Patents

Literature

47results about How to "Suppress residual vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

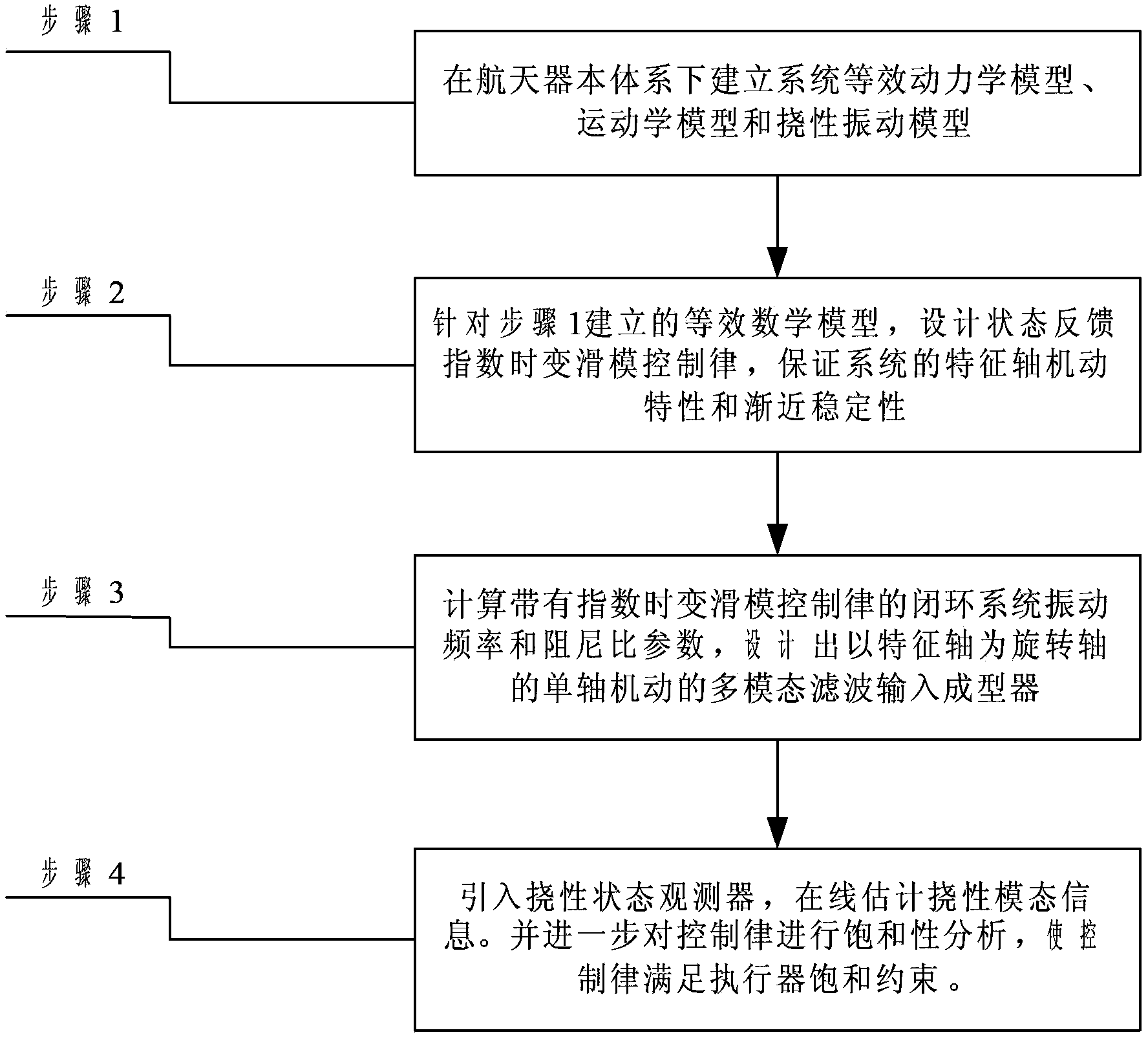

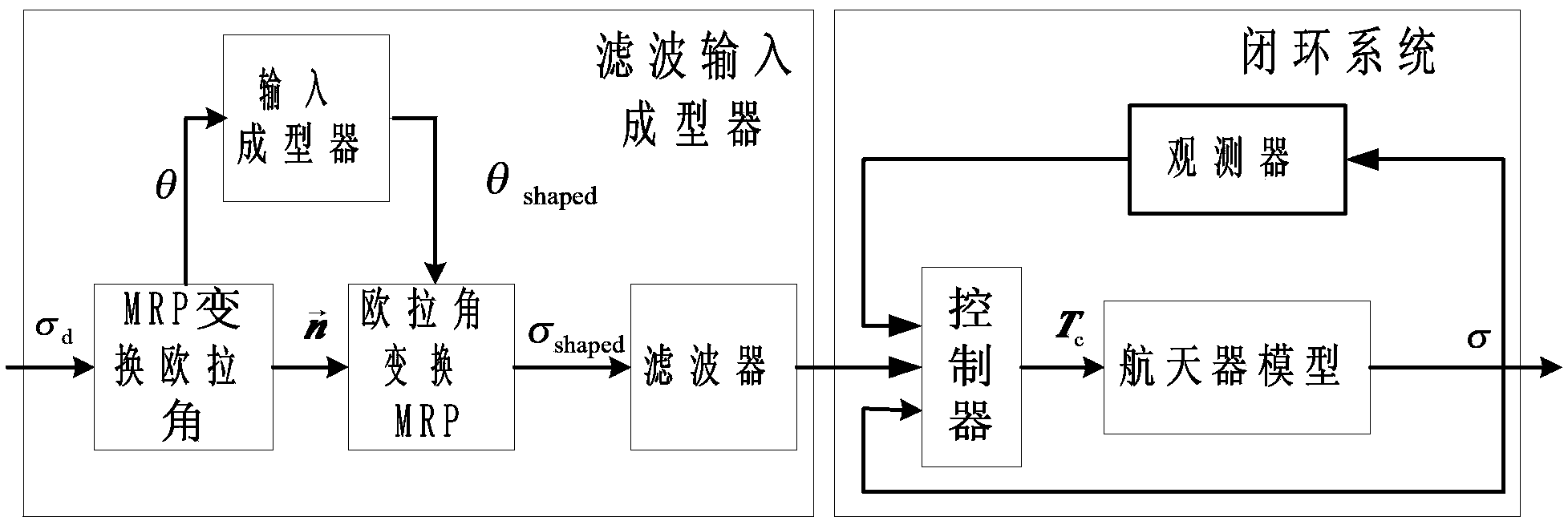

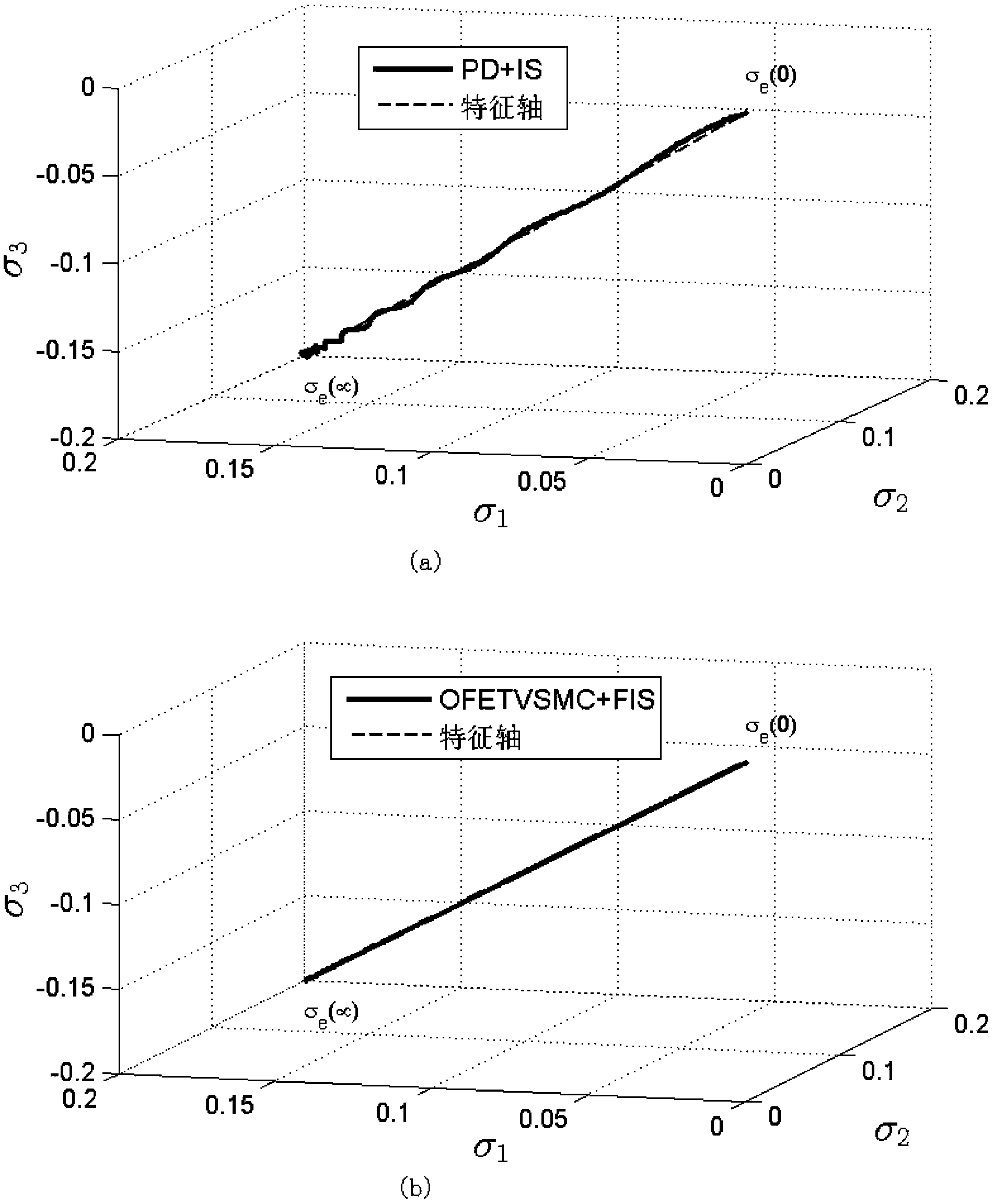

Method for controlling index time-varying slide mode of flexible spacecraft characteristic shaft attitude maneuver

ActiveCN103412491ASuppress residual vibrationAvoid complex coupling relationshipsAdaptive controlDynamic modelsSpace vehicle control

The invention relates to a method for controlling an index time-varying slide mode of flexible spacecraft characteristic shaft attitude maneuver, and belongs to the technical field of spacecraft control. The method comprises the steps that firstly, a system dynamically equivalent model, a dynamic model and a flexible vibration model are established under a spacecraft system, then, the vibration frequency and the damping ratio parameter of a closed loop system with the index time-varying slide mode control law are calculated, and a single-shaft multi-modality filtering input shaping device with a characteristic shaft as a rotary shaft is designed according to the designing method of the single-shaft input shaping device to restrain flexible vibration in three-shaft motion. Meanwhile, a state observer is designed to estimate flexible modal information in real time, and the method for controlling an output feedback index time-varying slide mode is formed. At last, saturability analysis is conducted on control torque so as to satisfy the physical saturation constraint of the control torque. By means of the method, the application range of existing input shaping is expanded, the input shaping technology is expanded from single-shaft maneuver to three-shaft maneuver, the self-robustness of filter input shaping is enhanced, and the purpose that the attitude maneuver path of the spacecraft is the shortest is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

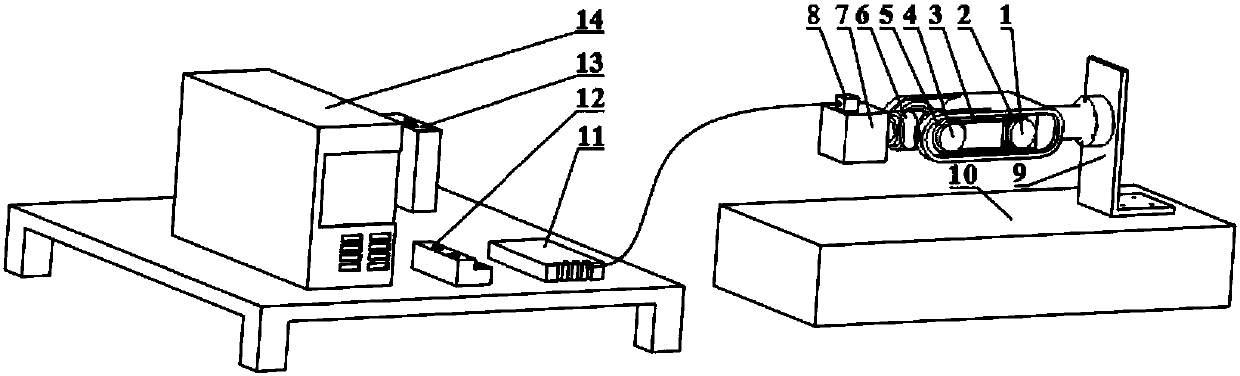

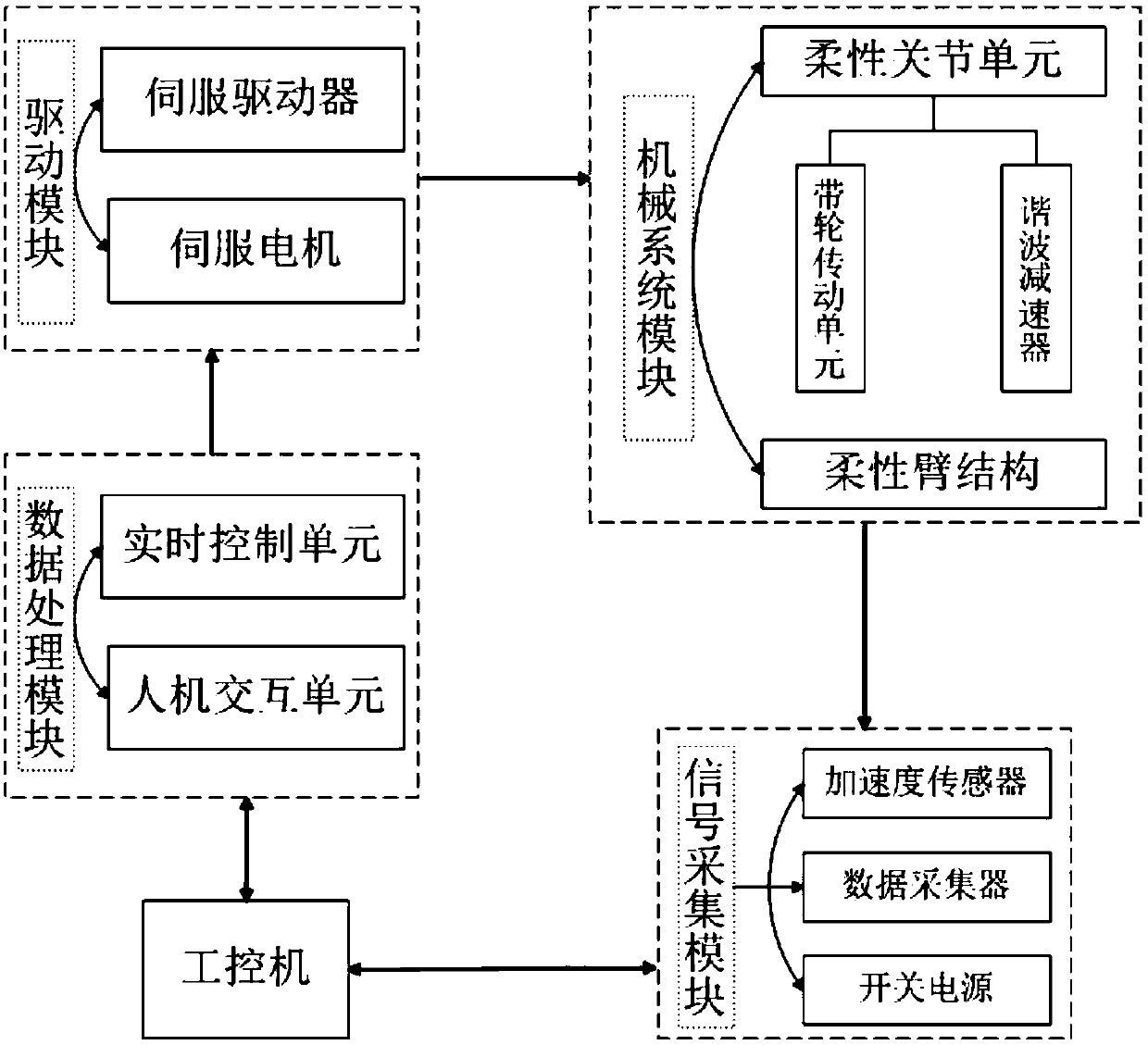

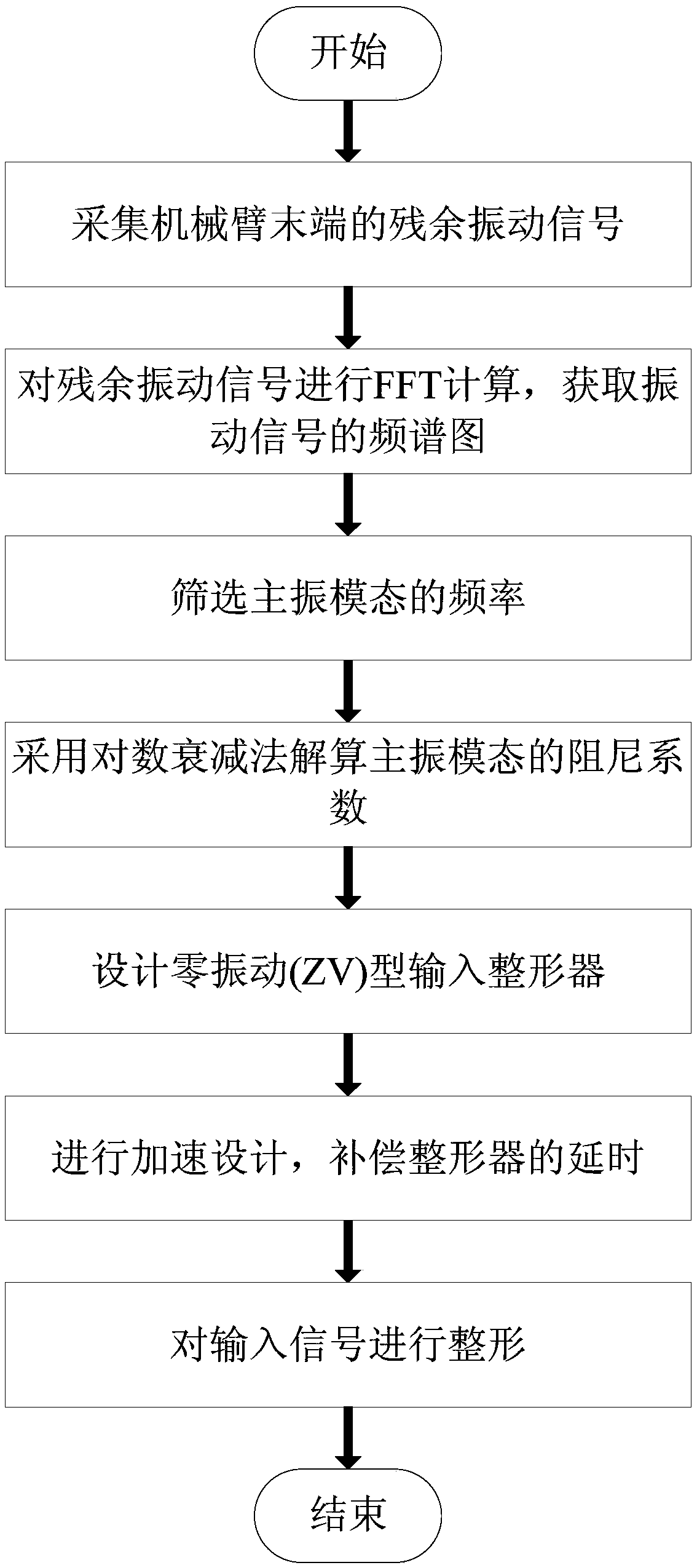

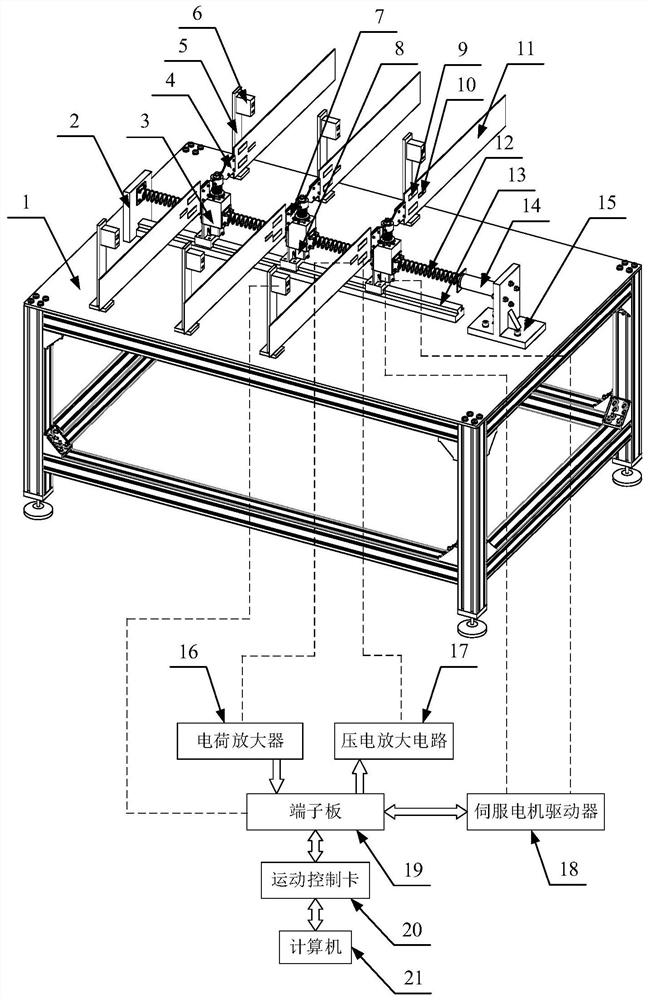

Testing device and method for residual oscillation restraining of flexible joint-flexible arm system

PendingCN107756448ASuppress residual vibrationPrecise positioningManipulatorControl cellData acquisition

The invention discloses a testing device for residual oscillation restraining of a flexible joint-flexible arm system. The testing device for the residual oscillation restraining of the flexible joint-flexible arm system comprises a data processing module, a drive module, a mechanical system module and a signal acquiring module. The data processing module adopts an industrial personal computer andcomprises a man-machine interaction unit and a real-time control unit. The drive module comprises an alternating current servo driver and an alternating current servo motor. The mechanical system module comprises a supporting base, a system pedestal, a flexible joint and a flexible arm. The signal acquiring module comprises a three-dimensional acceleration sensor, a switching power source and a data acquisition unit, and the three-dimensional acceleration sensor is arranged at the tail end of the flexible arm. The invention further provides a method for residual oscillation restraining of theflexible joint-flexible arm system. By means of the testing device and method, the main oscillation modal parameters of the flexible joint-flexible arm system can be rapidly acquired, the problem that system model parameters are not matched, and consequently an input reshaper is not reasonable in design is solved, the residual oscillation of the mechanical system is effectively restrained, and rapid and accurate positioning of a mechanism arm is achieved.

Owner:SOUTH CHINA UNIV OF TECH

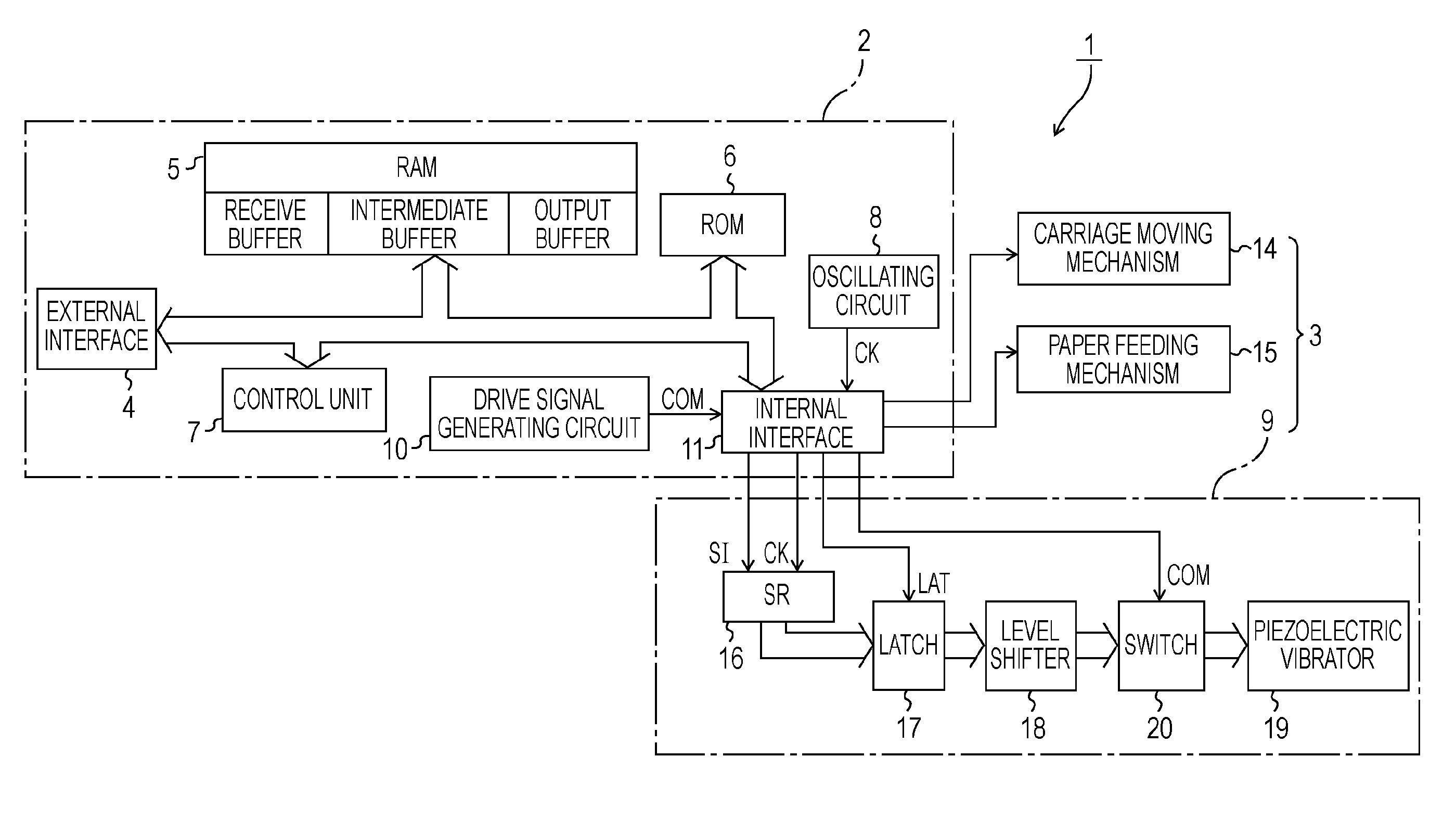

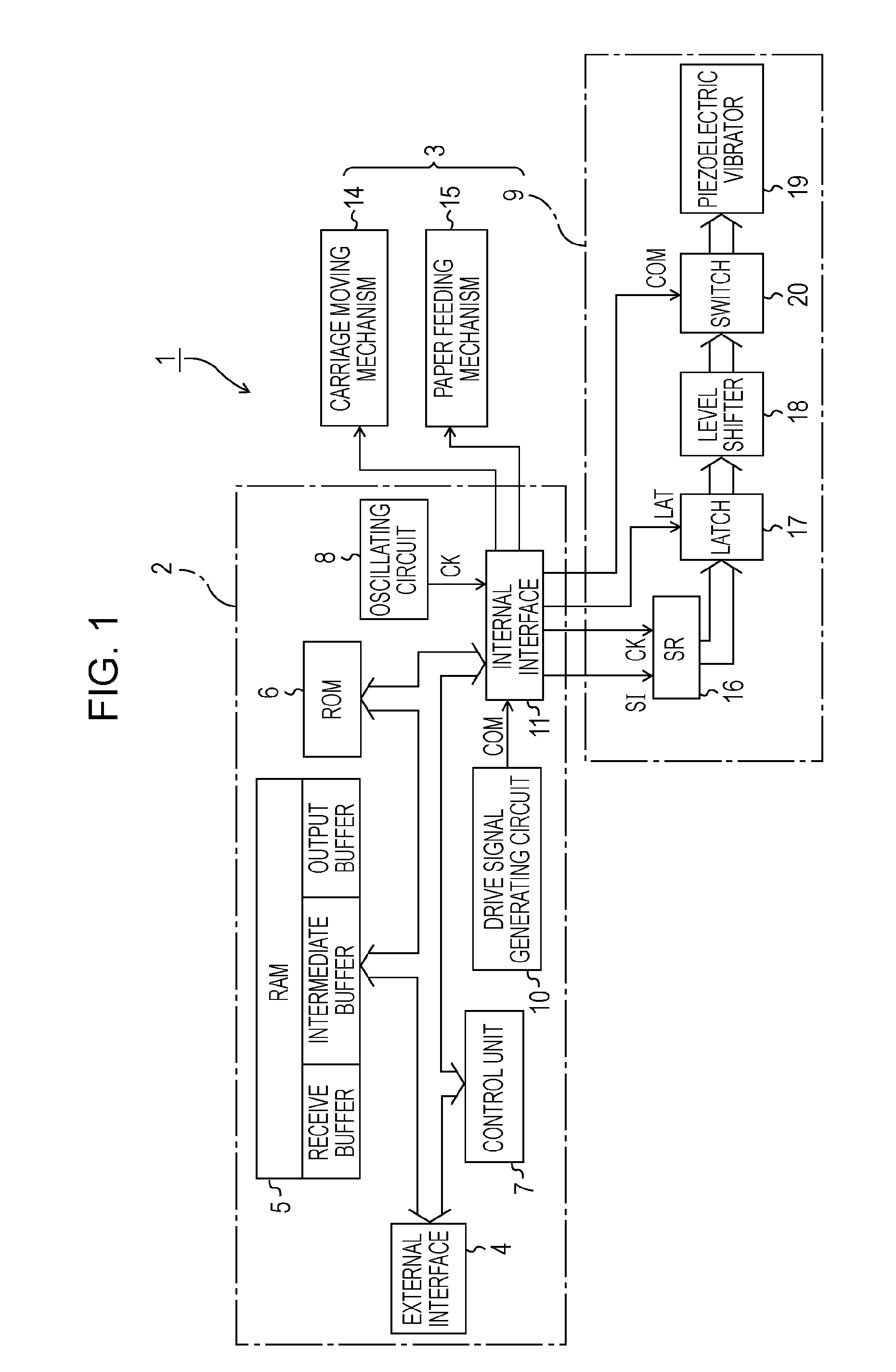

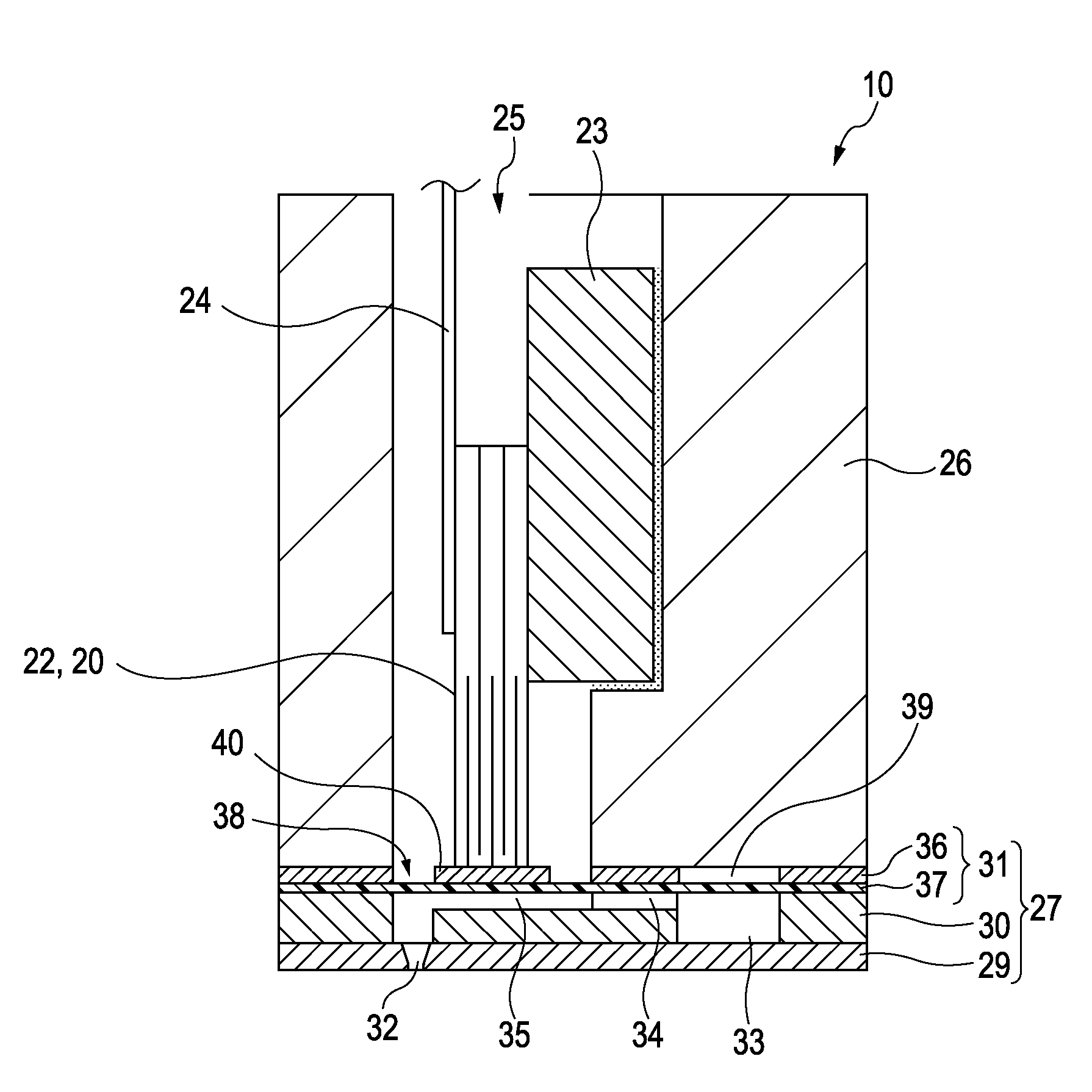

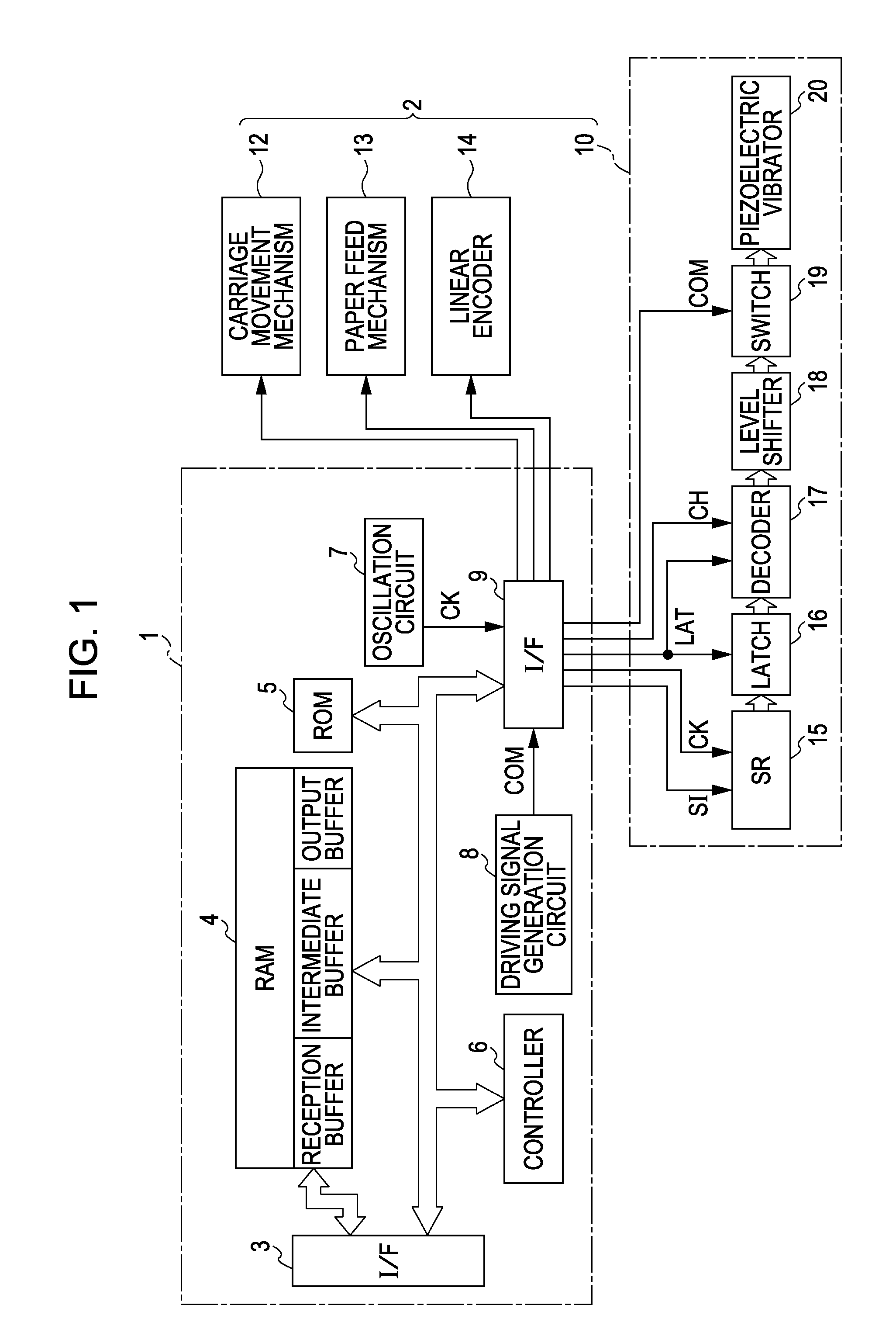

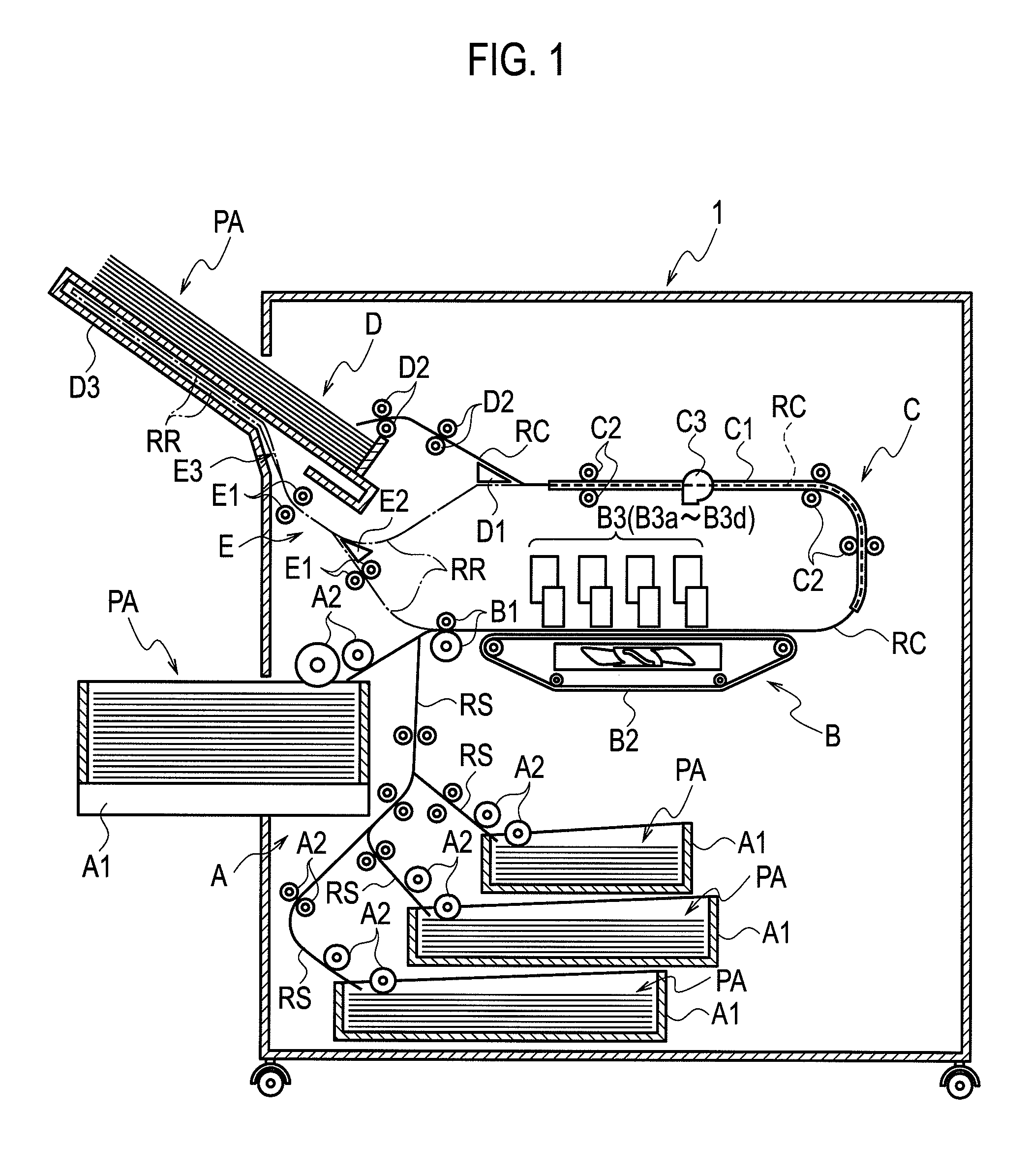

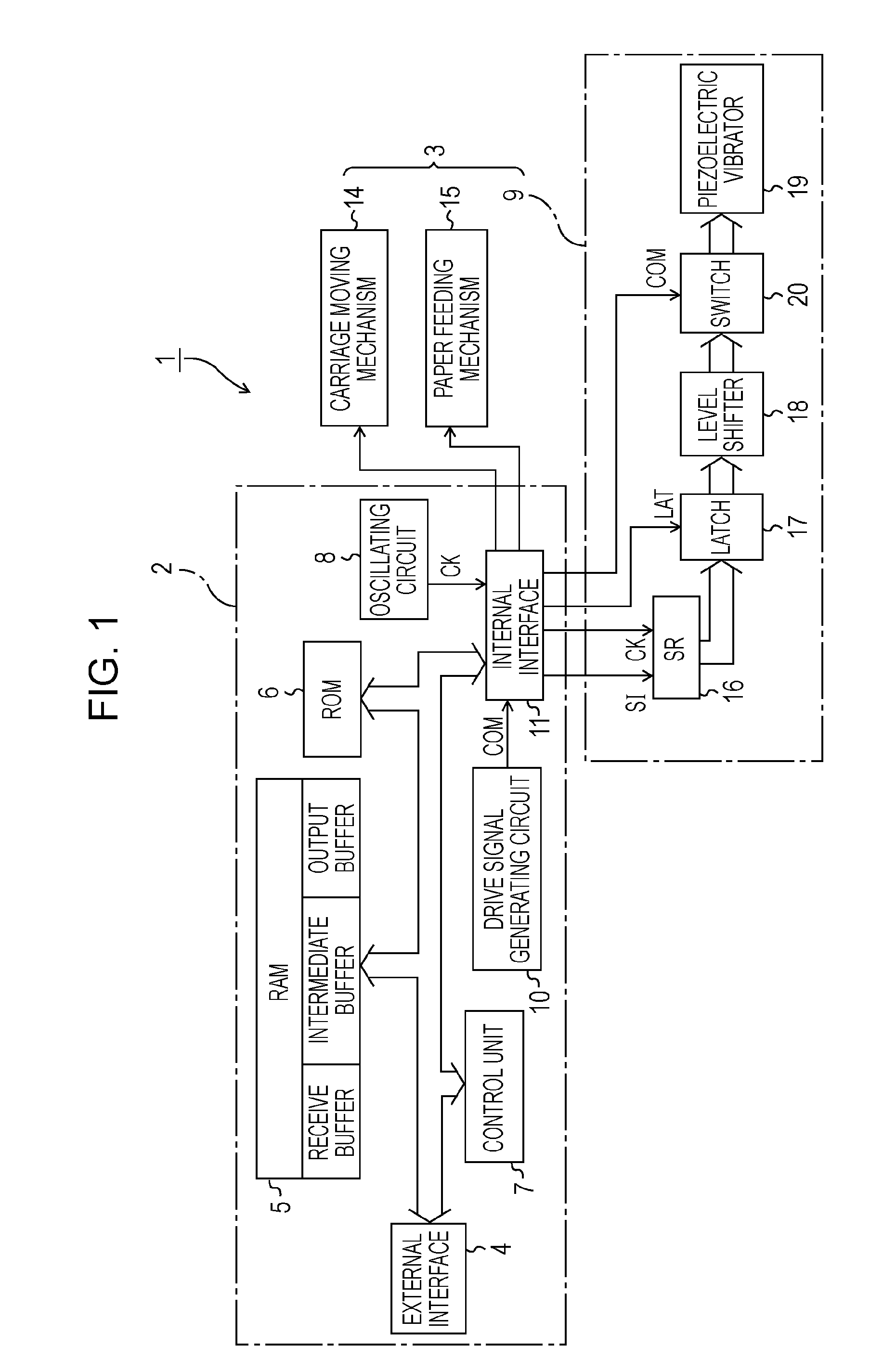

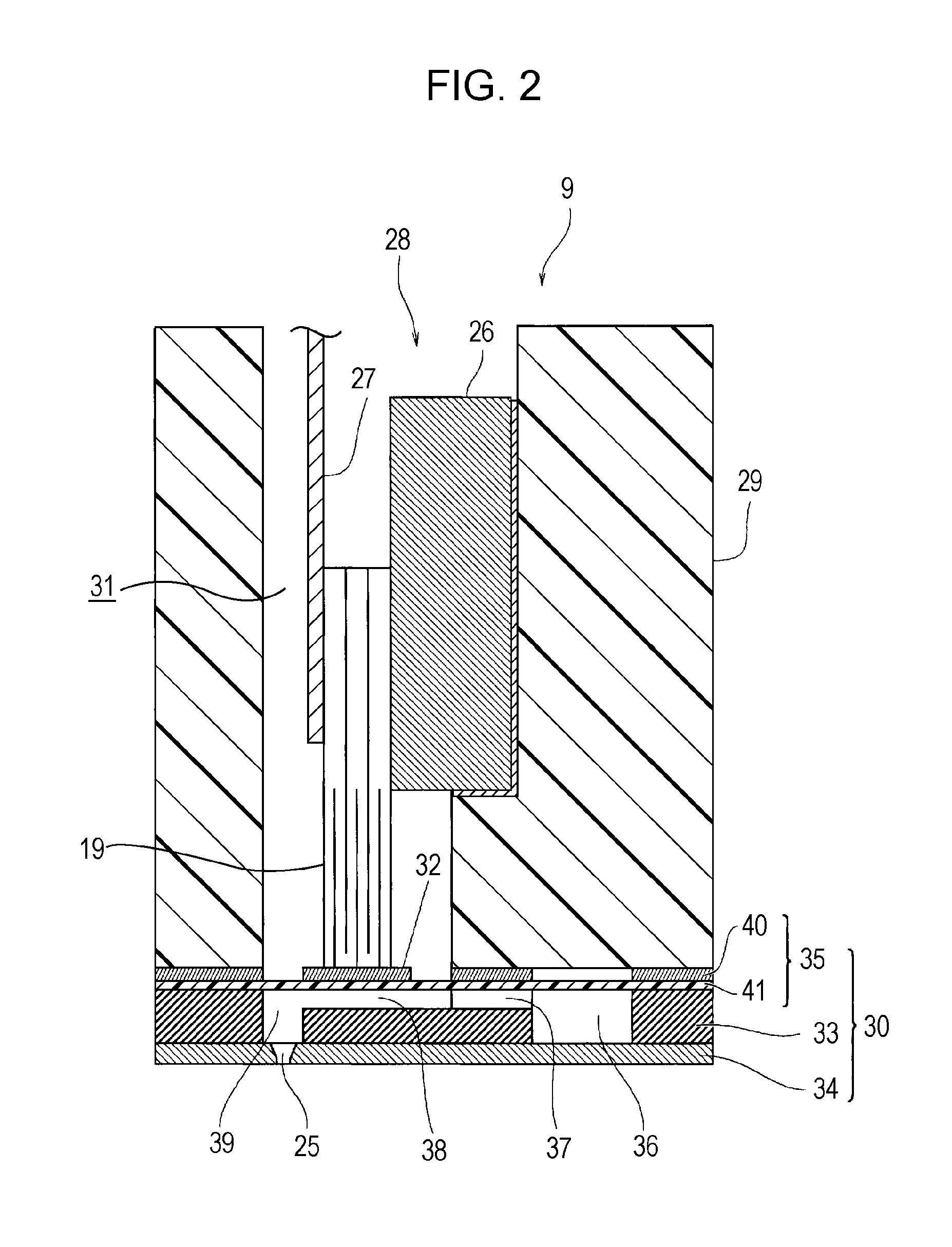

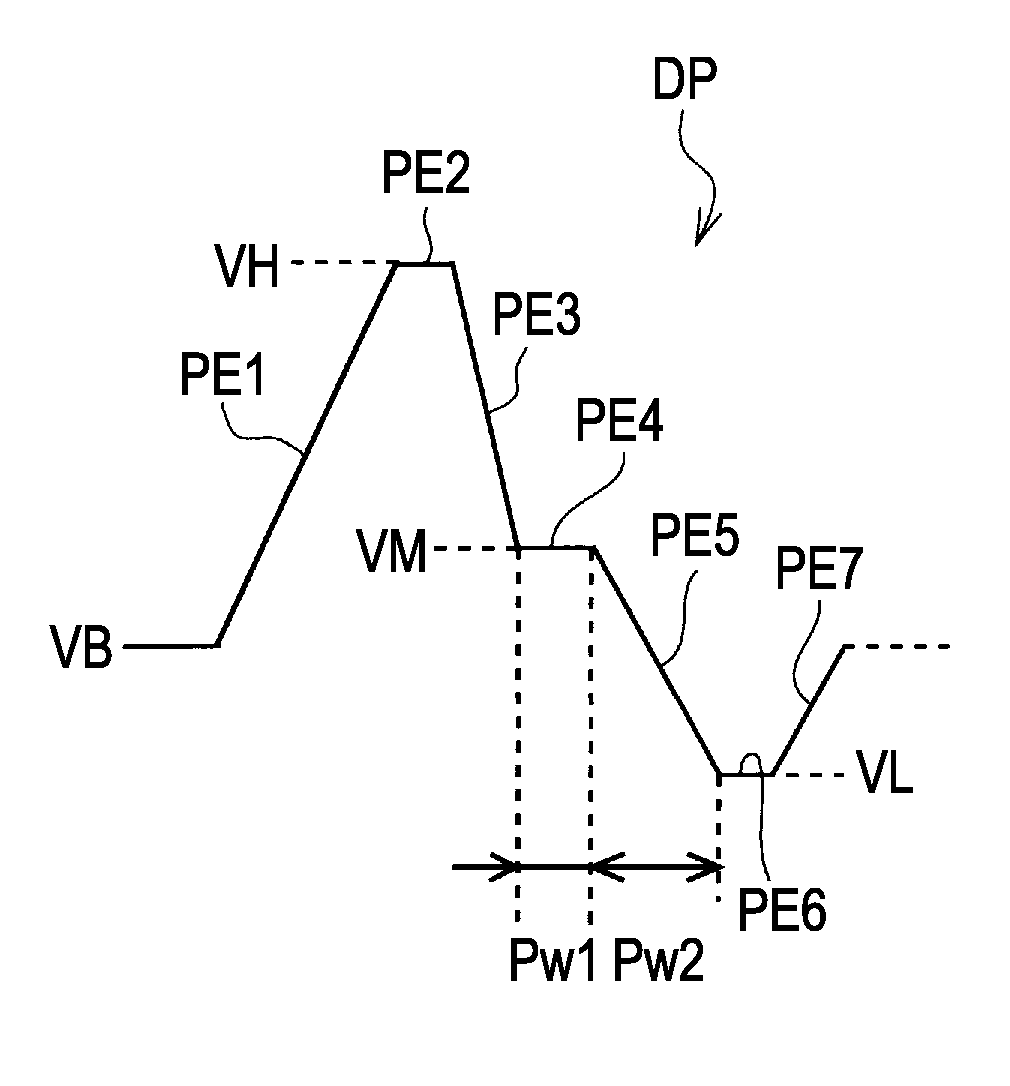

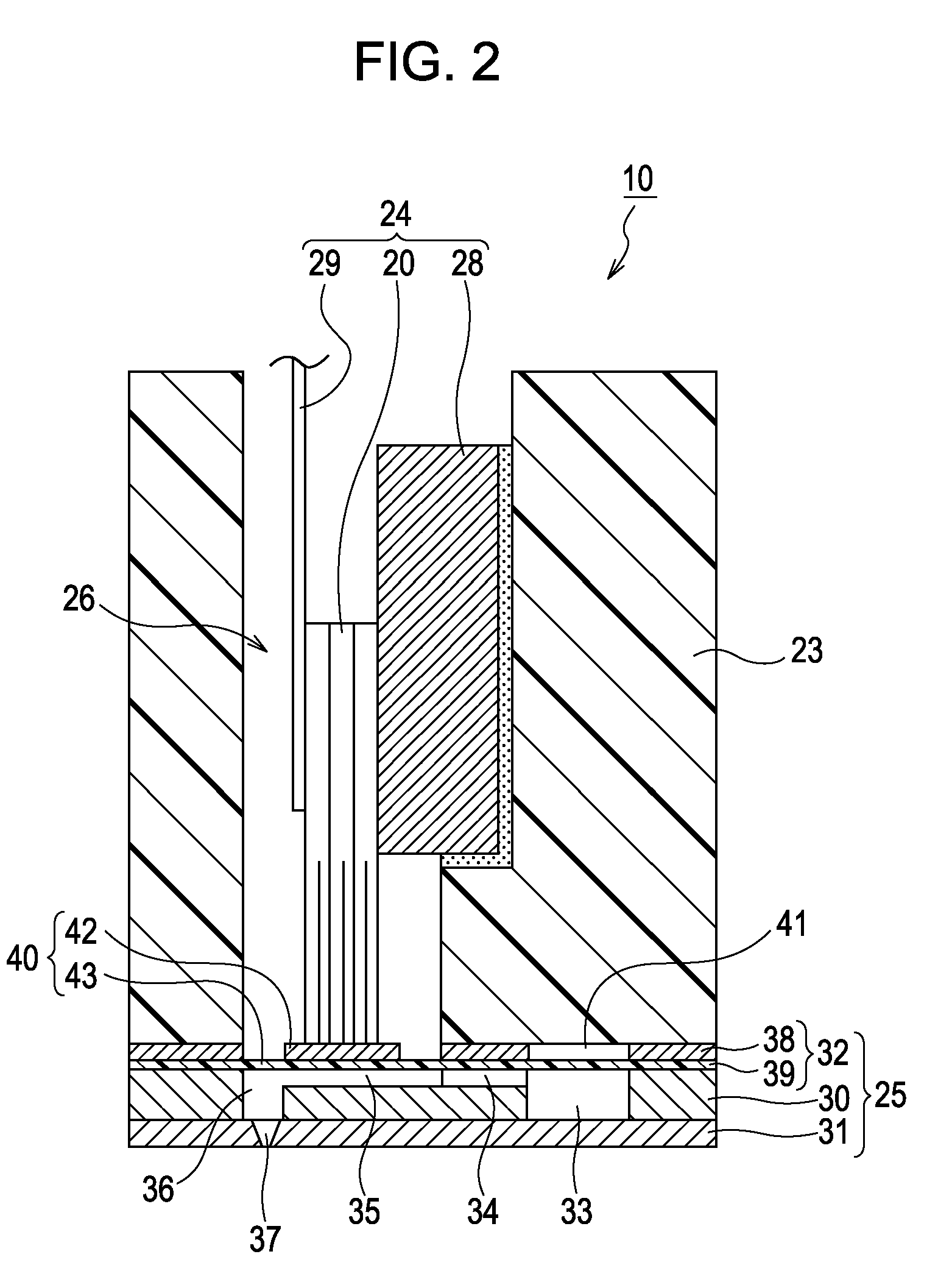

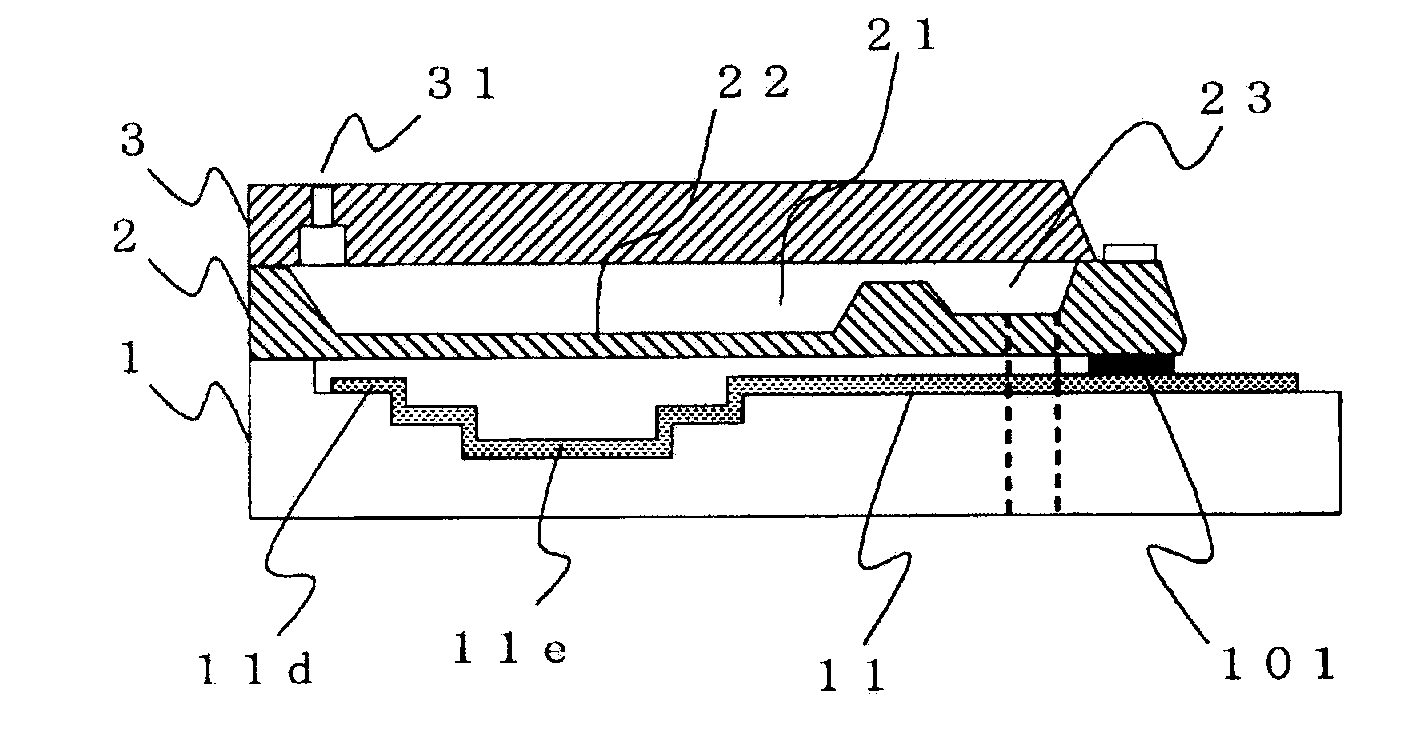

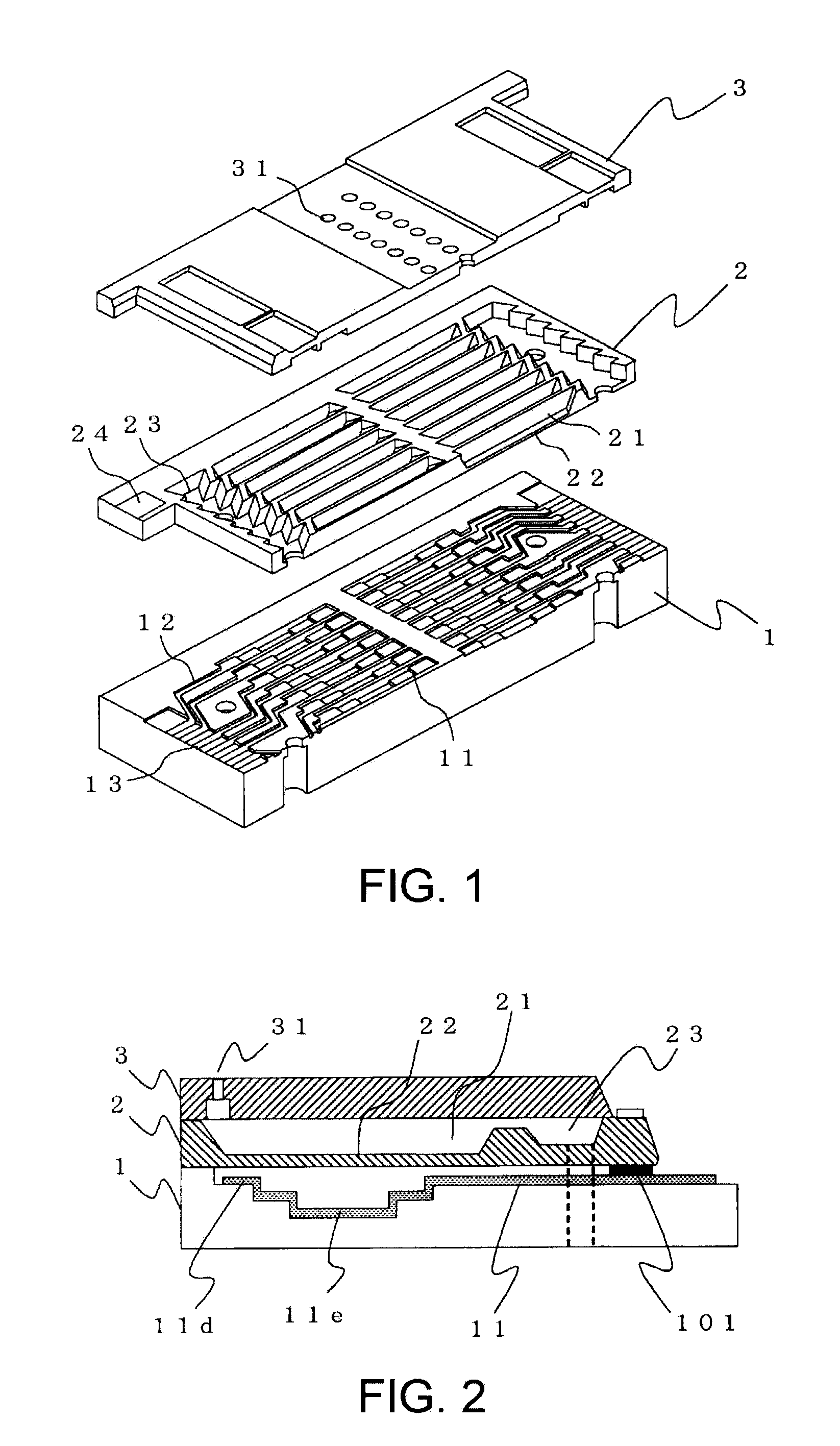

Liquid ejecting apparatus and method for controlling liquid ejecting apparatus

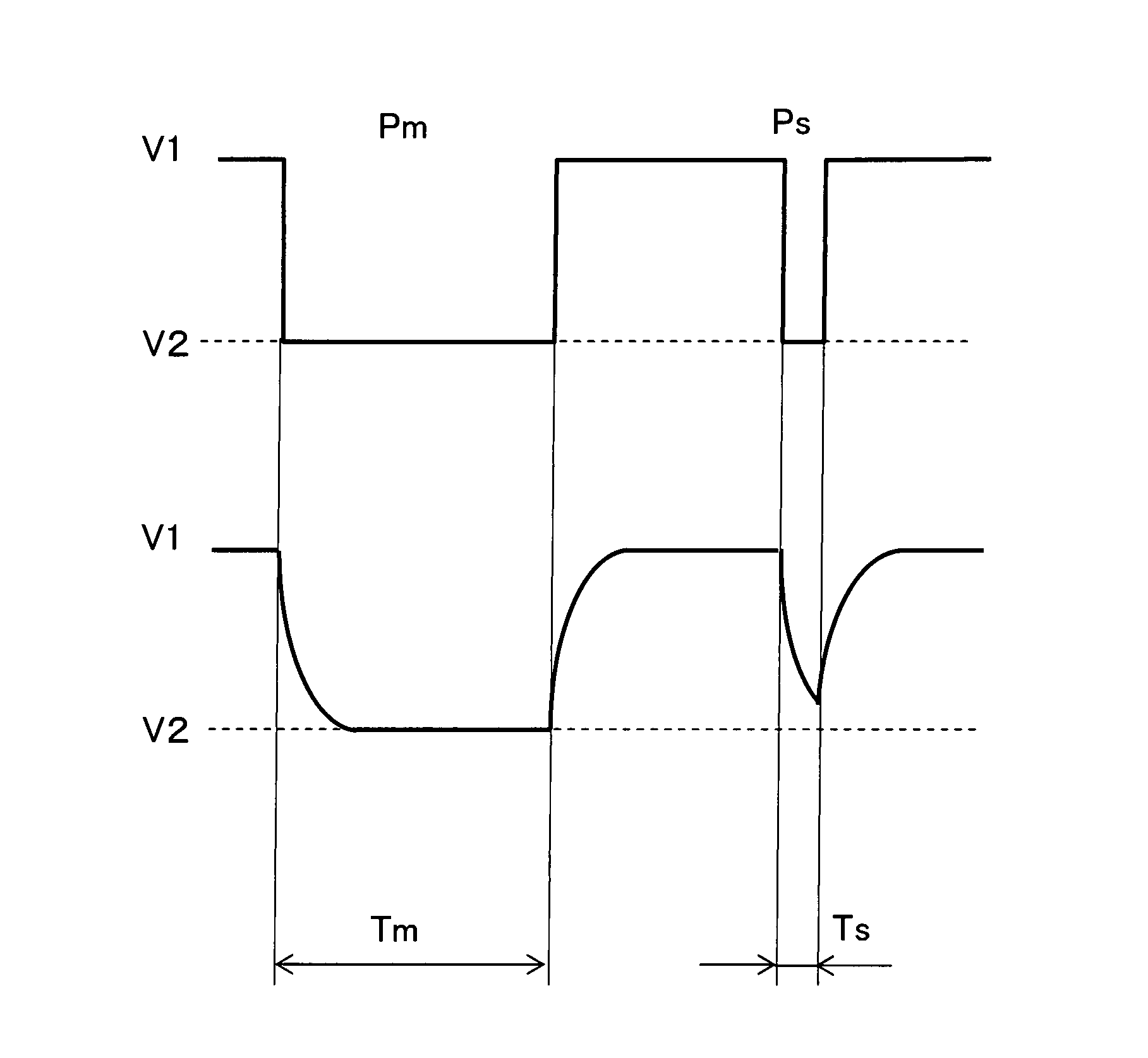

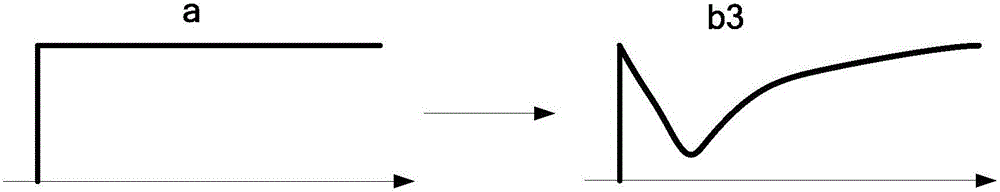

ActiveUS20080036807A1Stable and fastSuppress residual vibrationOther printing apparatusEngineeringSignal generator

A liquid ejecting apparatus includes a liquid ejecting head with a pressure chamber communicating with a nozzle opening and a pressure generator capable of causing a pressure fluctuation to liquid in the pressure chamber. The liquid ejecting head discharges liquid droplets by operating the pressure generator. The drive signal generator generates a drive signal including a drive pulse which includes a first expanding element that expands the pressure chamber, a first discharging element that contracts the pressure chamber expanded by the first expanding element in order to discharge a liquid droplet, a second expanding element that expands the pressure chamber, and a second contracting element that contracts the pressure chamber. The time from the beginning of the first discharging element to the end of the second contracting element is set to ½ to 1 of the natural vibration period of the liquid in the pressure chamber.

Owner:SEIKO EPSON CORP

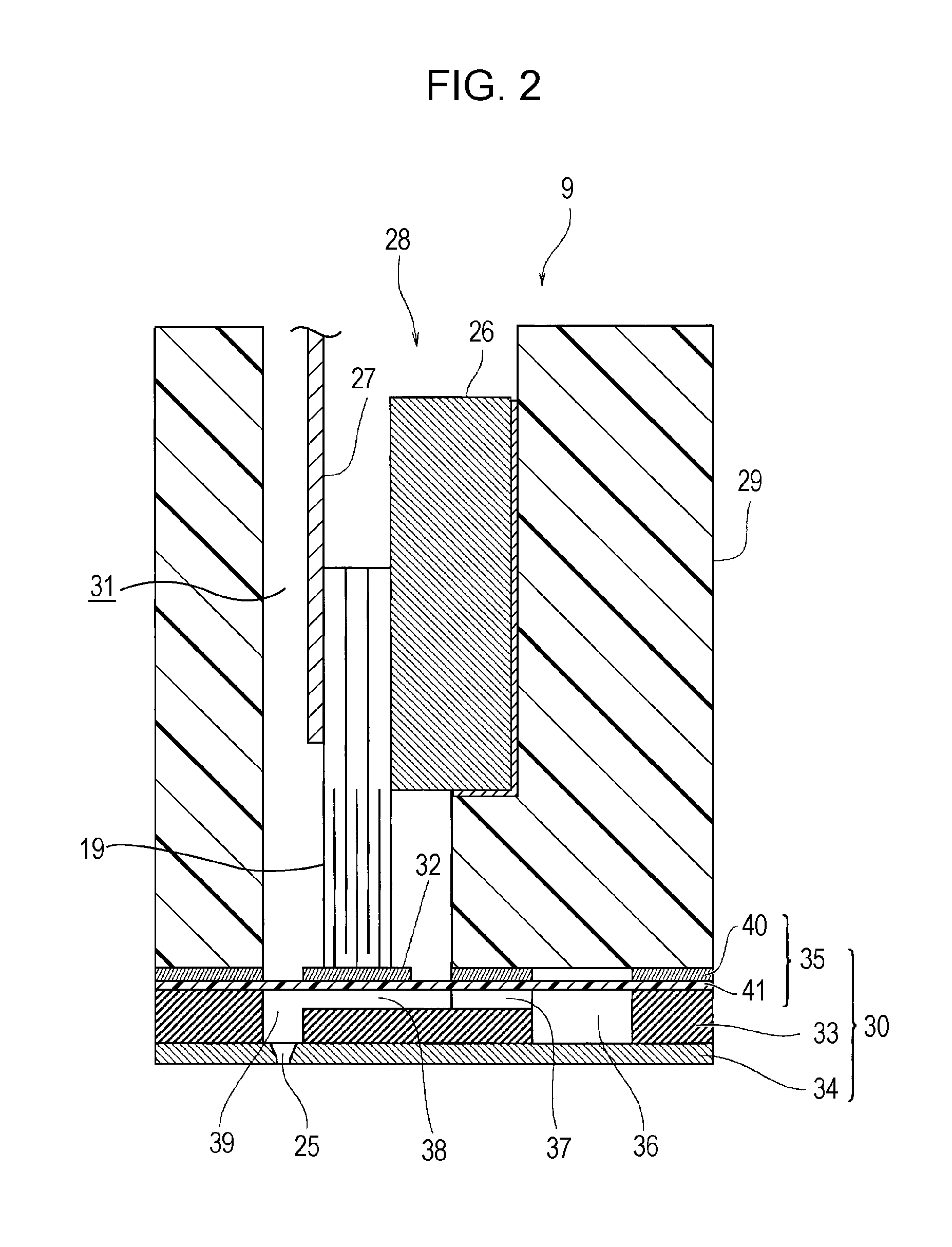

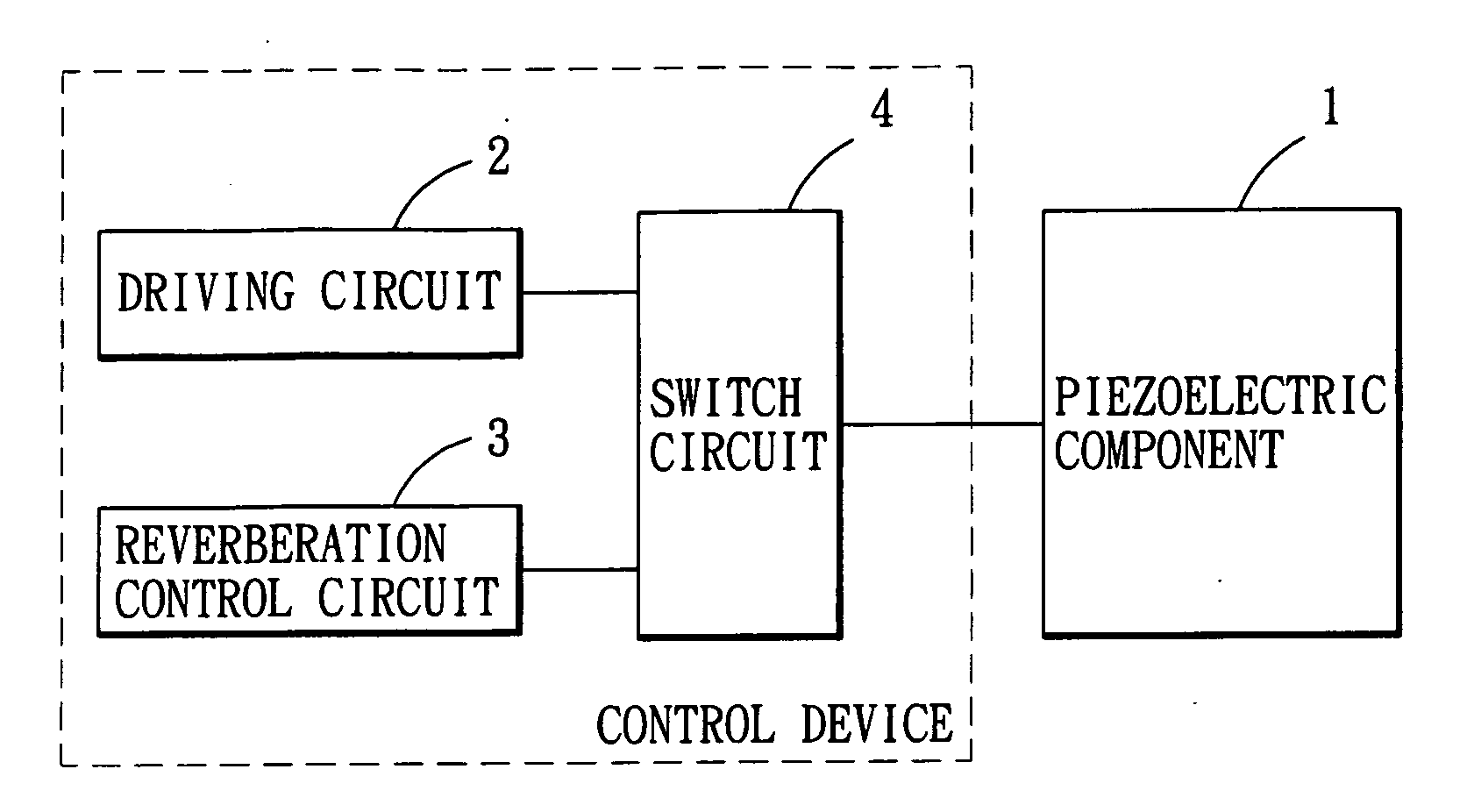

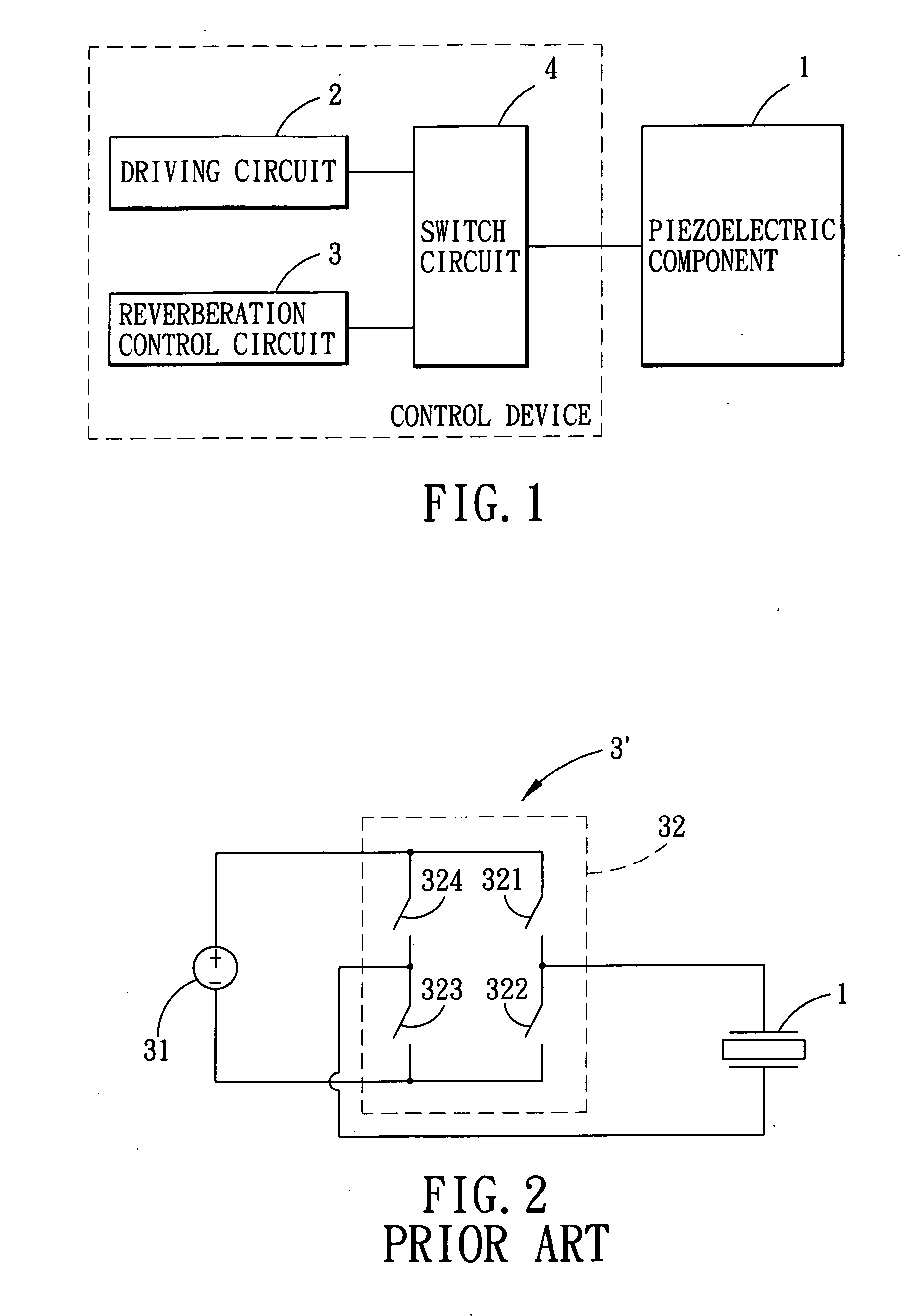

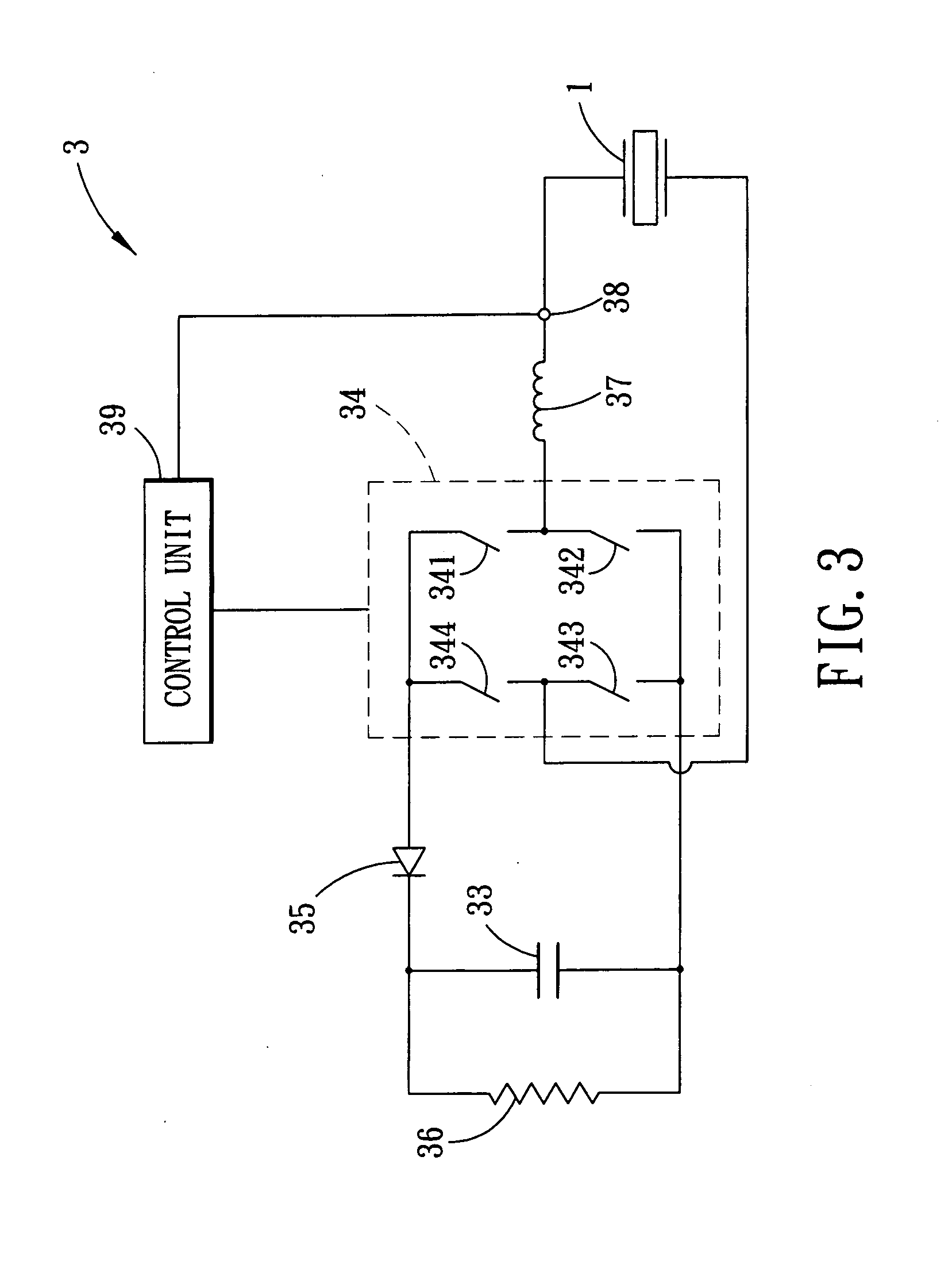

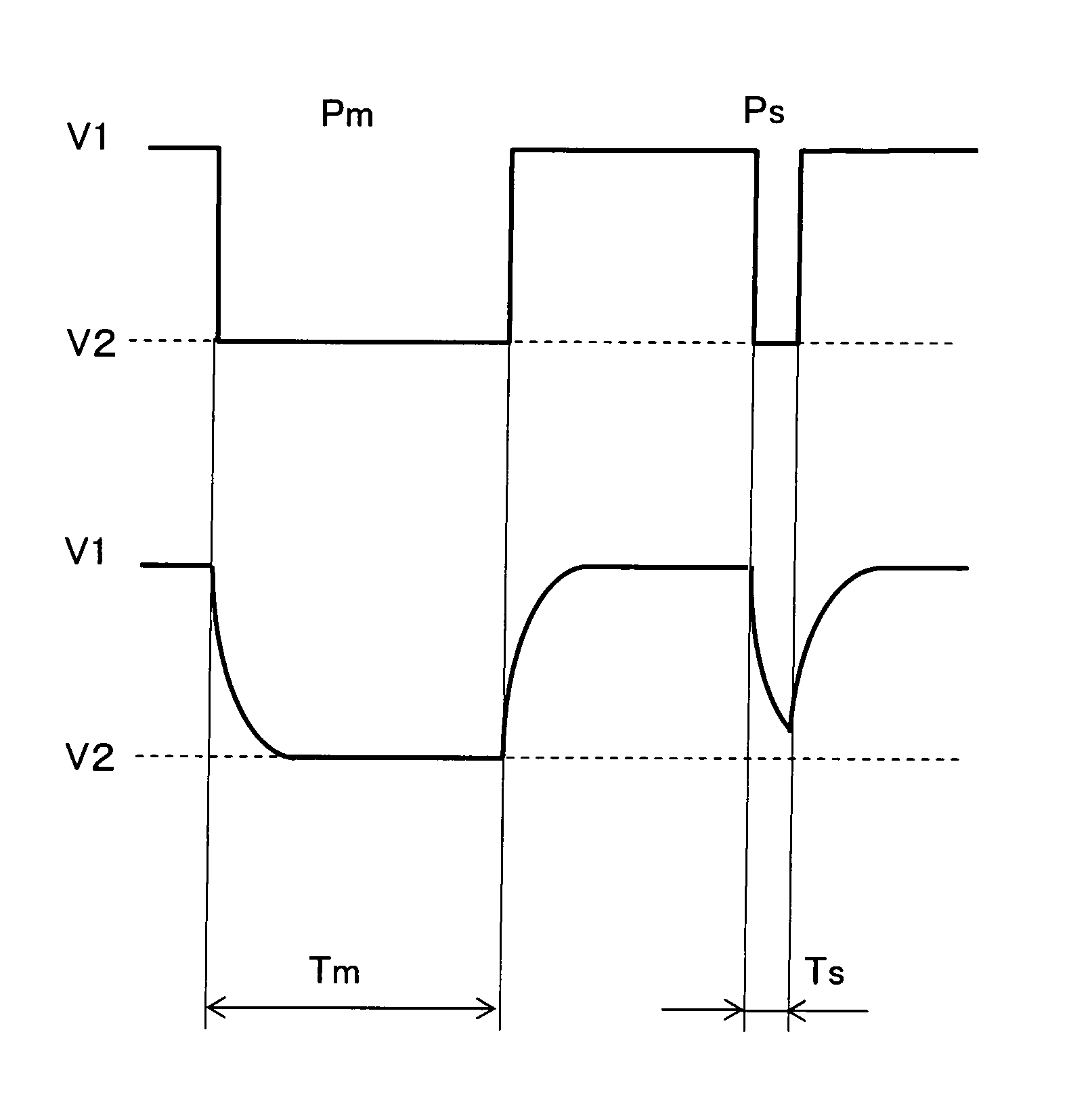

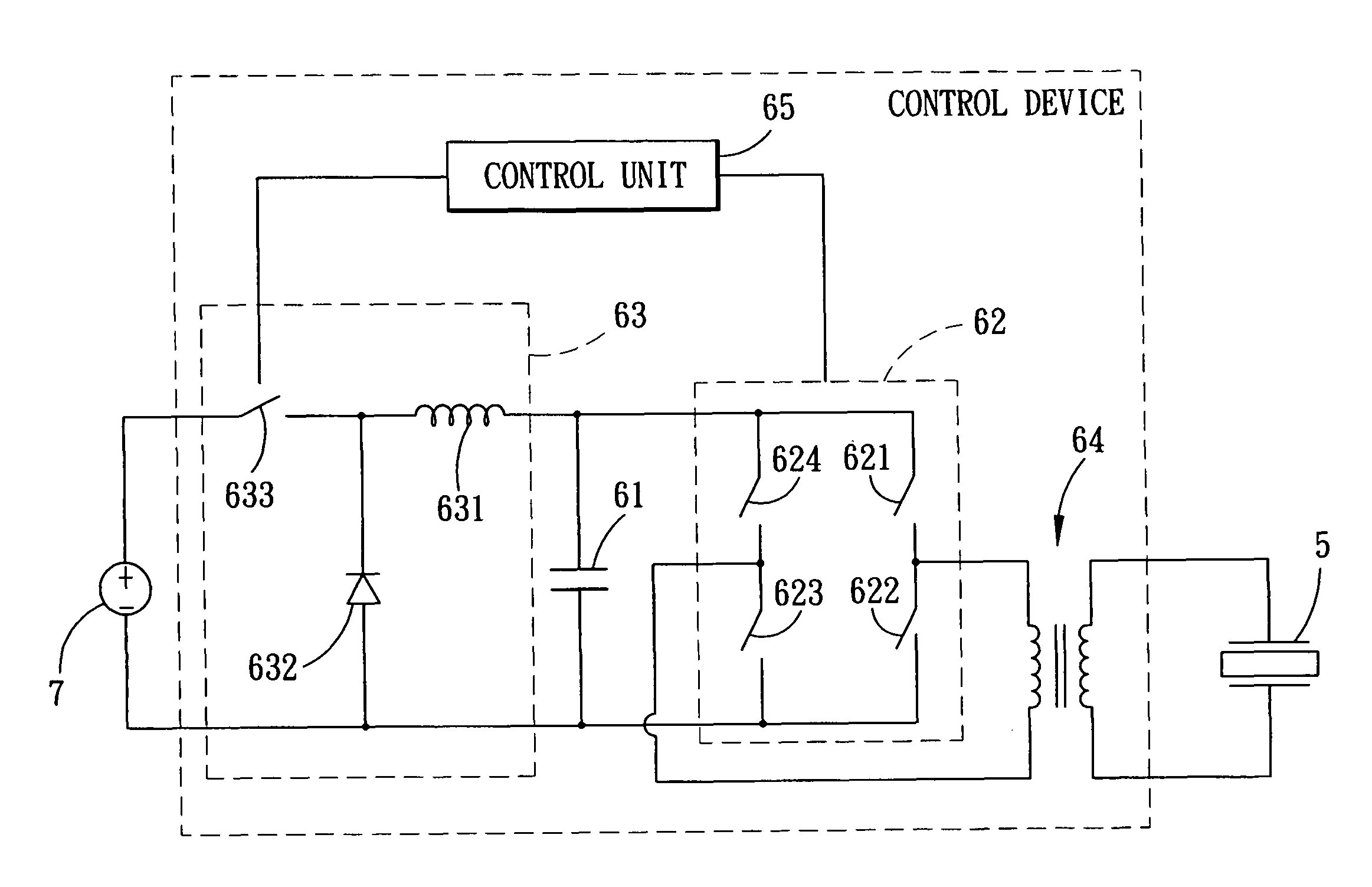

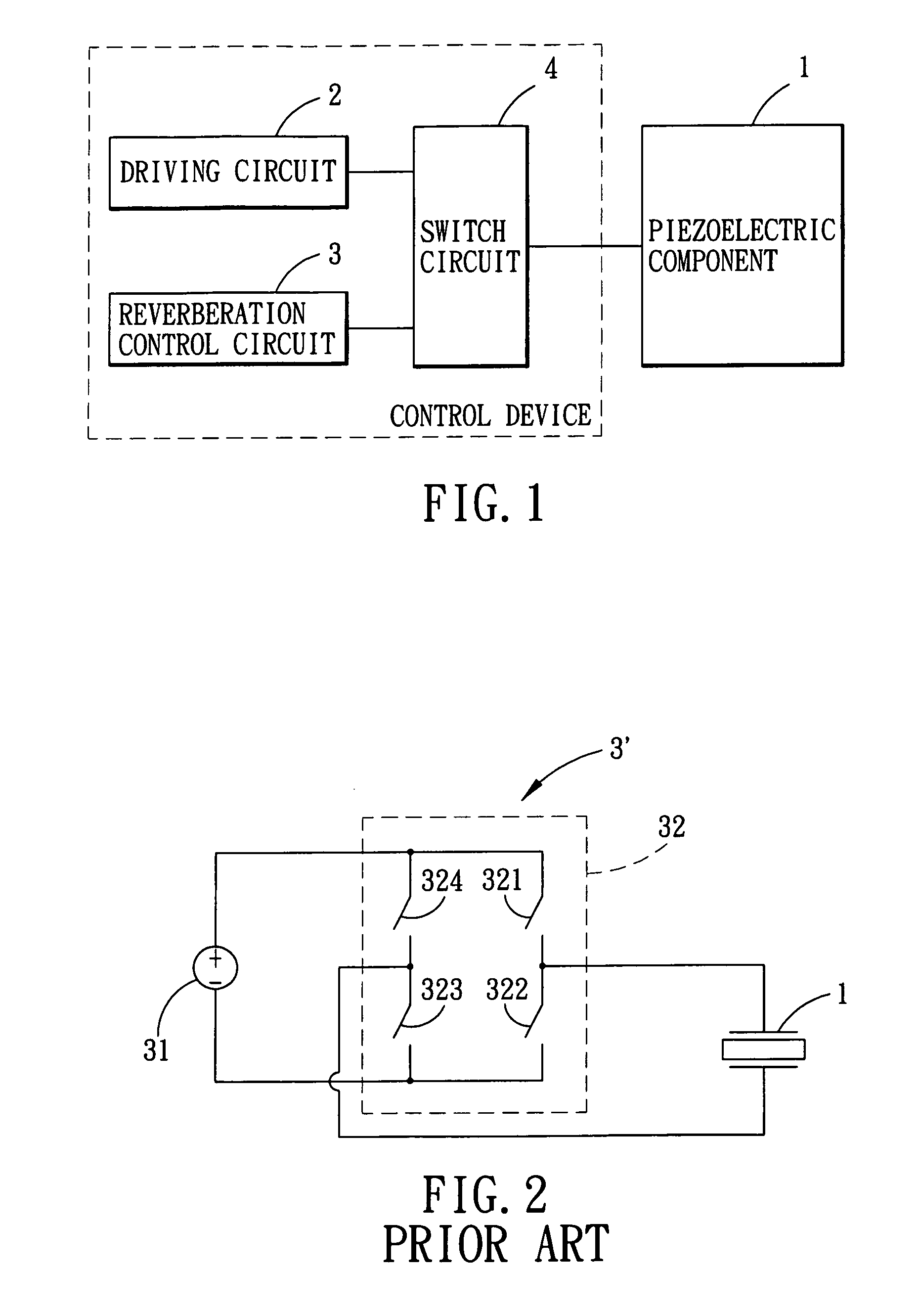

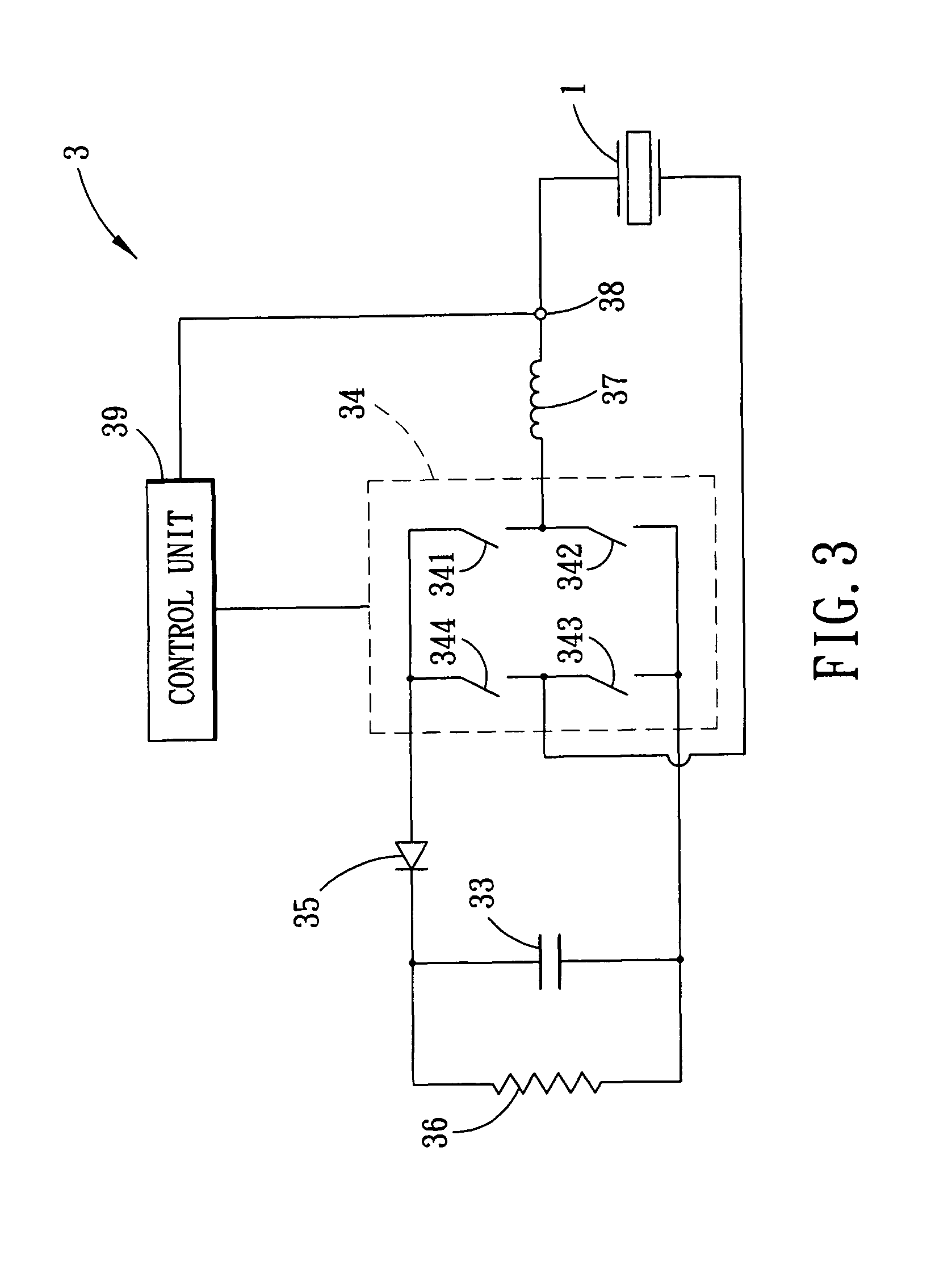

Control device for suppression of residual vibration of piezoelectric transducer

InactiveUS20120068574A1Reduce residual vibrationSuppress residual vibrationPiezoelectric/electrostriction/magnetostriction machinesSound producing devicesCapacitive energy storageCapacitance

A control device for suppression of residual vibration of a piezoelectric transducer includes a capacitive energy storage component, and a switch unit. The control device is operable in a non-working mode, in which the switch unit provides voltage on the capacitive energy storage component to the piezoelectric transducer for reducing the residual vibration of the piezoelectric transducer. The capacitive energy storage component has a capacitance value that is sufficient for enabling the voltage on the capacitive energy storage component to substantially track voltage on the piezoelectric transducer under the non-working mode.

Owner:TUNG THIH ELECTRONICS

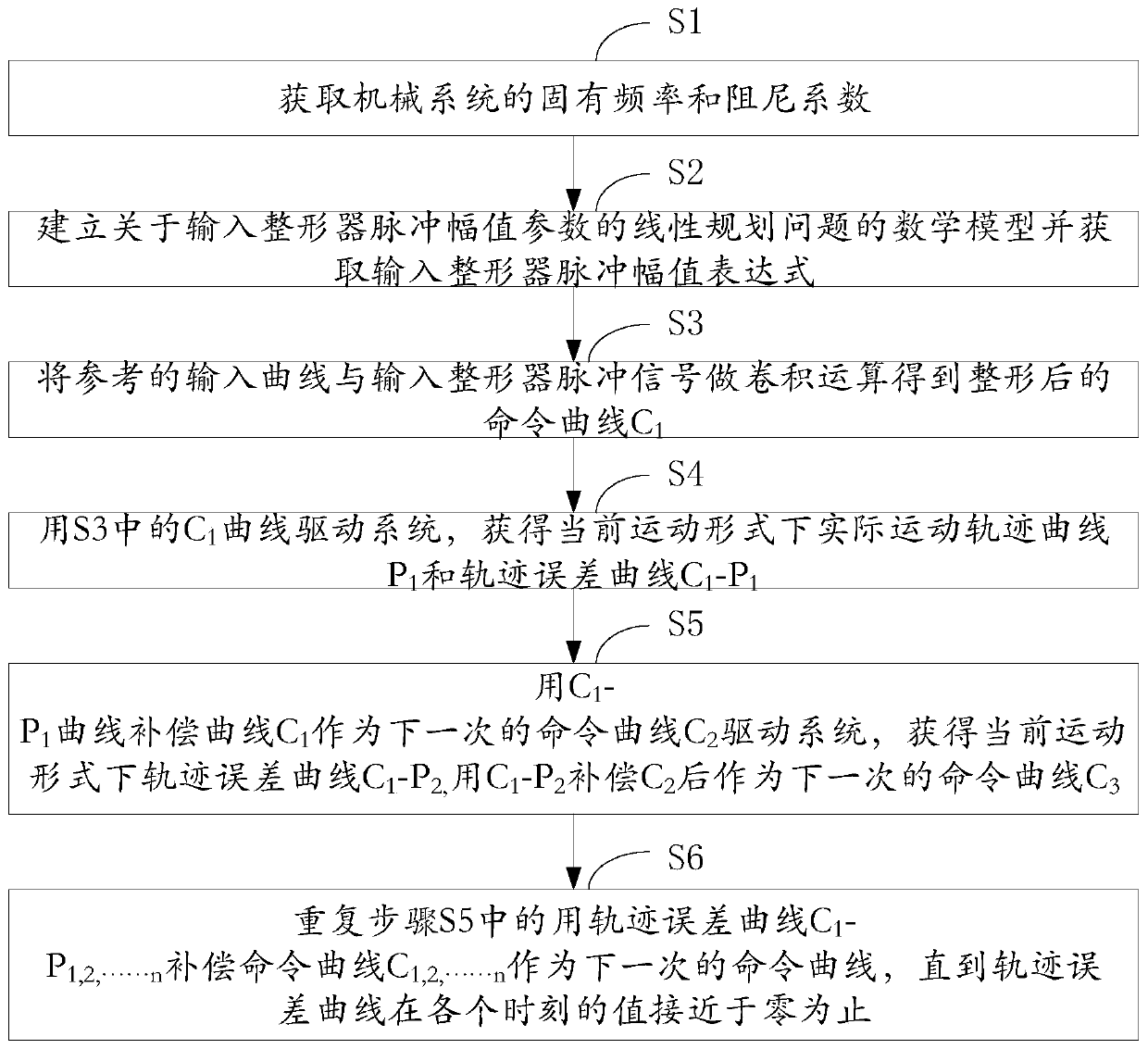

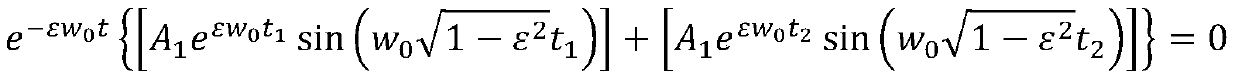

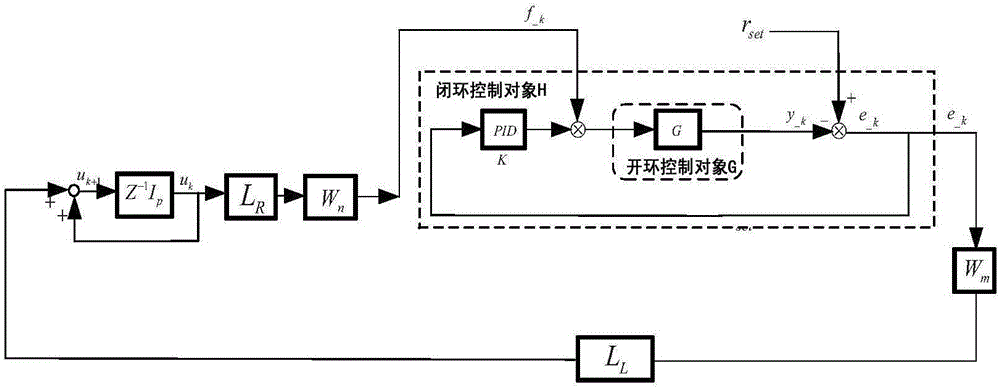

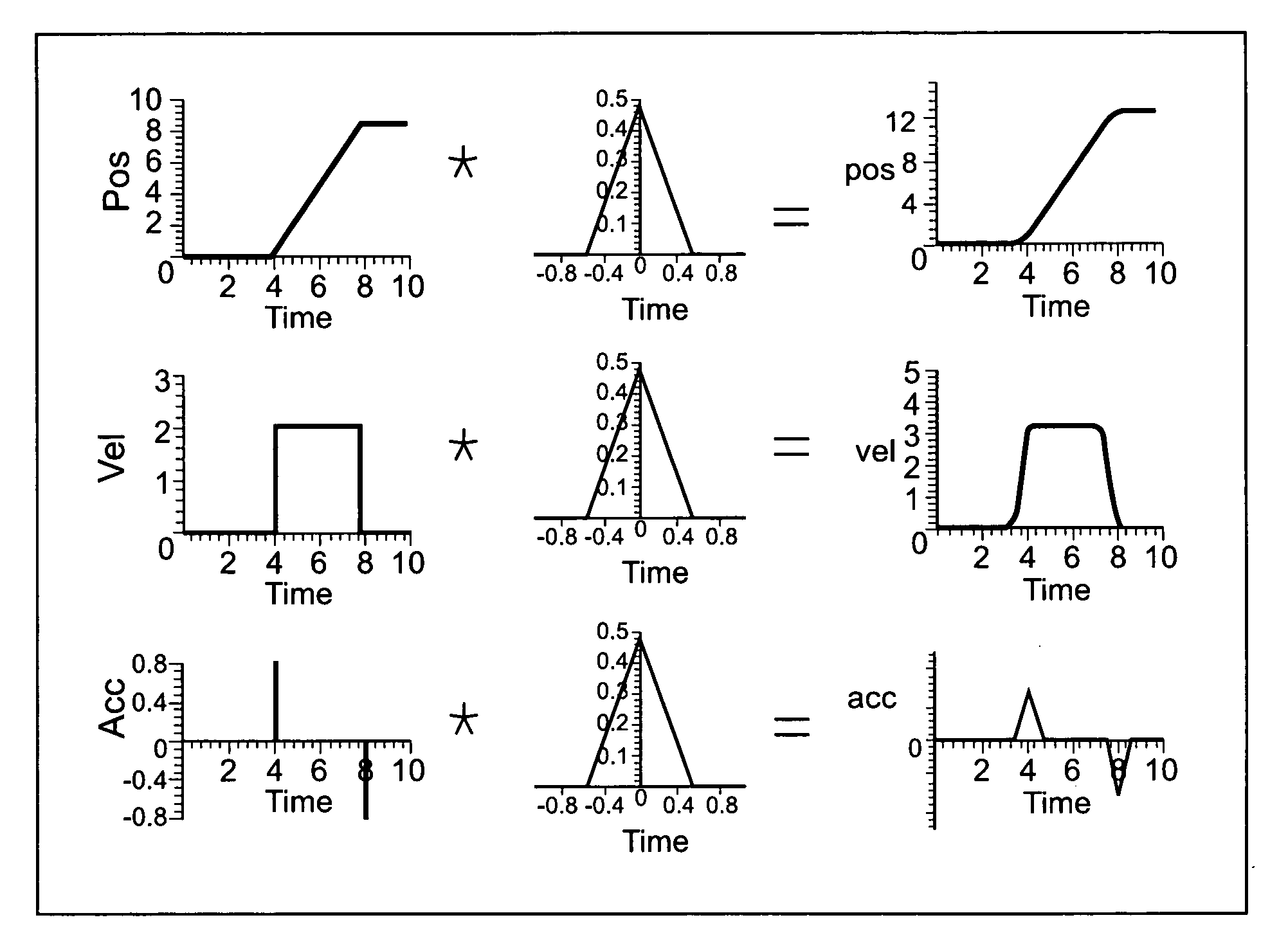

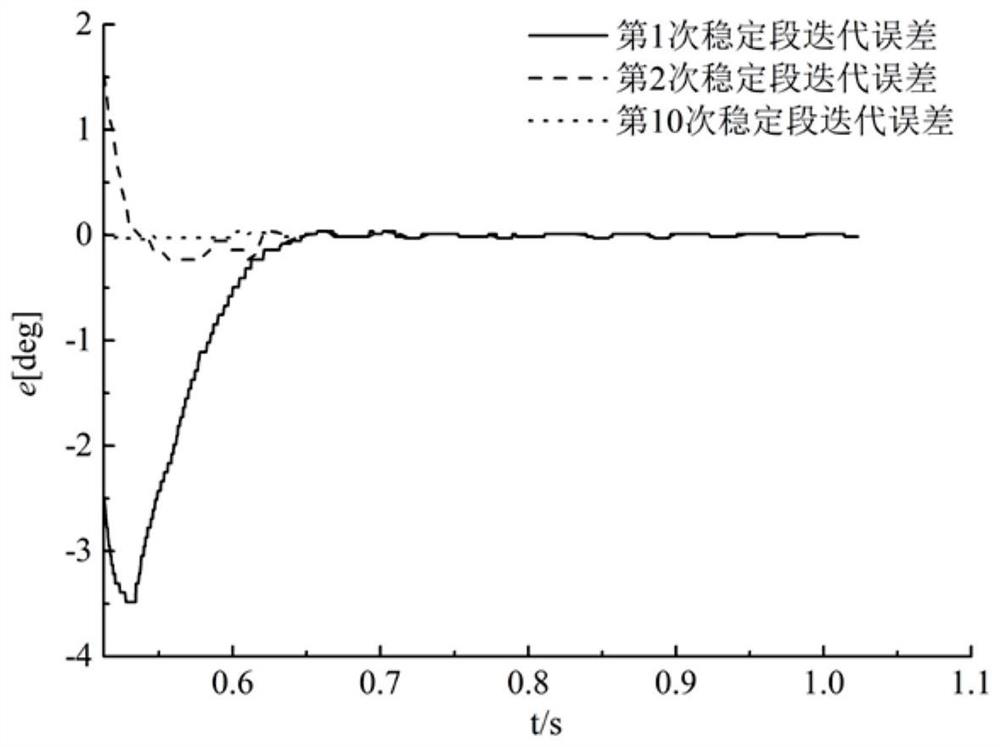

Input shaping residual vibration suppression method and system adapting to trajectory errors of motion system

ActiveCN110632892AStability is not affectedSuppress residual vibrationNumerical controlConvolutionMechanical system

The invention provides an input shaping residual vibration suppression method adapting to trajectory errors of a motion system, comprising the following steps: S1, acquiring the inherent frequency anddamping coefficient of a mechanical system; S2, establishing a mathematical model about a linear programming problem of pulse amplitude parameters of an input shaper, and acquiring a pulse amplitudeexpression of the input shaper; S3, performing convolution operation on an input signal for reference and a pulse signal of the input shaper to obtain a shaped command curve C1; S4, using the C1 curvein the S3 to drive the system to obtain an actual motion trajectory curve P1 and a trajectory error curve C1-P1 under the current motion form; S5, using the C1-P1 curve to compensate the curve C1 toobtain a next command curve C2, using the curve C2 to drive the system to obtain a trajectory error curve C1-P2 under the current motion form, and using C1-P2 to compensate C2 to obtain a next commandcurve P3; and S6, repeating S5 to use the trajectory error curves C1-P1, 2,...n to compensate the command curves P1, 2,...n to obtain a next command curve until the value of the trajectory error curve at each moment is close to zero. According to the method for suppressing residual vibration through the input shaper, other hardware equipment does not need to be added, and cost is saved.

Owner:SHENZHEN COLIBRI TECH

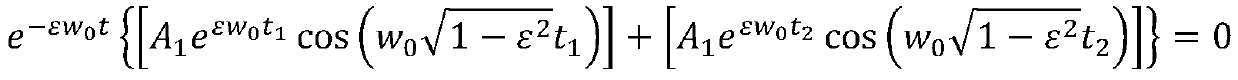

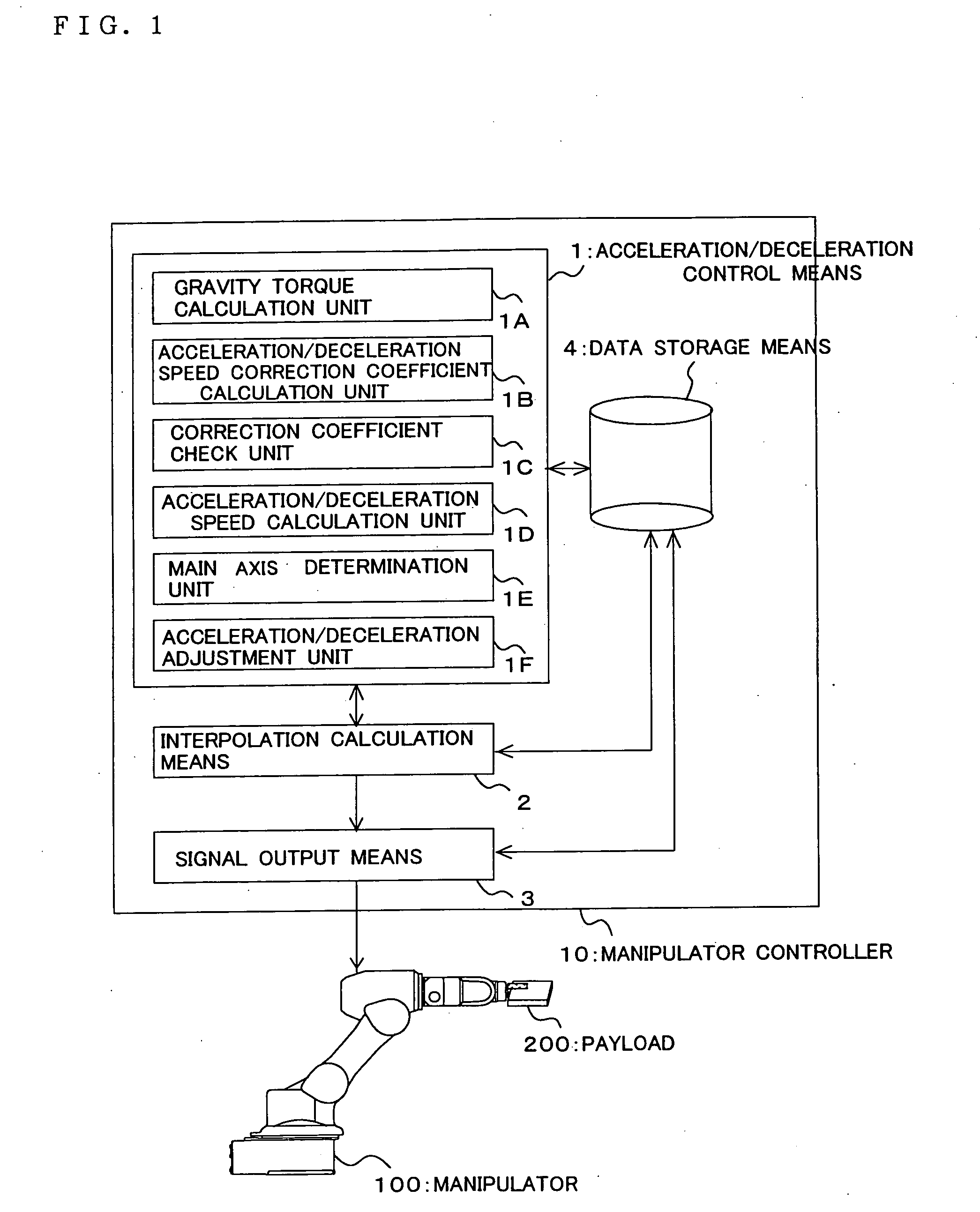

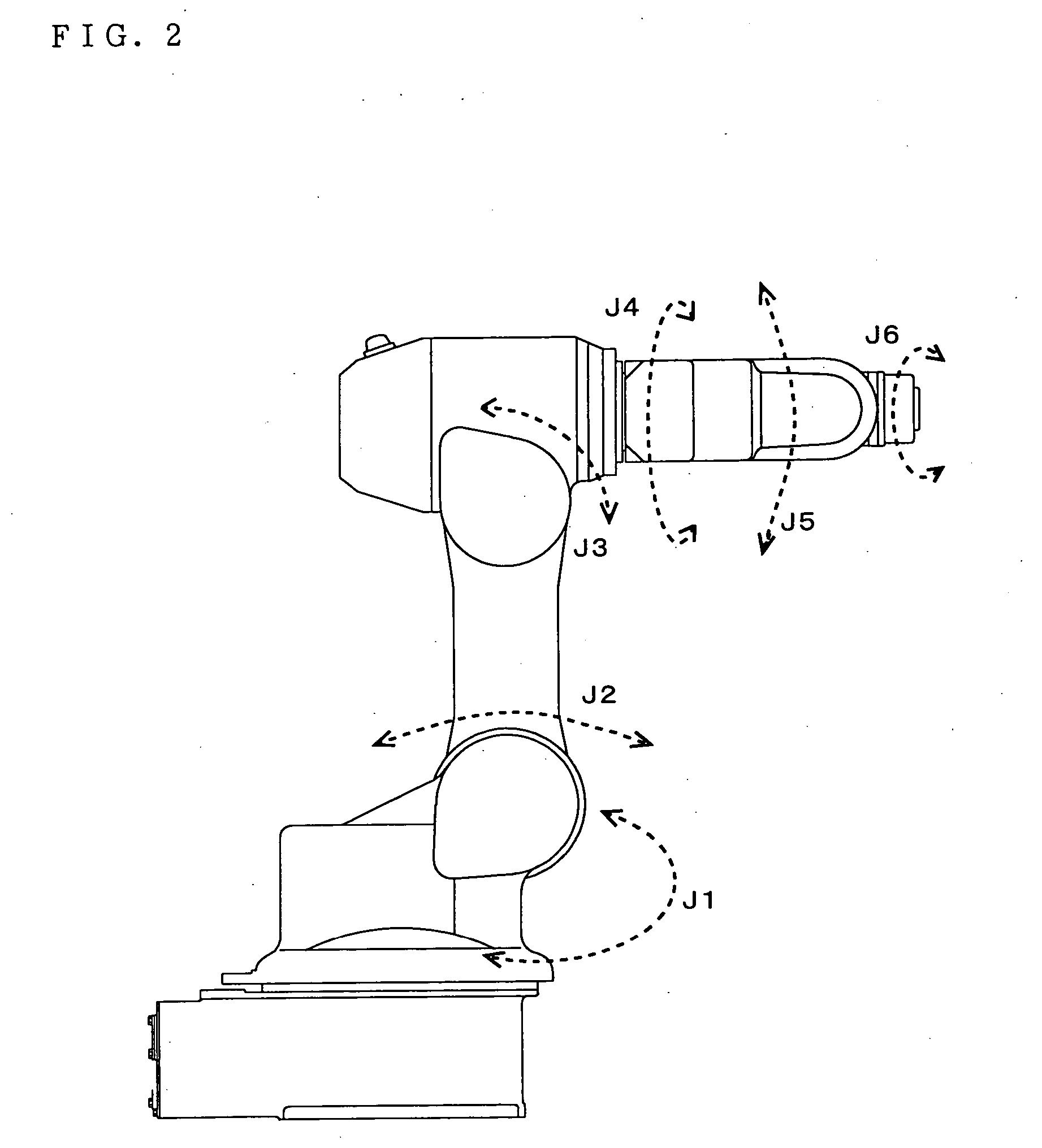

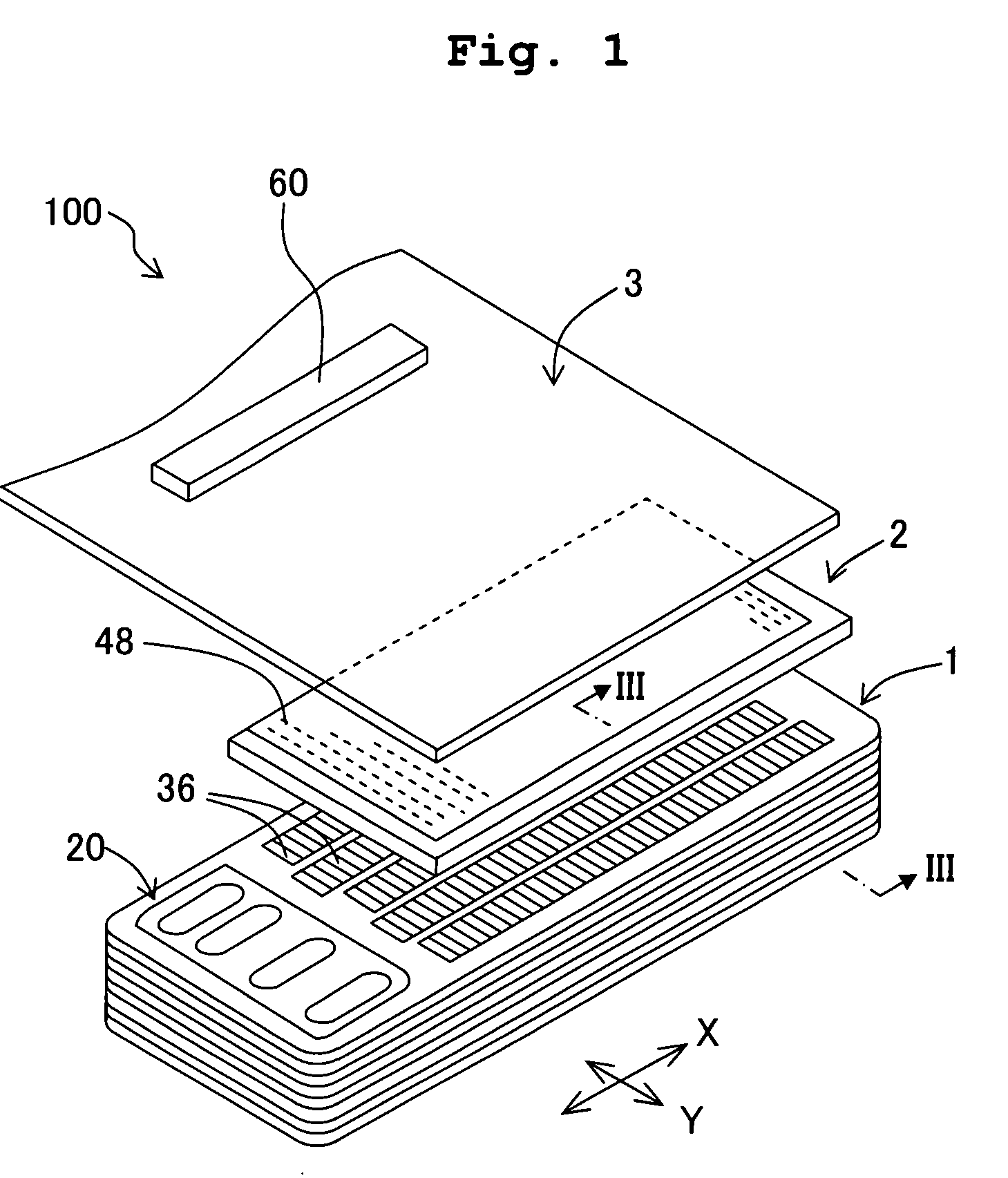

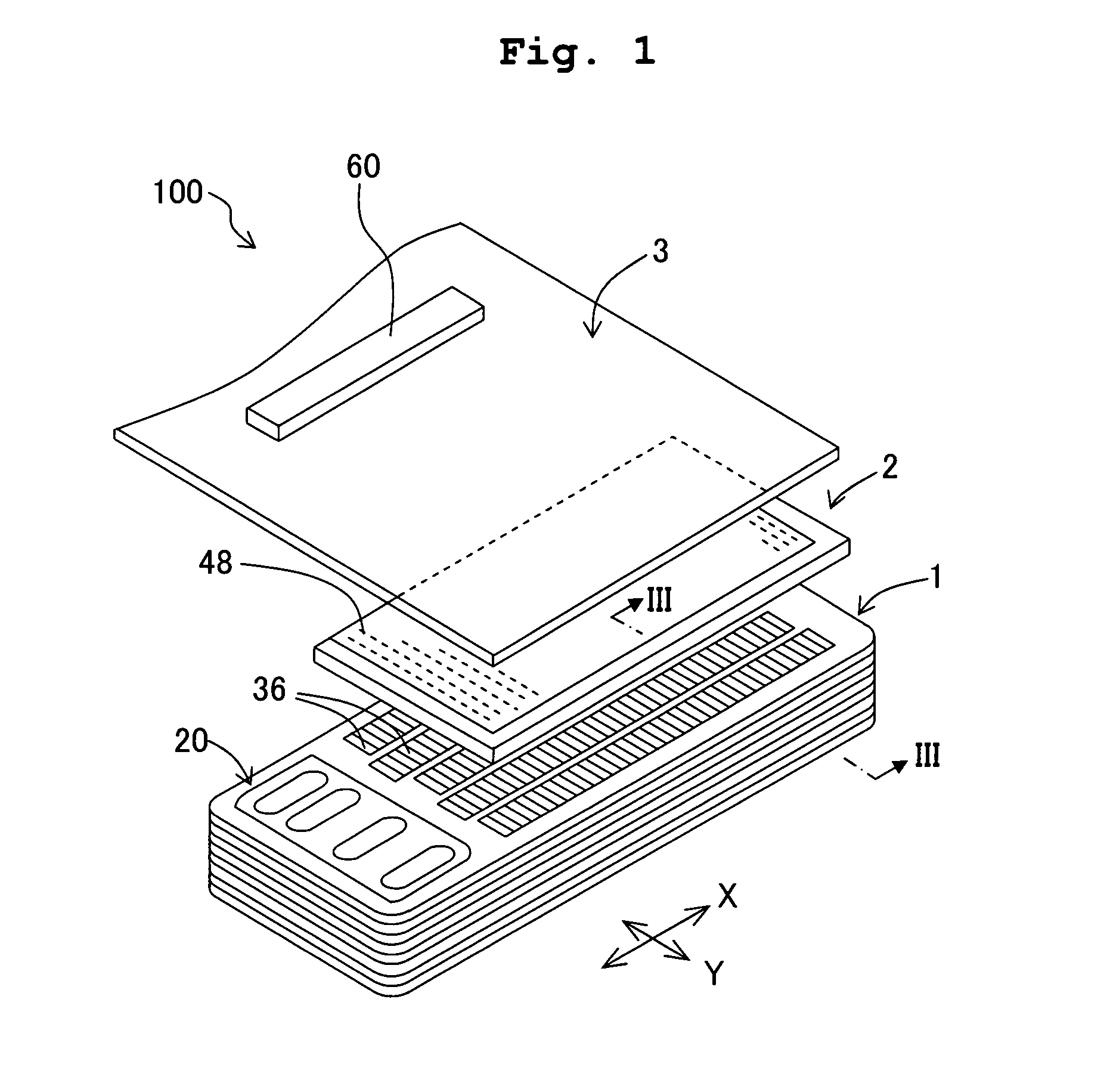

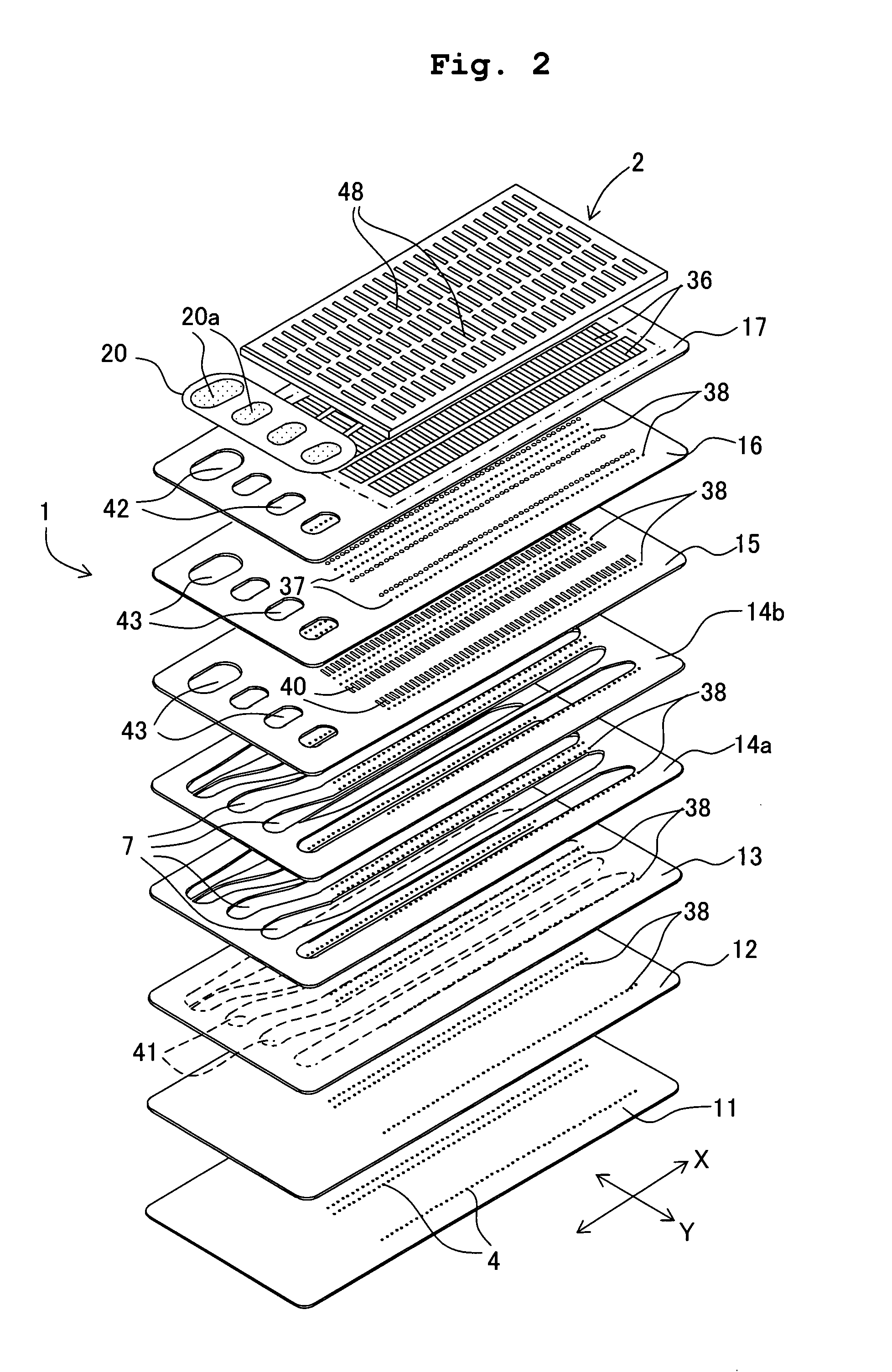

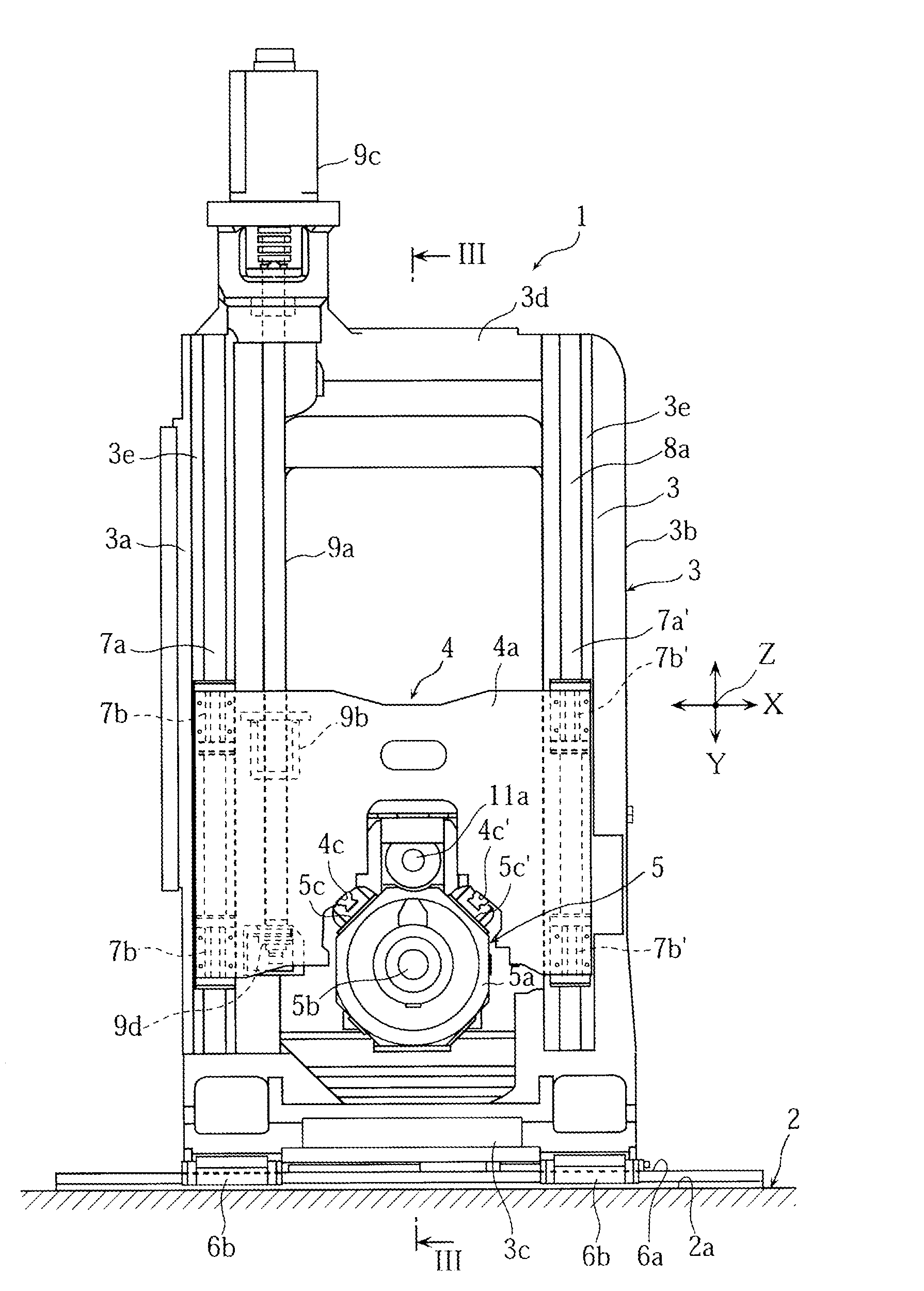

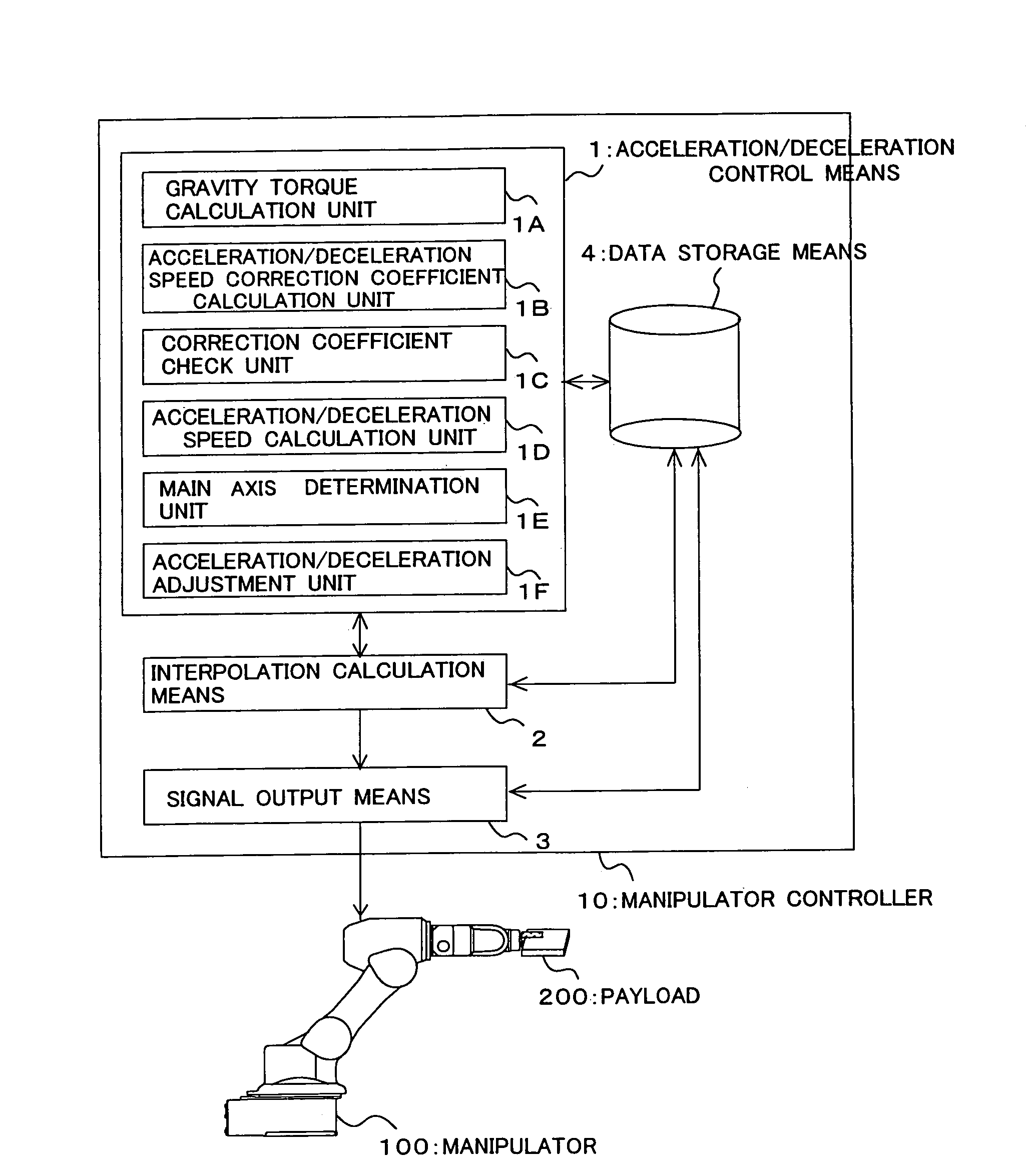

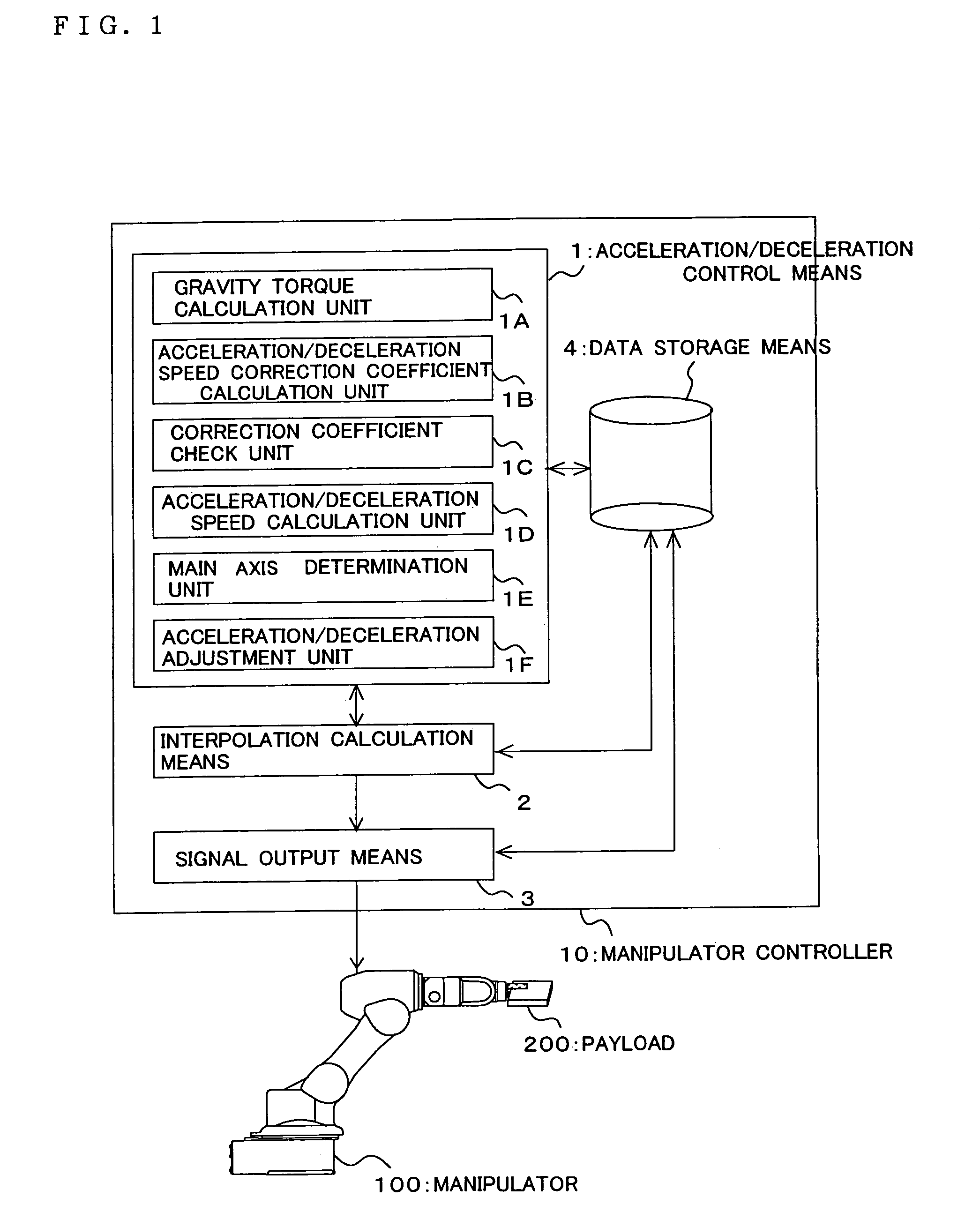

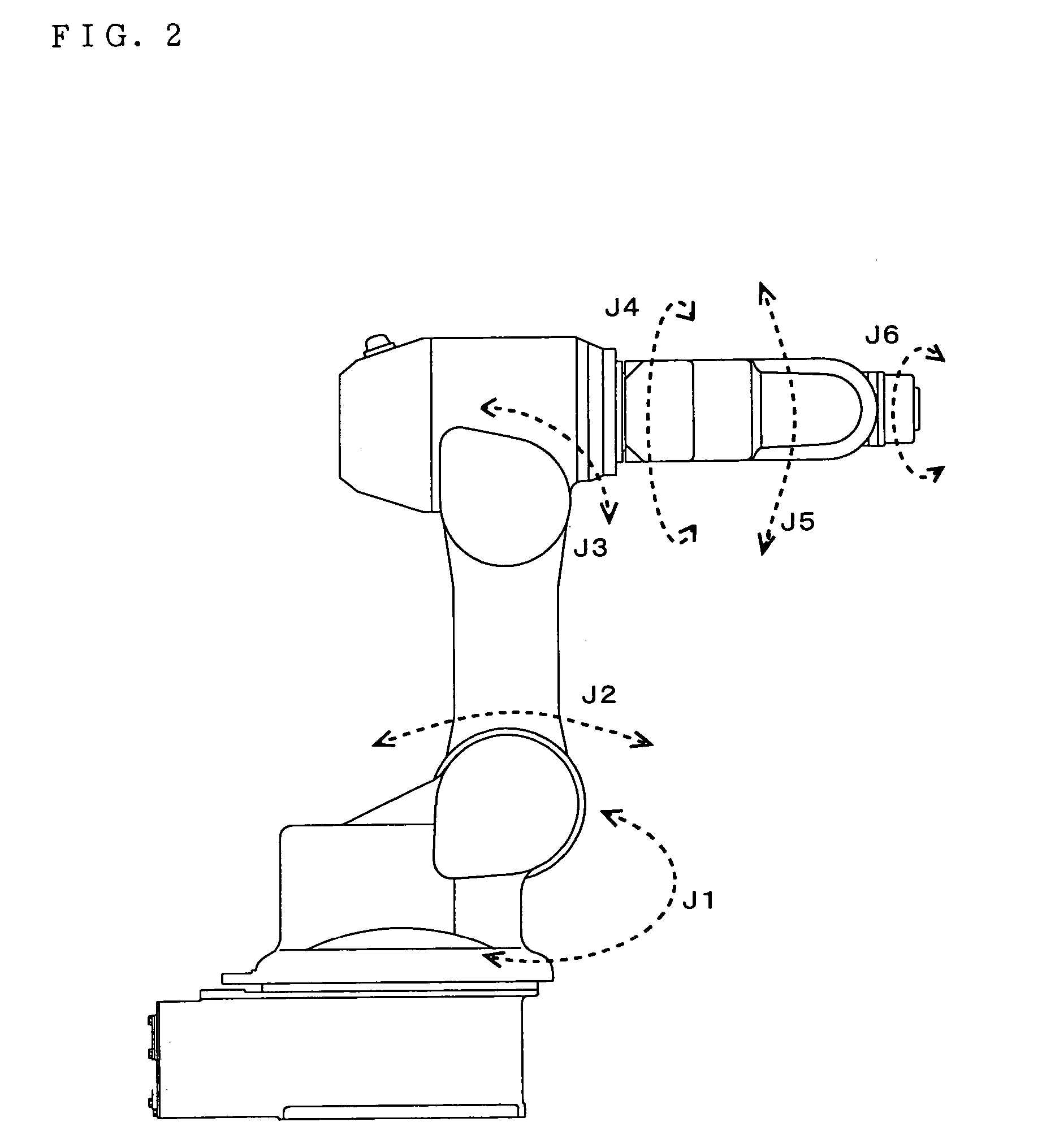

Acceleration/deceleration control method and apparatus as well as program of acceleration/deceleration control method

ActiveUS20060206284A1Easy to handleSimple procedureProgramme-controlled manipulatorDigital computer detailsEngineeringDrive motor

To provide an acceleration / deceleration control method, apparatus and the like for determining the acceleration / decelerations of motors according to, for example, the drive directions, acceleration and deceleration of the motors by a simple algorism. A gravity torque calculation unit 1A calculates gravity torque acting on a joint drive motors for operating a manipulator 100 as a machine having joints, and an acceleration / deceleration calculation unit 1D calculates an acceleration speed and / or a deceleration speed of the joint drive motor based on an acceleration / deceleration correction coefficient and a set basic acceleration / deceleration, wherein the acceleration / deceleration correction coefficient is calculated by an acceleration / deceleration correction coefficient calculation unit 1B based on the gravity compensation coefficient selected from a plurality of preset gravity compensation coefficients according to a drive condition affected by gravity and on the gravity torque.

Owner:SEIKO EPSON CORP

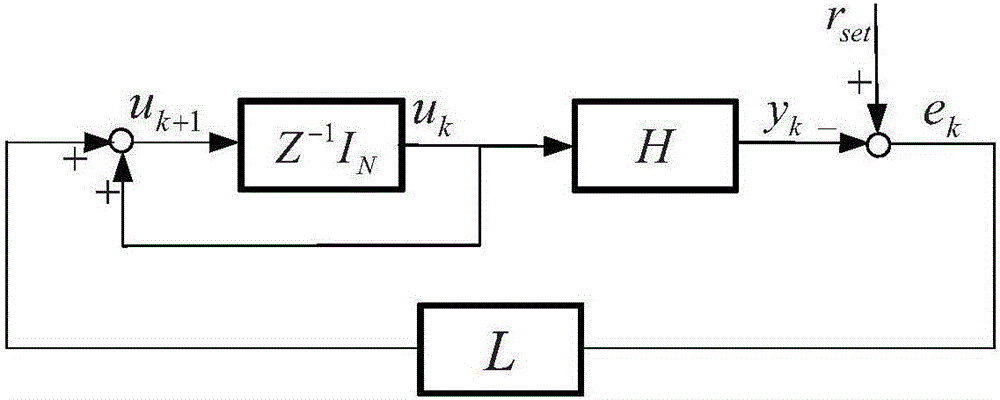

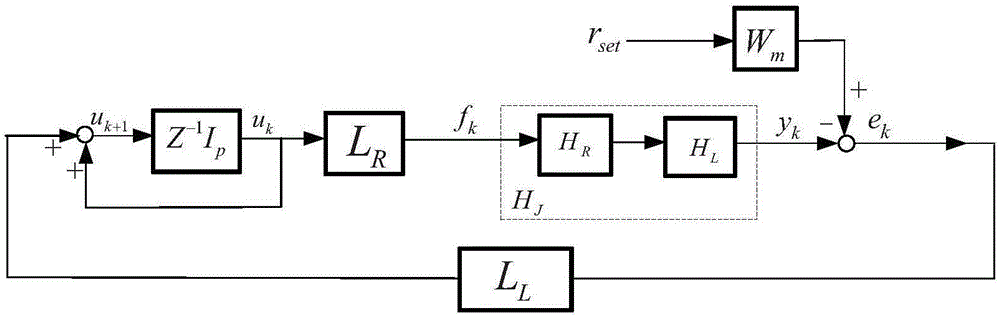

Method for controlling mechanical residual vibration of linear servo system

ActiveCN106325072ASuppress residual vibrationMeet control requirementsAdaptive controlResidual vibrationResonance

The invention discloses a method for controlling mechanical residual vibration of a linear servo system, and belongs to the technical field of mechanical device control. Most of current control methods for restraining residual vibration of the servo system are restraining methods based on input shapers, the methods have the shortcomings that pulse amplitudes and time period parameters are difficultly controlled, running errors are large, and control requirements of the linear servo system cannot be met. The method includes the steps: firstly, connecting the linear servo system, and downloading parameters into a chip on a motion control card; secondly, enabling the servo system to close a motor after controller parameters are downloaded; thirdly, collecting sampling points; fourthly, iterating error signals used for optimizing; fifthly, issuing iterative learning correction driving force to the motion control card again, and repeatedly iterating iterative learning processes to restrain resonance. Input signals subtract output signals to serve as error signals. The method is simple, practical and high in accuracy.

Owner:江苏希太芯科技有限公司

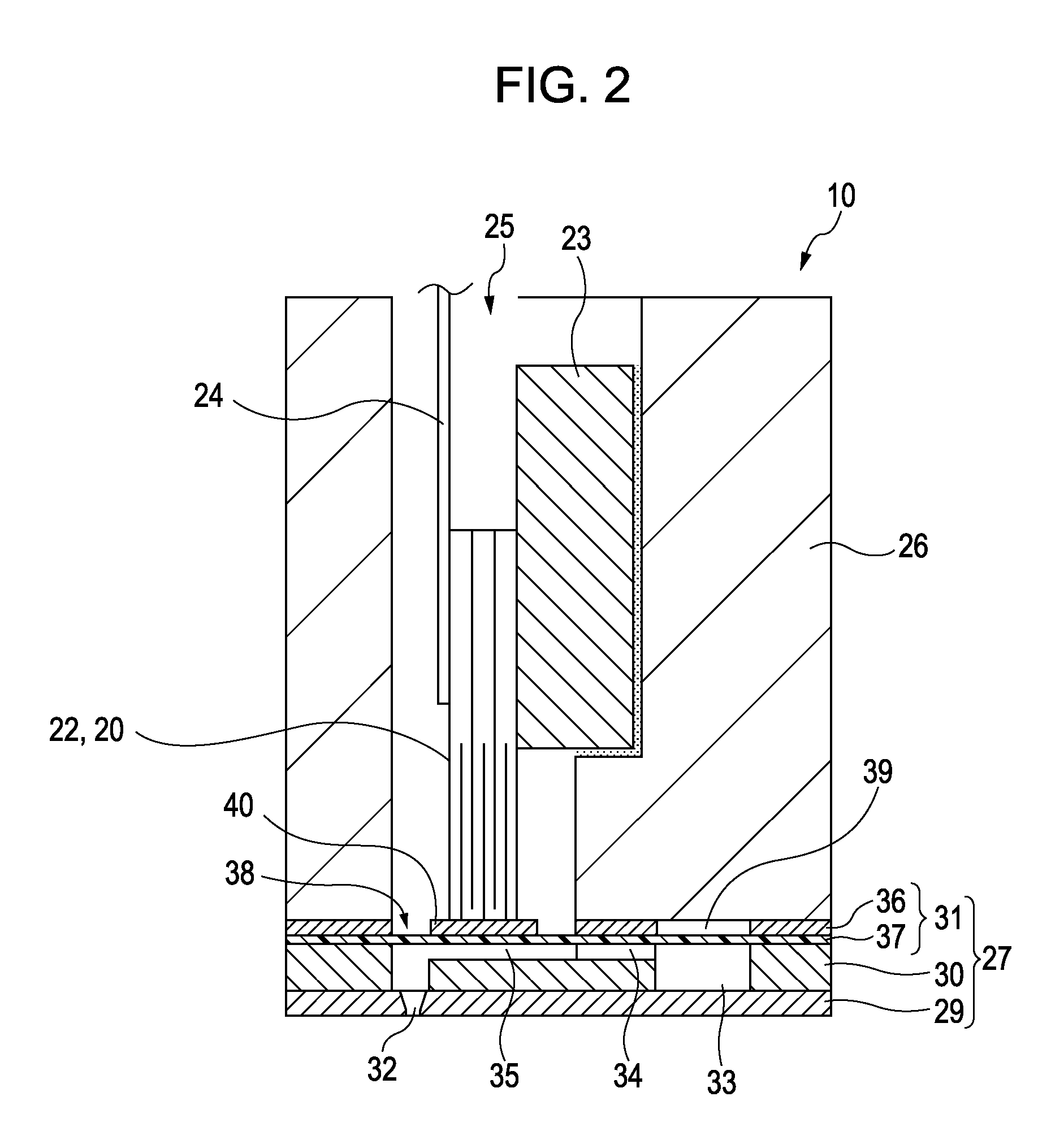

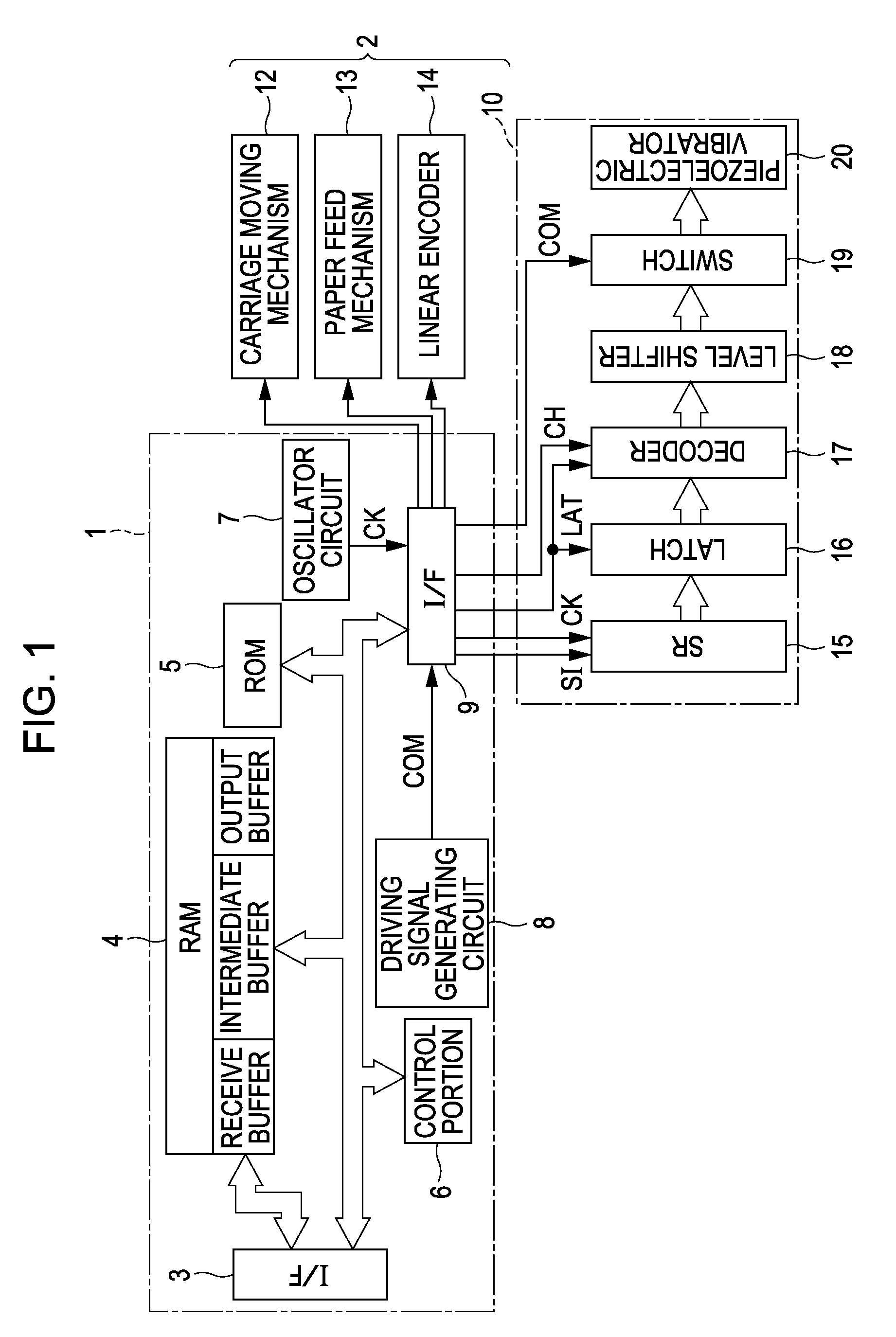

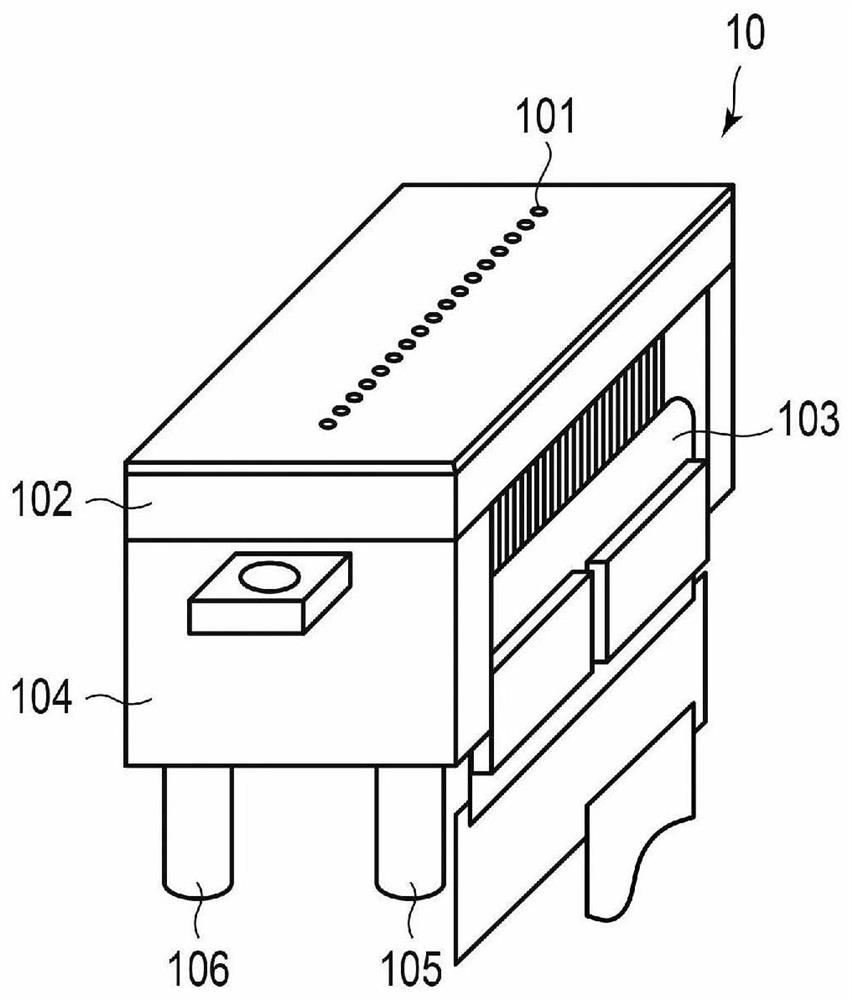

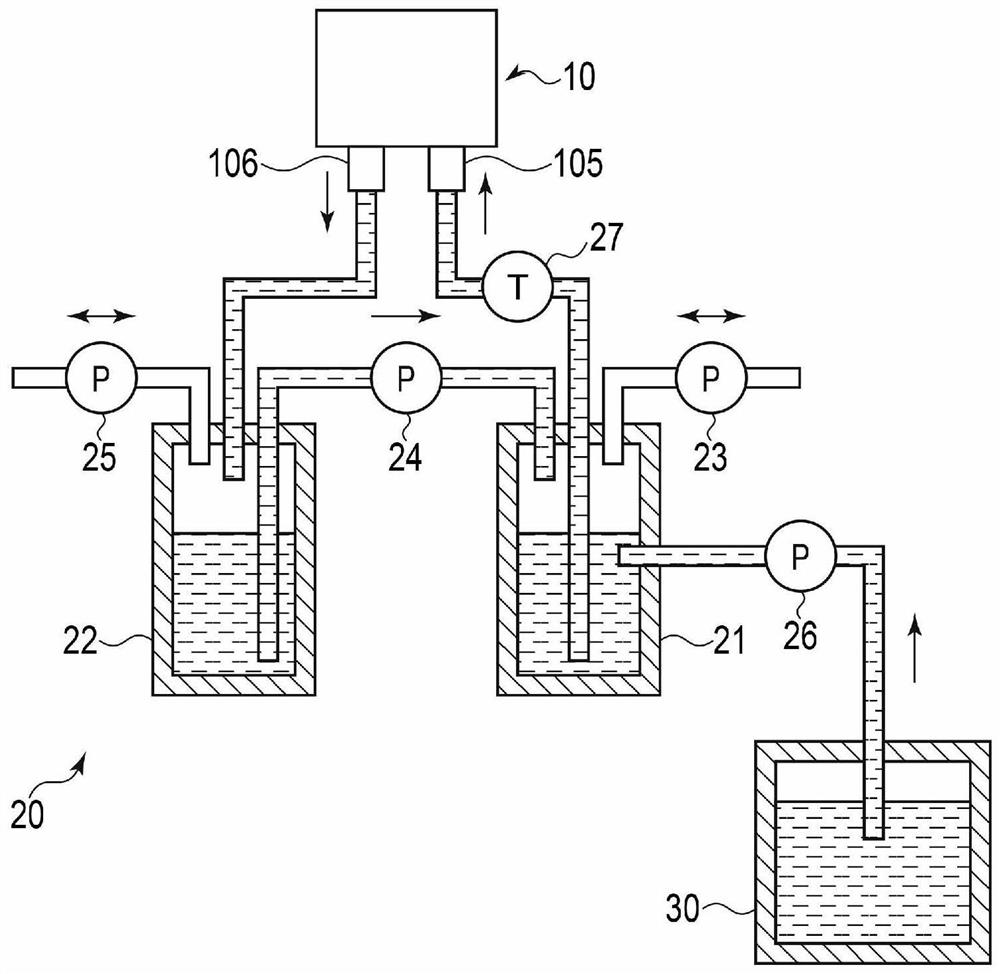

Liquid ejecting apparatus and control method of the same

ActiveUS20100245425A1High viscosityAvoid separationOther printing apparatusLiquid pressureEngineering

A liquid ejecting apparatus includes a liquid ejecting head having a nozzle, a pressurizing chamber that communicates with the nozzle, and a pressurizing element that causes a pressure change in liquid within the pressurizing chamber, the liquid ejecting head being capable of ejecting liquid from the nozzle by operating the pressurizing element; and a driving signal generation unit that generates a driving signal including a driving pulse that drives the pressurizing element. The driving signal includes an ejection driving pulse that ejects a liquid droplet and a non-ejection driving pulse that drives the pressurizing element to a degree whereby a liquid droplet is not ejected. The ejection driving pulse is a pulse waveform having an expansion element that causes the pressurizing chamber to expand and retract a meniscus toward the pressurizing chamber and a constriction element that causes the pressurizing chamber expanded by the expansion element to constrict and push the meniscus in the direction of ejection. The non-ejection driving pulse is a pulse waveform having an expansion element that causes the pressurizing chamber to expand and retract the meniscus toward the pressurizing chamber, a holding element that holds the voltage at the end of the expansion element for a set amount of time, and a constriction element that causes the pressurizing chamber expanded by the expansion element to constrict and push the meniscus in the direction of ejection. When the length of time from the end of the constriction element in the ejection driving pulse to the beginning of the expansion element in the non-ejection driving pulse is taken as t, the lengths of time of the expansion element, holding element, and constriction element in the non-ejection driving pulse are taken as a, b, and c, respectively, and the inherent vibration cycle of the liquid within the pressurizing chamber is taken as Tc, t, a, b, and c are within the ranges defined by the following equations (1) through (3):Tc / 4≦t≦Tc / 2 (1)(5Tc / 8)−t≦a≦(3Tc / 4)−t (2)b+c=Tc−t−a (3)

Owner:SEIKO EPSON CORP

Liquid droplet ejection method and liquid droplet ejection apparatus

InactiveUS20070019041A1Suppress residual vibrationVolume stabilityInking apparatusOther printing apparatusEngineeringLiquid drop

A liquid droplet ejection apparatus comprises: a nozzle from which a liquid droplet is ejected; a pressure chamber filled with liquid to which a pressure is applied in order to eject the liquid in a form of the liquid droplet from the nozzle; and a supply port which supplies the liquid to the pressure chamber, wherein inertance Mn of the nozzle, resistance Rn of the nozzle, compliance Cn of a nozzle section due to surface tension, inertance Ms of the supply port, and resistance Rs of the supply port satisfy the following two formulas: 1Mn+MsMn+MsCn-(Rn+Rs)24>π f-Rn+Rs2(Mn+Ms)×1f<log 0.01.

Owner:FUJIFILM CORP

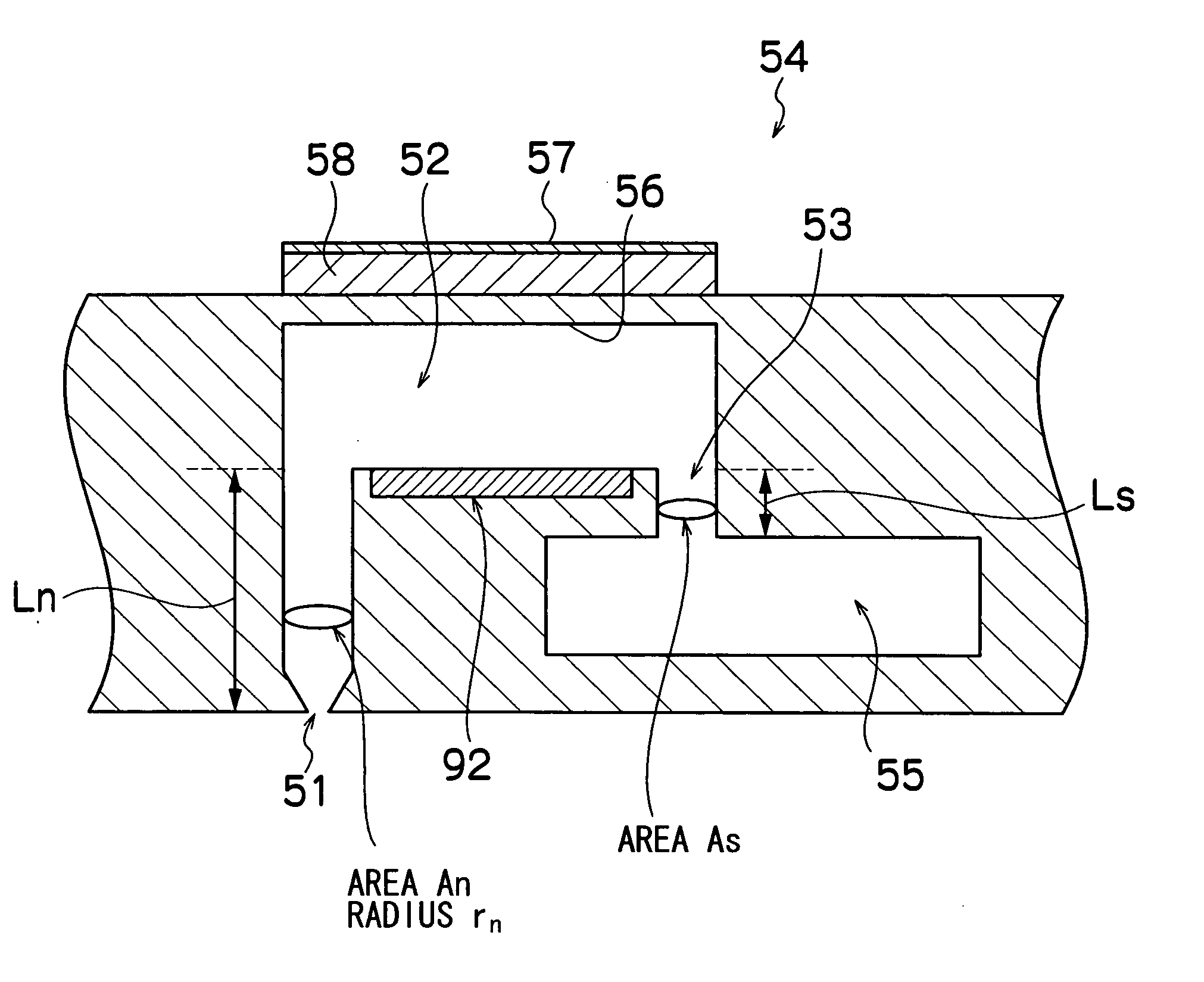

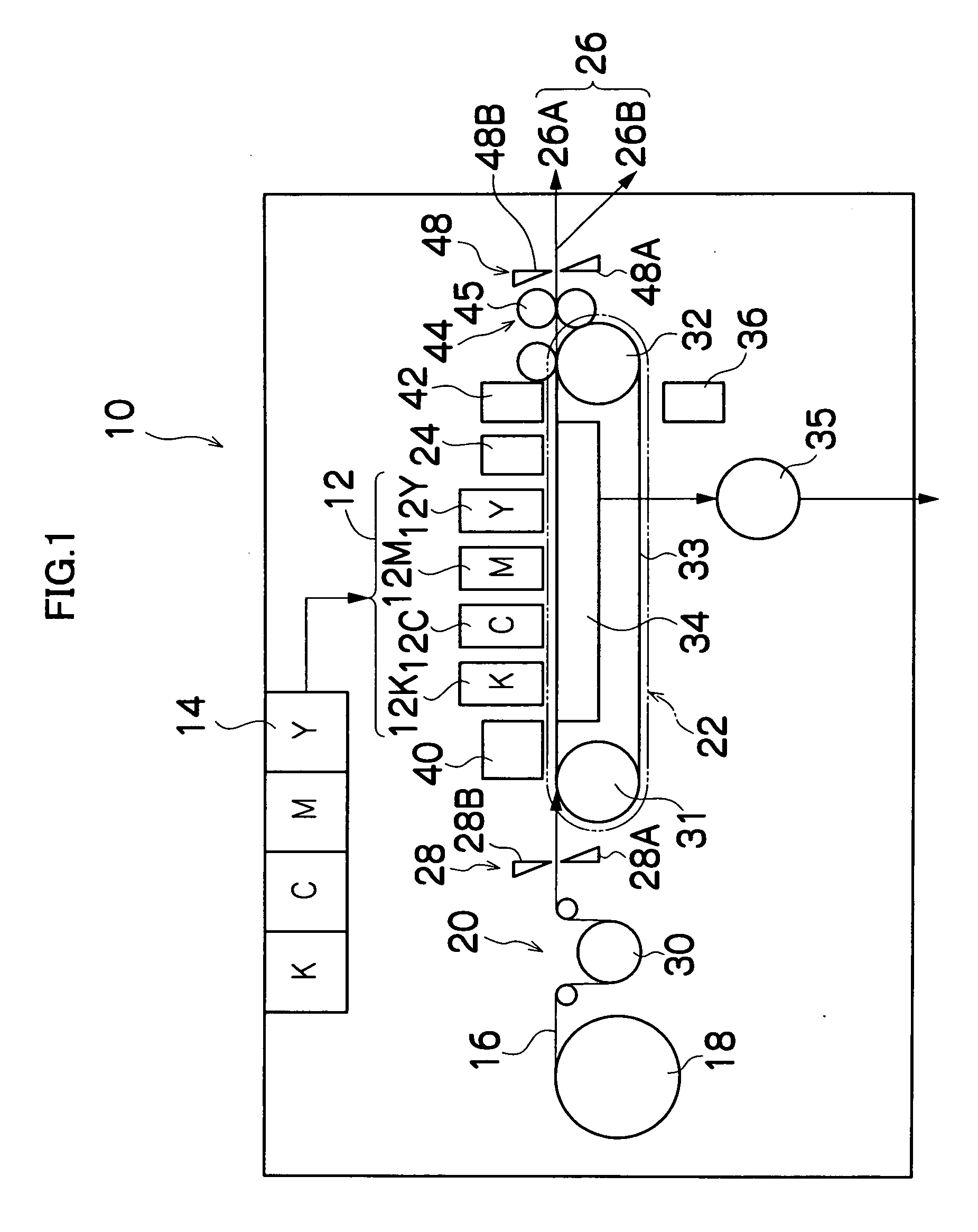

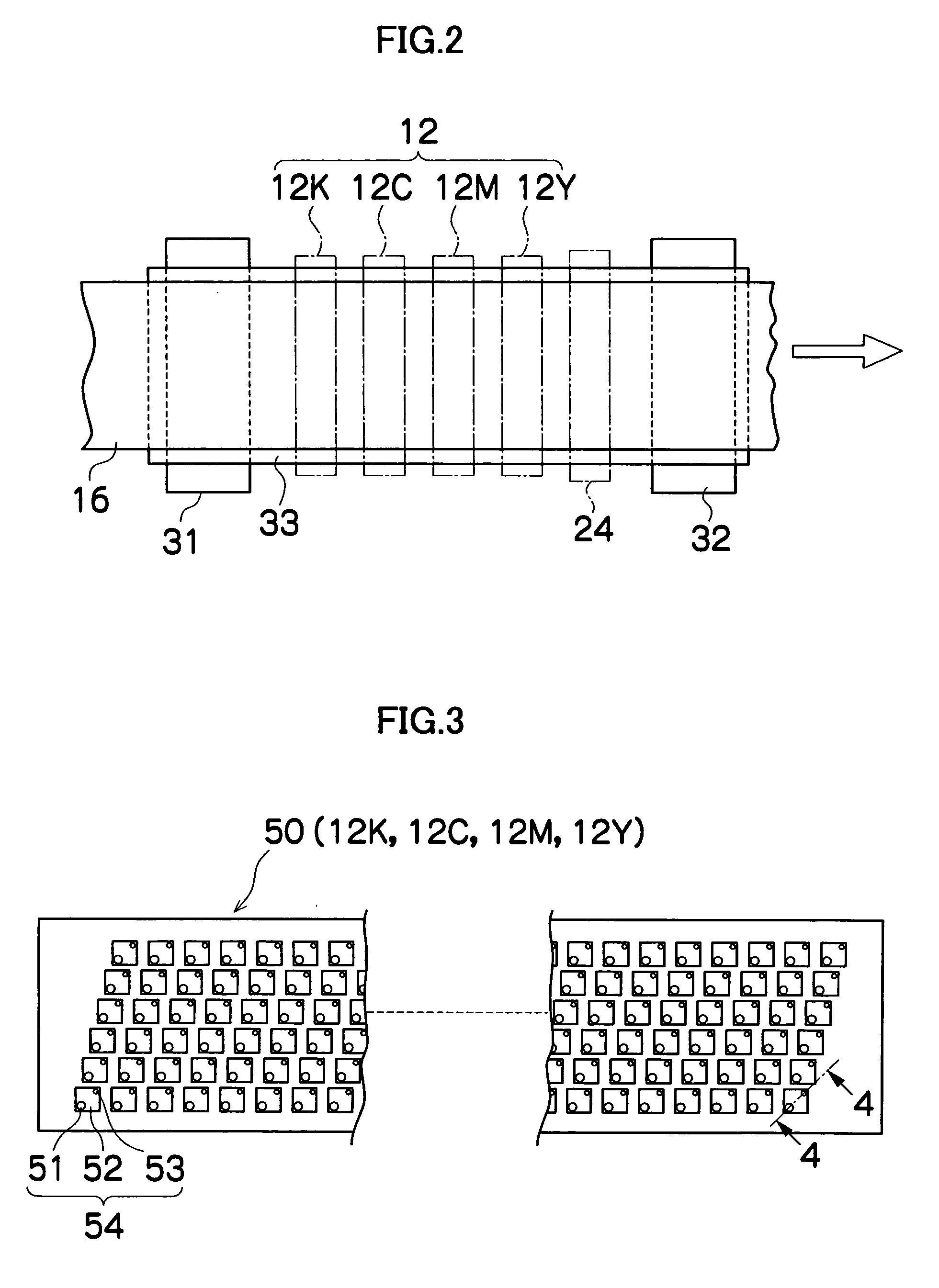

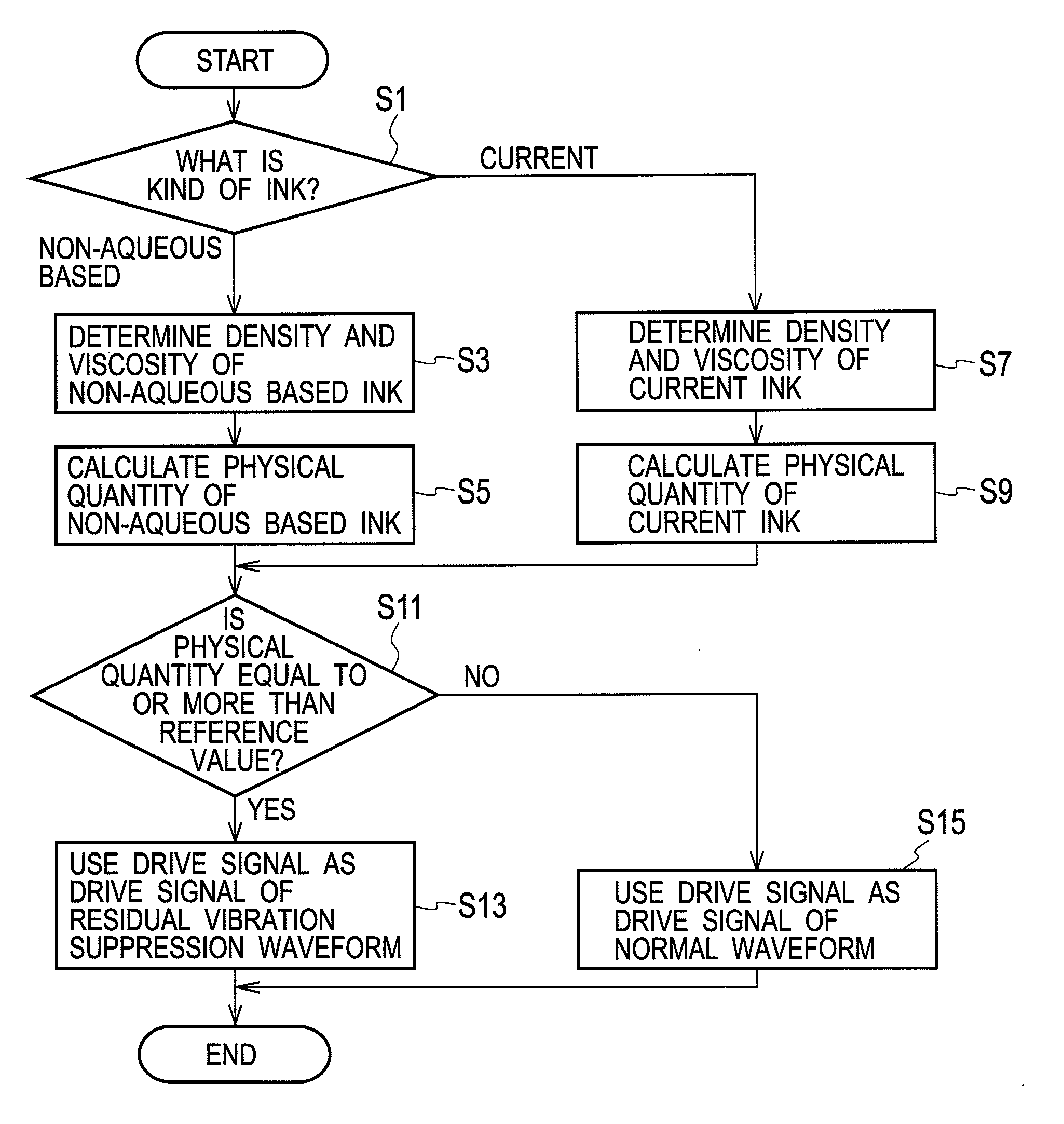

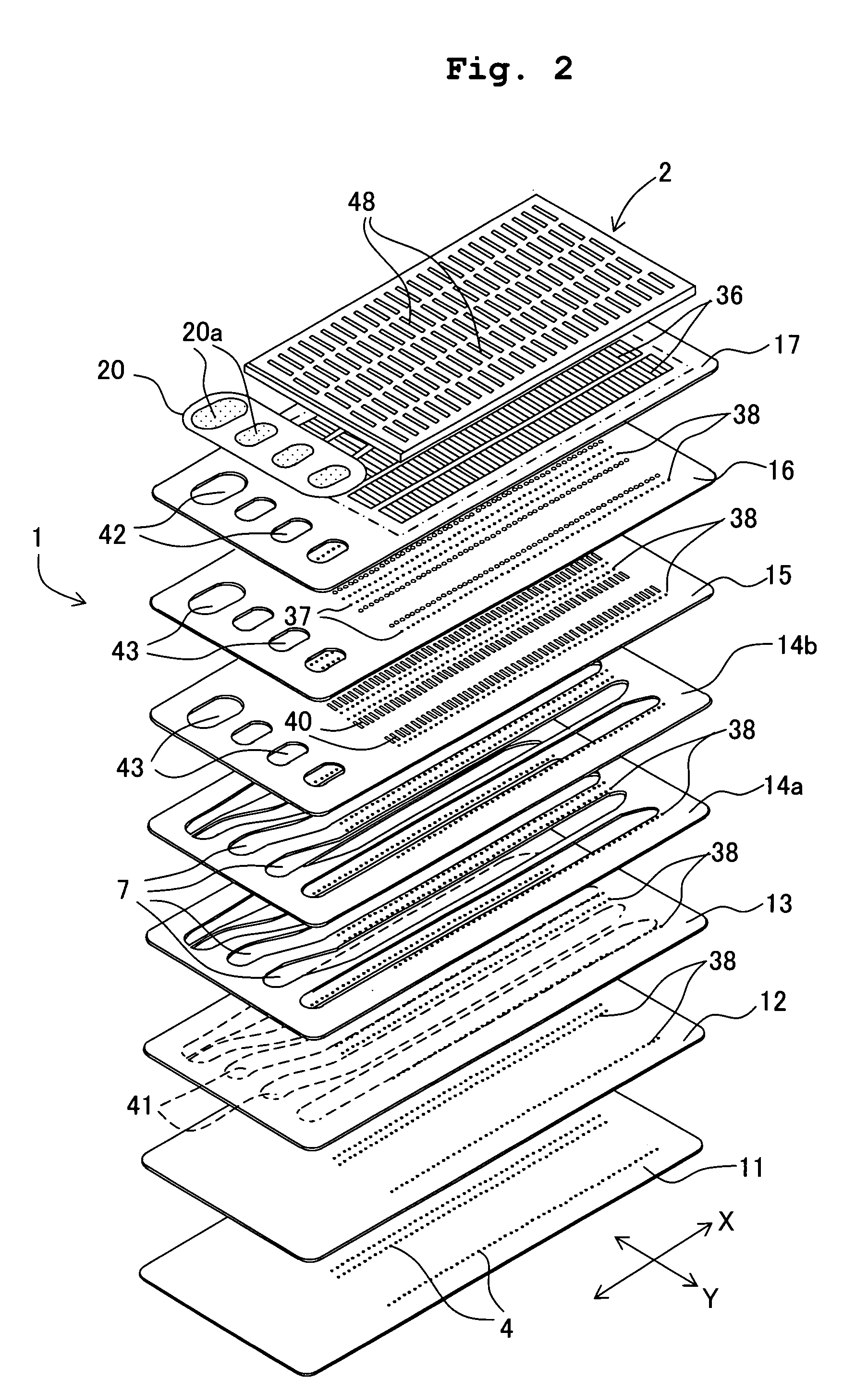

Inkjet recording apparatus

When a non-aqueous ink having a high density is used, a physical quantity defined as “density / viscosity” is equal to or more than a reference value, and therefore printing on a recording sheet is performed using a drive signal with a waveform for suppressing a residual vibration of the ink. Likewise, as to an ink having a low density, when the viscosity of the ink is low, the physical quantity is equal to or more than the reference value, and therefore printing on a recording sheet is performed using the drive signal with a waveform for suppressing a residual vibration of the ink. On the contrary, when the physical quantity is less than the reference value, printing on a recording sheet is performed using the drive signal with a normal waveform.

Owner:RISO KAGAKU CORP

Varifocal lens and liquid filling method for manufacturing same

InactiveUS20110222163A1Suppress residual vibrationHigh-speed responseSolid materialLiquid materialBiomedical engineeringFocal length

A varifocal lens which uses an interface between a first fluid and a second fluid that are mutually immiscible, as a light refracting surface, includes: a sealed vessel in which a first chamber into which the first fluid is filled is connected via an opening to a second chamber into which the second fluid is filled; and an elastic deformation section which is provided in elastically deformable fashion in a portion of a partition wall that divides the first chamber and the second chamber in the sealed vessel and which deforms in contact with both the first fluid filled into the first chamber and the second fluid filled into the second chamber, wherein: a lens section having the interface is formed in the opening, and a focal length of the lens section is changed by causing the interface to deform through altering volumes of the first chamber and the second chamber in mutually opposite directions by deformation of the elastic deformation section.

Owner:FUJIFILM CORP

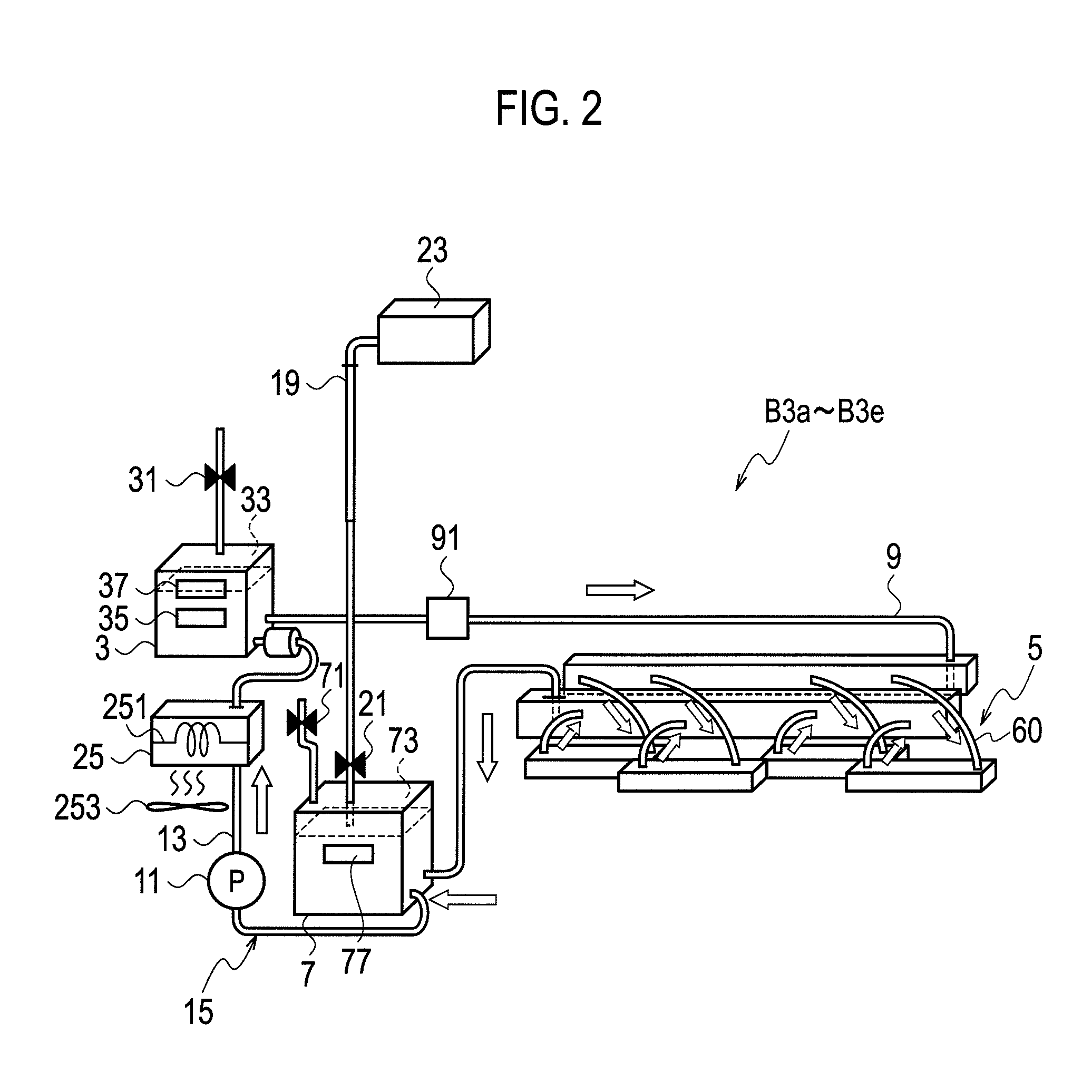

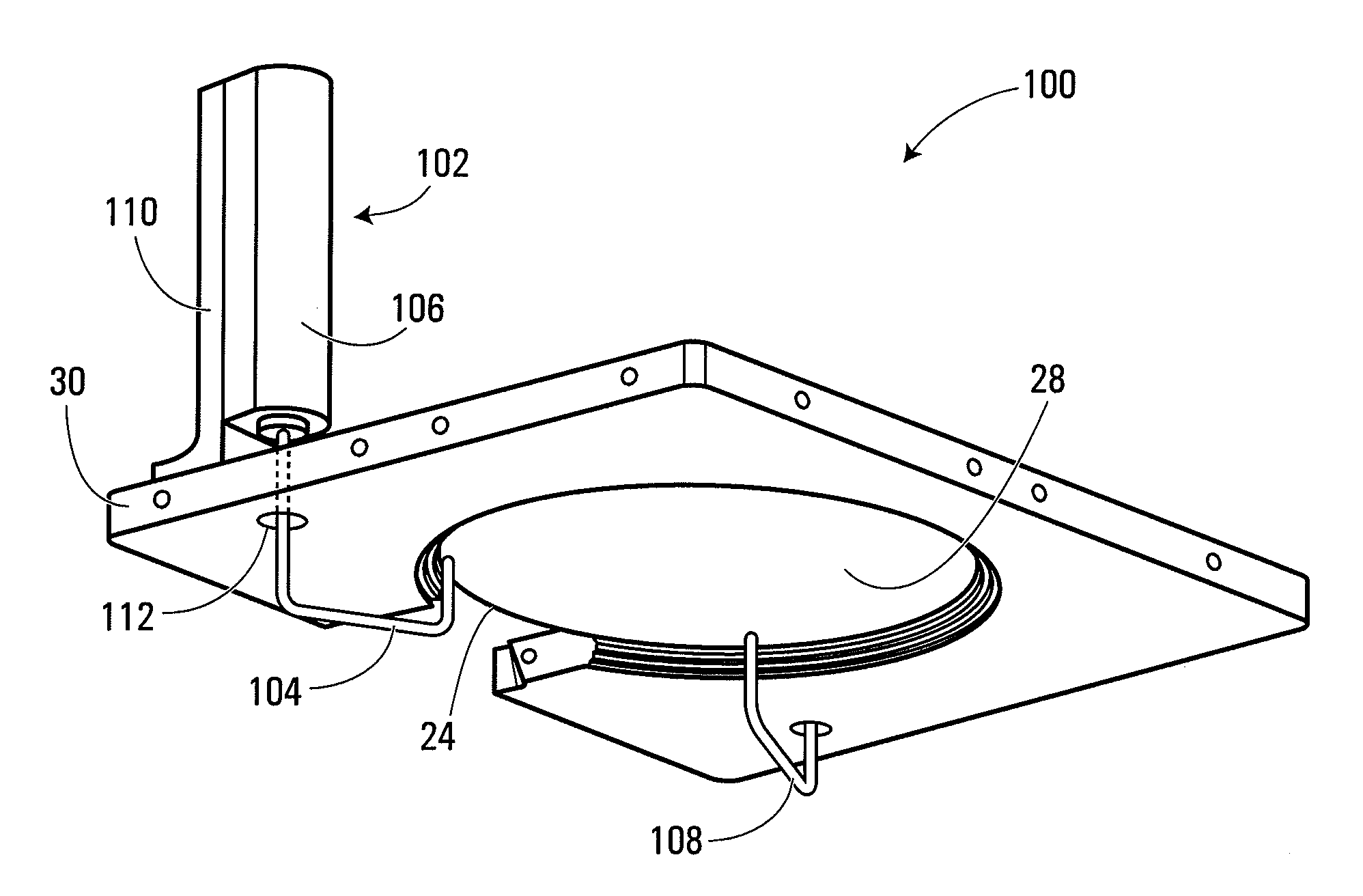

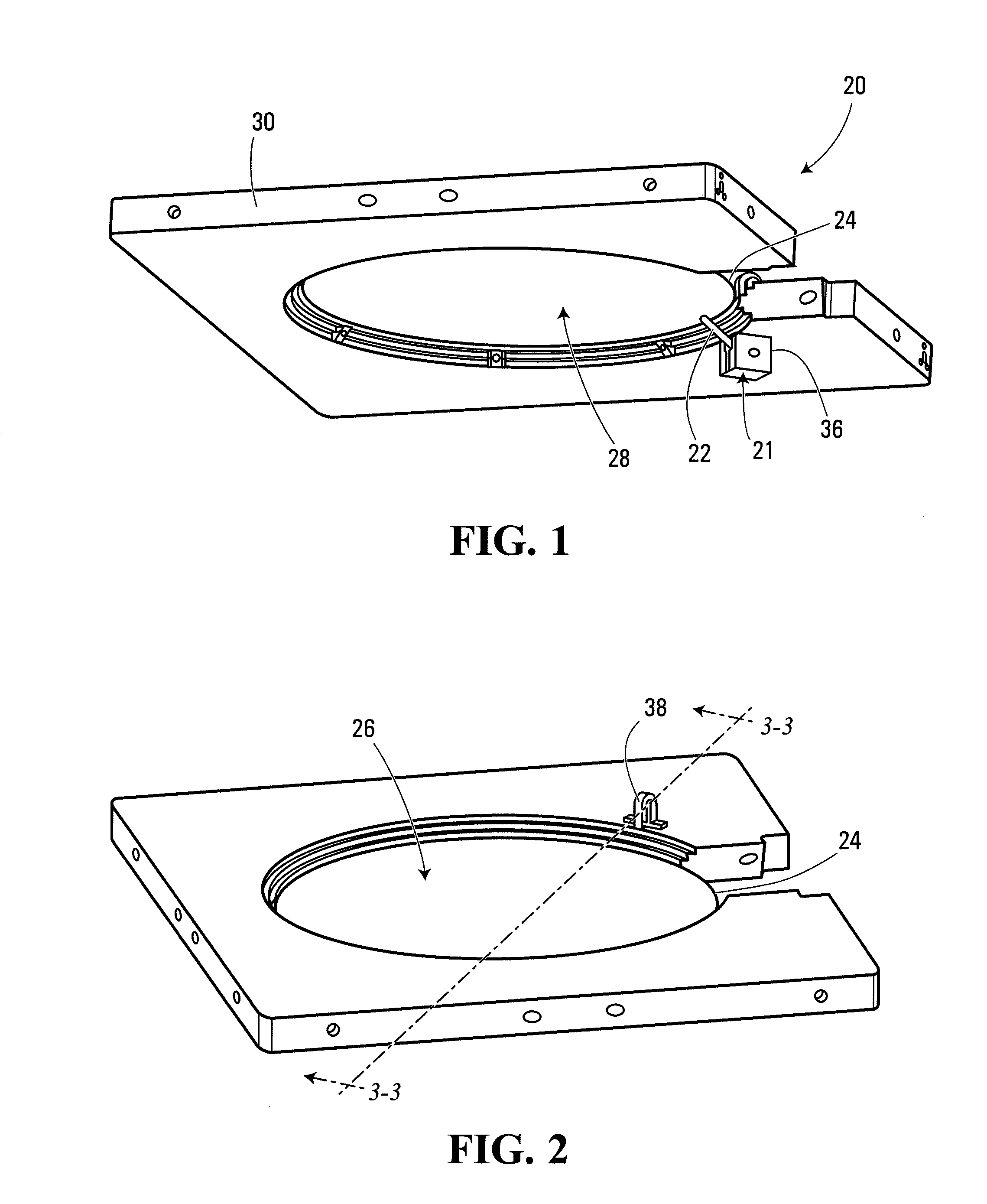

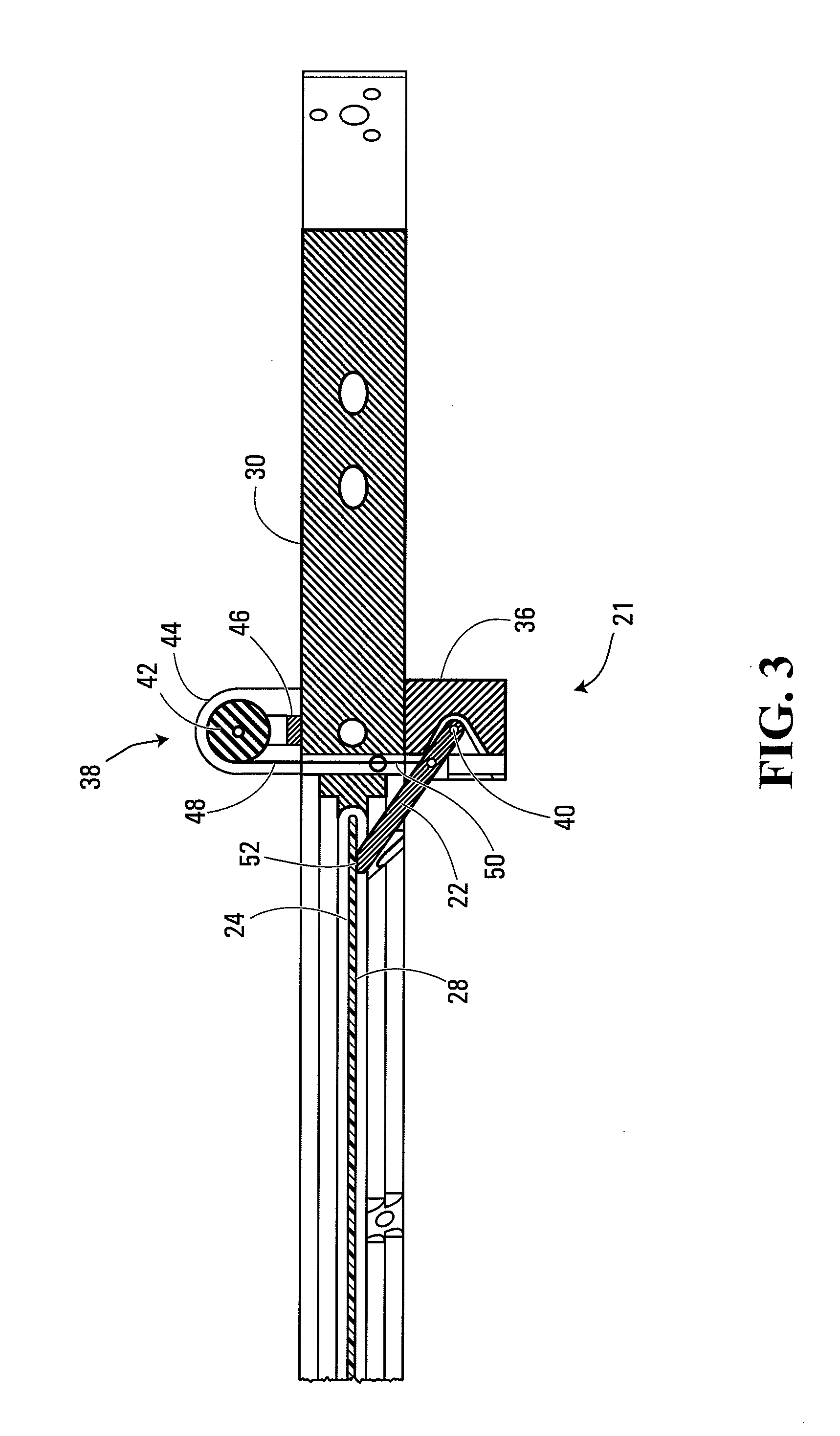

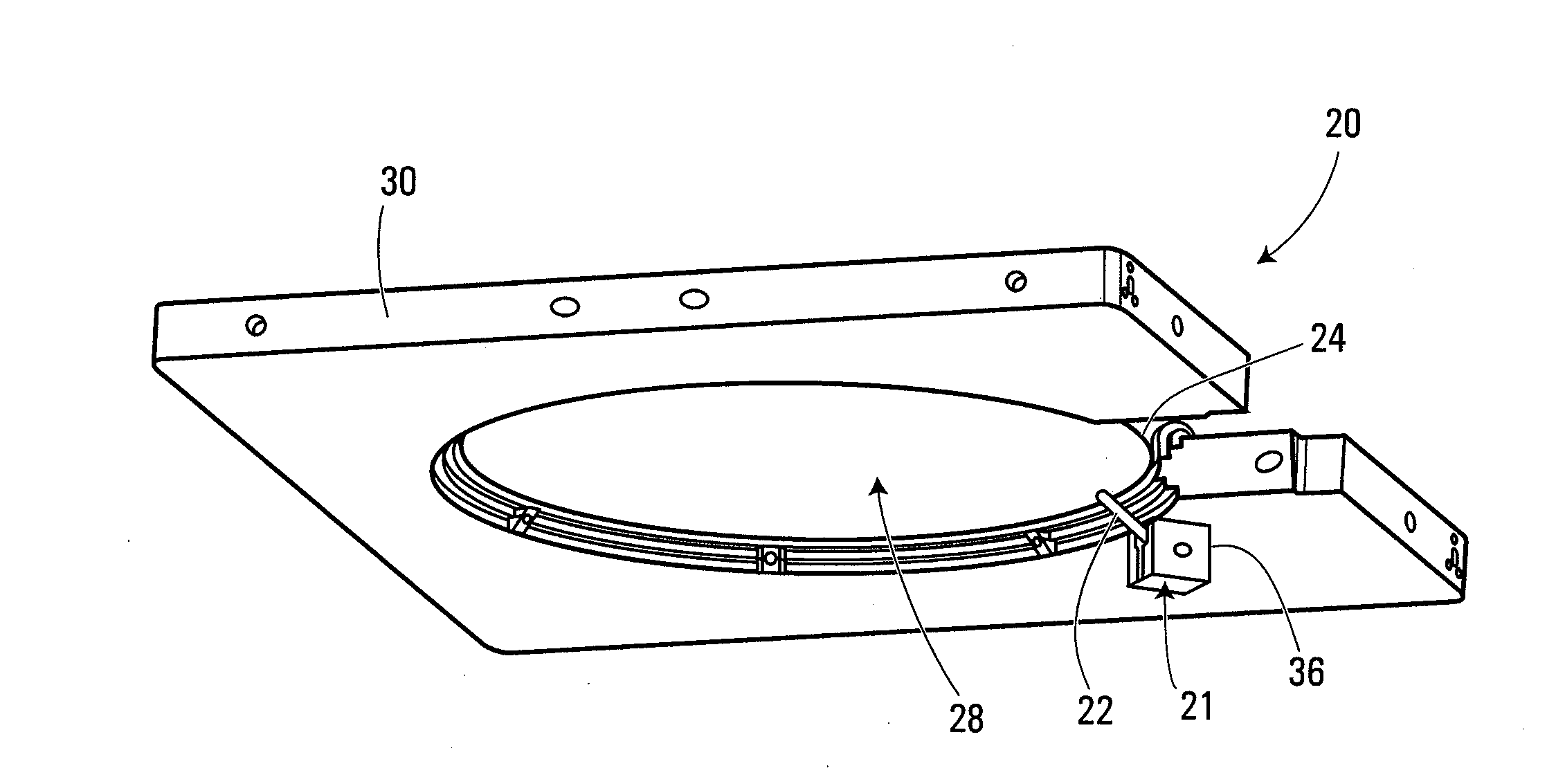

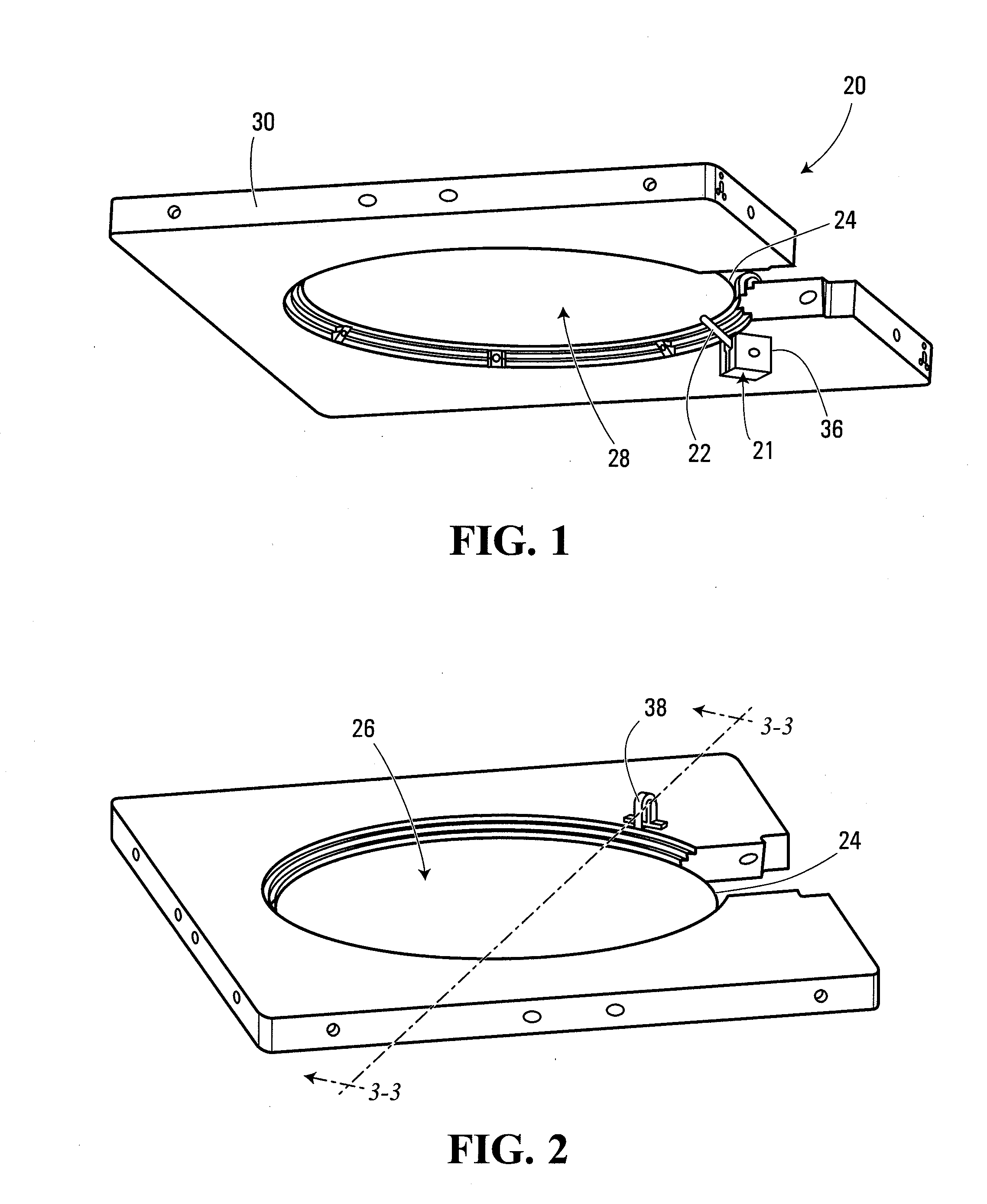

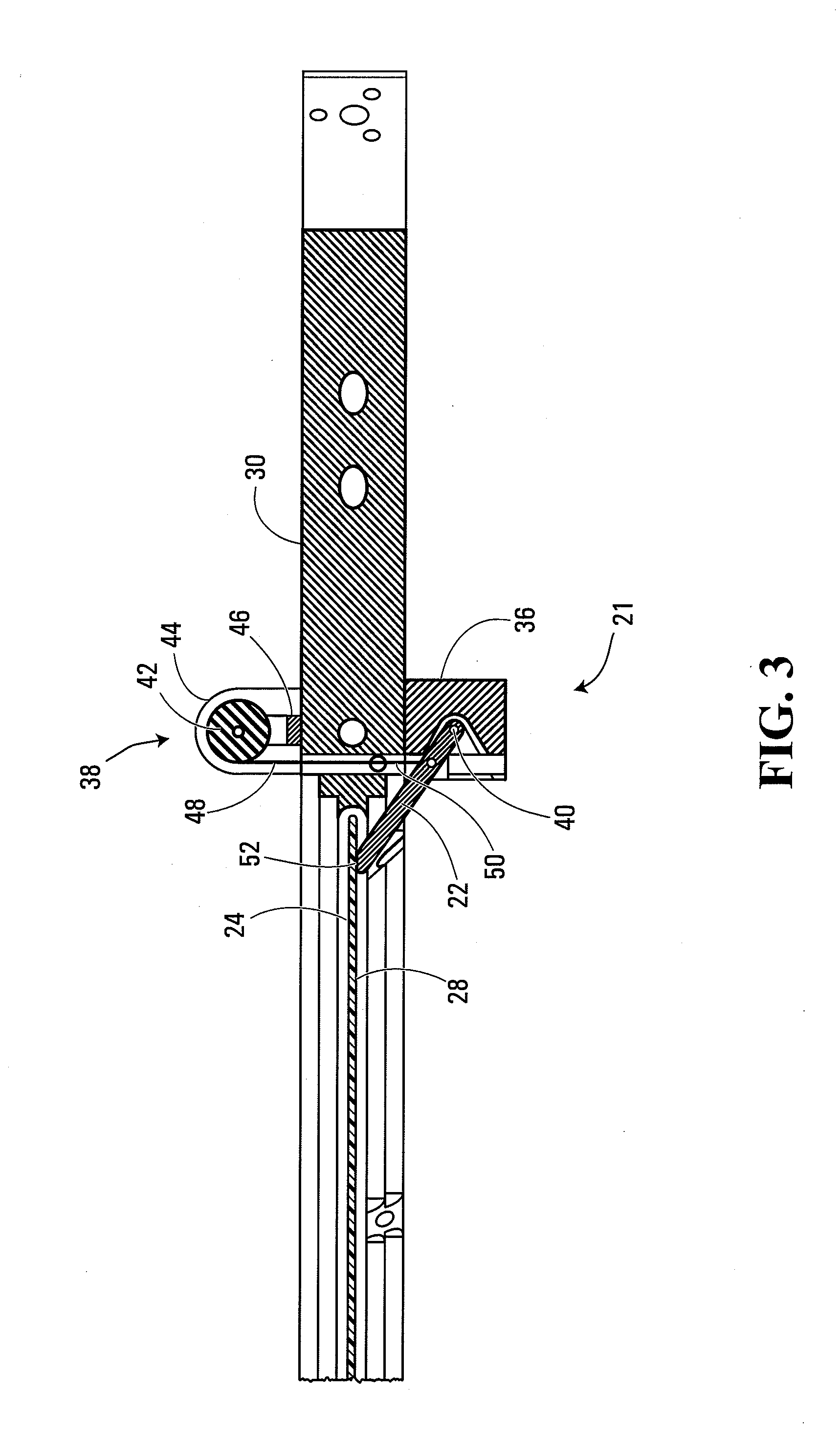

Methods and systems for supporting a workpiece and for heat-treating the workpiece

An apparatus for supporting a semiconductor workpiece includes a heating system configured to cause thermally-induced motion of the semiconductor workpiece by heating a surface of the workpiece relative to a bulk of the workpiece. The thermally-induced motion includes vertical motion of an outer edge region of the workpiece and a center of the workpiece relative to each other. The apparatus further includes a support system configured to allow the thermally-induced motion including the vertical motion of the outer edge region of the workpiece and the center of the workpiece relative to each other while supporting the workpiece.

Owner:MATTSON TECHNOLOGY +1

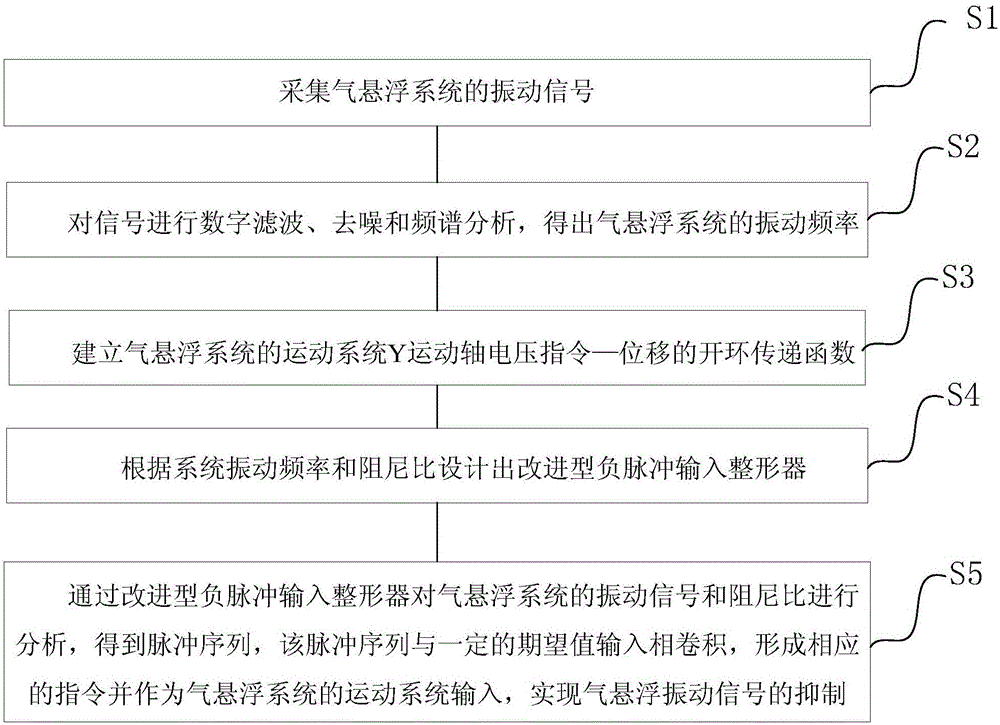

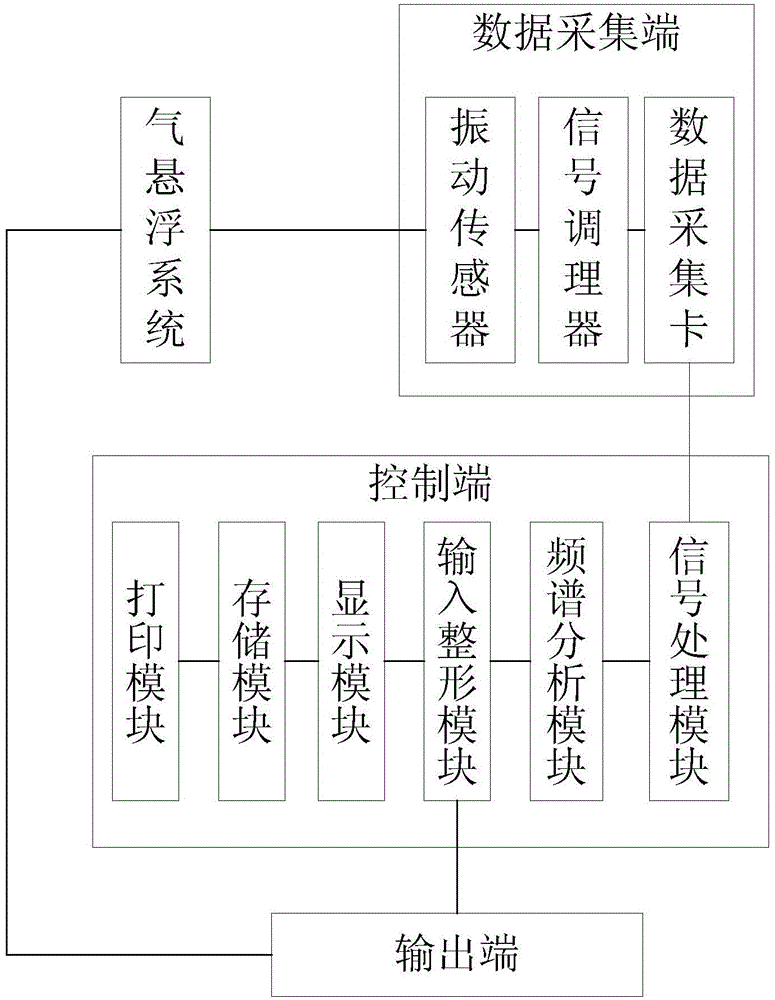

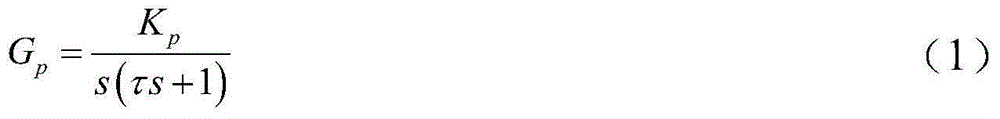

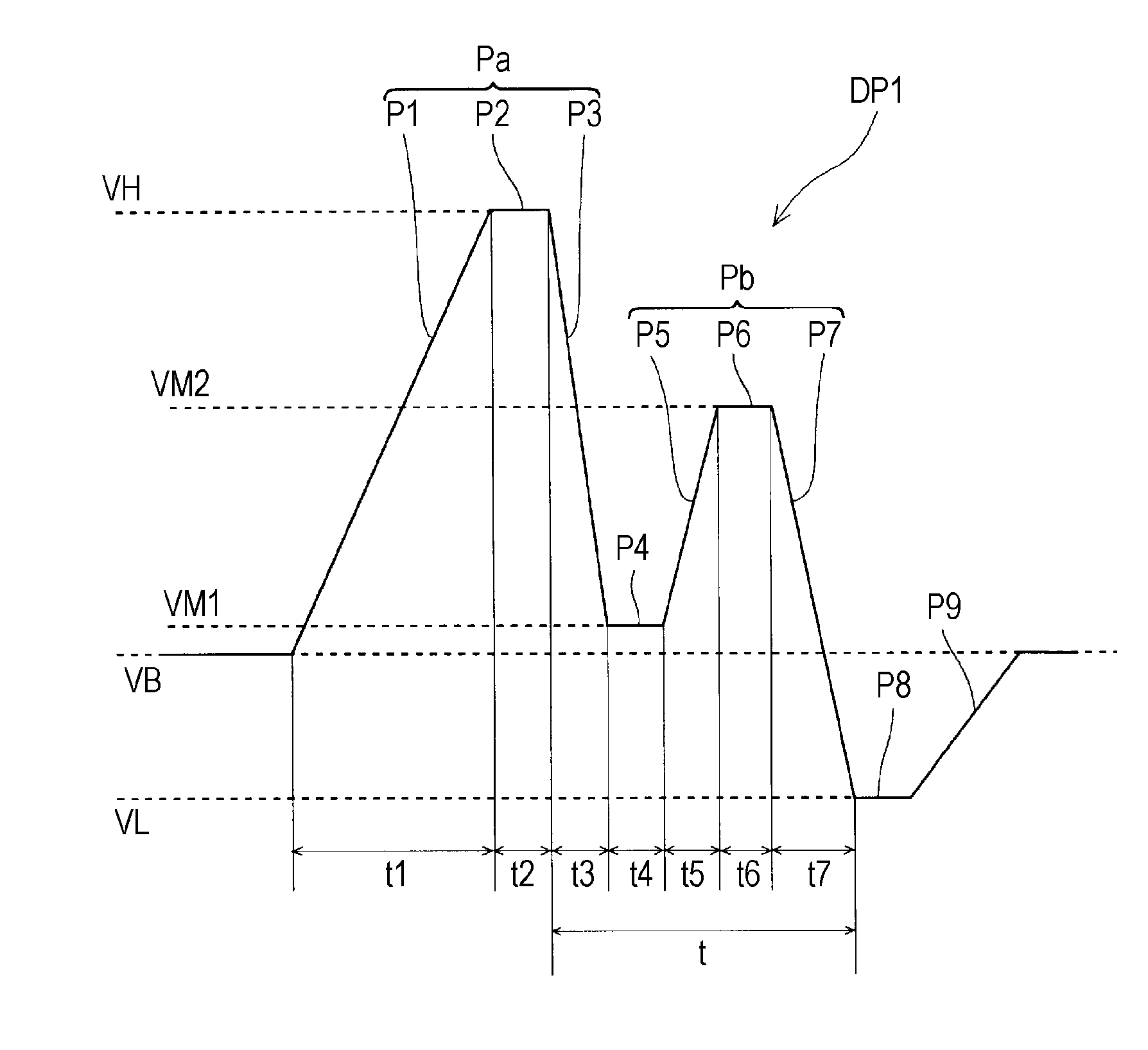

Air-suspending vibration signal inhibition-based method and system

ActiveCN105003537AAchieve inhibitionSuppress residual vibrationBearing assemblyBearingsResidual vibrationDelayed time

The invention relates to an air-suspending vibration signal inhibition-based method and system, a vibration signal of an air-suspending system and damping rate are analyzed by inputting designed improved negative pulse into a reshaper, a pulse sequence is obtained, the pulse sequence and a certain value of expectation are input to phase convolution to obtain a corresponding command and serve as motion system input of the air-suspending system, and inhibition of an air-suspending vibration signal is realized; the method has the advantages of improving rise time of the system and reducing the delay of motion response time of the system besides the characteristic of effectively inhibiting residual vibration of the air-suspending motion system, the improved negative pulse is input to the reshaper to obtain shorter delay time, and pulse number in the pulse sequence can be flexibly selected.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

Liquid ejecting apparatus and method for controlling liquid ejecting apparatus

ActiveUS8096632B2Stable and fastImprove discharge rateOther printing apparatusSpray nozzleEngineering

A liquid ejecting apparatus includes a liquid ejecting head with a pressure chamber communicating with a nozzle opening and a pressure generator capable of causing a pressure fluctuation to liquid in the pressure chamber. The liquid ejecting head discharges liquid droplets by operating the pressure generator. The drive signal generator generates a drive signal including a drive pulse which includes a first expanding element that expands the pressure chamber, a first discharging element that contracts the pressure chamber expanded by the first expanding element in order to discharge a liquid droplet, a second expanding element that expands the pressure chamber, and a second contracting element that contracts the pressure chamber. The time from the beginning of the first discharging element to the end of the second contracting element is set to ½ to 1 of the natural vibration period of the liquid in the pressure chamber.

Owner:SEIKO EPSON CORP

Liquid ejecting apparatus and method of controlling liquid ejecting apparatus

InactiveUS7871141B2Smooth dischargeSuppress residual vibrationOther printing apparatusResidual vibrationEngineering

Owner:SEIKO EPSON CORP

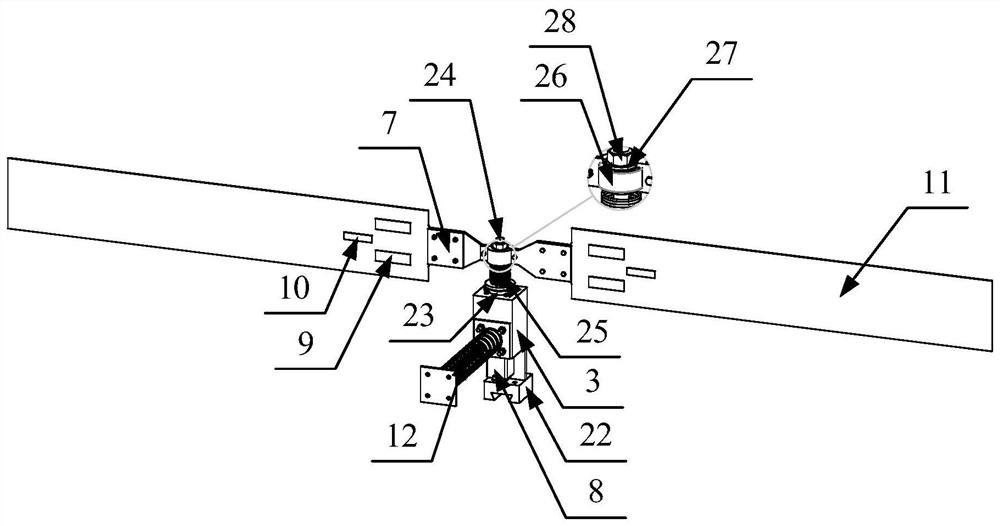

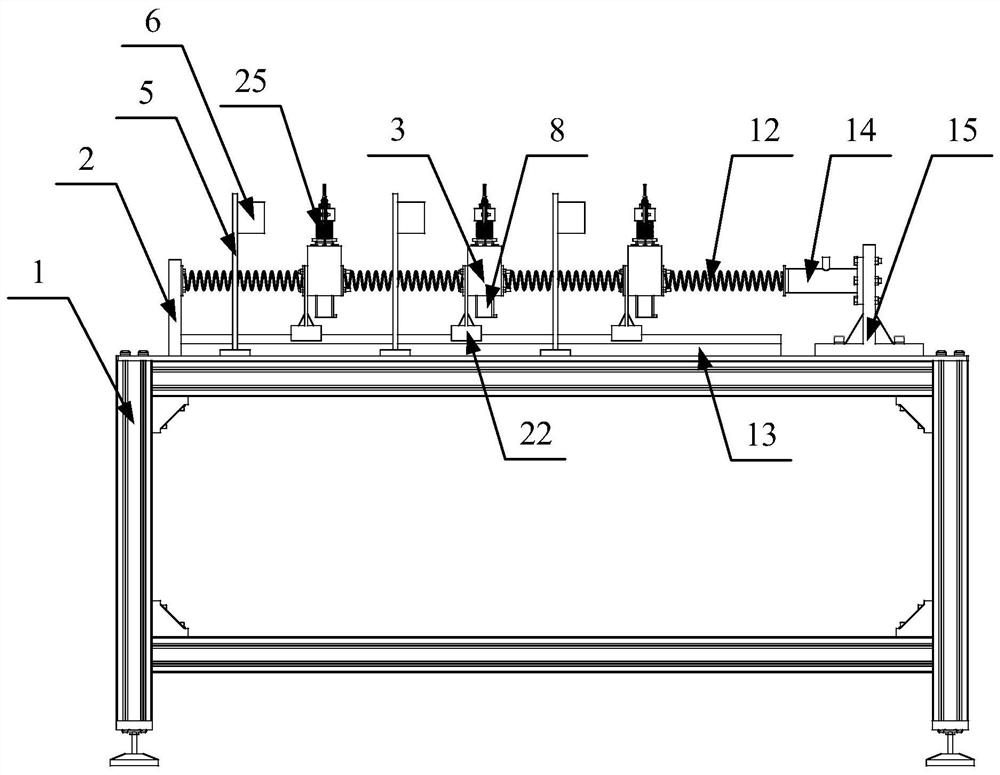

Flexible mechanical arm control device and method based on reciprocating vibration chain body elastic base

PendingCN111913507AReduce vibrationSuppress residual vibrationMechanical oscillations controlSubsonic/sonic/ultrasonic wave measurementVibration controlReciprocating motion

The invention discloses a flexible mechanical arm control device and method based on a reciprocating vibration chain body elastic base, and the device comprises a flexible arm body part, a vibration detection part, and a vibration control part; the flexible arm body part comprises three flexible single bodies, and the three flexible single bodies are sequentially connected through springs, and aredisposed on a linear guide rail. Under the action of a piston type vibration exciter, the three flexible single bodies reciprocate, vibration of each flexible beam is detected through a laser displacement sensor and a piezoelectric ceramic sensor, and a piezoelectric ceramic driver and a servo motor are used as actuators for vibration suppression. The device can be used for researching the influence of factors such as linear guide rail friction and spring rigidity on the coupling vibration of a flexible mechanical arm system of a chain body elastic base and a corresponding vibration control method.

Owner:SOUTH CHINA UNIV OF TECH

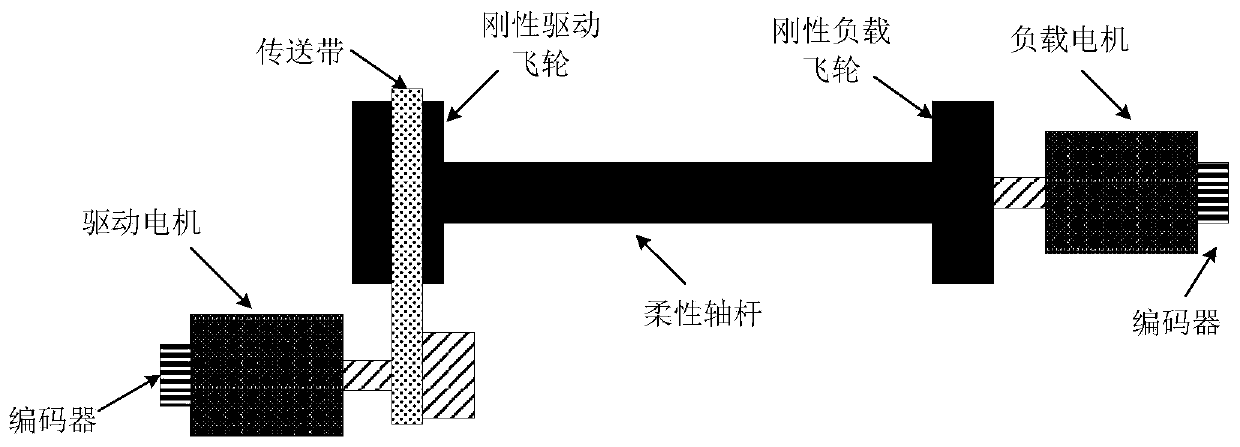

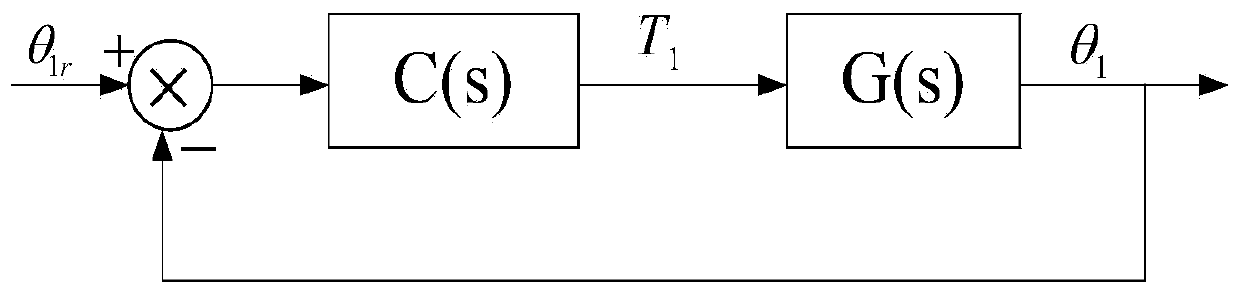

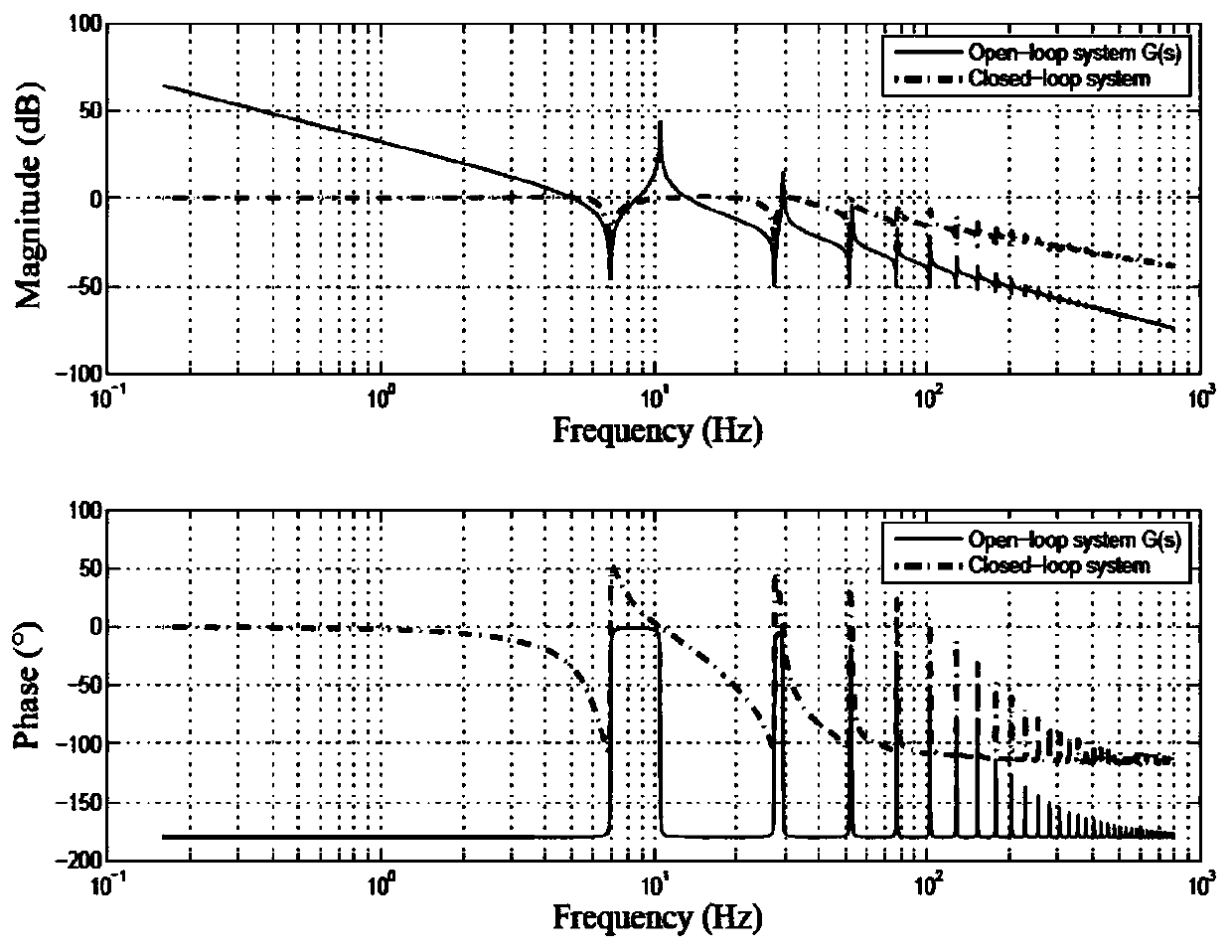

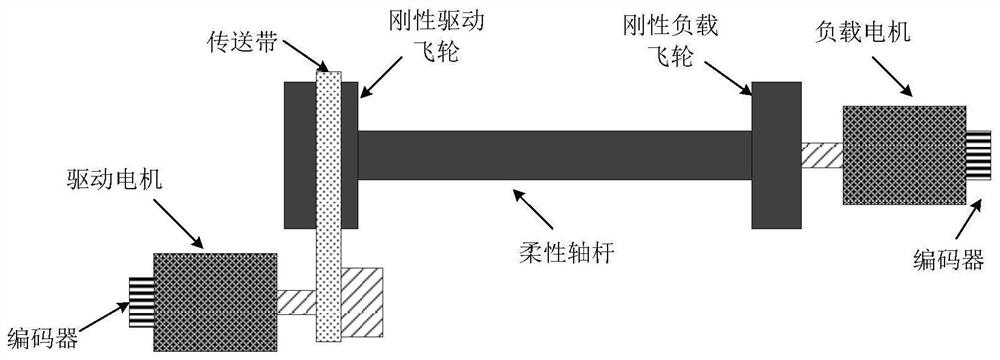

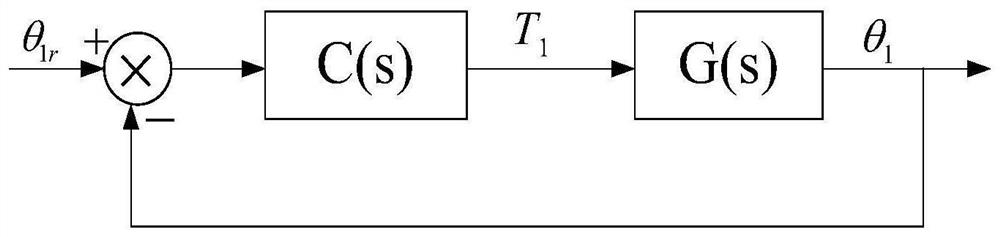

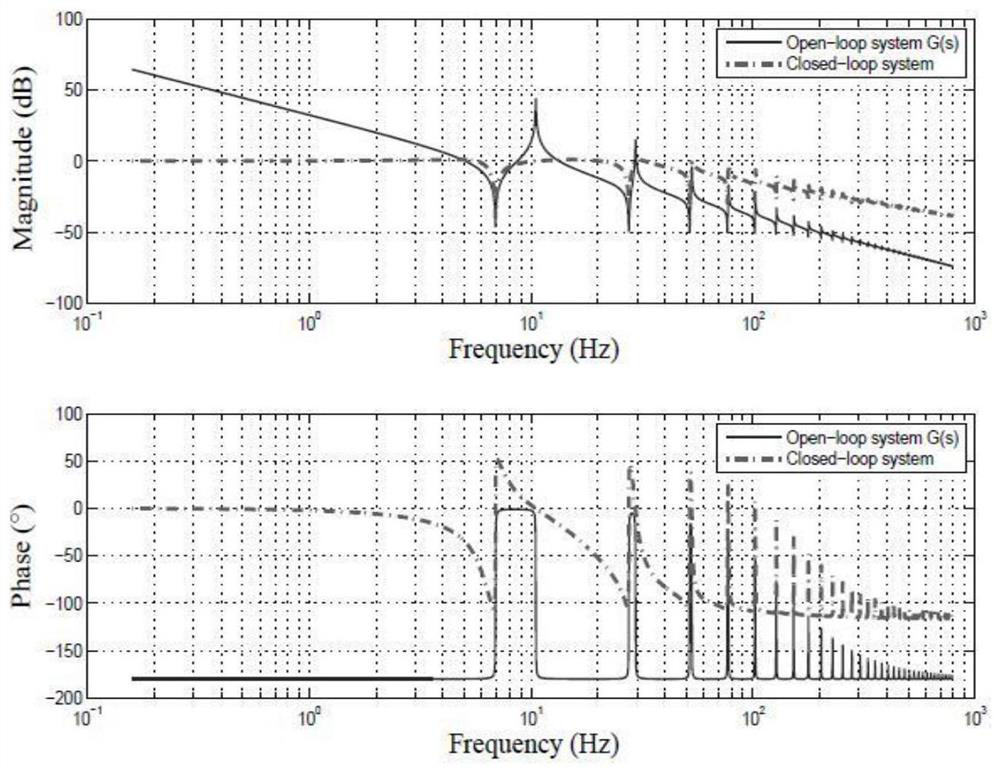

Vibration control method for rigid-flexible coupling electromechanical servo system

ActiveCN110187723AImprove controlSuppress residual vibrationMechanical oscillations controlControllers with particular characteristicsFractional-order controlResidual vibration

The invention discloses a vibration control method for a rigid-flexible coupling electromechanical servo system. The vibration control method comprises the steps of separately collecting encoder dataon a drive motor and a load motor, acquiring torsion angles of two ends of a flexible shaft rod, computing the torsion angle of a micro unit located at any position of the flexible shaft rod, and computing a frequency domain characteristic equation according to the length, polar moment of inertia, elasticity modulus and rotational inertia of the flexible shaft rod; by using the frequency domain characteristic equation, computing a coupling torque between the flexible shaft rod and a rigid driving flywheel; building a rigid driving flywheel balance equation; putting the coupling torque into thebalance equation to acquire a frictional order transfer function model of the system; and according to the frictional order transfer function model, building a fractional order controller, and controlling the vibration of the system by using the controller. According to the method provided by the invention, the dynamic behaviors of the viscous-elastic material is accurately described via the frictional order model, and the residual vibration of the system is effectively suppressed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

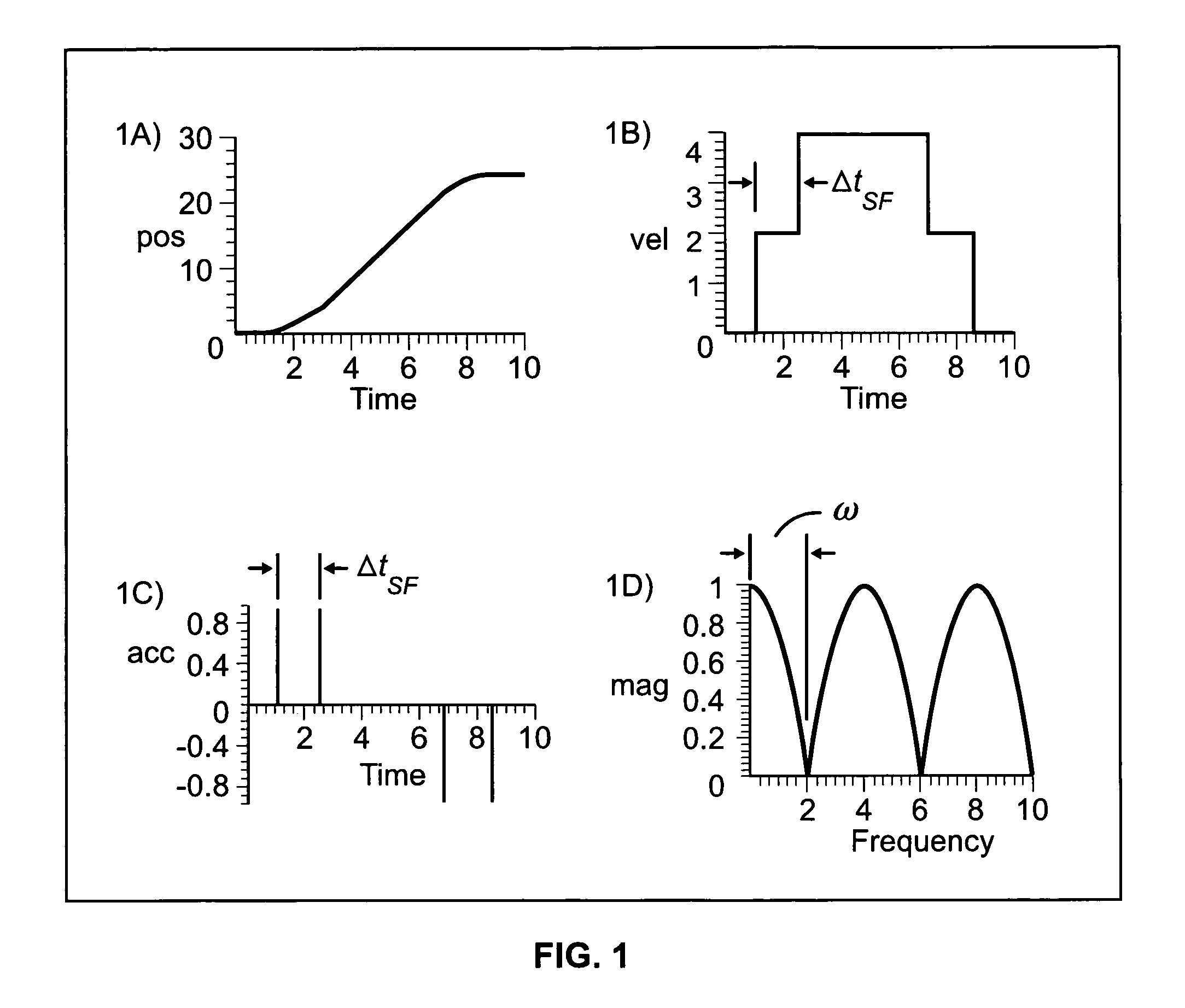

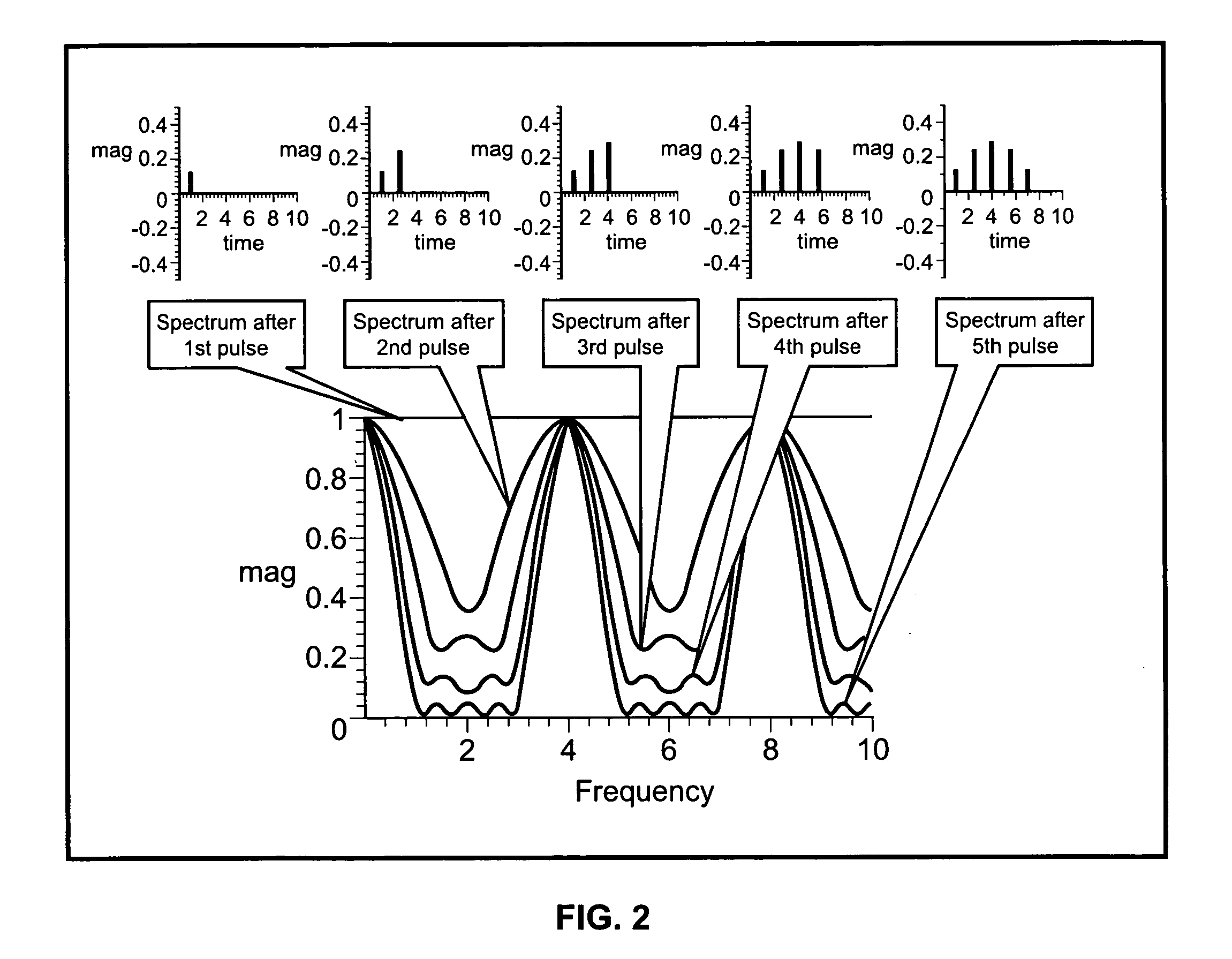

Wideband suppression of motion-induced vibration

InactiveUS20080320068A1Same computational efficiencySuppress residual vibrationDigital technique networkNumerical controlDigital signal processingRate limiting

The present invention is a new method to create motions based on the use of rate limited profiles convolved with FIR kernel filters, termed herein as Rate limited Boxcar Aliased IFIR (RBAI) motions, or profiles. The present invention demonstrates a simpler generalized view of the creation of pulse-based profiles based on digital signal processing windowing techniques. The method turns windowing functions into an IFIR filter using boxcar functions for the interpolation. The IFIR filter smoothes the pulse-based profiles, allowing the resultant filter to be applied directly over a simple rate limited base profile. The resulting motion profiles suppress residual vibration over a much wider band of frequencies than previous methods.

Owner:STC UNM

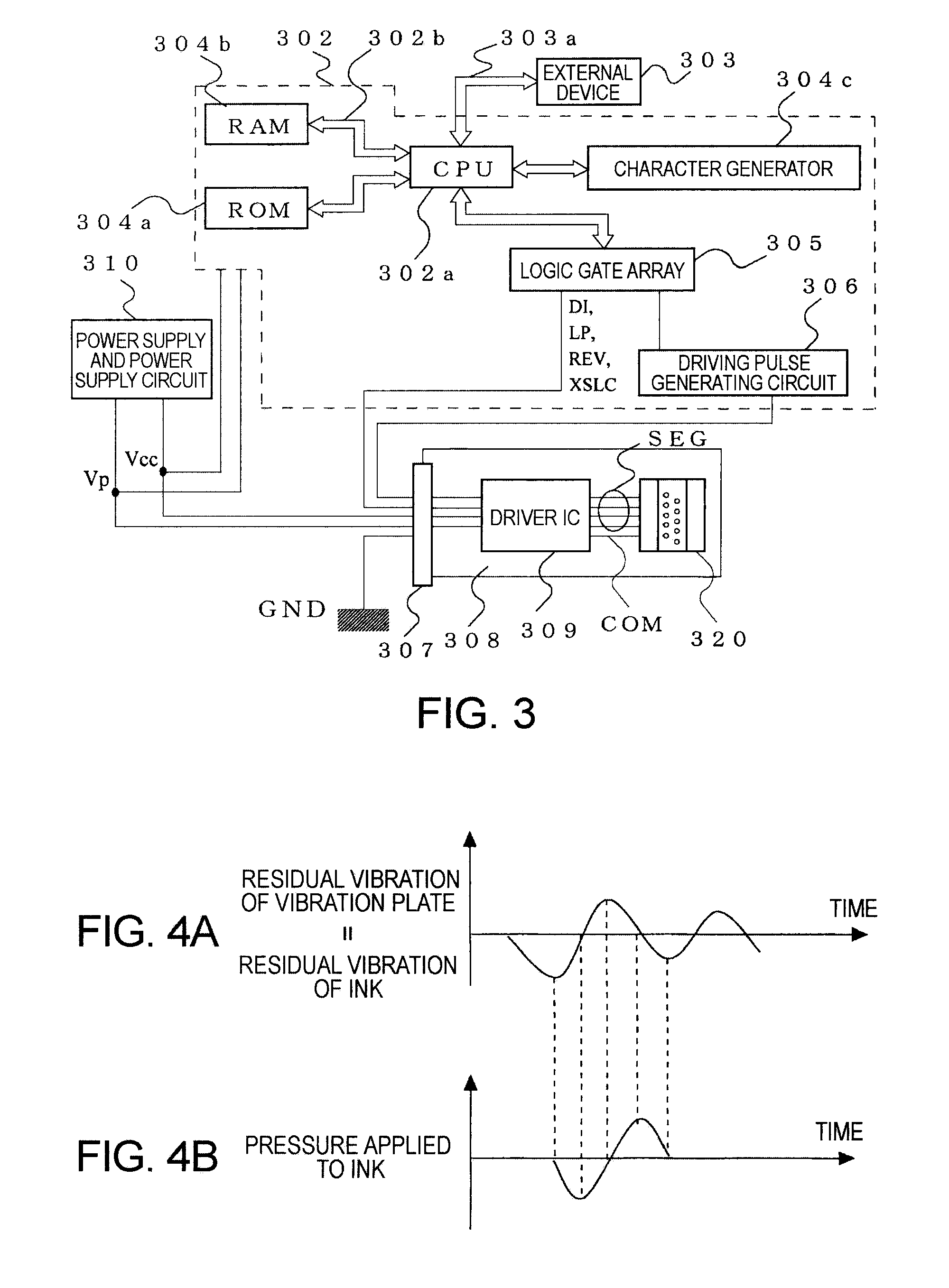

Ink-droplet ejecting apparatus

ActiveUS20070182774A1Increase drive frequencyShort pulse widthOther printing apparatusResidual vibrationPhysics

A driving pulse signal for forming one dot includes a first, a second, and a third main pulses applied intermittently with an intervals to eject an ink droplet, and a stabilizing pulse which is inserted between the main pulses, and which suppresses a residual vibration of an ink in a pressure chamber, generated by a main pulse applied previously. The third main pulse suppresses the residual vibration of the ink generated by the second main pulse, and also a pulse width of the third pulse is adjusted such that there is no residual vibration remained, due to application of the last main pulse. Consequently, it is possible to suppress effectively the residual vibration of the ink by the less number of the stabilizing pulses compared to the number of main pulses. As a result, an overall pulse width becomes short, and it is possible to increase the recording speed.

Owner:BROTHER KOGYO KK

Method for driving droplet ejecting head and droplet ejecting device

InactiveUS20100110126A1Suppress residual vibrationIncrease drive frequencyOther printing apparatusResidual vibrationEngineering

A method for driving a droplet ejecting head that includes a liquid pressure chamber communicating with a nozzle hole, and a pressure application unit applying pressure on liquid stored in the liquid pressure chamber for ejecting a droplet from the nozzle hole, includes applying on the liquid stored in the liquid pressure chamber pressure having a waveform whose phase is delayed by 90 degrees from a waveform of a residual vibration of the liquid by the pressure application unit after an ejection of the droplet from the nozzle hole.

Owner:SEIKO EPSON CORP

Ink-droplet jetting apparatus

ActiveUS7600838B2Jet stabilityIncrease speedOther printing apparatusEngineeringElectrical and Electronics engineering

For forming one dot by jetting a plurality of ink droplets, a drive pulse signal in an ink-droplet jetting apparatus includes a first main pulse for jetting, a first regulating signal which is inserted at a first interval from the first main pulse, and a second regulating pulse which is inserted at a second interval from the first main pulse. The first interval is almost the same as or more than the second interval. Accordingly, the ink-droplet jetting apparatus is capable of jetting the ink droplets stably, and printing at a high speed.

Owner:BROTHER KOGYO KK

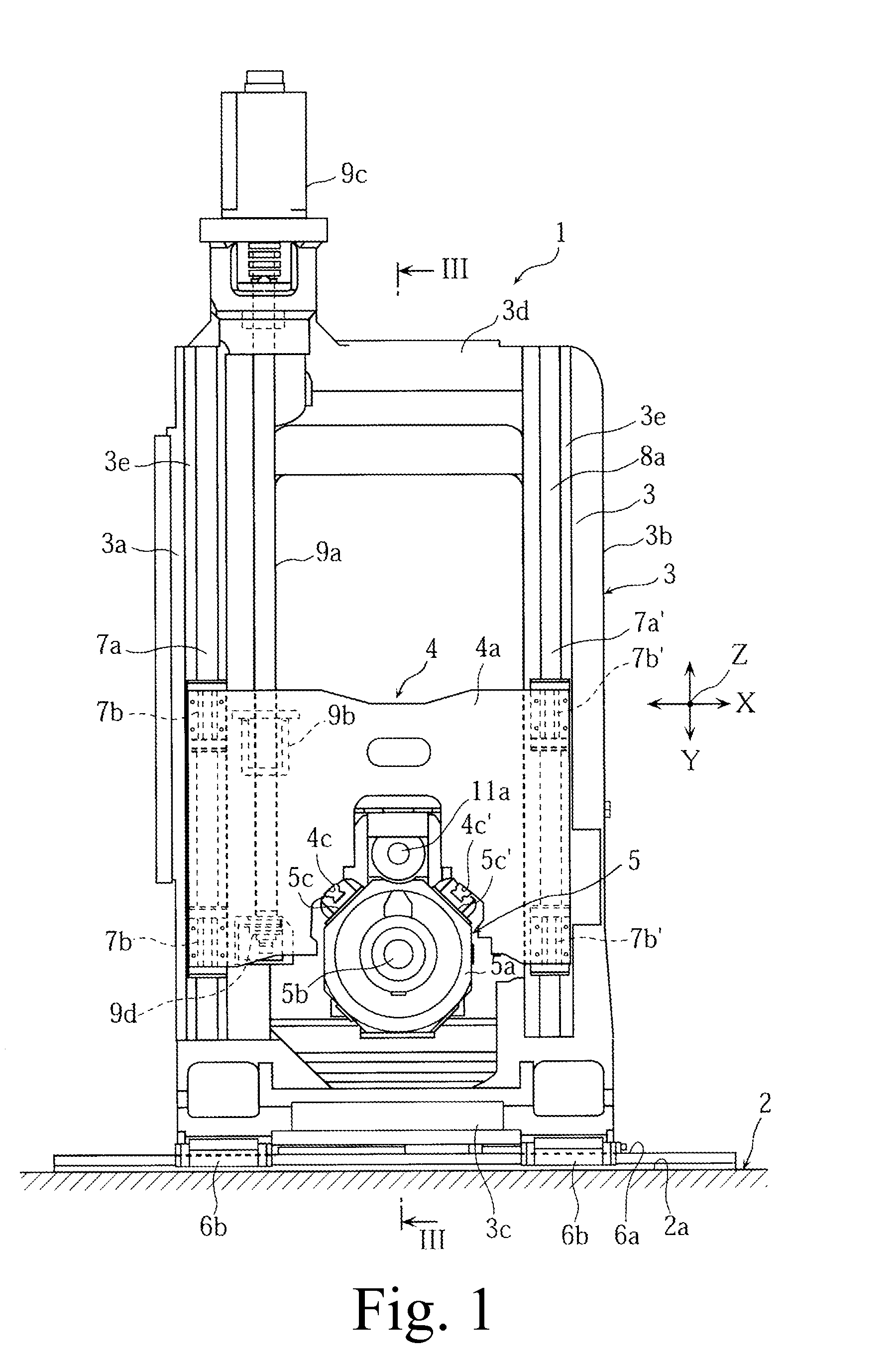

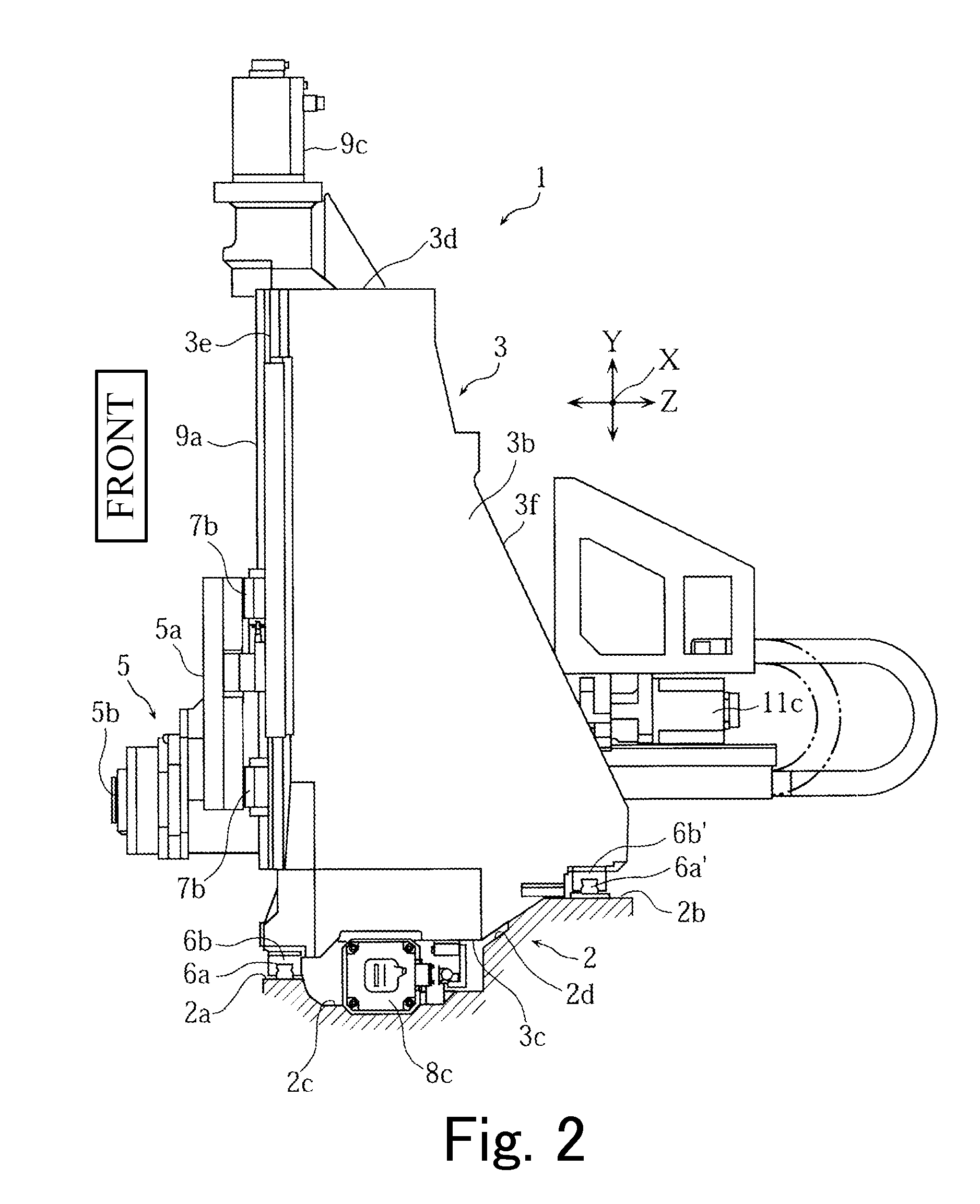

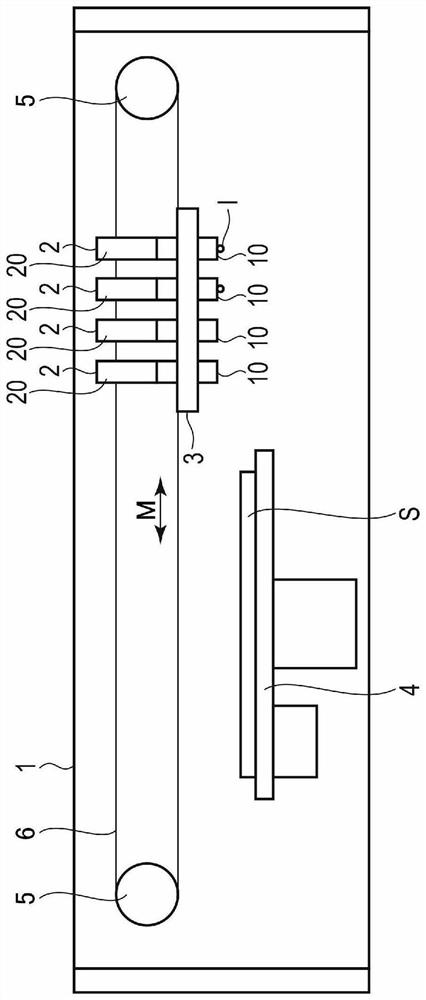

Moving body guide mechanism of machine tool

ActiveUS20150239083A1Suppress residual vibrationAcceleration can be increasedMilling machinesFeeding apparatusEngineeringMachine tool

A moving body guide mechanism of a machine tool includes at least two bar-shaped guide members, and sliders engaged with the two guide members, respectively, movably with respect to the guide members so that a moving body is guided along an axis parallel to a moving axis extending in a longitudinal direction of the guide members. Attaching surfaces of the two guide members or the sliders to the moving body are provided symmetrically across a plane including the axis parallel to the moving axis in such a manner that an angle formed by the attaching surfaces becomes smaller than 180°.

Owner:DMG MORI CO LTD

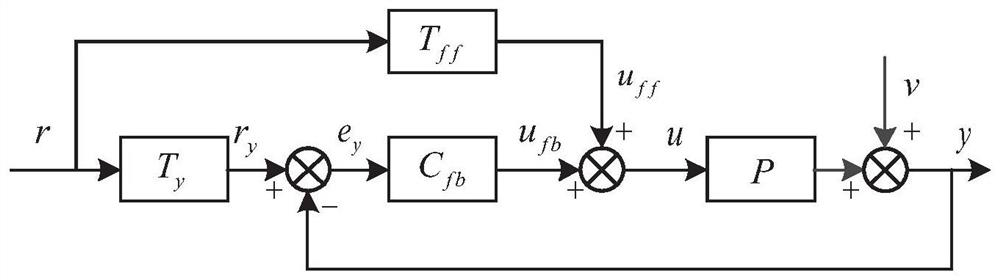

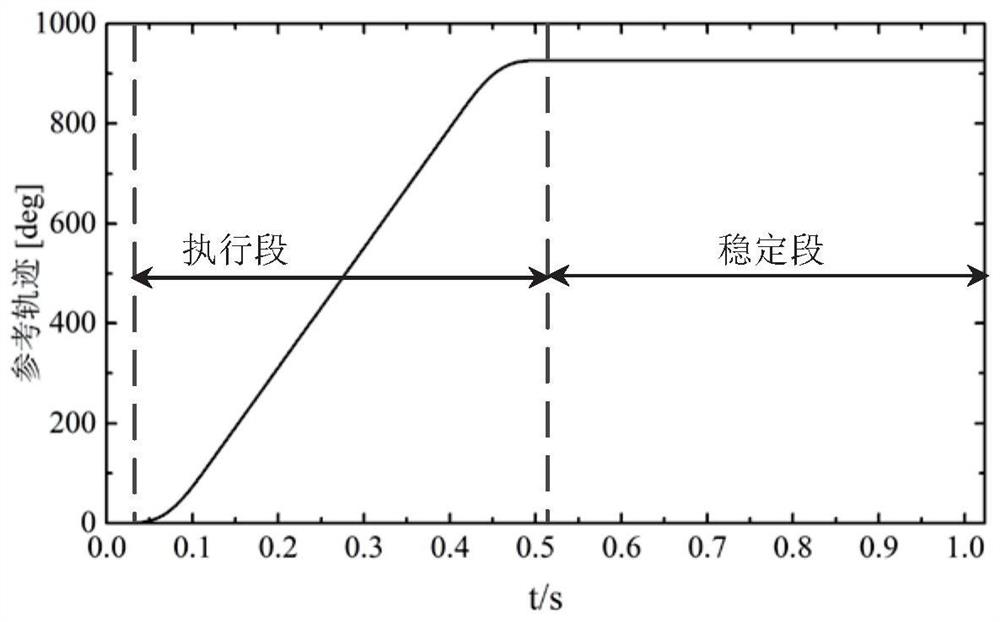

Servo system residual vibration suppression method based on parameterized feedforward

PendingCN112612211AReduce control difficultyMeet control requirementsAdaptive controlResidual vibrationControl engineering

The invention discloses a servo system residual vibration suppression method based on parameterized feedforward, and belongs to the technical field of mechanical equipment control. The invention discloses a servo system residual vibration suppression method based on parameterized feedforward, which comprises the following steps of: calculating a feedforward force through an input track and a parameterized feedforward controller by utilizing a primary function parameterized feedforward controller; introducing a performance objective function of a parameterized feed-forward control algorithm according to an optimal control theory to identify parameters of the input shaping filter and the feed-forward controller; analyzing the error of the parameterized feedforward control and the convergence of the identification parameters; and solving the optimal value of each parameter. Through continuous exploration and test, a parameterized feed-forward control algorithm is adopted, the control difficulty of the servo system can be effectively reduced, the calculated amount of a processor is reduced, the flexibility is high, the operation speed is high, the robustness is good, the control effect is good, and the control requirement of the servo system can be met.

Owner:ZHEJIANG SCI-TECH UNIV

Acceleration/deceleration control method and apparatus as well as program of acceleration/deceleration control method

ActiveUS7328120B2Simple procedureSafety of the manipulator can be securedProgramme-controlled manipulatorDigital computer detailsDrive motorEngineering

To provide an acceleration / deceleration control method, apparatus and the like for determining the acceleration / decelerations of motors according to, for example, the drive directions, acceleration and deceleration of the motors by a simple algorism. A gravity torque calculation unit 1A calculates gravity torque acting on a joint drive motors for operating a manipulator 100 as a machine having joints, and an acceleration / deceleration calculation unit 1D calculates an acceleration speed and / or a deceleration speed of the joint drive motor based on an acceleration / deceleration correction coefficient and a set basic acceleration / deceleration, wherein the acceleration / deceleration correction coefficient is calculated by an acceleration / deceleration correction coefficient calculation unit 1B based on the gravity compensation coefficient selected from a plurality of preset gravity compensation coefficients according to a drive condition affected by gravity and on the gravity torque.

Owner:SEIKO EPSON CORP

Control device for suppression of residual vibration of piezoelectric transducer

InactiveUS8513855B2Reduce residual vibrationSuppress residual vibrationPiezoelectric/electrostriction/magnetostriction machinesSound producing devicesCapacitanceResidual vibration

A control device for suppression of residual vibration of a piezoelectric transducer includes a capacitive energy storage component, and a switch unit. The control device is operable in a non-working mode, in which the switch unit provides voltage on the capacitive energy storage component to the piezoelectric transducer for reducing the residual vibration of the piezoelectric transducer. The capacitive energy storage component has a capacitance value that is sufficient for enabling the voltage on the capacitive energy storage component to substantially track voltage on the piezoelectric transducer under the non-working mode.

Owner:TUNG THIH ELECTRONICS

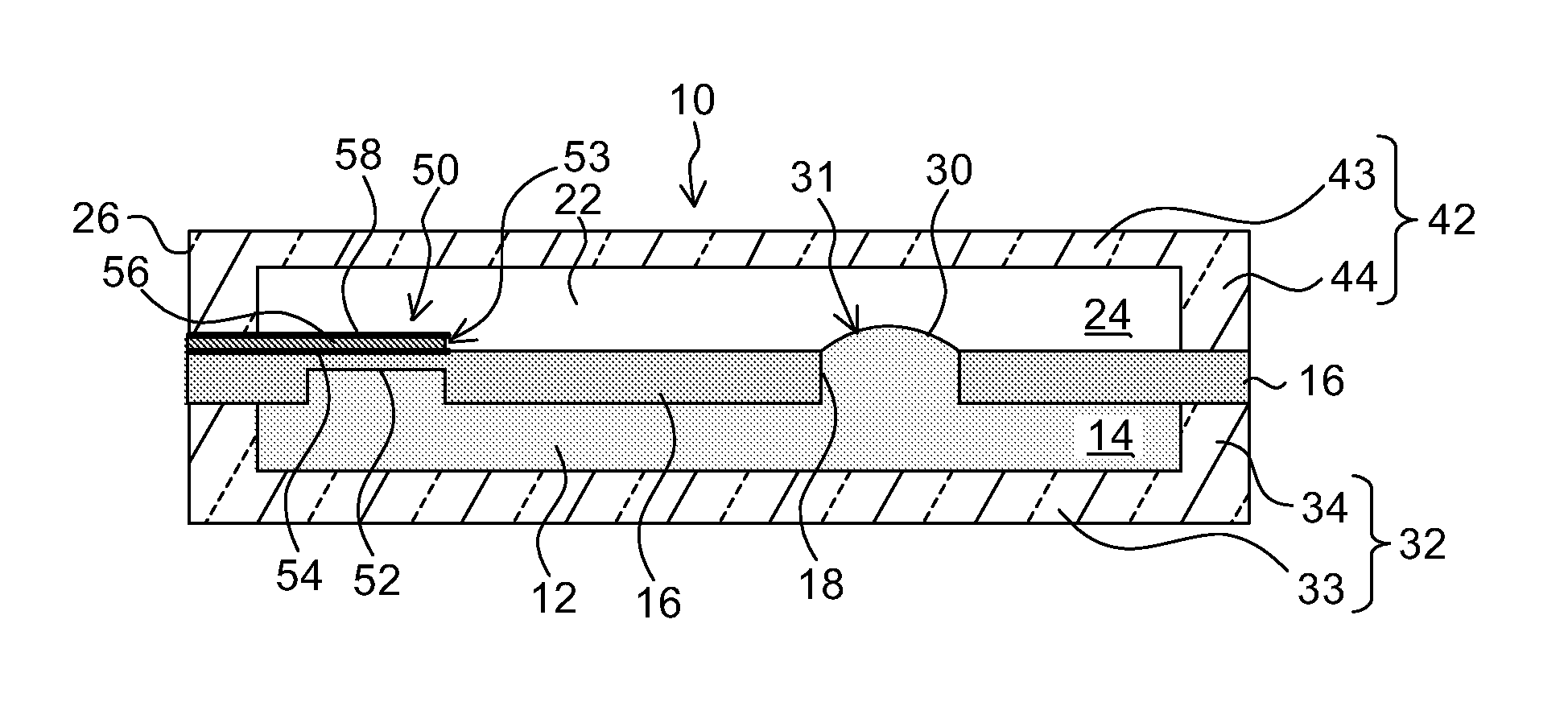

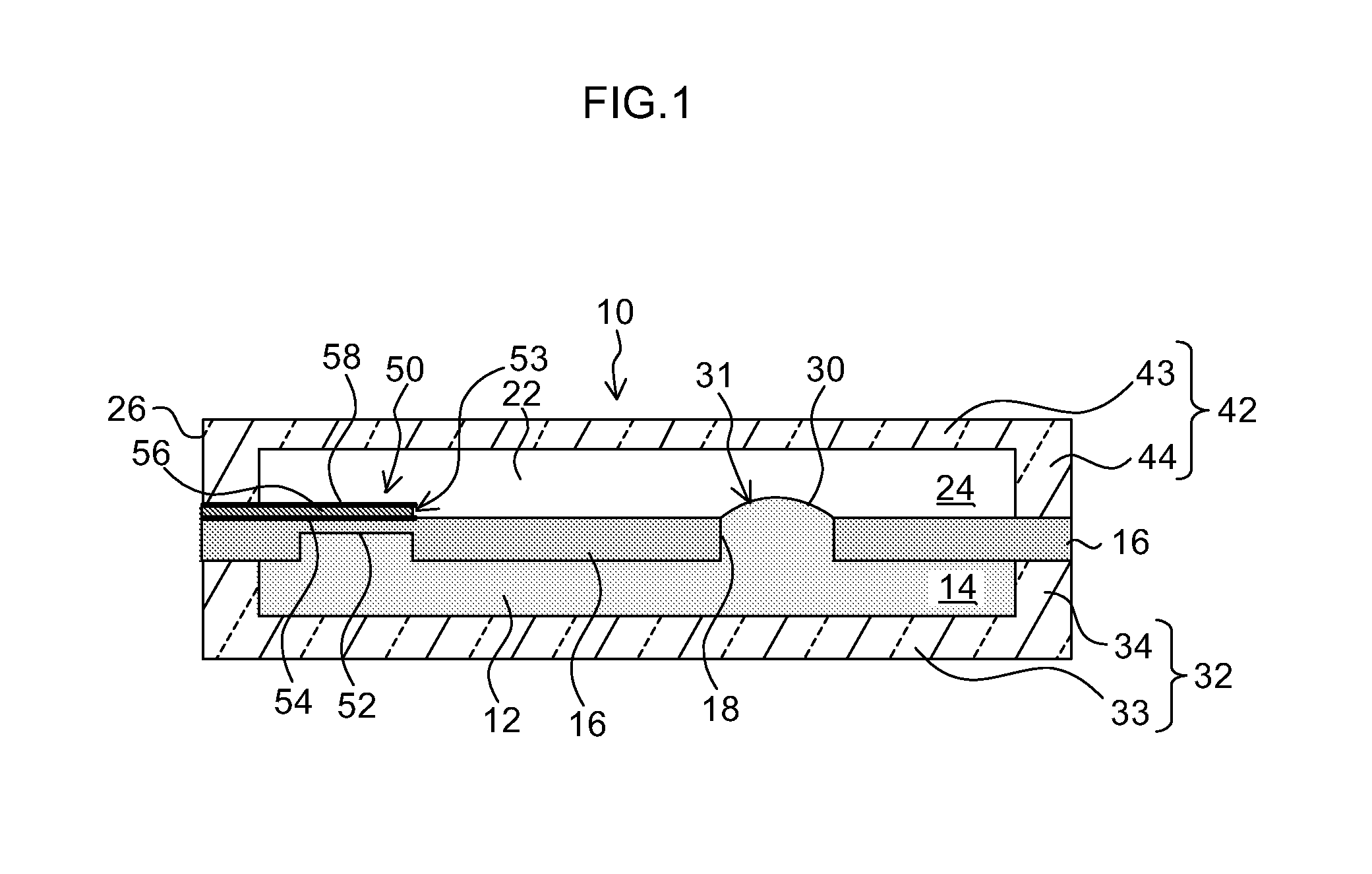

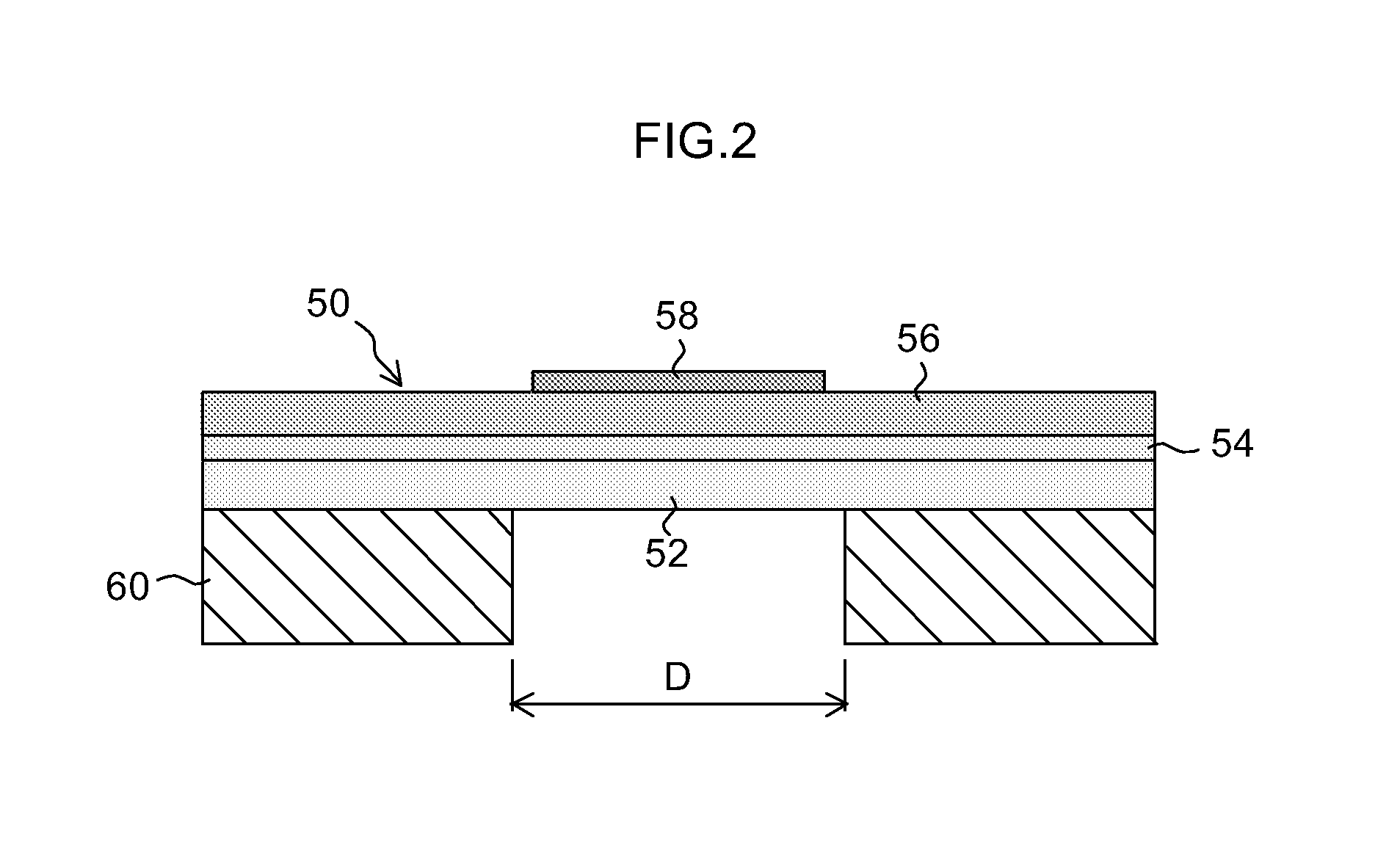

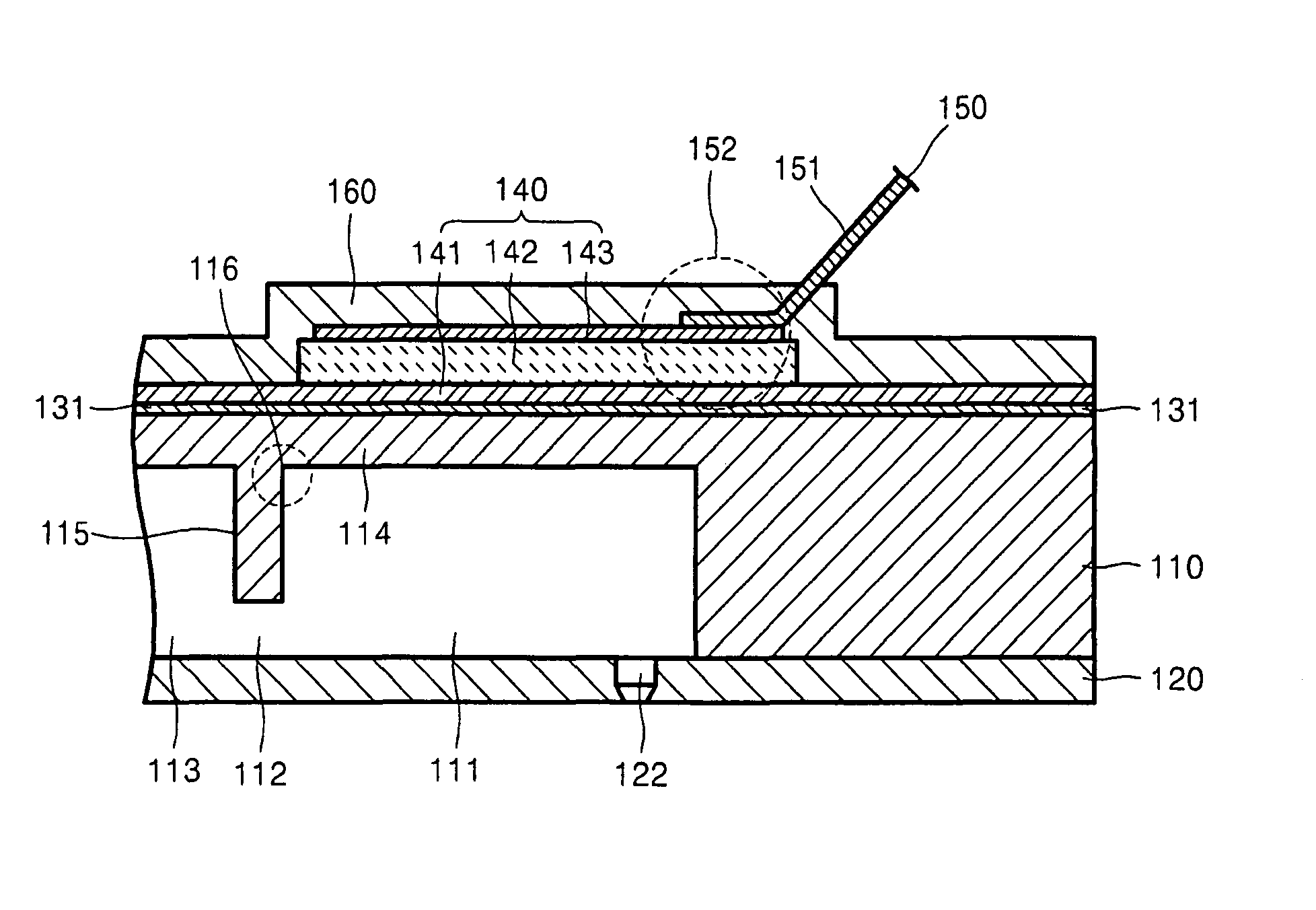

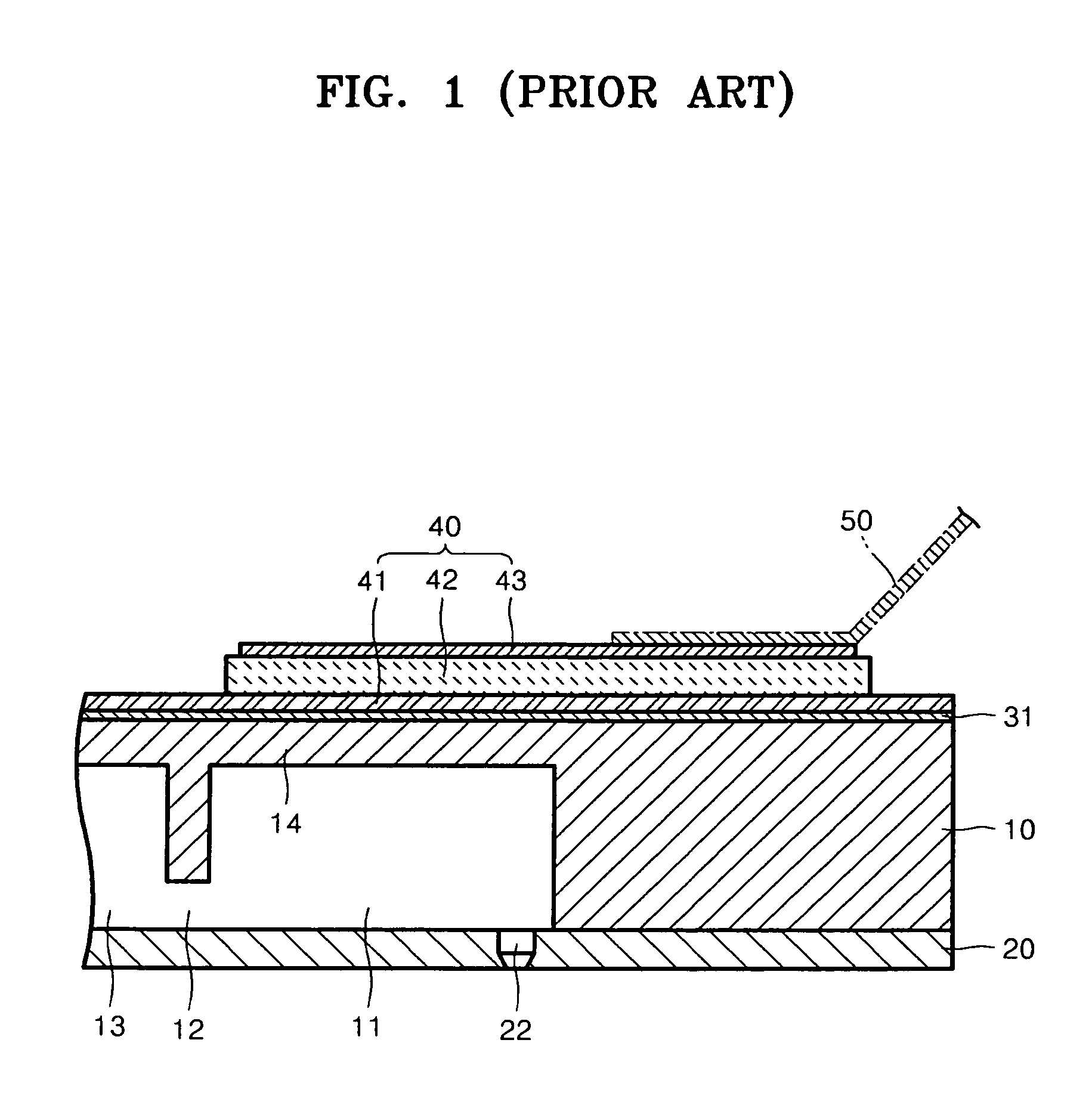

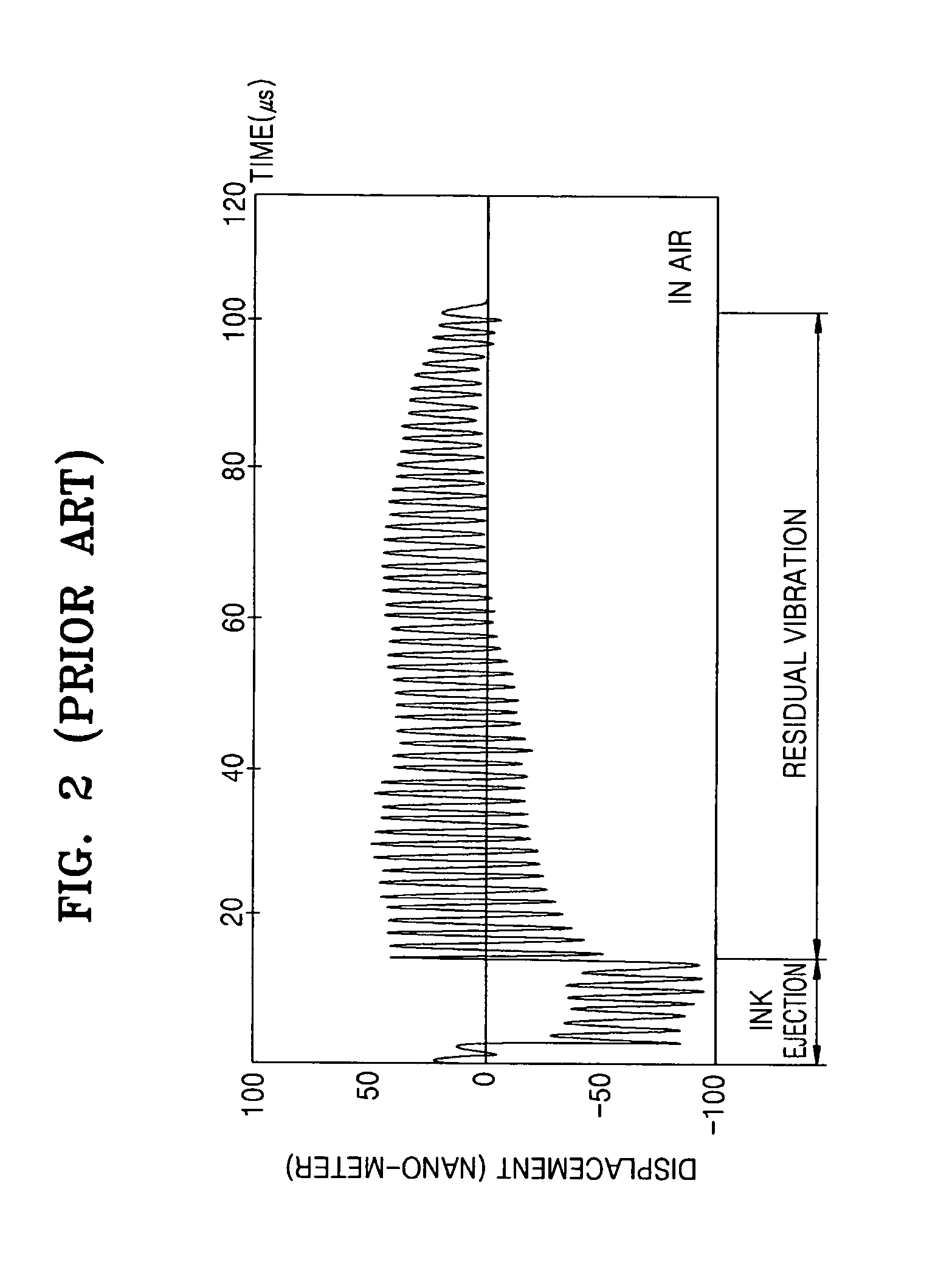

Inkjet printhead employing piezoelectric actuator and method of manufacturing the inkjet printhead

A piezoelectric inkjet printhead includes a fluid path forming substrate having a pressure chamber, a piezoelectric actuator formed on the fluid path forming substrate to provide a drive force to the pressure chamber to eject ink, and a damping layer formed on the piezoelectric actuator to dampen a residual vibration of the piezoelectric actuator.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

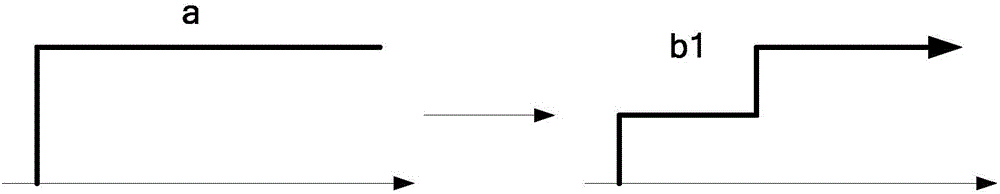

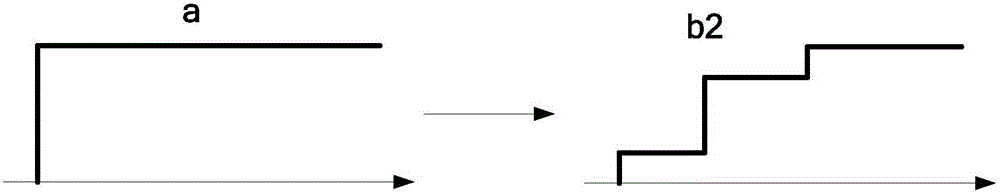

Input reshaper for suppressing residual vibration of mechanical system

ActiveCN105786037AReduce wearEliminate shockMechanical pressure/force controlResidual vibrationSystem impact

The invention discloses an input reshaper for suppressing residual vibration of a mechanical system. The reshaper is characterized in that a transfer function of the reshaper is shown in the specification, wherein k1, k2, k3 and k4 are gain coefficients, n is a time delay coefficient. According to the invention, the system impact is reduced, the first-order differential can be performed on a step signal, which is similar to a first-order filter, the medium-high frequency vibration and impact of torque are eliminated, the reshaper is suitable for the mechanical system with relatively poor rigidity, and the mechanical wearing can be reduced.

Owner:CHINA LEADSHINE TECH CO LTD +1

Liquid ejection head and liquid ejection device

The invention provides a liquid ejection head and a liquid ejection device, by which, the discharge amount can be changed without changing the nozzle structure. According to one embodiment, a drive signal includes an auxiliary pulse, an ejection pulse, a cancel pulse, and a damping pulse, in this order. The auxiliary pulse drives an actuator so that the pressure is increased. The ejection pulse drives the actuator so that the pressure is reduced to eject the liquid. The cancel pulse drives the actuator so that the pressure is increased to suppress residual vibration of the liquid. The damping pulse drives the actuator so that the pressure is reduced to suppress the residual vibration. A pulse width of the auxiliary pulse is AL or less . A pulse width of the cancel pulse is 2 AL. A length from an end of the application of the cancel pulse to a start of the application of the damping pulse is 0.2 AL to 0.4 AL. A pulse width of the damping pulse is 0.2 AL to 0.4 AL.

Owner:TOSHIBA TEC KK

Methods and systems for supporting a workpiece and for heat-treating the workpiece

ActiveUS20120118867A1Avoid relative motionEffectively shortenCellsShaping toolsSupporting systemEngineering

An apparatus for supporting a semiconductor workpiece includes a heating system configured to cause thermally-induced motion of the semiconductor workpiece by heating a surface of the workpiece relative to a bulk of the workpiece. The thermally-induced motion includes vertical motion of an outer edge region of the workpiece and a center of the workpiece relative to each other. The apparatus further includes a support system configured to allow the thermally-induced motion including the vertical motion of the outer edge region of the workpiece and the center of the workpiece relative to each other while supporting the workpiece.

Owner:MATTSON TECHNOLOGY +1

A Vibration Control Method of Rigid-Flexible Electromechanical Servo System

ActiveCN110187723BSuppress residual vibrationMechanical oscillations controlControllers with particular characteristicsFractional-order controlVibration control

The invention discloses a vibration control method of a rigid-flexible coupling electromechanical servo system, comprising: separately collecting encoder data on a drive motor and a load motor, obtaining the torsion angles at both ends of a flexible shaft in real time, and calculating the flexible shaft The torsion angle of the micro-element at any position on the above is calculated according to the length, polar moment of inertia, elastic modulus and moment of inertia of the flexible shaft to obtain the frequency domain characteristic equation; using the frequency domain characteristic equation to calculate the described The coupling torque between the flexible shaft and the rigid drive flywheel; the balance equation of the rigid drive flywheel is established; the coupling torque is brought into the balance equation to obtain the fractional transfer function model of the system; according to the fractional transfer function model, establish a fractional order controller, and use the controller to control the vibration of the system. The method involved in this patent accurately describes the dynamic behavior of the viscoelastic material through the fractional order model, and effectively suppresses the residual vibration of the system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com