Patents

Literature

426results about How to "Meet control requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

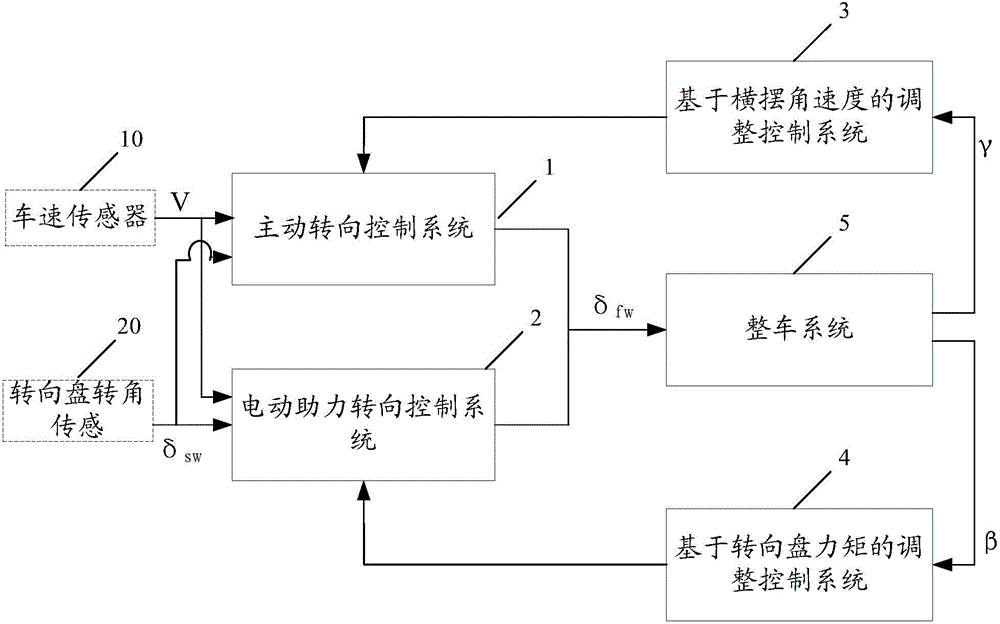

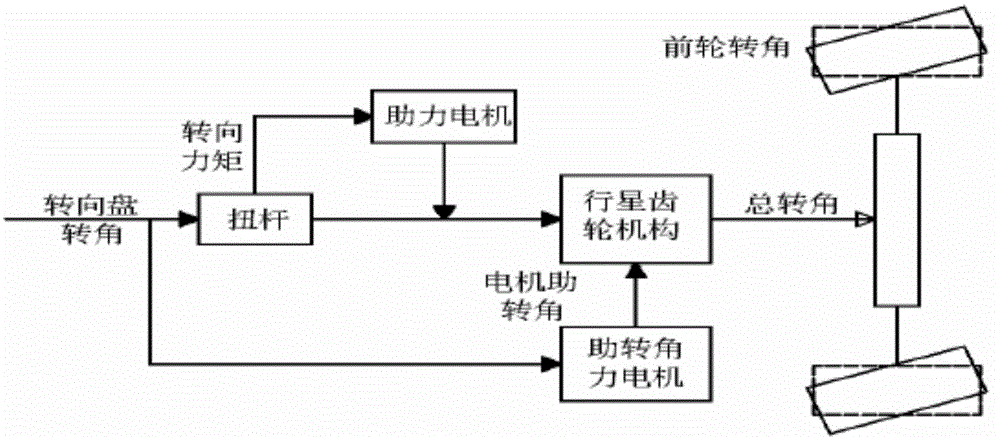

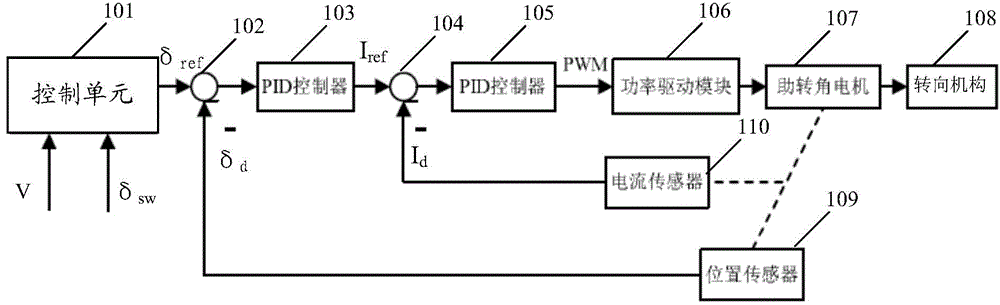

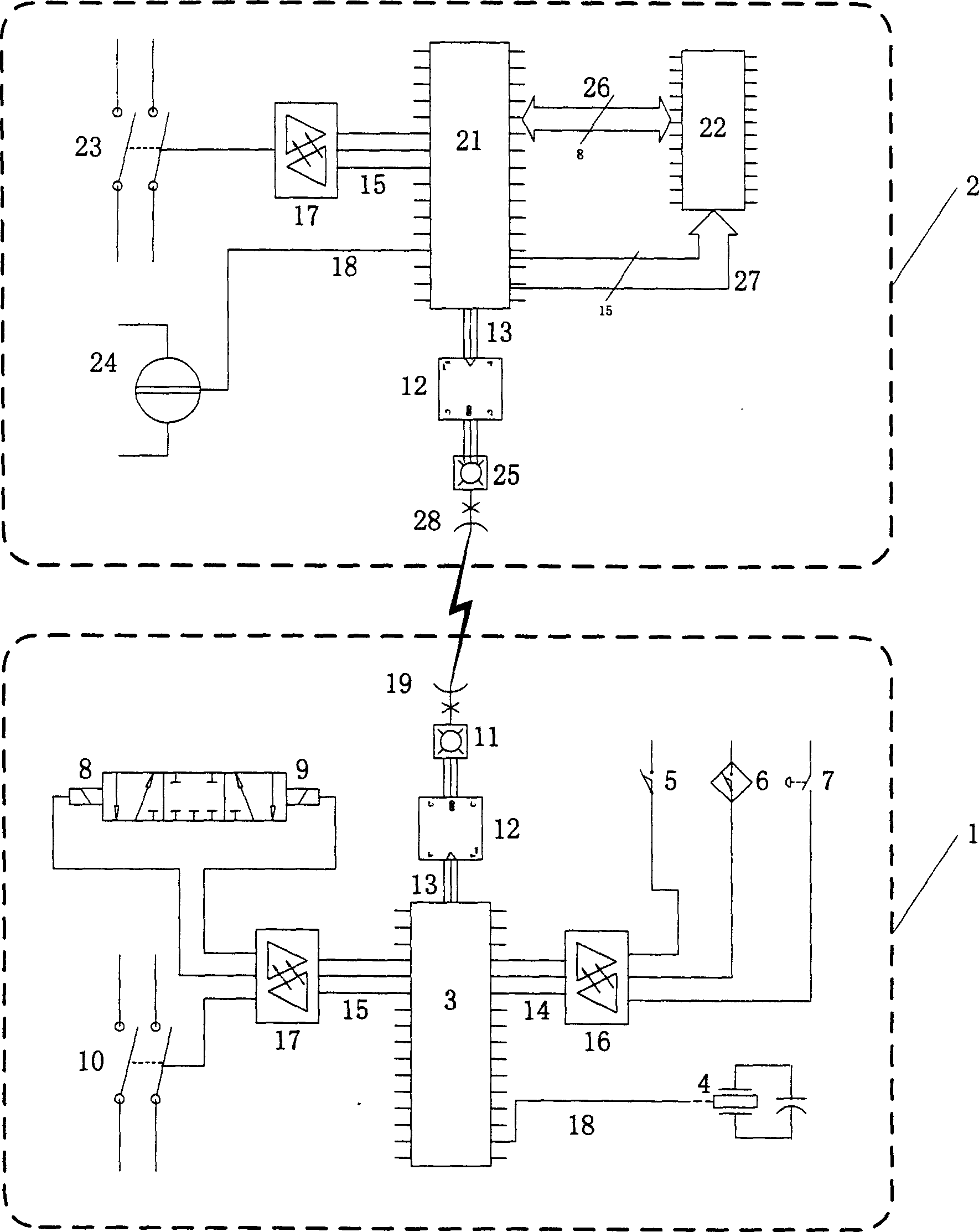

Combination control system for integration electric power steering and active steering

InactiveCN104477231AImprove stabilityRealize active steering functionSteering linkagesAutomatic steering controlElectric power steeringSteering wheel

The invention discloses a combination control system for integration electric power steering and active steering. The combination control system for integration electric power steering and active steering comprises an active steering control system, an electric power steering control system, an adjustment control system based on yaw velocity and an adjustment control system based on steering wheel moment, the active steering control system and the electric power steering control system are respectively connected with a vehicle speed sensor and a steering wheel angle sensor for calculating and processing the inputted vehicle speed and steering wheel angle and outputting the total front wheel angle control signal to the total system for steering the front wheel actively; the adjustment control system based on yaw velocity is used for adjusting the obtained yaw velocity value for having feedback to the active steering control system for amending the front wheel angle control signal; the adjustment control system based on steering wheel moment is used for adjusting the obtained steering wheel moment for having feedback to the electric power steering control system for amending the outputted front wheel angle control signal.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

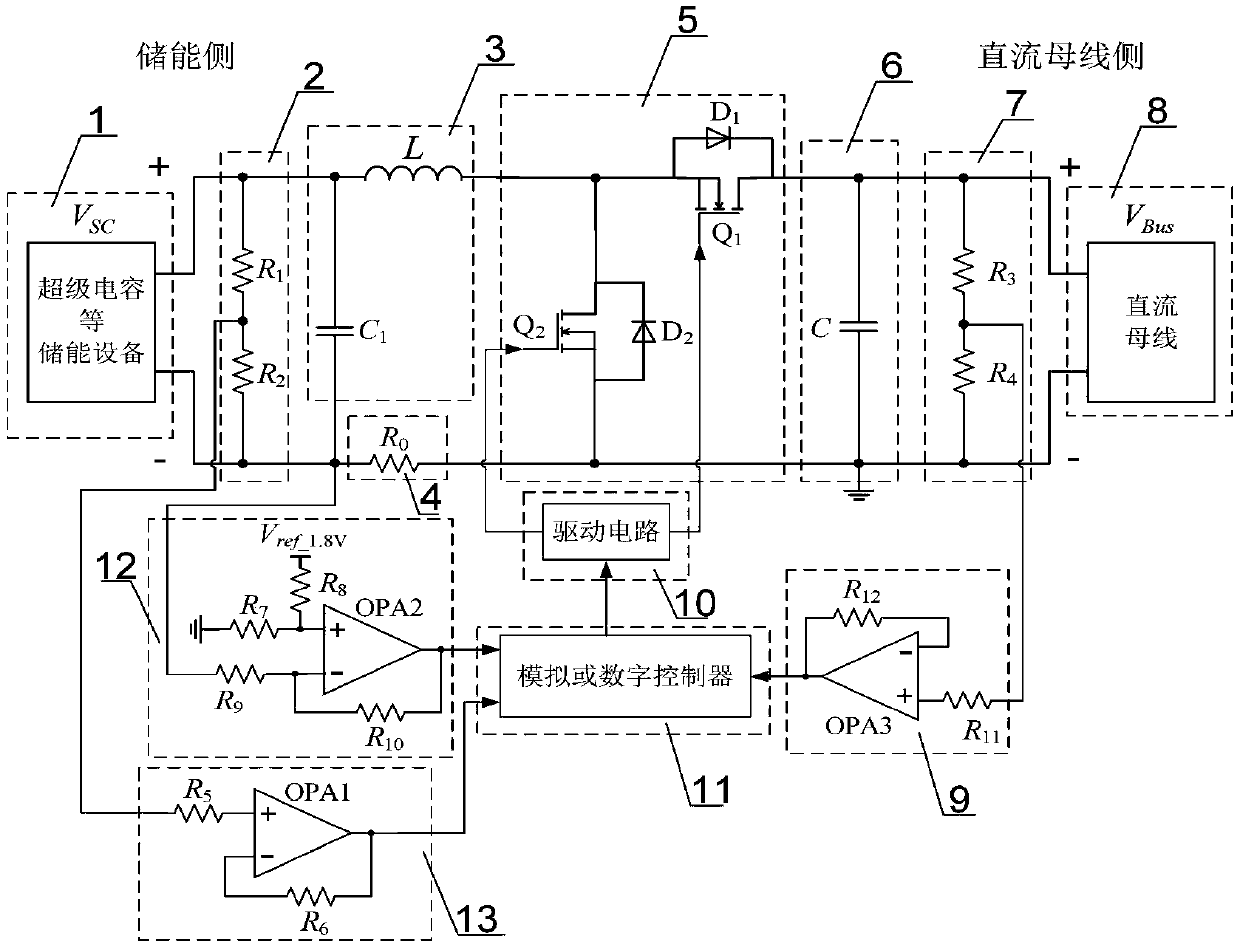

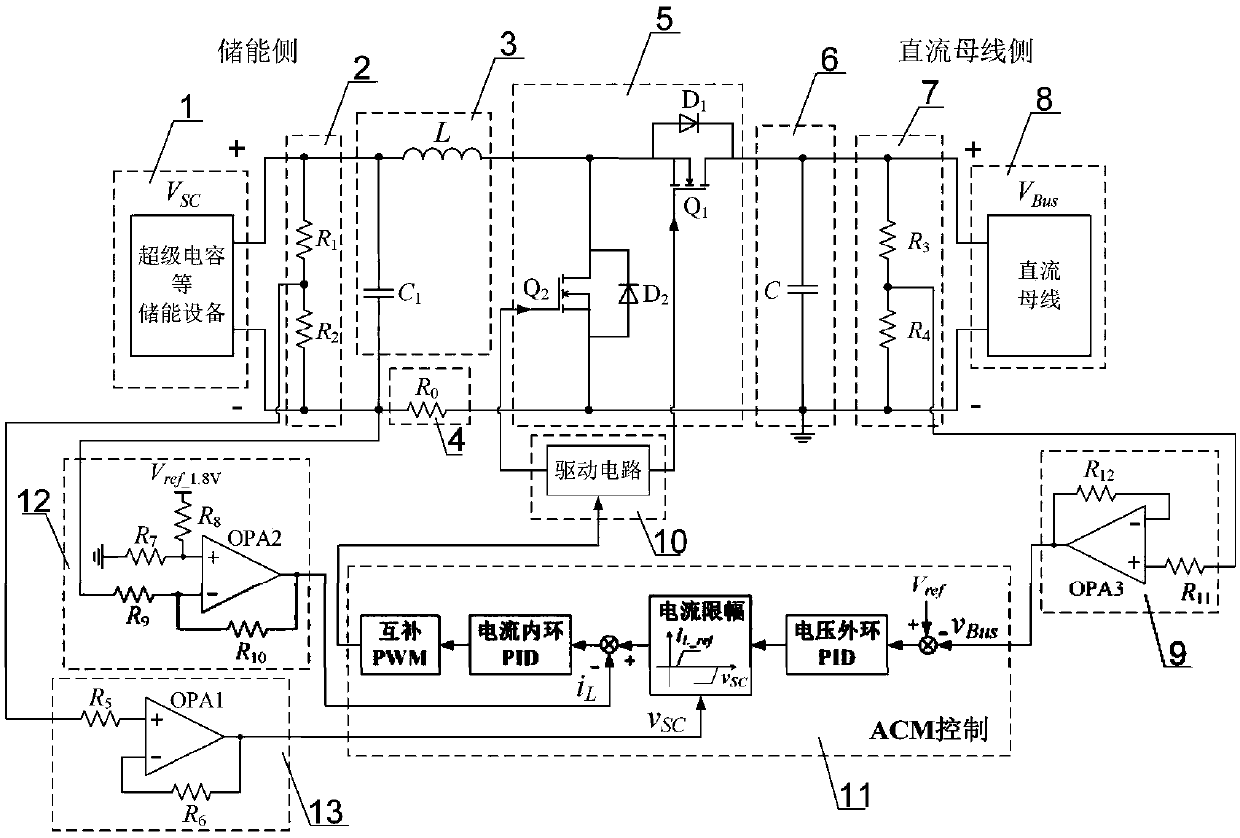

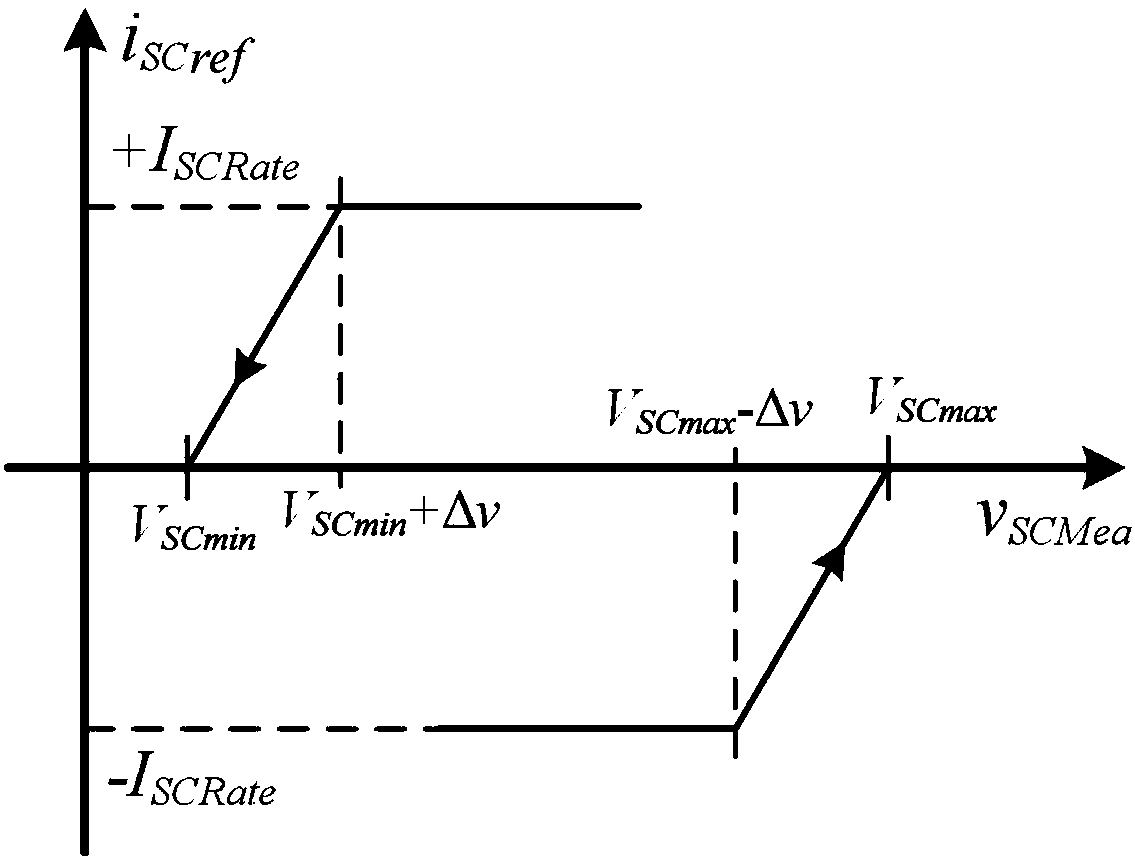

Double-port stable control method and circuit and bidirectional DC/DC power converter

ActiveCN108574411AMeet control requirementsAchieve smooth switchingDc-dc conversionElectric variable regulationCapacitanceOvervoltage

The invention relates to a double-port stable control method and circuit and a bidirectional DC / DC power converter, and belongs to the technical field of power converters. A controller of the controlcircuit provides a PWM control signal, a driving circuit is controlled to switch on or switch off a corresponding MOS in a switch tube power circuit, and a DC bus voltage VBus in certain stability andprecision is formed between the two ends of a DC bus side capacitor C via a DC bus side filtering circuit. The controller controls the driving circuit by carrying out under-voltage protection of an energy-storage unit when the voltage in the energy storage side is lower than the lower limit of the working voltage; carrying out overvoltage protection of the energy-storage unit when the voltage inthe energy storage side is higher than the upper limit of the working voltage; and limiting the maximal continuous charging / discharging current of the energy-storage unit via an ACM control algorithmwhen the voltage in the energy storage side is within the upper limit and the lower limit of the working voltage. PWM output control is combined with ACM control to realize double-port stable controlof the bidirectional DC / DC power converter, and the method and circuit are suitable for any type of bidirectional DC / DC power converter.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

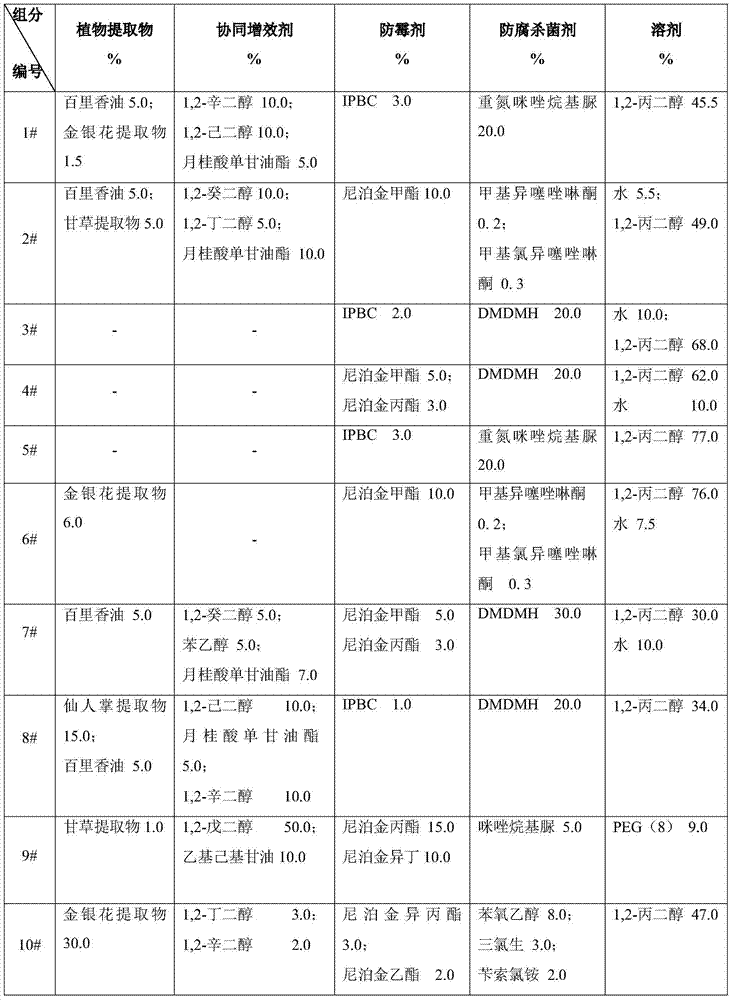

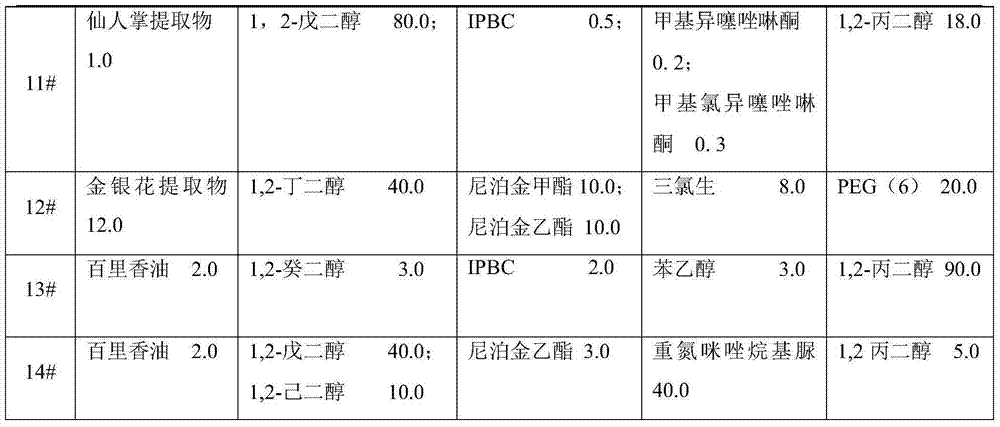

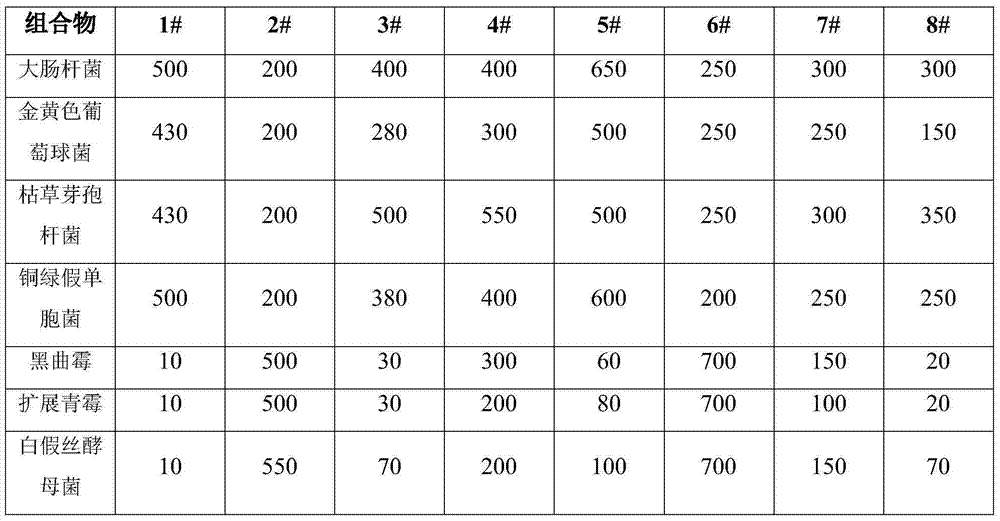

Plant extract and synergist contained antimicrobial composition

ActiveCN103535385AMeet control requirementsImprove the safety of useCosmetic preparationsBiocideMicroorganismAdditive ingredient

The invention discloses a plant extract and synergist contained antimicrobial composition. The composition contains a plant extract (A), a synergist (B), a mildew preventive (C), an antiseptic (D) and a solvent (E). The composition disclosed by the invention has a good inhibiting effect on bacteria and fungi (molds nod saccharomycetes); through the synergistic effect of all the components, the consumption of the traditional chemical antiseptic IPBC (Iodopropynyl Butylcarbamate) or nipagin esters is remarkably reduced, the safety in using the composition is improved, the irritation is reduced, and the possible risks are reduced. Meanwhile, the antiseptic is compounded in the composition, so that the antibacterial spectrum of an antiseptic system of the composition is effectively expanded, and the bacteriostatic ability is enhanced.

Owner:BEIJING SUNPU BIOCHEM TECH

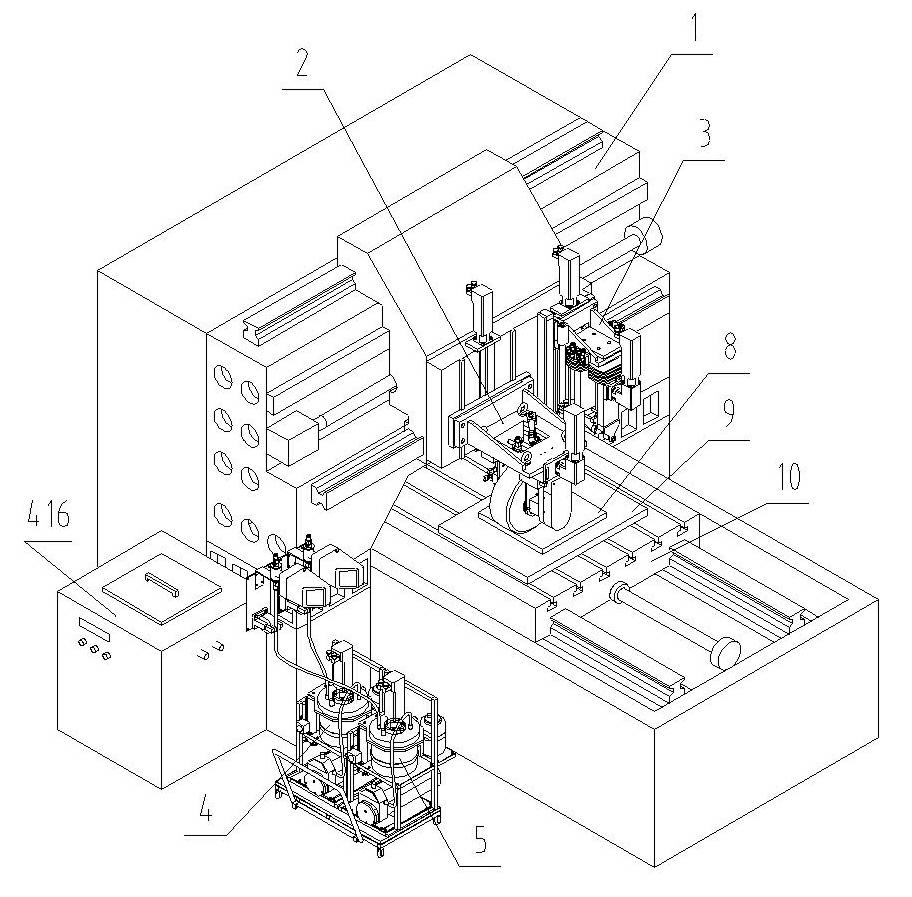

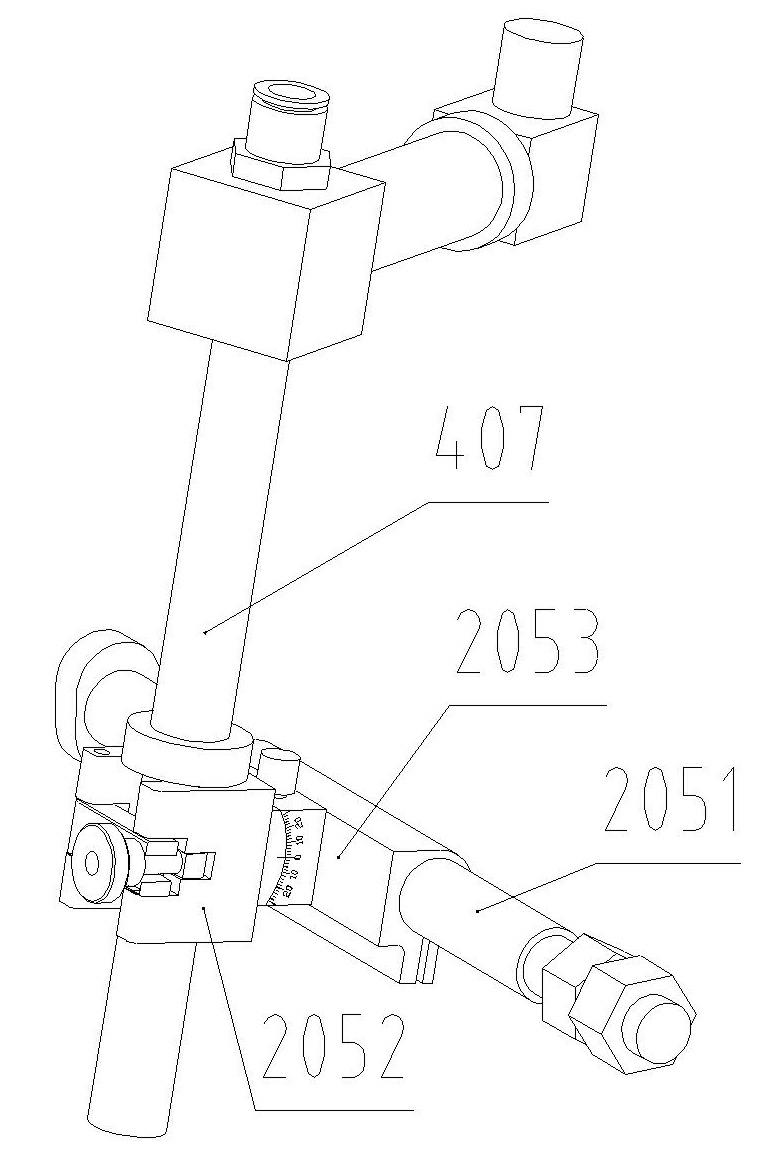

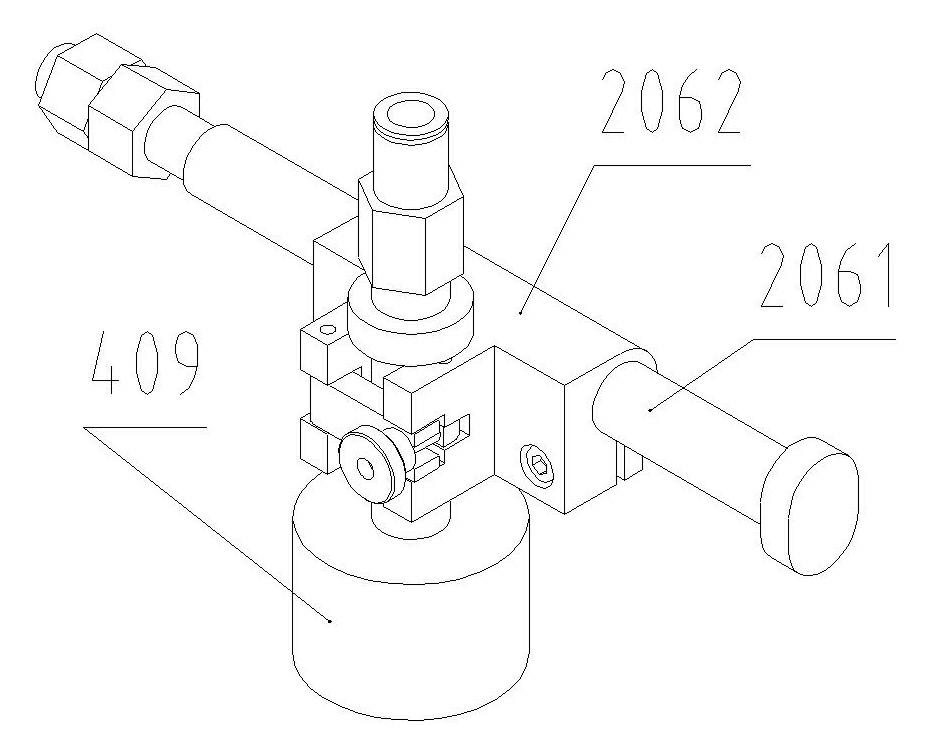

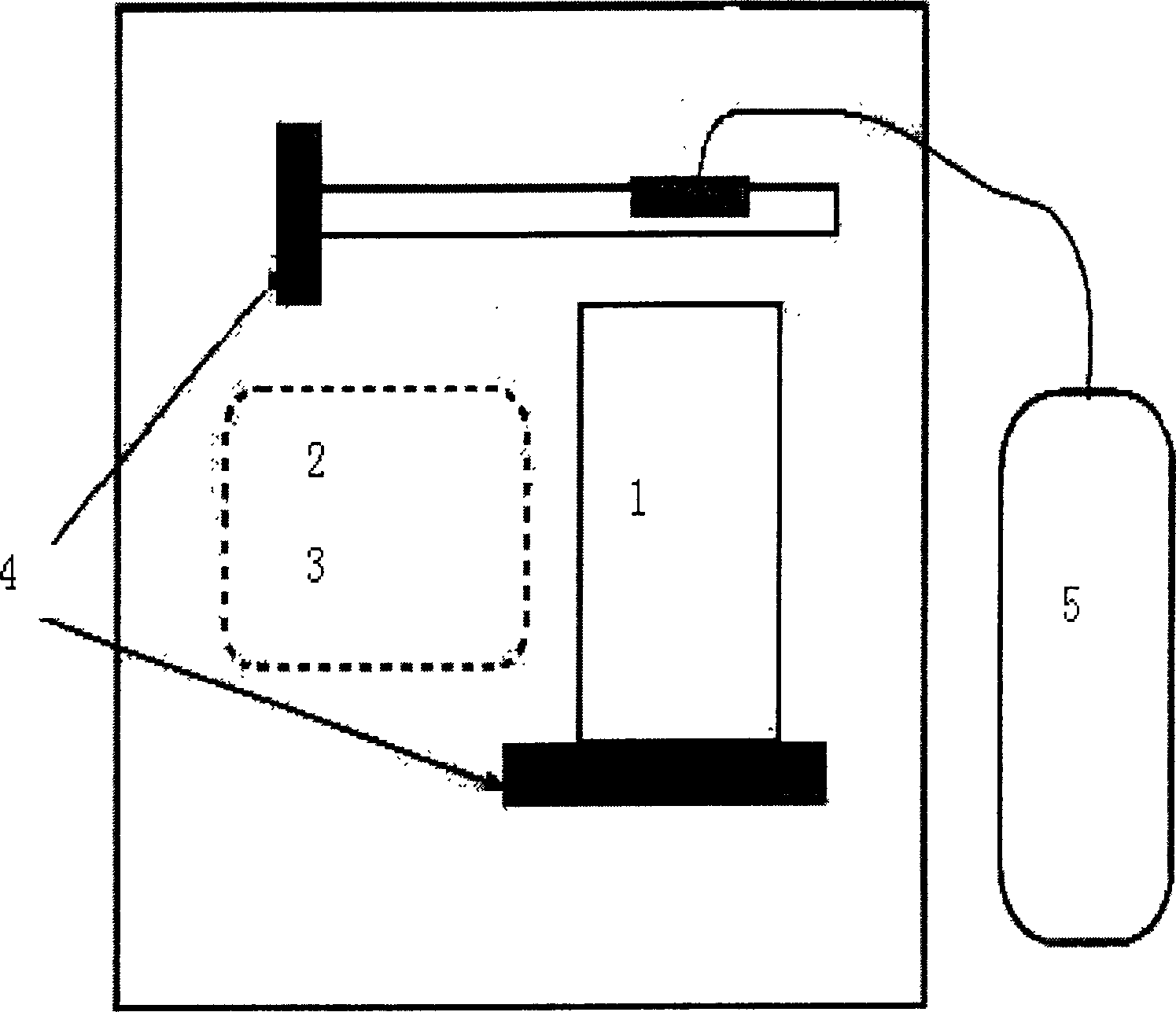

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

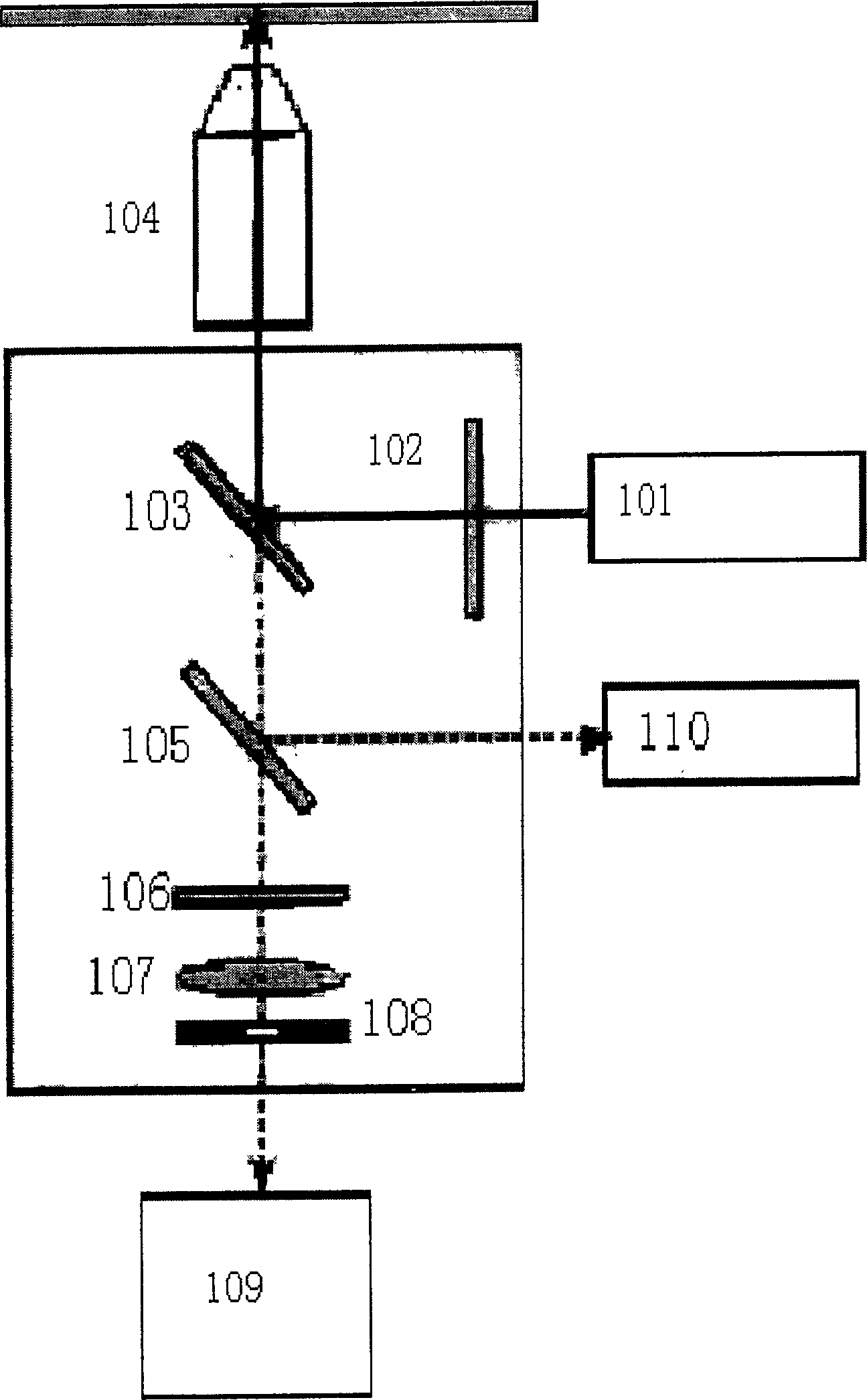

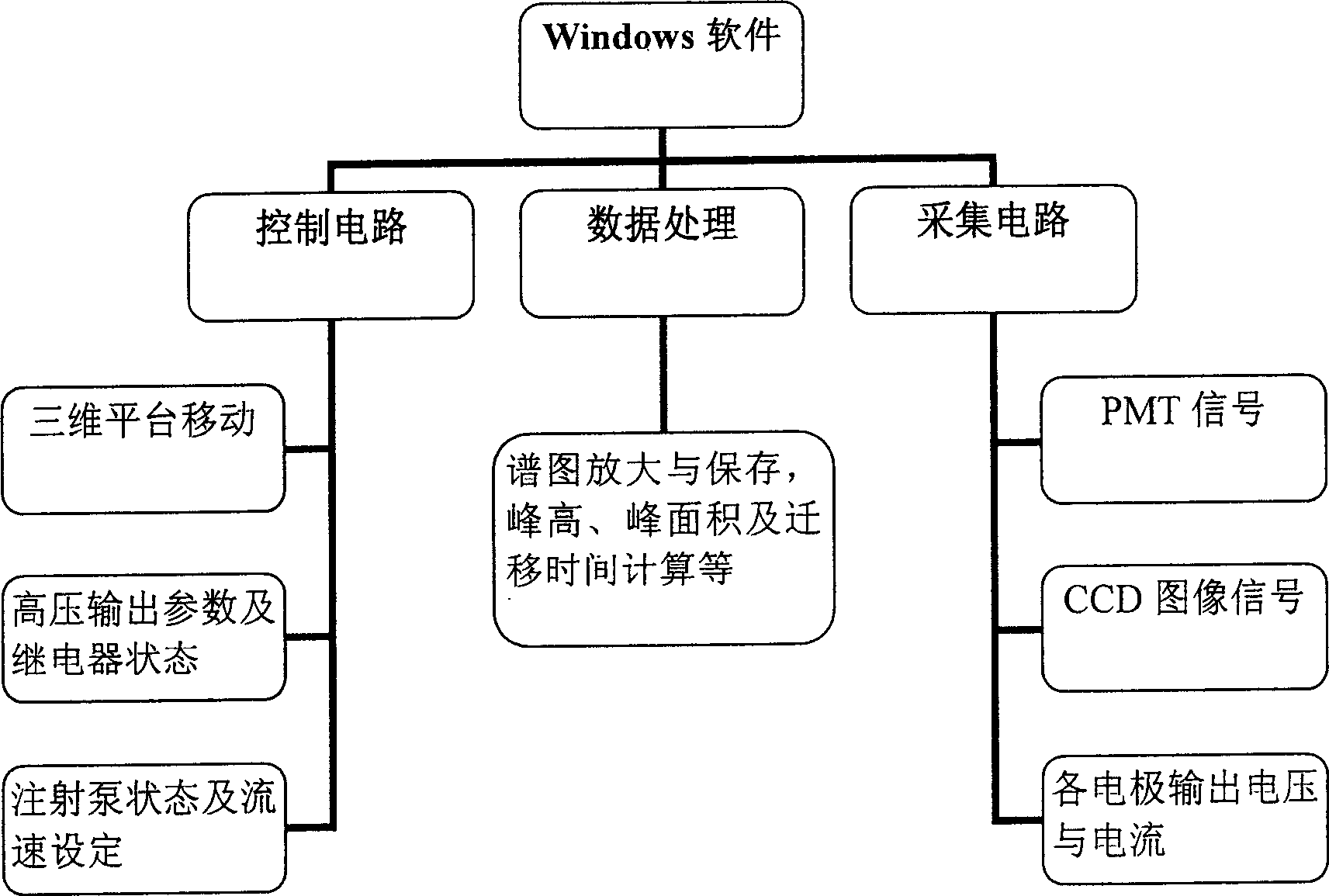

Integrated micro flow control chip control and analysis platform

InactiveCN1715881AEasy to operateMeet control requirementsFluorescence/phosphorescenceWater filterFluorescence

The integrated control and analysis platform with micro flow control chip includes mainly laser induced fluorescent detection and CCD image monitoring optical module, eight electrode high voltage DC power source module, program controlled 3D platform, precise injection pump module and control circuit module. The optical module is designed on co-focusing principle and the emitted water filter may be replaced conveniently to suit for different dyes. The PMT and the CCD camera are set in 90 deg angle and have incident light strengths distributed with the transmitting and reflecting light splitting lens. The present invention has two functions of laser induced fluorescent detection and CCD image monitoring on chip channel. The power source module and the precise injection module can the meet requirement of controlling micro fluid in chip of different integration degrees. The present invention has completely computer software control to realize many functions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

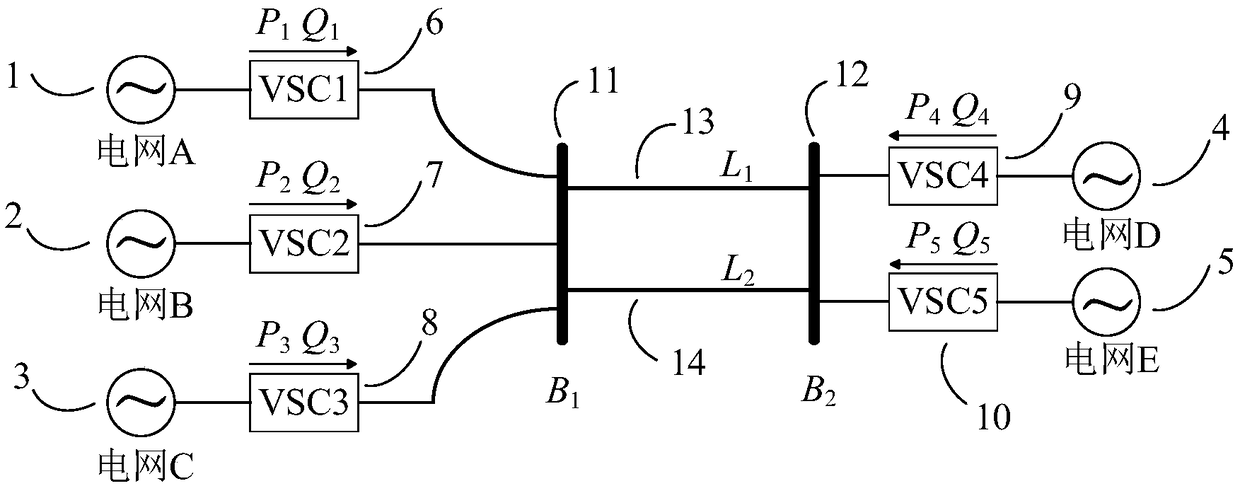

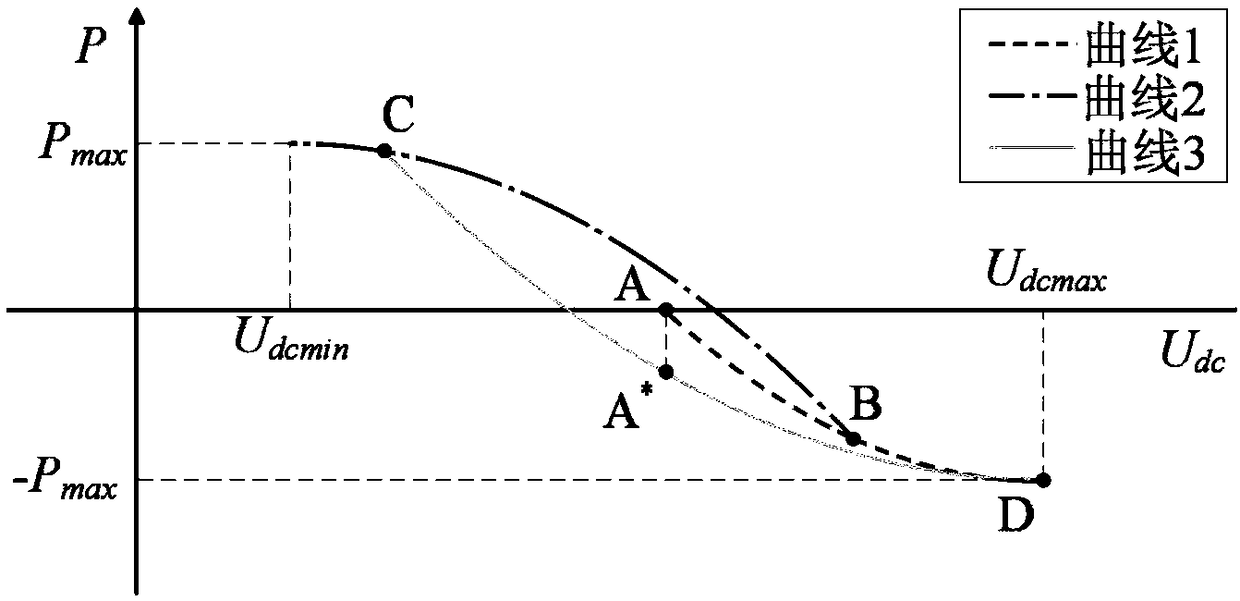

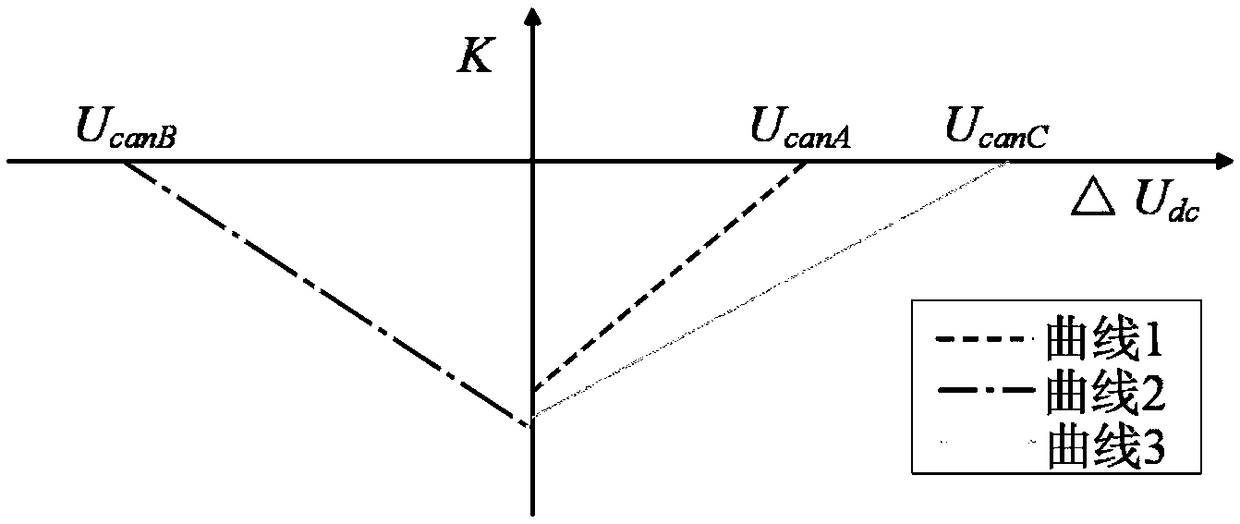

Power coordinated control method for multi-terminal flexible DC transmission system

ActiveCN109120005AFull utilization of active power capacityImprove control qualityElectric power transfer ac networkSingle network parallel feeding arrangementsNameplate capacityControl quality

The invention relates to a power coordinated control method for a multi-terminal flexible DC transmission system. According to the method, a converter station with larger rated capacity is selected from a VSC-MTDC (Voltage Source Converter Multi-Terminal DC) system to serve as a main converter station, constant DC voltage control is performed on the main converter station, the other converter stations are divided into two groups, adaptive droop control and constant active power control are respectively performed on the two groups of converter stations, the main converter station performs regulation independently when the unbalanced power in the system is within a regulating range of the main converter station, and when the main converter station is fully loaded or out of operation, the redundant unbalanced power is regulated by a converter station adopting the droop control, the active power outputted by the converter station is automatically regulated according to DC side voltage changes caused by the unbalanced power so as to enable the system power to achieve a balance again. The power coordinated control method can avoid a phenomenon of out-of-limit voltage, reduce voltage fluctuations at the DC side and make full use of the active power capacity of the converter station. The method can effectively improve the control quality of the multi-terminal flexible DC transmission system, and meet control requirements of the system under different operating conditions.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

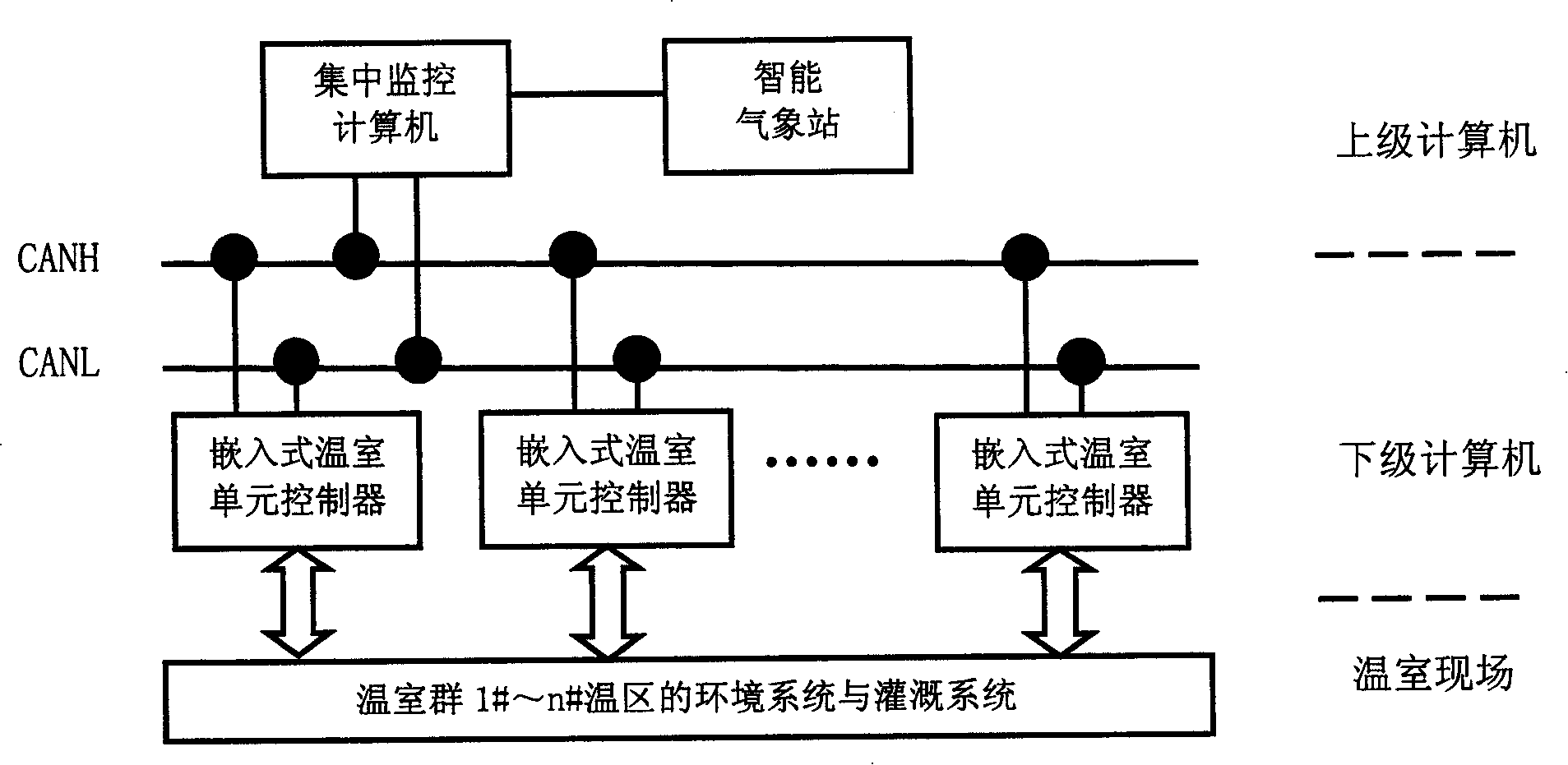

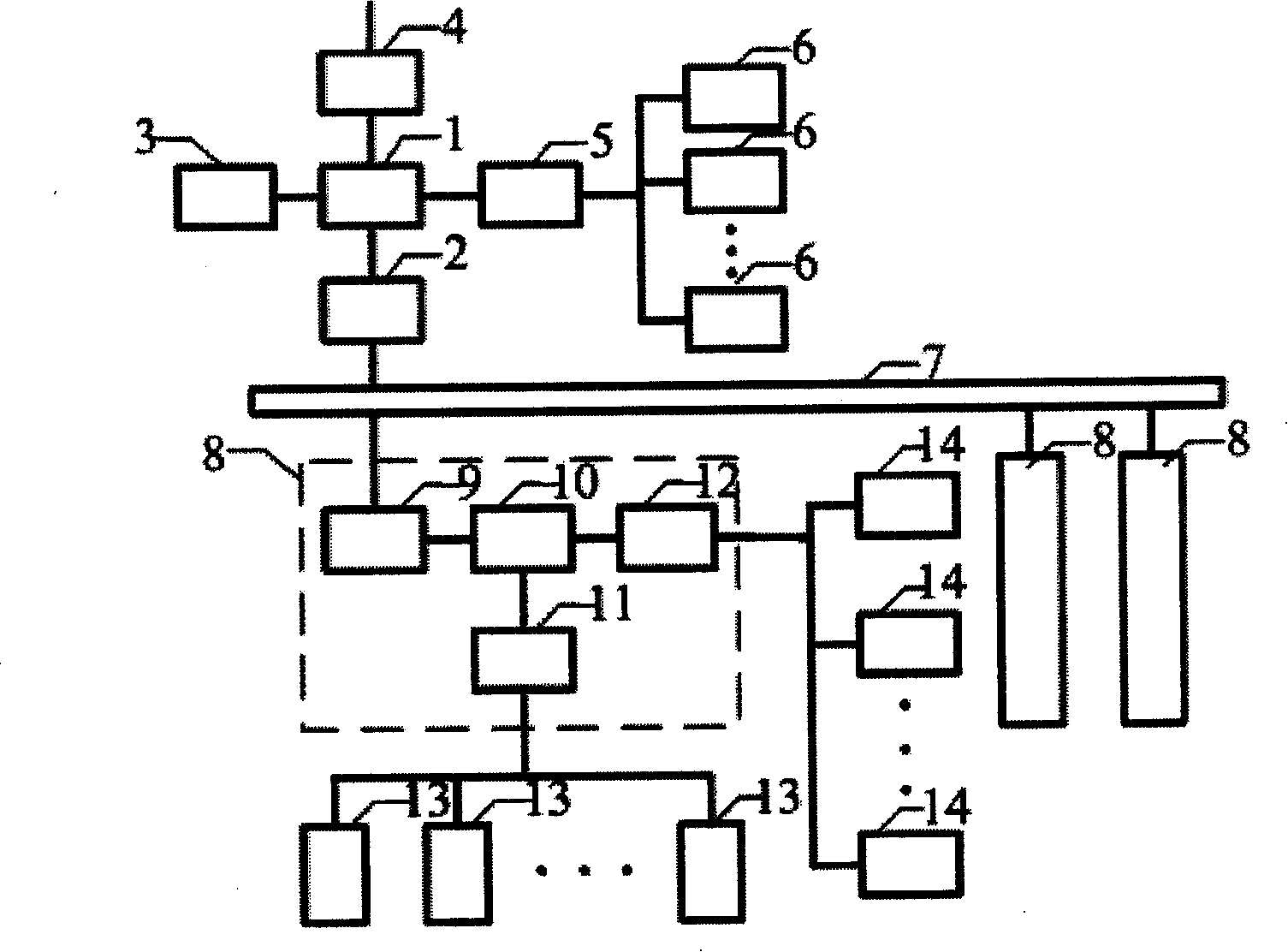

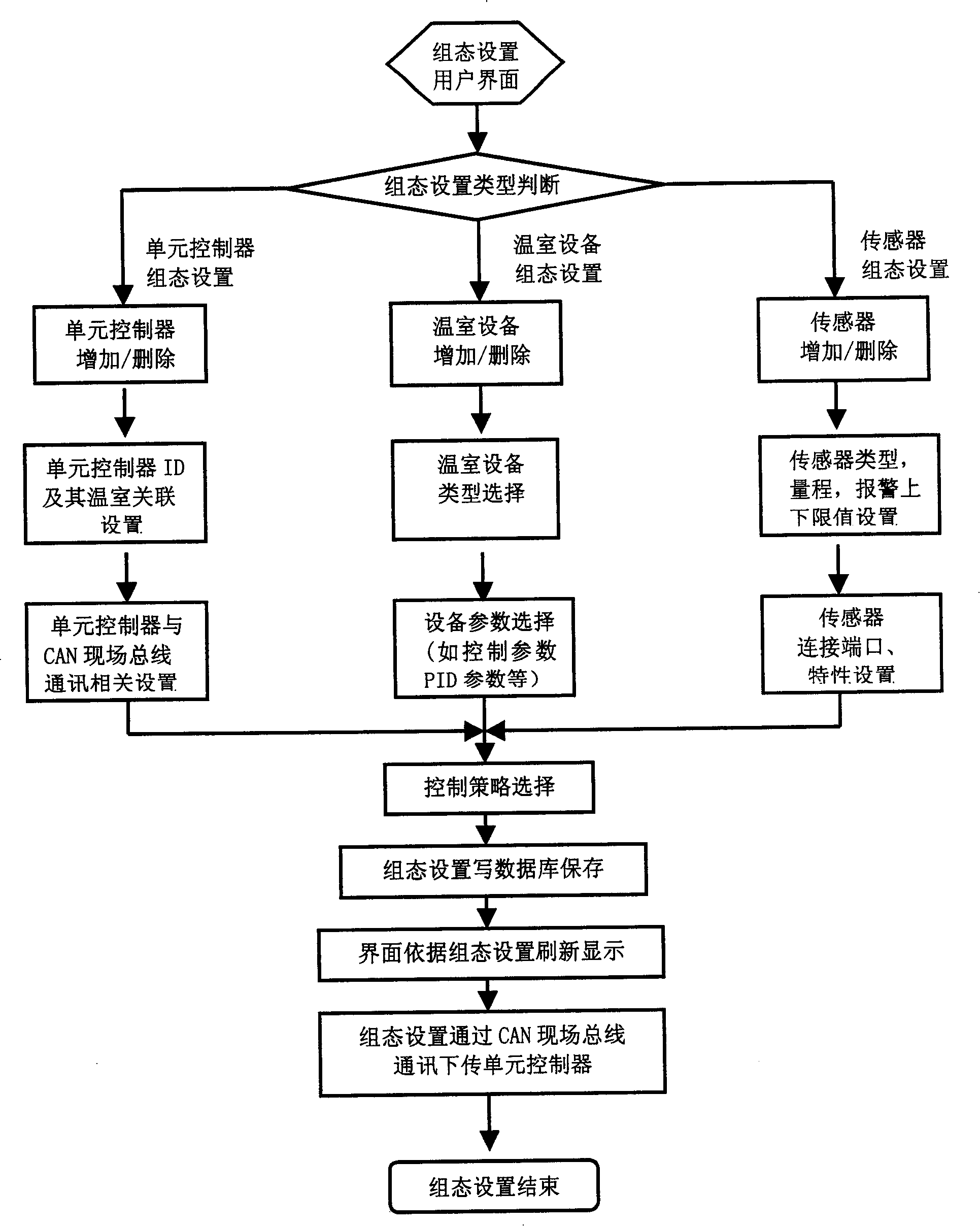

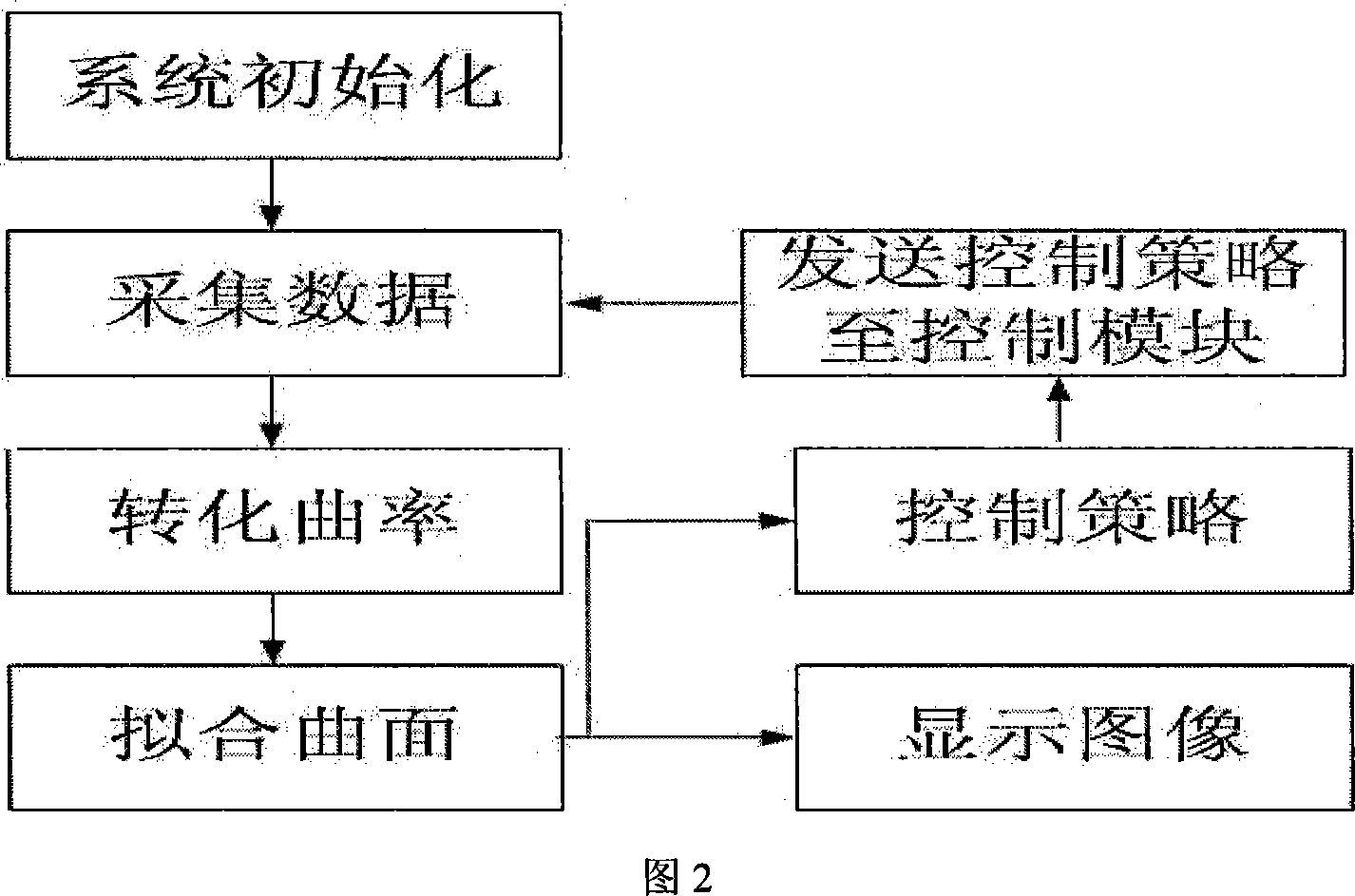

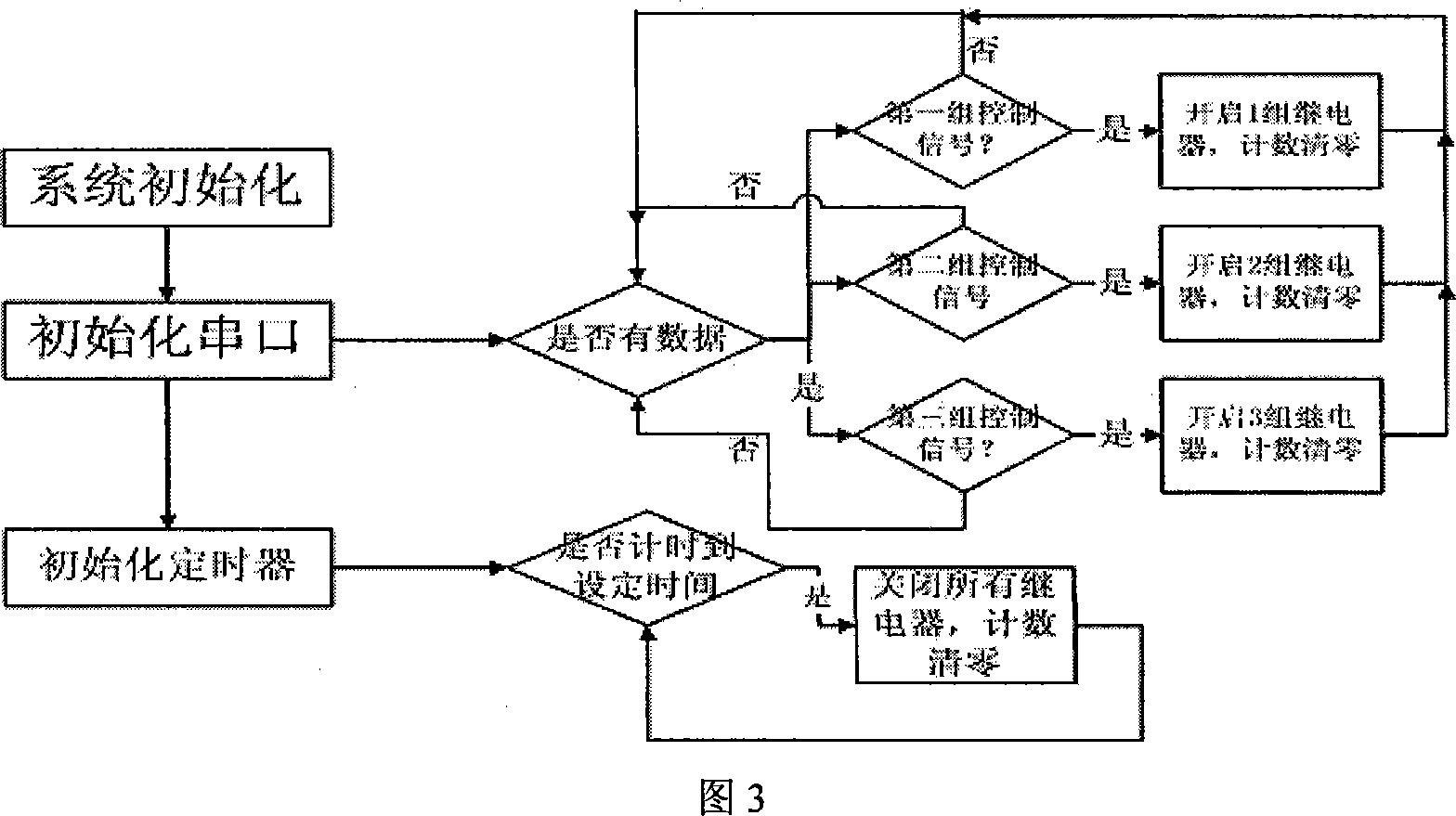

Multi-temperature area group control greenhouse environment and irrigation control system

InactiveCN101211178AReasonable structureImprove performanceClimate change adaptationGreenhouse cultivationMicrocontrollerSoftware system

The invention relates to a greenhouse environment and irrigation control system with group control of multi-temperature regions, which mainly comprises a greenhouse control software system run in a centralized monitoring computer, a communication network system based on a CAN field bus and unit controllers distributed in various temperature regions. The unit controller comprises a microcontroller, a CAN field bus communication module, an input / output interface module for digital quantity and analog quantity, an input module for collecting sensing signals from environmental sensors and plant physiological sensor in a greenhouse and performing signal processing, and an output module for driving and controlling the operation of various equipments in the greenhouse. The greenhouse control software in the centralized monitoring computer is used for processing environmental and plant physiological information of the multi-temperature regions, performing control algorithm and strategy selection and algorithmic calculation, and real-time transmitting a control implantation action obtained based on calculation results to each unit controller to control the operation of greenhouse equipments. The greenhouse environment and irrigation control system with group control of the multi-temperature regions adopts a development method of configuration software, so that the overall system can perform software configuration setting on the unit controller, the sensors, the control equipments, the display interface and the greenhouse control strategy according to specific conditions of the greenhouse, so as to adapt to different requirements of different greenhouse agricultural production managements on the control system.

Owner:SHANGHAI DUSHI GREEN ENG +1

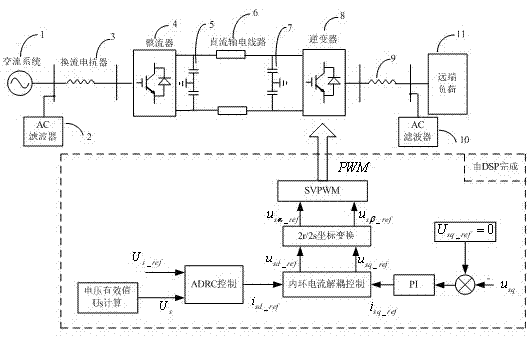

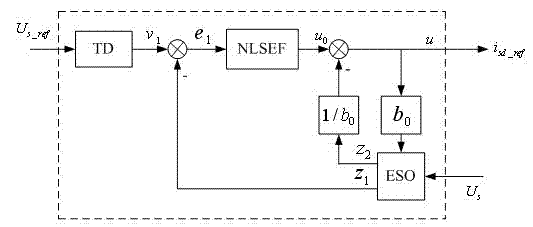

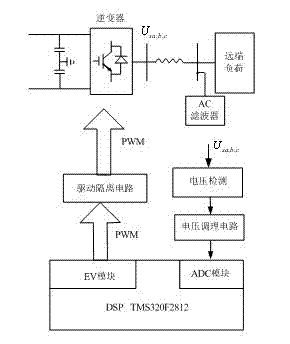

Active disturbance control method of flexible direct current power transmission system

ActiveCN103050967ASmall overshootMeet control requirementsDc network circuit arrangementsElectric power transfer ac networkPassive networksClosed loop

The invention relates to an active disturbance control method of a flexible direct current power transmission system. The method adopts the technical scheme that the method comprises the following steps that a rectifier controller is arranged at the head end of a direct current power transmission line of the flexible direct current power transmission system to carry out the constant direct current voltage control on a rectifier at the alternating current system side, an inverter controller is arranged at the tail end of the direct current power transmission line to carry out the constant alternating current voltage control on an inverter, and a double-closed loop type vector control strategy is adopted for the constant alternating current voltage control of the inverter, wherein an outer loop of the voltage is controlled by an active disturbance controller, an inner loop is controlled by current decoupling, and the direction of bus voltage at the inverter alternating current side is fixed to the direction of an axis d. The method has the advantages that the overshoot of the bus voltage at the passive network alternating current side is reduced when the flexible direct current power transmission system starts to respond, the precision and the stability of the alternating current voltage control are improved, the inside and outside total disturbance of the flexible direct current power transmission system can be evaluated in a real-time way, the feedforward compensation can be timely carried out, the disturbance control capability of the flexible direct current power transmission system is improved, and the control requirements of a non-linear system can be met.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for improving thickness of decarburized layer of small square billet of tire cord steel

ActiveCN102534155AIncreasing the thicknessMeet the thickness control requirementsTemperature controlEngineering

The invention belongs to the technical field of the metallurgy and processing of iron and steel and provides a method for improving the thickness of a decarburized layer of a small square billet of tire cord steel. The tire cord steel is produced by adopting the technological processes of heating, rough rolling, intermediate rolling, pre-finishing, finishing and air cooling. The method for improving the thickness of the decarburized layer of the small square billet of the tire cord steel comprises the following steps that: prior to the technological process of heating, corner grinding or whole-stripping treatment is carried out on the square billet; the total detention time for the square billet in a heating furnace is less than 150 min, and the detention time in a soaking section is lessthan 45 min; fuel gas is fully combusted in the soaking section, wherein the air-fuel ratio in a heating I section is set to be 1.1, the air-fuel ratio in a heating II section is set to be 0.9, and the air-fuel ratio in the soaking section is set to be 0.7; the temperature of the heating I section is 600-700 DEG C, the temperature of the heating II section is 950-1,050 DEG C, the temperature of the soaking section is 1,150-1,180 DEG C; the temperature for starting rolling is controlled at 1,100-1,150 DEG C; and the temperature difference between coil rod overlapping points and a center duringthe whole process of rolling is no more than 50 DEG C. With the adoption of the method, the thickness of the decarburized layer of the small square billet of the tire cord steel is greatly improved, and the thickness of a total decarburized layer (ferrite and transition layer) of a hot-rolled coil rod of a tire cord steel finished product can be less than 0.06 mm, so that the requirements of tirecord steel users on the control of the thickness of the decarburized layer are met.

Owner:NANJING IRON & STEEL CO LTD

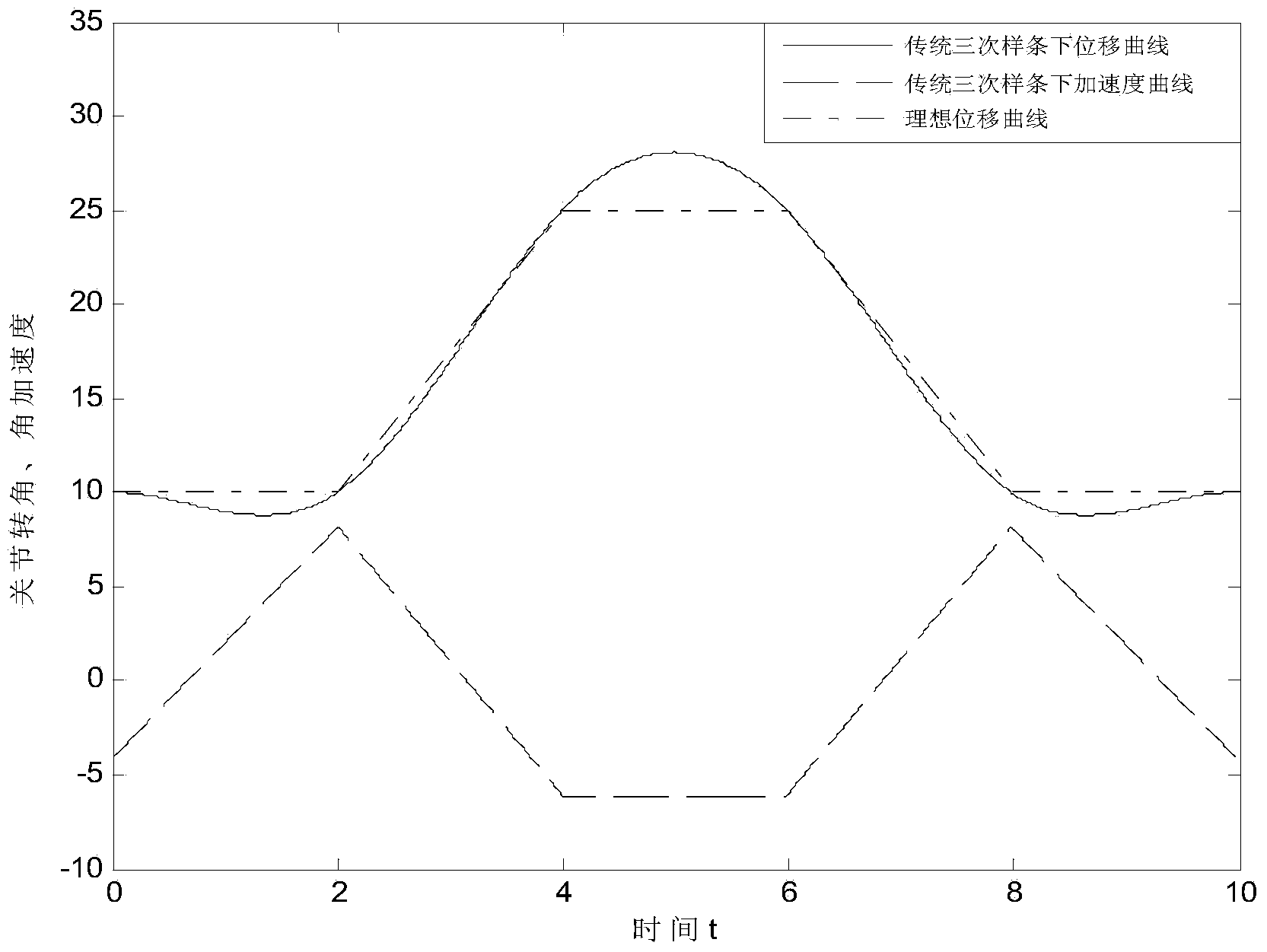

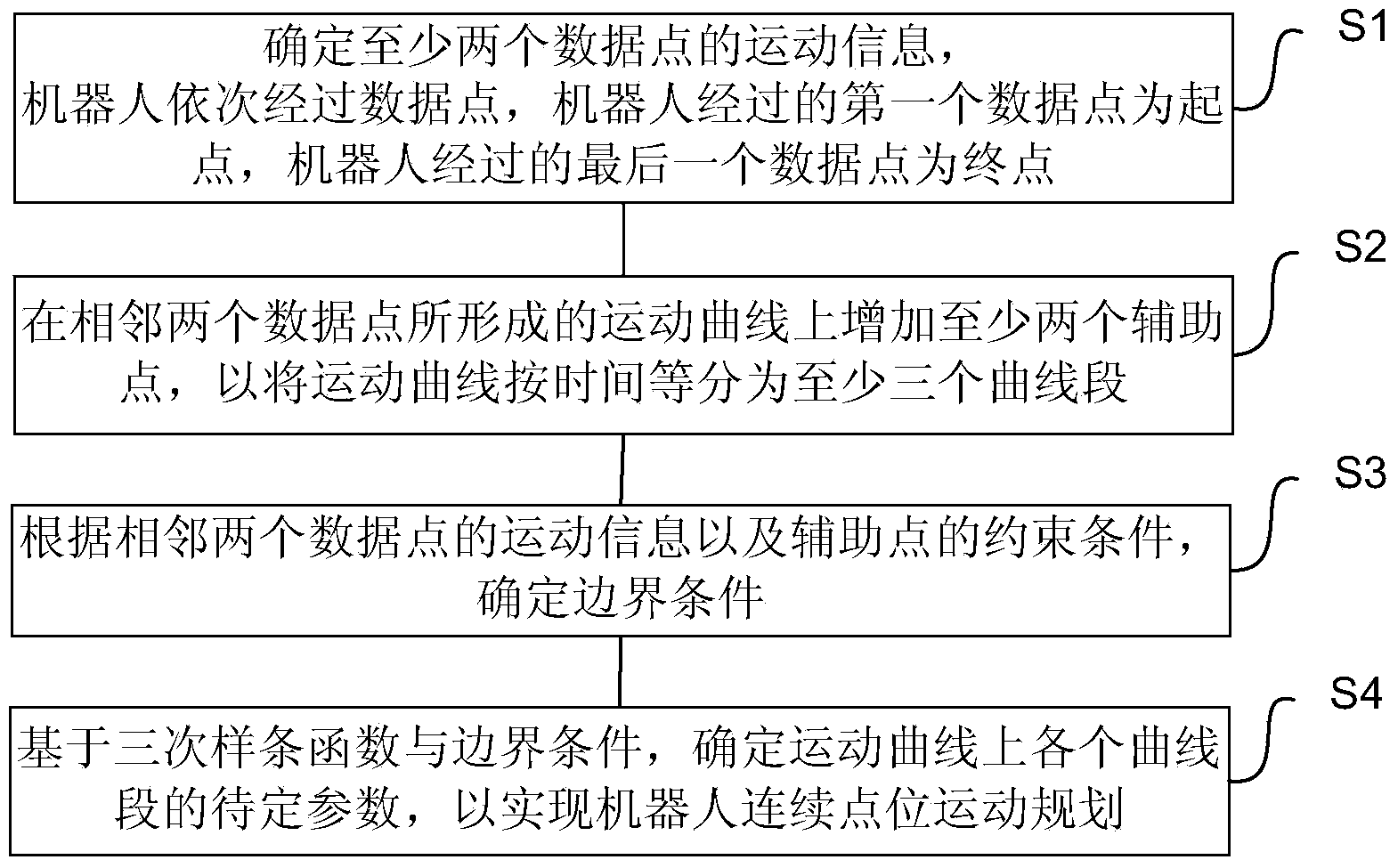

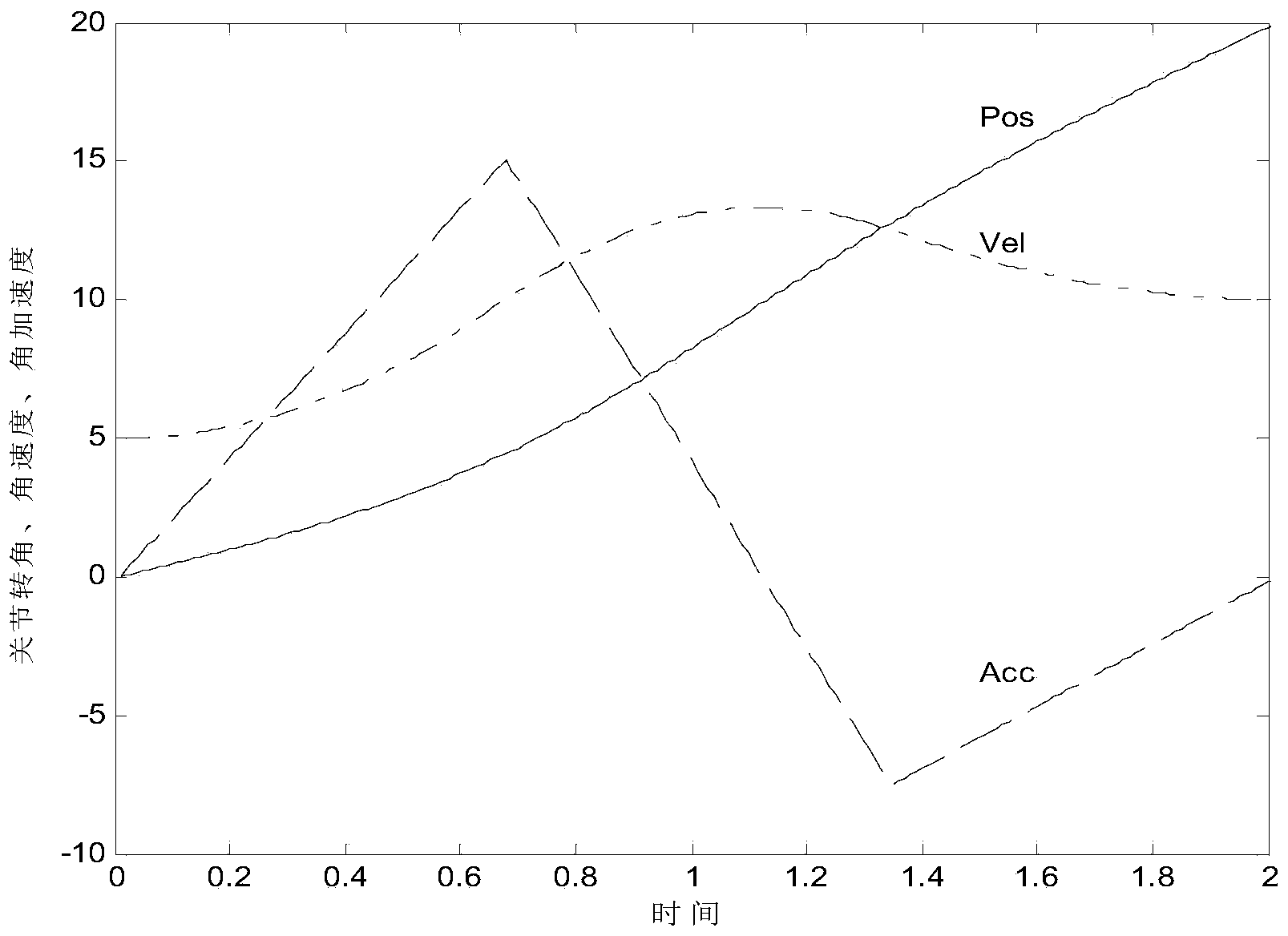

Robot continuous point position motion planning method and motion controller thereof

InactiveCN103970139AMeet the boundary conditionsSmooth movementPosition/course control in two dimensionsMotion controllerComputer science

The invention discloses a robot continuous point position motion planning method. The method comprises the steps of (1) determining the motion information of at least two data points; (2) adding at least two auxiliary points on a motion curve formed by two adjacent data points to divide the motion curve into at least three curve sections equally according to time; (3) determining boundary conditions according to the motion information of the two adjacent data points and the restriction conditions of the auxiliary points; (4) determining the parameters to be determined of all curve sections on the motion curve on the basis of a cubic spline function and boundary conditions so that the robot continuous point position motion planning can be achieved. According to the technical scheme, the cubic spline function is adopted to carry out the continuous point position motion planning, more boundary conditions can be assigned, and therefore the fact that the whole motion process is smooth, stable and free of shock is achieved; the problem of overshoot callback can be solved at the same time. The invention further provides a motion controller for achieving the robot continuous point position motion planning method.

Owner:SHANGHAI JIAO TONG UNIV

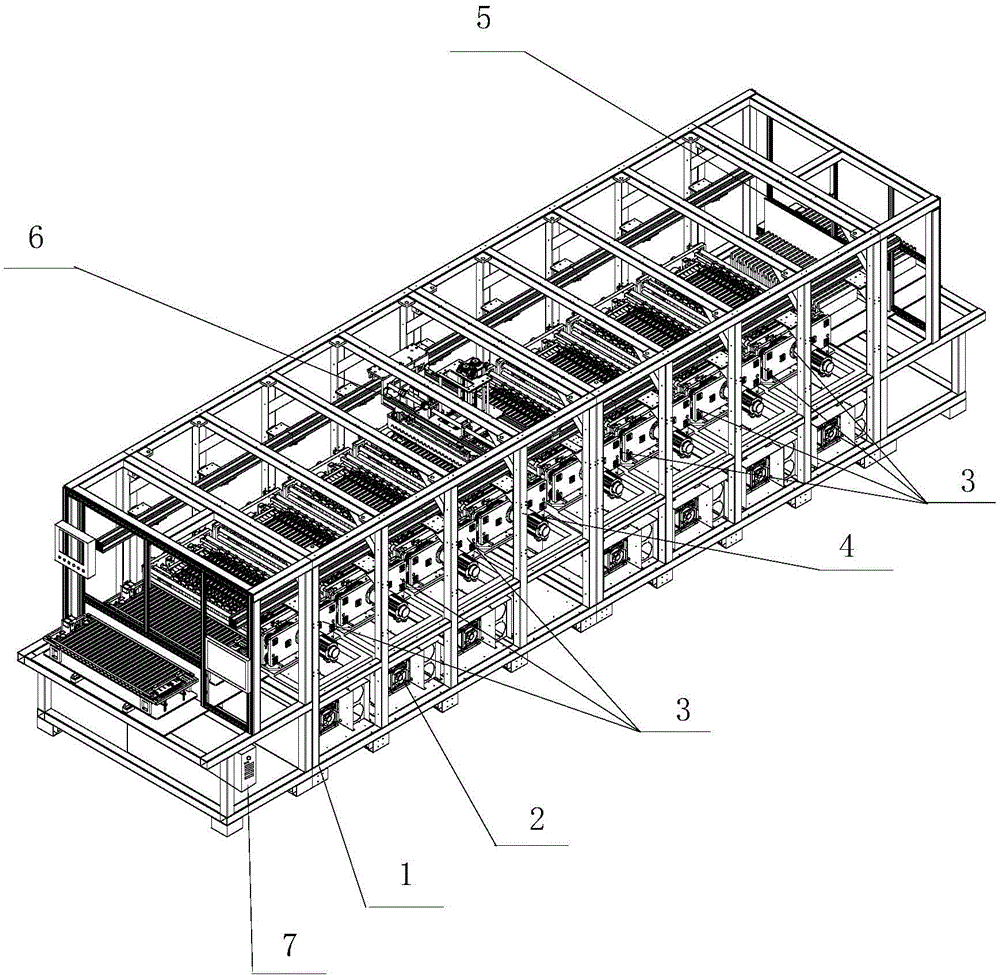

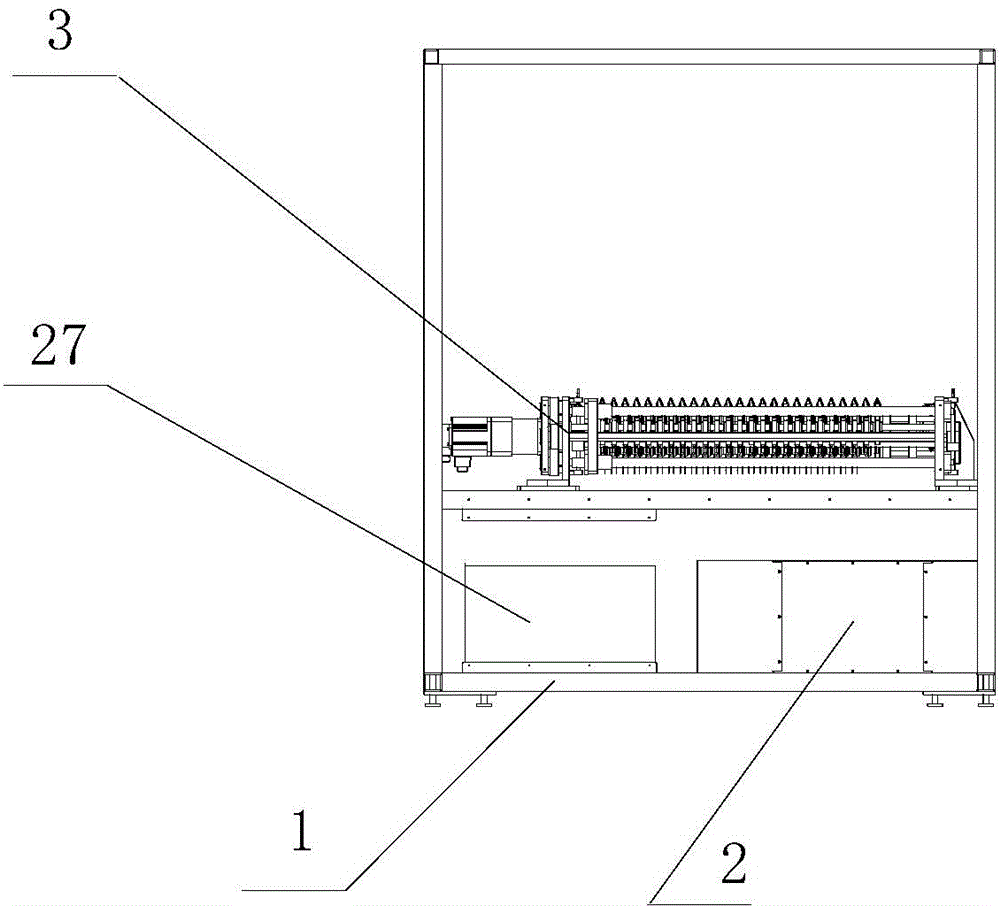

Soft-packed lithium ion battery hot and cold pressing formation device

ActiveCN104953183AEasy to moveReduce manual interventionFinal product manufactureElectrolyte accumulators manufactureLithium-ion batteryCharge and discharge

The invention discloses a soft-packed lithium ion battery hot and cold pressing formation device. The device comprises a rack, a variable-condition charging and discharging power supply, hot pressing formation fixtures, cold pressing fixtures, feeding and discharging mechanisms and a battery grabber. The variable-condition charging and discharging power supply, the hot pressing formation fixtures, the cold pressing fixtures, the feeding and discharging mechanisms and the battery grabber are all arranged on the rack and all controlled by a control mechanism. The feeding and discharging mechanisms are arranged at the two ends of the rack. The cold pressing fixtures are arranged between the hot pressing formation fixtures. The variable-condition charging and discharging power supply is electrically connected with the hot pressing formation fixtures. The hot pressing formation fixtures and the cold pressing fixtures all comprise an aluminum layer pressing plate making contact with a battery. The battery grabber grabs the battery at a time so that the battery can be conveyed among the feeding and discharging mechanisms, the hot pressing formation fixtures and the cold pressing fixtures. The three procedures of formation, hot pressing and cold pressing of the battery are integrated in the same device, the procedures are simplified, product performance and appearance are improved.

Owner:ZHEJIANG HANGKE TECH

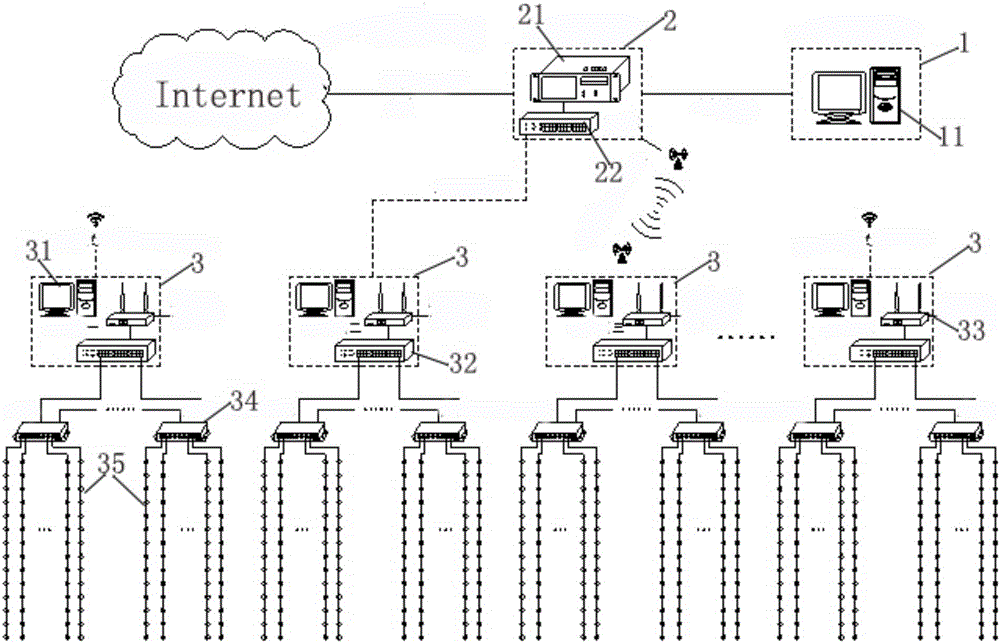

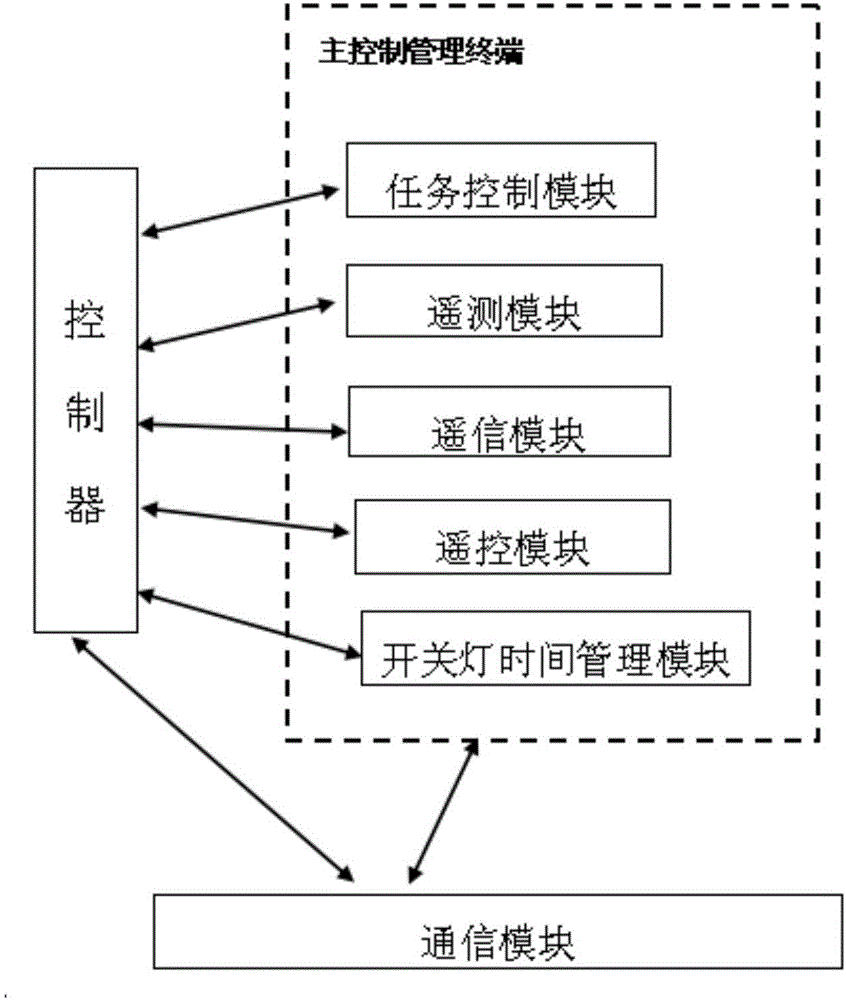

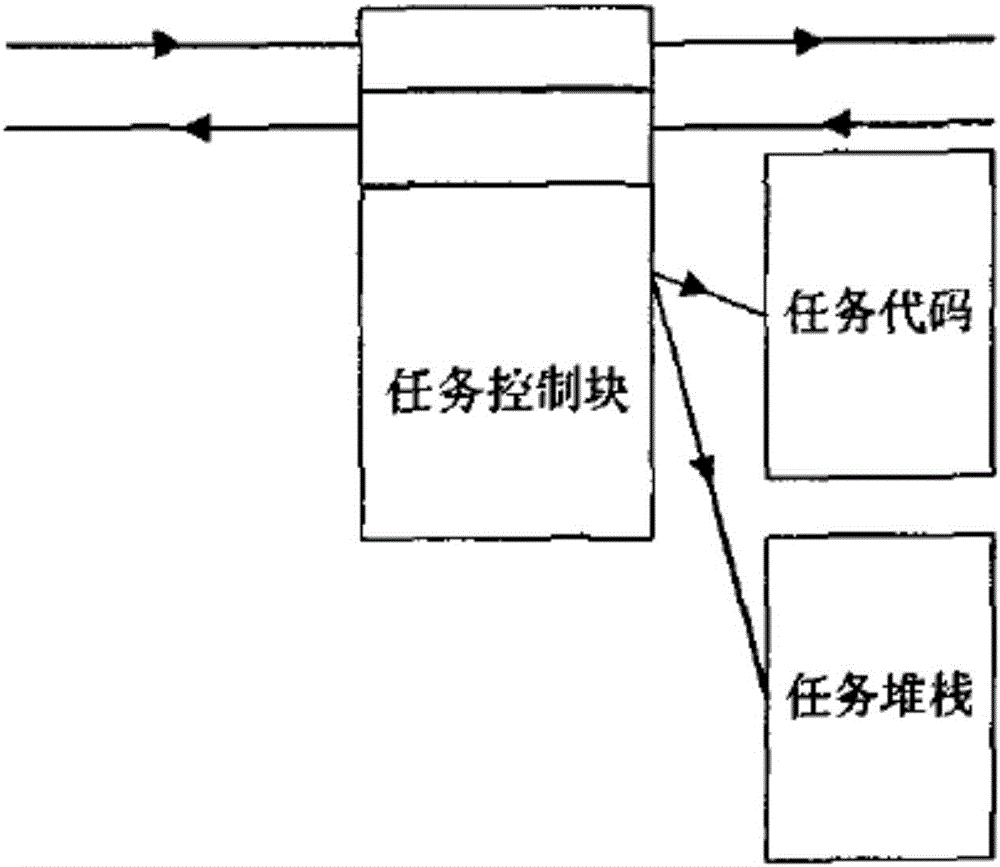

LED landscape city building facade cluster light Internet control system

ActiveCN106163017AImprove scalabilityImprove stabilityElectrical apparatusElectroluminescent light sourcesTTEthernetData information

The invention discloses an LED landscape city building facade cluster light Internet control system, which comprises a centralized control terminal, a server terminal and node terminals, wherein the centralized control terminal is configured to be in communication connection with the server terminal and the node terminals through a wired and / or wireless network, so as to control the node terminal to combine or integrally link a node LED lamp, the server terminal is configured to receive data information sent by the centralized control terminal and send the data information to the node terminals, and monitor the work states of the node terminals in real time and feed the work states of the node terminals back to the centralized control terminal, and the node terminals are configured to control the data uploading, downloading and lighting of verious node LED lamps according to the received data information. The Internet control system provided by the invention can meet the linkage control and remote control on multi-node building facade cluster light, and has high flexibility.

Owner:SHENZHEN EX LIGHTING TECH HLDG

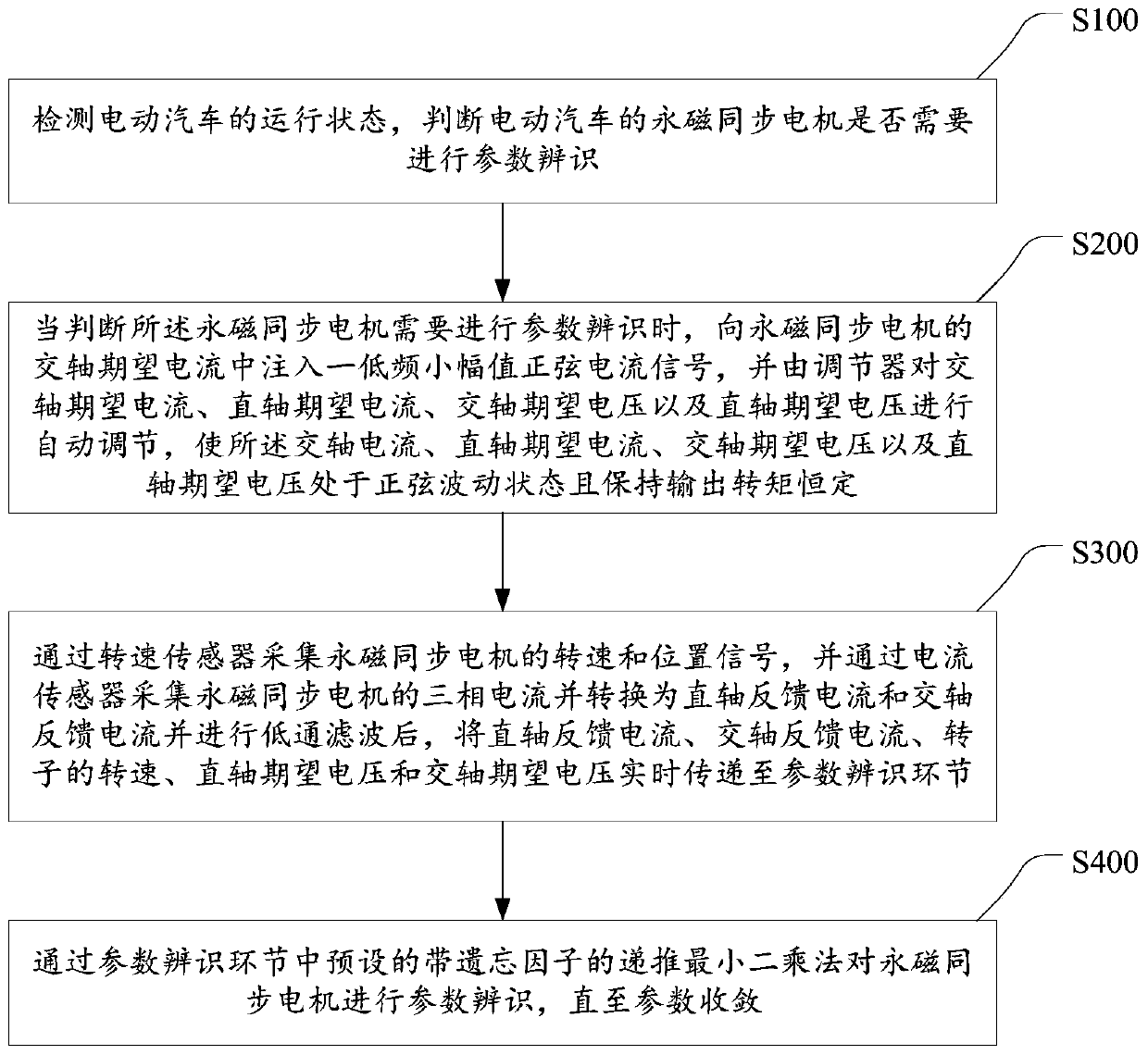

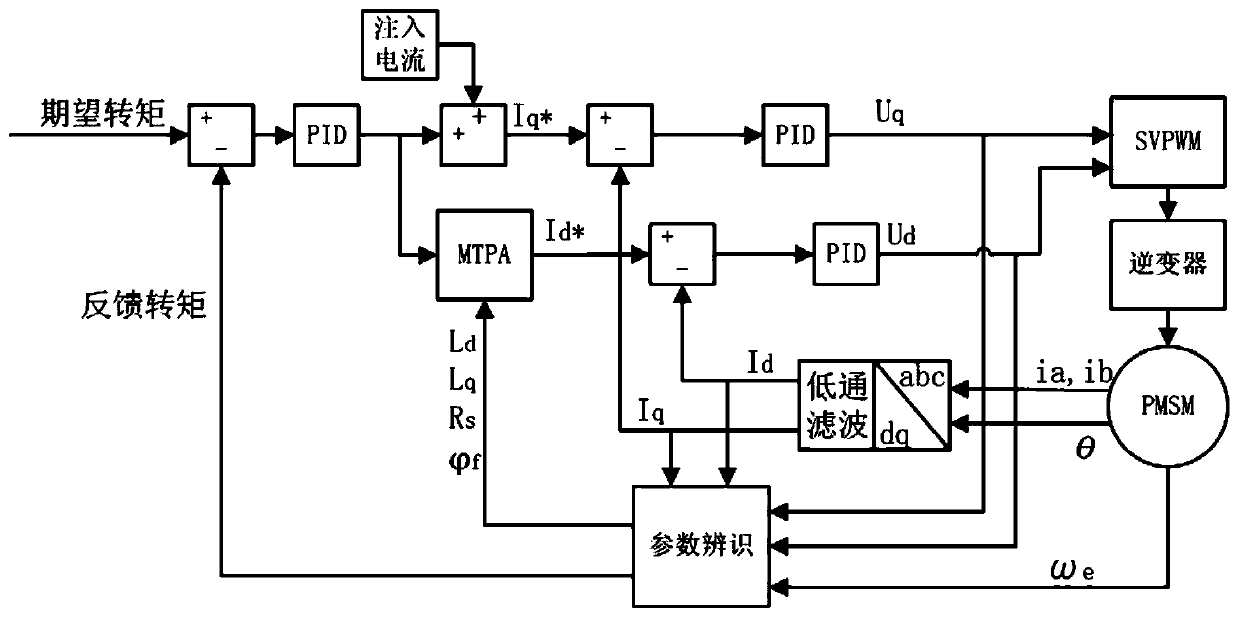

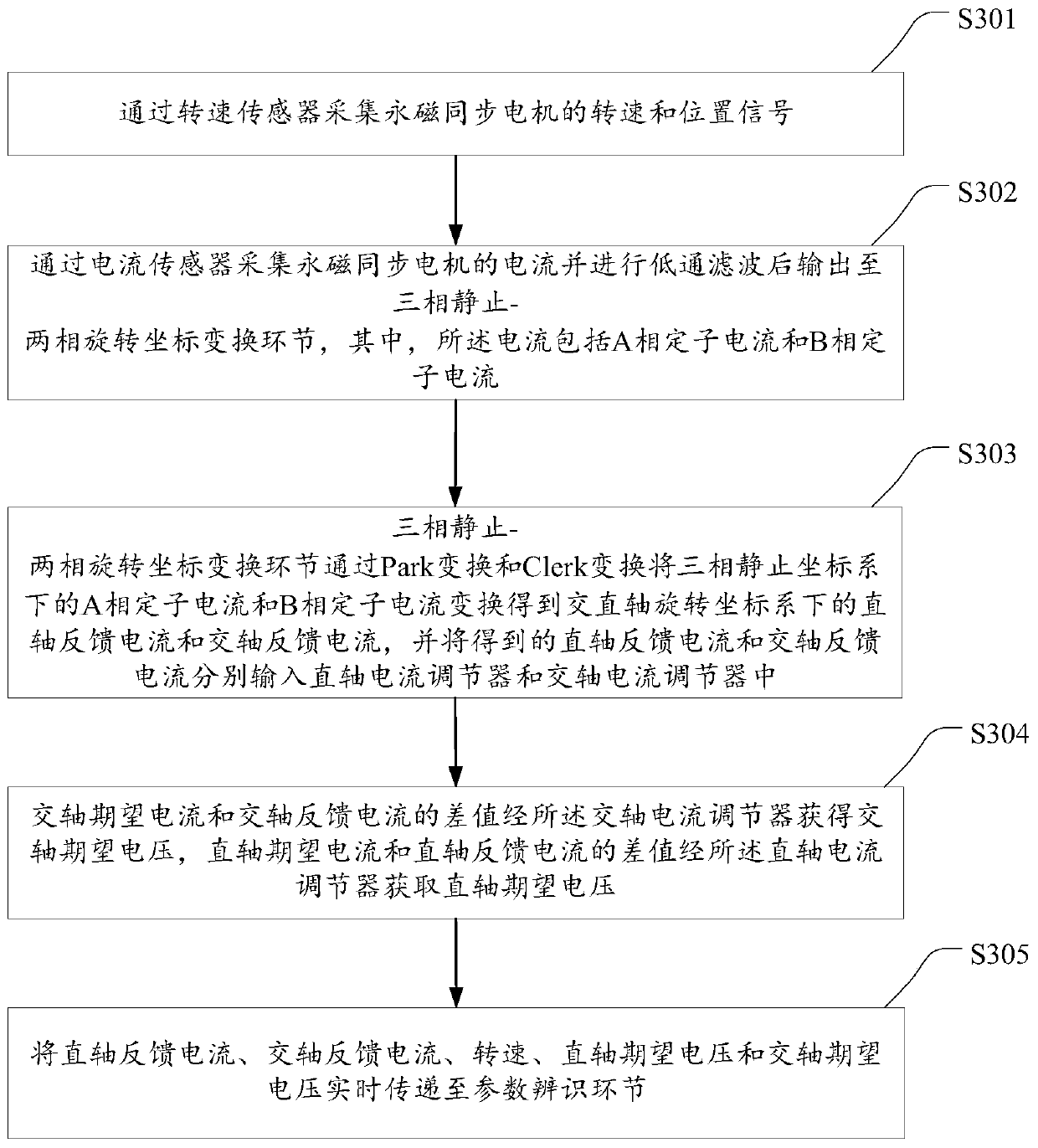

Parameter recognition method for permanent magnet synchronous motor of electric vehicle

InactiveCN110890855AMeet control requirementsAccurate identificationElectronic commutation motor controlAC motor controlElectric machinePermanent magnet synchronous motor

The invention discloses a parameter recognition method for a permanent magnet synchronous motor of an electric vehicle. The method comprises the steps of judging whether the permanent magnet synchronous motor of the electric vehicle needs parameter recognition or not; when parameter recognition needs to be carried out, injecting a low-frequency small-amplitude sinusoidal current signal into quadrature-axis expected current of the permanent magnet synchronous motor, and automatically adjusting the quadrature-axis expected current, direct-axis expected current, quadrature-axis voltage and direct-axis voltage by an adjuster; the rotating speed and position signals of the permanent magnet synchronous motor are measured through a rotating speed sensor, three-phase current of the permanent magnet synchronous motor is collected through a current sensor and converted into direct-axis feedback current and quadrature-axis feedback current, and data are transmitted to a parameter recognition linkin real time; and performing parameter recognition on the permanent magnet synchronous motor through the parameter recognition link until the parameters converge. According to the method, parameter recognition can be carried out under any operation state of the motor, the control requirements of the permanent magnet synchronous motors with different structures can be well met, the identified parameters are accurate, and the application range is wide.

Owner:WUHAN UNIV OF TECH

Injection mold cavity pressure control system and method

The invention discloses an injection mold cavity pressure control system and method. The injection mold cavity pressure control system comprises a high-pressure nitrogen source, wherein the high-pressure nitrogen source is connected with a mould air inlet through a pipeline, a first pressure reducing valve is arranged on the part, which is close to the high-pressure nitrogen source, of the pipeline, the pipeline is divided into two paths after passing through the first pressure reducing valve, one path is connected with an air control regulating valve through a second pressure reducing valve, a first pressure meter and an electronic pressure controller, the other path is connected with the air control regulating valve through a second pressure meter, the outlet of the air control regulating valve is connected with the mould air inlet, a third pressure meter, a pressure sensor and a pressure relieving pipeline unit are sequentially arranged on the pipeline, the electronic pressure controller, the pressure relieving pipeline unit and the pressure sensor are connected with a data processing and controlling system, and the data processing and controlling system is connected with an injection molding machine signal unit. The invention also discloses a control method of the injection mold cavity pressure control system. The injection mold cavity pressure control system has the characteristics of high pressurizing rate and pressure relieving rate of a mould cavity, capabilities of maintaining high pressure of the mould cavity and controlling the acting time of the high pressure of the mould cavity, and the like.

Owner:SHANDONG UNIV

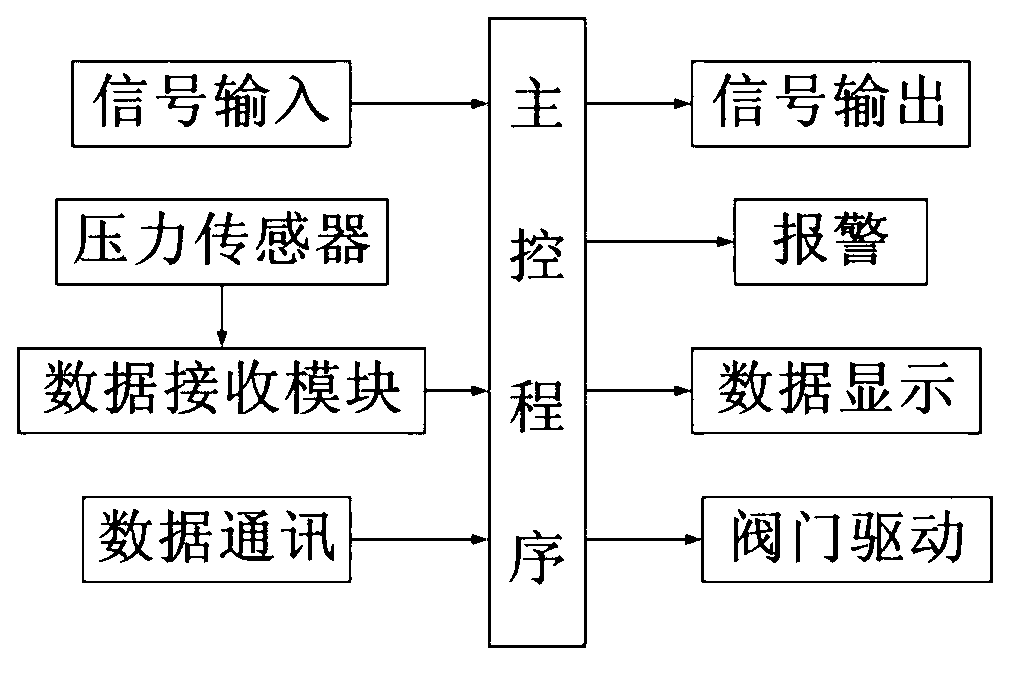

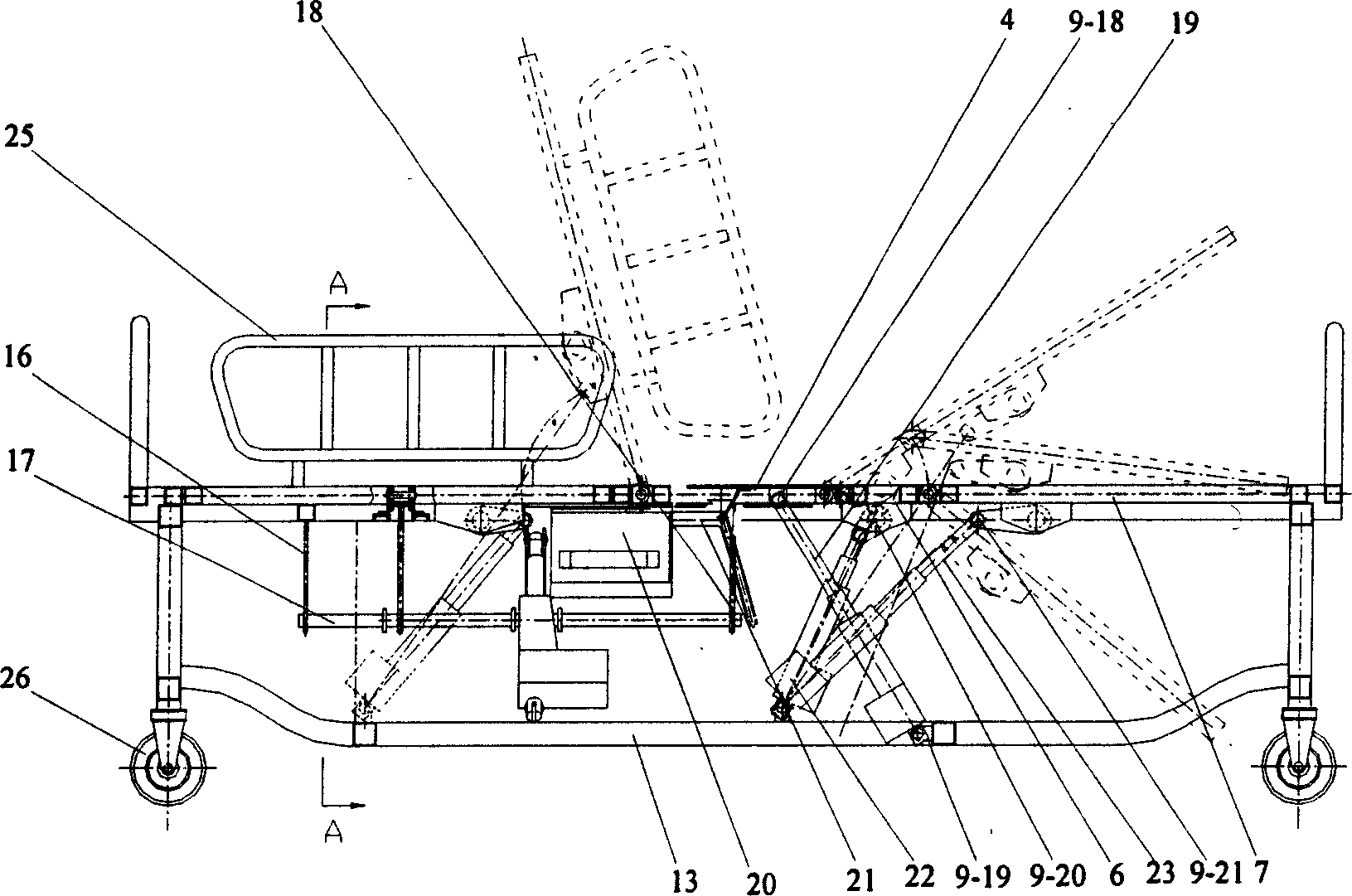

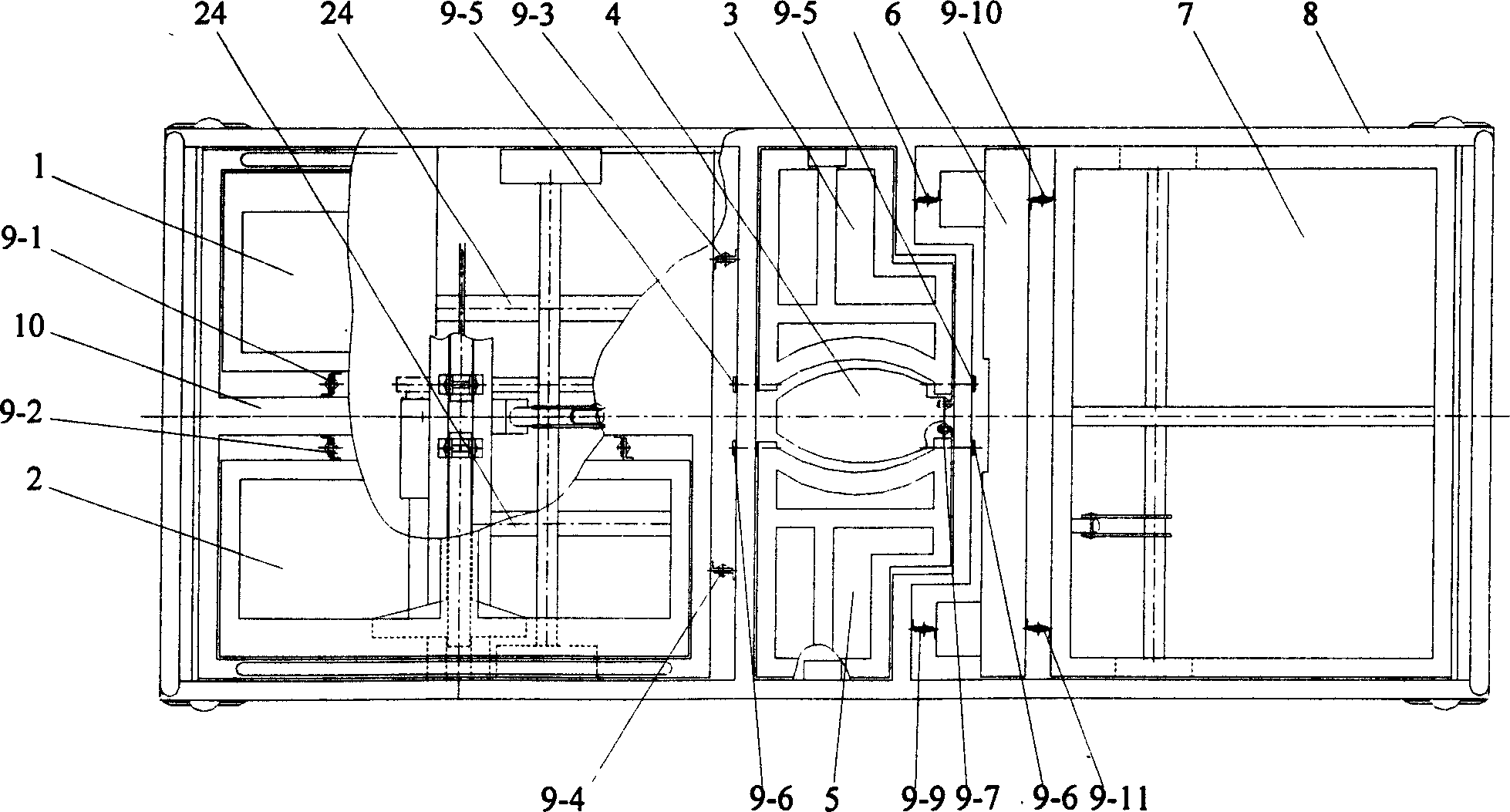

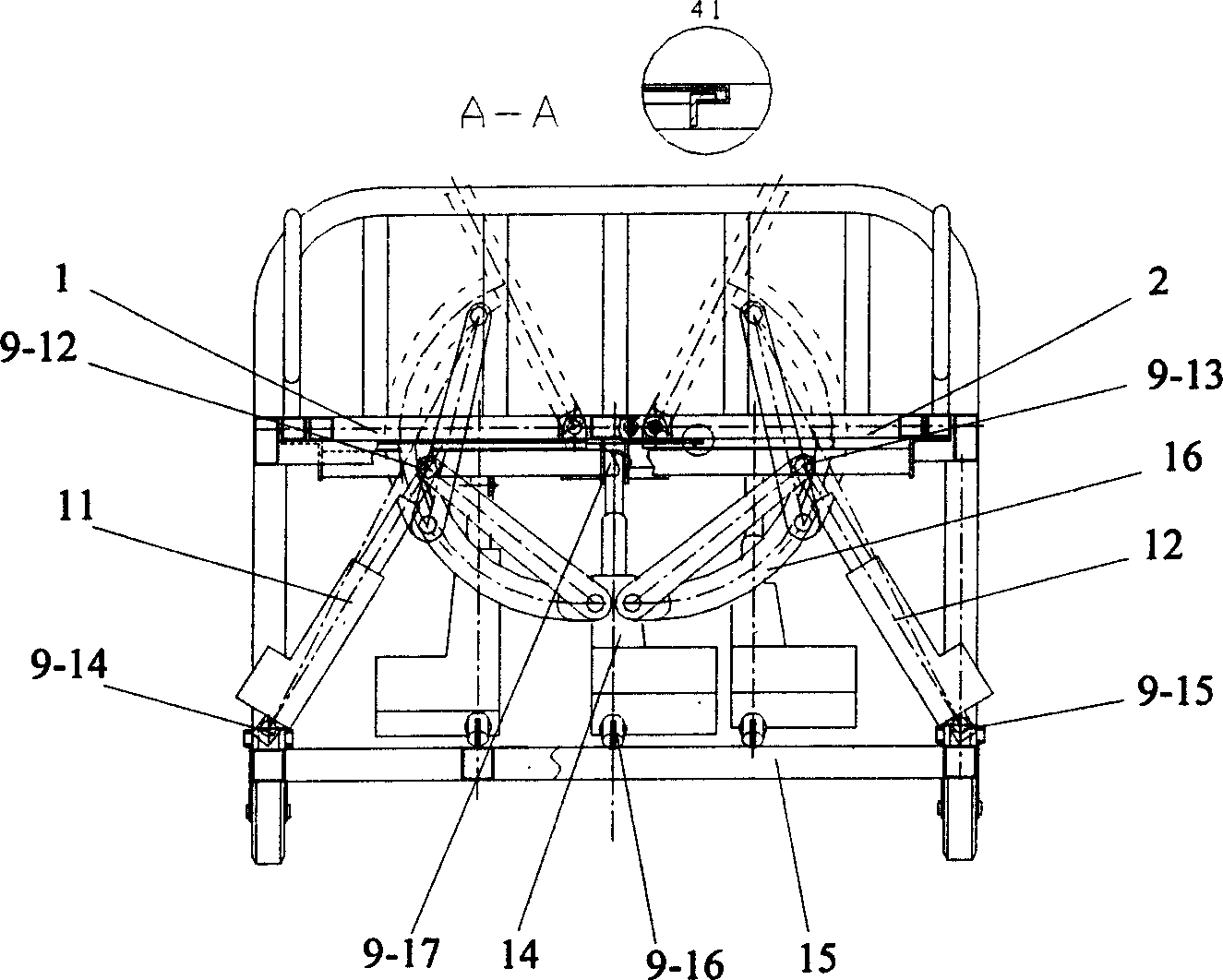

Multi-functional nursing bed, and its controlling system

A multifunctional nursing bed is composed of left and right boards for turning body over, left and right buttock boards, cover plate of bedpan, thigh board, shank board and supporting frame. Its control system consists of information input module, control module with single-chip microprocessor, and PLC control system.

Owner:SOUTH CHINA UNIV OF TECH

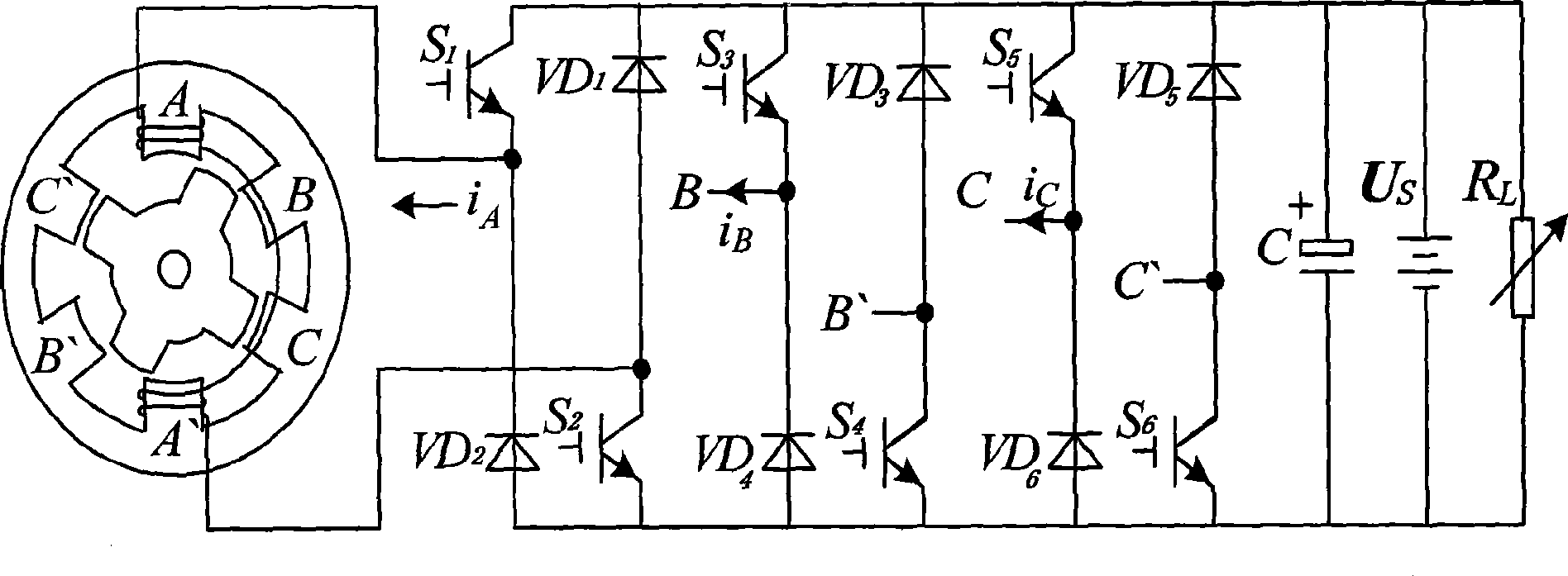

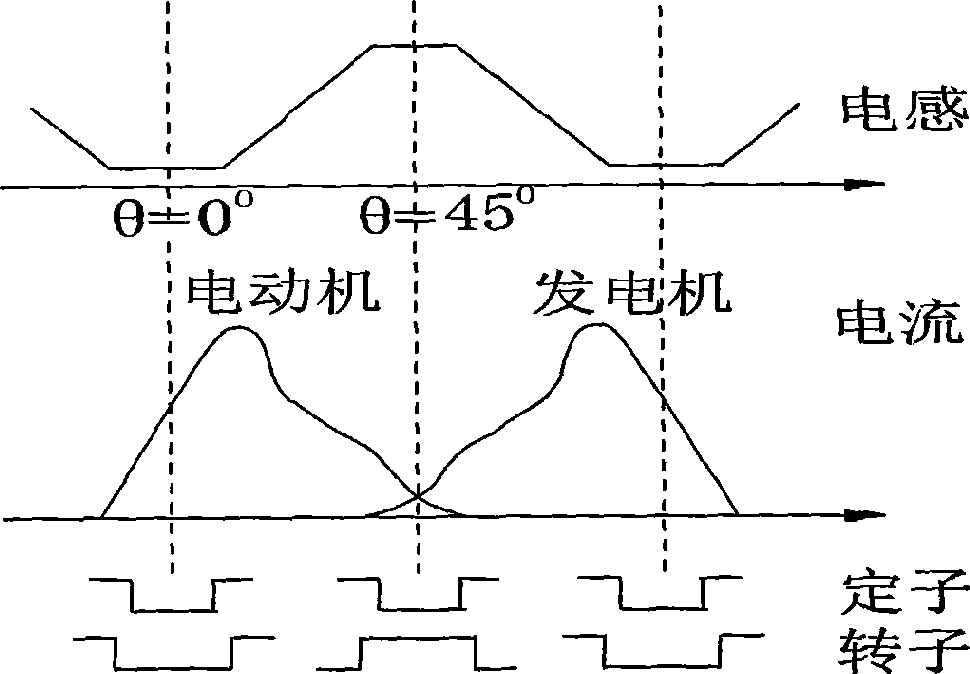

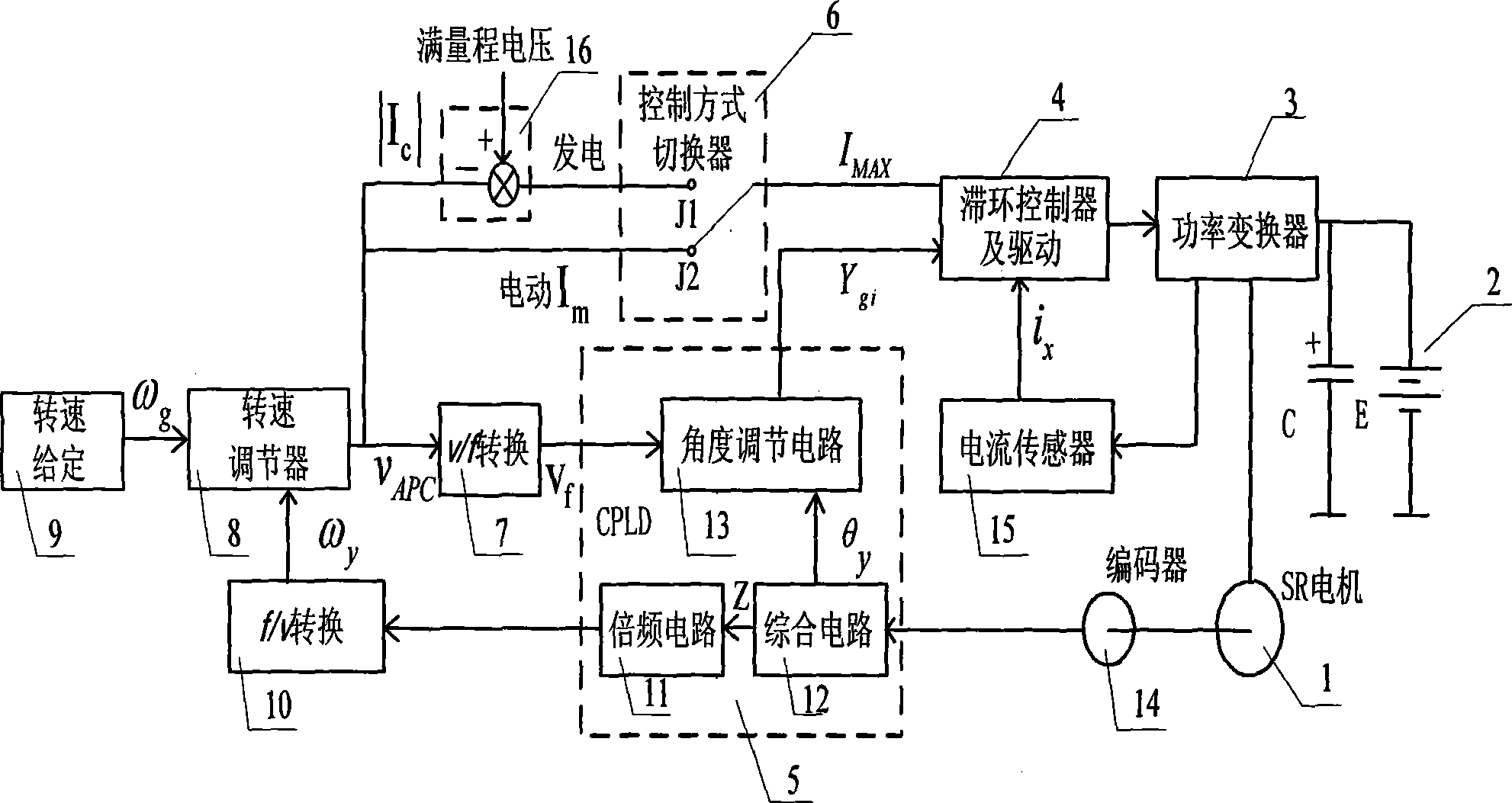

Device and method for controlling switched reluctance motors for electric vehicles on basis of CPLD

InactiveCN101534086AMeet control requirementsNo operation delayElectronic commutatorsHysteresisLow speed

The invention discloses a device and a method for controlling switched reluctance motors for electric vehicles on basis of a CPLD (a programmable logic device). A hysteresis controller and a drive are connected in series with the CPLD device and then are connected between a current sensor and a power inverter; the output of the CPLD device is connected f / v conversion, v / f conversion and different input ends of the CPLD device connected with an encoder; a rotation-speed setting circuit is connected in series with a rotation-speed regulator and then is connected between the v / f conversion and the f / v conversion; a complementation circuit is connected between the rotation-speed regulator and a control-mode switch; the control-mode switch is connected with the inputs of the hysteresis controller and the drive; and a motor is connected with the input of the encoder. The device and the method can control the low-speed electrokinetic state, power-generation state and high-speed electrokinetic state of the electric vehicles respectively, meets control requirements in high-temperature, high-humidity, vibration dustiness and other severe working environment, have the advantages of reconfiguration property, no operation time delay, better real-time control and anti-interference capability, can simplify structure, raise operating speed, and control flexibility and reliability.

Owner:JIANGSU UNIV

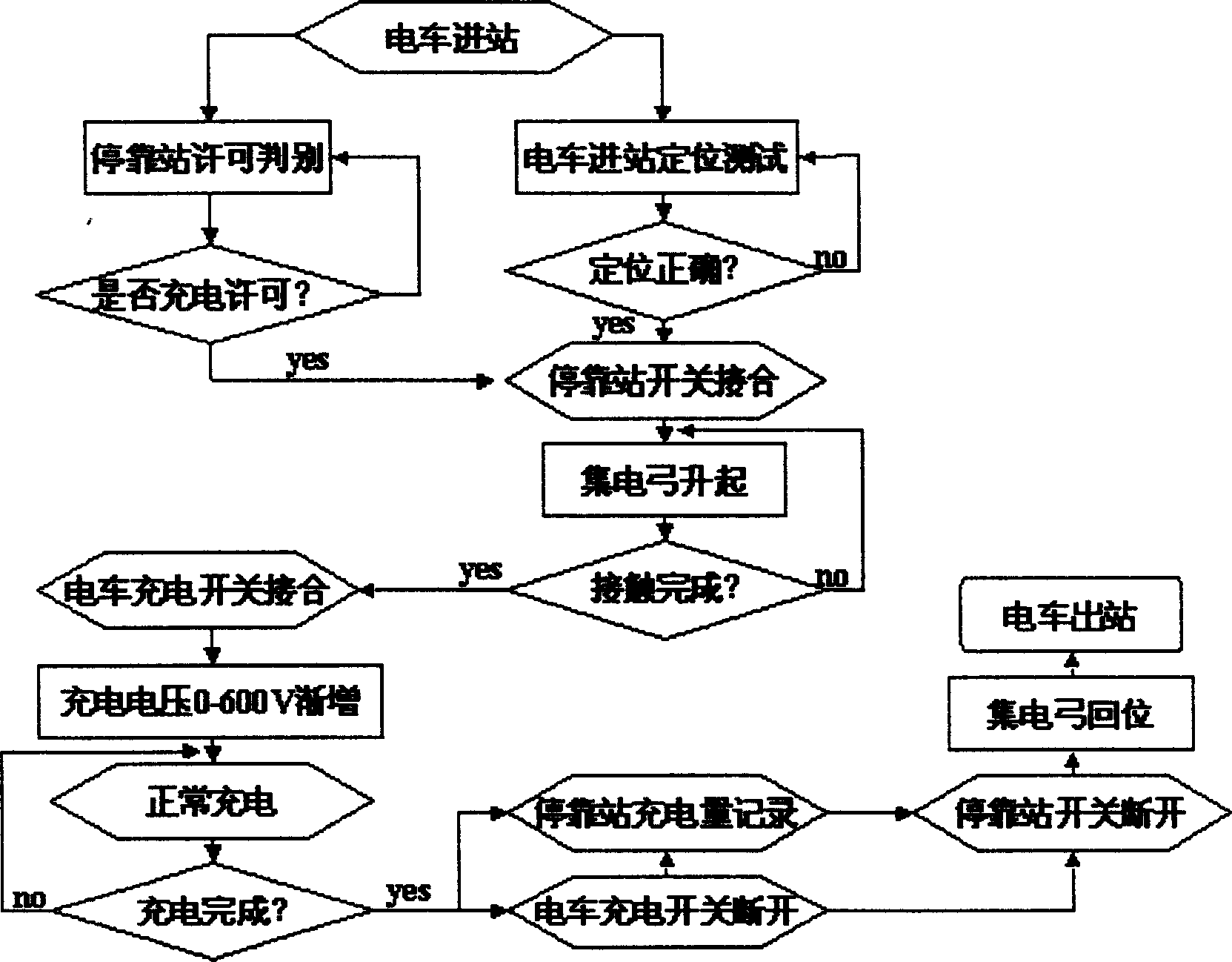

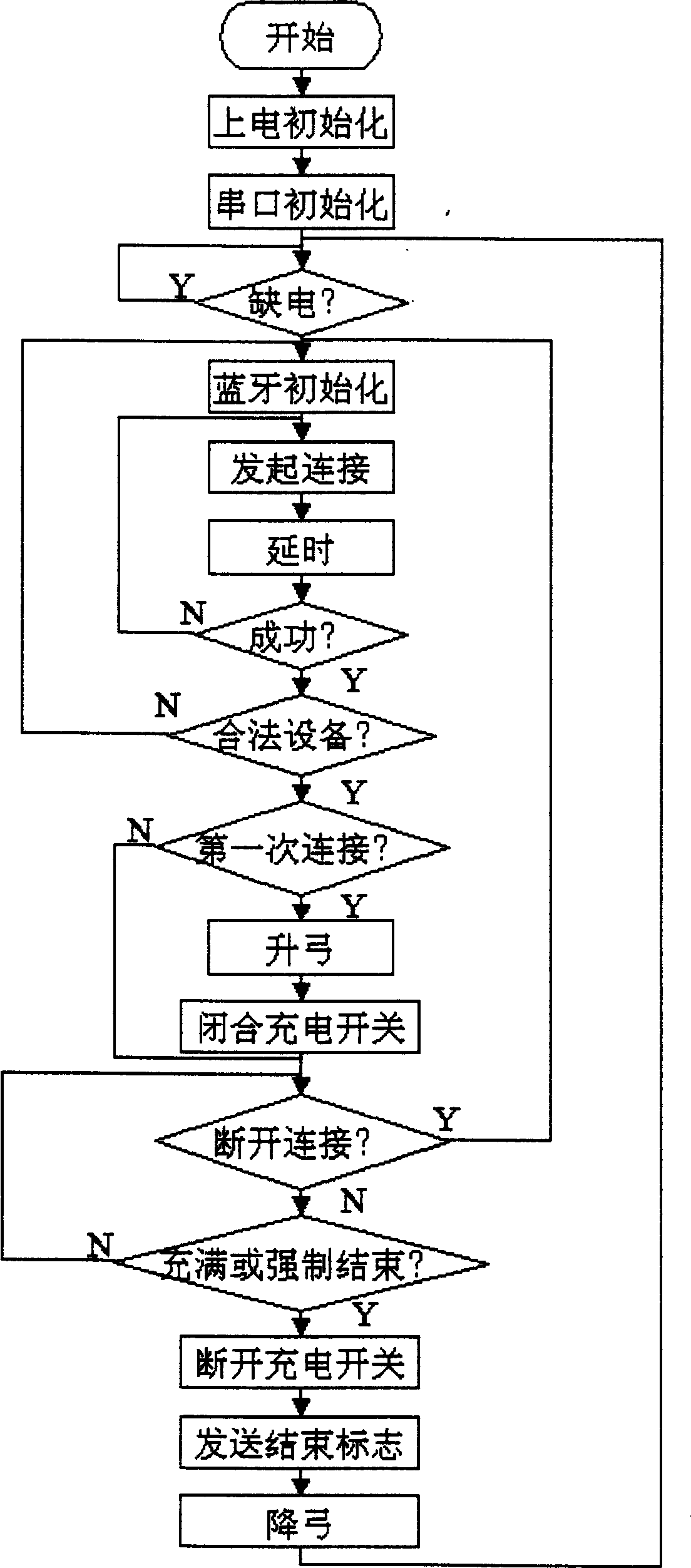

Charge controlling system of super capacitive electric car

InactiveCN1524726ASolve energy rationingMeet control requirementsPower supply linesVehicular energy storageCapacitanceCharge control

The invention is a super capacitor tramcar charging control system. It adopts a master-slave control structure, composed of master controller on the tramcar and slave controller on the stop, when the tramcar enters in the stop range, the Bluetooth modules of the two controllers makes wireless link. It is specially designed for a super capacitor tramcar collecting bow charging system. The two controllers can cooperate to complete the automatic charging course of the super capacitor tramcar, resolving the energy ration of the tramcar in the whole course. It meets the demand of the super capacitor tramcar collecting bow charging system. The control structure is modulized, easy to transplant.

Owner:SHANGHAI JIAO TONG UNIV

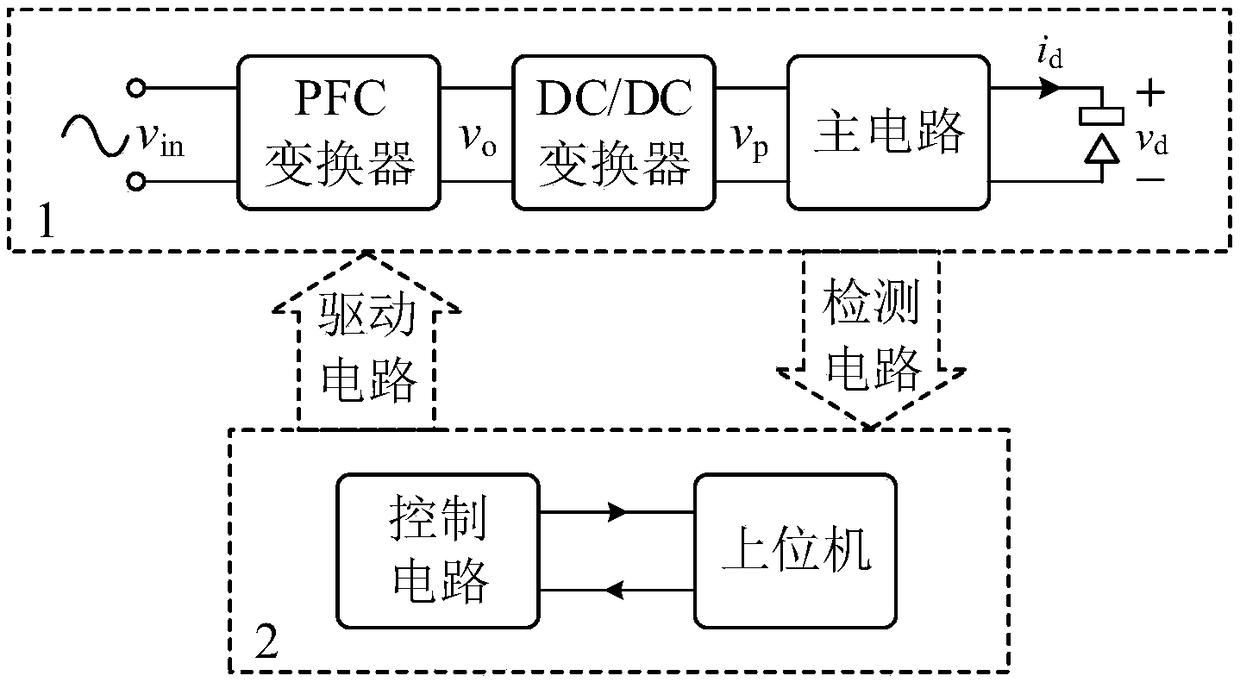

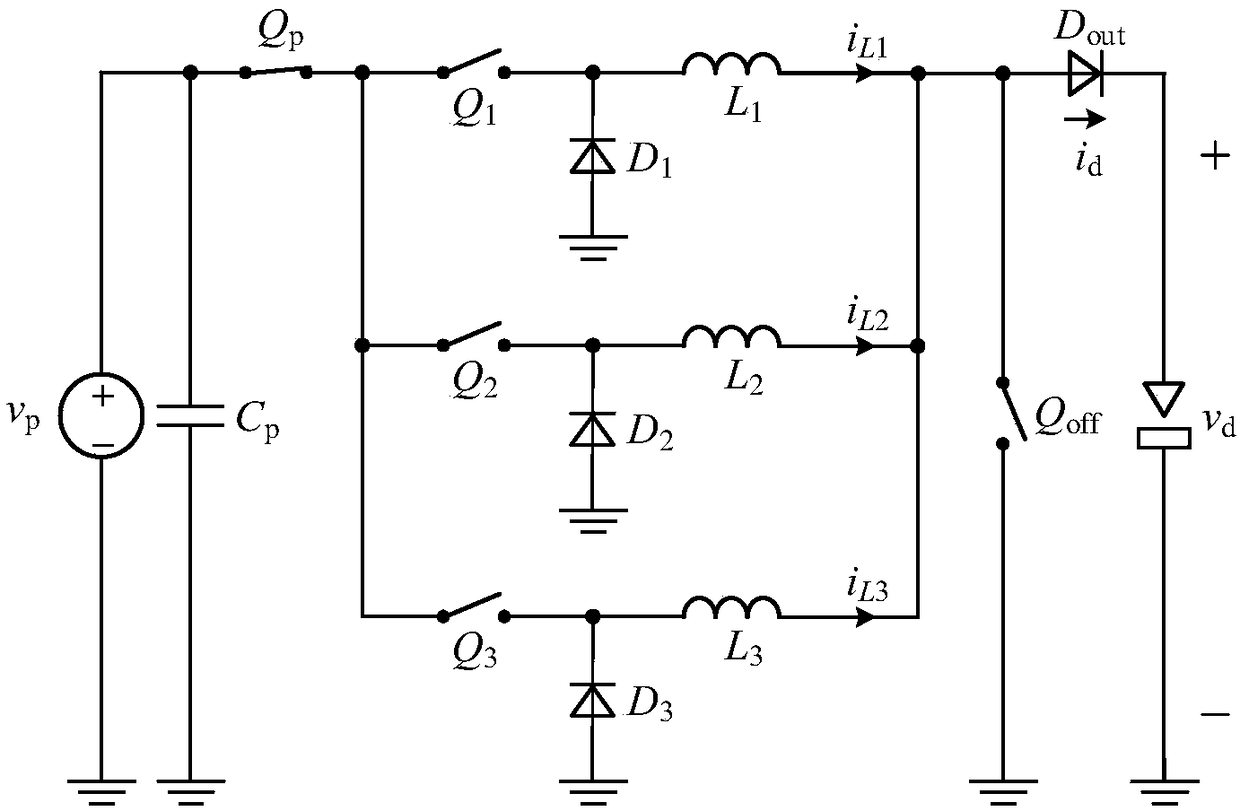

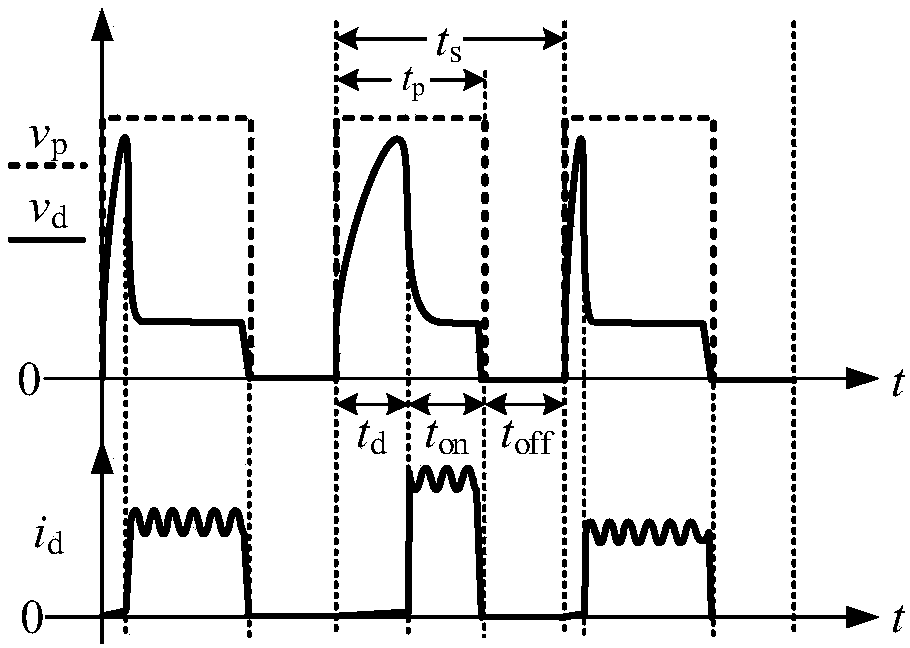

Electrospark wire-electrode cutting pulsed power supply and control method thereof

ActiveCN108380988AImprove power densityImprove reliabilityProgramme controlComputer controlLoop controlClosed loop

The invention discloses an electrospark wire-electrode cutting pulsed power supply and a control method thereof. The electrospark wire-electrode cutting pulsed power supply comprises an alternating-current power supply, a PFC convertor, a DC / DC convertor, a main circuit, a detecting circuit, a driving circuit, a control circuit and an upper computer, wherein a three-way staggered in-parallel Buckcircuit is adopted as the main circuit, supplies unipolar voltage to a gap and replaces current-limiting resistance with energy-storage inductance. According to the control method of the electrosparkwire-electrode cutting pulsed power supply, feedback closed-loop control is conducted by taking the sum of gap voltage and gap currents as the unique control quantity of feedback closed-loop control.Therefore, the machining efficiency and the switching frequency of a system are improved, the dynamic response capability of the system is improved, the current-resistant requirement on a switching tube is lowered, and on the condition that the discharge frequency is kept constant, the single-time discharge energy can be maintained consistent, and high-speed uniform micromachining can be achieved.

Owner:NANJING UNIV OF SCI & TECH

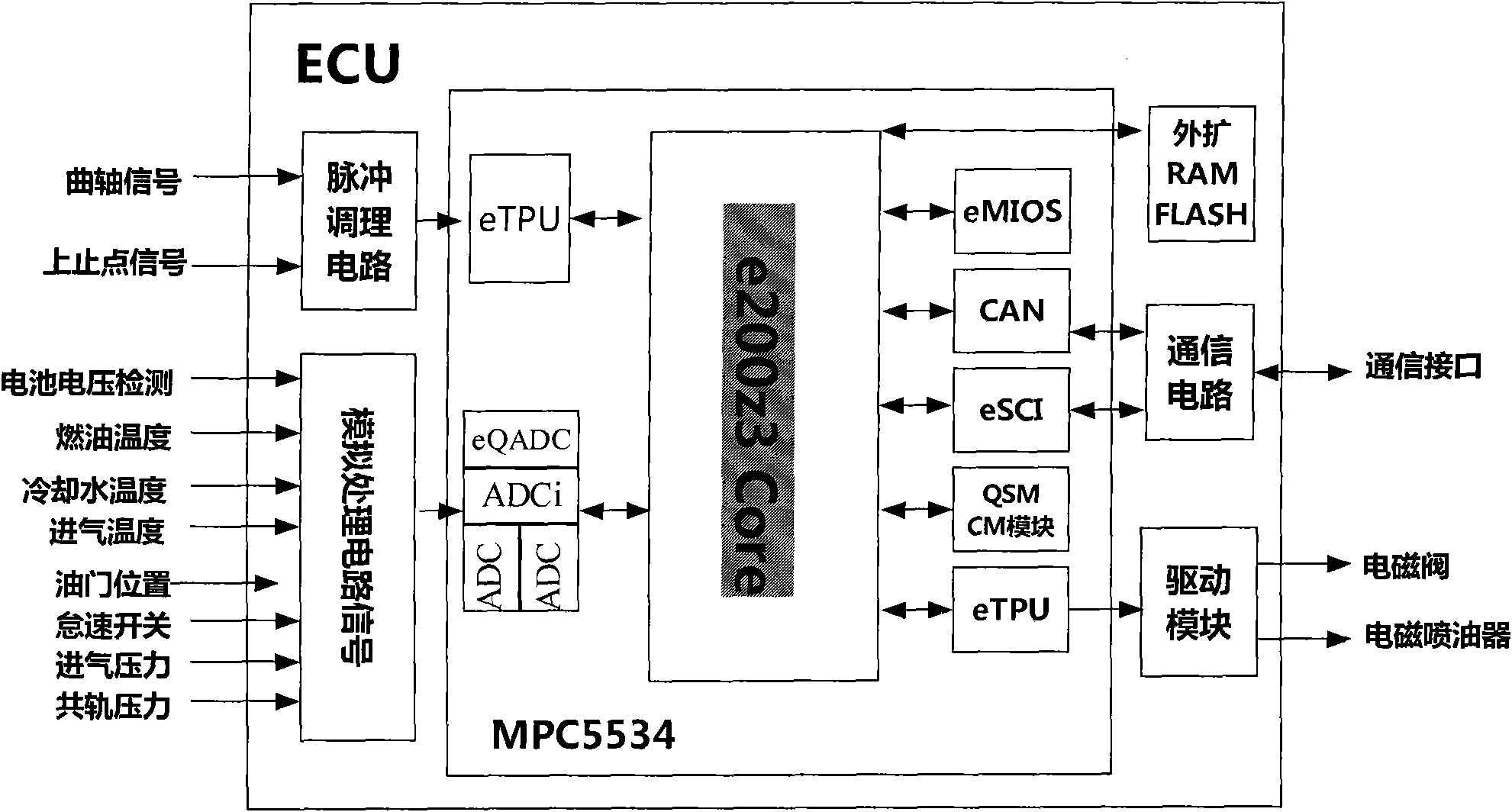

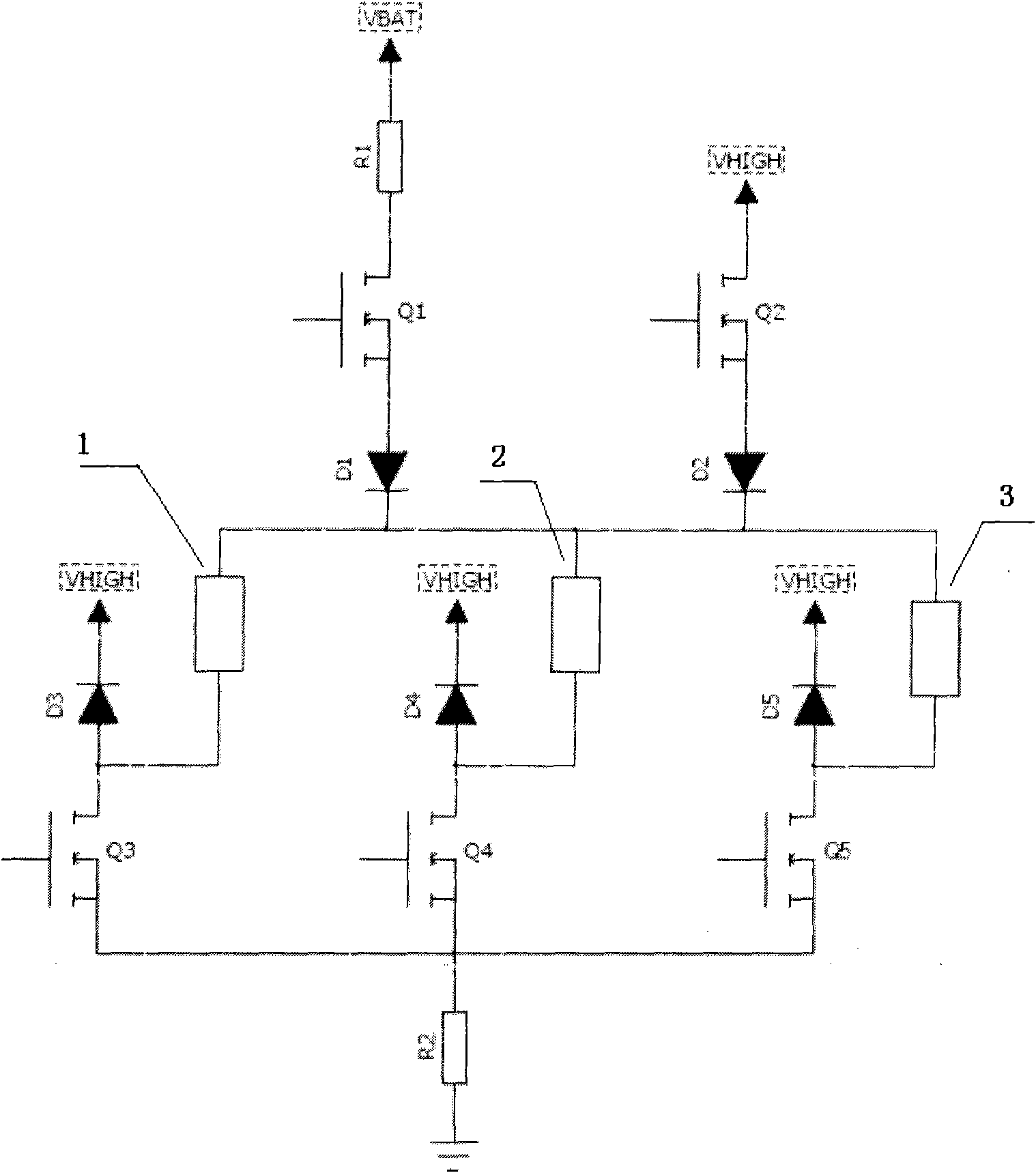

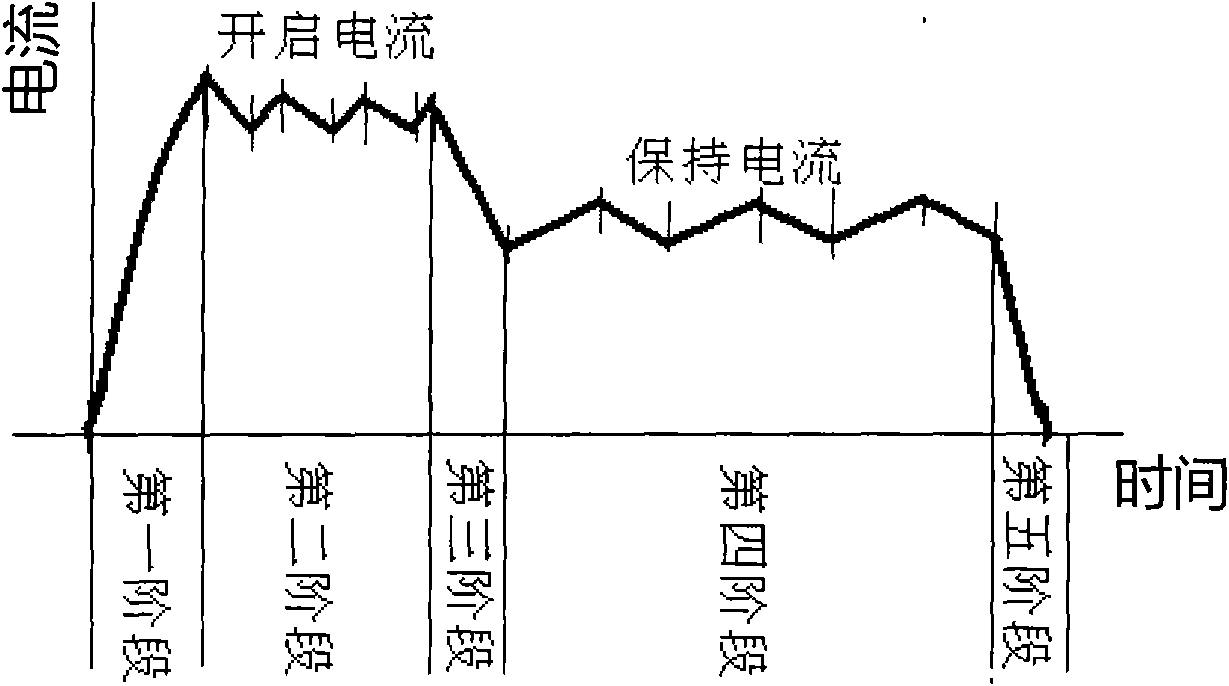

Electronic control unit (ECU) of electromagnetic-type high-pressure common-rail injection system for vehicle diesel engine

InactiveCN101684757AReduce volumeReduce power consumptionElectrical controlMachines/enginesMicrocontrollerInjection volume

The invention relates to an electronic control unit (ECU) of an electric-control high-pressure common-rail injection system for a vehicle diesel engine, mainly applied to a high-pressure common-rail system of a diesel engine for accurately controlling the injection volume, the injection pressure, the injection timing, the injection rule, and the like; an ECU input module comprises digital quantityinput and analog quantity input which comprise signal-processing circuits; a microcontroller module adopts an MPC5534 of an ALE technology as a microcontroller; an output module is used as a drivingcircuit of a high-pressure common-rail pressure control valve and an electromagnetic valve of an oil injector, adopts a 250V high-pressure driving technology to realize rapid starting performance, adopts TPU multipath combination to control injection, applies a CPLD technology to realize the double closed-ring control of currents and voltages and adopts inductors to store and recycle energy so asto reduce the consumption of driving energy; and a communication module mainly comprises a CAN circuit and a serial communications interface (SCI) circuit. The size of an ECU circuit board is reducedby applying a modularized heat-dissipation technology and an EMC circuit design technology is applied.

Owner:BEIJING YAO JIA AUTOMOTIVE ELECTRONICS

3104Aluminum alloy spectral standard sample and preparation method

ActiveCN101210872AMeet analysis requirementsMeet control requirementsMaterial analysis by optical meansStandard samplesAluminium alloy

The invention discloses a 3104 aluminum alloy spectrum standard sample, which is characterized in that the aluminum comprises Si 0.04-0.70%, Fe 0.18-0.90%, Cu 0.02-0.34%, Mn 0.65-1.3%, Mg 0.65-1.58%, Zn 0.04- 0.34%, Ti 0.04-0.91%, Ni 0.05-0.11%, Cd 2-70ppm, Pb 8- 170ppm, Ga 0.008-0.11%, V 0.008-0.11% and Na 1-40ppm. The invention also discloses a preparation method thereof. The inventive aluminum alloy spectrum standard sample can be used for the control and the analysis of 3104 aluminum alloy.

Owner:SOUTHWEST ALUMINUM GRP

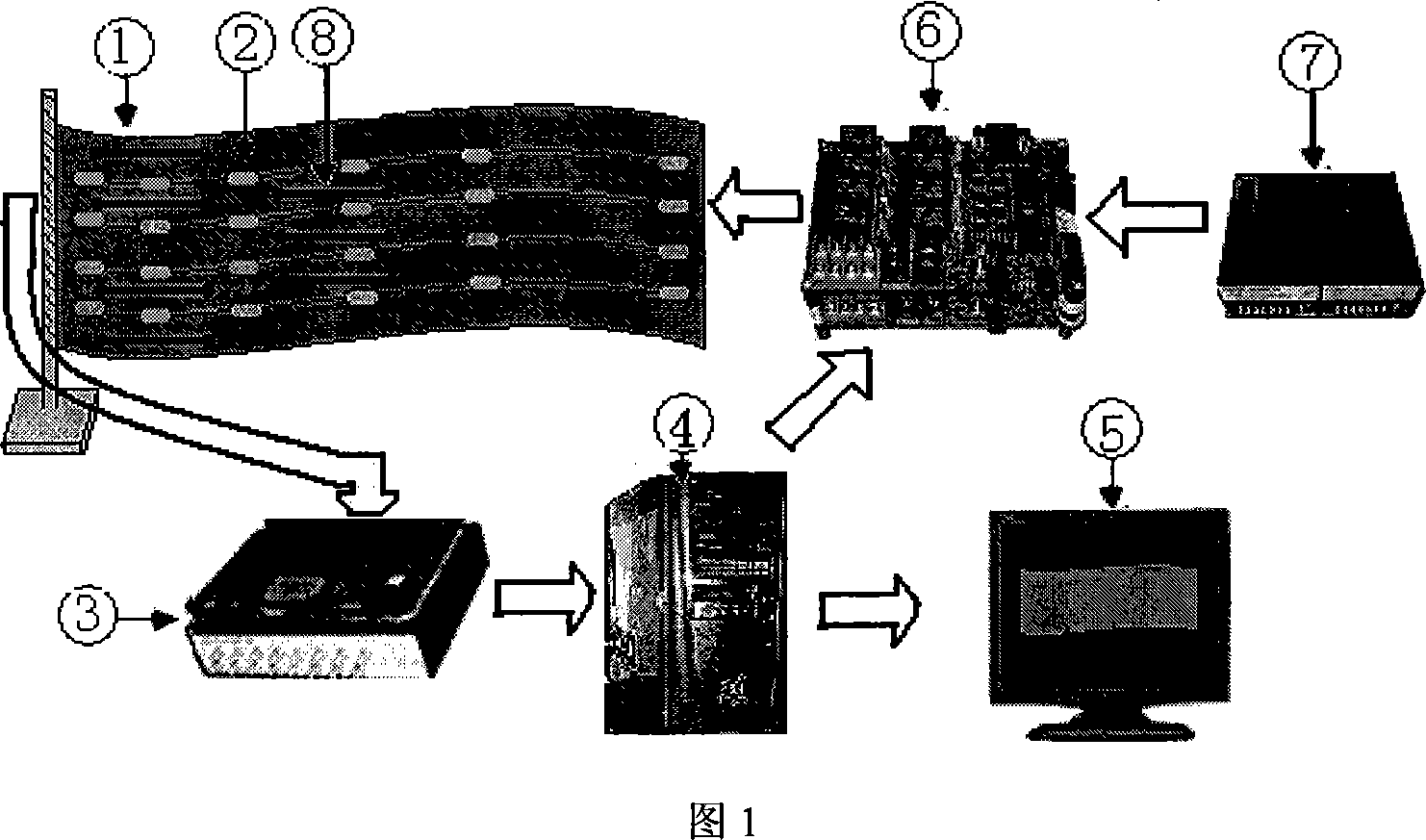

Active control method and device for space sail board structure low modal vibration based on form sensing

InactiveCN101051217AEasy to integrateImprove stabilityCosmonautic vehiclesCosmonautic partsGratingDisplay device

A method for actively controlling low mode vibration of space board-sail structure based on form-sending includes carrying out real time sense on vibration form of board-sail structure by optical fiber grating sensing network, generating control policy according to sensed vibration information of said structure, driving form memory alloy spring by using control driving unit to generate control action and utilizing form memory effect and super-elastic effect of said spring to realize purpose of eliminating structure vibration response. The device used for realizing said method is also disclosed.

Owner:SHANGHAI UNIV

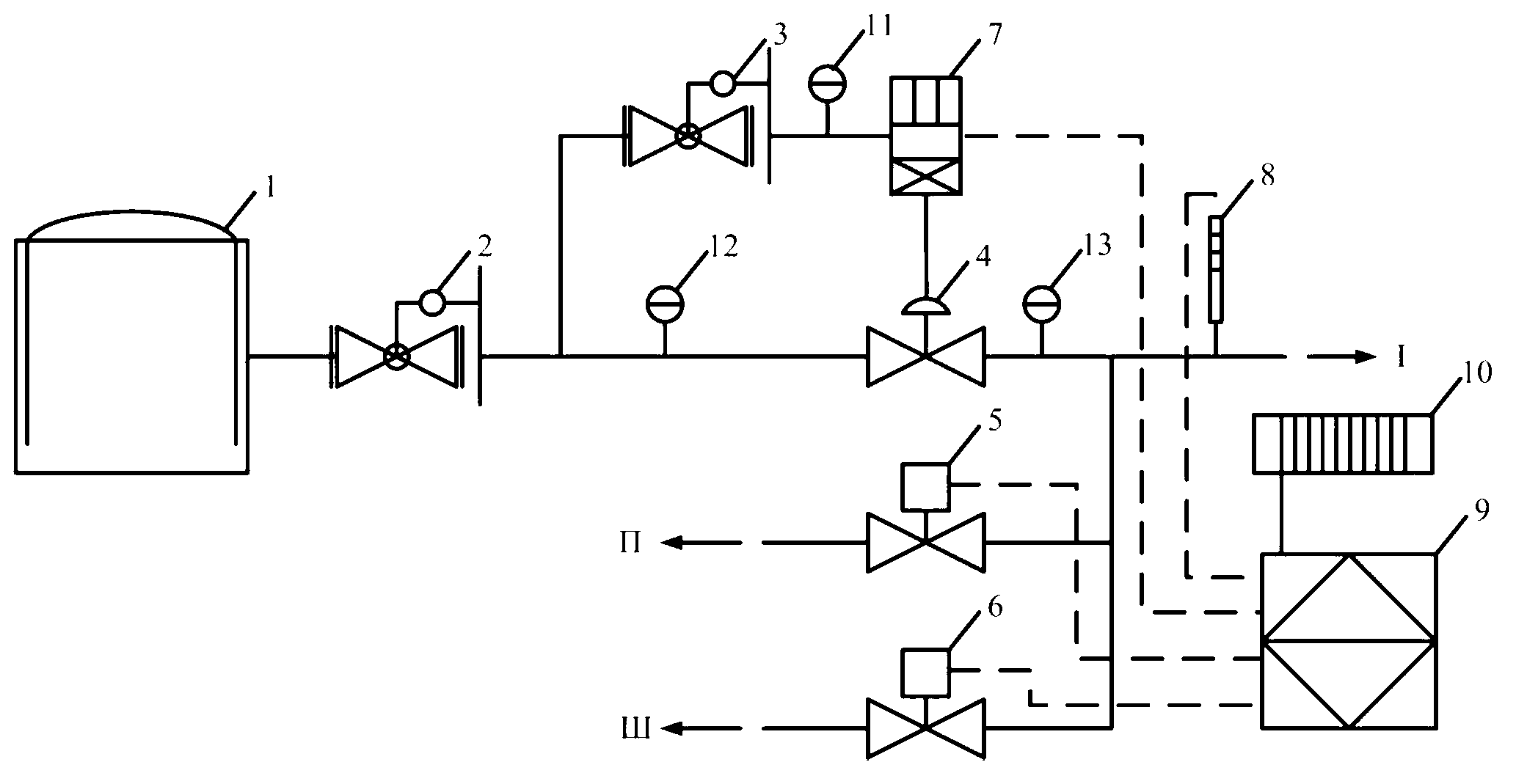

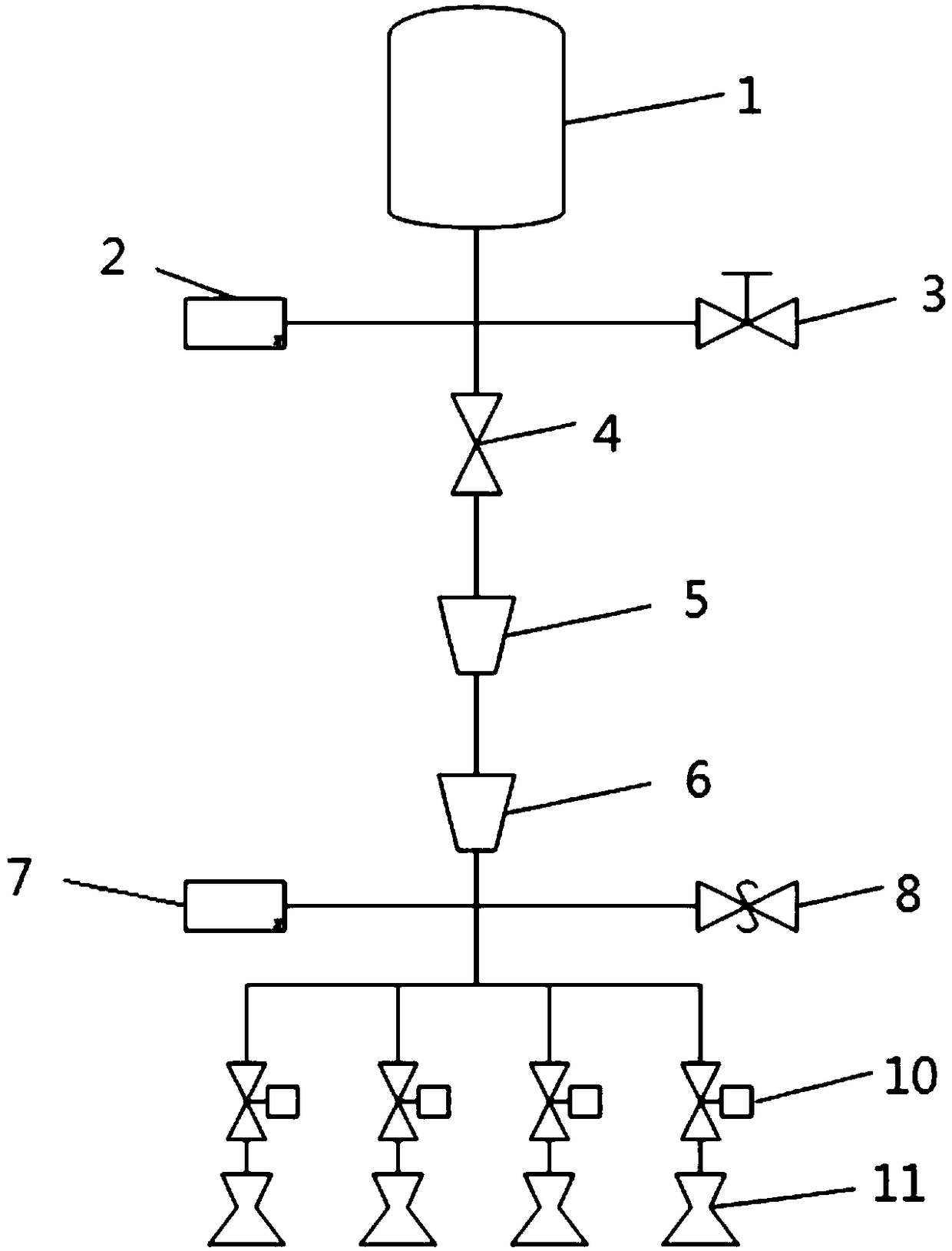

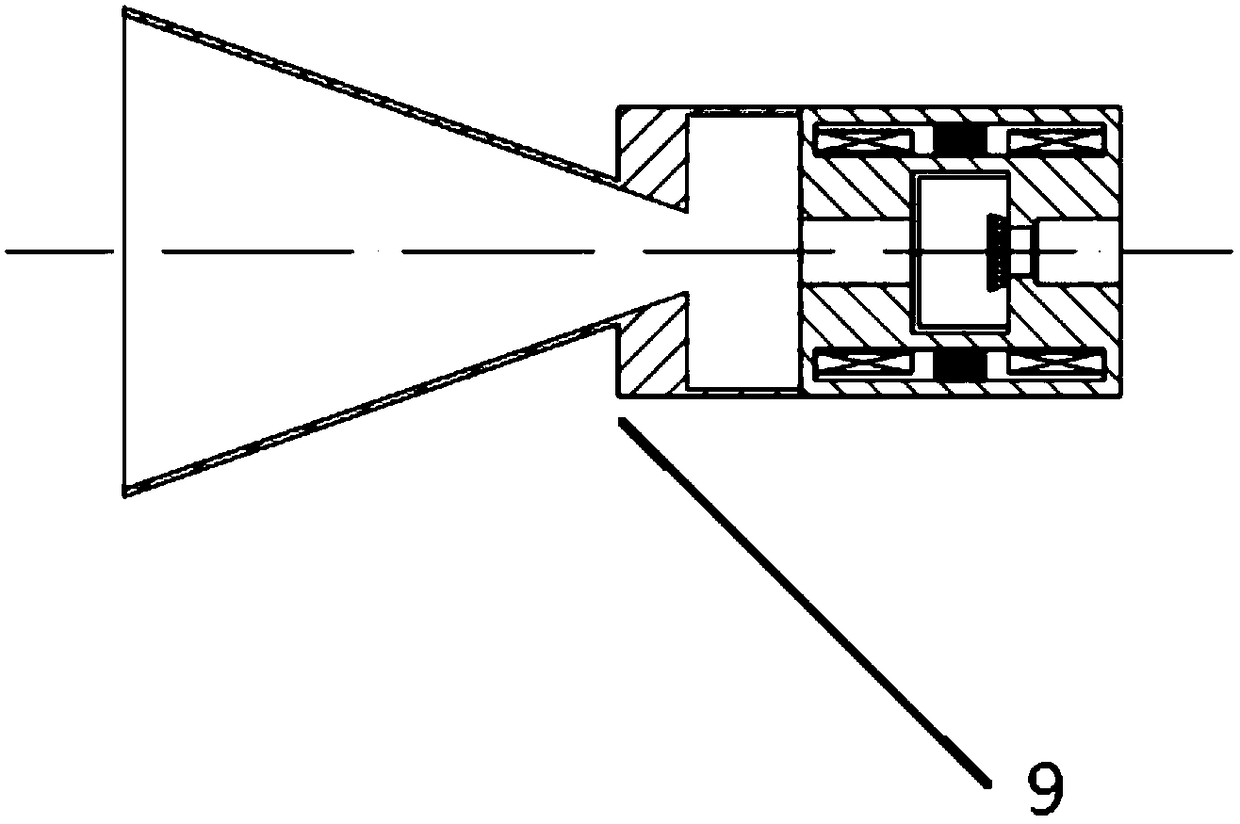

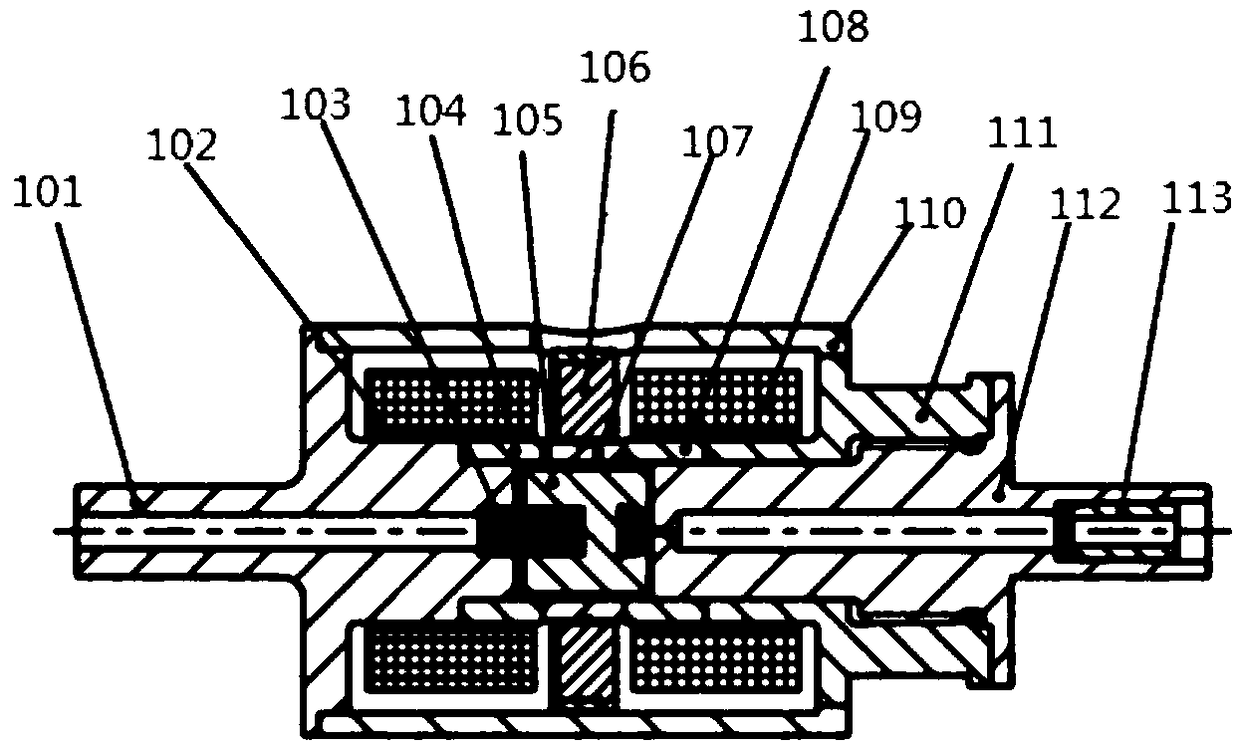

Attitude control system and small rocket launcher

The invention provides an attitude control system and a small rocket launcher, and relates to the technical field of rockets. The technical problems of low carrying capacity and high cost of an existing small rocket launcher are solved. The attitude control system comprises a high-pressure nitrogen bottle, a first pressure sensor, a second pressure sensor, an electric explosion valve, a pressure reduction device, a safety valve and a cold air thruster, wherein the first pressure sensor is arranged between the high-pressure nitrogen bottle and the electric explosion valve and is used for detecting pressure of the nitrogen which flows out of the high-pressure nitrogen bottle; the pressure reduction device is connected with the electric explosion valve; the second pressure sensor is arrangedbetween the pressure reduction device and the safety valve and is used for detecting the pressure of the nitrogen which flows out of the pressure reduction device; and the safety valve is connected with the cold air thruster. The device has the advantages of simple structure and low cost, and the provided thrust force just meets a control requirement of the small rocket launcher, and therefore, waste is avoided.

Owner:BEIHANG UNIV

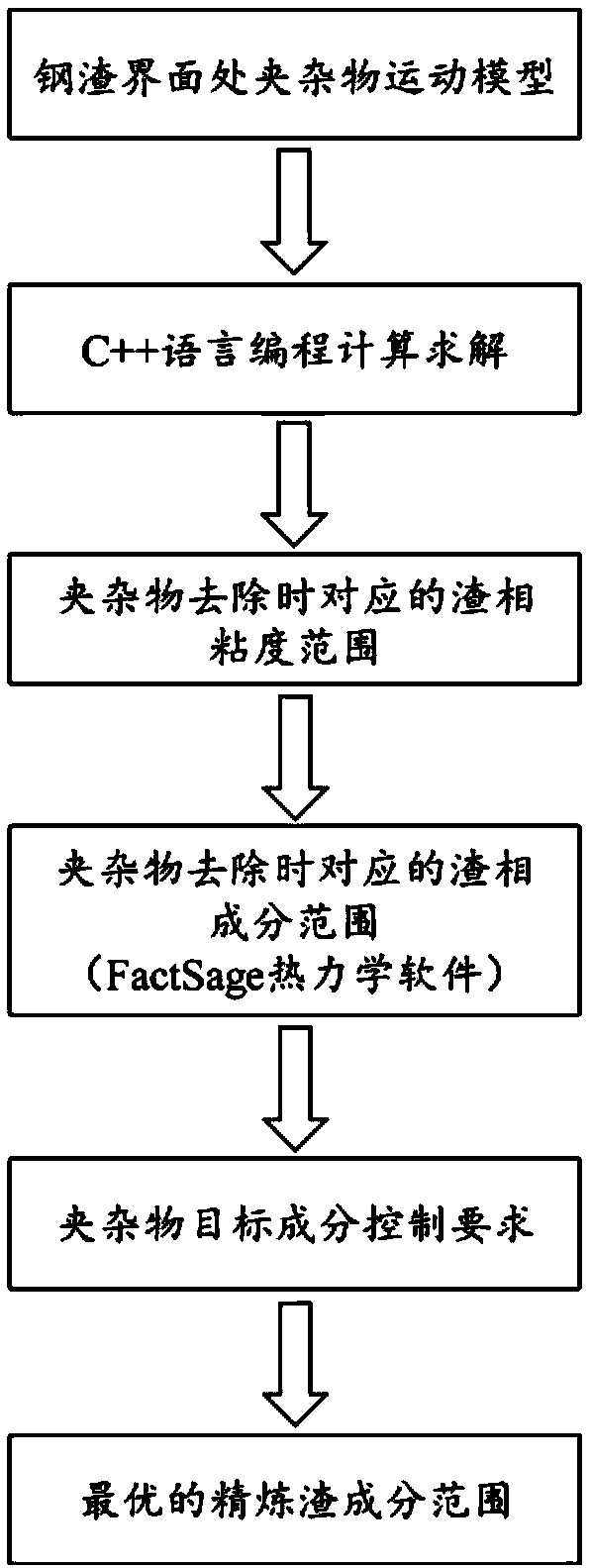

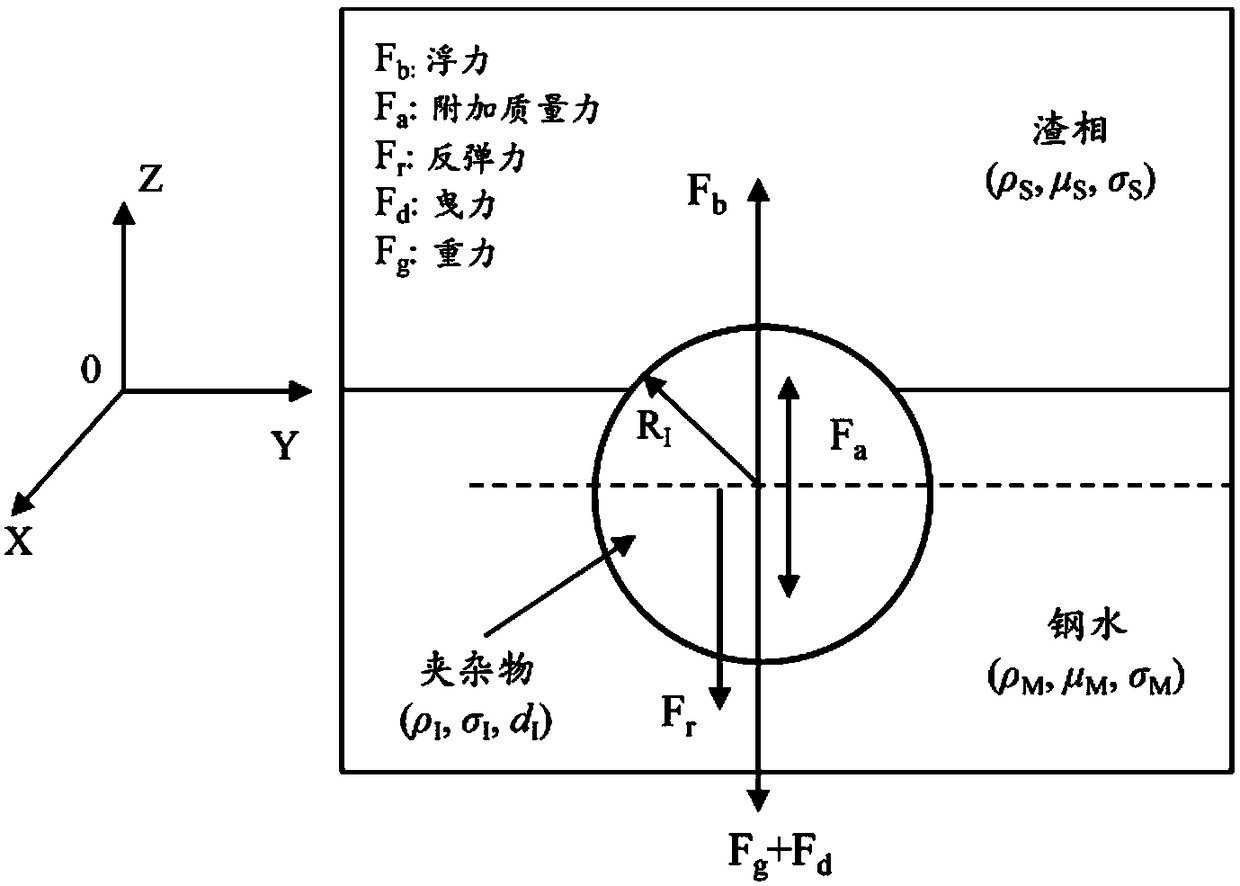

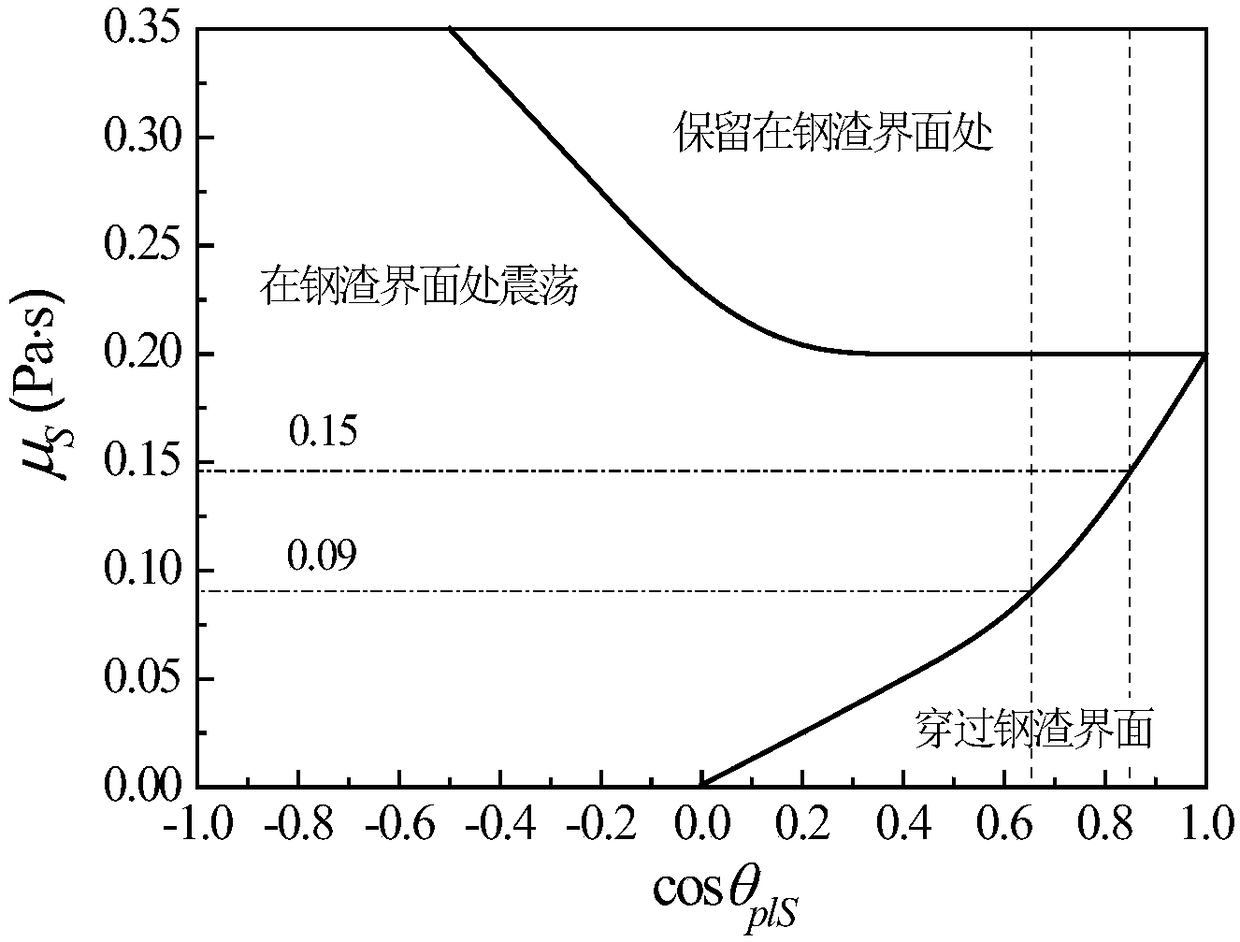

Molten steel refining slag composition design method

InactiveCN108875285AMeet control requirementsEasy to useDesign optimisation/simulationSpecial data processing applicationsSlagMolten steel

The invention provides a molten steel refining slag composition design method and belongs to the technical field of clean steel smelting. The method includes: building and solving a steel slag interface inclusion motion model, quantitatively evaluating the influence of inclusion size, inclusion density, slag phase density, slag phase viscosity, molten steel density, molten steel viscosity and thewettability of inclusion at the steel slag interface on the motion removing process of the inclusion at the steel slag interface, determining the slag phase viscosity range and slag phase compositionrange when the inclusion can be removed, and determining the optimal refining slag composition range according to the target composition control requirement of the inclusion in steel. The method has the advantages that the defect that the prior art cannot give consideration to both inclusion target composition control and inclusion quantity reduction is overcome, the required refining slag composition suitable for the production of different types of steel can be determined in advance, enterprise production cost can be lowered favorably, and steel product quality can be increased favorably.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

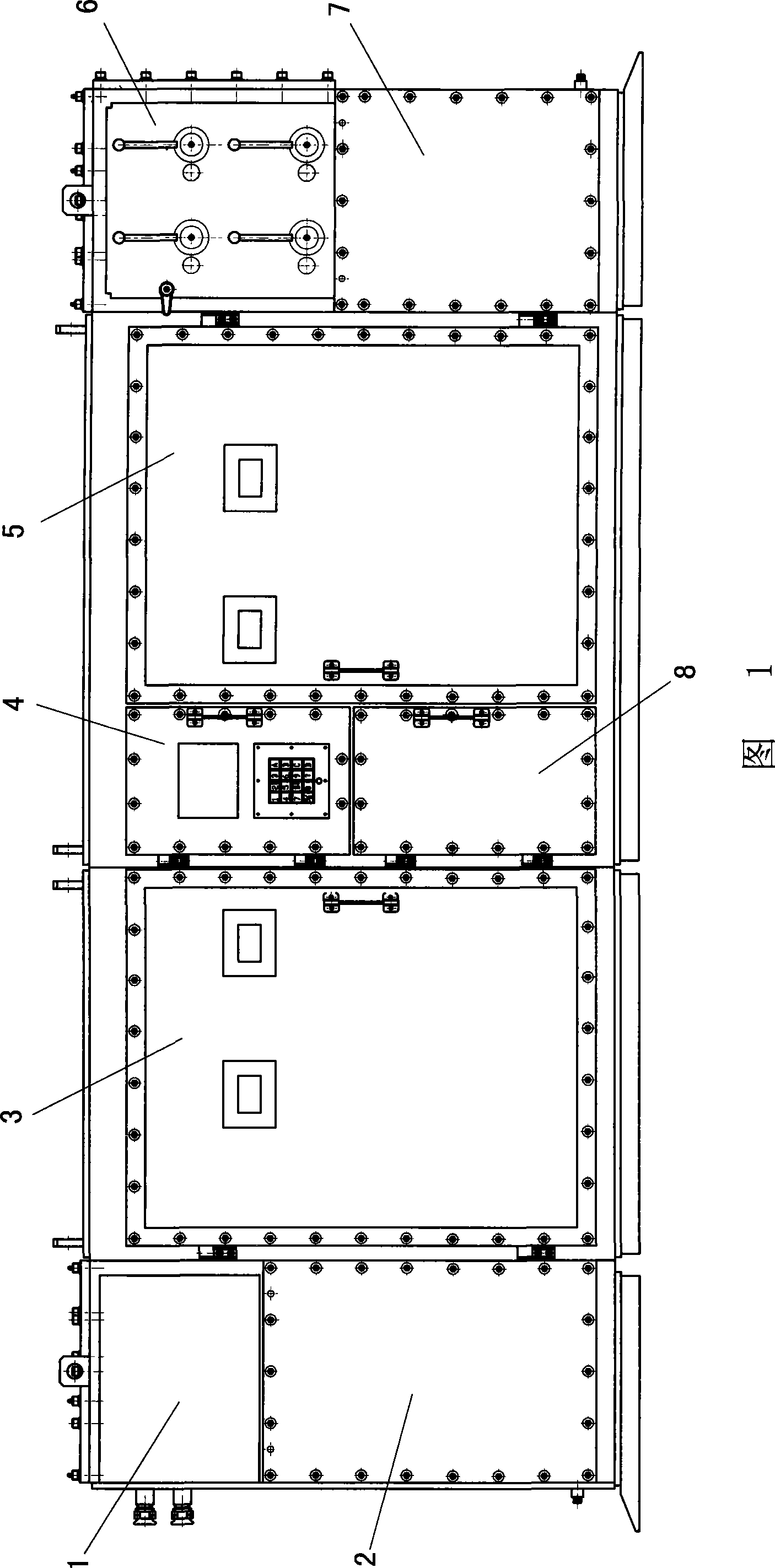

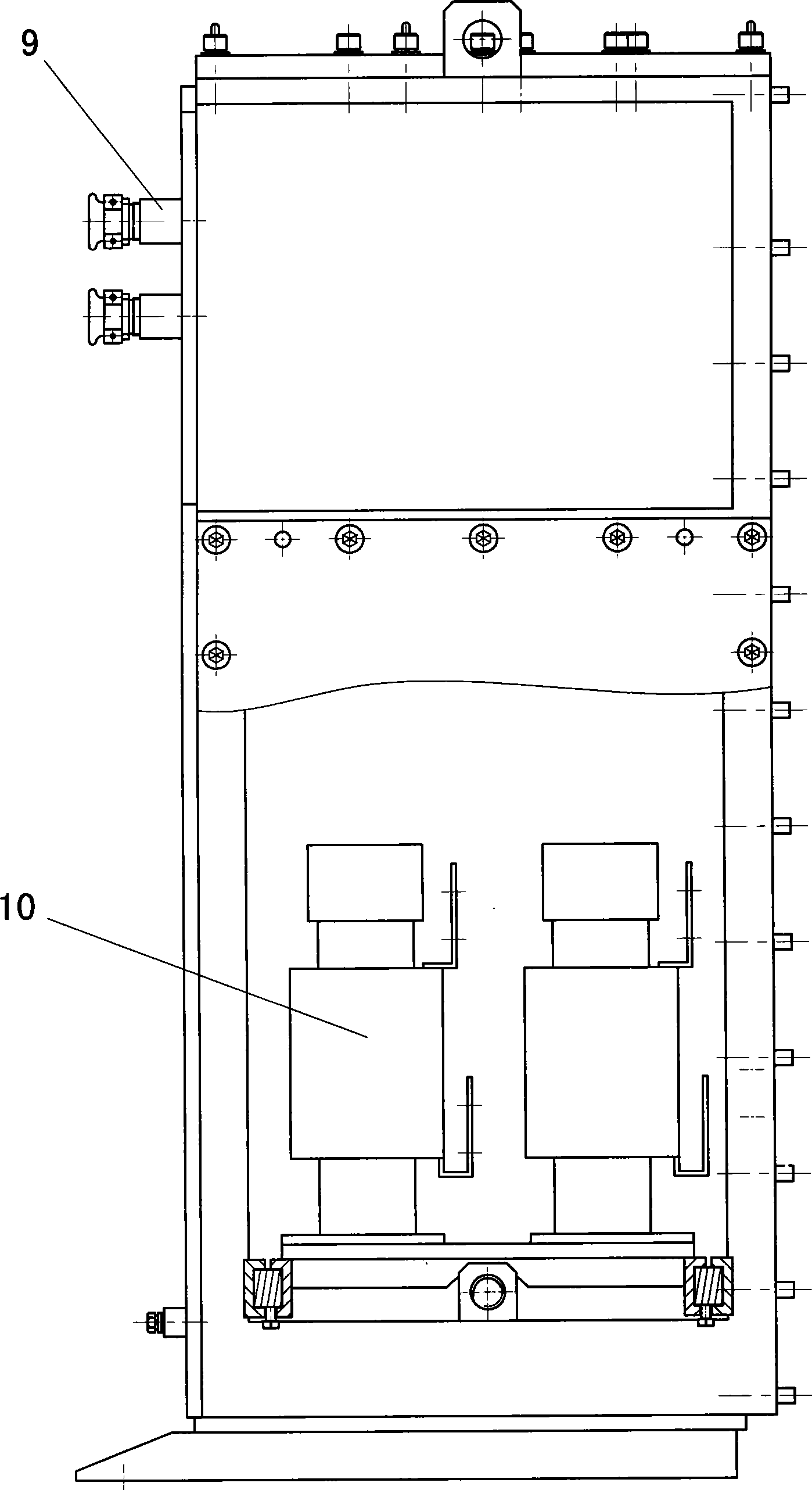

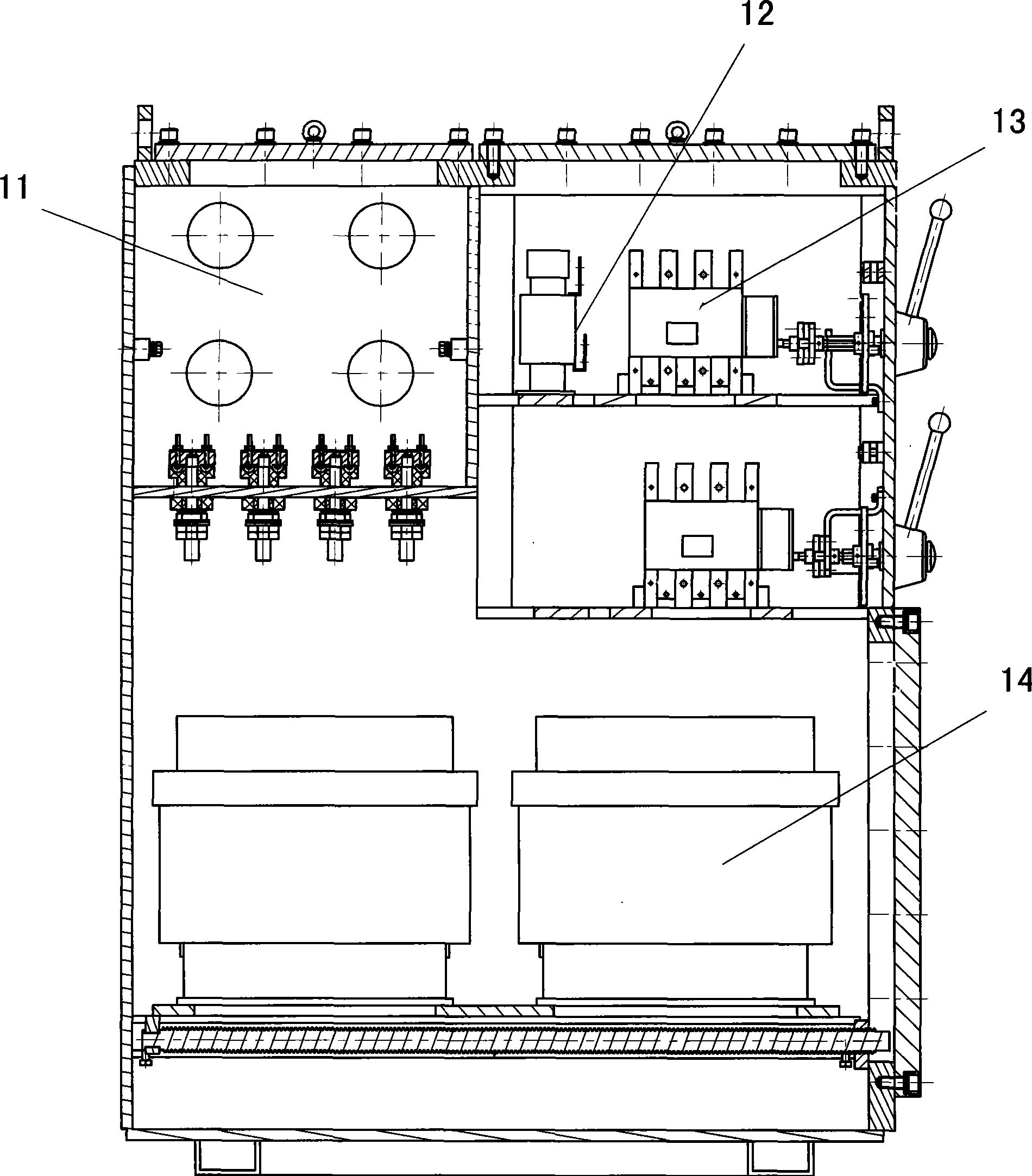

Combined frequency changer for mining

InactiveCN101442250AReduce connectionsReduce installationAC motor controlCircuit arrangements on support structuresFrequency changerDisplay device

The invention discloses a mine-used combined frequency converter, which consists of an explosion-resistant enclosure, frequency converters, a cooling device, built-in electric reactors and filters and so on, and has a combined structure, that is, a plurality of frequency converters are arranged in the explosion-resistant enclosure. A main controller for controlling the frequency converters, a refrigeration device, an isolating switch, and a pilot control circuit can be arranged in the explosion-resistant enclosure. The mine-used combined frequency converter is applicable to the frequency control and centralized control of multi-point driving and single-point driving of a plurality of equipment motors in explosive gas environments such as underground coal mines. The combined structure has centralized equipment and small occupation space, reduces installation and maintenance workload, and reduces the cost. The built-in main controller can intensively control the working state of the frequency converters and meet various control requirements; and the man-machine conversation is realized through a keyboard display, which has flexible control and convenient setting. A heat pipe radiator has high efficiency; and the built-in refrigeration device strengthens the temperature reduction and improves the service life of the frequency converters. An alternating current voltage-stabilizing pilot circuit has simple external connection. The mine-used combined frequency converter has the advantages of simple structure and easy production.

Owner:张永亮

Preparation method of low-yellowness antibacterial calcium carbonate functional composite powder for ventilated membrane

ActiveCN102675918AEnsure maximum sizeMeet the control requirements of the distribution state below the maximum particle sizePigment physical treatmentPigment treatment with non-polymer organic compoundsCalciteUltimate tensile strength

The invention discloses a preparation method of low-yellowness antibacterial calcium carbonate functional composite powder for a ventilated membrane. The method comprises the following steps of: cleaning calcite raw ore, drying in the air and smashing; grading with a vibration sieve; mixing for preparing; coating; drying; and modifying. The composite powder has the beneficial effects: when added into the ventilated membrane, the composite powder plays a role in filling and increasing volume; the yellowness of the ventilated membrane is lowered by over 50 percent in comparison to a ventilated membrane into which an equal amount of ordinary calcium carbonate is added; the processing flowability, tensile strength and air permeability uniformity of a ventilated membrane product can be improved remarkably; and the ventilated membrane added with the calcium carbonate-based functional composite powder has antibacterial property.

Owner:ANHUI JIANGDONG TECH POWDER CO LTD

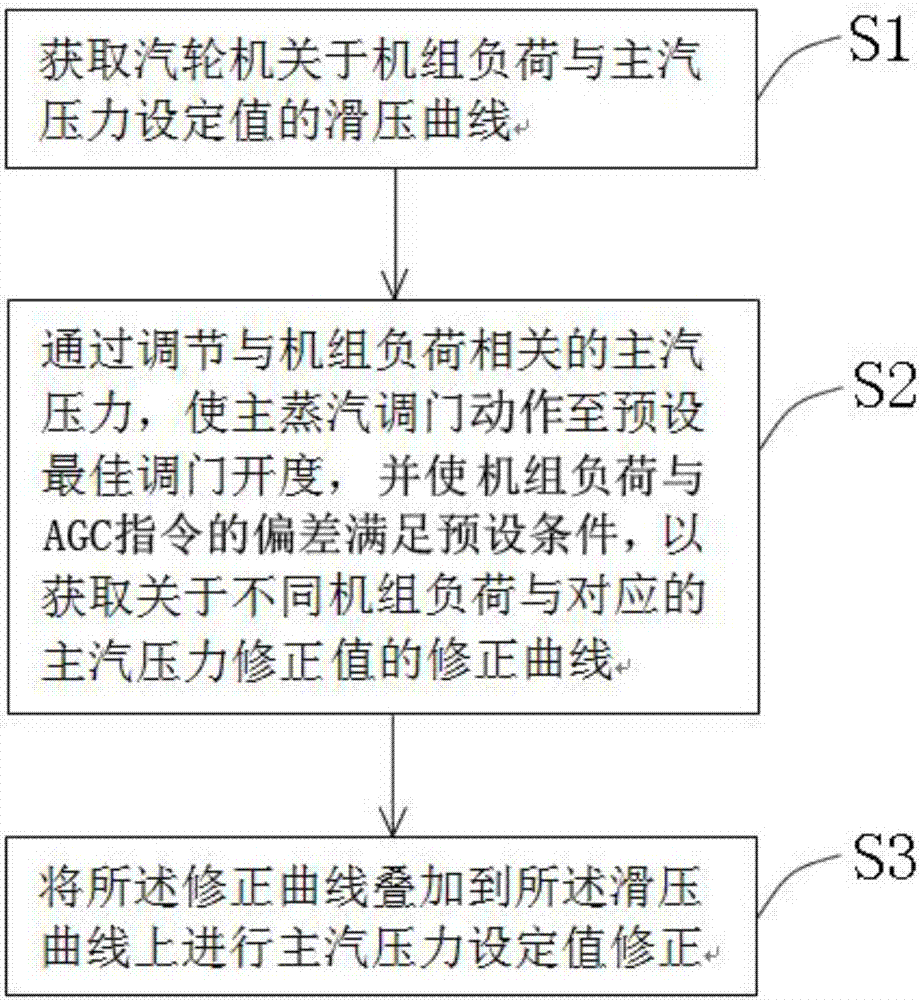

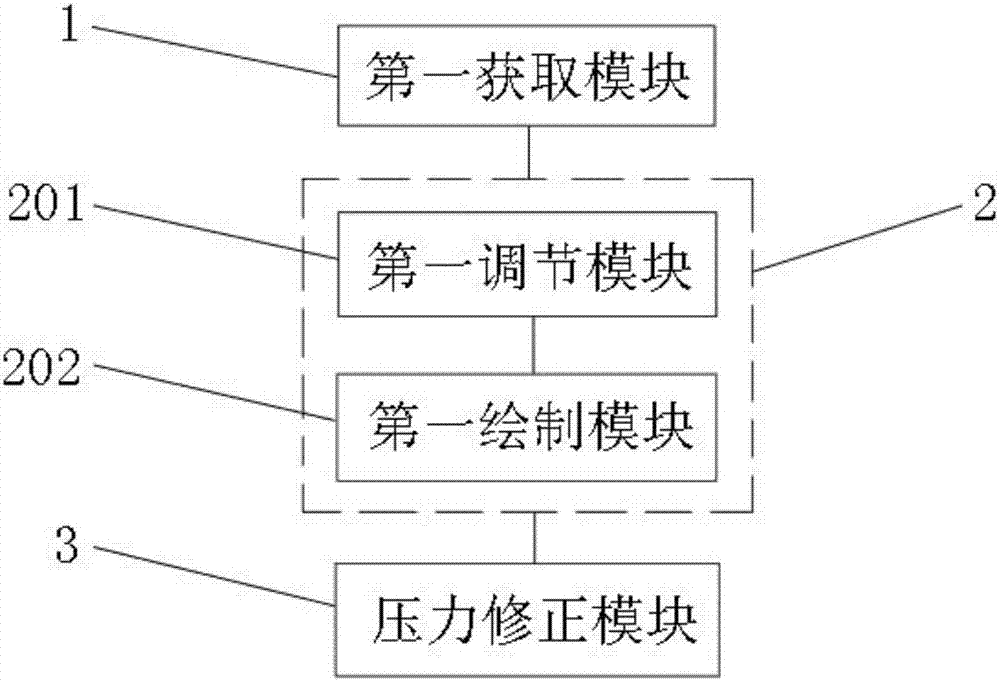

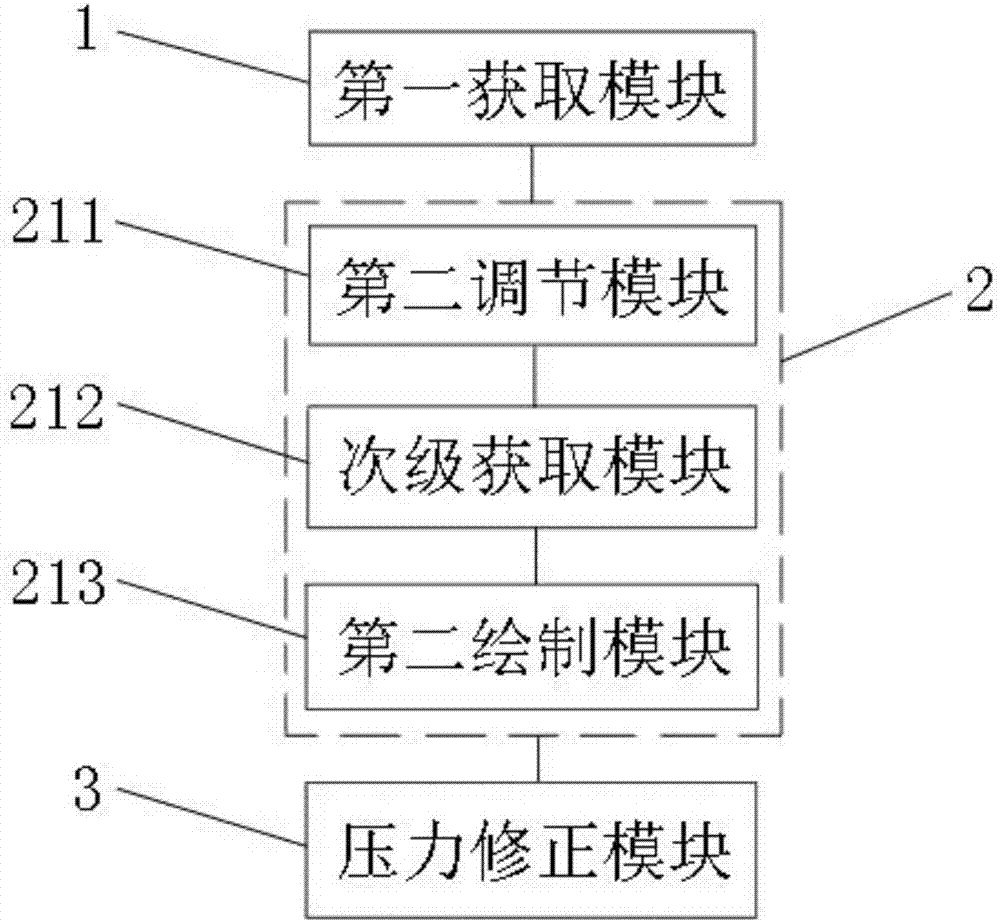

Steam turbine and sliding pressure curve correction method and system based on load reception capacity of steam turbine

ActiveCN107218086AMeet control requirementsImprove performanceMachines/enginesSafety/regulatory devicesCorrection methodPressure curve

The invention discloses a sliding pressure curve correction method based on the load reception capacity. The method comprises the steps that a sliding pressure curve about unit loads and main steam pressure set values of a steam turbine is obtained; a main steam regulation door is moved to the reset optimal regulation door opening by adjusting the main steam pressure related to the unit loads, the deviation between the unit loads and an AGC instruction is made to meet the preset condition, and thus a correction curve about different unit loads and the corresponding main steam pressure correction values is obtained; and the correction curve is overlapped to the sliding pressure curve for correction of the main steam pressure set values. According to the sliding pressure curve correction method disclosed by the invention, pressure adjustment is performed according to the main steam pressure set values corrected by the correction values, and the current main steam pressure of the steam turbine can reach the set values of the ideal state; and meanwhile, the regulation door opening of the steam turbine is made to reach the optimal position, and thus influences of the environmental temperature, the steam turbine characteristics, the heat supply steam extraction capacity change and other environmental factors on the sliding pressure curve are eliminated.

Owner:HUANENG PINGLIANG POWER GENERATION CO LTD

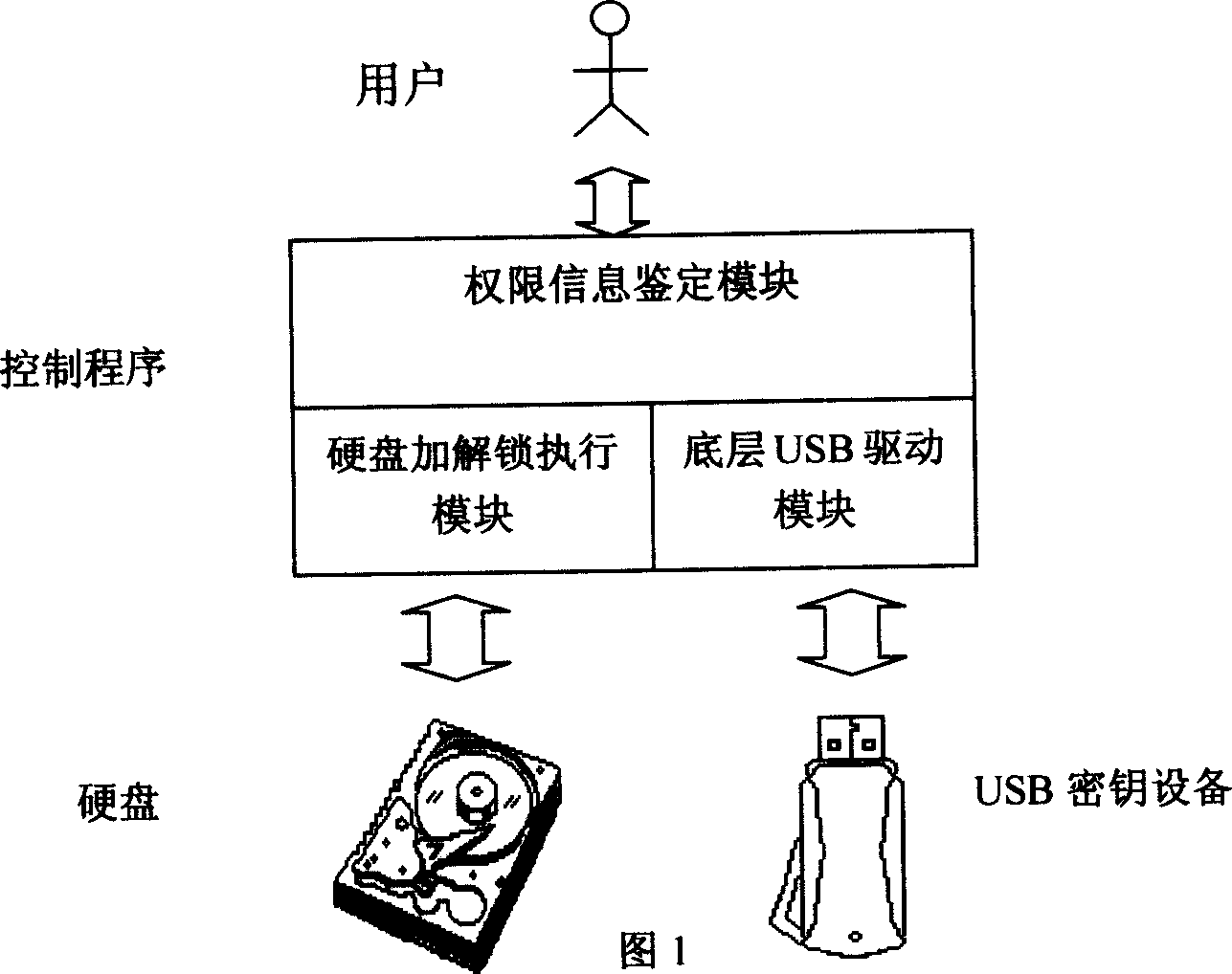

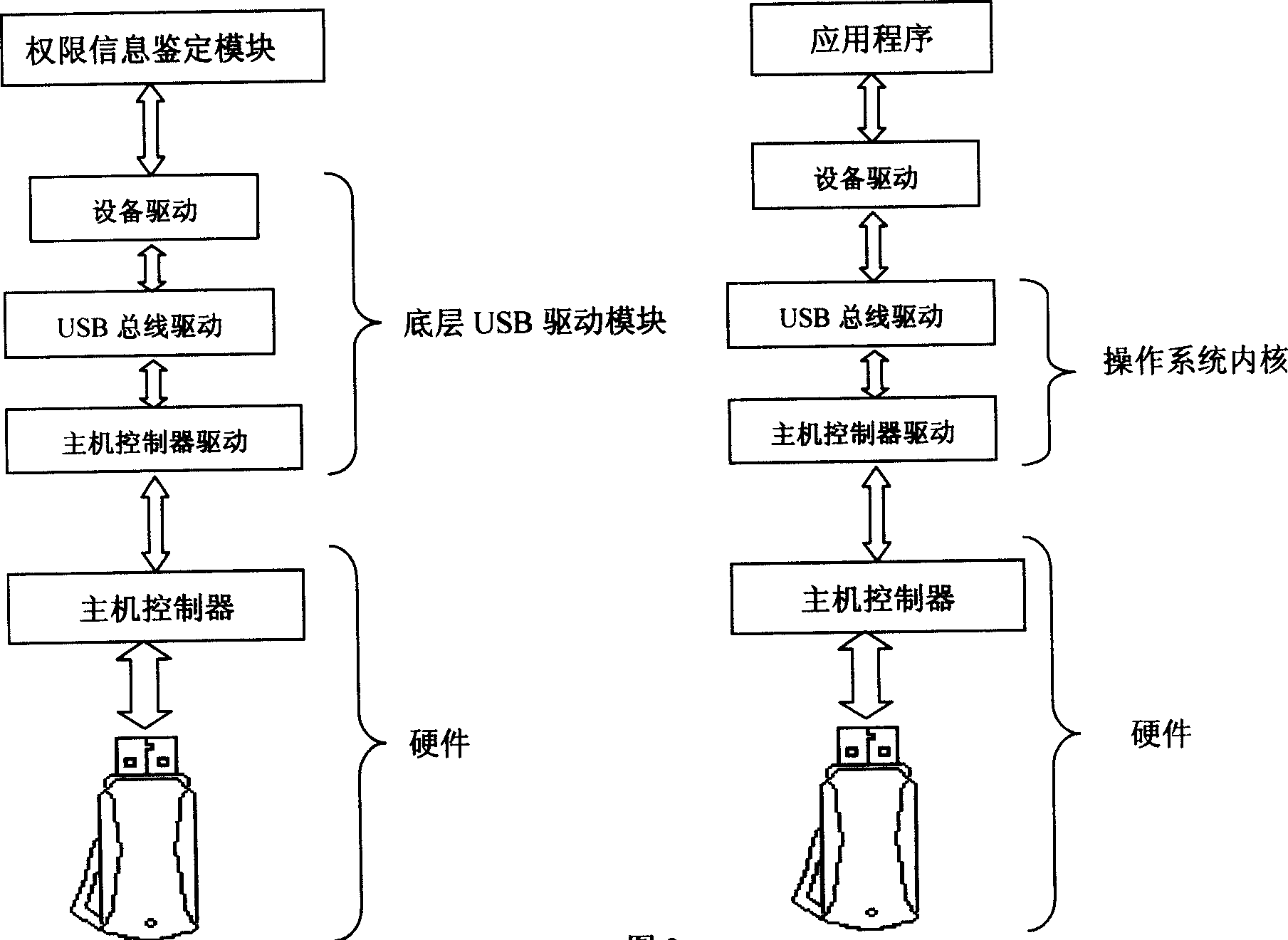

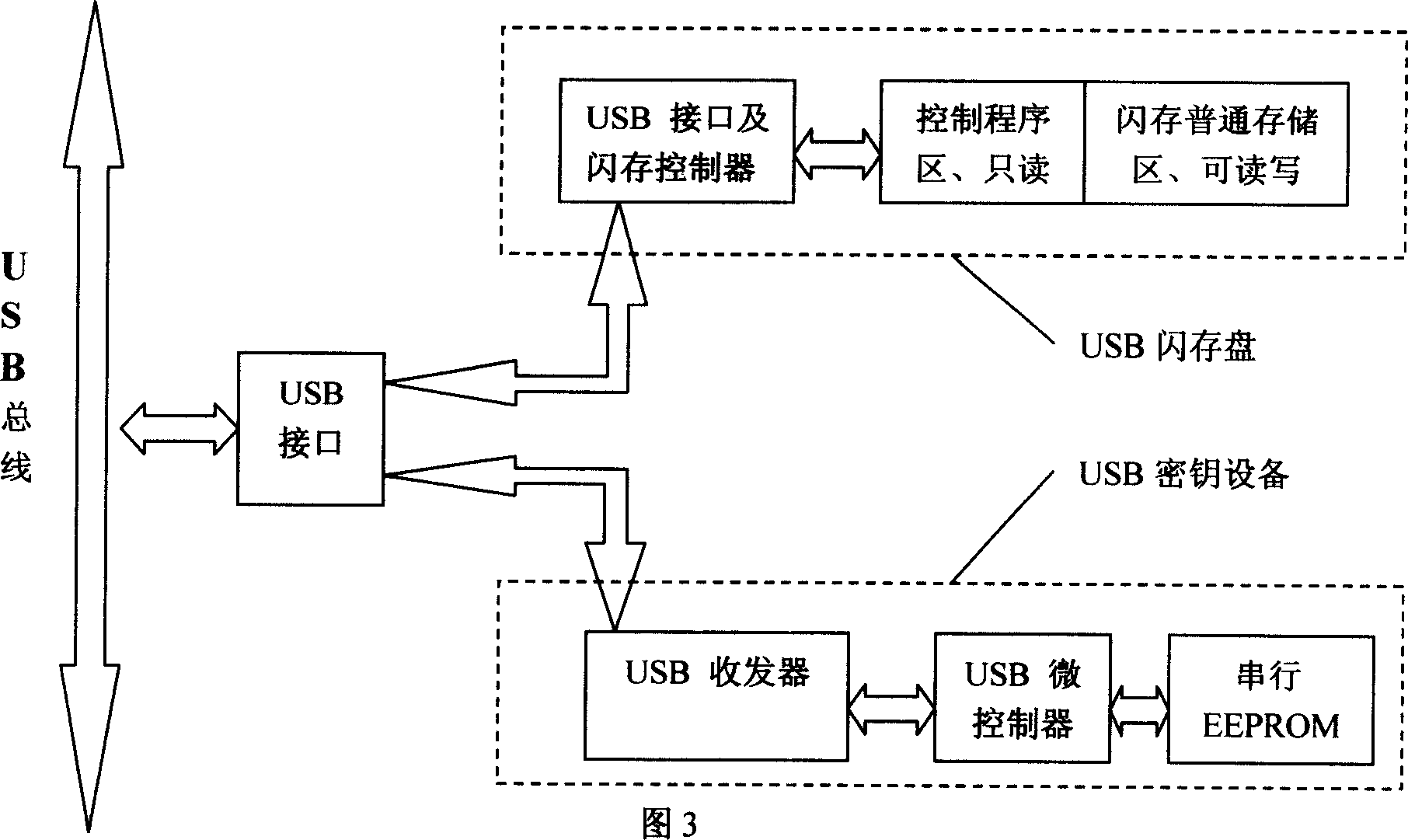

Hand disk locking and de-locking control scheme based on USB key apparatus

InactiveCN1702591AImpossible to leakDon't worry about accessDigital data processing detailsUnauthorized memory use protectionRights managementUSB

A control scheme for hard disc can realize reading and writing any sector of hard disc with corresponding rights through locking and unlocking hard disc finished instantly, and provides a managerial approach with multi-rights for USB key device. The scheme comprises a USB key device, a control program for locking and unlocking hard disc, said control program locks and unlocks hard disc according to the right information in key device through computer USB bus and USB key device communication.

Owner:西安三茗科技股份有限公司

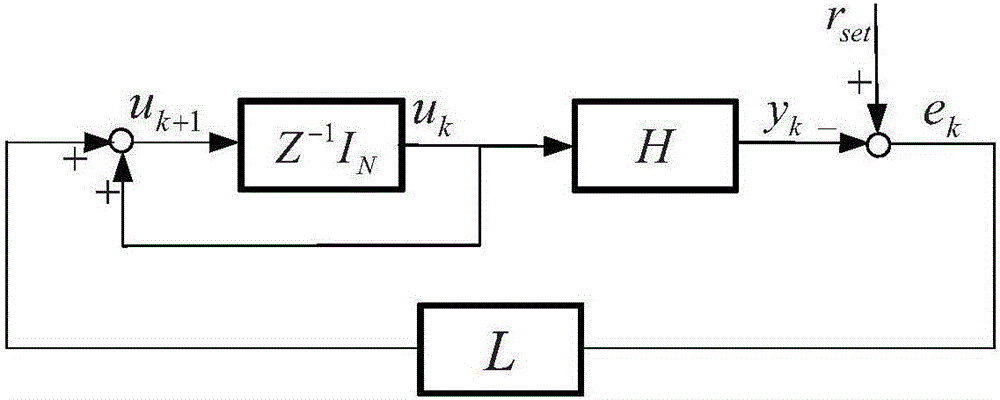

Method for controlling mechanical residual vibration of linear servo system

ActiveCN106325072ASuppress residual vibrationMeet control requirementsAdaptive controlResidual vibrationResonance

The invention discloses a method for controlling mechanical residual vibration of a linear servo system, and belongs to the technical field of mechanical device control. Most of current control methods for restraining residual vibration of the servo system are restraining methods based on input shapers, the methods have the shortcomings that pulse amplitudes and time period parameters are difficultly controlled, running errors are large, and control requirements of the linear servo system cannot be met. The method includes the steps: firstly, connecting the linear servo system, and downloading parameters into a chip on a motion control card; secondly, enabling the servo system to close a motor after controller parameters are downloaded; thirdly, collecting sampling points; fourthly, iterating error signals used for optimizing; fifthly, issuing iterative learning correction driving force to the motion control card again, and repeatedly iterating iterative learning processes to restrain resonance. Input signals subtract output signals to serve as error signals. The method is simple, practical and high in accuracy.

Owner:江苏希太芯科技有限公司

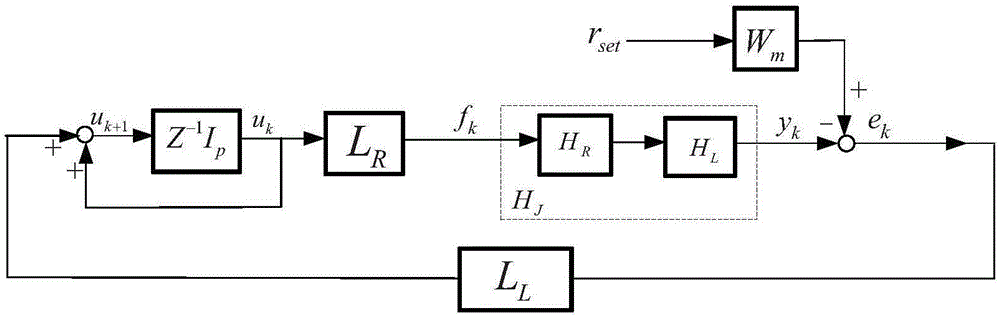

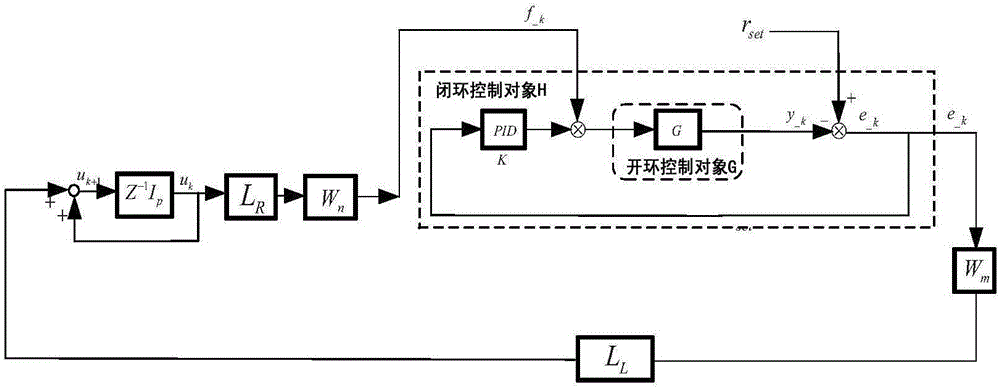

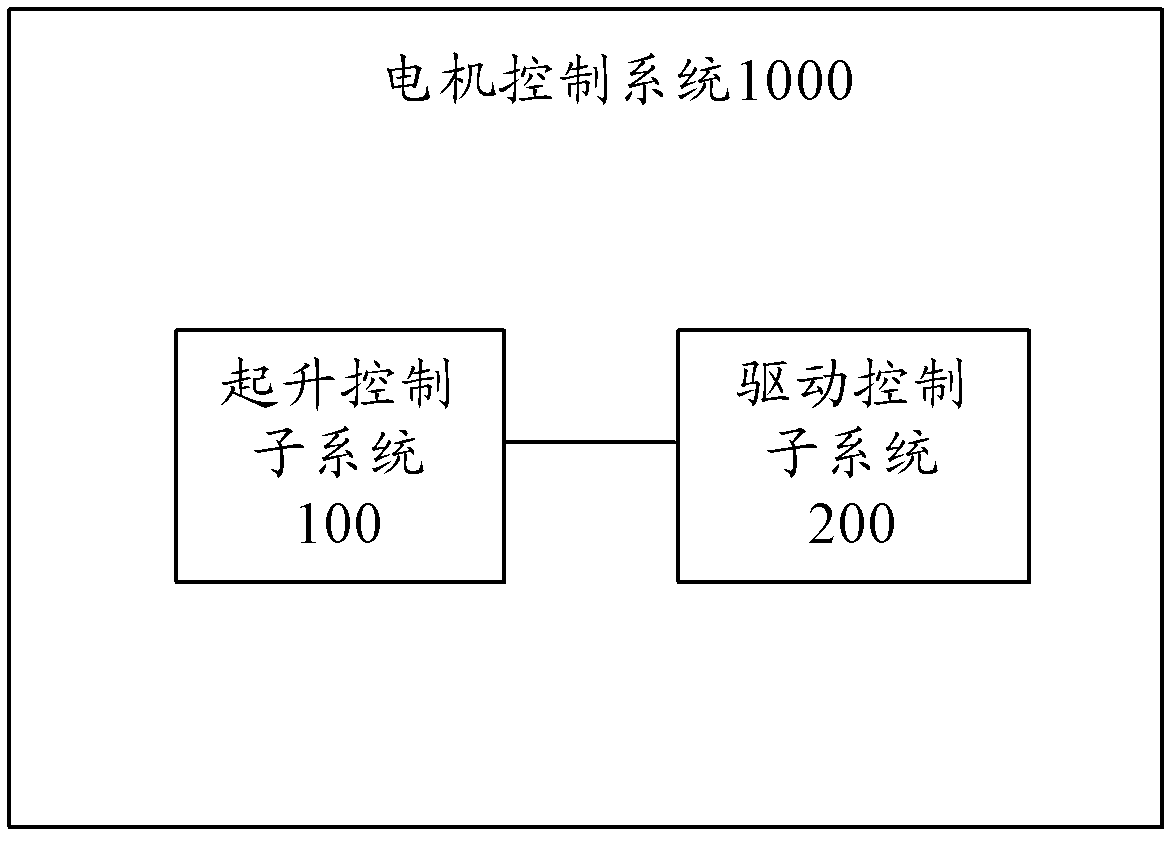

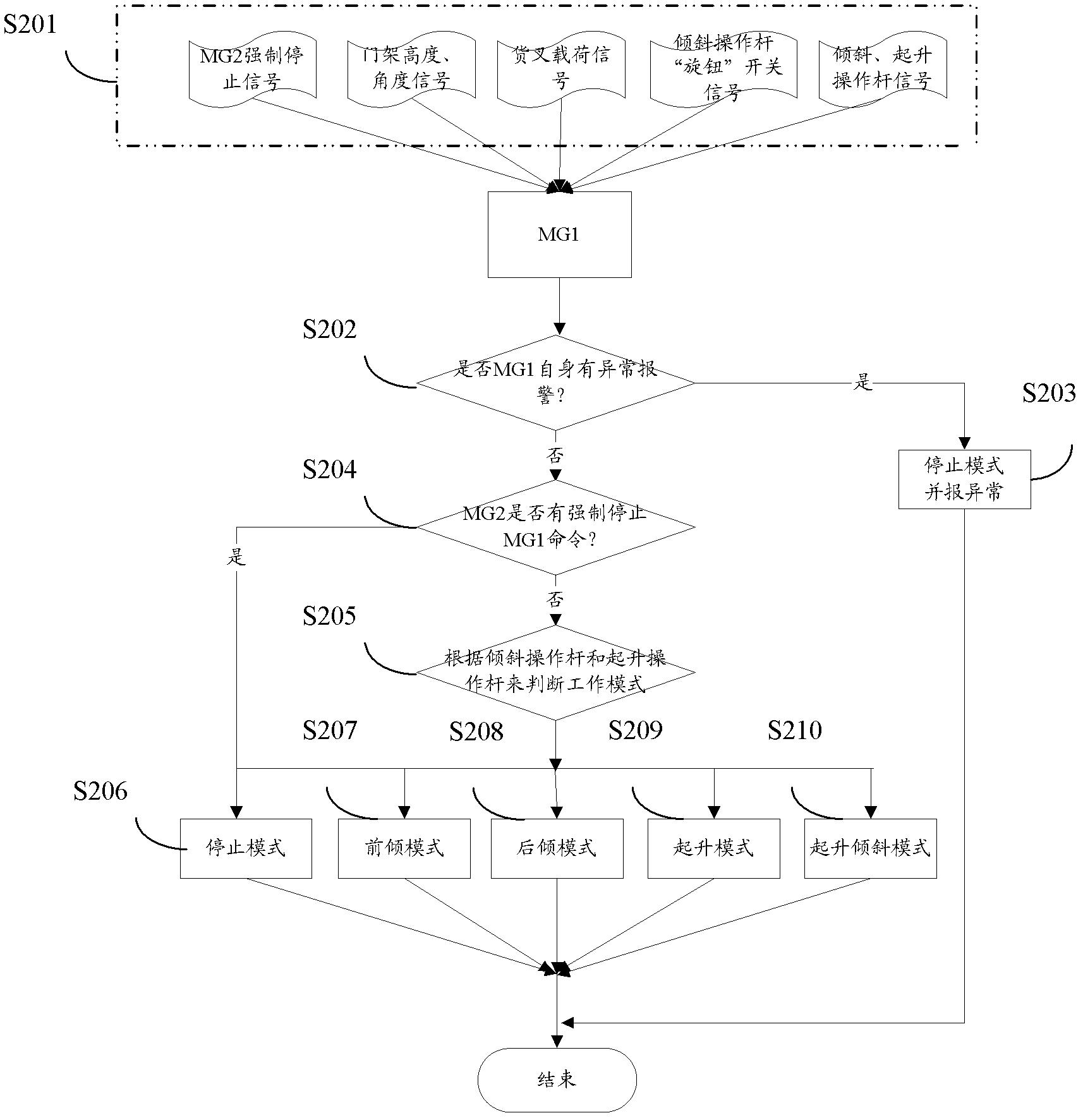

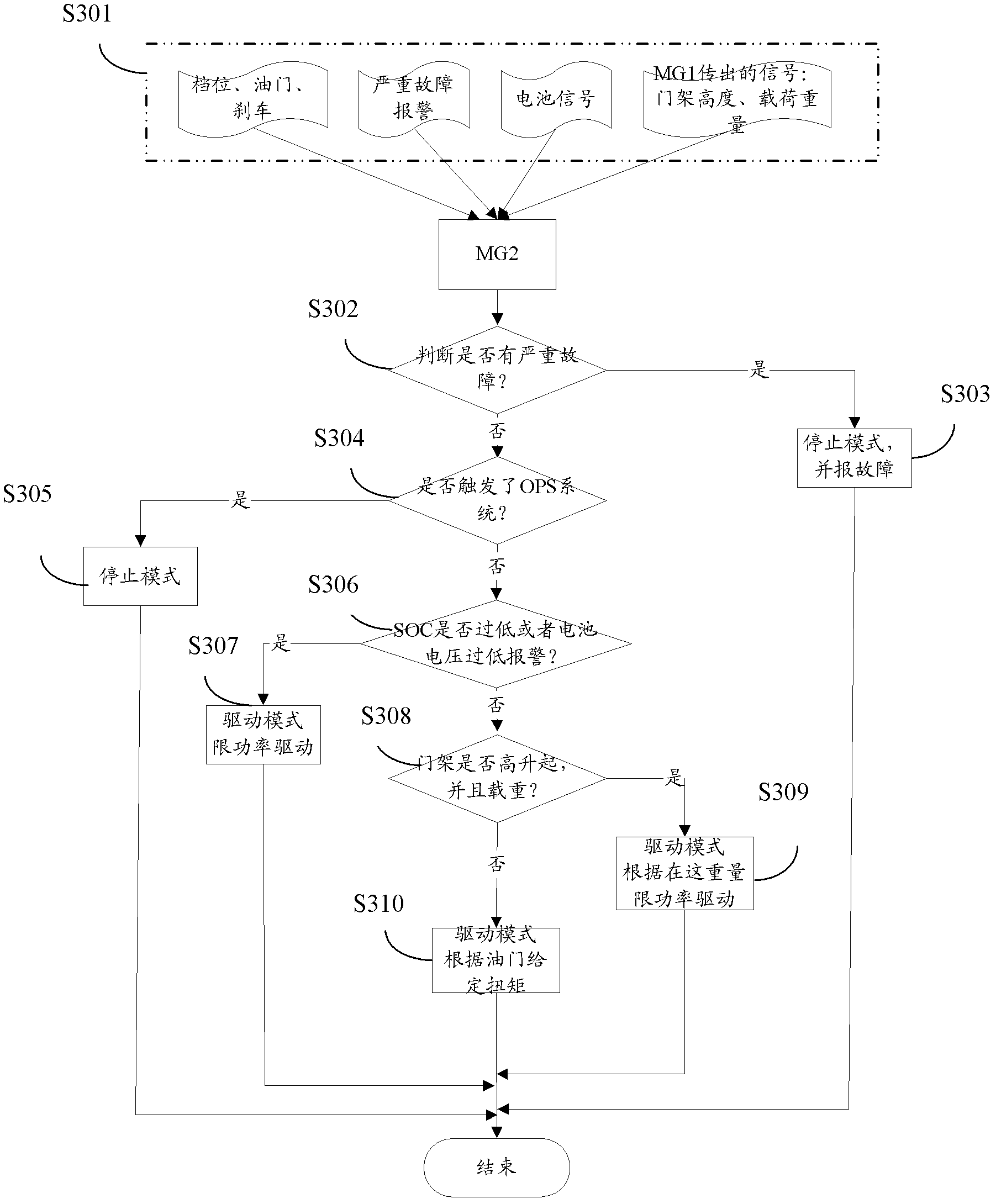

Motor control system for electric fork-lift truck

ActiveCN103187916AMeet control requirementsEasy to controlElectronic commutation motor controlAC motor controlControl systemMotor control

The invention discloses a motor control system for an electric fork-lift truck, which comprises a lifting control subsystem and a drive control subsystem, wherein the lifting control subsystem is used for controlling output power of a lifting motor of the electric fork-lift truck in order to adjust a working mode of the electric fork-lift truck, and comprises a first collection module, a first detection module and a first control module; the drive control subsystem is used for controlling output power of the drive control subsystem of the electric fork-lift truck in order to adjust a speed of the electric fork-lift truck, and comprises a second collection module, a second detection module and a second control module. The motor control system can control the lifting motor and a drive motor of the electric fork-lift truck, and meet a control requirement of the electric fork-lift truck.

Owner:BYD CO LTD

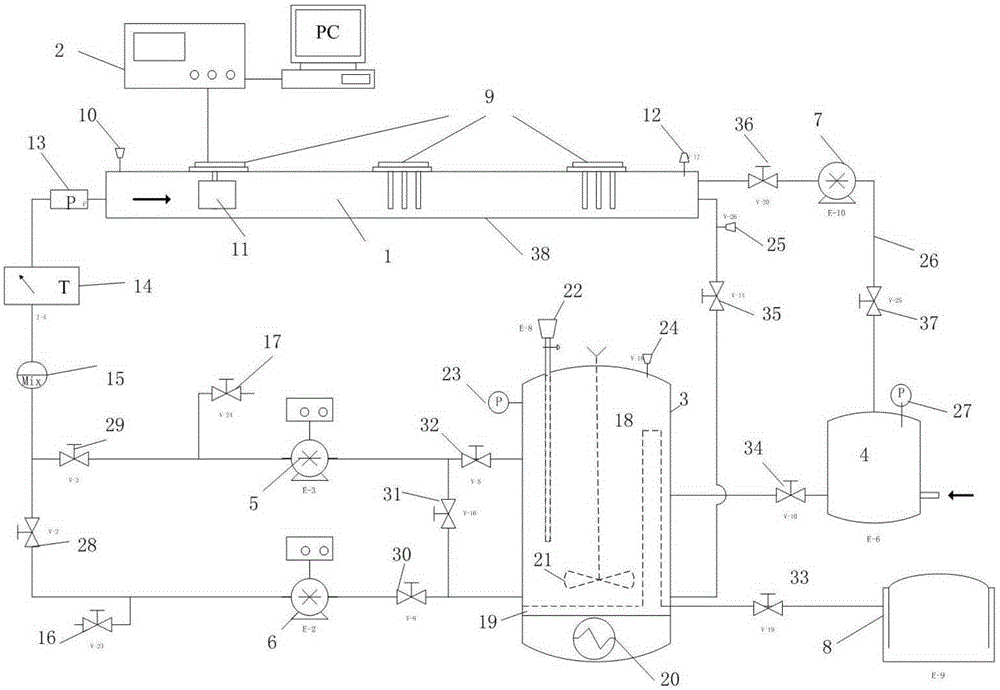

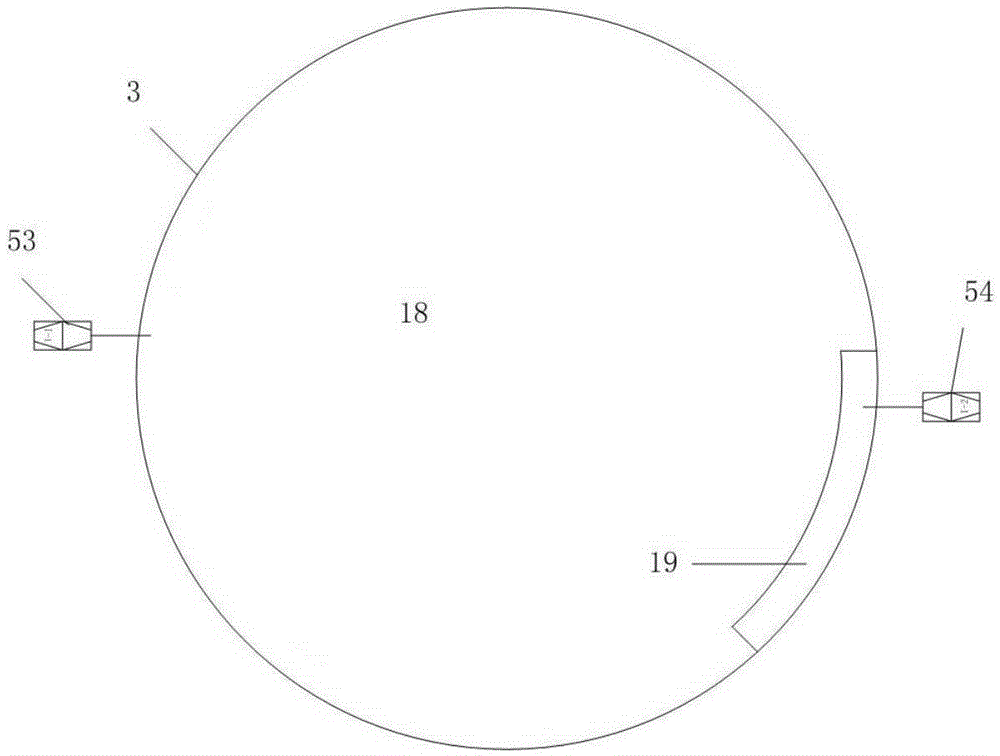

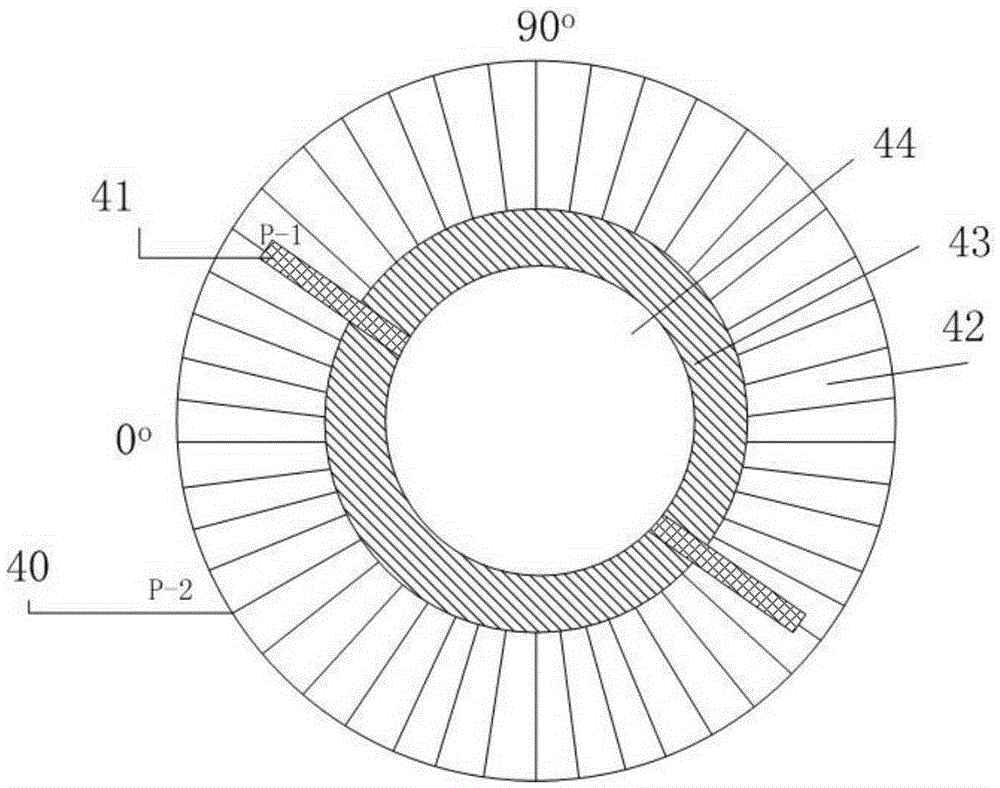

High-temperature corrosion and erosion testing device of bent pipe column of oil well pipe

ActiveCN105403503ARealize the supplyFulfill control requirementsWeather/light/corrosion resistanceElectricityProcess engineering

The invention provides a high-temperature corrosion and erosion testing device of a bent pipe column of an oil well pipe. The high-temperature corrosion and erosion testing device comprises an erosion and corrosion channel, an electrochemical work station and a storage tank, wherein the storage tank comprises a storage tank secondary cavity and a storage tank main cavity, which are arranged in sequence from bottom to top; the upper end of the storage tank secondary cavity is communicated with the upper part of the storage tank main cavity through a connection channel, and a secondary temperature controller is arranged at the bottom of the lower end of the storage tank secondary cavity; the erosion and corrosion channel comprises an erosion and corrosion box body, and the two ends of the erosion and corrosion box body are communicated with the storage tank main cavity through a main pipeline and a main loop respectively; the erosion and corrosion box body is provided with a plurality of sample mounting holes; the main pipeline is communicated with the storage tank main cavity through a gas pipeline and a liquid pipeline, which are arranged in parallel; a gas flow controller and a gas control valve are arranged on the gas pipeline connected onto the upper part of the storage tank main cavity respectively; a liquid flow controller and a liquid control valve are arranged on the liquid pipeline connected onto the lower part of the storage tank main cavity respectively; the upper end of the gas flow controller is connected with the upper end of the liquid flow controller through a communication pipeline and the communication pipeline is provided with a regulating and controlling valve; and the electrochemical work station is connected with a sample.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com