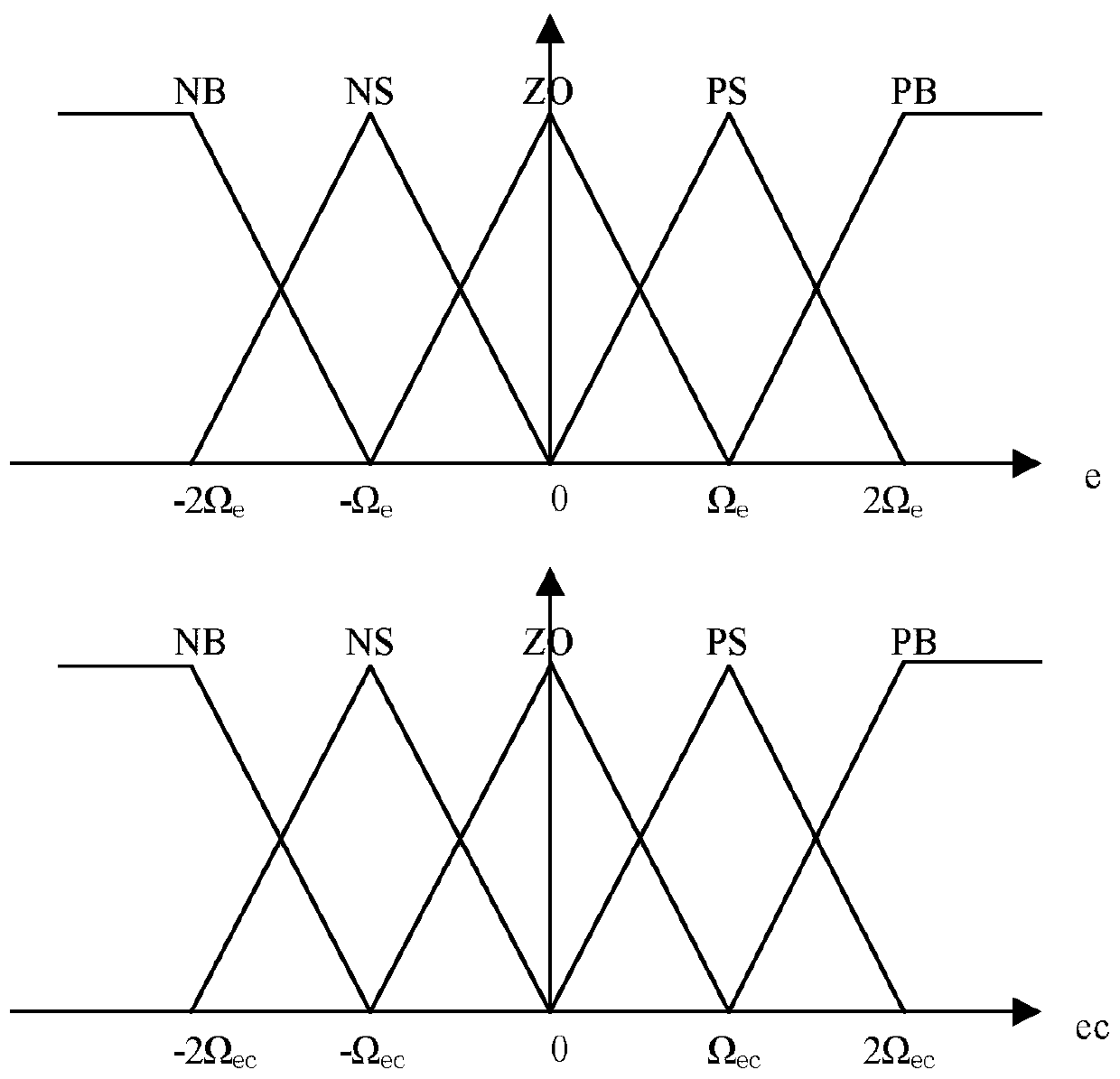

Servo control method for gasoline engine speed in hydraulic system of legged robot

ActiveCN106870181AStable speedReduce speed fluctuationElectrical controlSpeed sensing governorsLegged robotGasoline

The invention provides a servo control method for the gasoline engine speed in a hydraulic system of a legged robot. The servo control method comprises the following steps: (1) calculating the engine speed error e and the engine speed error change rate ec; (2), after the fuzzy logic calculation of e and ec, outputting the proportionality coefficient increment delta kp and the integral coefficient increment delta ki; (3) calculating the proportionality coefficient and the integral coefficient according to the following formulas correspondingly: kp = kp0 + delta kp and ki = ki0 + delta ki; (4) calculating the accelerator opening degree according to the following formula: S1 = S1_old + kp*ec + ki*e; (5) calculating the accelerator opening degree change caused by the hydraulic oil flow rate change according to the following formula: S2 = kQ*detal Q; and (6) calculating the final accelerator opening degree Sf = S1 + S2, wherein the rotation of a steering engine is controlled through the accelerator opening degree in the PWM form, the air inlet volume is controlled by controlling the opening degree of an engine throttle valve through an accelerator cable, and finally the engine speed is controlled. The servo control method provided by the invention has the advantages that the feedforward control is adopted, so that the stable engine speed can be guaranteed well under the circumstance that the flow rate changes suddenly; parameters are modified online by adoption of fuzzy self-tuning, so that the different control requirements can be met; and accordingly, the hydraulic system can have the good dynamic property and static property.

Owner:SHANDONG UNIV

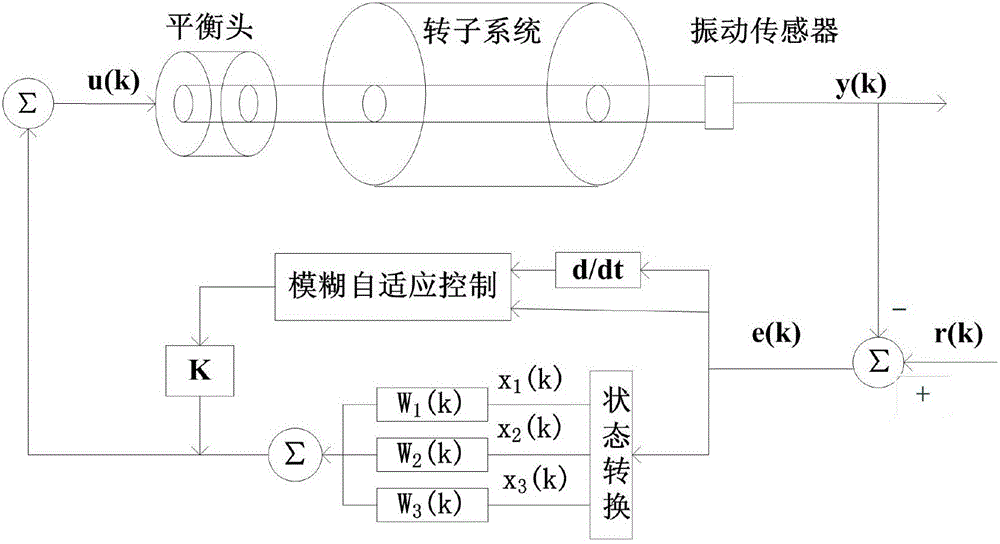

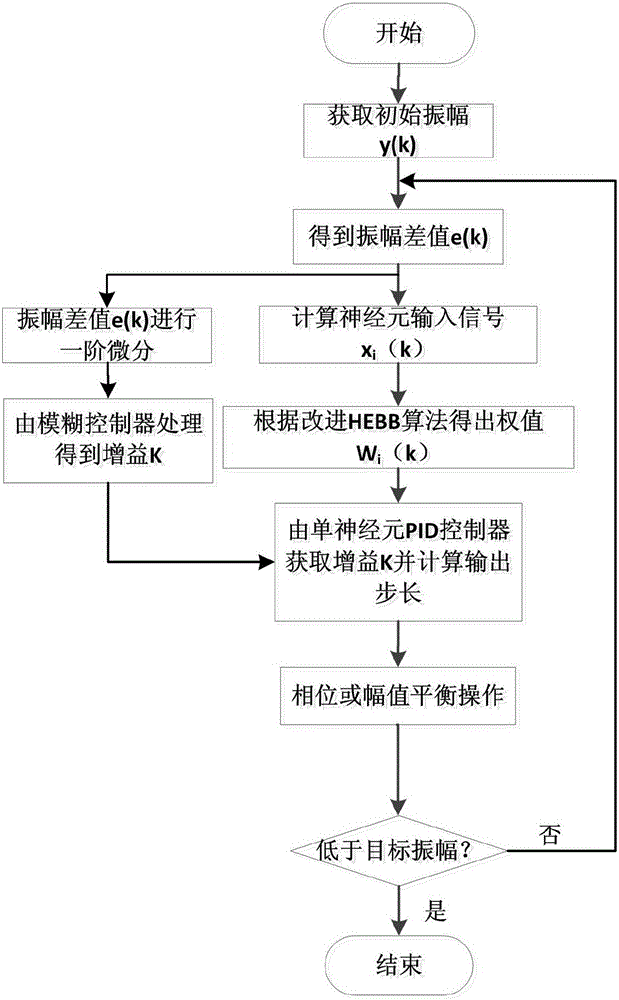

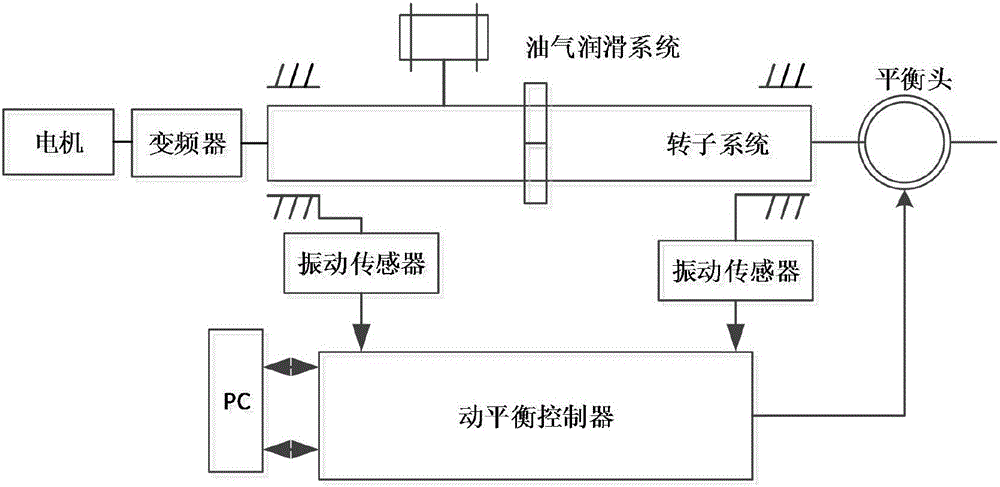

Rotor dynamic balancing control system based on fuzzy self-tuning single neure PID control and method thereof

InactiveCN106406100AShort equilibration timeQuick responseAdaptive controlControl systemDynamic balance

The invention discloses a system based on fuzzy self-tuning single neure PID control and a method thereof. A fuzzy controller is used to calculate the gain K needed by a single neure PID controller, after the single neure PID controller obtains the gain K, a control step length is solved and obtained through the single neure PID controller, and finally the effective control of rotor unbalance is realized. The defects of low balance efficiency and low balance precision of a traditional PID control method can be overcome, thus the control efficiency is improved, and the effective control of a balance head is realized.

Owner:HEFEI UNIV OF TECH

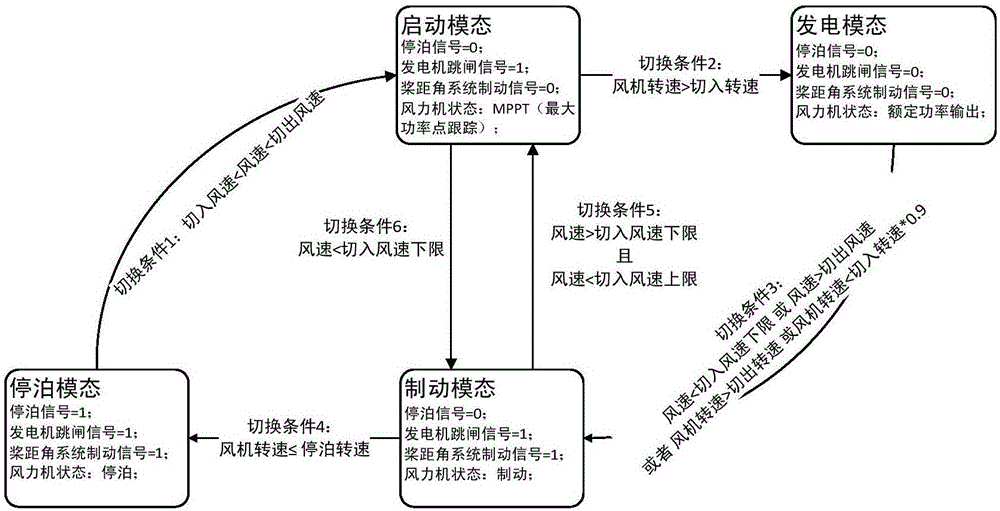

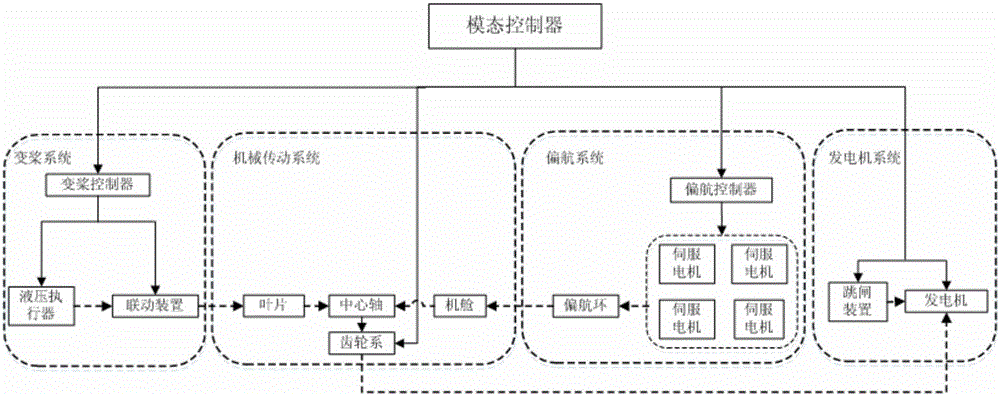

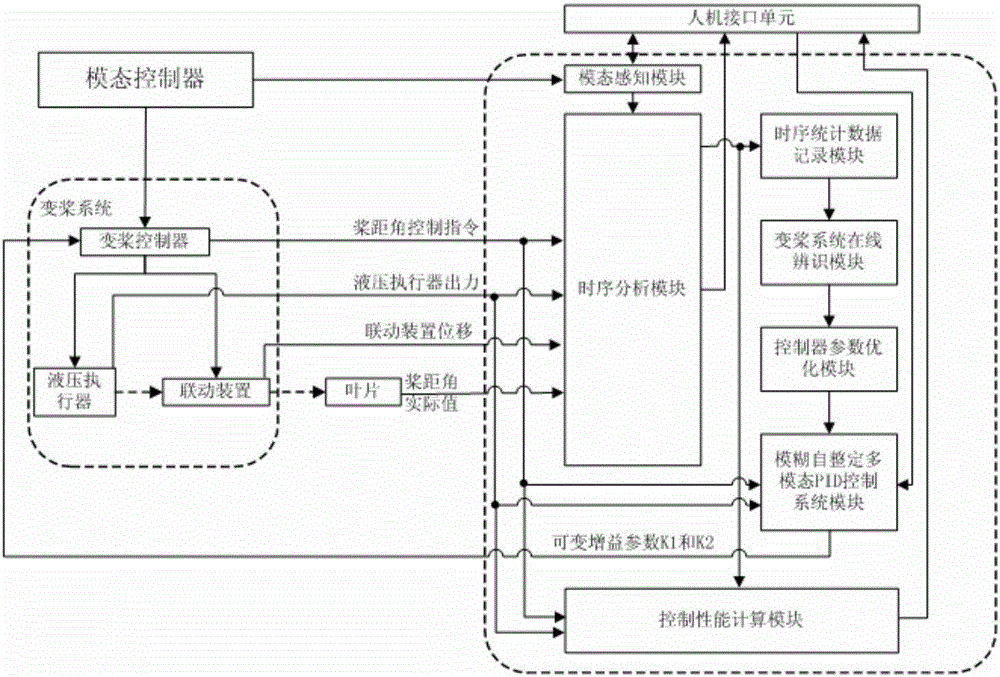

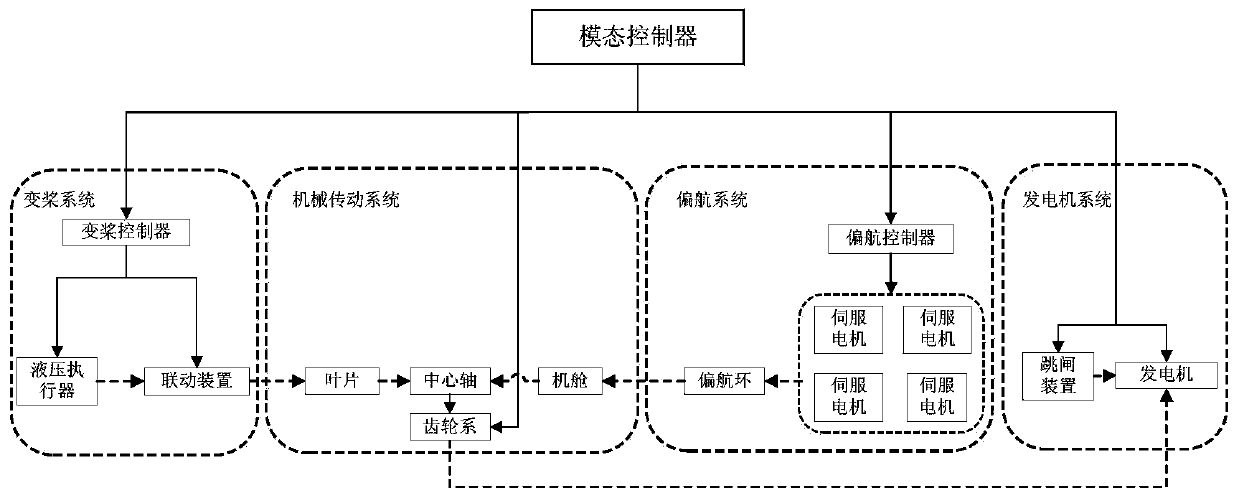

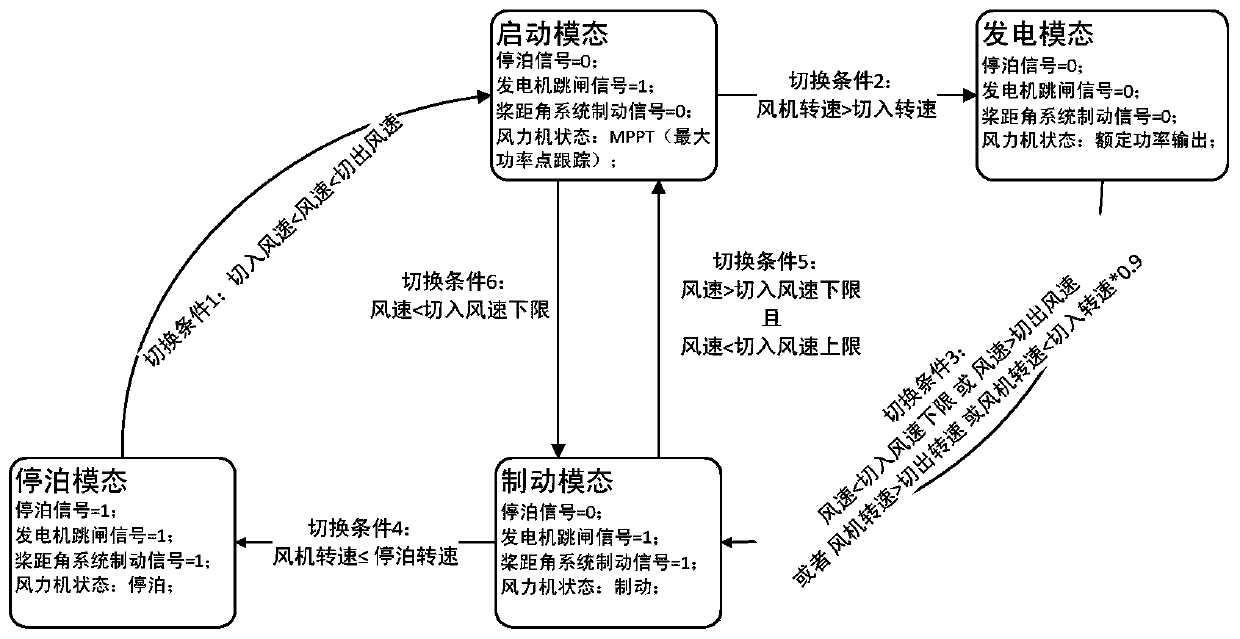

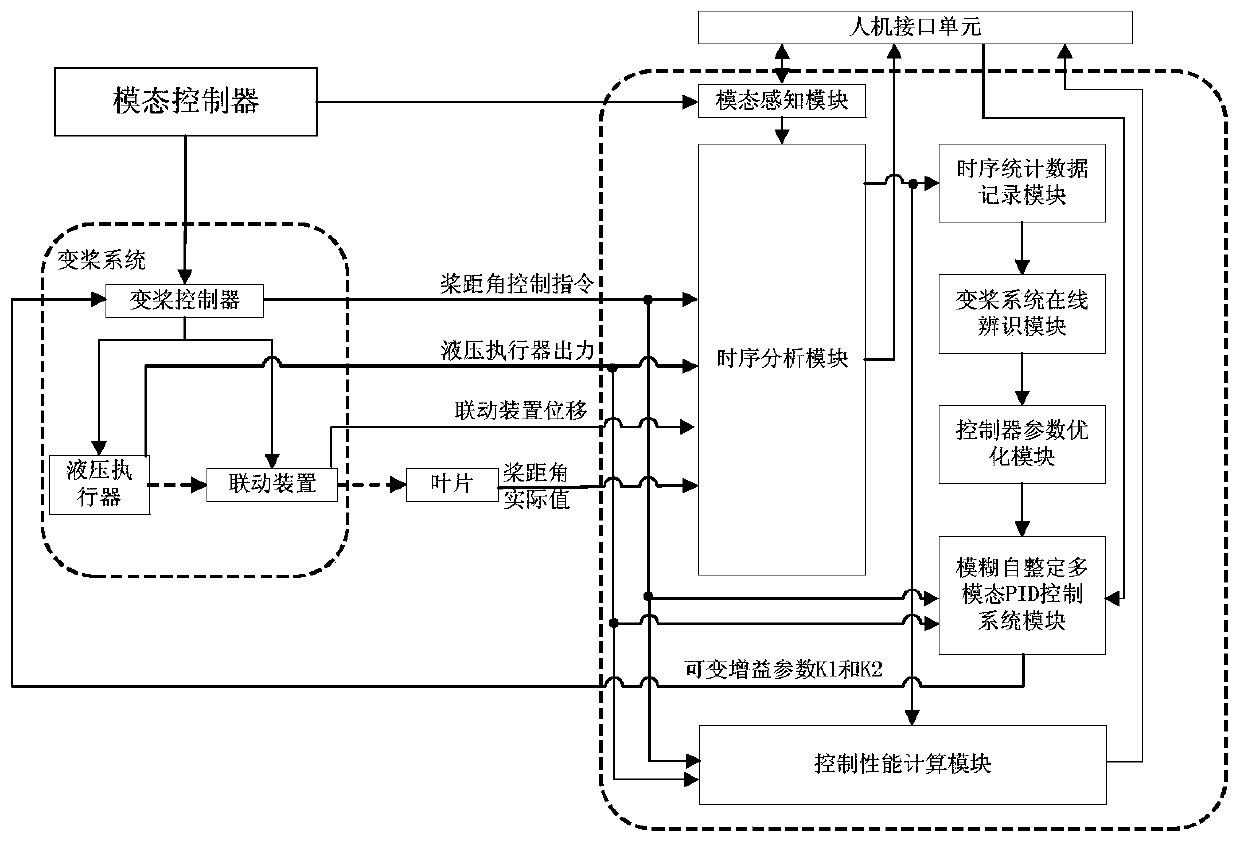

Multi-mode operation optimization controlling device of variable pitch wind turbine based on time series analysis and operation method thereof

ActiveCN106681151AShorten the timeExcellent performance indexAdaptive controlFuzzy self tuningEngineering

Provided is a multi-mode operation optimization controlling device of a variable pitch wind turbine based on time series analysis and an operation method thereof. The multi-mode operation optimization controlling device of variable pitch wind turbine based on time series analysis comprises a human interface module, a modal perception module, a timing analysis module, a module for time series statistics recording, an online identification module of a variable pitch system, a parameter optimization module of a controller, a fuzzy self-tuning multi-mode PID controlling system module, a calculating module for control performance. From a systemic level, the invention includes the steps of categorizing various devices contained in the variable pitch wind power generation system as 'assembly' by zones and functions, wherein the assembly is regarded as fundamental elements and used for building the modal perception module; time series analyzing for the modal perception module in the transient process of various modal switching on the basis of the assembly; obtaining the time series statistic data through the time series analyzing during the transient process of the various modal switching; online identifying and controller parameter optimizing for the various pitch system utilizing the time series statistics; synthesizing the optimized controlling parameter through the fuzzy self-tuning multi-mode PID controlling system, the step that eventually realizes the optimal performance of the variable pitch system under full working conditions.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

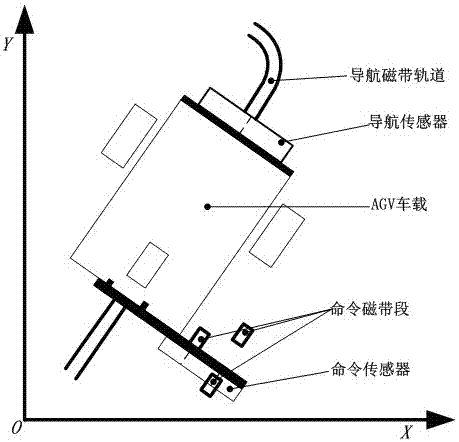

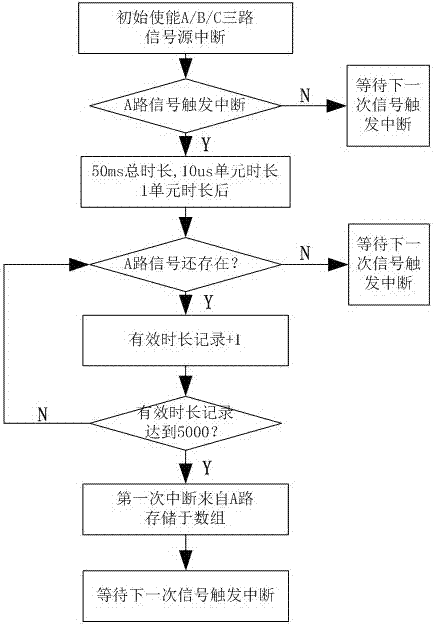

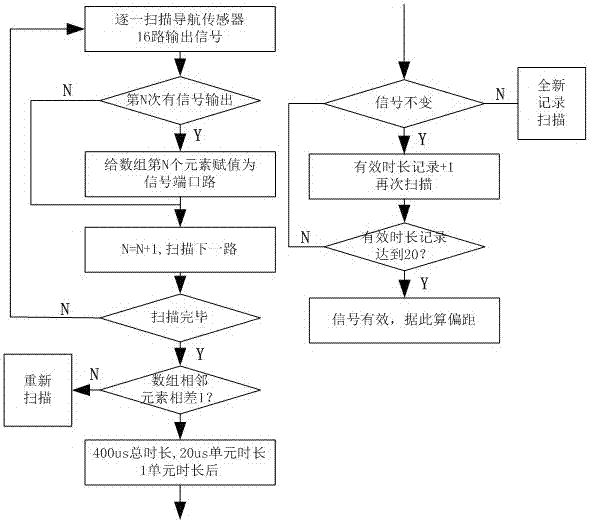

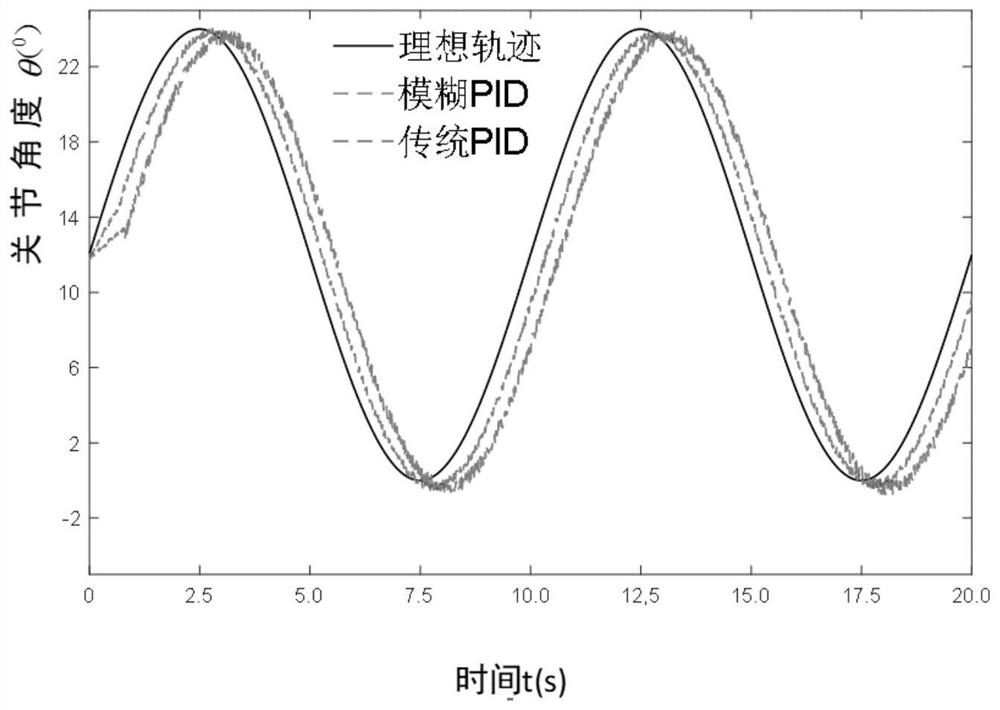

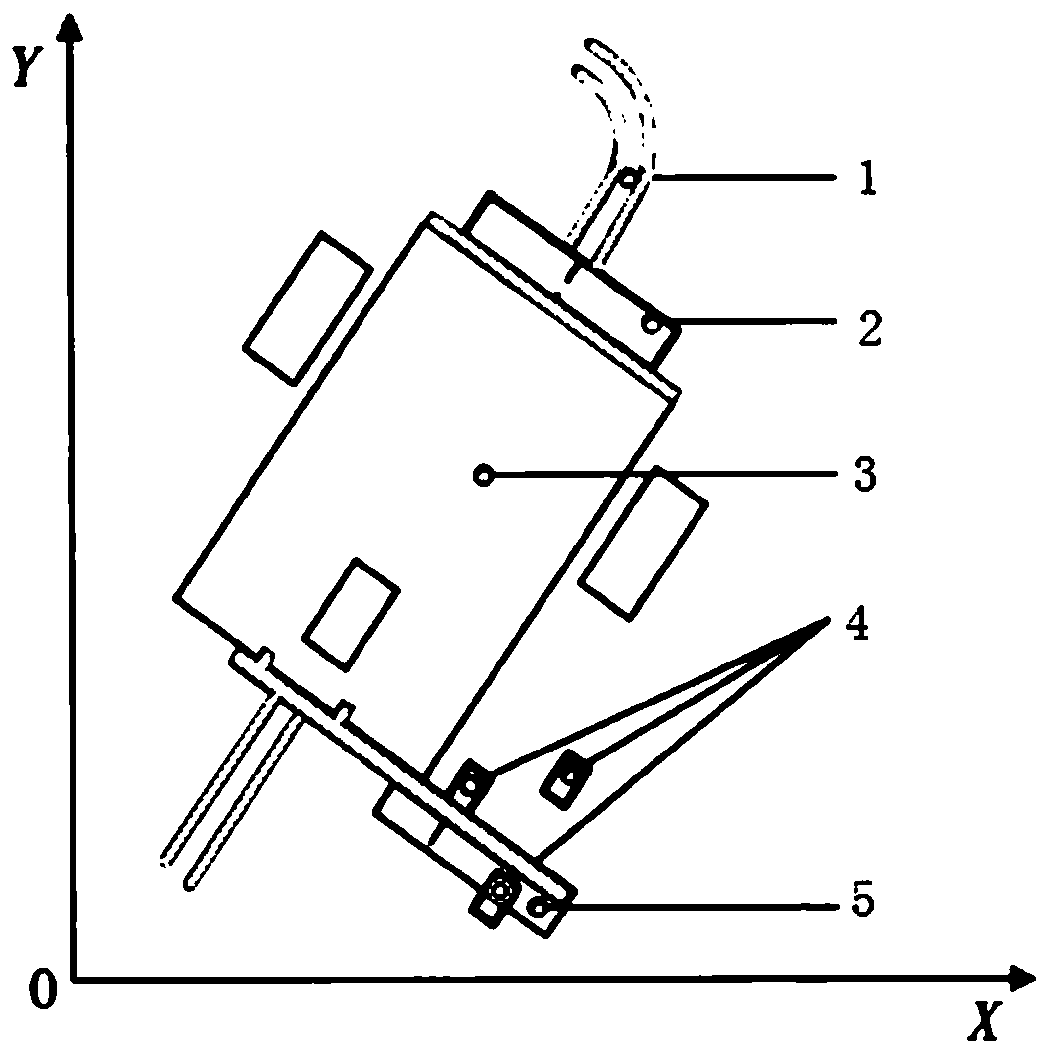

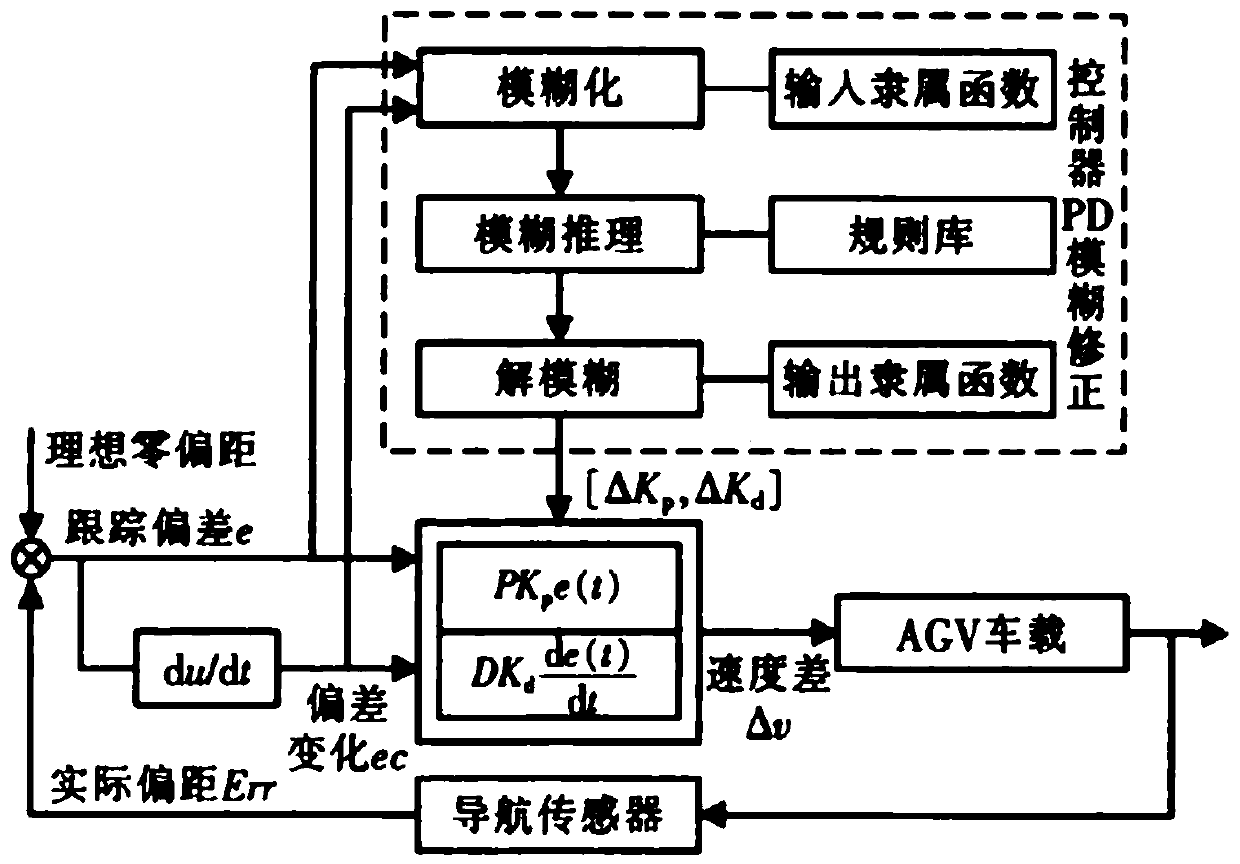

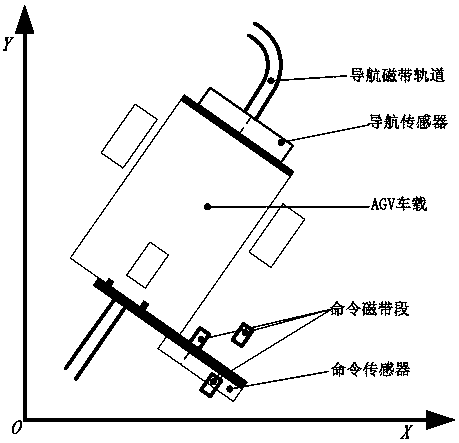

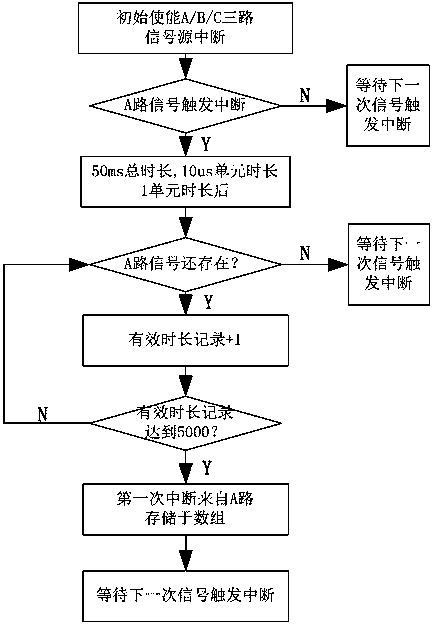

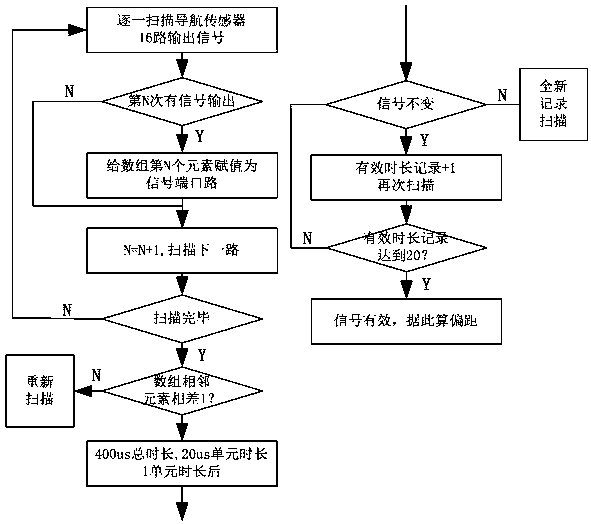

Magnetic combined navigation method of AGV (automated guided vehicle)

ActiveCN107015565AAccurate detectionImprove fault tolerancePosition/course control in two dimensionsElectric machineMagnetic tape

The present invention relates to a magnetic combined navigation method of an AGV (automated guided vehicle). The method mainly comprises a combination method of command magnetic tapes, a signal filtering algorithm and an AGV navigation control algorithm. According to the magnetic combined navigation method, a plurality of magnetic tapes are combined into a function command; magnetic tapes are laid in a crossed manner between commands; command magnetic tapes of the same polarity are laid inconsecutively at the same sampling point; the signals of a command sensor are received through IO external triggering interruption, the effectiveness of the signals is analyzed through detecting the duration and receiving sequence of the signals; the signals of a navigation sensor are received through an IO scanning mode, and whether the signals are discarded is determined through detecting the continuity of the sampling points and the duration of the signals; and control speed is calculated based on the deviation distances of the center of the navigation sensor and the centers of the magnetic tapes through using the fuzzy self-tuning PD control law, and the control speed is provided for a motor, and therefore, the pose of the AGV is adjusted. The method of the invention has the advantages of reliable signal sampling, effective and robust controller and good navigation control effect.

Owner:FUZHOU UNIV

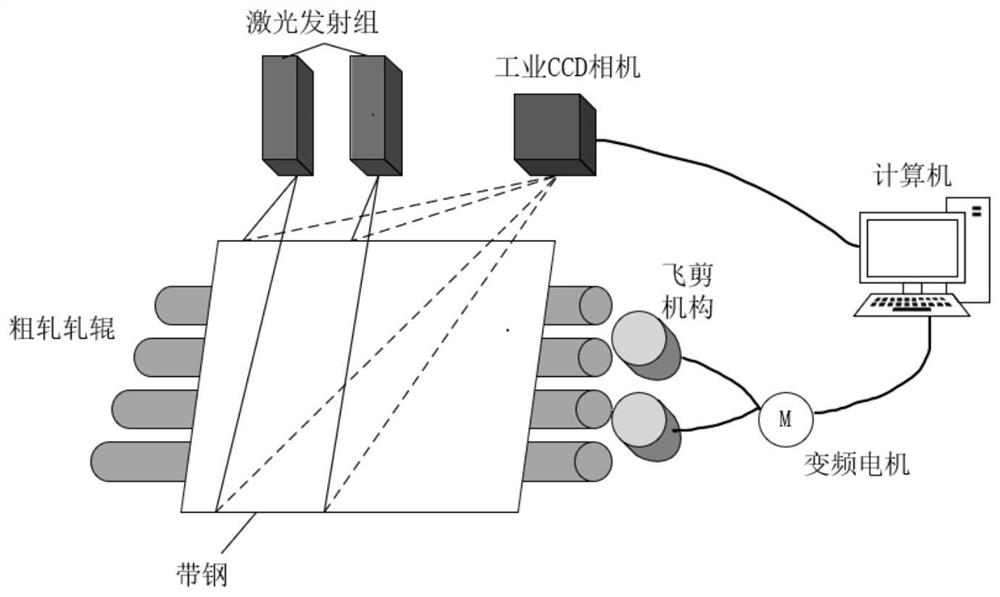

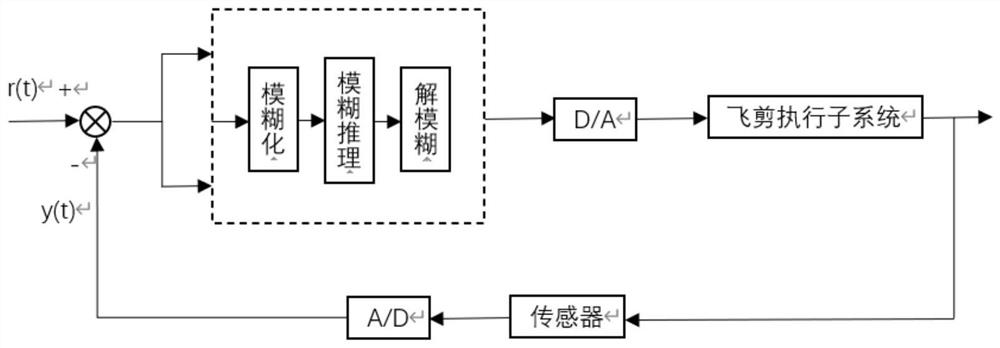

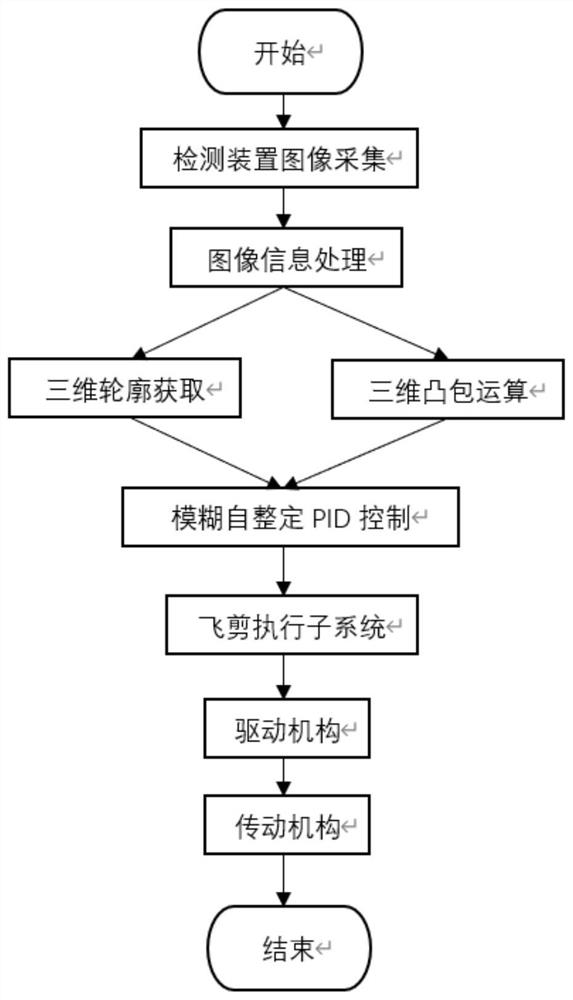

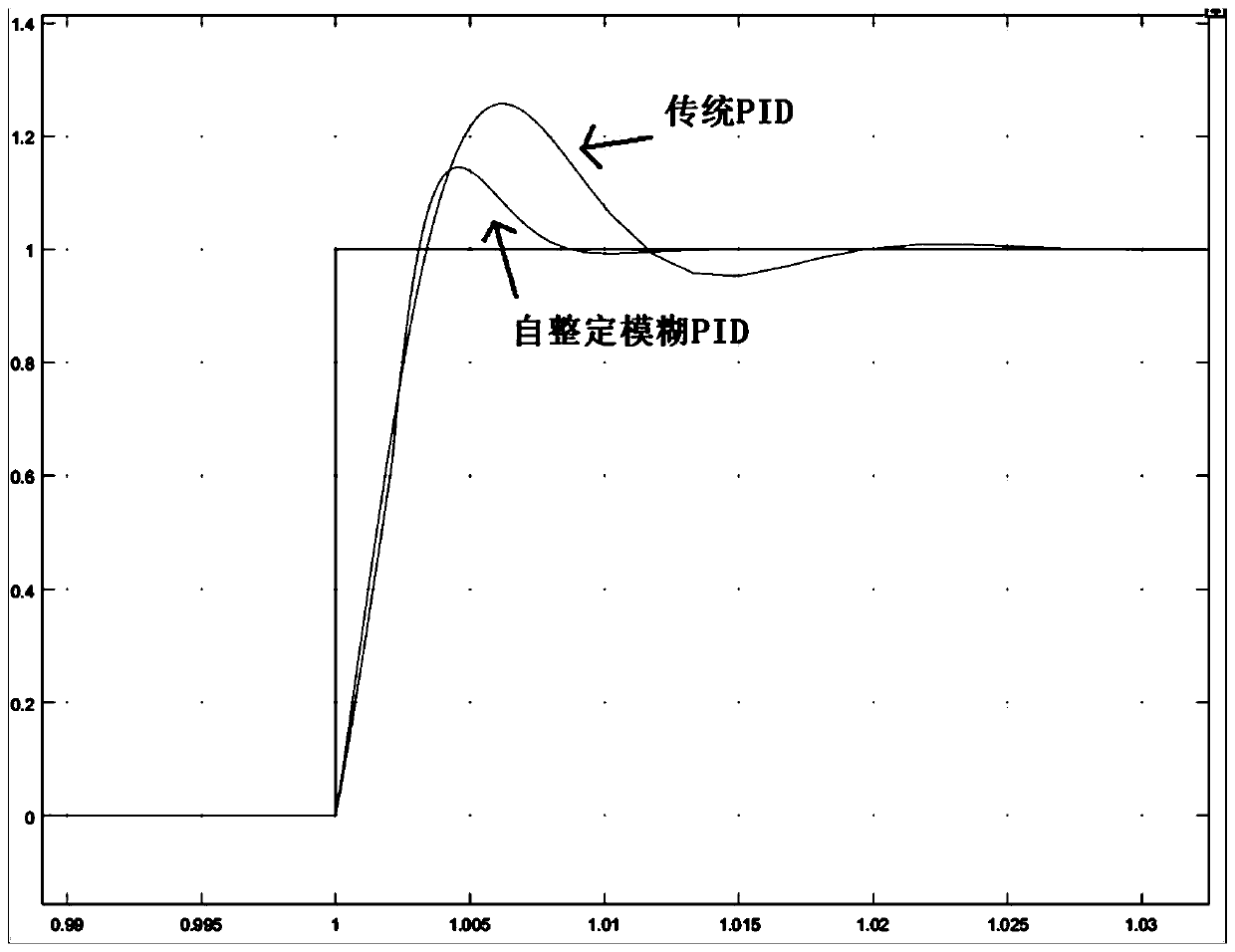

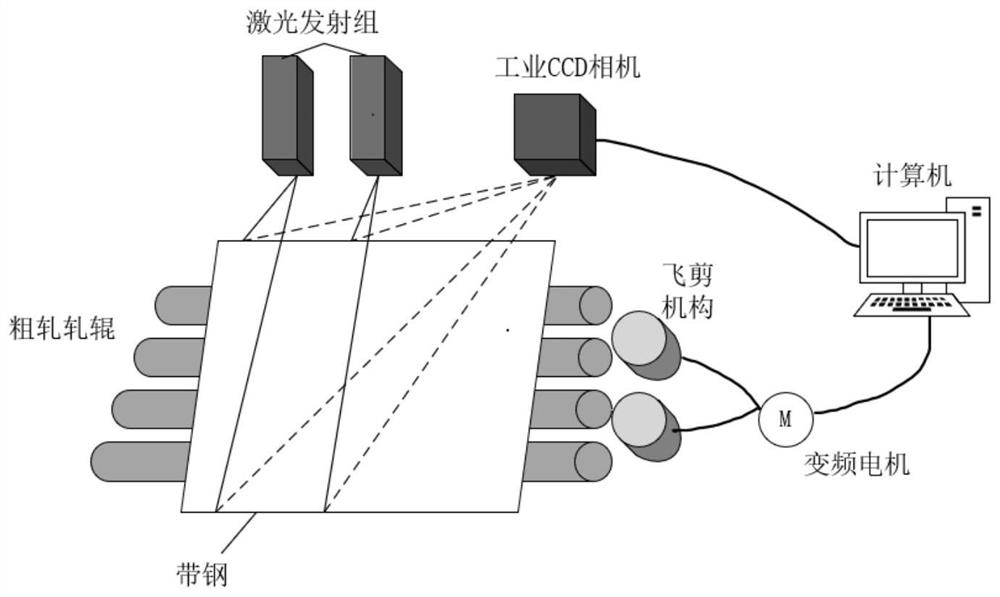

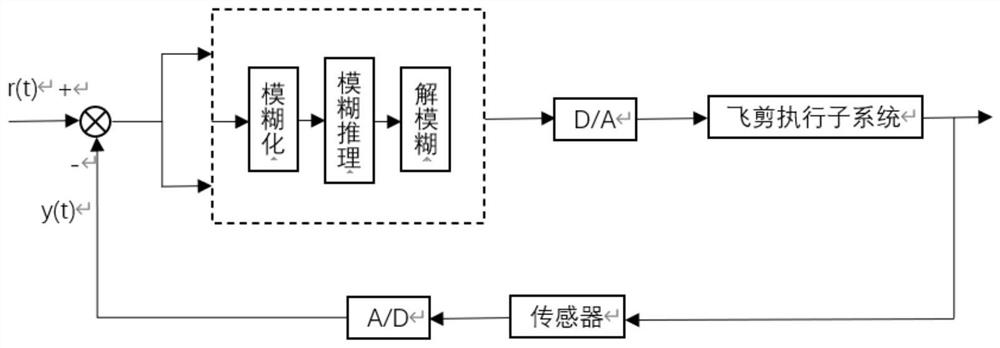

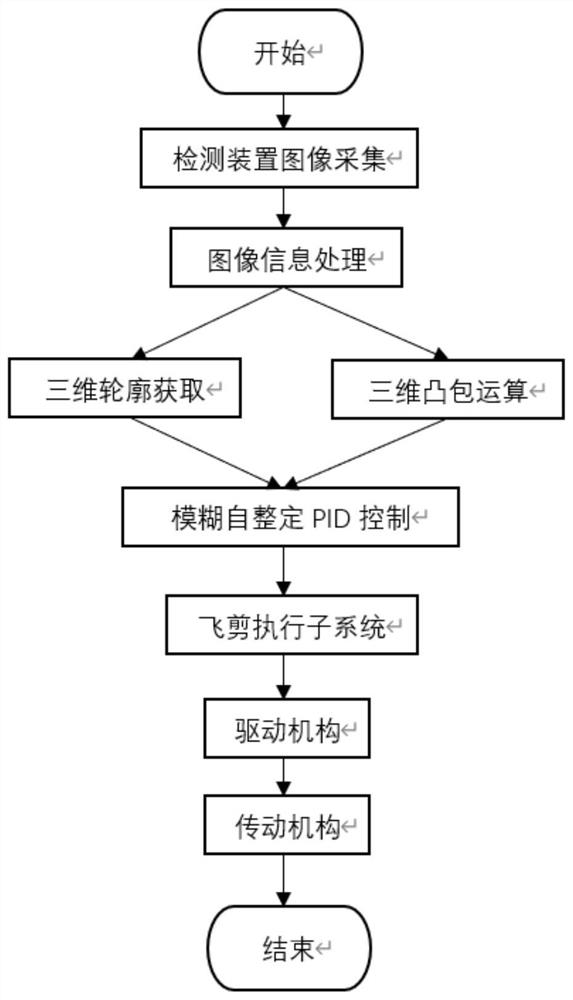

Hot-rolled strip steel optimized shearing method based on machine vision

ActiveCN113198854AOvercome speedOvercome efficiencyRoll mill control devicesMeasuring devicesLoop controlImaging processing

The invention belongs to the field of hot-rolled strip steel flying shear control engineering, and relates to a hot-rolled strip steel optimized shearing method based on machine vision. The method is mainly combined with a machine vision principle, non-contact measurement is performed on a strip steel end deformation part caused by rough rolling on a hot rolling production line, optimization control is performed on a flying shear system through a fuzzy self-tuning PID controller, and the method comprises the following operation steps: 1) collecting a strip steel end image; 2) processing image information; 3) obtaining a three-dimensional contour; 4) performing three-dimensional convex hull operation; 5) making a fuzzy self-tuning PID controller decision; 6) transmitting a shearing signal by the controller; and (7) shearing by an executing mechanism. Based on a machine vision detection system, the three-dimensional profile of the end of strip steel is obtained in combination with an image processing unit, a flying shear mechanism is controlled through the fuzzy self-tuning PID controller, and a shearing mechanism carries out accurate shearing after receiving a signal sent by the controller. By means of a closed-loop control structure, online optimization of a hot-rolled strip steel flying shear system is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Method for controlling rolling angle of underwater robot

InactiveCN110531615AHigh control precisionImprove control stabilityControllers with particular characteristicsResearch ObjectFuzzy self tuning

The invention discloses a method for controlling the rolling angle of an underwater robot. The method comprises the following steps of (1) an input preprocessing process, (2) a fuzzy logic controllerprocessing process, and (3) a PID controller processing process, wherein output is sent to an executing mechanism. According to the method, the underwater robot serves as a research object, PID control and fuzzy control are combined through experiments and simulation, the method for controlling the rolling angle of the underwater robot through fuzzy self-tuning PID is obtained, and therefore, thecontrol precision and stability of the rolling angle are improved.

Owner:NANJING INST OF TECH

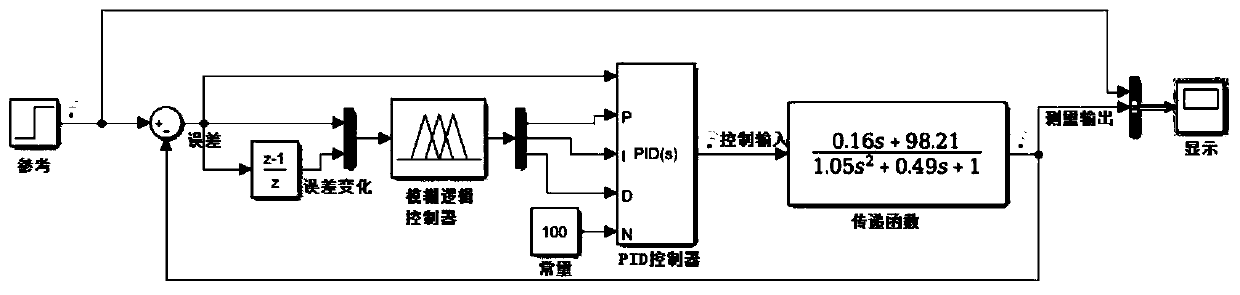

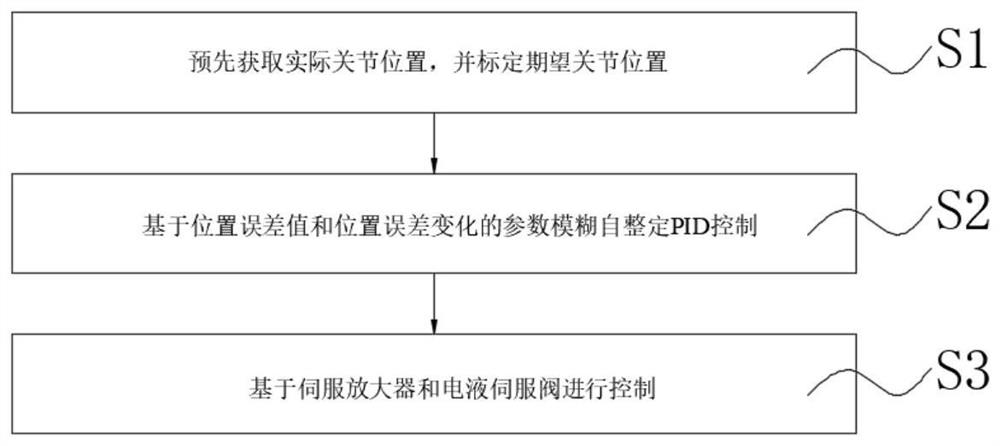

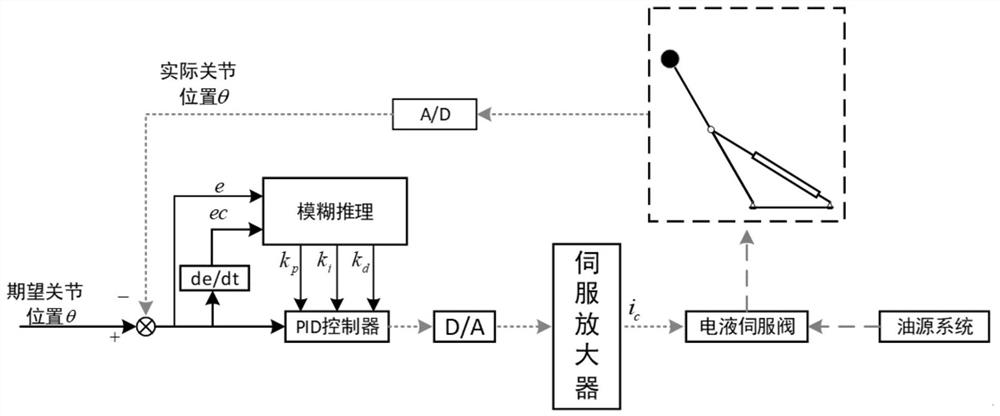

Hydraulic system control method based on parameter self-adaption

ActiveCN112555202ARealize automatic adjustmentSmall overshootServomotor componentsServomotorsControl engineeringFuzzy self tuning

The invention discloses a hydraulic system control method based on parameter self-adaption, and relates to the technical field of hydraulic system control. The hydraulic system control method comprises the following steps that an actual joint position is obtained in advance, and an expected joint position theta is calibrated; parameter fuzzy self-tuning PID control based on a position error valuee and a position error change ec comprises the steps that the error value e is calibrated, and the position error change ec is calibrated as input, and kp, ki and kd are obtained as output parameters;and control is carried out based on a servo amplifier and an electro-hydraulic servo valve. The hydraulic system control method has fuzzy control robustness and PID control steady-state error weakening performance, uses a fuzzy control rule for automatically adjusting PID parameters, adopts fuzzy control within a large deviation range and converts fuzzy control into PID control within a small deviation range, and automatically achieves conversion of the fuzzy control and the PID control according to a given deviation threshold value, has smaller overshoot in composite control, and obviously has higher control precision in the aspect of joint position control.

Owner:上海凯科疏水阀业有限公司

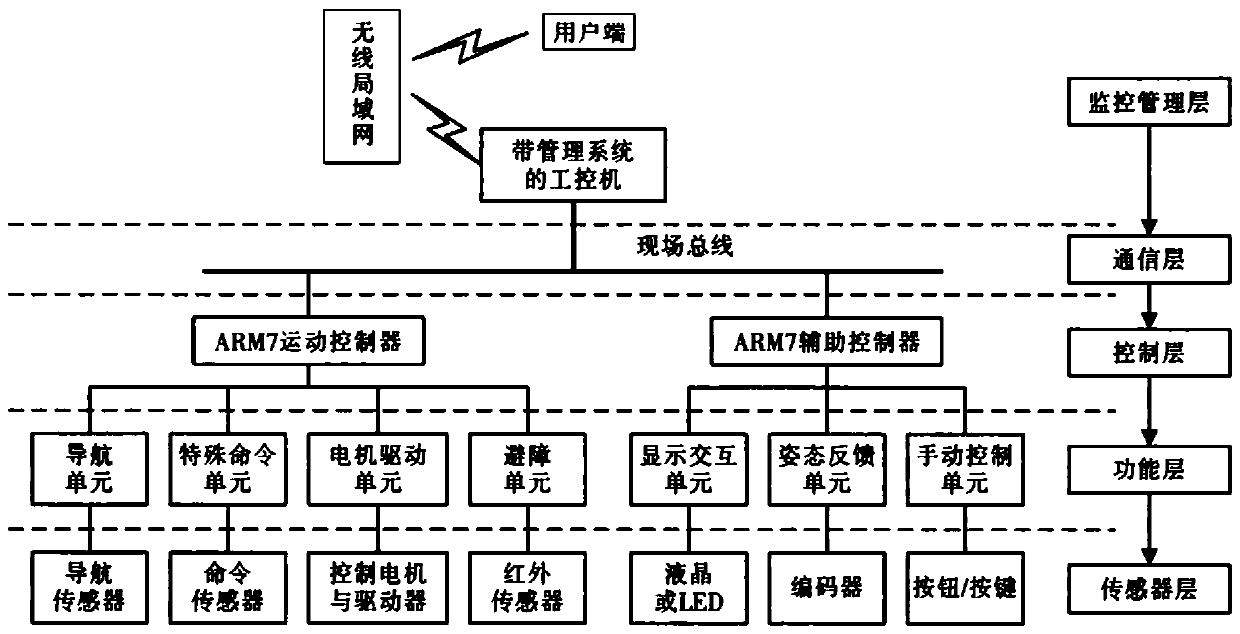

Magnetic navigation AGV control system

InactiveCN107783532AAchieve sharingHelp with debuggingPosition/course control in two dimensionsHardware architectureControl system

In order to ensure the scalability and stability of the magnetic navigation AGV control system, a magnetic navigation AGV control system was invented. Its hardware architecture is based on an embedded industrial computer, and multiple ARM processors that control peripheral devices are connected through the CAN bus. . Emphasis is given on the implementation of the system's motion controller and monitoring and management system. The motion controller is implemented based on the interrupt task scheduling mode, and the dynamic tracking behavior of the AGV is improved by the fuzzy self-tuning PD regulator; the monitoring and management system includes six interactive modules. Its sending and receiving communication process is completed cooperatively through timely thread suspension and step-by-step receiving matching operations. The on-site measurement shows that the AGv works stably and reliably, and the tracking effect is good.

Owner:郭琳

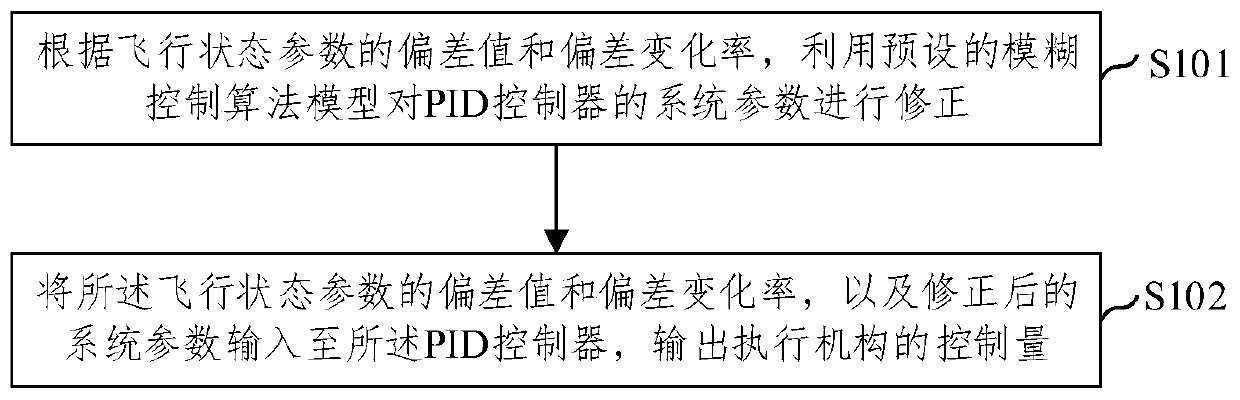

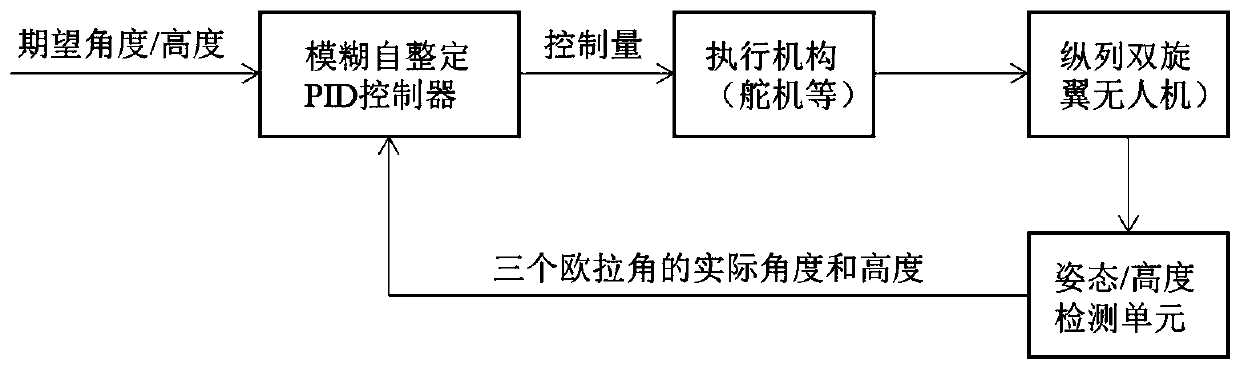

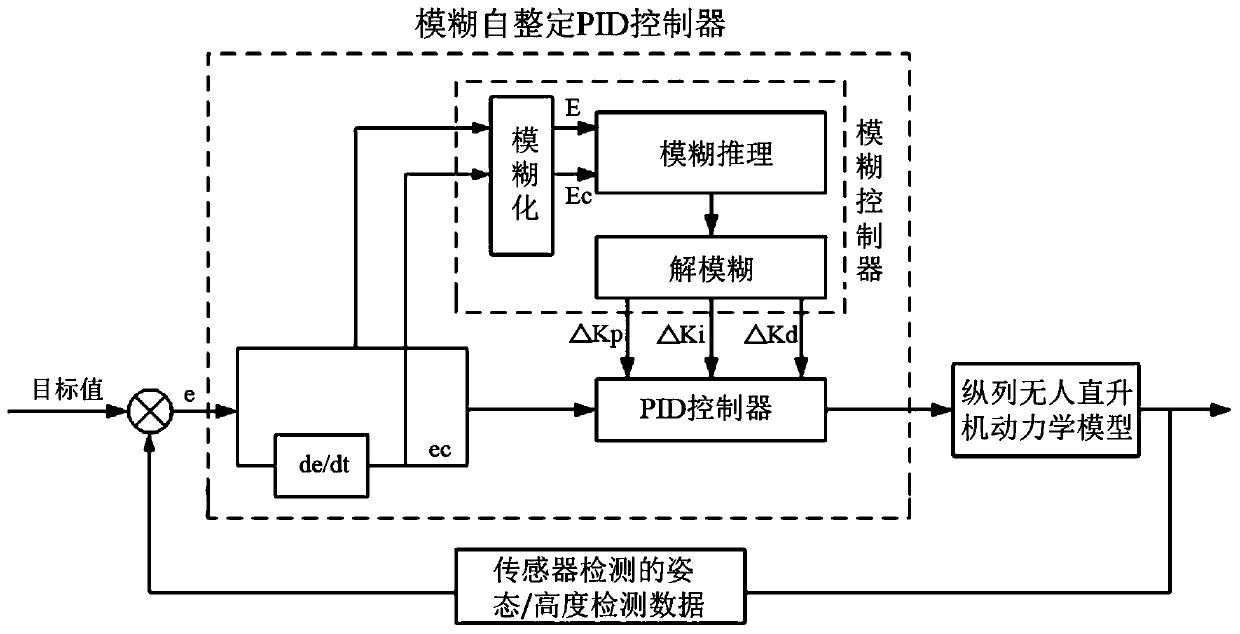

Method and device for fuzzy self-tuning PID controlling of tandem unmanned helicopters

InactiveCN110376888ARealize online self-tuningTroubleshoot real-time auto-tuning issuesAttitude controlPosition/course control in three dimensionsSelf-tuningState parameter

The embodiment of the invention provides a method and device for fuzzy self-tuning PID controlling of tandem unmanned helicopters. The method comprising: according to a deviation value and a deviationchange rate of a flight state parameter, correcting system parameters of a PID controller based on a preset fuzzy control algorithm model; and inputting the deviation value and deviation change rateof the flight state parameter and the corrected system parameters into the PID controller, and outputting a control amount of an execution mechanism. According to the method and device for fuzzy self-tuning PID controlling of tandem unmanned helicopters, the fuzzy intelligence idea is introduced based on the classical PID control; and on-line self-tuning of system parameter correction values of the PID controller is realized by finding out relationships between the system parameters and the deviation value and the deviation change rate of the PID controller, so that a real-time self-tuning problem of the PID controller system parameters is solved. Therefore, the static and dynamic control performances of the tandem unmanned helicopters are improved; and the robustness and immunity to interference of the system are enhanced.

Owner:CHINA AGRI UNIV

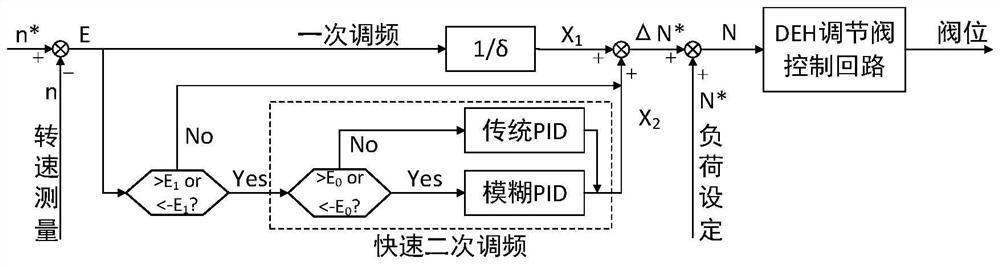

Isolated network frequency control method and system based on double-loop PID composite control

ActiveCN112310977AFlexible controlAdaptableSingle network parallel feeding arrangementsPower oscillations reduction/preventionSelf-tuningControl system

The invention provides an isolated network frequency control method based on double-loop PID composite control. A rapid secondary frequency modulation function is added to a DEH system of an isolatedgenerator set, and the secondary frequency modulation function comprises outer loop fuzzy self-tuning PID control and inner loop traditional PID control; and when the rotating speed deviation is greater than a switching threshold value, the fuzzy self-tuning PID control is carried out through an outer loop, and when the rotating speed deviation is less than the switching threshold value, traditional PID control is carried out through an inner loop. The invention further discloses a corresponding control system. The fuzzy self-tuning PID has the advantages of being flexible in control and highin adaptability; the fuzzy self-tuning PID is switched into the traditional PID in an undisturbed mode under the assistance of small deviation so as to rapidly eliminate static errors, and therefore,the whole rapid secondary frequency modulation loop has the advantages of being rapid in dynamic response, small in overshoot, high in robustness, accurate in control effect and the like; frequency stability during isolated network operation is guaranteed; and production safety of enterprises is maintained.

Owner:NR ELECTRIC CO LTD +1

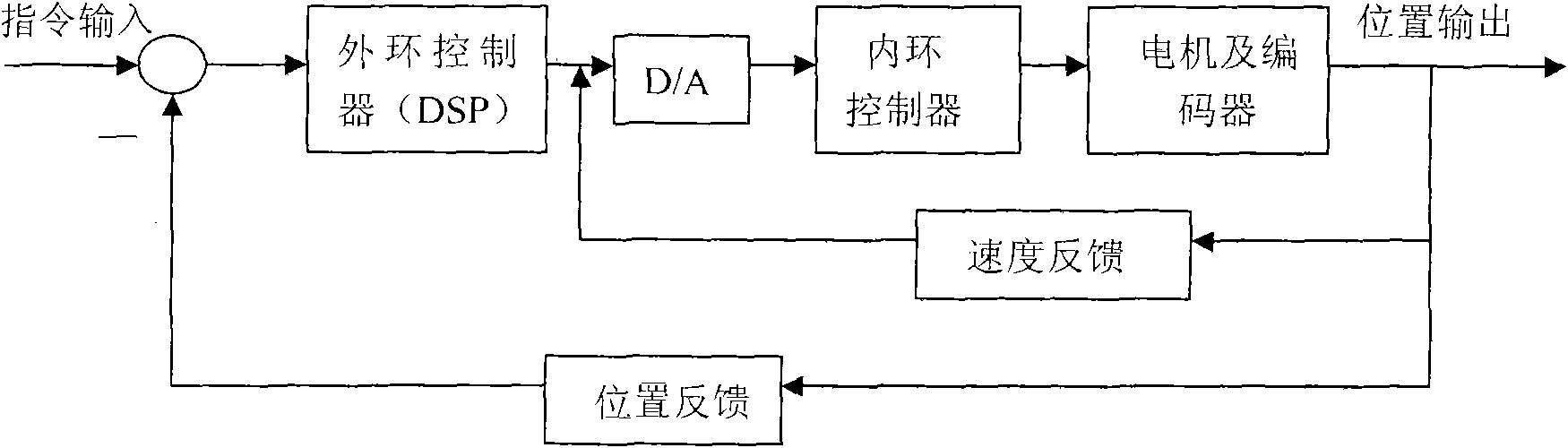

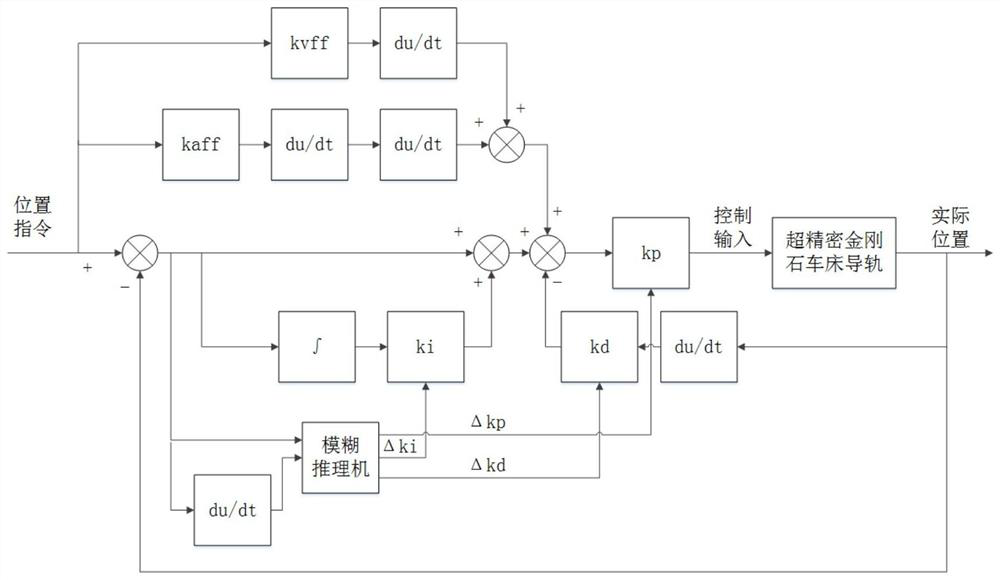

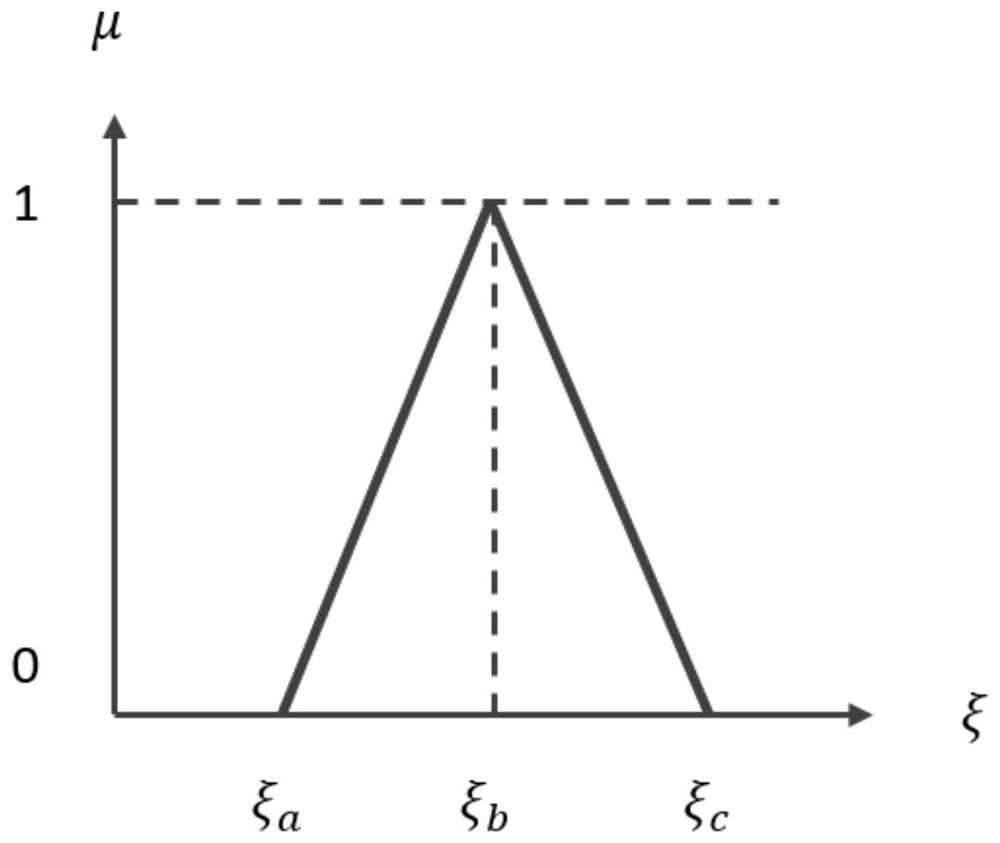

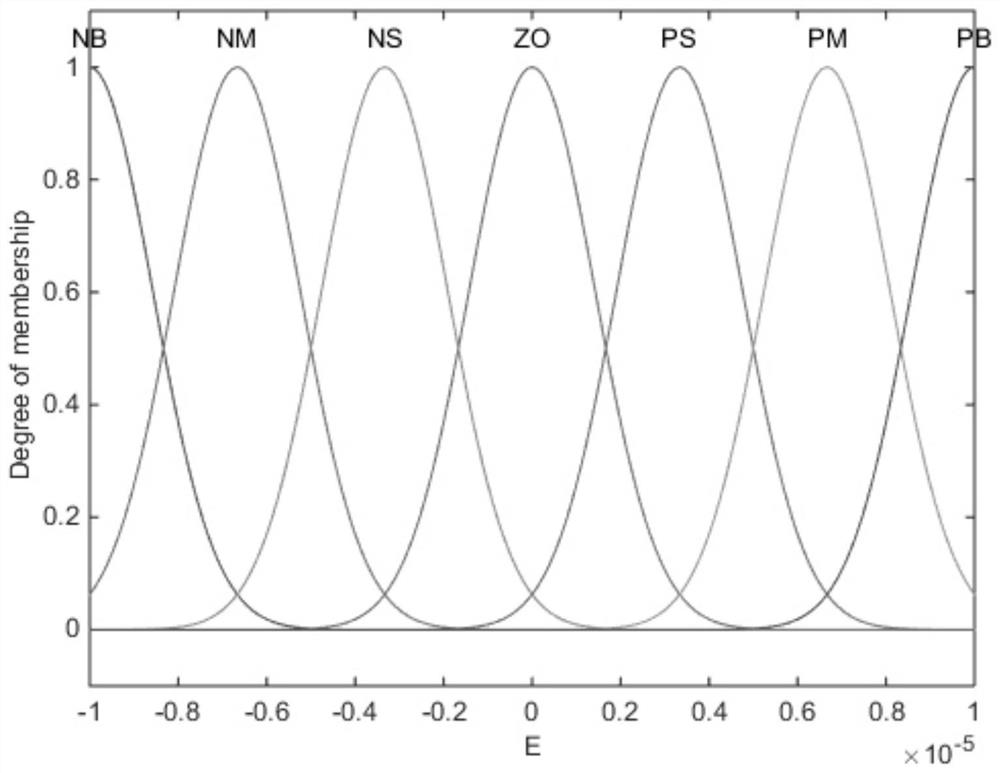

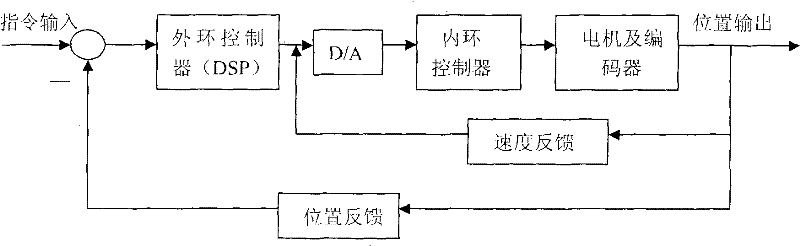

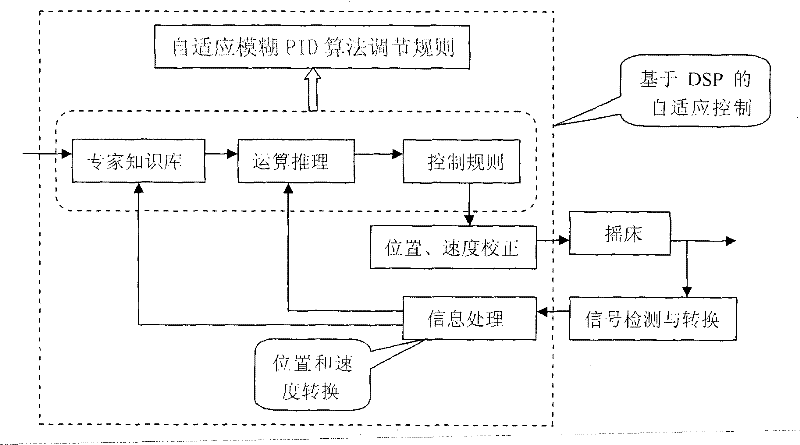

Motion control method of ultra-precision lathe based on fuzzy pid self-tuning calculation

ActiveCN112486099BOptimize blur outputOptimizing the Discourse Distribution Parameters of Fuzzy Output QuantitiesProgramme controlComputer controlIndustrial engineeringLinear motion

The invention discloses an ultra-precision lathe motion control method based on fuzzy PID self-tuning calculation, relates to the technical field of ultra-precision cutting, and mainly includes the following steps: taking the linear motion guide rail of the lathe as the controlled object, and obtaining the linear motion guide rail According to the preset position information and actual position information, according to the deviation value and deviation value change rate between the preset position and the actual position, the fuzzy PID control algorithm is used to calculate the control output, and the control output is input into the control system to control all Describe the motion of the linear motion guide rail. The present invention adopts a domain parameter self-tuning method in the fuzzy PID control, introduces it into the fuzzy PID control, can realize self-learning and improve the static and dynamic performance of the ultra-precision lathe guide rail control system, and then achieve the improvement of ultra-precision cutting The purpose of machining accuracy.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

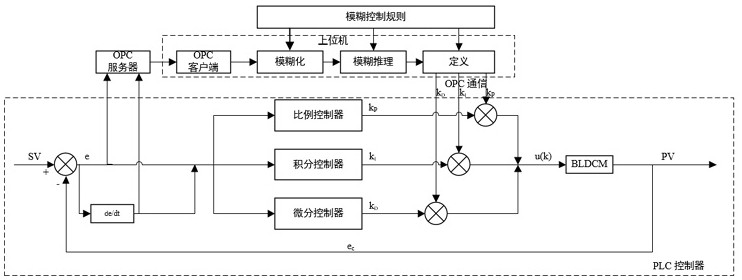

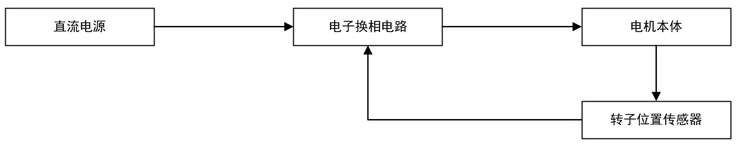

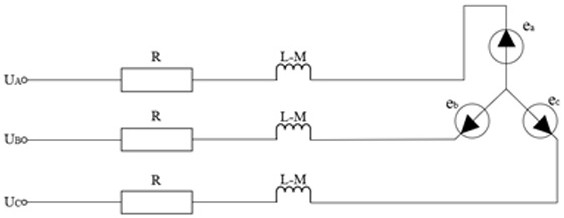

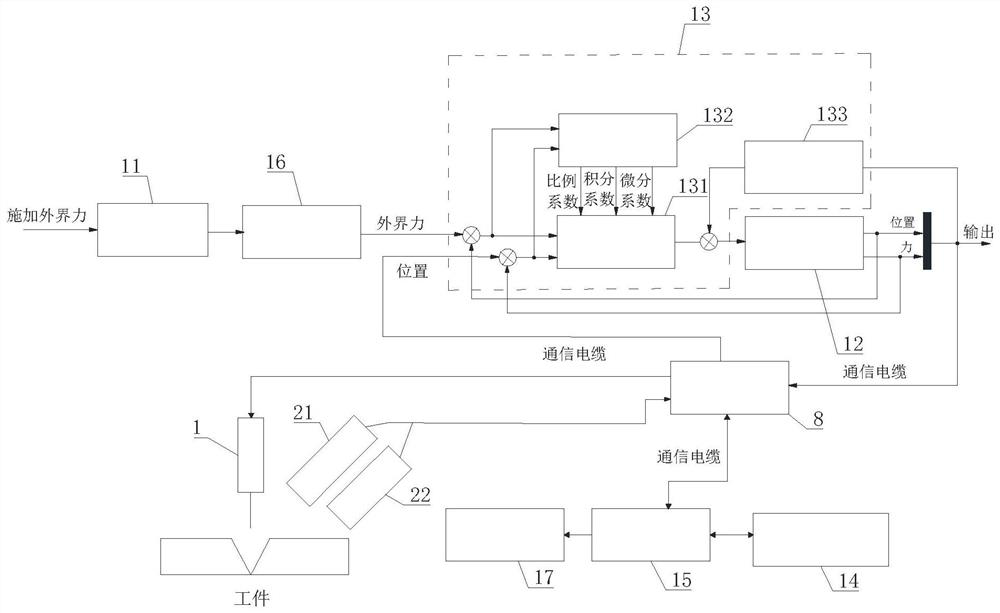

High-precision position control system and method for belt transmission device

InactiveCN113671824ARealize fuzzy self-tuningImprove stabilityControllers with particular characteristicsReduction driveElectric machine

The invention discloses a high-precision position control system for a belt type transmission device. The system is characterized by comprising a direct-current brushless servo motor and a speed reducer connected to the direct-current brushless servo motor, and a central shaft of a conveying belt is electrically connected to the direct-current brushless servo motor through a coupler; and an OPC client is connected to an OPC server, the OPC server is connected with a PLC, and the PLC is connected with the direct-current brushless servo motor for real-time control. According to the invention, a PID algorithm is realized in the PLC, the functions of fuzzy operation and judgment are realized by applying MATLAB, and the two functions are organically combined through an OPC technology, so that the real-time online fuzzy self-tuning of PID parameters is realized, and the stability and accuracy of the motor in a load state are improved.

Owner:YANCHENG INST OF TECH

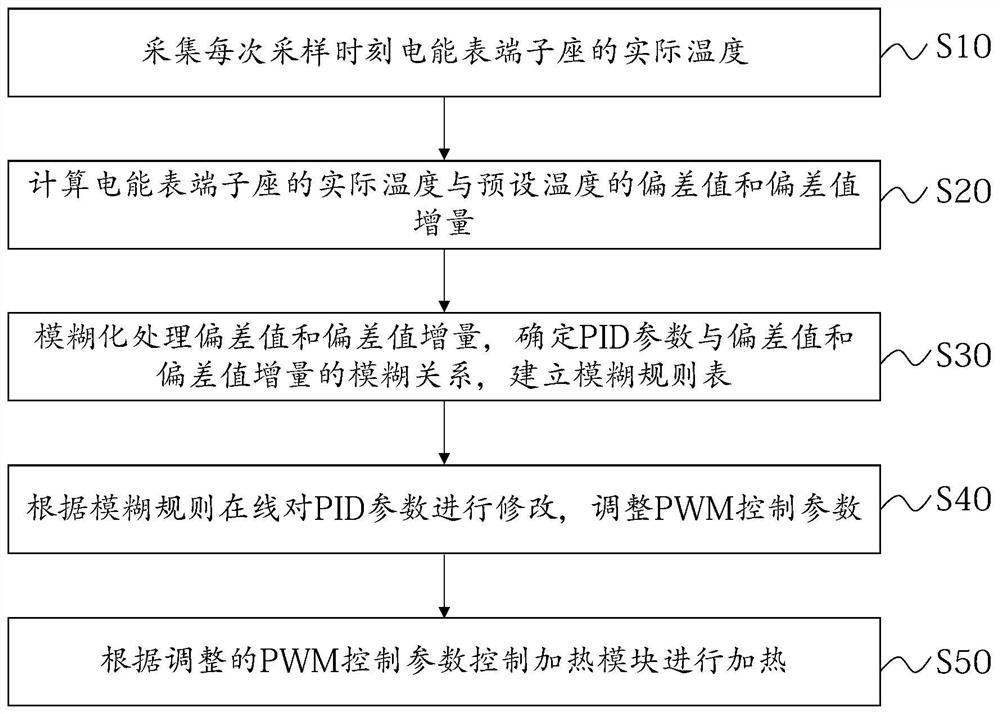

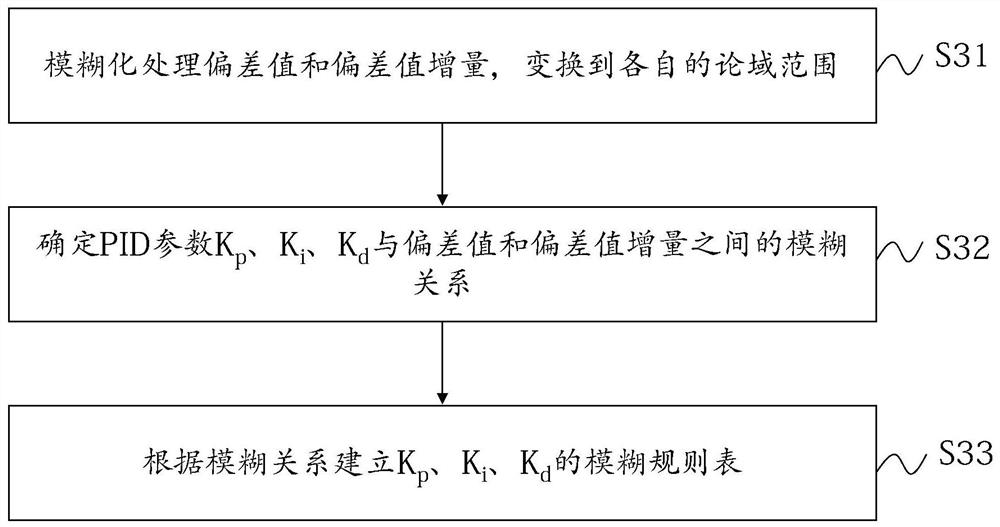

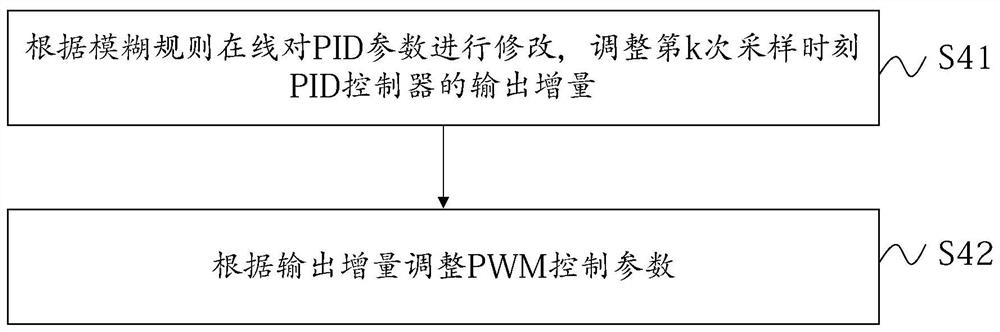

Electric energy meter terminal base temperature control method and device based on fuzzy PID algorithm

ActiveCN112783233AAvoid damageRealize fuzzy self-tuningTemperatue controlTemperature controlHeating time

The invention discloses an electric energy meter terminal base temperature control method and device based on a fuzzy PID algorithm, and relates to the field of electric energy meter terminal base temperature control. The electric energy meter terminal base temperature control method comprises the steps of collecting the actual temperature of an electric energy meter terminal base at each sampling moment; calculating a deviation value and a deviation value increment between the actual temperature of the electric energy meter terminal base and a preset temperature; carrying out fuzzy processing on the deviation value and the deviation value increment, determining a fuzzy relation between the PID parameter and the deviation value and the deviation value increment, and establishing a fuzzy rule table; modifying the PID parameter on line according to a fuzzy rule, and adjusting a PWM control parameter; and enabling a heating module to heat according to the adjusted PWM control parameter. According to the method, fuzzy self-tuning of PID parameters is realized, the control precision and stability of temperature control of the terminal base of the electric energy meter are improved, the heating time is effectively controlled, the temperature of the heating module is prevented from being too high, and the service life of the heating module is prolonged.

Owner:深圳市科陆精密仪器有限公司

A machine vision-based optimal shearing method for hot-rolled strip steel

ActiveCN113198854BReduce complexityAvoid disturbanceRoll mill control devicesMeasuring devicesInformation processingMachine

The invention belongs to the field of hot-rolled strip steel flying shear control engineering and relates to a machine vision-based optimal shearing method for hot-rolled strip steel. The method is mainly combined with the principle of machine vision to conduct non-contact measurement of the deformation of the strip end caused by rough rolling on the hot rolling production line, and optimize the control of the flying shear system through a fuzzy self-tuning PID controller, including the following operations Steps: 1) image acquisition of strip end; 2) image information processing; 3) three-dimensional contour acquisition; 4) three-dimensional convex hull calculation; 5) fuzzy self-tuning PID controller decision-making; ) actuator for shearing. The invention is based on a machine vision detection system, combined with an image processing unit to obtain the three-dimensional profile of the steel strip end, and controls the flying shear mechanism through a fuzzy self-tuning PID controller, and the shear mechanism performs precise cutting after receiving a signal sent by the controller. The invention realizes the online optimization of the hot-rolled steel strip flying shear system through the closed-loop control structure.

Owner:UNIV OF SCI & TECH BEIJING

Servo Control Method of Gasoline Engine Speed in Legged Robot Hydraulic System

ActiveCN106870181BStable speedReduce speed fluctuationElectrical controlSpeed sensing governorsLegged robotGasoline

Owner:SHANDONG UNIV

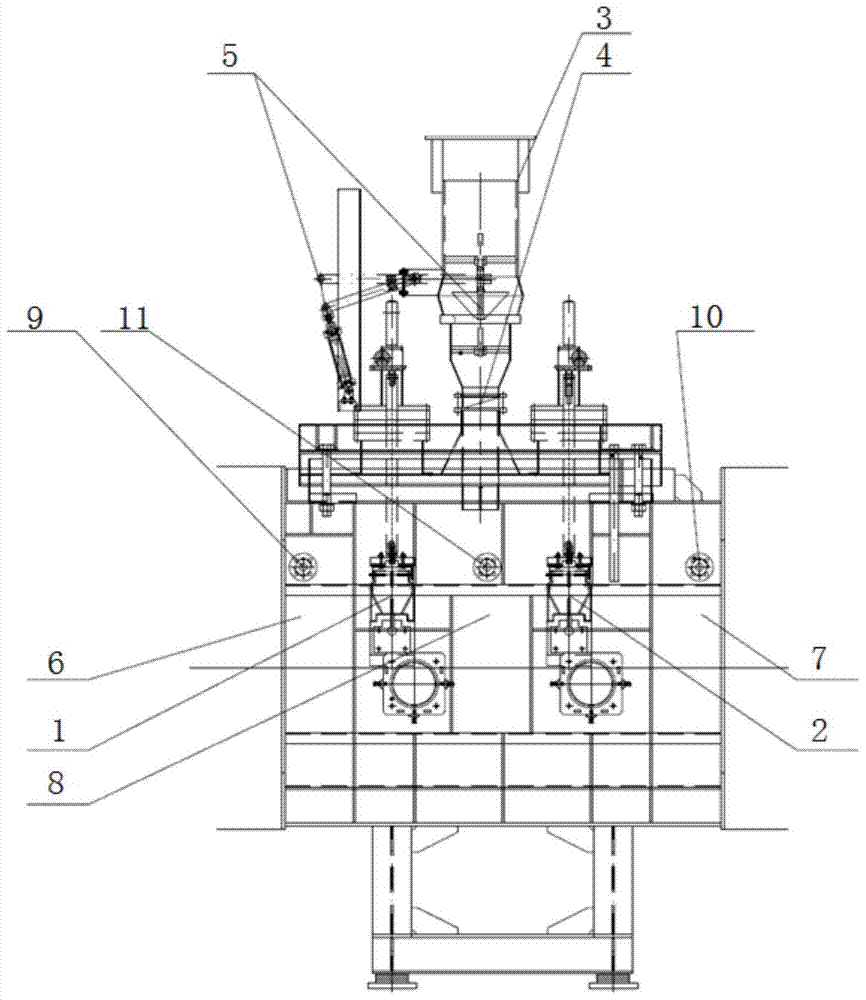

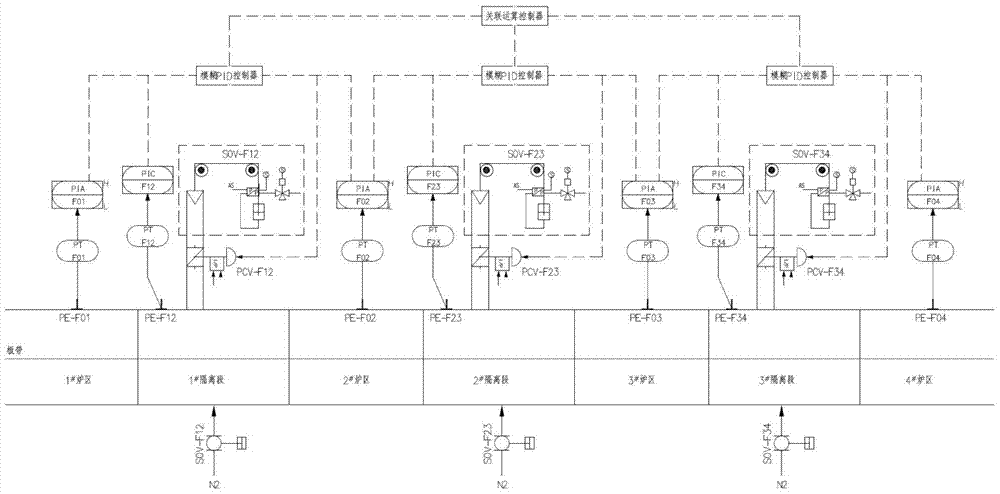

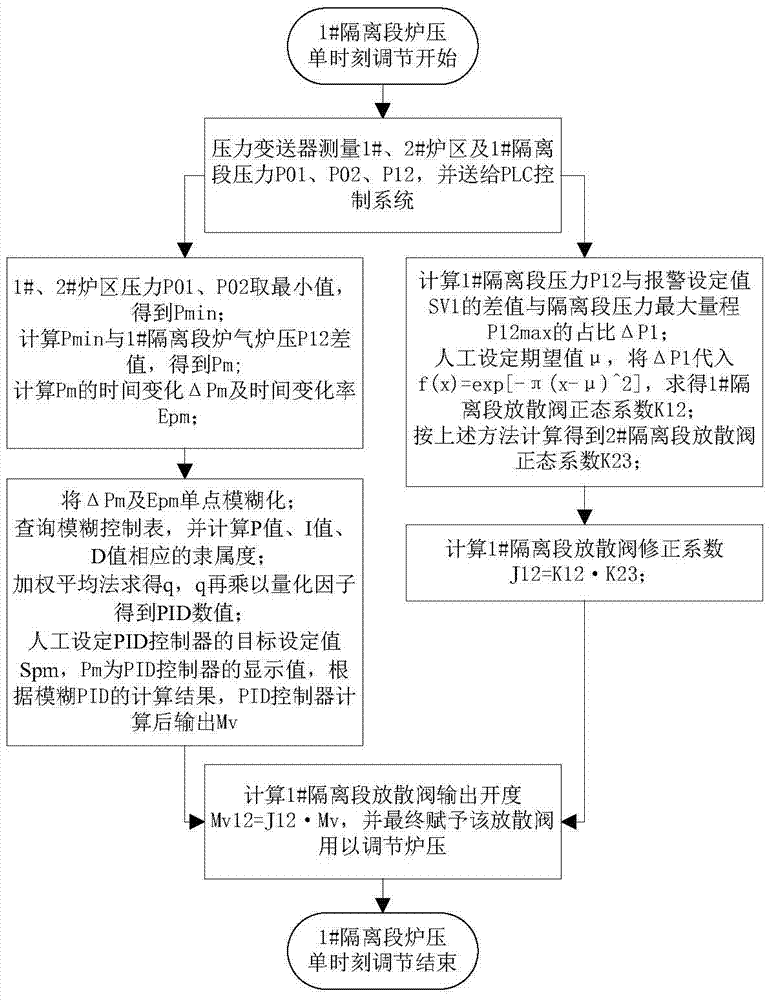

A method for controlling furnace pressure in isolation section of silicon steel continuous annealing furnace

ActiveCN105132668BImprove Segmentation IsolationImprove response speedFurnace typesHeat treatment process controlIsolation valvePositive pressure

The invention provides a method for controlling the furnace pressure in the isolation section of a continuous annealing furnace for silicon steel. The furnace pressure P01 in the 1# furnace area, the furnace pressure P02 in the 2# furnace area and the furnace gas pressure in the 1# isolation section are measured by a pressure transmitter. P12 is sent to the PLC control system; the PLC control system executes the PID parameter fuzzy self-tuning program, calculates the PID parameters, and then outputs the MV from the PID controller, and sends it to the associated operation controller; at the same time, the PLC control system also uses the normal distribution function Obtain the correction coefficient J12 of the relief valve in the 1# isolation section, and finally calculate the output opening of the relief valve in the 1# isolation section through the associated calculation controller MV12=J12×MV, and assign the calculation result of MV12 to the relief valve in the 1# isolation section to adjust the isolation Section furnace gas furnace pressure. The invention reduces the frequency of starting the nitrogen protection program to reduce the interference to the pressure and atmosphere in the furnace under the condition of ensuring the airflow isolation function of the isolation section and the micro positive pressure state of the isolation section.

Owner:WISDRI ENG & RES INC LTD

Multi-mode operation optimization control device and operation method of variable pitch fan based on timing analysis

ActiveCN106681151BShorten the timeExcellent performance indexAdaptive controlPerformance computingComputer module

Provided is a multi-mode operation optimization controlling device of a variable pitch wind turbine based on time series analysis and an operation method thereof. The multi-mode operation optimization controlling device of variable pitch wind turbine based on time series analysis comprises a human interface module, a modal perception module, a timing analysis module, a module for time series statistics recording, an online identification module of a variable pitch system, a parameter optimization module of a controller, a fuzzy self-tuning multi-mode PID controlling system module, a calculating module for control performance. From a systemic level, the invention includes the steps of categorizing various devices contained in the variable pitch wind power generation system as 'assembly' by zones and functions, wherein the assembly is regarded as fundamental elements and used for building the modal perception module; time series analyzing for the modal perception module in the transient process of various modal switching on the basis of the assembly; obtaining the time series statistic data through the time series analyzing during the transient process of the various modal switching; online identifying and controller parameter optimizing for the various pitch system utilizing the time series statistics; synthesizing the optimized controlling parameter through the fuzzy self-tuning multi-mode PID controlling system, the step that eventually realizes the optimal performance of the variable pitch system under full working conditions.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

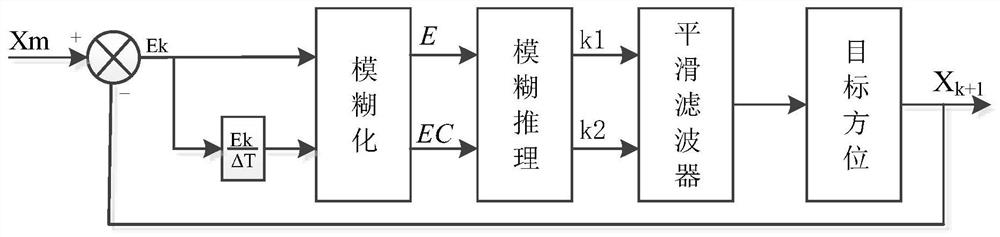

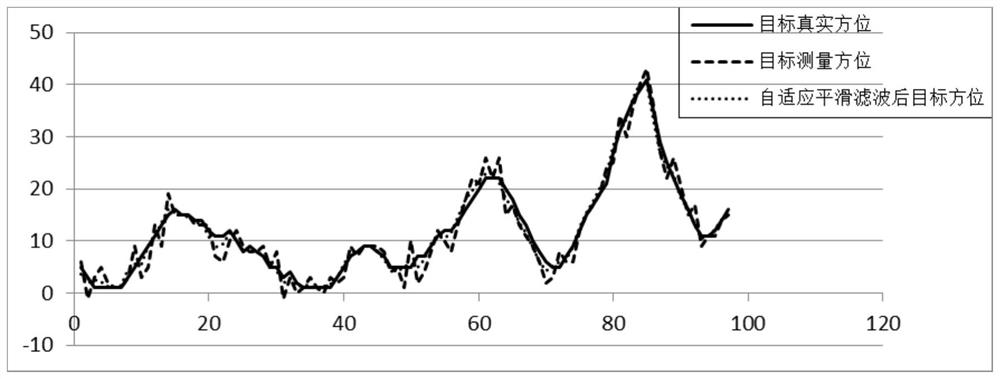

Adaptive smoothing filtering method for target orientation

PendingCN114021600ASmall overshootAnti-interferenceCharacter and pattern recognitionElectronic systemsFuzzy self tuning

The invention discloses an adaptive smoothing filtering method for a target orientation, and the method comprises the steps of enabling the current target orientation to be Xk, and intercepting a target through an electronic system; enabling the target orientation measured this time to be Xm, and obtaining the target orientation Xk + 1 after smoothing filtering through the following formula: Xk + 1 '= Xk + [delta] T * Vk; Ek = Xm-Xk + 1 '; Xk + 1 = Xk + 1 '+ k1 * Ek; wherein Xk + 1'is the target orientation predicted this time, delta T represents the data sampling period, Vk represents the change rate of the current target orientation, and the initial value is 0; Ek represents the difference value between the currently measured target orientation and the predicted target orientation; k1 represents a target azimuth change coefficient. According to the method, the fuzzy self-tuning smoothing filter is adopted for target azimuth smoothing filtering, and actual operation shows that interference can be effectively resisted, azimuth tracking rapidity is improved, and azimuth smoothing filtering overshoot is reduced.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

A kind of AGV magnetic combined navigation method

ActiveCN107015565BAccurate detectionImprove fault tolerancePosition/course control in two dimensionsMagnetic tapeElectric machinery

The present invention relates to a magnetic combined navigation method of an AGV (automated guided vehicle). The method mainly comprises a combination method of command magnetic tapes, a signal filtering algorithm and an AGV navigation control algorithm. According to the magnetic combined navigation method, a plurality of magnetic tapes are combined into a function command; magnetic tapes are laid in a crossed manner between commands; command magnetic tapes of the same polarity are laid inconsecutively at the same sampling point; the signals of a command sensor are received through IO external triggering interruption, the effectiveness of the signals is analyzed through detecting the duration and receiving sequence of the signals; the signals of a navigation sensor are received through an IO scanning mode, and whether the signals are discarded is determined through detecting the continuity of the sampling points and the duration of the signals; and control speed is calculated based on the deviation distances of the center of the navigation sensor and the centers of the magnetic tapes through using the fuzzy self-tuning PD control law, and the control speed is provided for a motor, and therefore, the pose of the AGV is adjusted. The method of the invention has the advantages of reliable signal sampling, effective and robust controller and good navigation control effect.

Owner:FUZHOU UNIV

Method for controlling operations of shaker of computerized flat knitting machine

InactiveCN101655704BPrevent deviationSolve the unstable accuracyNumerical controlFuzzy pid controlPid control algorithm

The invention belongs to the technical field of computerized flat knitting machines, in particular to a method for controlling operations of a shaker of a computerized flat knitting machine. The method comprises the following steps: collecting real-time operation information of a servo motor; inputting the obtained operation information of the servo motor into an information processor to calculate; calculating an offset value in the step (2) by adopting an adaptive fuzzy PID control algorithm so as to obtain current revised data and then inputting the revised data into a program controller; calculating current Kp, Ki and Kd values by utilizing a fuzzy self-tuning rule and carrying out discretization processing through an incremental PID calculation; and outputting control signals to the servo motor by the program controller according to a control program to realize the automatic operation error correction and the precise operation control of the shaker. The invention can avoid needle transferring and connecting deviations and ensure that the computerized flat knitting machine works in an optimal state all the time, thereby solving the problem of unstable precision of the shaker inan operation process of the computerized flat knitting machine.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

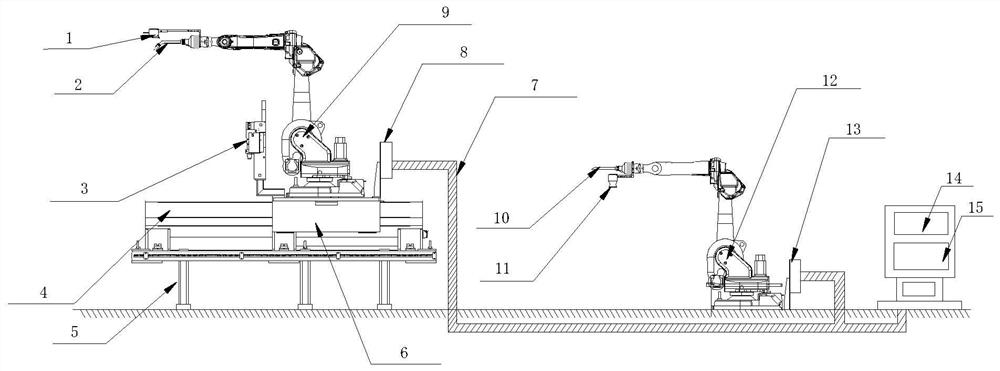

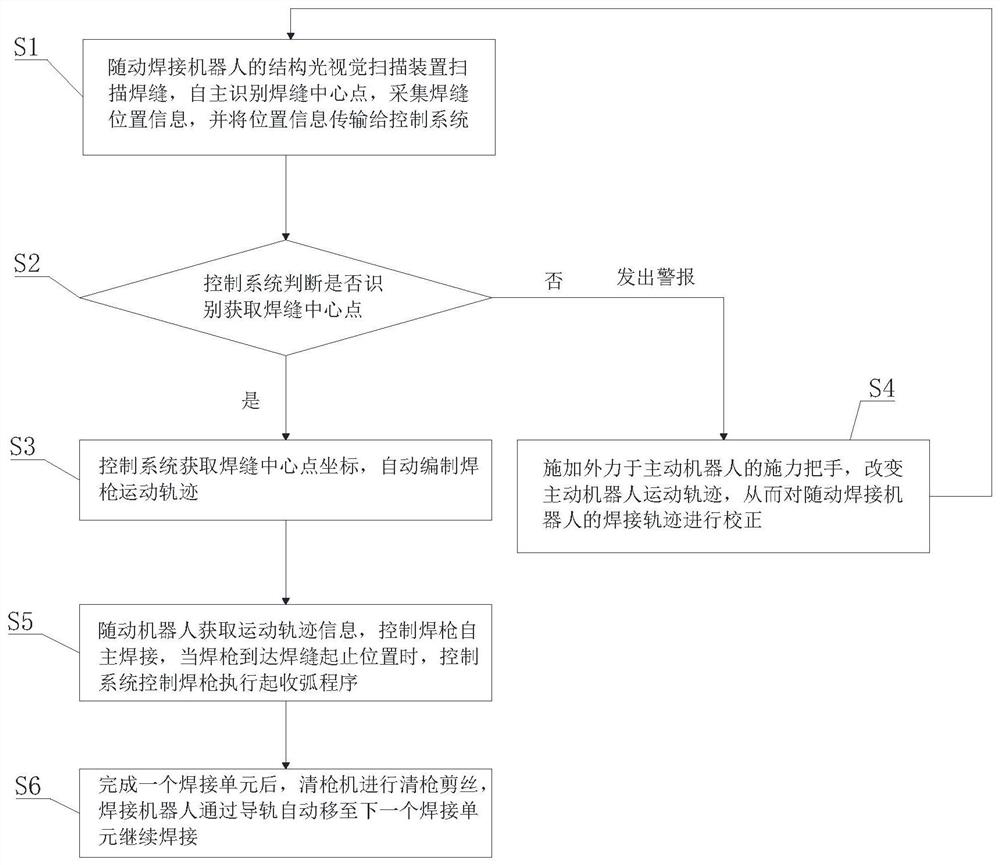

Ship assembly plate welding robot and welding method based on remote correction

ActiveCN111590165BReal-time correctionGuaranteed robustnessProgramme-controlled manipulatorWeld torches cleaningDynamic modelsControl system

The present invention relates to the technical field of ship equipment, in particular to a welding robot for ship erecting plates based on remote correction, including a follow-up welding robot, an active robot, a control system and a human-computer interaction system; the end of the follow-up welding robot is equipped with structured light vision scanning Device, welding torch, welding robot controller is installed on the follow-up welding robot, welding torch model and force application handle are installed on the end of the active robot, active robot controller is installed on the top of the active robot, and a force sensor is installed on the bottom of the force application handle; Robot controllers include impedance controllers, fuzzy self-tuning controllers, and inverse dynamic models. The follow-up welding robot of the present invention is controlled by the follow-up of the active robot, and by applying external force to the force-applying handle, the position and force compliance control of the end of the active robot can be realized, so that the welding track of the follow-up welding robot returns to the autonomous scanning range. , to achieve remote calibration.

Owner:BEIBU GULF UNIV

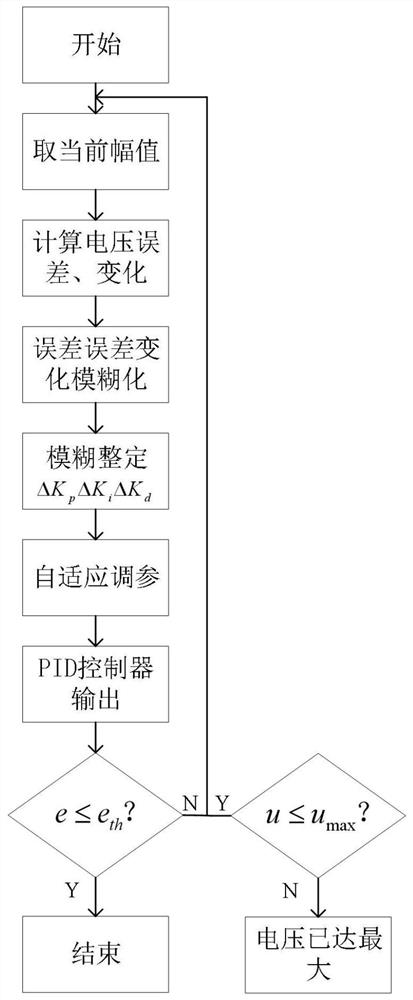

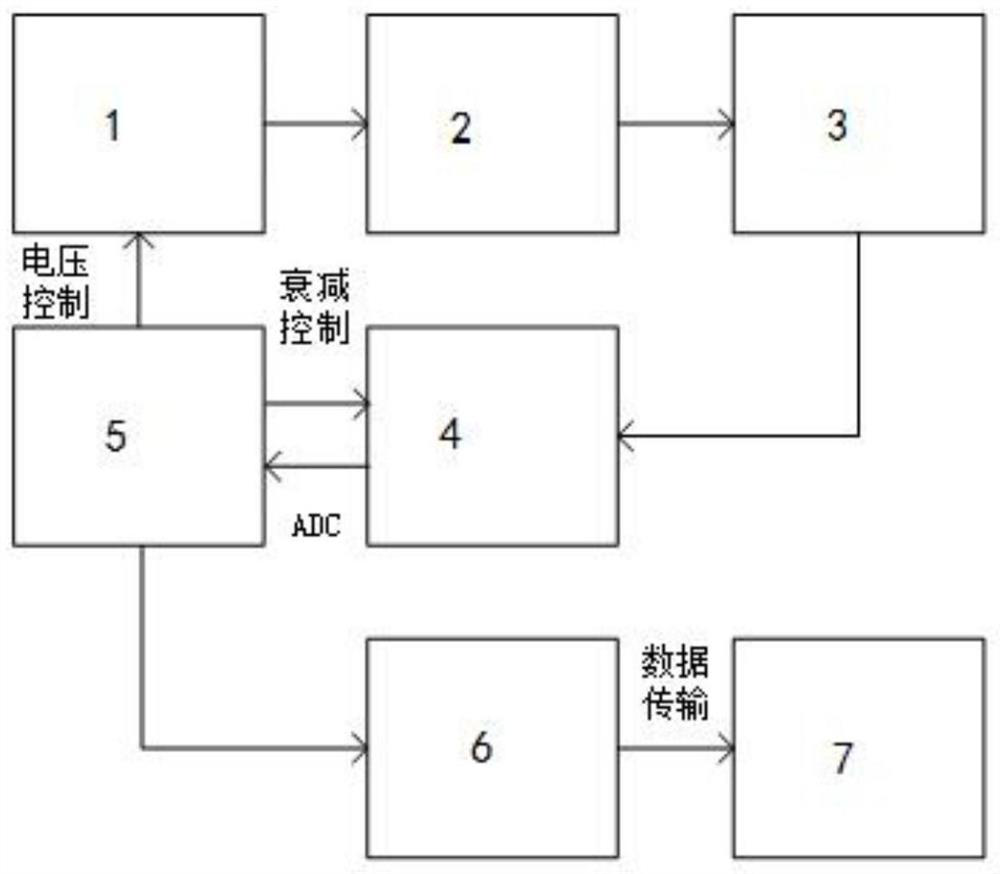

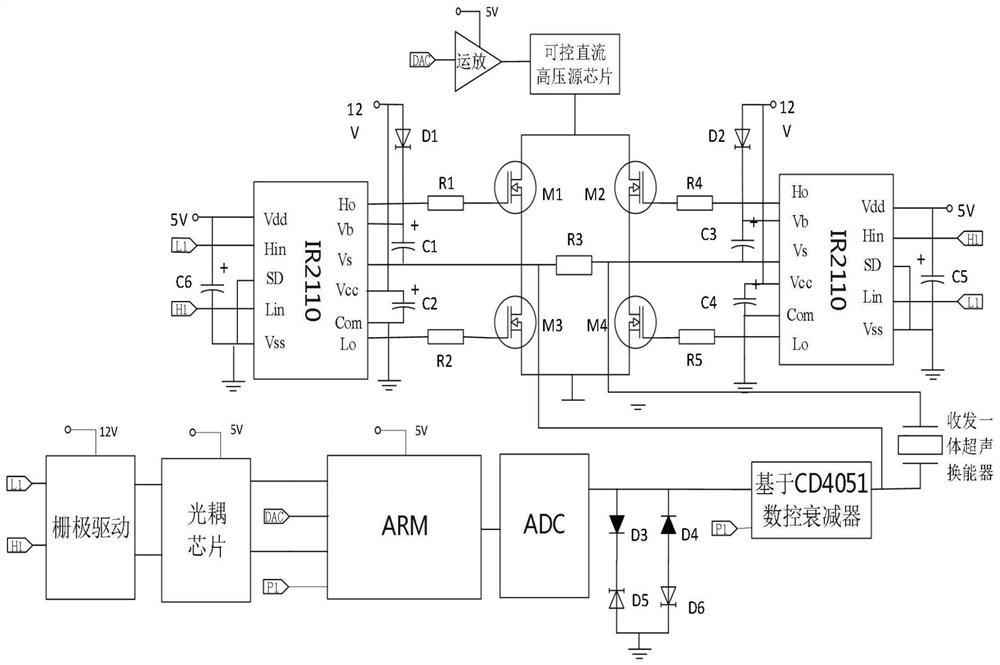

Ultrasonic detection system with self-adaptive emission voltage and voltage adjusting method

PendingCN113050096AEasy to observeEase of subsequent signal processingControllers with particular characteristicsAcoustic wave reradiationFuzzy ruleControl theory

The invention relates to an ultrasonic detection system with self-adaptive emission voltage and a voltage regulation method. The method includes design of a numerical control bipolar ultrasonic excitation power supply, design of an ultrasonic echo receiving circuit and design of a fuzzy self-tuning PID control scheme. The method comprises the steps of setting an optimal ultrasonic echo signal amplitude according to system noise and an expected echo peak signal-to-noise ratio, setting a corresponding attenuation multiple, collecting the amplitude of an echo signal, calculating an error and an error change rate, carrying out fuzzy reasoning by using a fuzzy rule, searching a fuzzy rule table to carry out adjustment on parameters Kp, Ki and Kd, controlling the emission voltage of the numerical control bipolar ultrasonic excitation power supply according to the control quantity obtained by the PID controller, and providing an ultrasonic echo signal with a high signal-to-noise ratio and a stable amplitude for subsequent signal processing.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com