Charge controlling system of super capacitive electric car

A super capacitor, charging control technology, applied in the field of traffic engineering, to achieve the effect of convenient transplantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

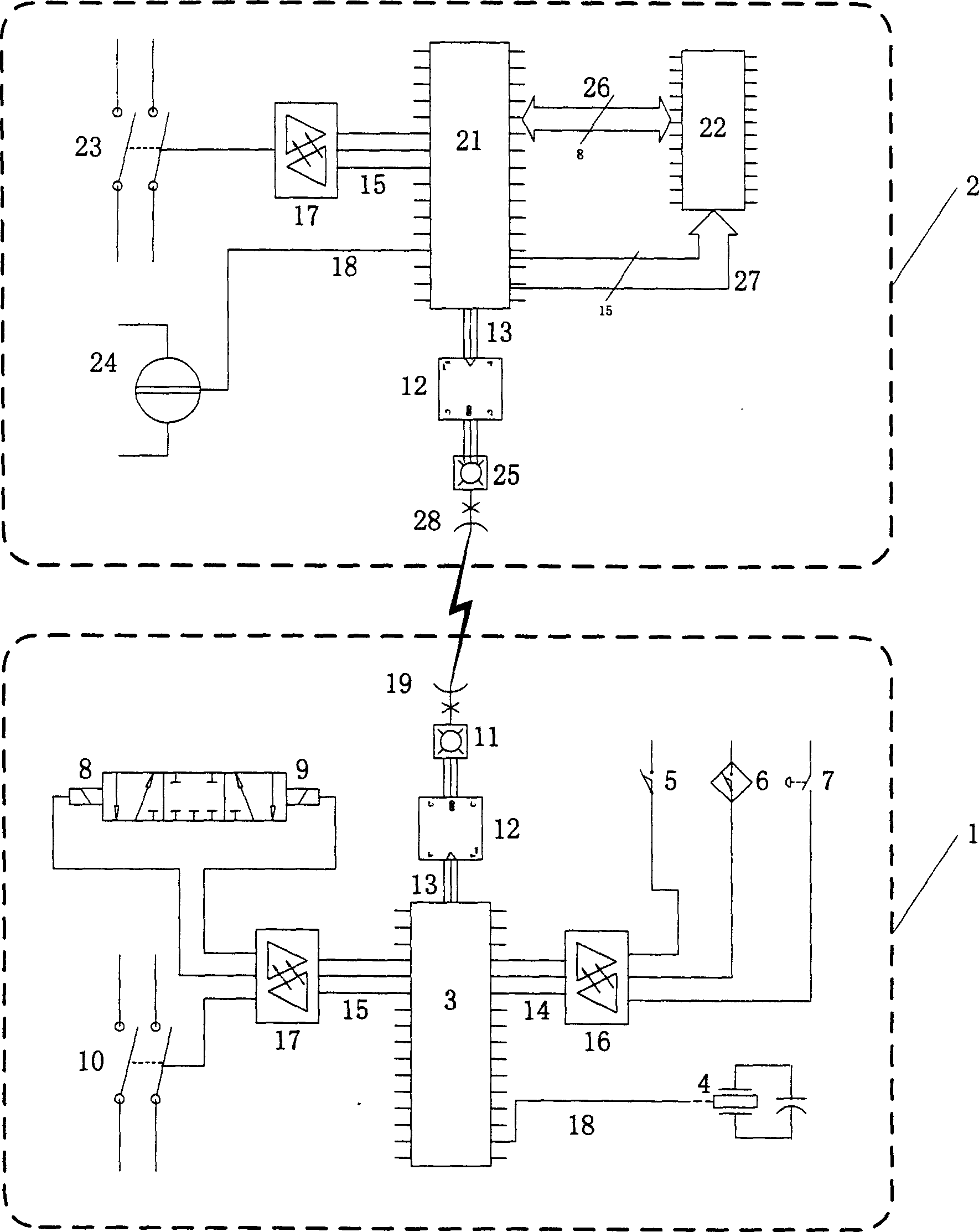

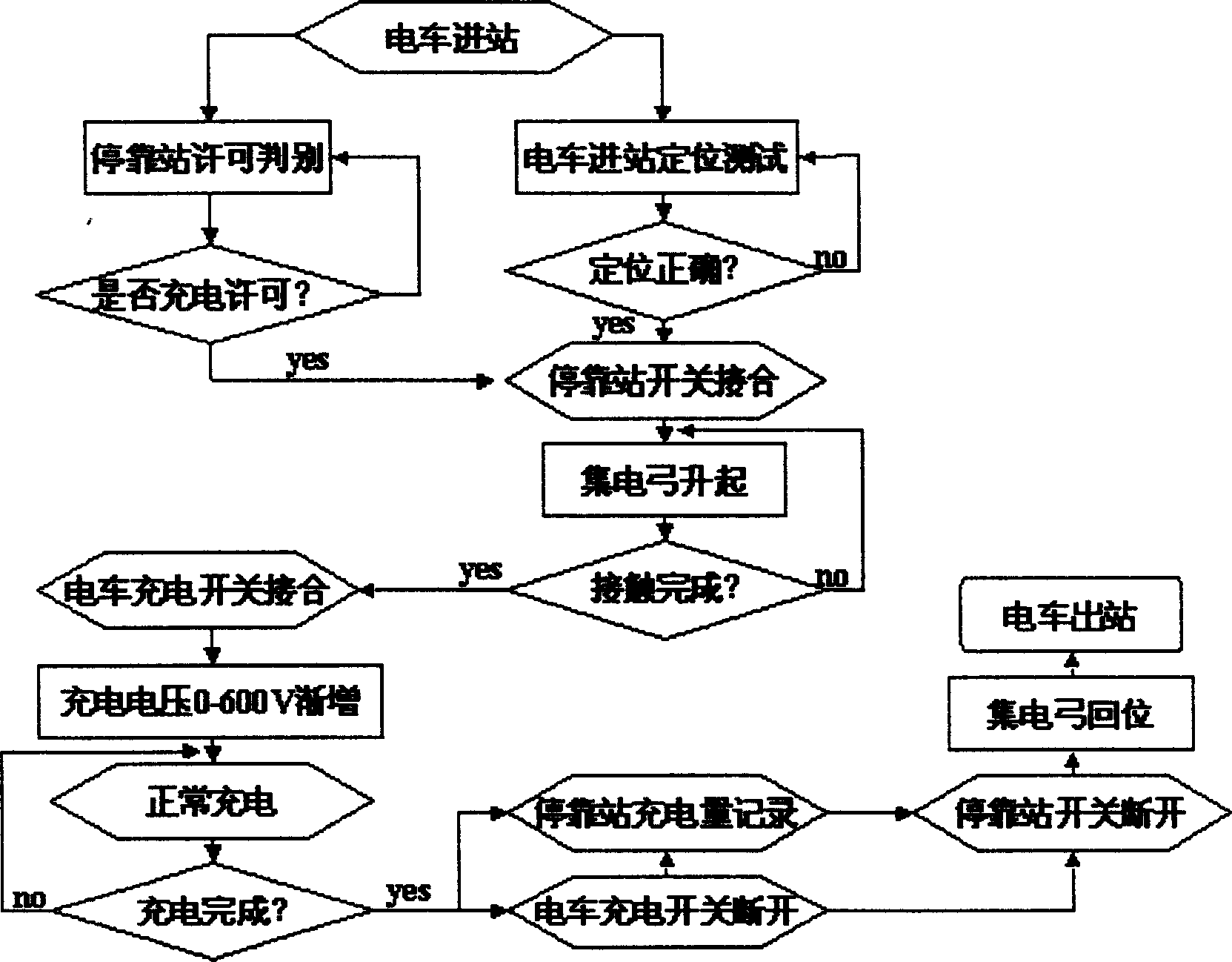

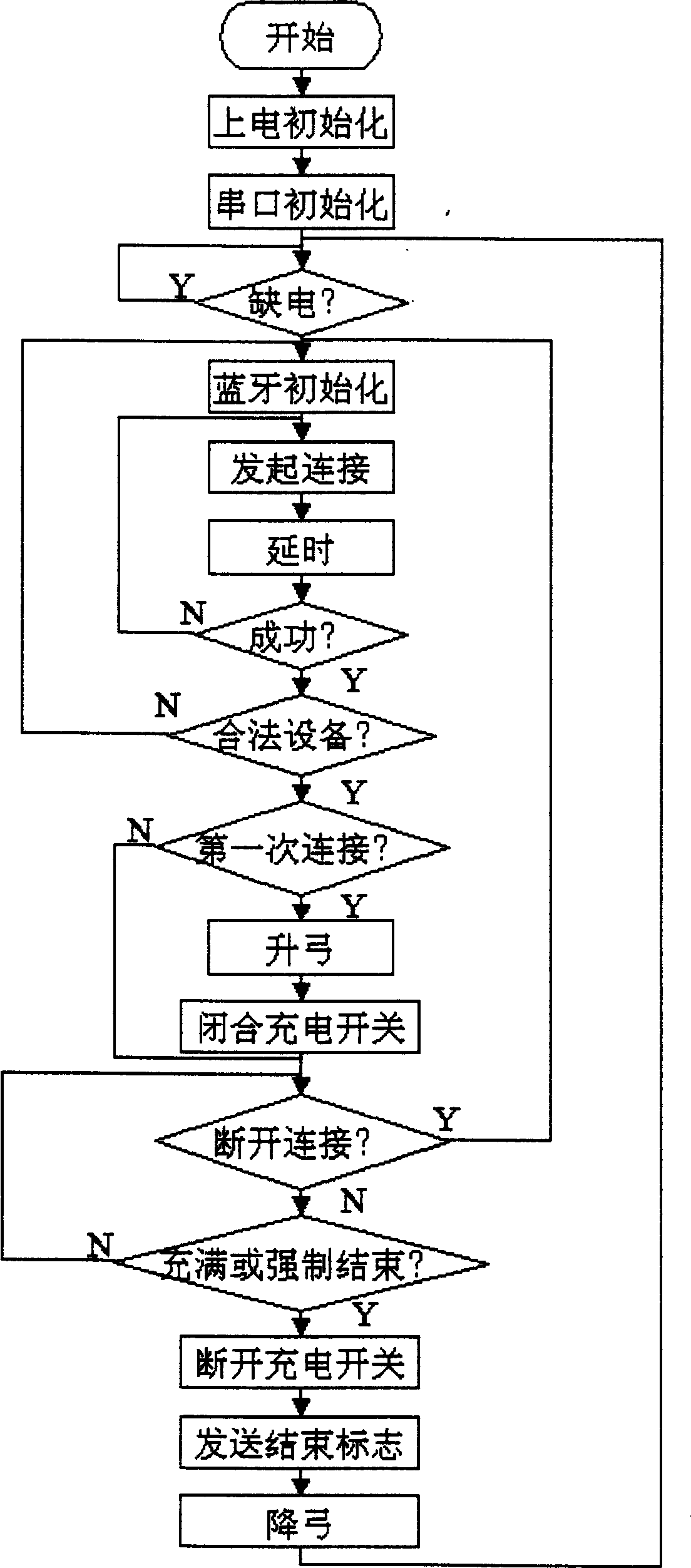

[0015] Such as figure 1 As shown, the control system of the present invention adopts a master-slave control structure, and is composed of a master controller 1 arranged on the electric car and a slave controller 2 arranged on the stop. When the electric car enters the range of the stop, The master controller 1 and the bluetooth wireless communication module of the slave controller 2 perform wireless link connection.

[0016] The main controller 1 is composed of a microprocessor 3, a supercapacitor voltage sensor 4, a positioning sensor 5, a contact sensor 6, a charging end button 7, a pantograph raising solenoid valve 8, a pantograph lowering solenoid valve 9, a trolley charging switch 10 and Bluetooth wireless communication module 11 is formed. Microprocessor 3 is connected with switching value input devices such as positioning sensor 5, contact sensor 6, charging end button 7 through basic input interface 14 and through photoelectric isolation 16; Pantograph up solenoid va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com