CompactLogix-based fuzzy self-tuning PID liquid level control method

A technology of liquid level control and fuzzy controller, which is applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc. It can solve the problems of difficult setting of control parameters, low efficiency, and difficulty in achieving the best control effect. Good control effect, improve efficiency and save calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

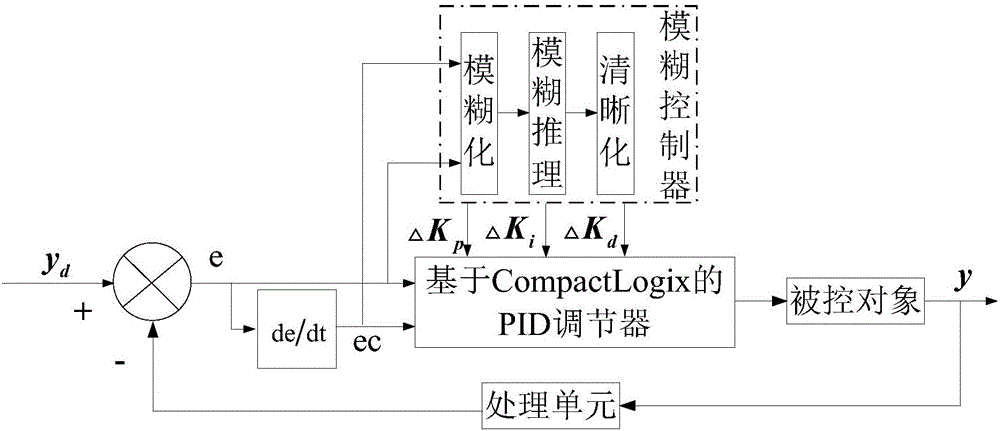

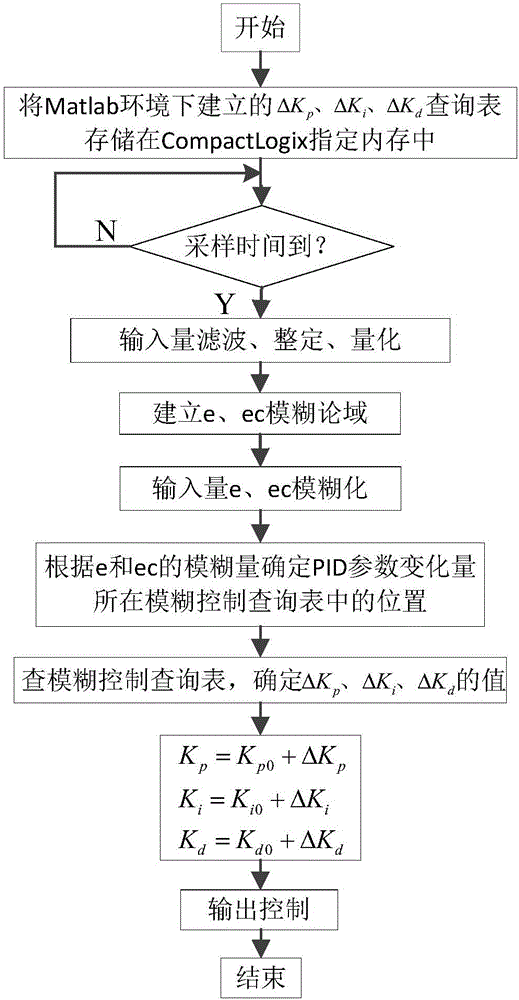

[0047] The present invention is a liquid level control method based on CompactLogix-based fuzzy self-tuning PID, the control structure is as follows figure 1 As shown, the actual liquid level signal y is sampled, filtered, adjusted and quantized, and then the set liquid level signal y is calculated d The deviation e and the deviation change rate ec between the actual liquid level signal y; take e and ec as the input variables of the fuzzy controller, and perform fuzzy, fuzzy reasoning, and clear processing on the input variables to obtain the output of the fuzzy controller ΔK p , ΔK i , ΔK d , combined with the initial reference value set by the conventional PID controller, the three parameters of the PID controller can be obtained, and finally the control signal is calculated by the PID regulator formula, and acts on the controlled object....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com