High-temperature corrosion and erosion testing device of bent pipe column of oil well pipe

A technology of high-temperature corrosion and test equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of not being able to simulate the erosion and corrosion of oil well pipe strings, and cannot provide erosion and corrosion thermodynamic information, etc., to meet the requirements of The effect of experimenting with demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

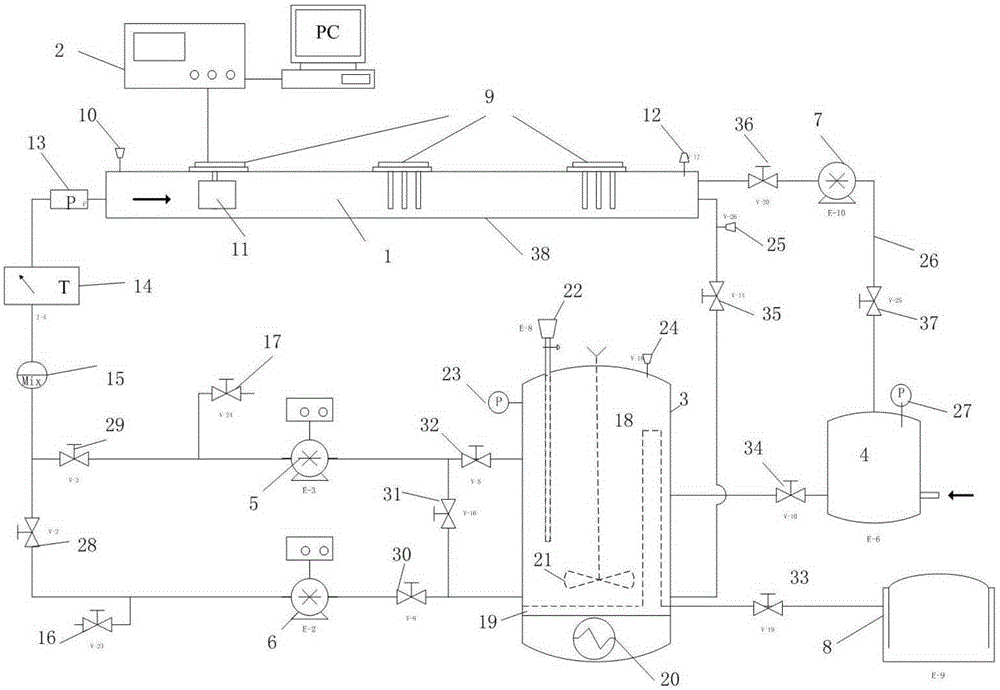

[0032] Such as figure 1 As shown, the present invention proposes a test device for evaluating the high-temperature corrosion and erosion performance of oil well tubular buckling strings, which includes an erosion corrosion channel 1, an electrochemical workstation 2, a storage tank 3, and an air supply tank 4 , a gas flow controller 5 , a liquid flow controller 6 , a vacuum pump 7 and a waste gas and liquid treatment system 8 .

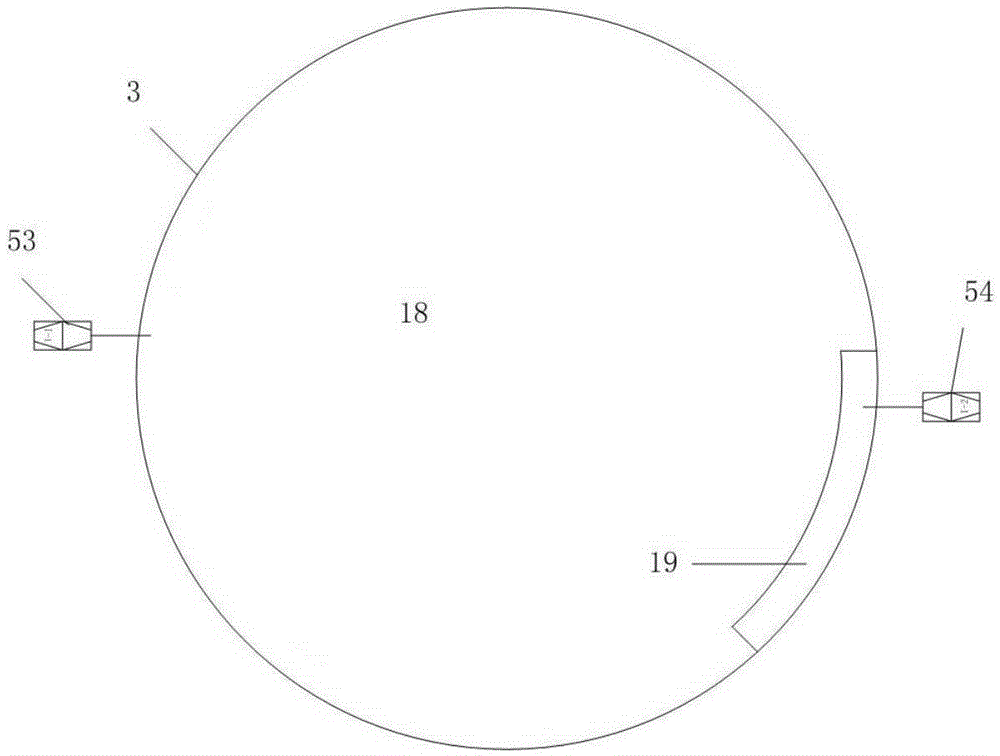

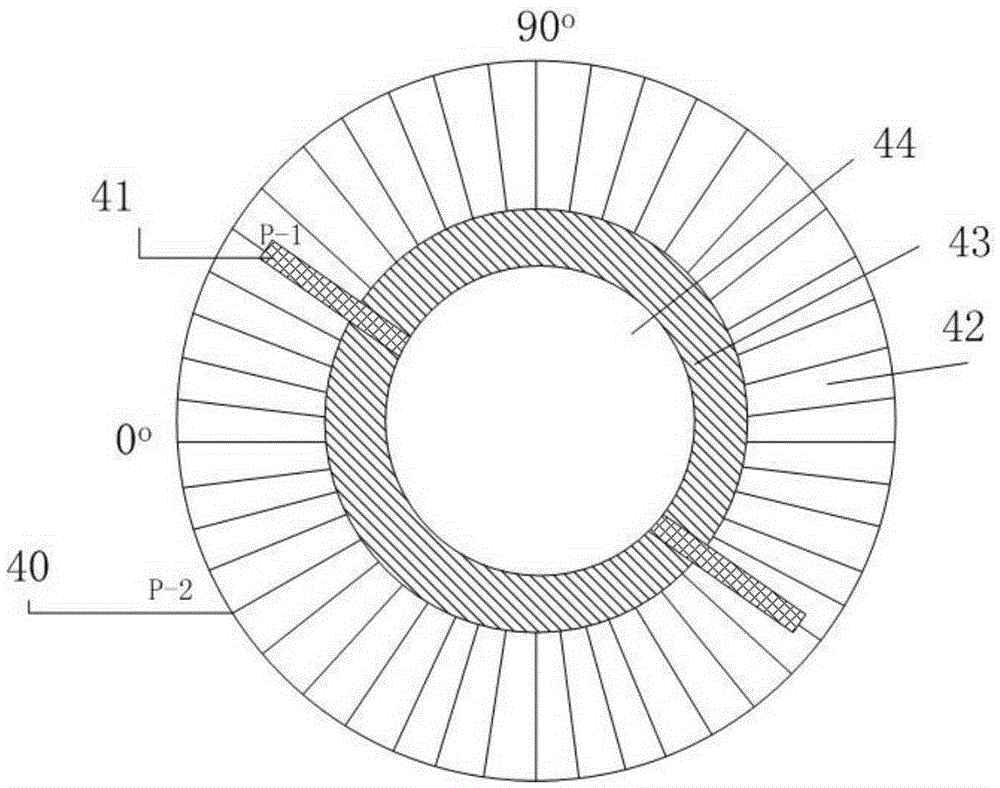

[0033] Such as figure 1 and figure 2As shown, the scour corrosion channel 1 includes a scour corrosion tank 38, a plurality of sample installation ports 9 located above the scour corrosion tank 38, a hygrometer 10 and a pH meter 12 positioned on the scour corrosion tank 38, and one located at Scouring the transparent observation window 11 on the side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com