Ultrasonic detection system with self-adaptive emission voltage and voltage adjusting method

A technology of self-adaptive adjustment and emission voltage, which is applied in the direction of radio wave measurement systems, measurement devices, electrical components, etc., can solve the problems of low accuracy of manual adjustment, and achieve the effect of excellent control, high signal-to-noise ratio, and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

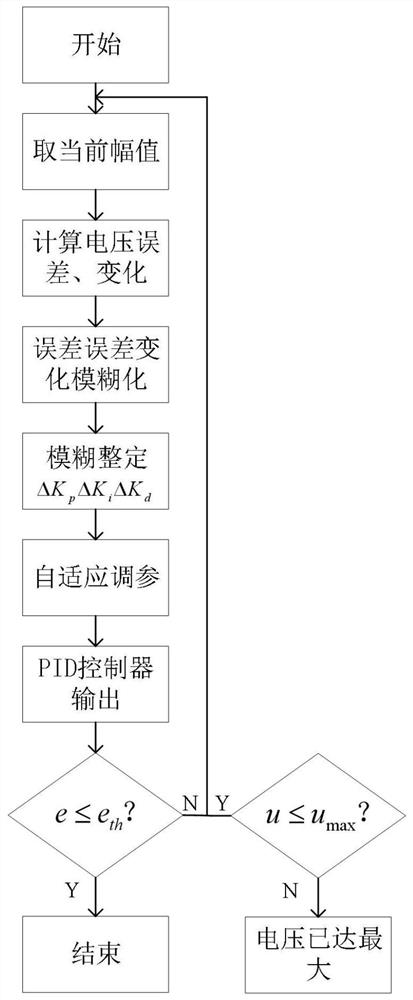

[0055] see figure 1 , an embodiment of the present invention provides a transmission voltage adaptive adjustment method of an ultrasonic testing system, the method comprising:

[0056] S1. Calculate the optimal echo voltage amplitude according to the system noise of the ultrasonic testing system and the preset expected signal-to-noise ratio;

[0057] Measure the system noise amplitude V of the ultrasonic testing system n , set the expected echo peak signal-to-noise ratio SNR, calculate the optimal echo voltage and set the attenuation multiple according to the voltage value according to the ADC voltage input amplitude range, the optimal echo voltage amplitude is V=V n .SNR; where the attenuation factor is set to ensure that the voltage amplitude range of the ADC converter is met. The amplitude of the system noise is the average value of the system noise, and the unit of the signal-to-noise ratio is times.

[0058] System noise is a kind of random noise generated by the elect...

Embodiment 2

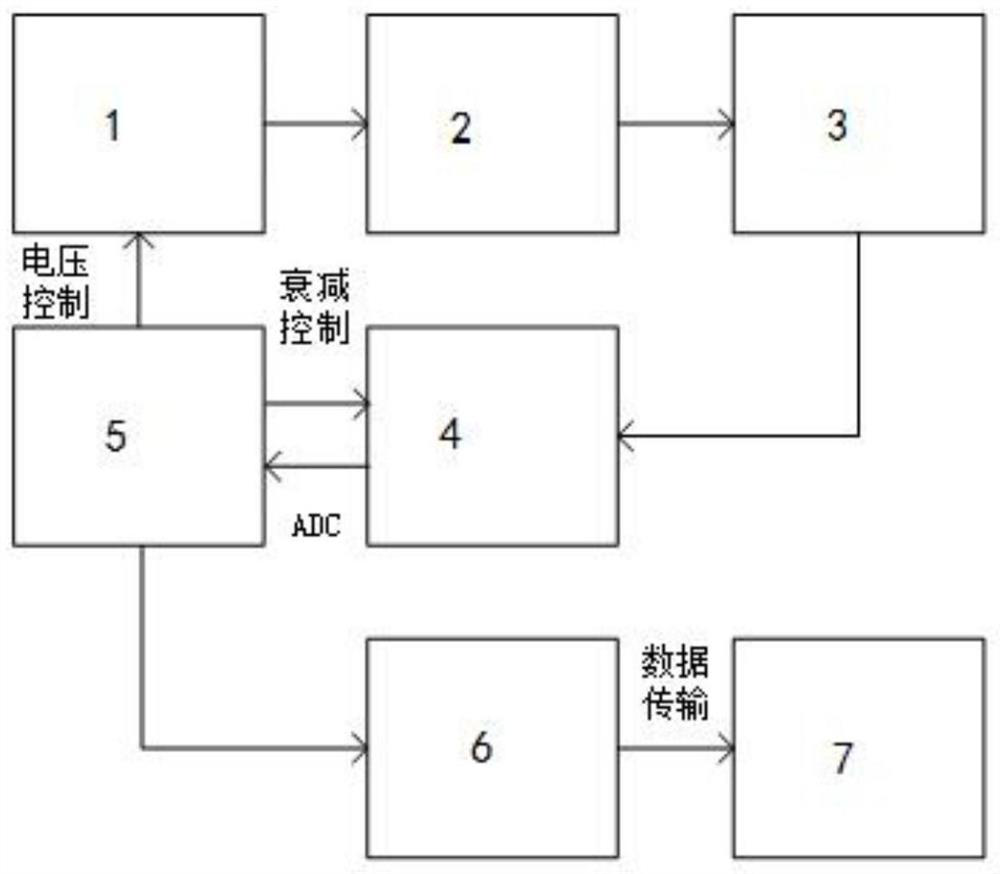

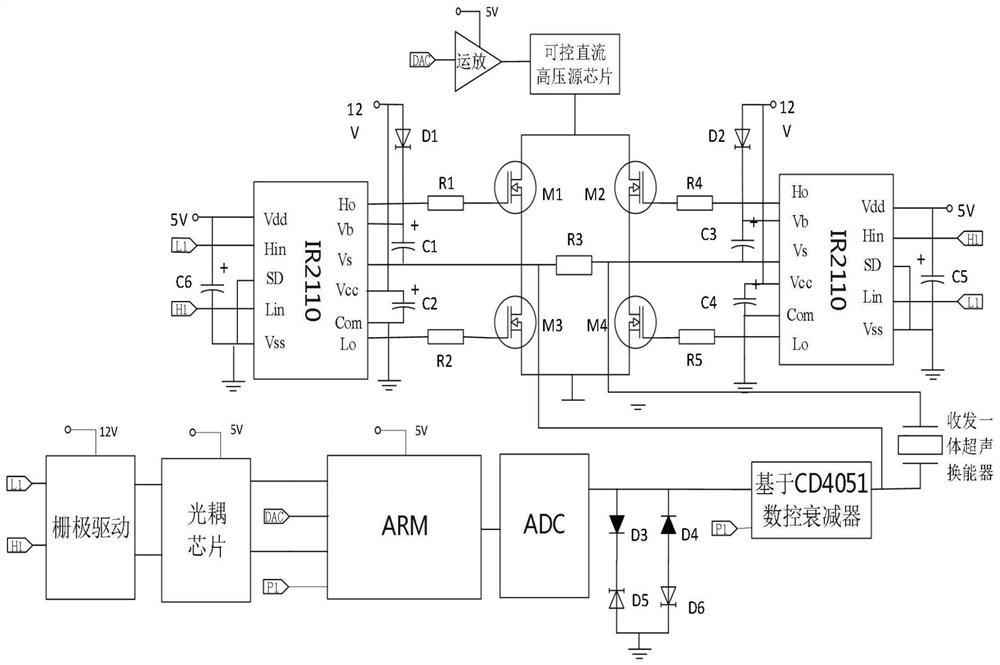

[0081] see figure 2 , the embodiment of the present invention provides an ultrasonic testing system with self-adaptive emission voltage, its specific circuit diagram is as follows image 3 As shown, the system includes:

[0082] An ultrasonic excitation power supply, an ultrasonic echo receiving circuit and a fuzzy PID controller; the fuzzy PID controller is respectively connected to the ultrasonic excitation power supply and the ultrasonic echo receiving circuit; the ultrasonic excitation power supply includes: a controllable DC high voltage source 1 and a full bridge drive circuit 2; The ultrasonic echo receiving circuit includes: a numerically controlled attenuator 4; the fuzzy PID controller includes: an ARM main control chip 5.

[0083] The ultrasonic excitation power supply is used for transmitting voltage; the transmitting voltage is adjusted by the fuzzy PID controller; the ultrasonic echo receiving circuit is used for collecting echo signals; the echo signal is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com