Patents

Literature

123results about How to "Jet stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrospinning direct-writing closed-loop control system and control method

ActiveCN102582293ARealize controllable adjustmentImprove uniformityOther printing apparatusFiberLoop control

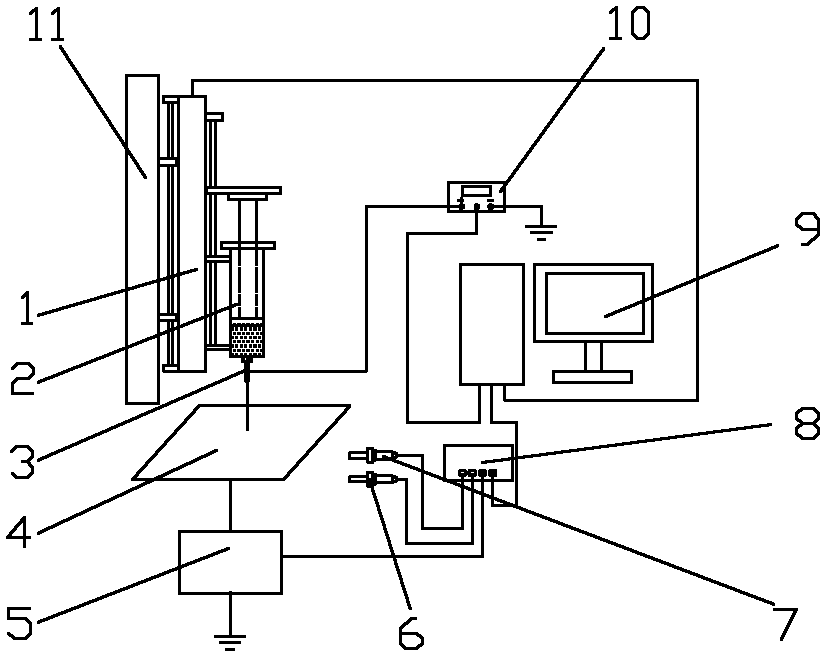

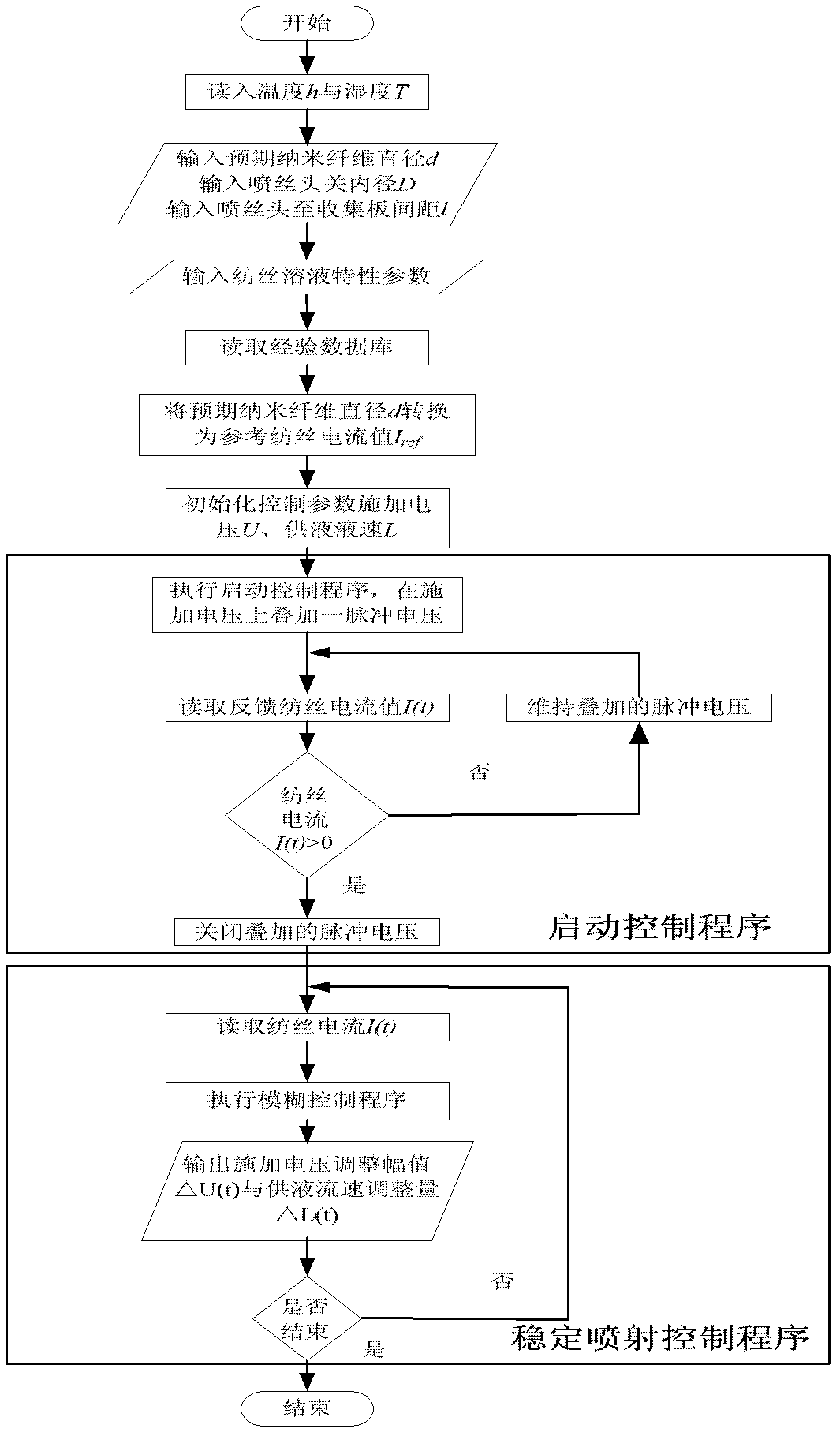

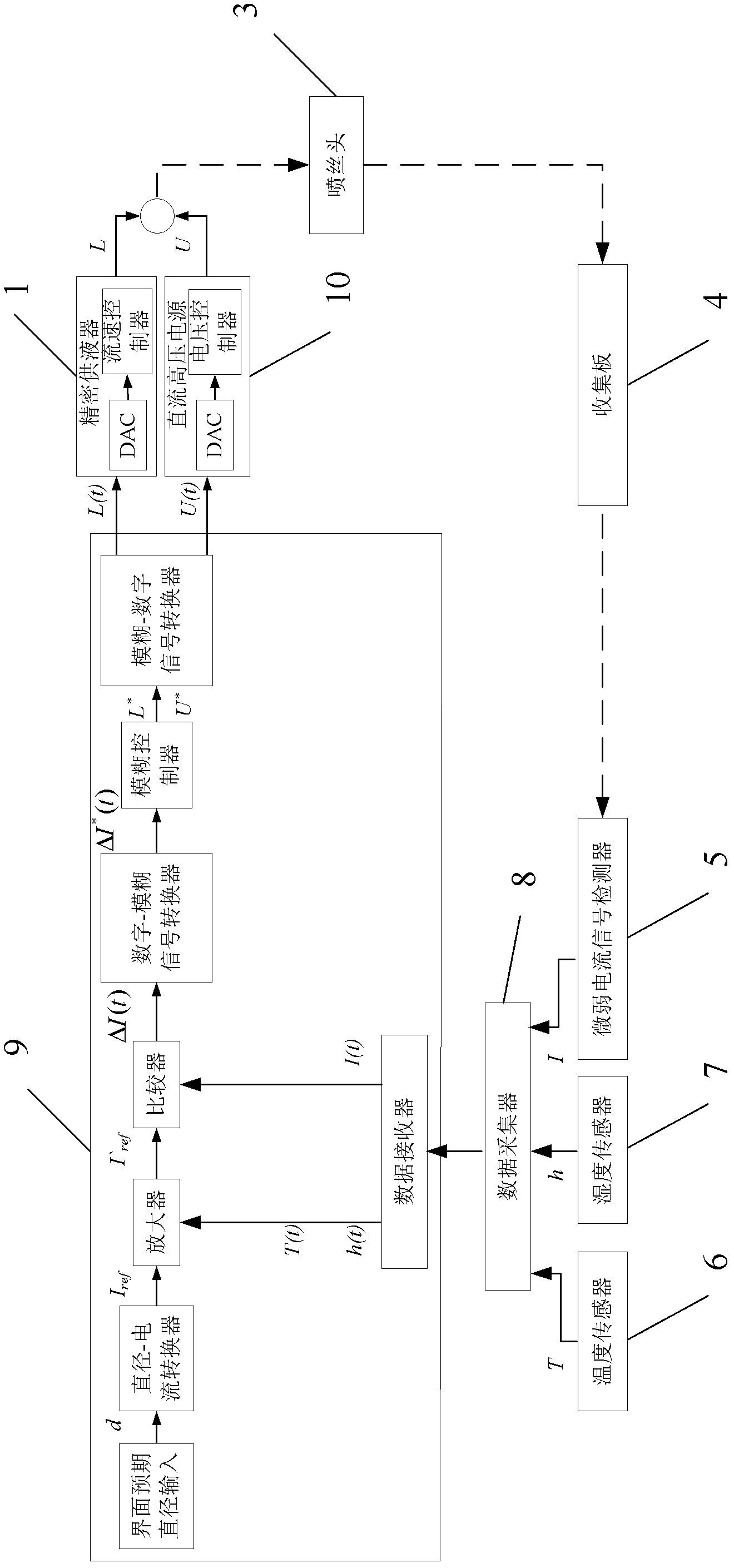

The invention relates to an electrospinning direct-writing closed-loop control system and a control method, which relate to electrospinning direct writing equipment. The invention provides the electrospinning direct-writing closed-loop control system which is capable of realizing the controllable adjustment of the electrospinning direct-writing nano fibre diameter and improves the jet injection stability of spinning and the uniformity of nano fibre diameter and the control method of the electrospinning direct-writing closed-loop control system. The system comprises a liquid storage tank, a liquid feeder, a spinning nozzle, a collecting plate, a weak current detector, a temperature sensor, a humidity sensor, a data collector, a control computer, a direct current high voltage power supply and an adjustable frame. The system establishes a fuzzy controller to obtain the jet injection state by detecting the spinning current, adjusts the applied voltage and the flow rate of the feeding liquid according to the change of the spinning current so as to avoid the influence of various interference factors and realize long time stable jet of the spinning jet flow. The set current of the fuzzy controller is adjusted to control the electrospinning direct-writing nano fibre diameter. The electrospinning direct-writing closed-loop control system is beneficial to improving the controllability of the electrospinning direct-writing nano fibre diameter and well promoting the industrialized application of the electrospinning direct-writing technology.

Owner:XIAMEN UNIV

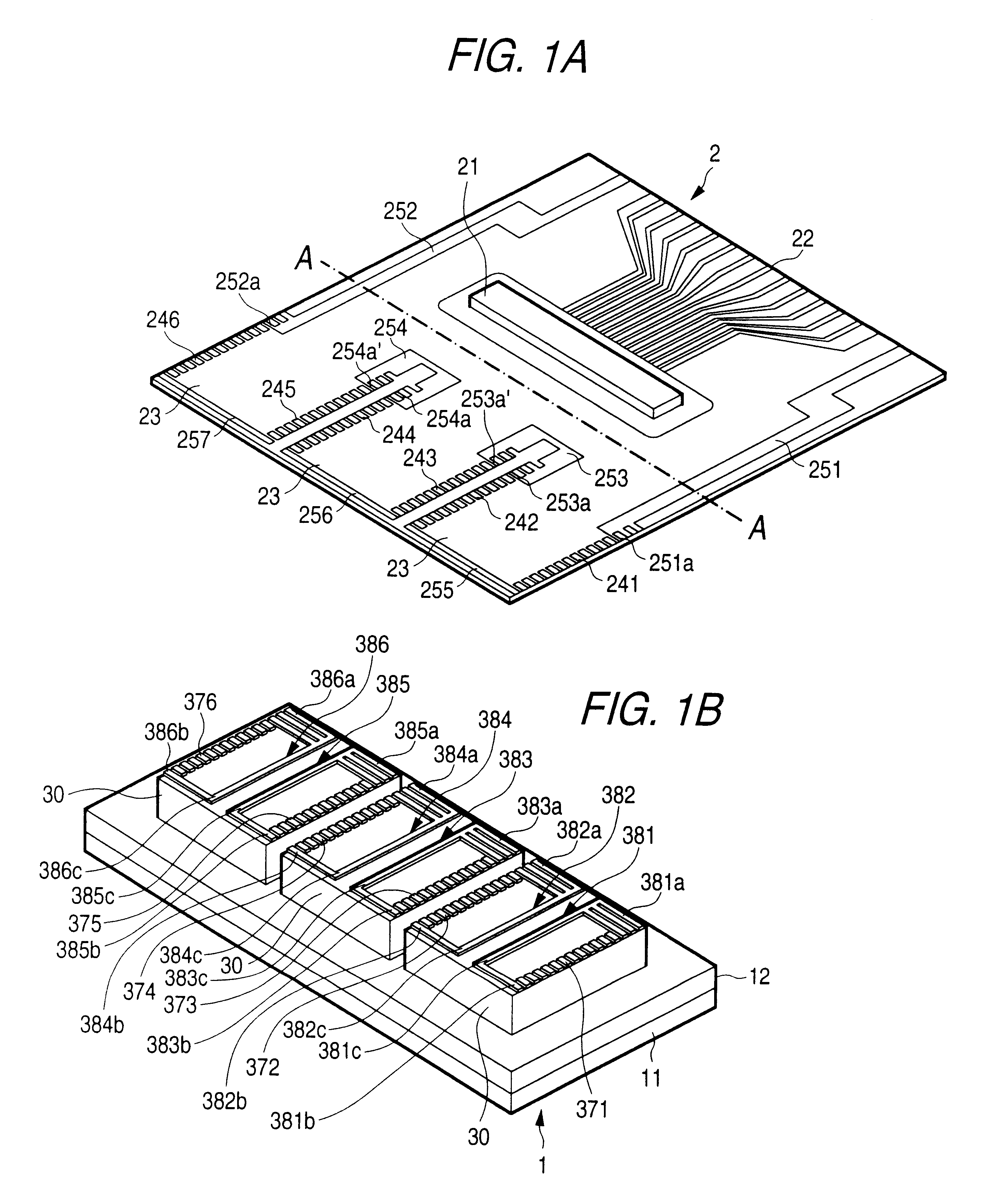

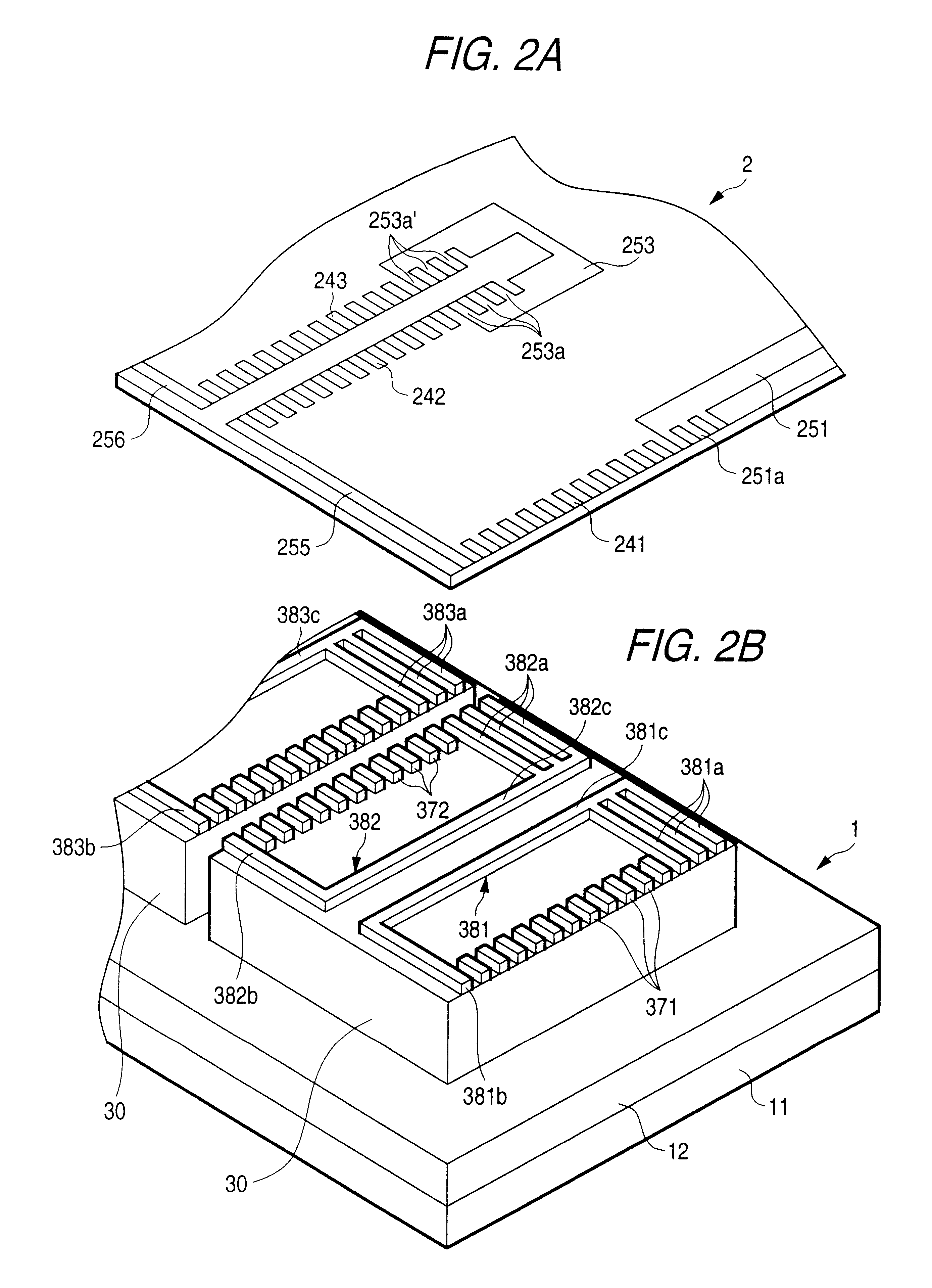

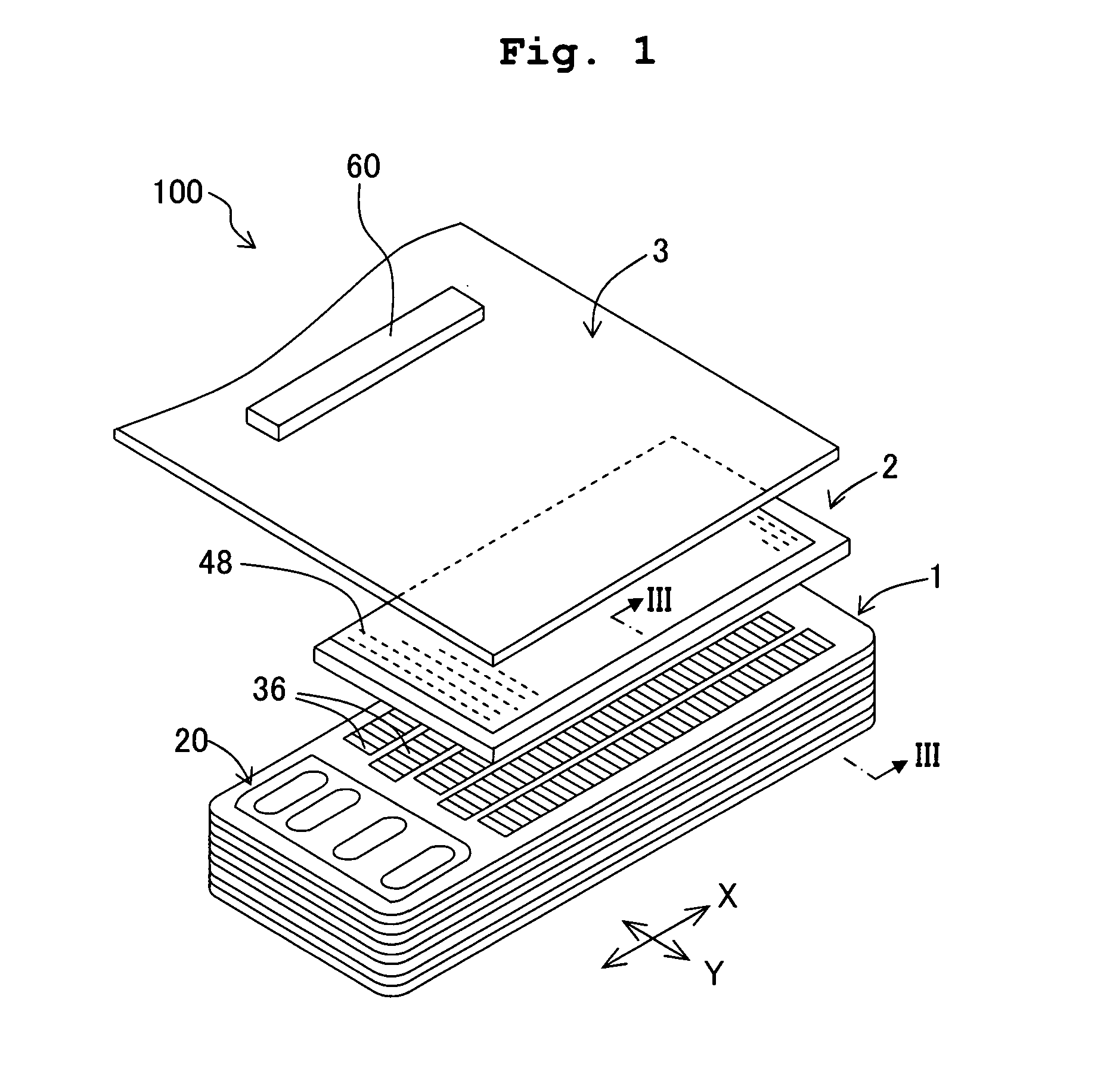

Ink-jet recording head

InactiveUS6190006B1Electric potential of the piezoelectric vibrator can be prevented from varyingJet stabilityPrintingElectrical conductorEngineering

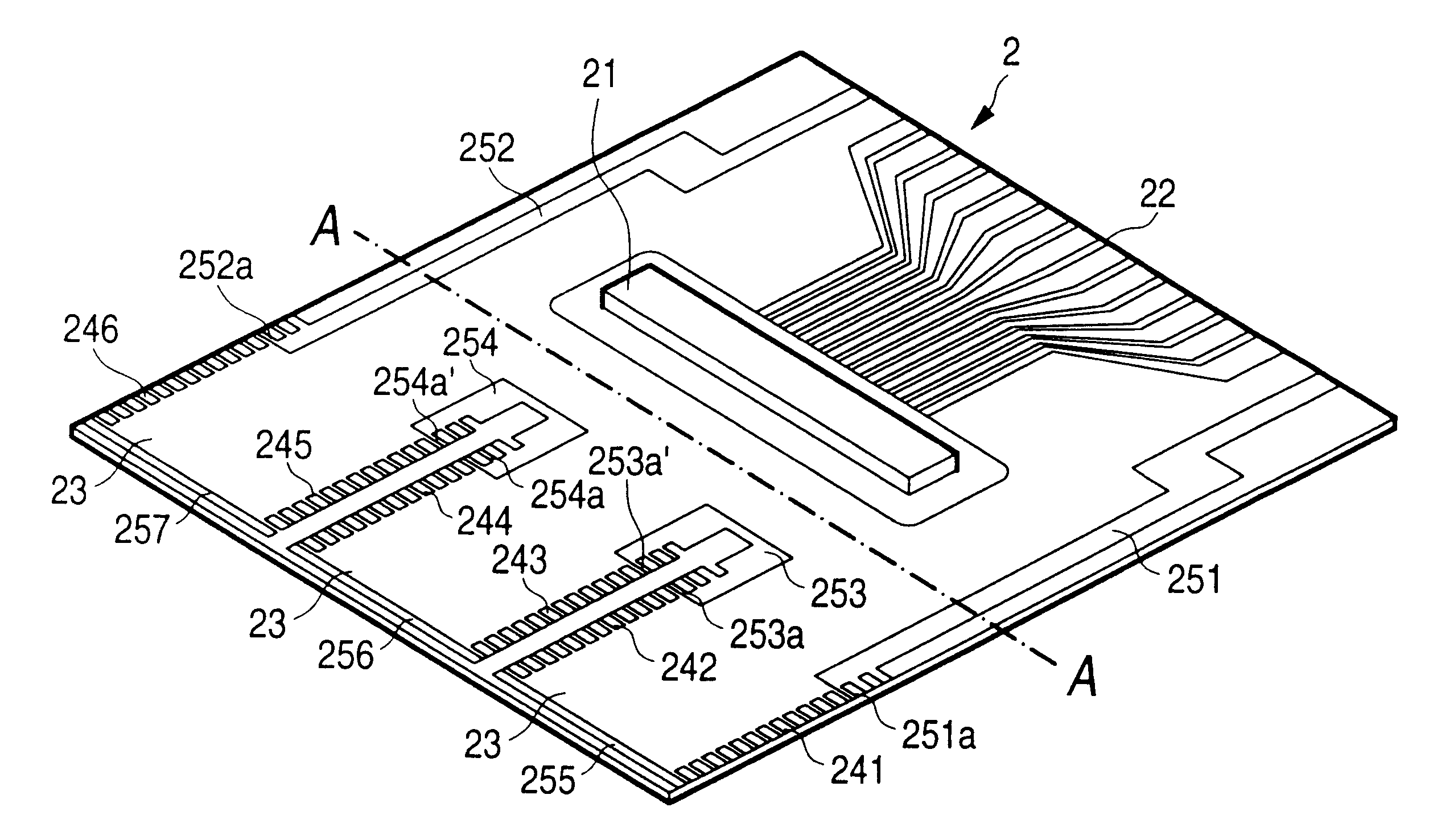

Segment terminal electrodes for connecting to the segment terminals of TCP and common terminal electrodes at both ends in a direction in which these segment terminal electrodes are arranged are formed on the surface of an actuator unit and the common terminal electrodes at both ends of each row are connected via conductive members. Each grounding conductor on TCP is mutually connected via each common terminal electrode component on the actuator unit. Therefore, the common terminal electrodes on plural actuator units can conduct to grounding conductors.

Owner:SEIKO EPSON CORP

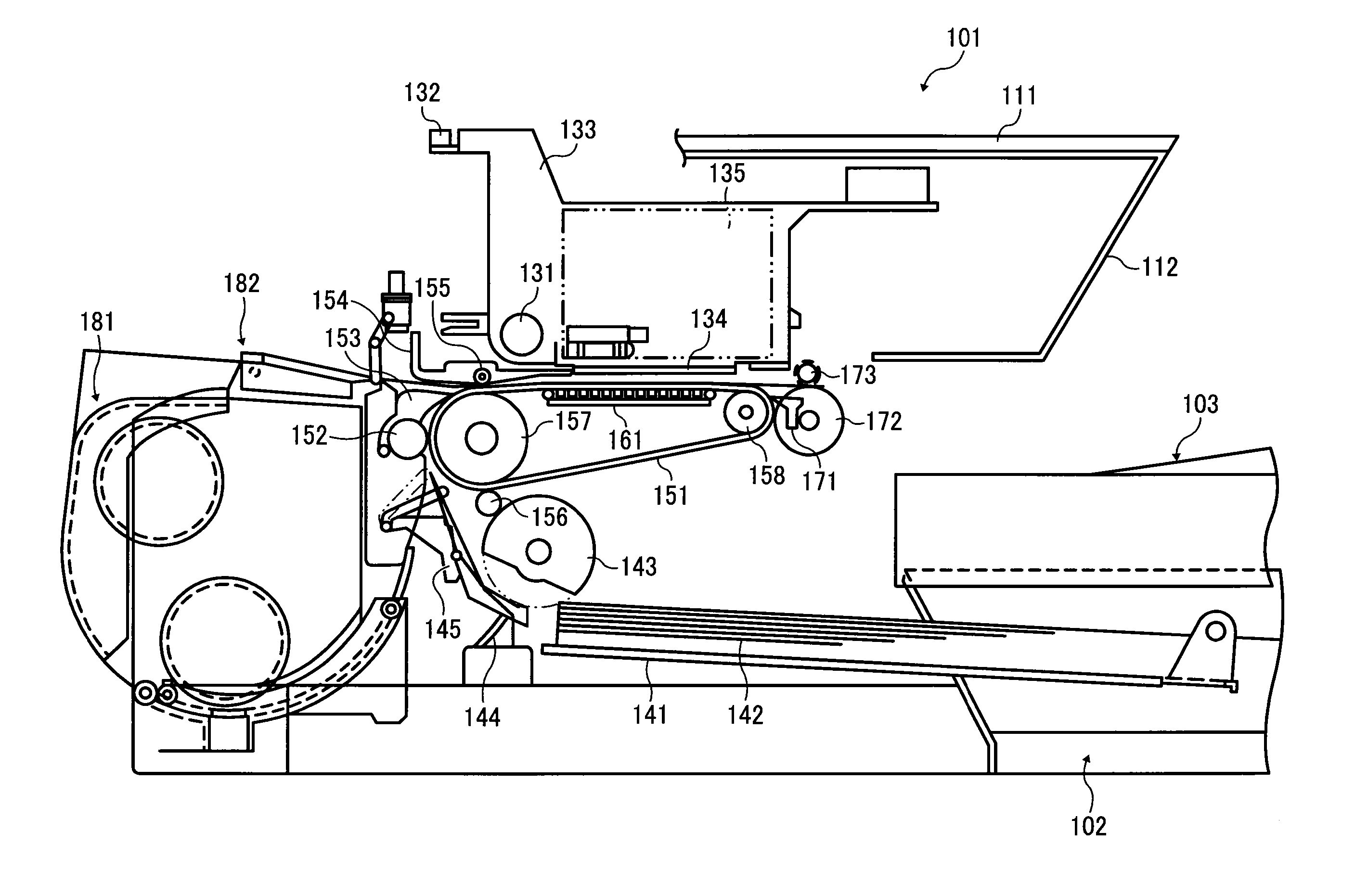

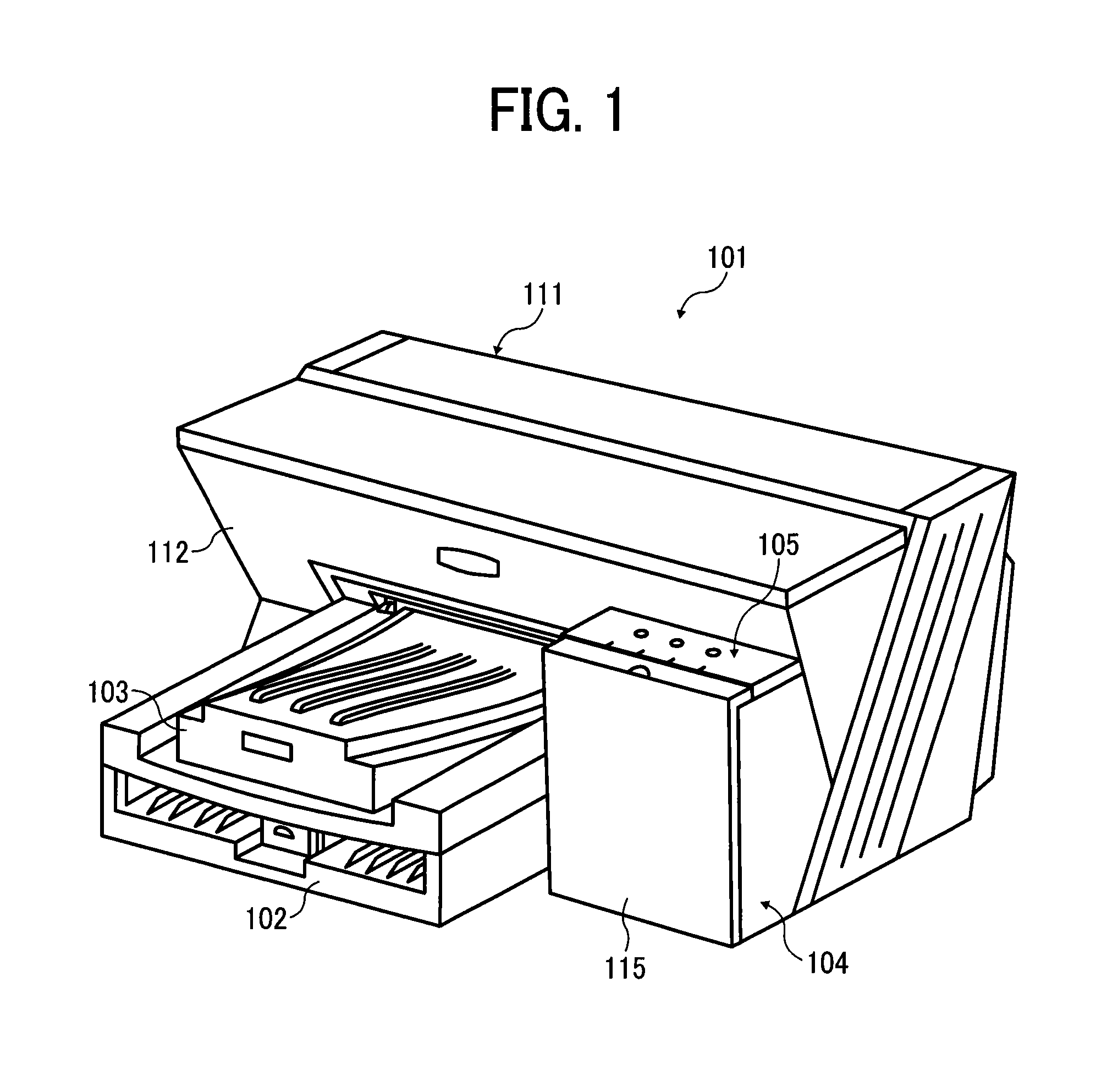

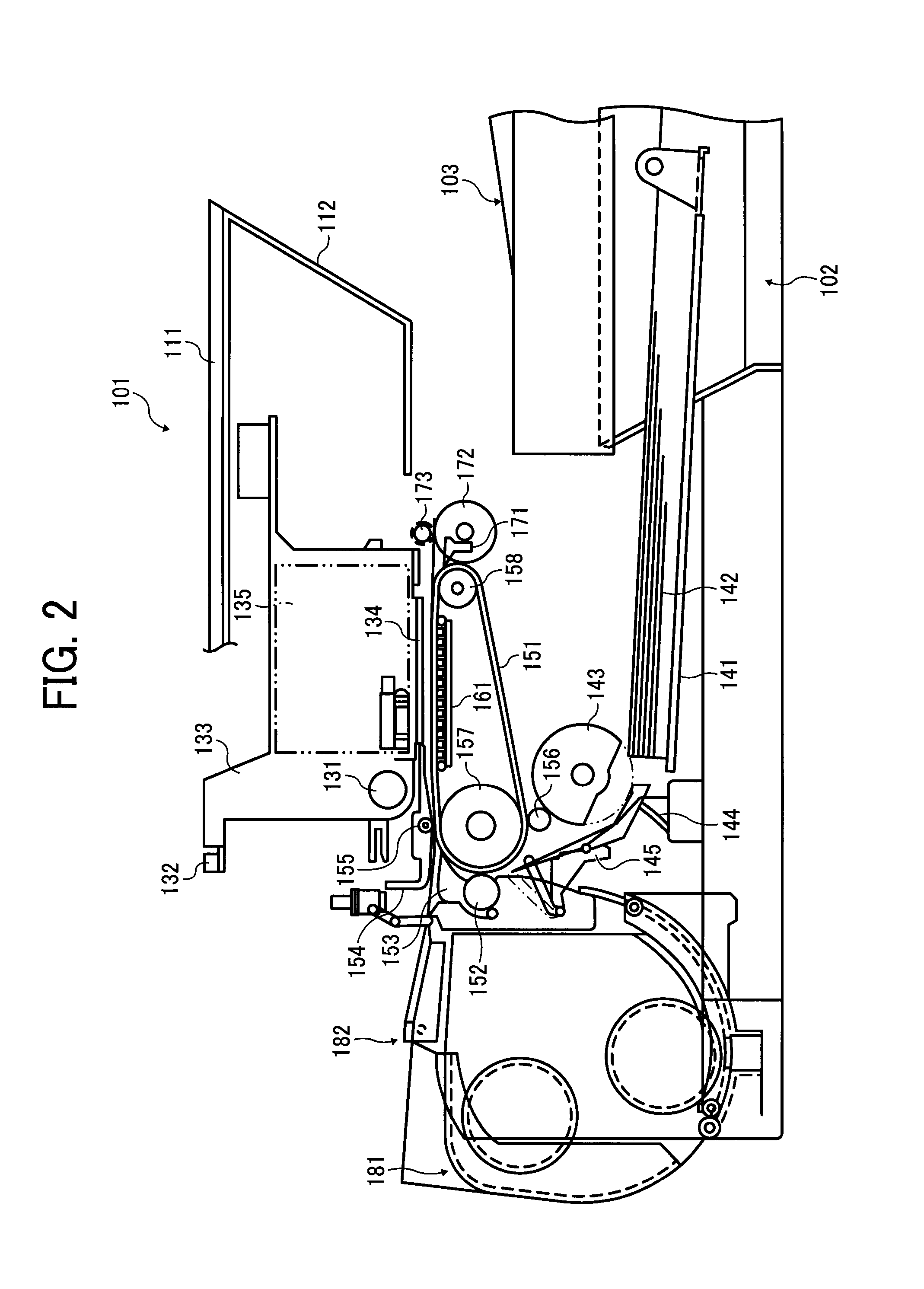

Inkjet recording apparatus

ActiveUS7137695B2Jet stabilityReduce the amount requiredOther printing apparatusUV curingUltraviolet

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

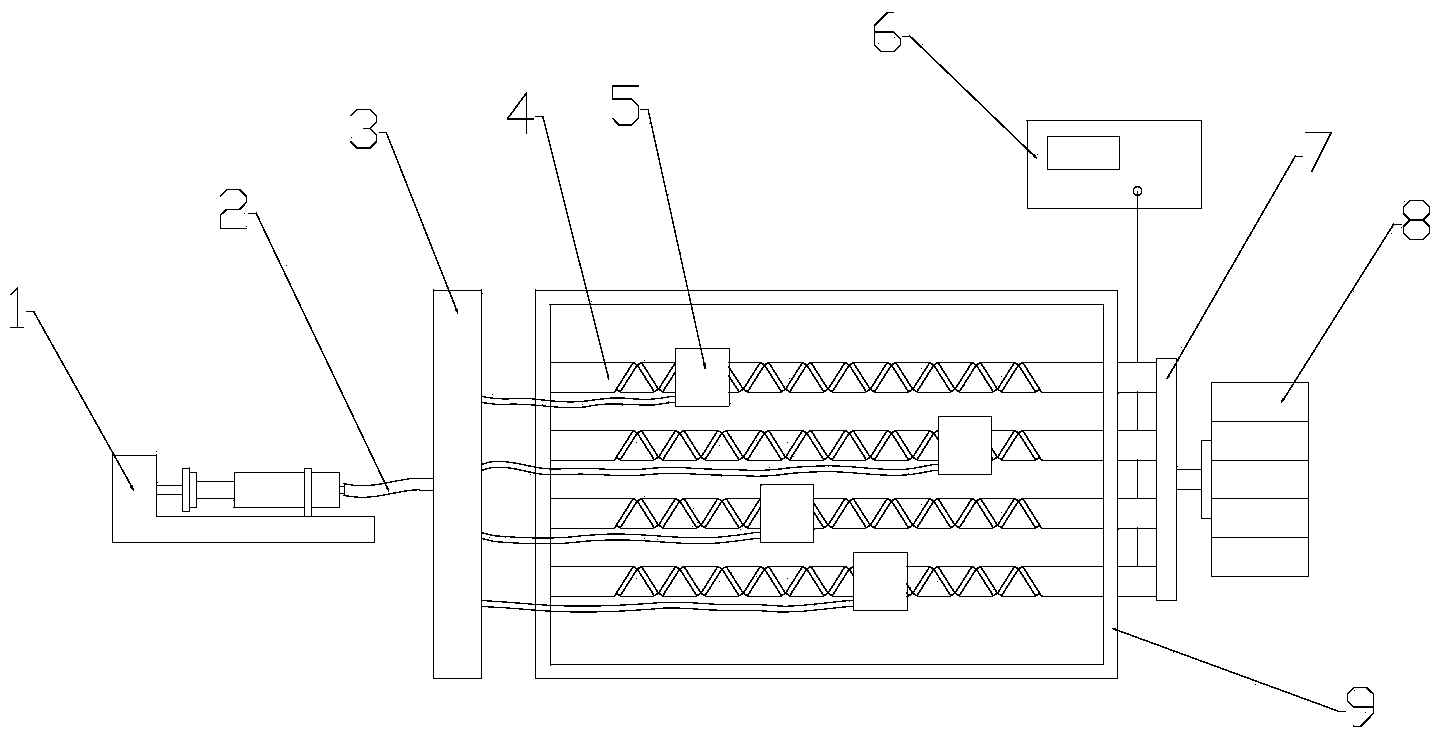

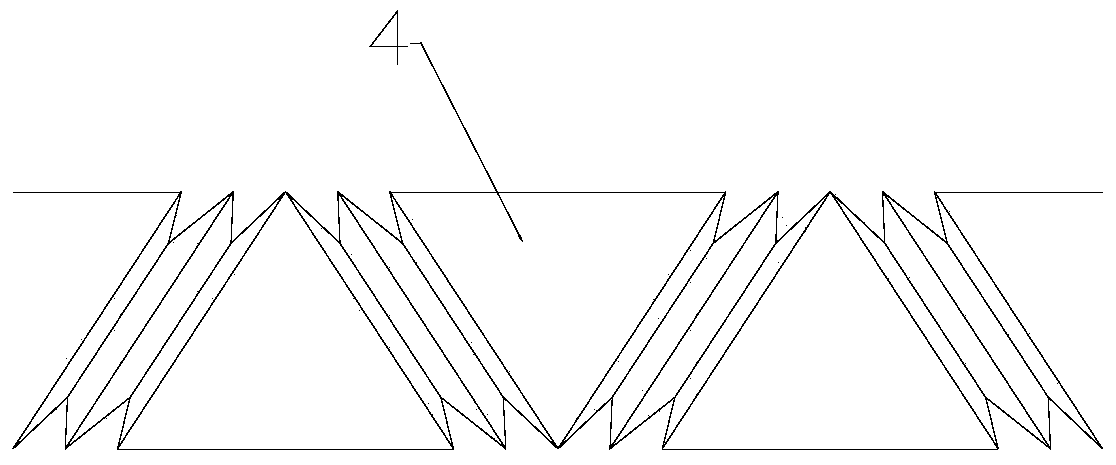

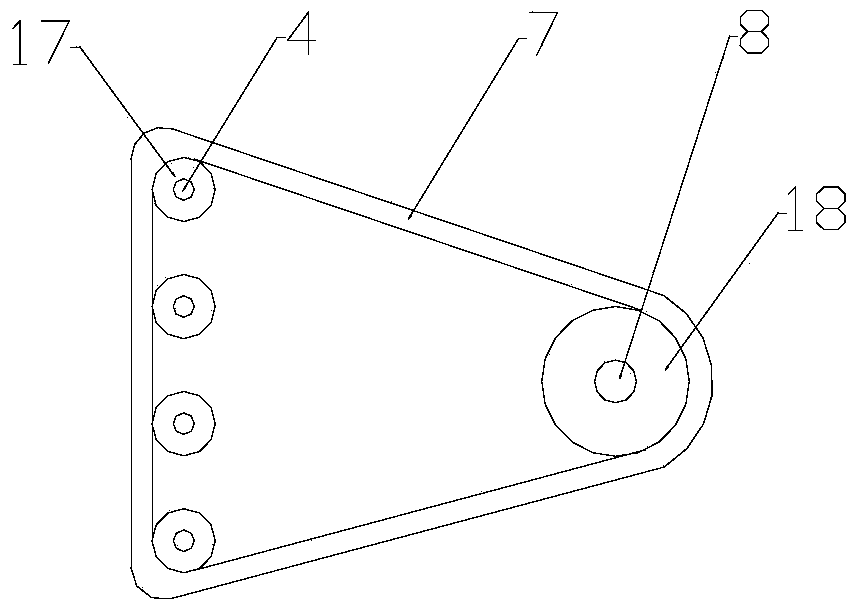

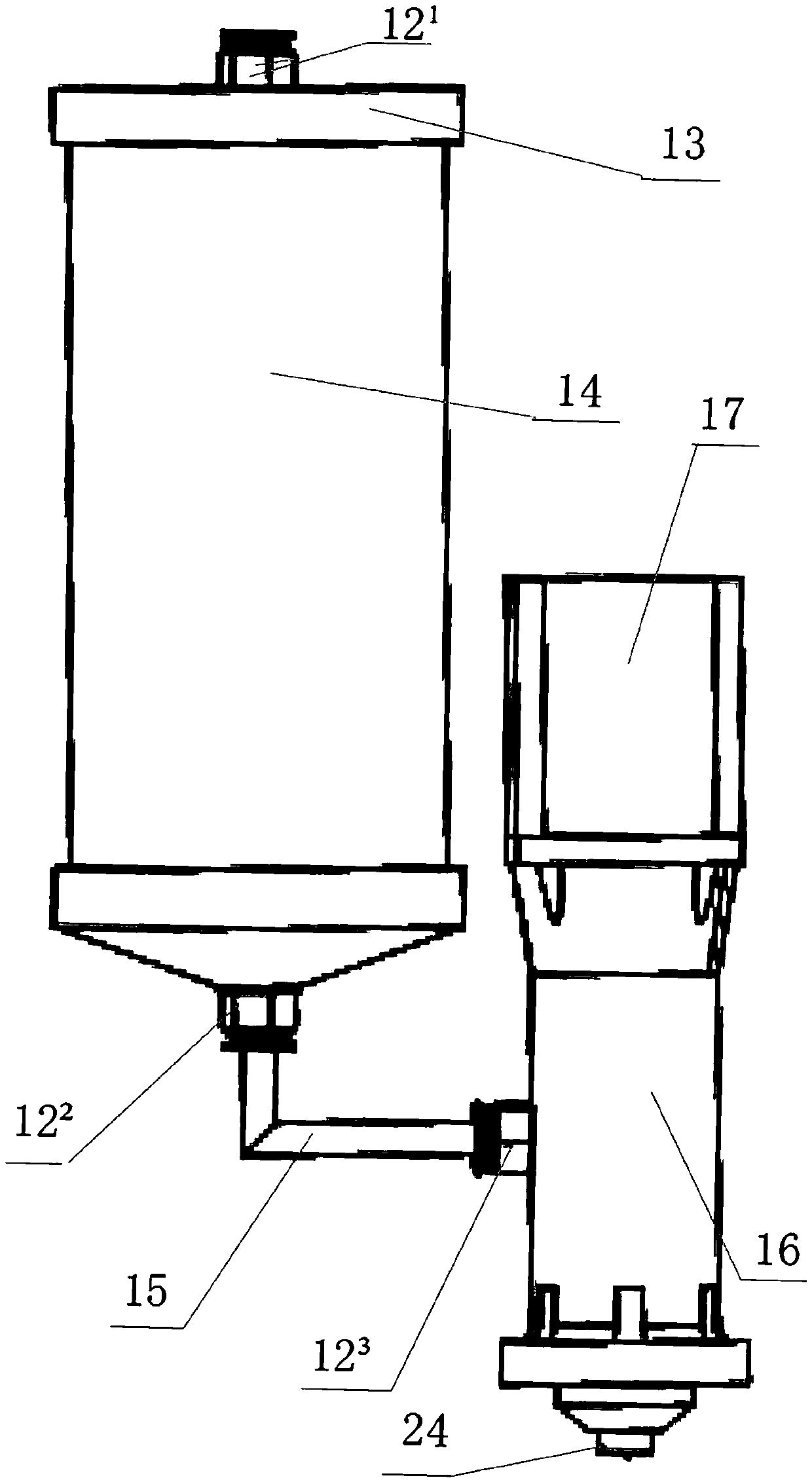

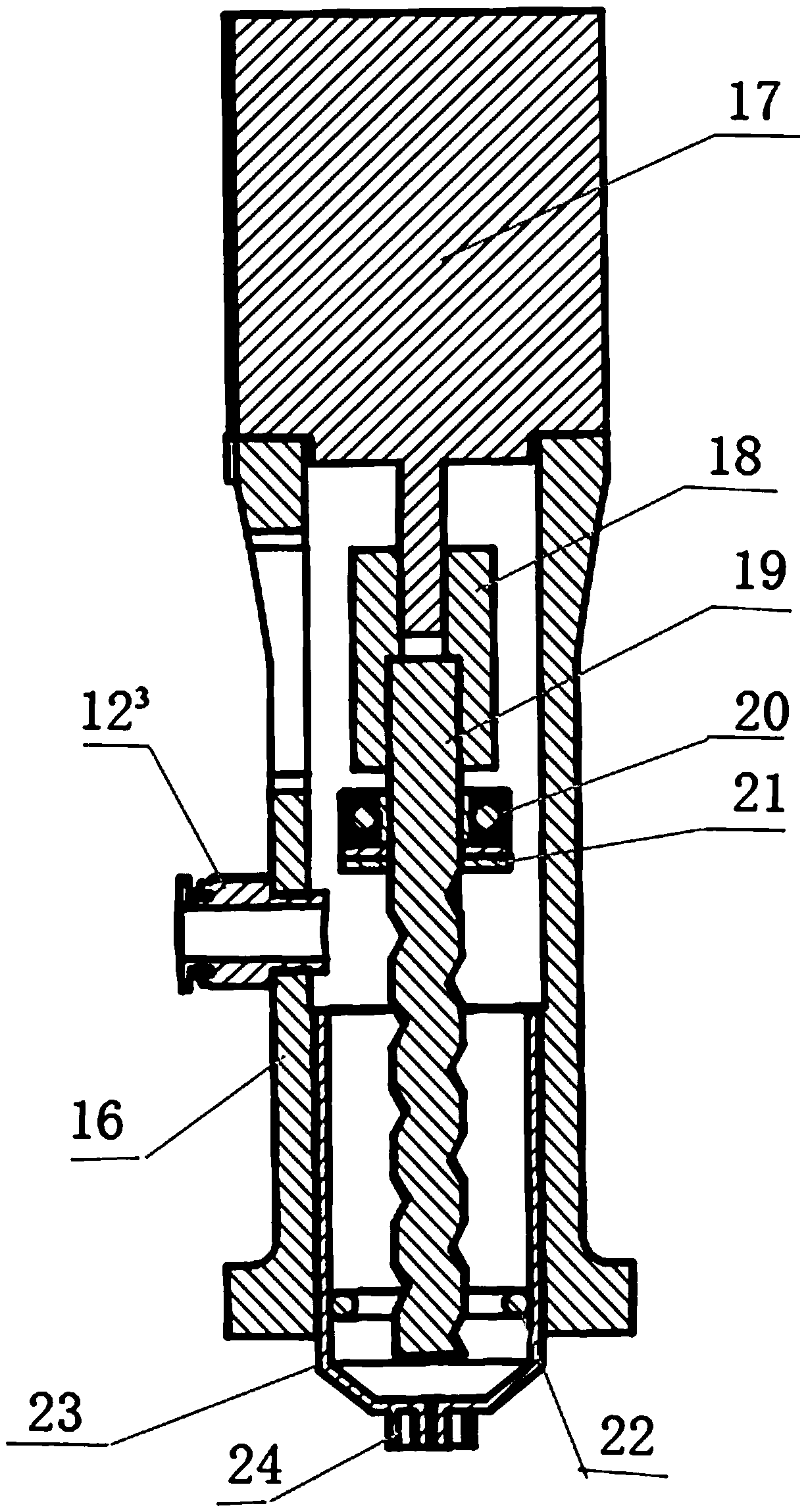

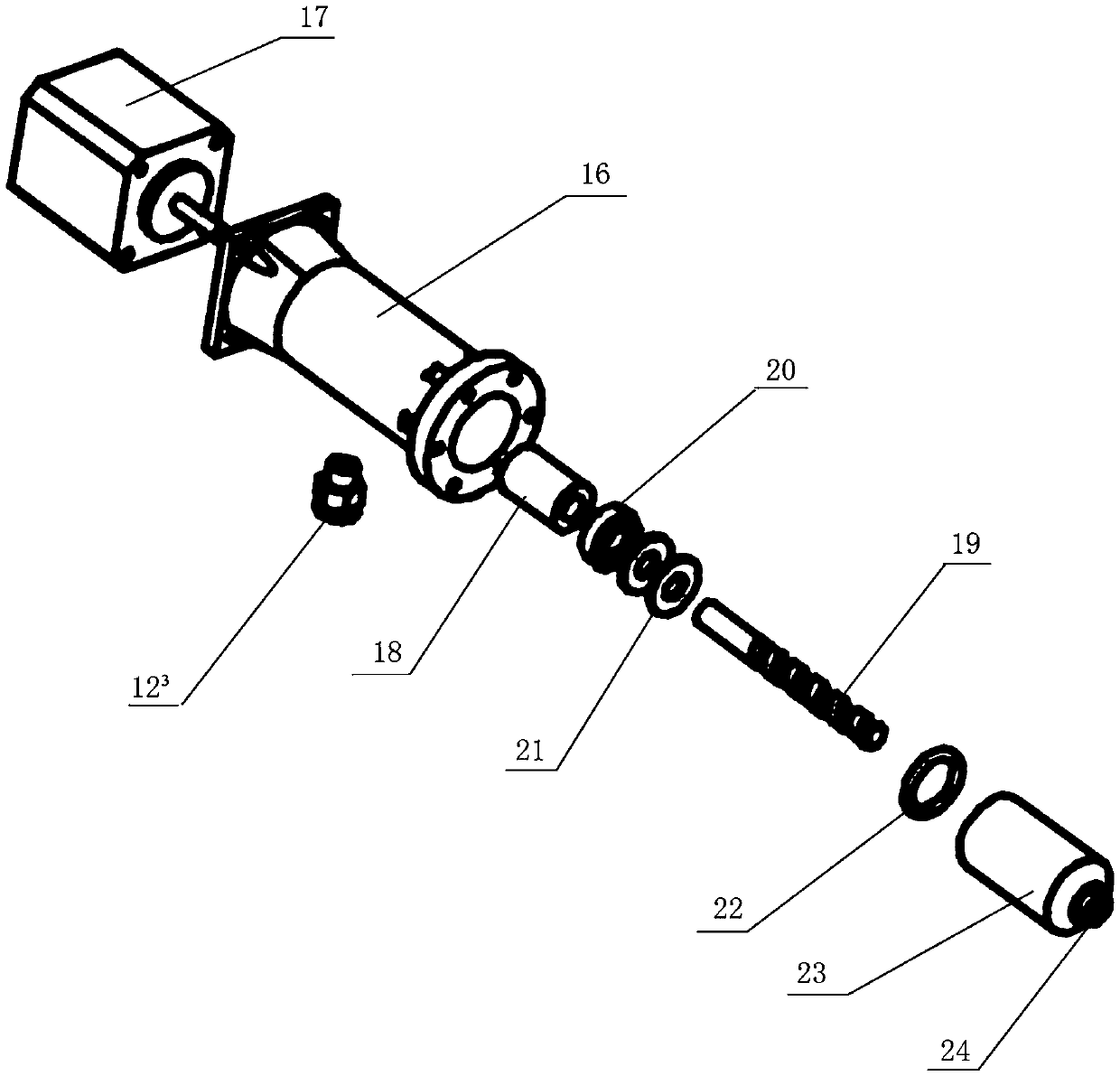

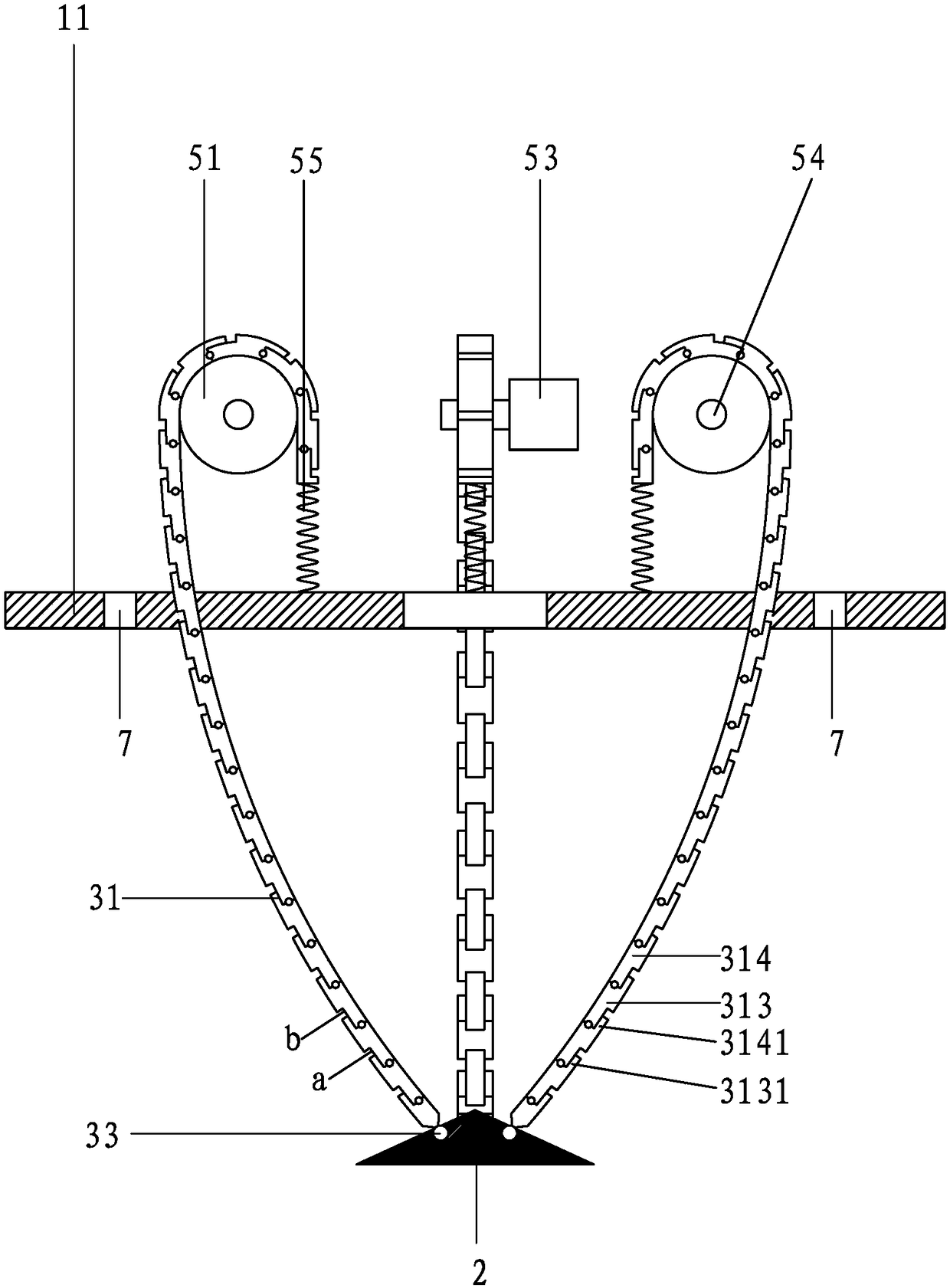

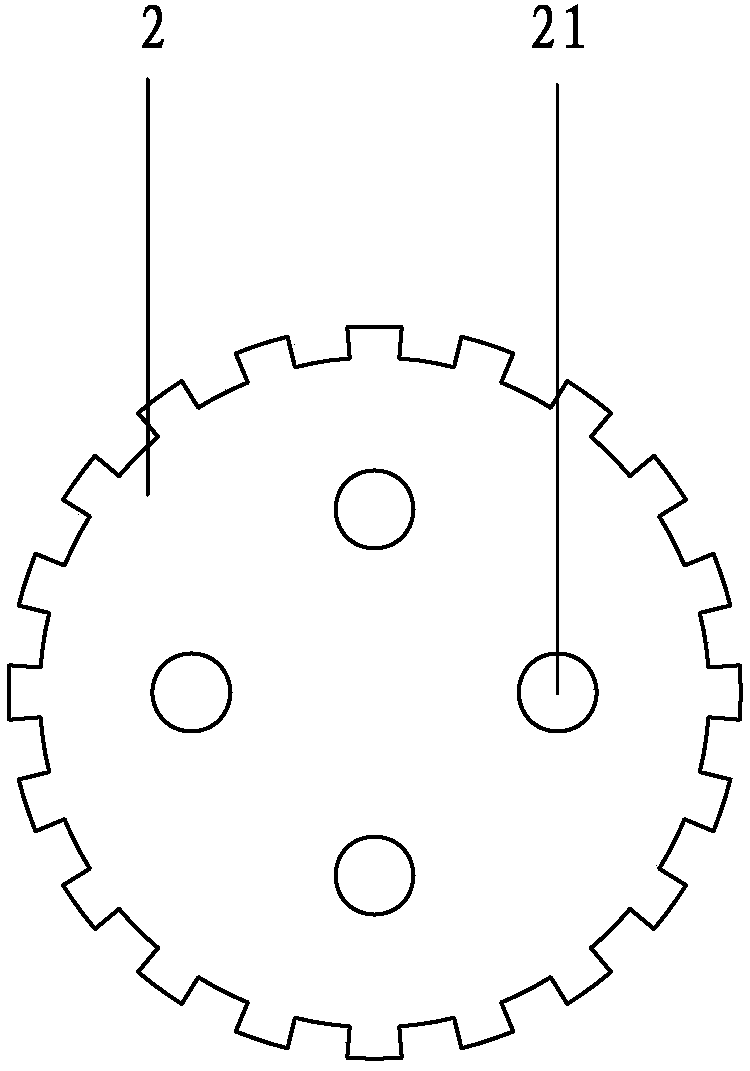

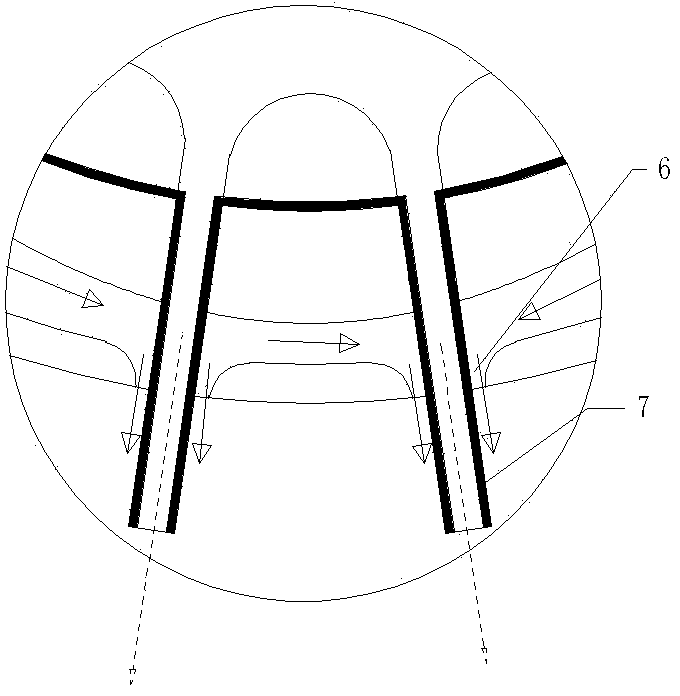

Bidirectional spiral electrostatic spinning device

ActiveCN104032383AJet stabilityImprove thickness uniformitySpinning head liquid feederFilament/thread formingFiberElectrospinning

The invention discloses a bidirectional spiral electrostatic spinning device, and relates to an electrostatic spinning device. The bidirectional spiral electrostatic spinning device is provided with bidirectional threaded guide rods, liquid storage sliders, vertical slide bars, guide rails, a framework, a controllable injection device, a liquid guide pipe, a liquid distributing device, a high-voltage power source, air pumps, pressure regulating valves, air guide pipes, partition plates, motors, driven belt pulleys, driving belt pulleys, V-shaped belts, air hole arrays and collecting devices. The bidirectional spiral electrostatic spinning device has the advantages that large-area and multi-jet injection effects can be realized by the aid of the bidirectional threaded guide rods, so that the electrostatic spinning efficiency further can be improved, phenomena of electrostatic interference among spinning jets and electric field concentration can be reduced, uniform distribution of nano-fibers on collecting plates can be promoted, the thickness uniformity of collected nano-fiber membranes can be improved, the quality of the nano-fiber membranes can be enhanced, the multiple jets can be assuredly stably and quickly injected, and large-area uniform nano-membranes can be collected; the bidirectional spiral electrostatic spinning device is applicable to injection devices with different bidirectional threaded guide rods and different thread shapes, and the lengths, the quantities and the shapes of the bidirectional threaded guide rods of the injection devices can be different from one another.

Owner:XIAMEN UNIV

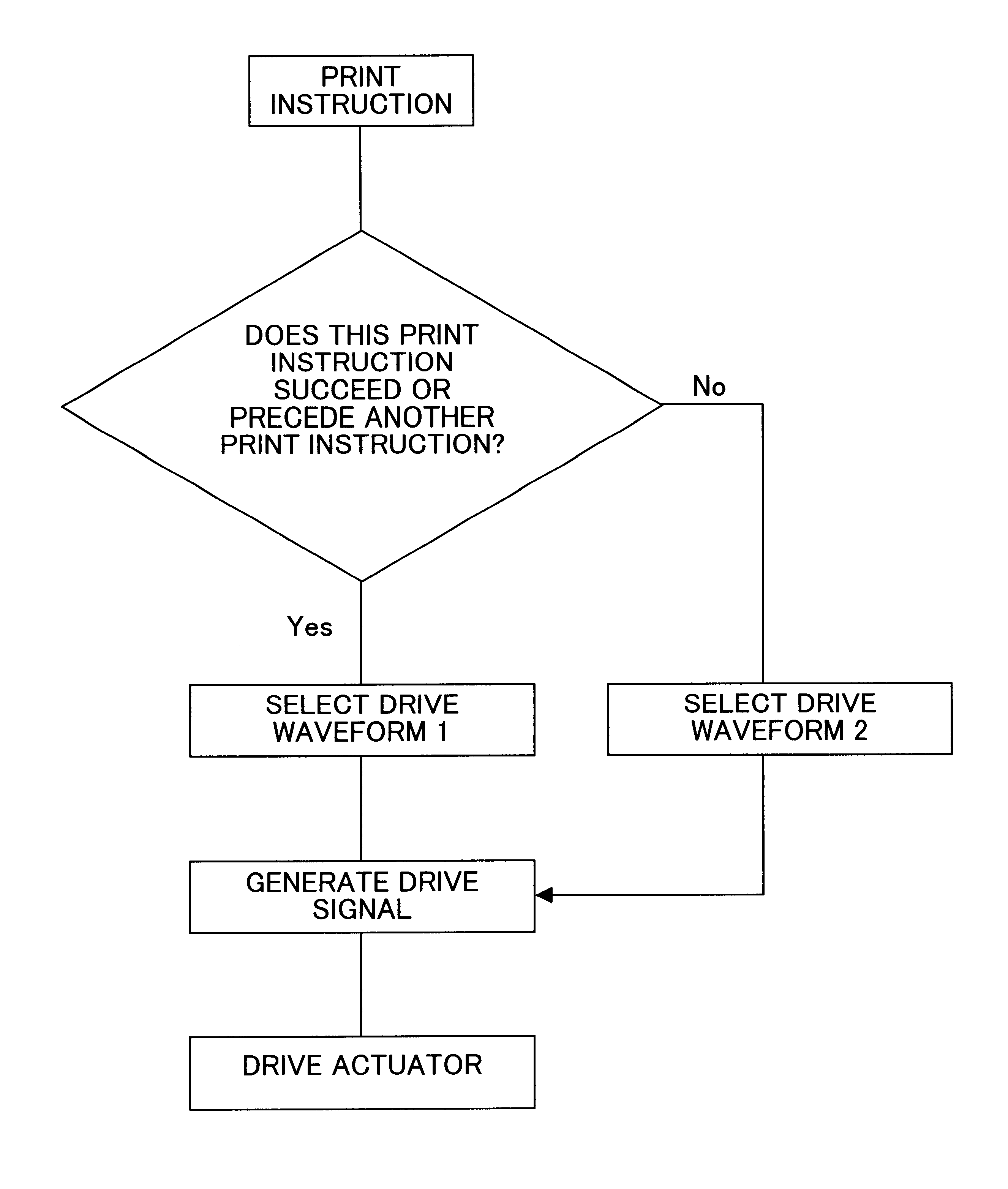

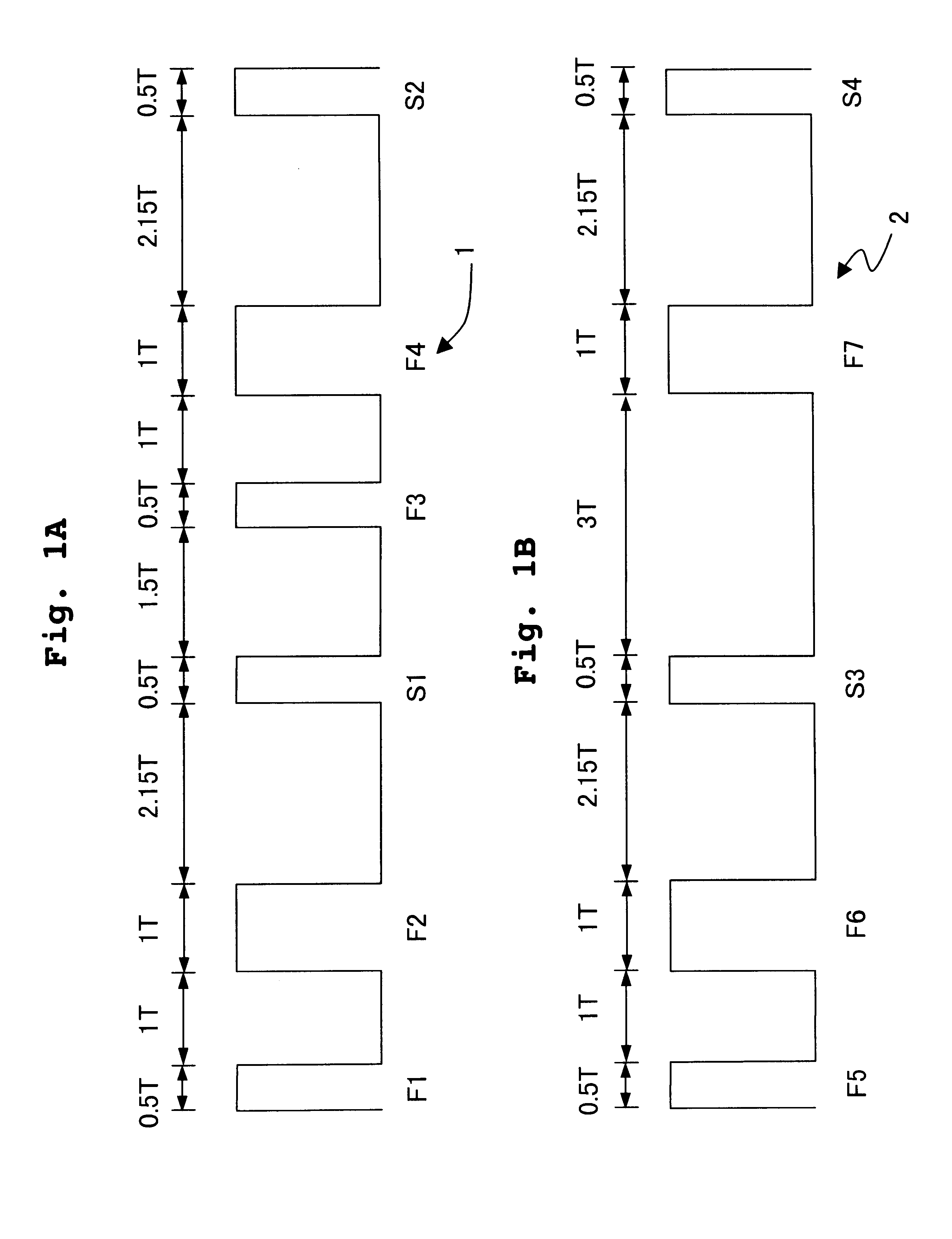

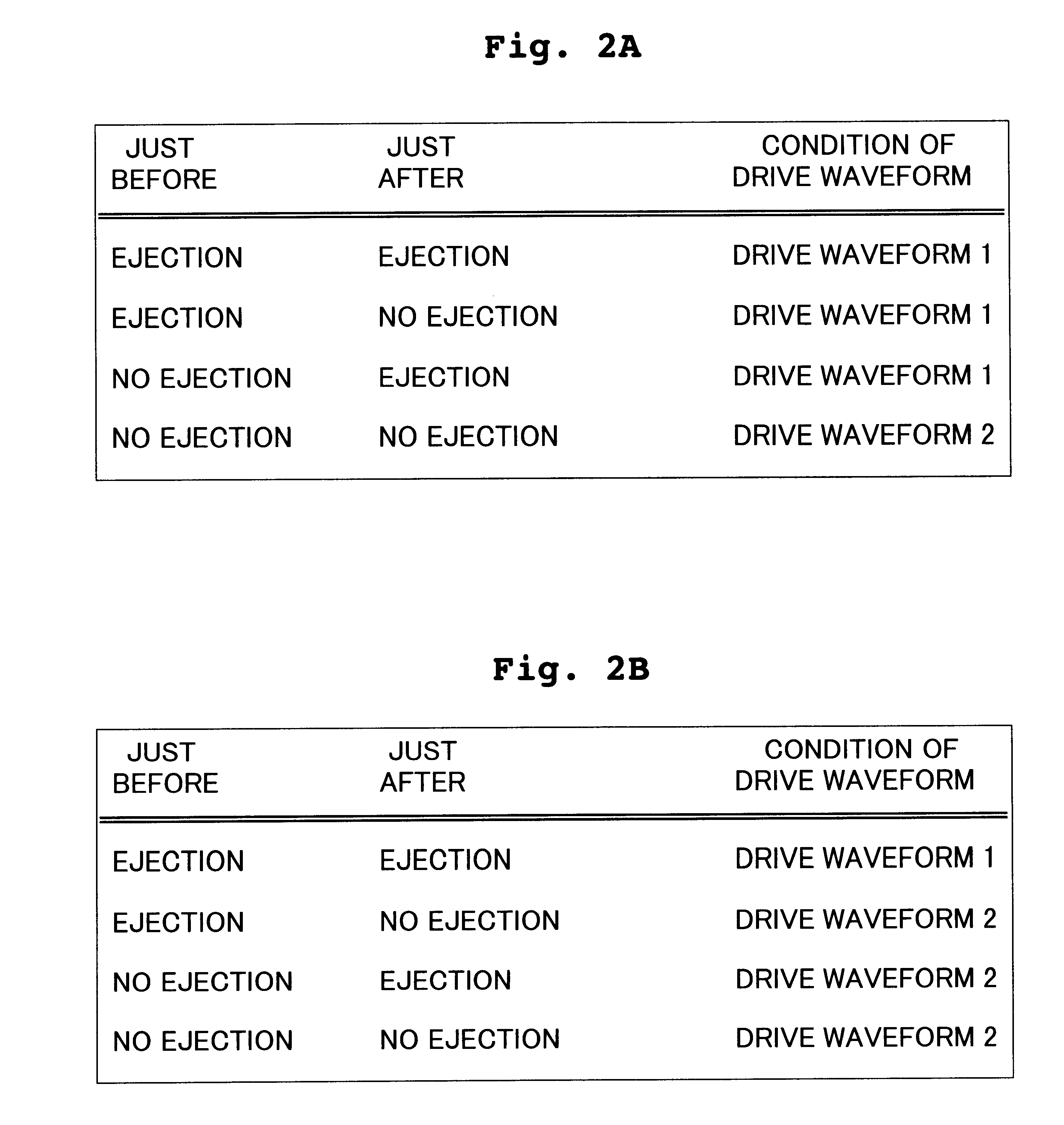

Ink jet recording method and ink jet recorder for ejecting controlled ink droplets

InactiveUS6419339B2Quality improvementStably eject inkInking apparatusOther printing apparatusWrong directionEngineering

Serial dots are printed with a drive waveform 1 for section of four ink droplets per dot from a nozzle. If one print instruction for a dot immediately follows and immediately precedes no others, a drive waveform 2 for ejection of less than four ink droplets per dot from a nozzle is selected for stable printing even under a condition where, if the drive waveform 1 were used, the ink droplets might be ejected in wrong directions, and / or useless ink droplets might be ejected.

Owner:BROTHER KOGYO KK

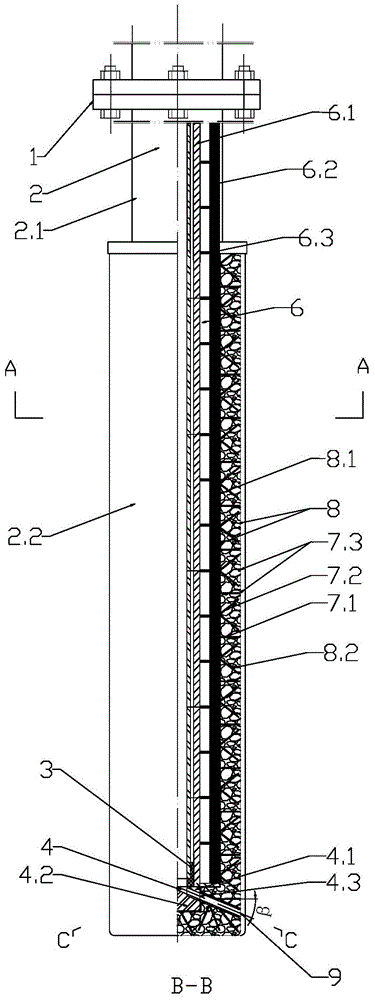

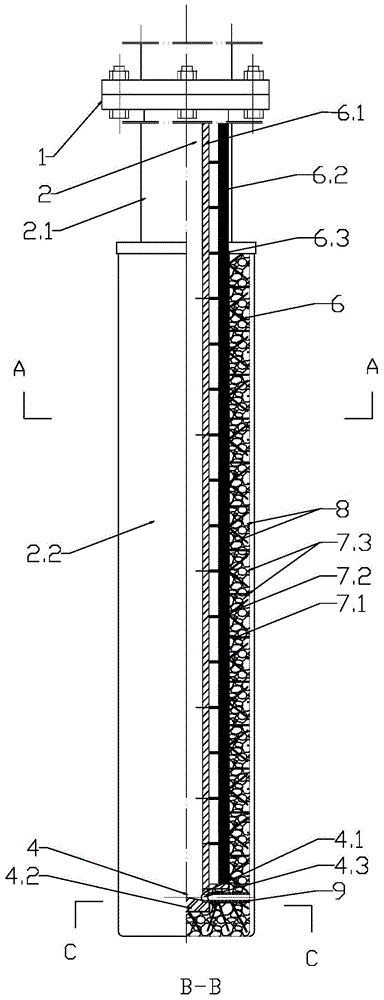

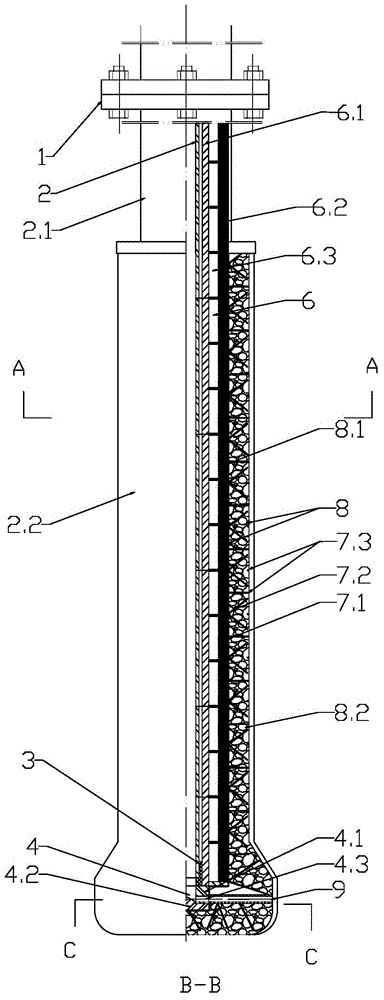

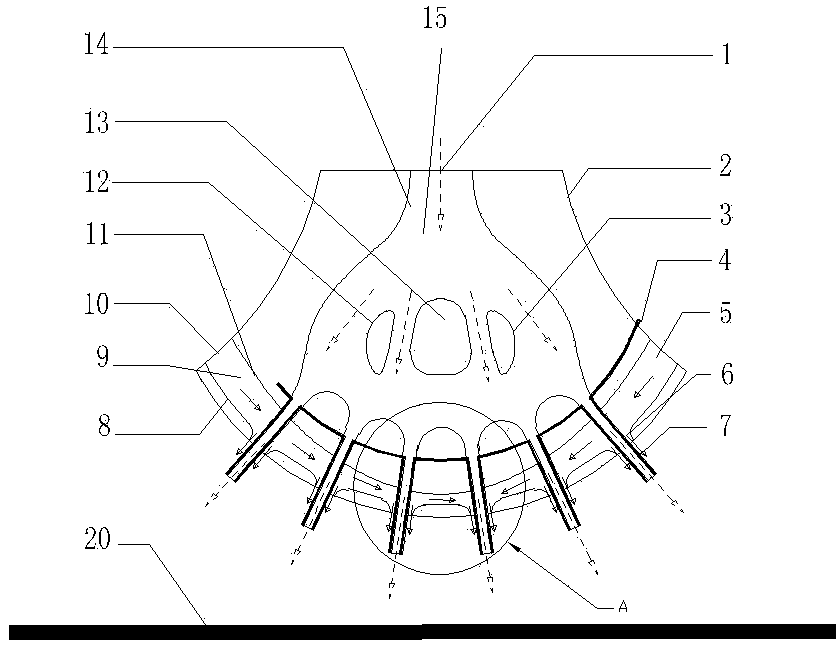

Direct injection molten iron desulphurization spray gun

The invention discloses a direct injection molten iron desulphurization spray gun for a metal particle magnesium or magnesium-based or calcium-based desulphurization agent. The direct injection molten iron desulphurization spray gun comprises a connecting flange and a gun barrel which are sequentially connected and communicated, wherein the gun barrel comprises a connecting section gun barrel and a gun body section gun barrel; the connecting section gun barrel comprises a gun core; a distributor is connected with the lower end of the gun core of the gun body section gun barrel; the distributor comprises an upper end short connecting pipe, a lower end plug platform and a plurality of through holes formed in the wall of the short connecting pipe; and each through hole is communicated with a jetting pipe, and the jetting pipes are distributed in a fire-proof pouring material liner positioned outside the side wall of the distributor. The direct injection molten iron desulphurization spray gun disclosed by the invention can be used for enhancing the jetting strength, extending the desulphurization reaction area and intensifying the gasification and dissolution of metal particle magnesium through structural design, and can be used for enhancing the adaptability on low-quality metal particle magnesium and jetting desulphurization of molten iron tanks with different sizes, extending the adaptive capacity of a process and reducing the consumption cost of the molten iron desulphurization metal particle magnesium through the improvement of desulphurization process steps.

Owner:武汉钢铁有限公司

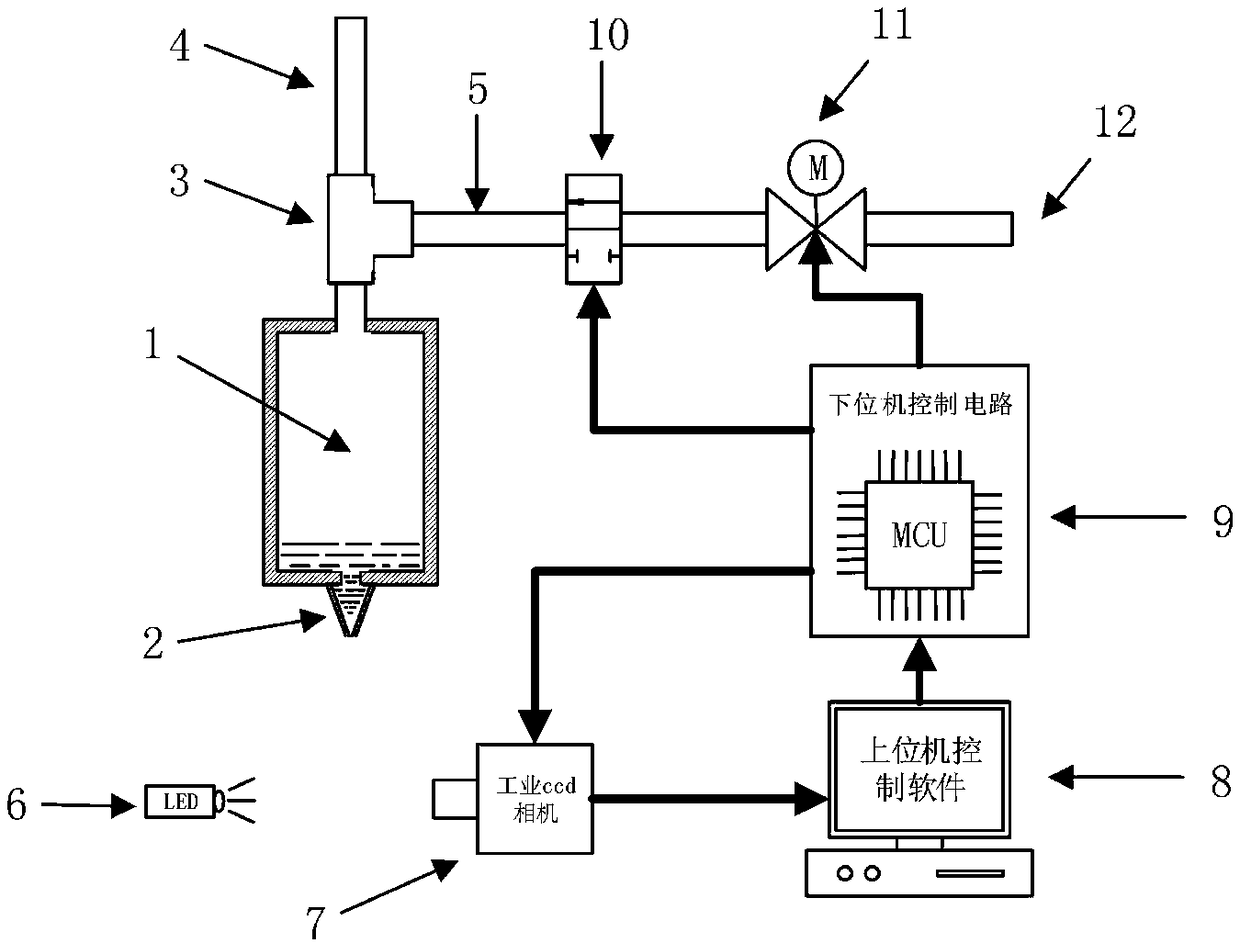

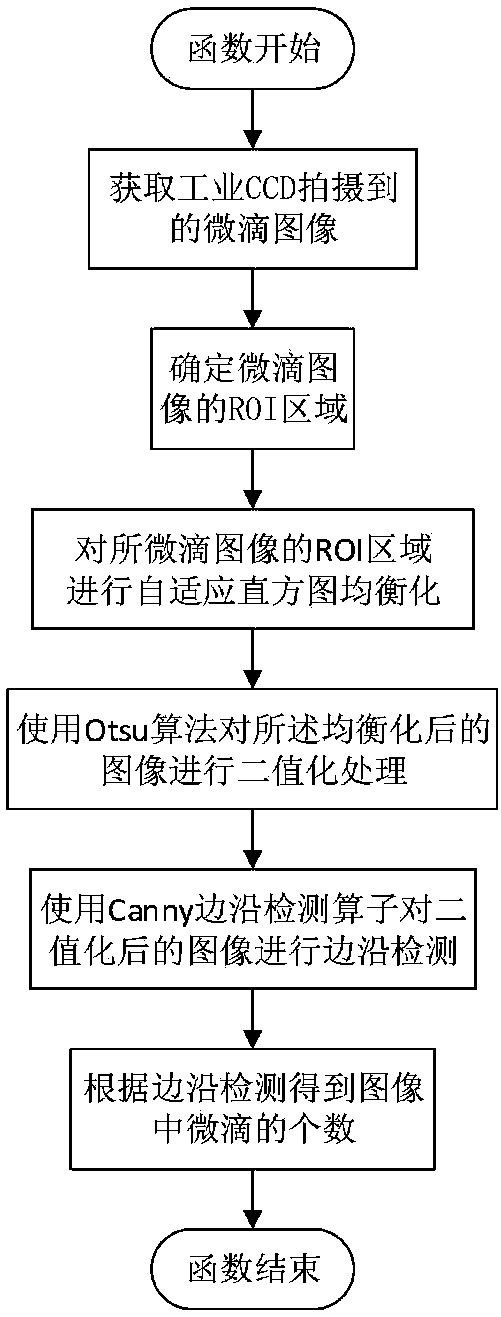

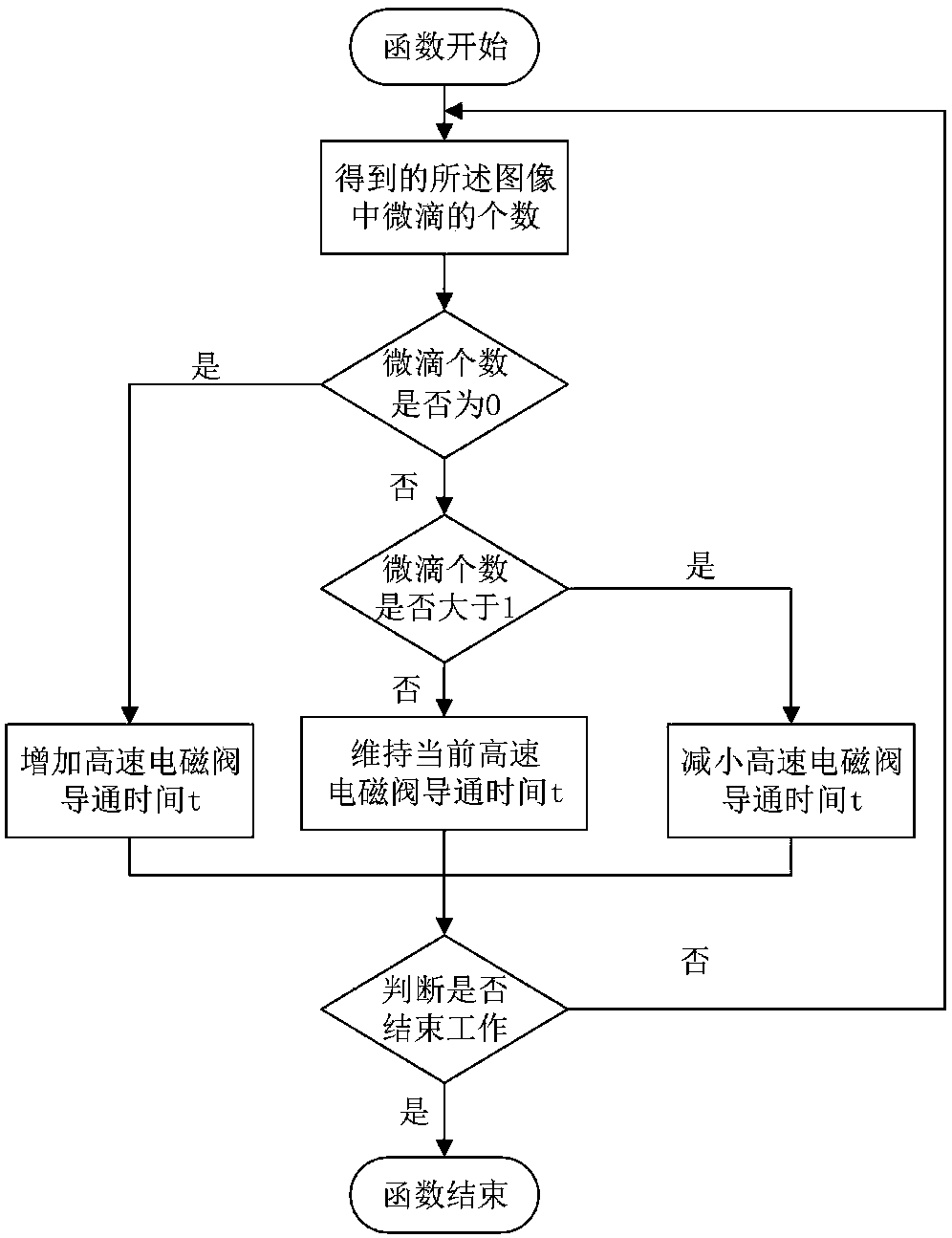

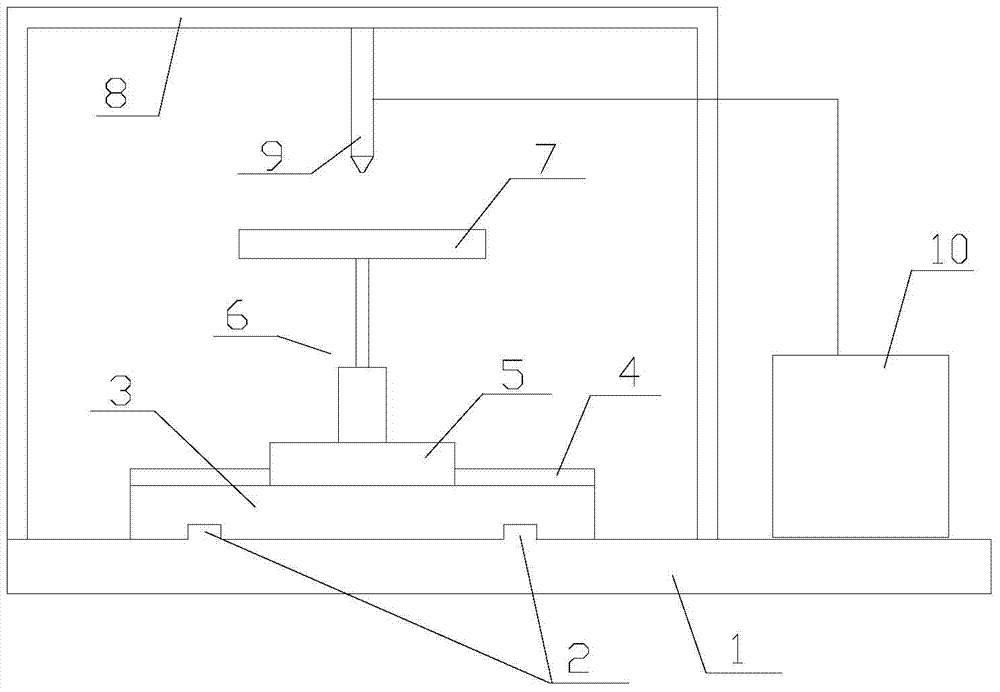

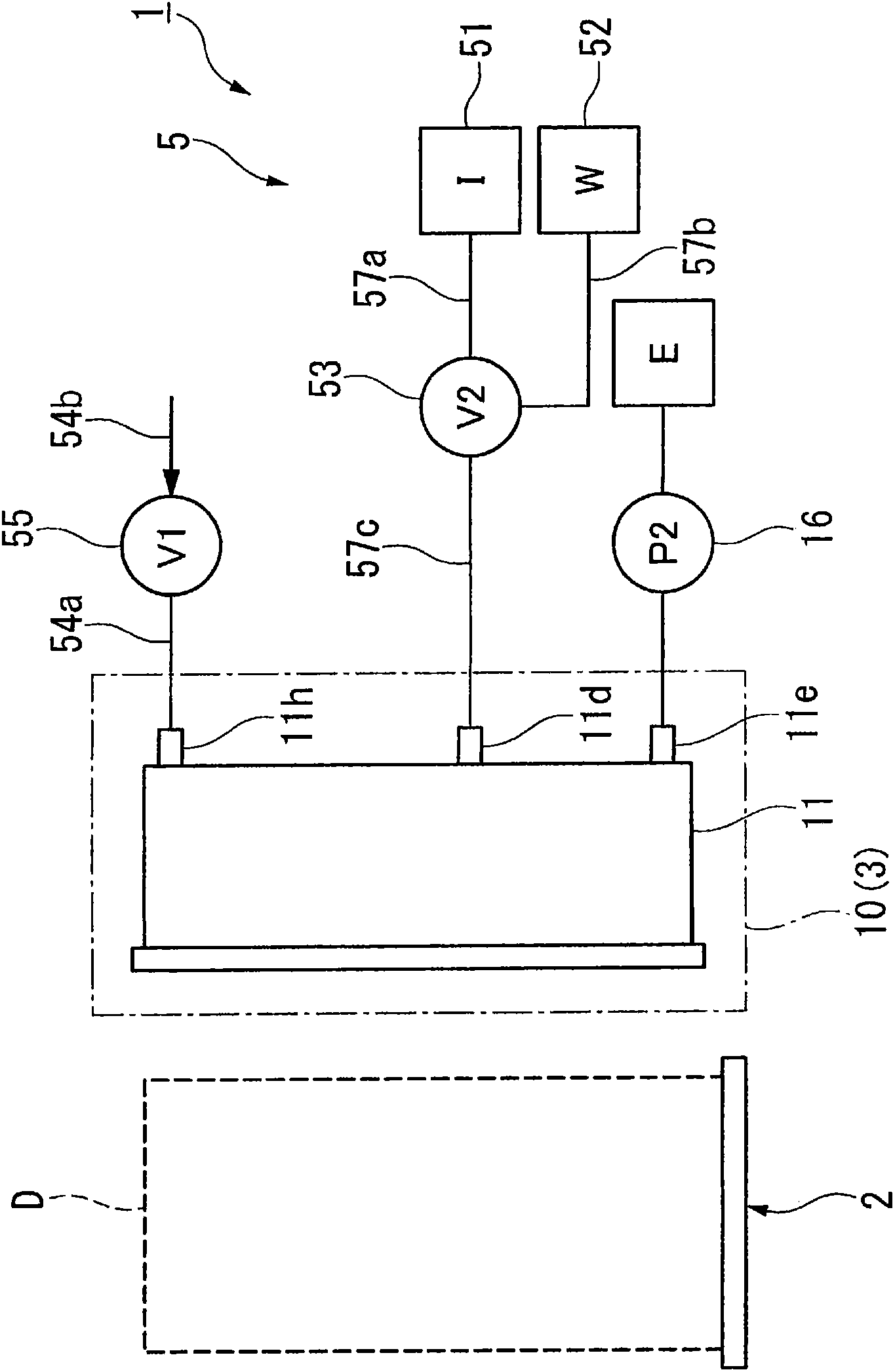

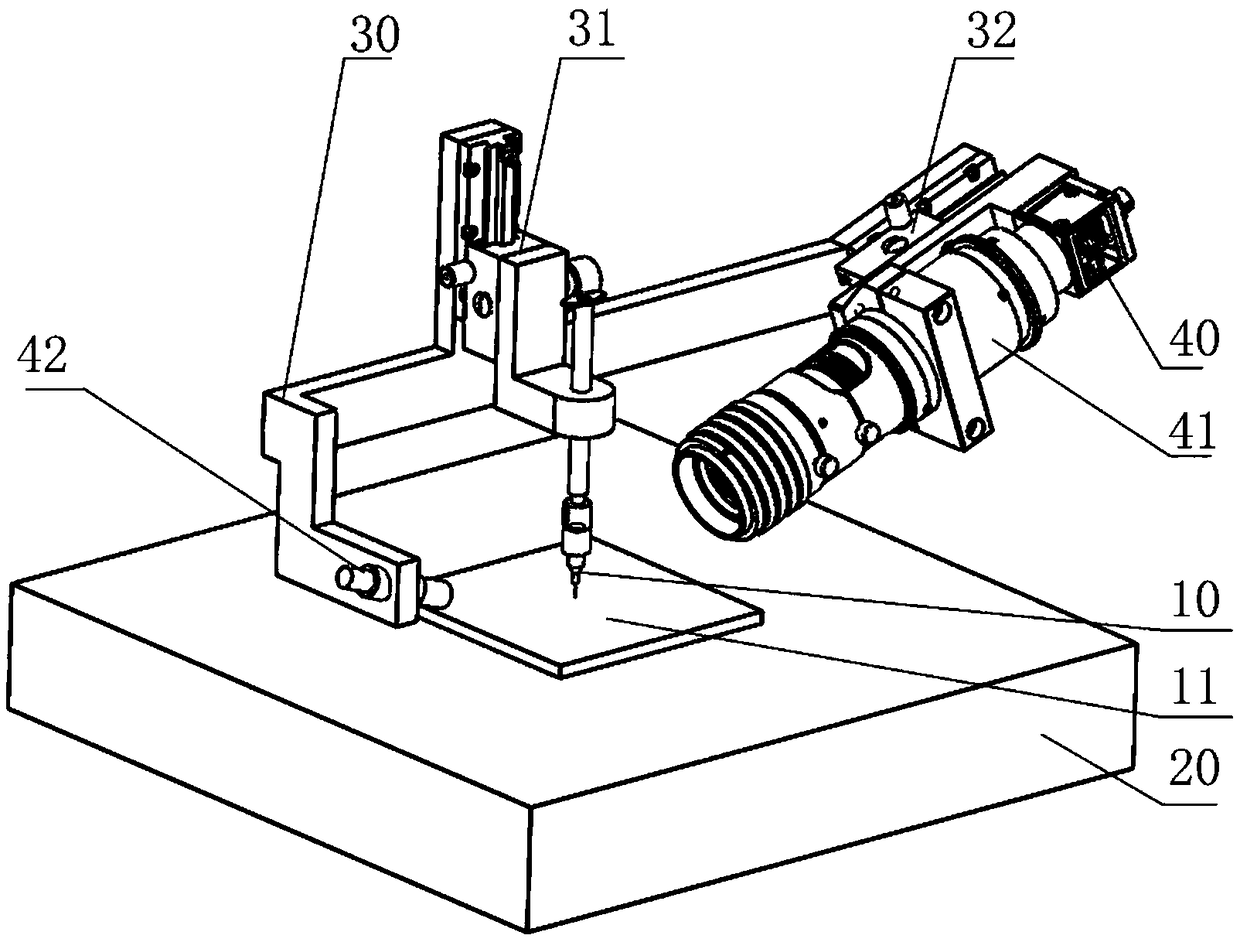

Pneumatic microdroplet jetting state control system and method based on machine vision

The invention discloses a pneumatic microdroplet jetting state control system and method based on machine vision, and belongs to the field of microdroplet jetting. By means of the method, the high speed solenoid valve breakover time t or the high speed solenoid valve front end air pressure P can be singly controlled, and single microdroplets can be stably jetted out in the initialized jetting andjetting process of the system. According to the system and method, a pneumatic microdroplet jetting device can automatically identify the microdroplet jetting state from shot microdroplet images in the initialized jetting and jetting process, the opening degree of an electric proportional valve is controlled to adjust the high speed solenoid valve front end air pressure P and the high speed solenoid valve breakover time t, and it can guarantee that the system can stably jet out single microdroplets all the time. The operation that an operator needs to judge the microdroplet jetting state according to the microdroplet images shot by a CCD camera in real time, the high speed solenoid valve front end air pressure P and the high speed solenoid valve breakover time t need to be manually adjusted is replaced, and the using efficiency of the device is improved.

Owner:BEIJING UNIV OF TECH

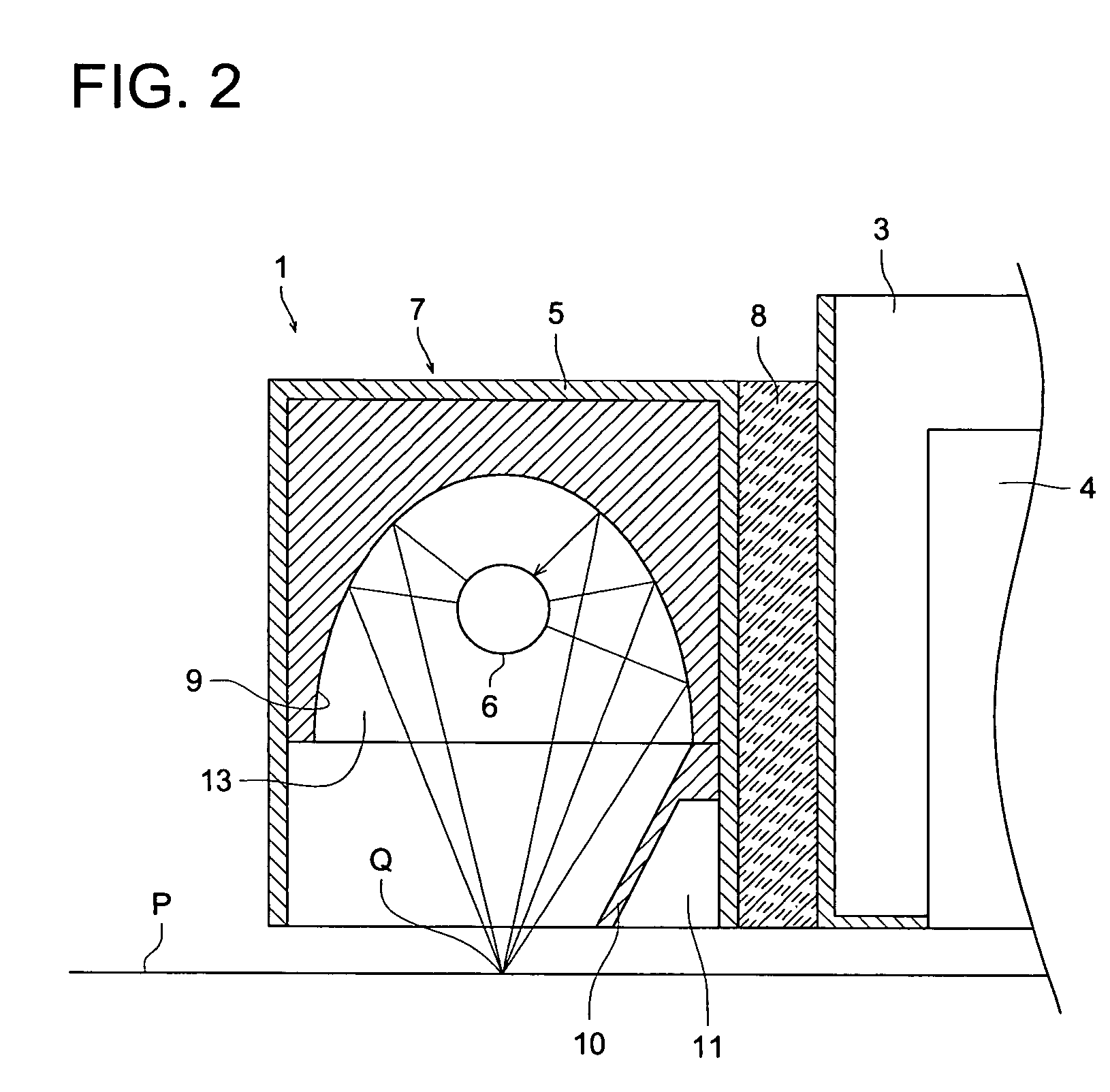

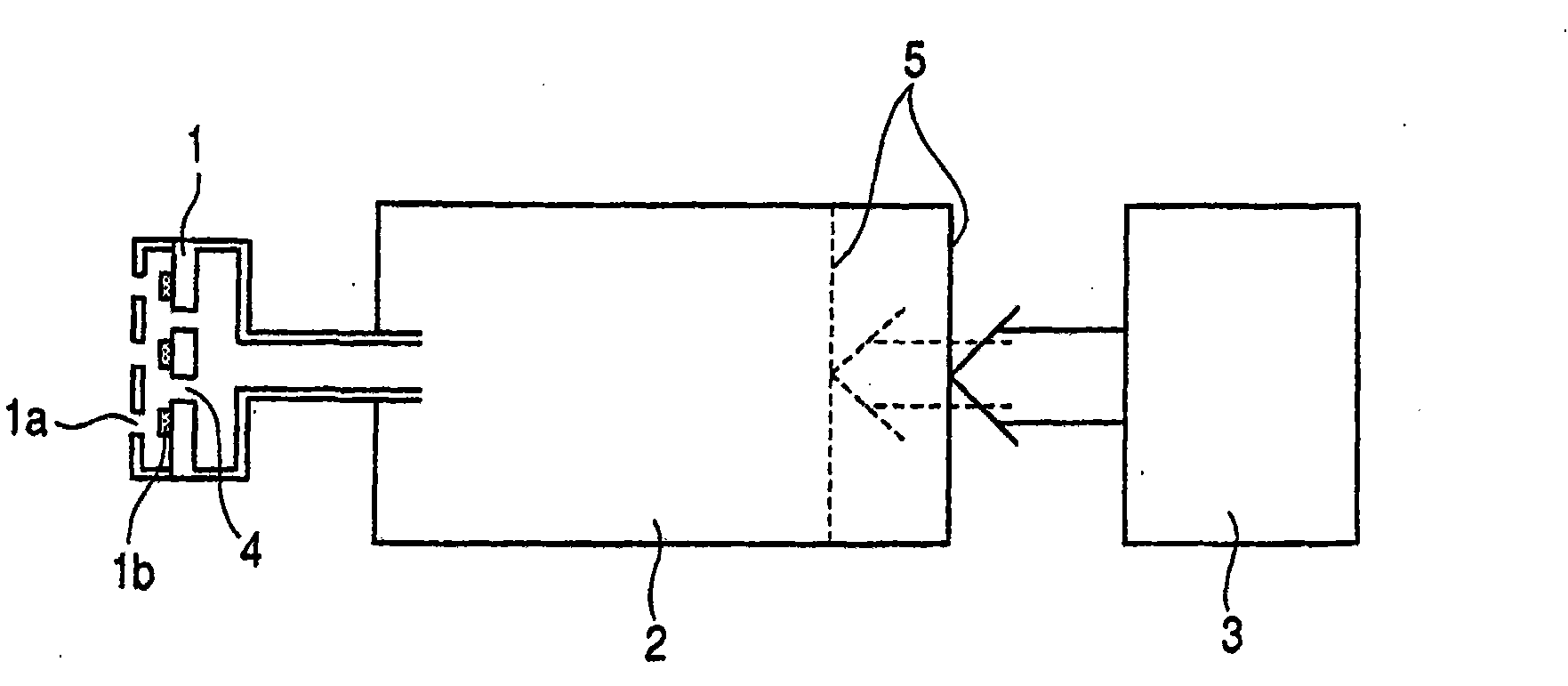

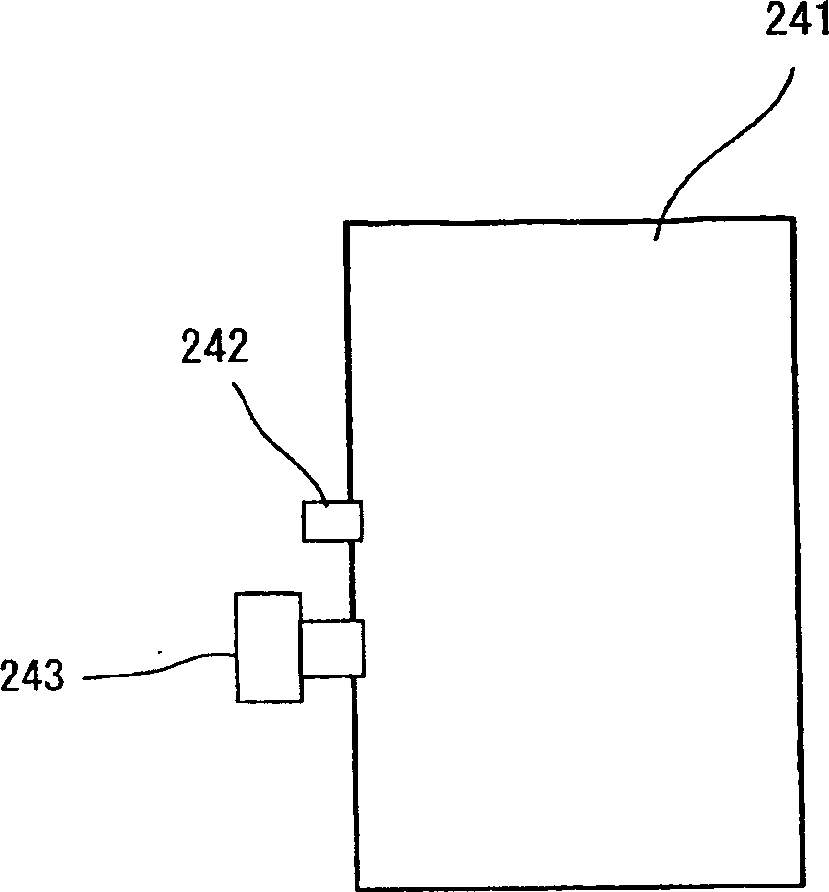

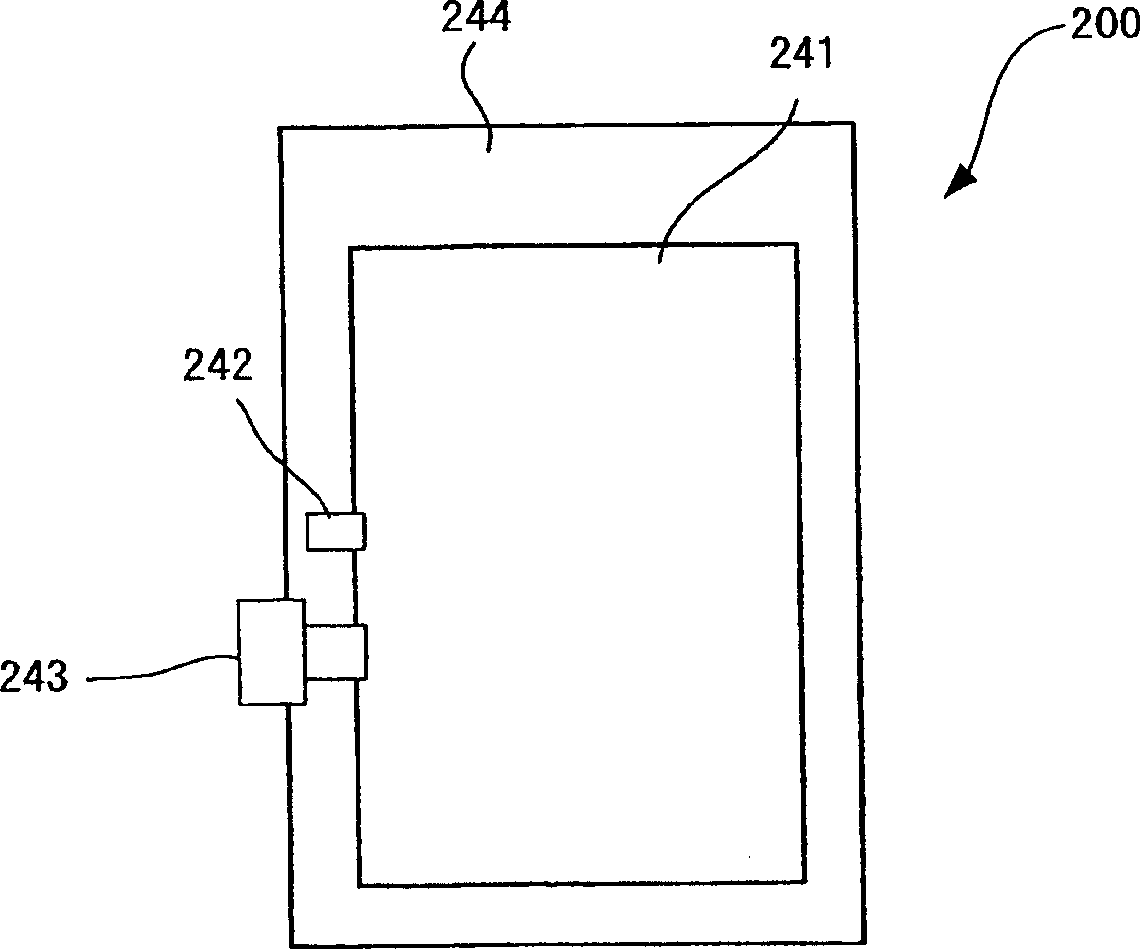

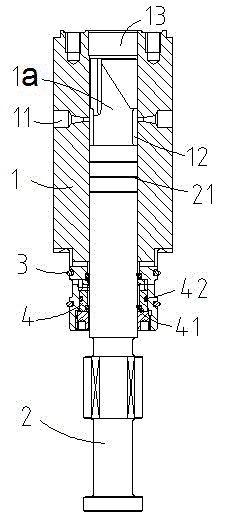

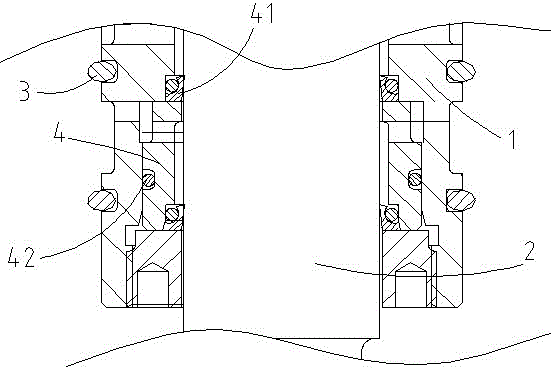

Medicine ejection device and controlling method thereof

InactiveCN101854971ASmall volumeJet stabilityMedical devicesMedical atomisersMedicinePressure difference

The invention provides a medicine ejection device which provides stable ejection even when a reservoir with high sealability is used and can eject an appropriate amount of medicine. A medicine ejection portion 1 includes an ejection nozzle 1a and an element 1b which generates energy for ejecting the medicine, and is connected to a medicine storing portion 2. The medicine storing portion 2 is blocked from the outside air except a path through the ejection nozzle 1a, so that when the medicine is ejected from the ejection nozzle 1a, a pressure difference is formed between the outside and the inside of the medicine storing portion 2. A pressure unit 3 which is a feature of the present invention pressurizes a movable wall 5 when ejecting a medicine, which is displaced so that the volumetric capacity of the medicine storing portion 2 decreases due to the pressure difference.

Owner:CANON KK

Clay 3D (Three Dimensional) printer and extruding device thereof

InactiveCN105500494AOvercome technical difficulties with air bubblesPrecision injectionCeramic shaping apparatusSpray nozzleEngineering

The invention discloses a clay 3D (Three Dimensional) printer. The clay 3D printer comprises a rack, and a material storage device and an extruding device which are arranged on the rack, wherein the material storage device comprises a material storage tank, an air compressor, a piston and a material conveying pipe; the air compressor is communicated with a top air inlet of the material storage tank; the piston is arranged in the material storage tank; and the extruding device comprises a shell, a feeding part, an extruding charging barrel arranged in the shell and a nozzle arranged at the lower part of the extruding charging barrel. The difficulty that materials have air bubbles in a printing process is overcome and the problem of the viscosity of the materials is effectively solved; and meanwhile, an extruding amount of the nozzle also can be effectively controlled, and the printing quality and precision of a product are guaranteed. With the adoption of the clay 3D printer provided by the invention, the material storage tanks with different sizes can be replaced according to clay with different viscosities and an applicable range of the clay 3D printer is expanded; and the material conveying pipe adopts a PU (Polyurethane) hose so that the resistance of flowing-state clay can be reduced and the clay is prevented from being blocked in the material conveying pipe.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Large-flow adjustable firefighting water-sprinkling sprayer

The invention discloses a large-flow adjustable firefighting water-sprinkling sprayer. During practical use, the large-flow adjustable firefighting water-sprinkling sprayer is mainly used for large-flow firefighting conditions during big fire; when fire breaks out, after a glass ball is broken due to heating, temperature sensors on a bearing plate perform temperature induction on a fire source direction and transmit signals to a controller; after the controller receives the signals of the temperature sensors, the controller controls a motor of a telescopic driving device which is opposite to afire source in direction to be started; and the motor drives a corresponding gear to rotate, and further a corresponding connection chain is pulled upwards. Besides, when the fire source is located between a left side and a right side, telescopic driving devices close to two sides of the fire source can perform contraction control on corresponding connection chains synchronously, so that targetedfire extinguishing can be performed in the direction; besides, elastic supporting sleeves which sleeve the connection chains exert an elastic supporting effect on the connection chains, so that supporting strength of the connection chains to a water spilling disc can be enhanced; and a large-flow water flow can be stably baffled and guided by the water spilling disc, so that precise spraying fireextinguishing is realized.

Owner:南安市祥发消防设备有限公司

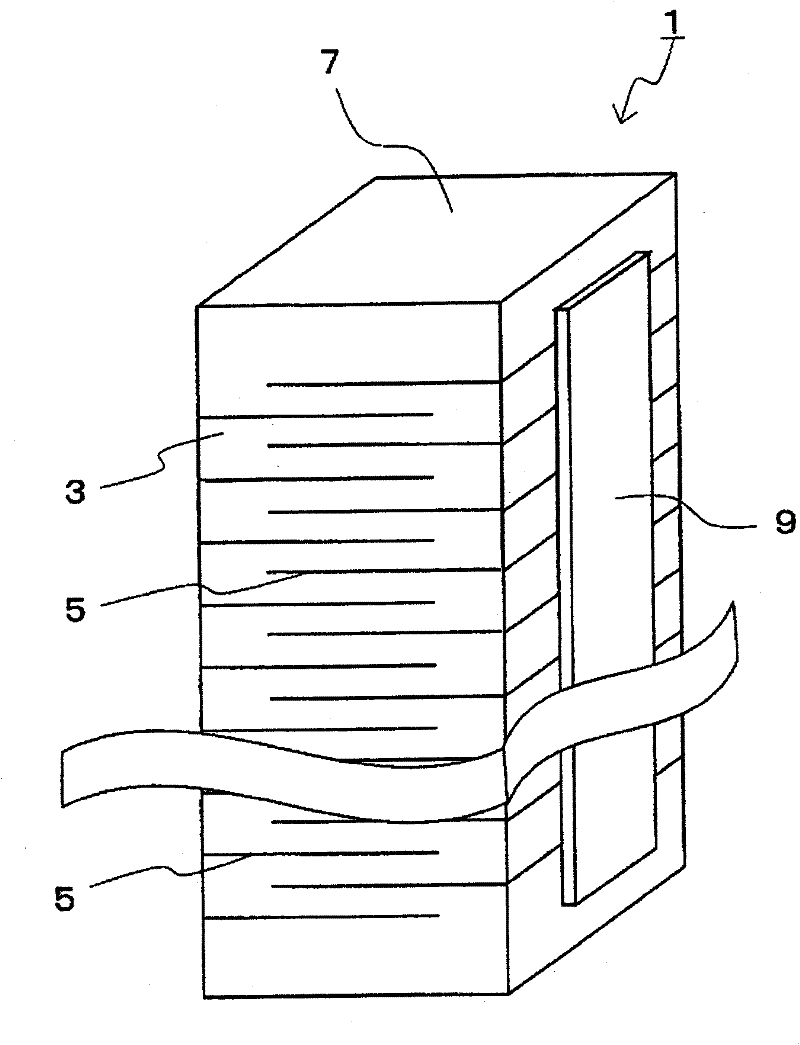

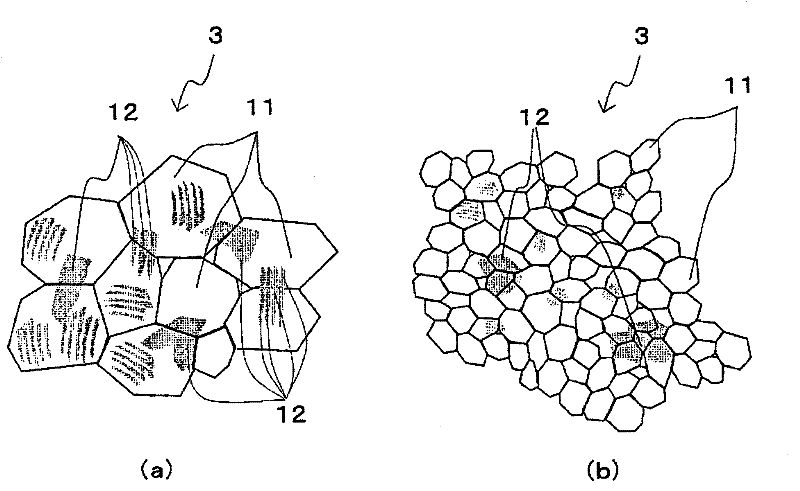

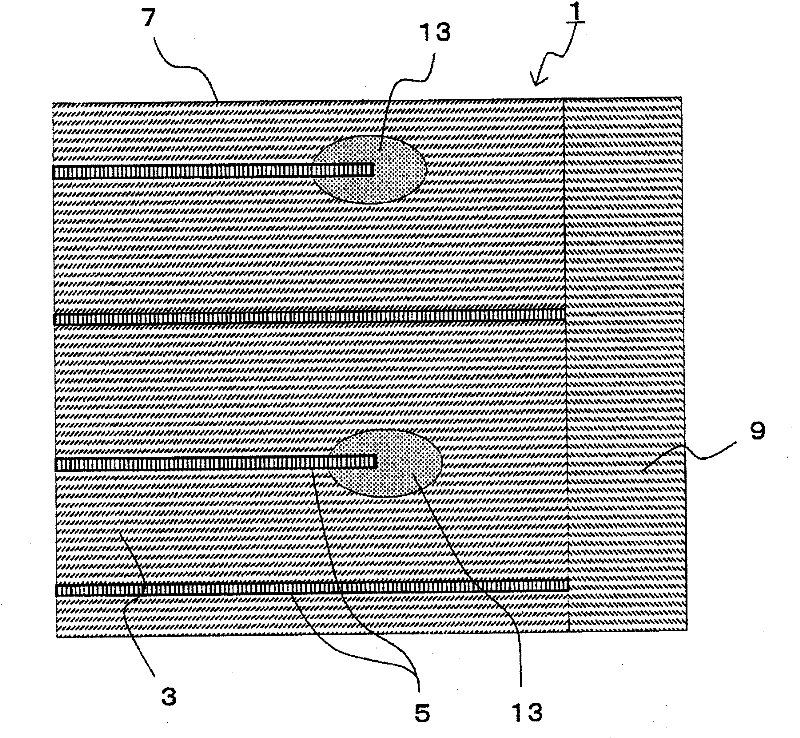

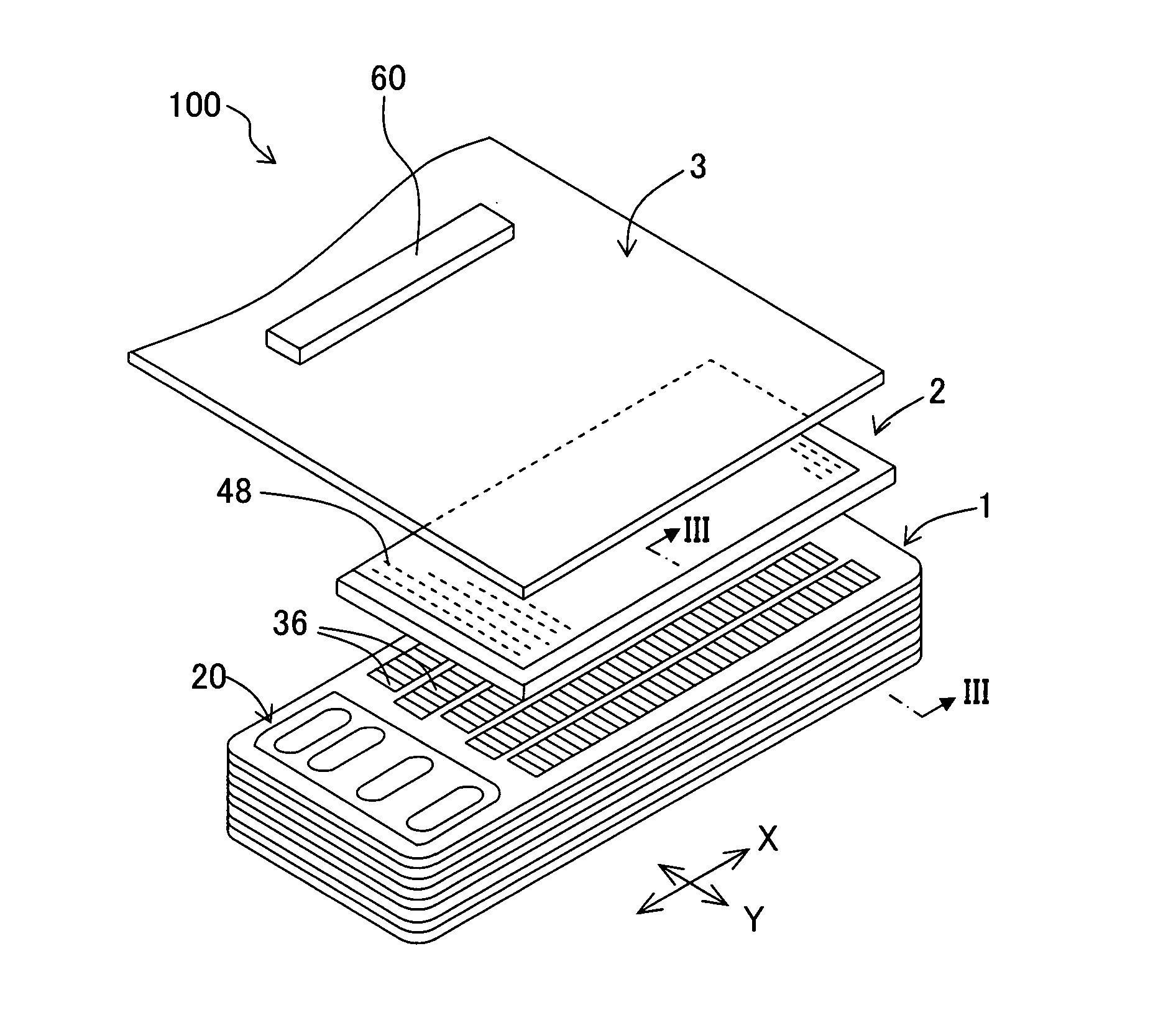

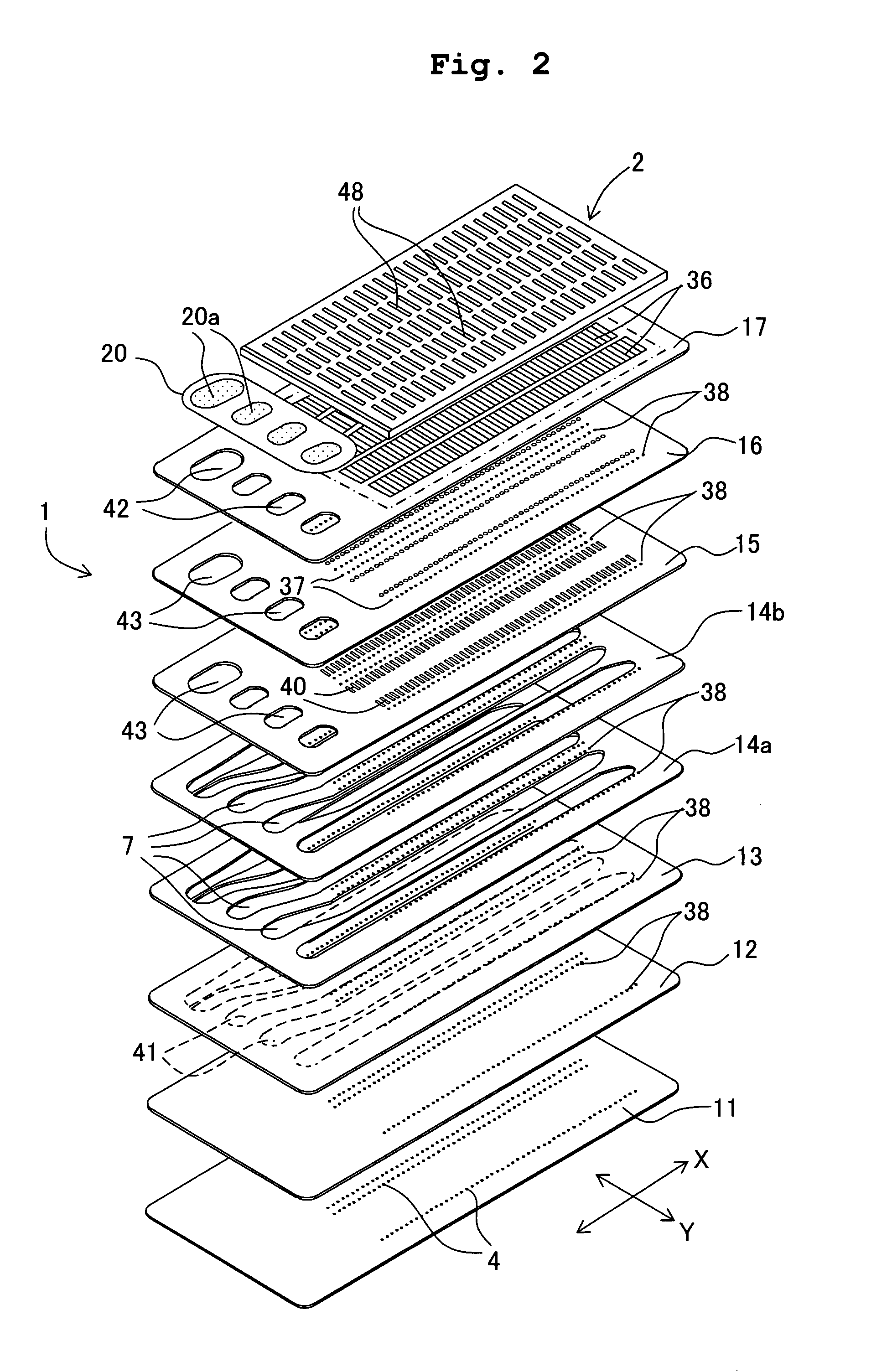

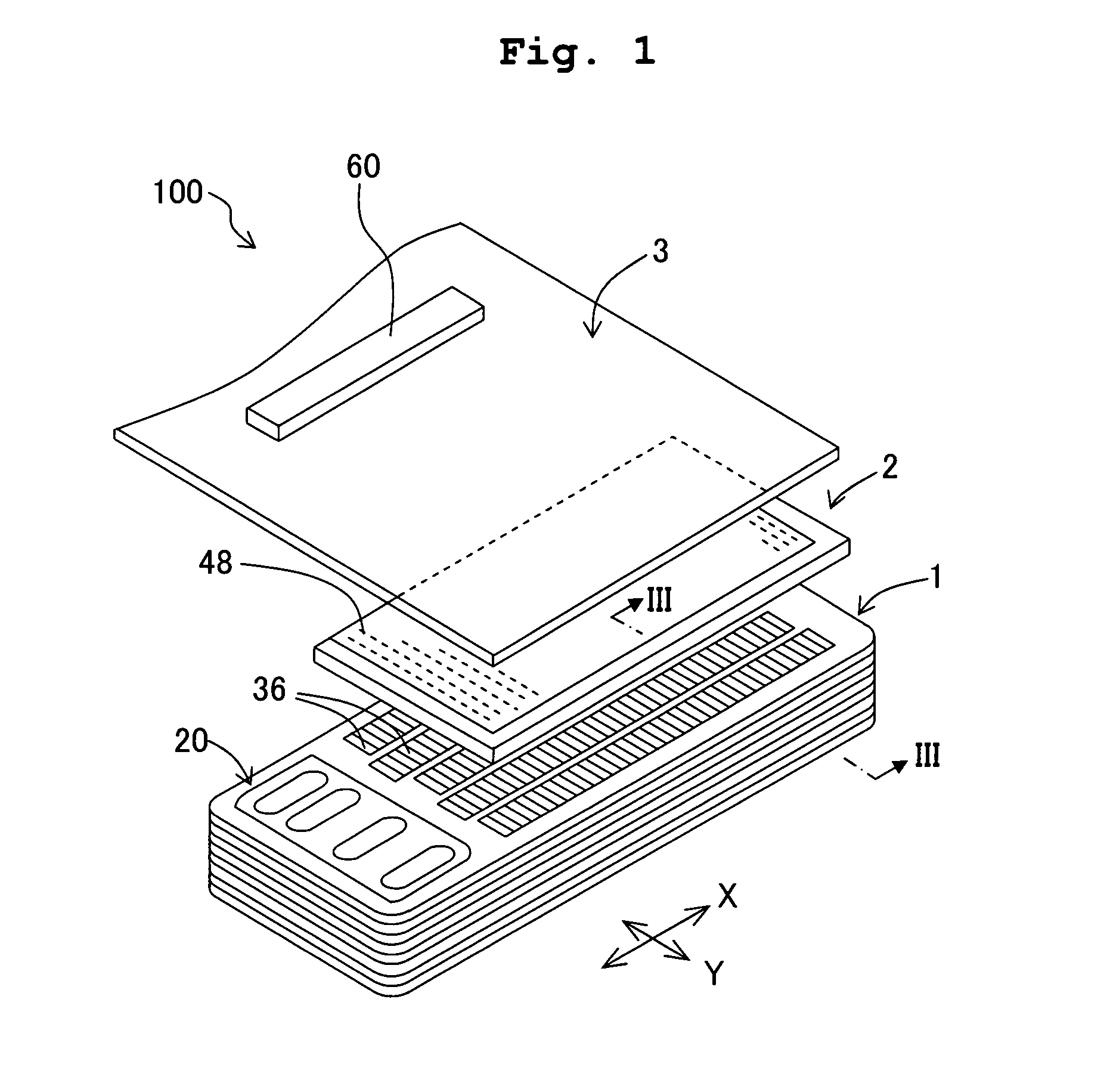

Multilayer piezoelectric element, injection apparatus, and fuel injection system

ActiveCN102132433AReduce constraintsIncrease movement speed and movement amountPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCrystalliteEngineering

Provided is a multilayer piezoelectric element which achieves a high response speed and an increase in the displacement amount, ensures sufficient mechanical strength, and can suppress degradation of characteristics. A multilayer piezoelectric element (1) includes a layered body (7) in which a piezoelectric layer (3) and an internal electrode layer (5) are alternately layered. In the multilayer piezoelectric element (1), a polarization domain (12) lying astride a plurality of crystal grains (11) is formed in the piezoelectric layer (3). Since the polarization domain (12) lying astride the crystal grains (11) is formed in the piezoelectric layer (3), in the multilayer piezoelectric element (1), the response speed and the displacement amount can be increased, high mechanical strength is ensured, and degradation of characteristics can be suppressed.

Owner:KYOCERA CORP

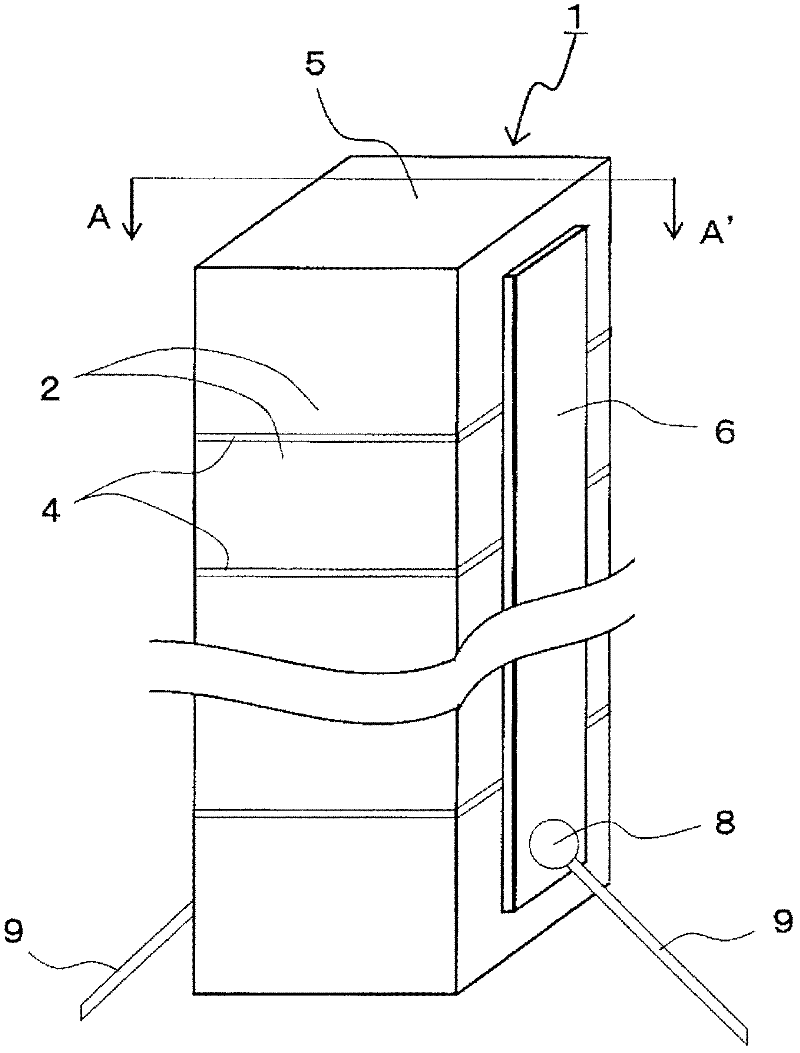

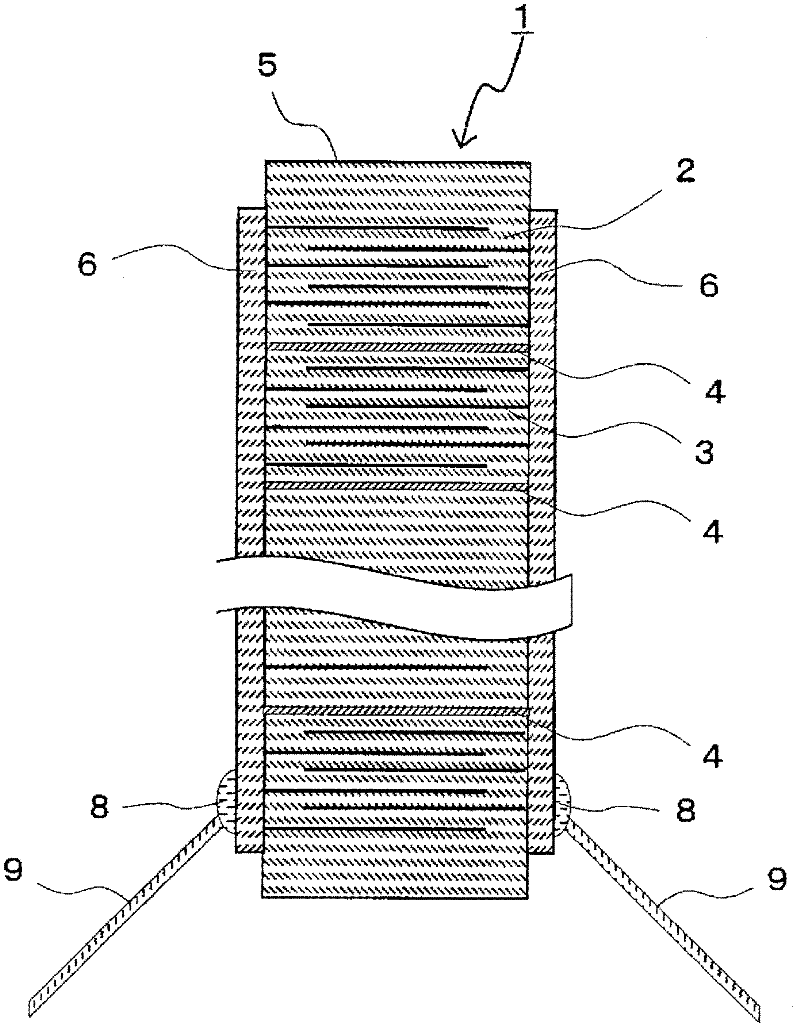

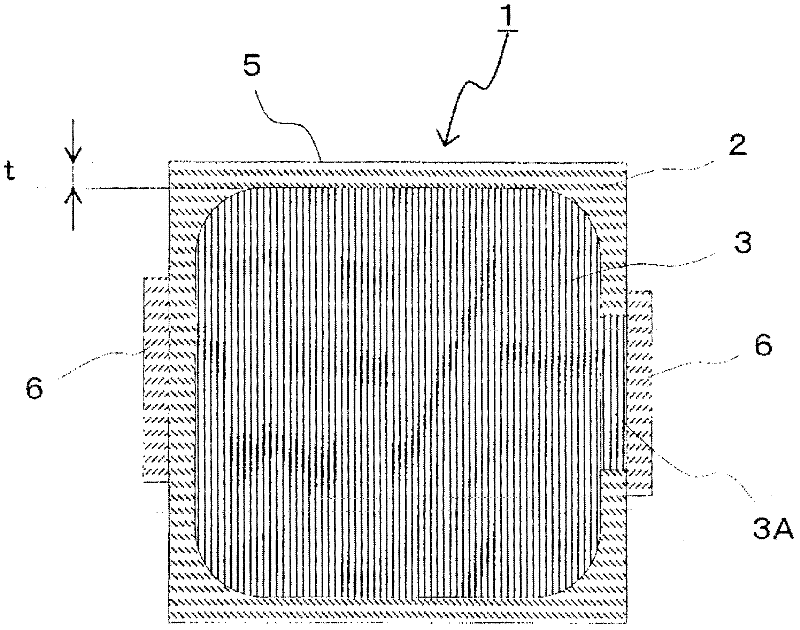

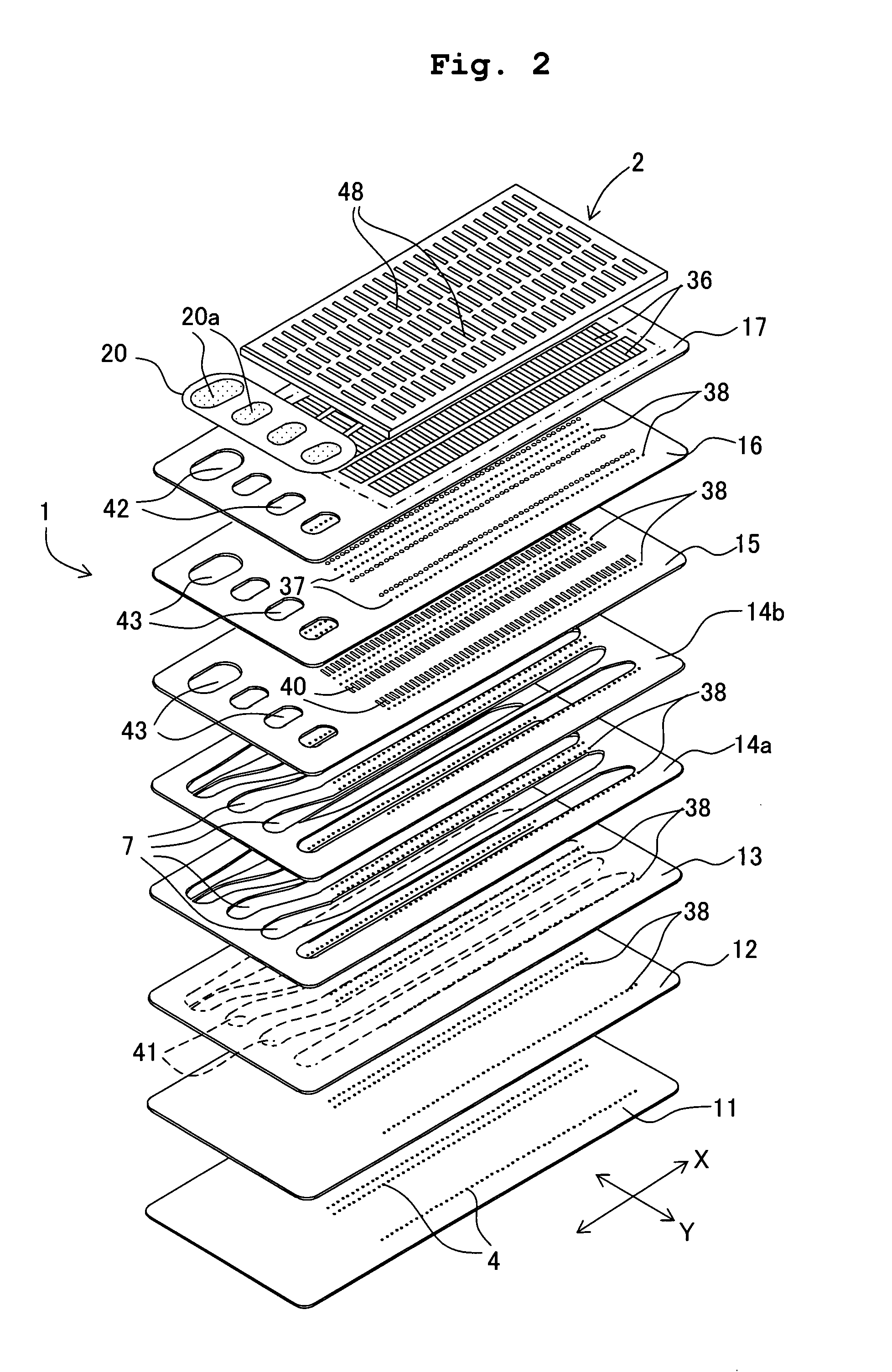

Stacked piezoelectric element, injection device using same, and fuel injection system

InactiveCN102473834AThere is no danger of short circuits or the likeDisplacement is not restrictedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesStress relaxationEngineering

Conventional stacked piezoelectric elements sometimes cannot be stably driven because cracking sometimes occurs in a stack when the amount of displacement is large and when being driven at high speed. Specifically provided is a stacked piezoelectric element (1), the stacked piezoelectric element (1) comprising: a stack (5) in which piezoelectric layers (2) and internal electrode layers are alternately stacked and stress relaxation layers (4) are disposed between some of the piezoelectric layers (2); and external electrodes (6) joined to side surfaces of the stack (5) and electrically connected to the internal electrode layers, wherein the internal electrode layers are not exposed on the side surfaces of the stack (5), and the stress relaxation layers (4) are exposed on the side surfaces of the stack (5). The stacked piezoelectric element (1) with excellent durability can be provided in which cracking that occurs due to stress caused by the expansion and contraction of the stack (5) can be selectively caused to occur from the stress relaxation layer (4) so that the stress can be relaxed to thereby prevent the occurrence of a short circuit between the internal electrode layers caused by cracking and achieve high displacement.

Owner:KYOCERA CORP

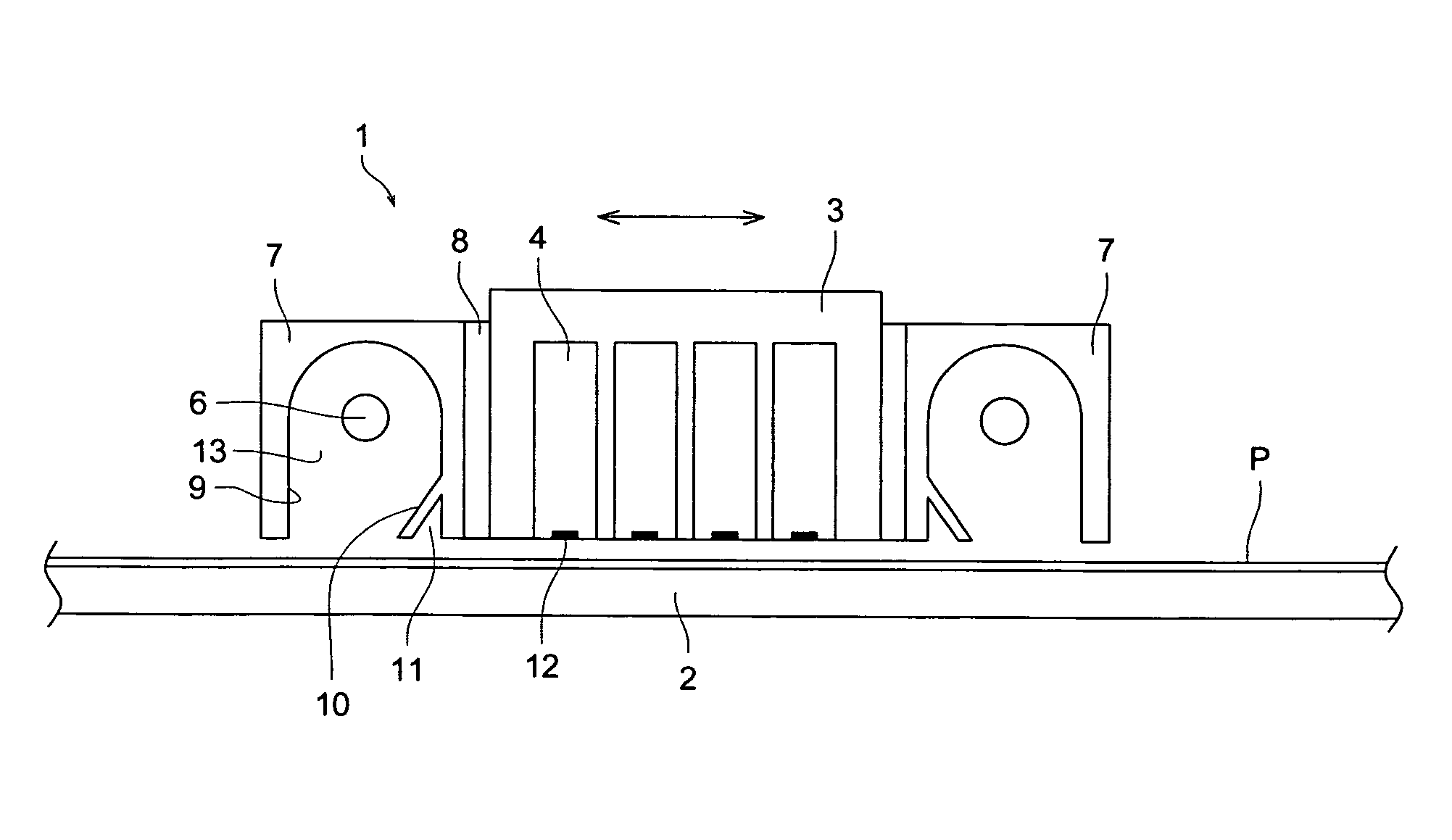

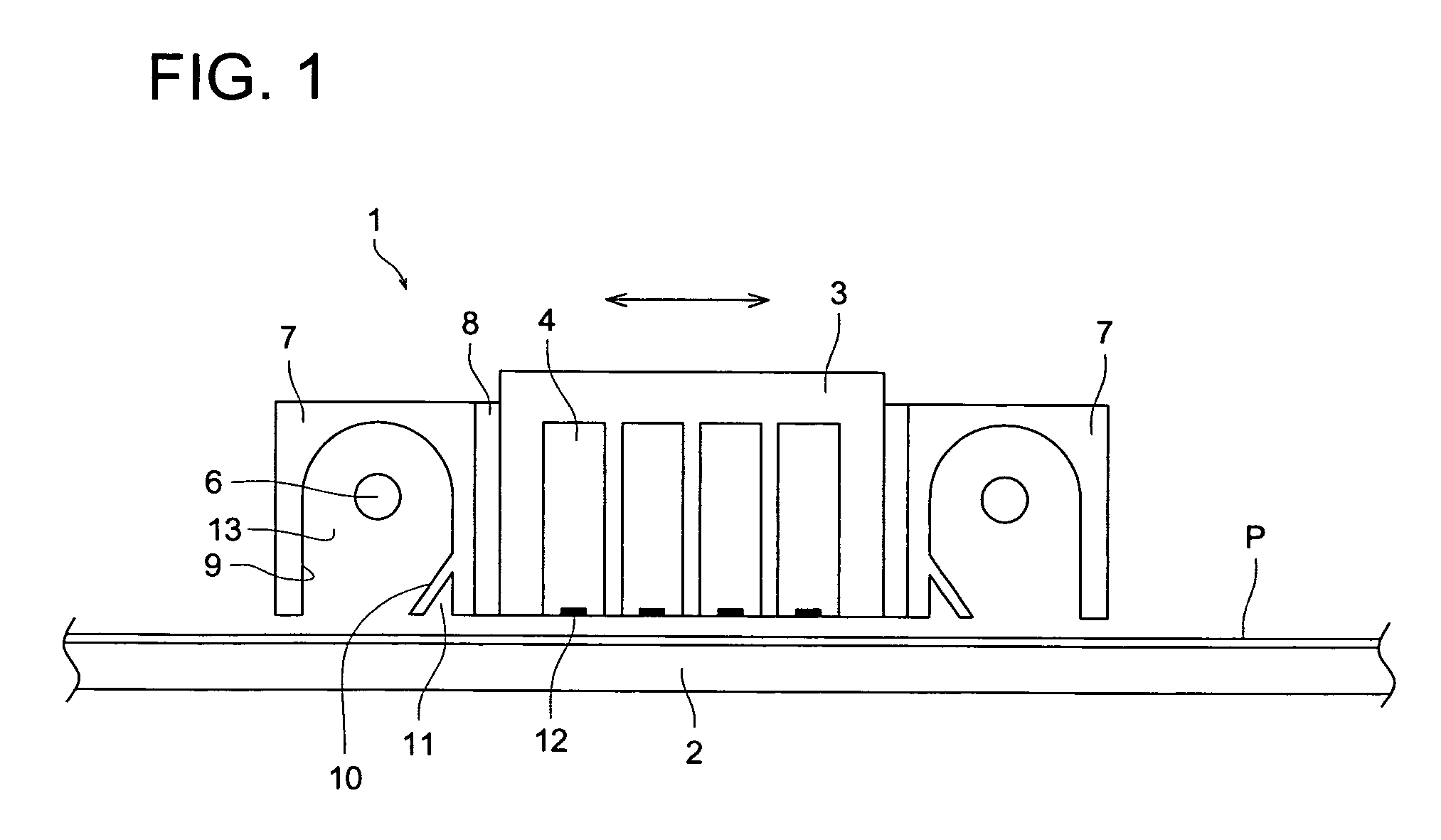

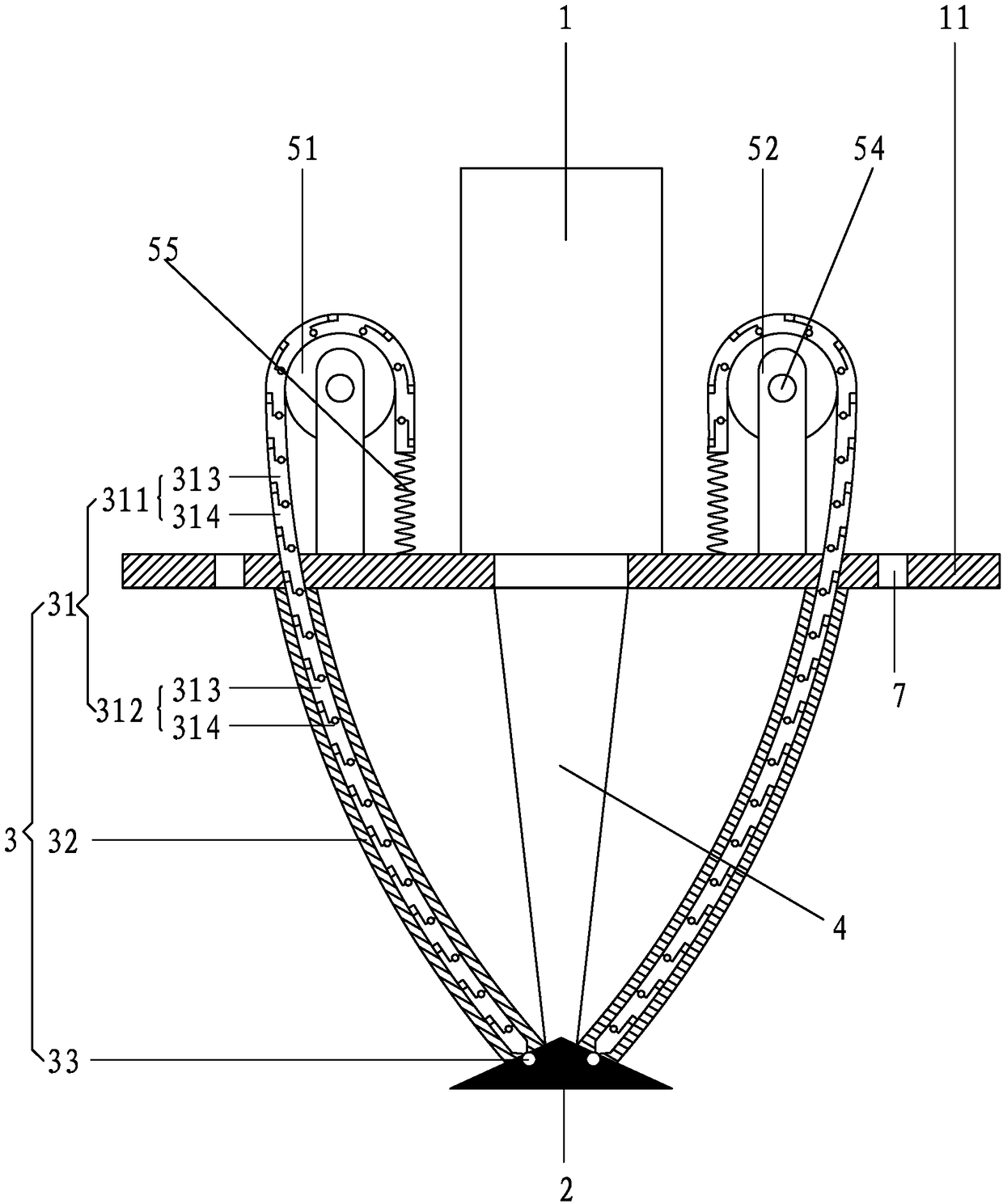

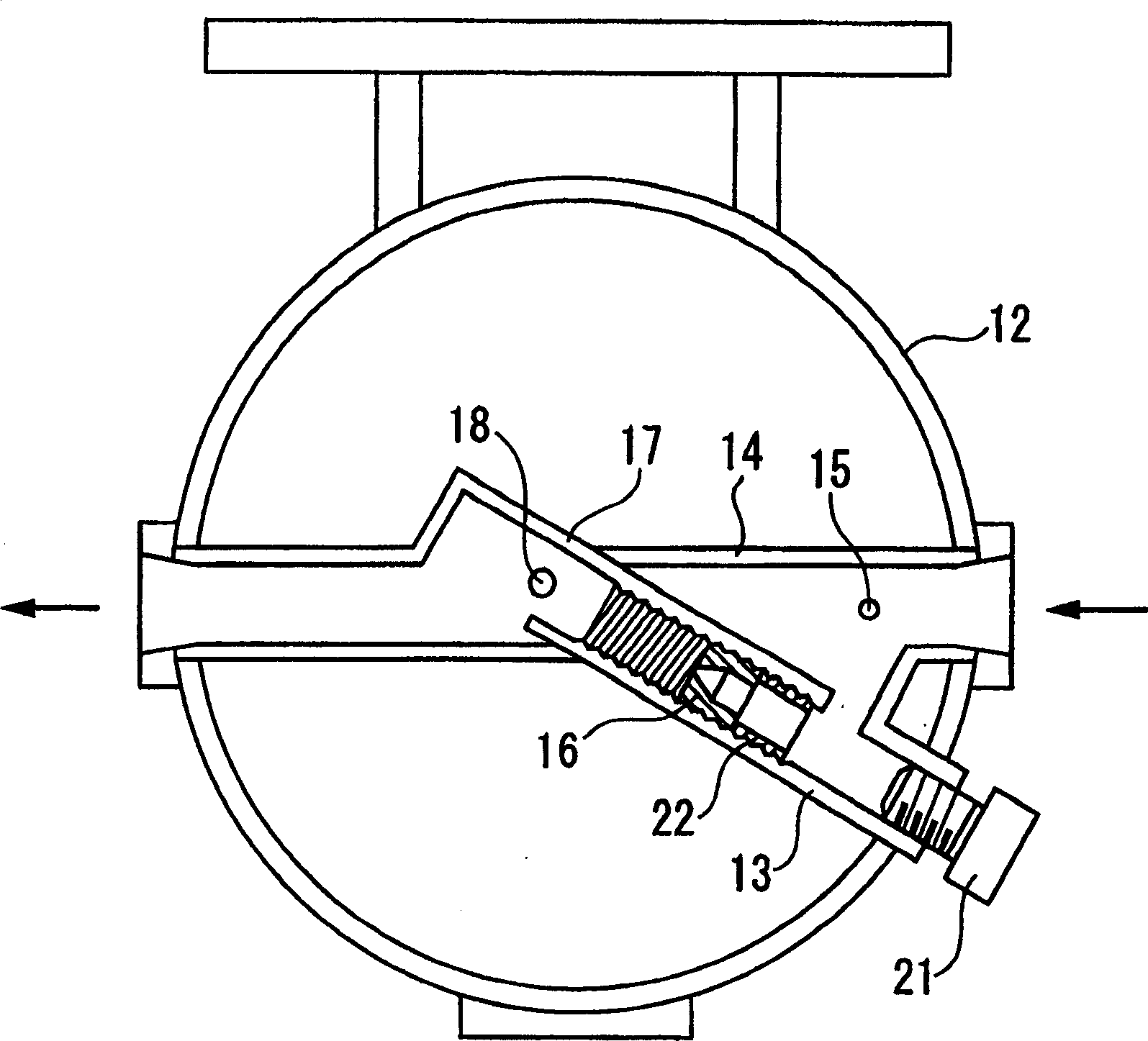

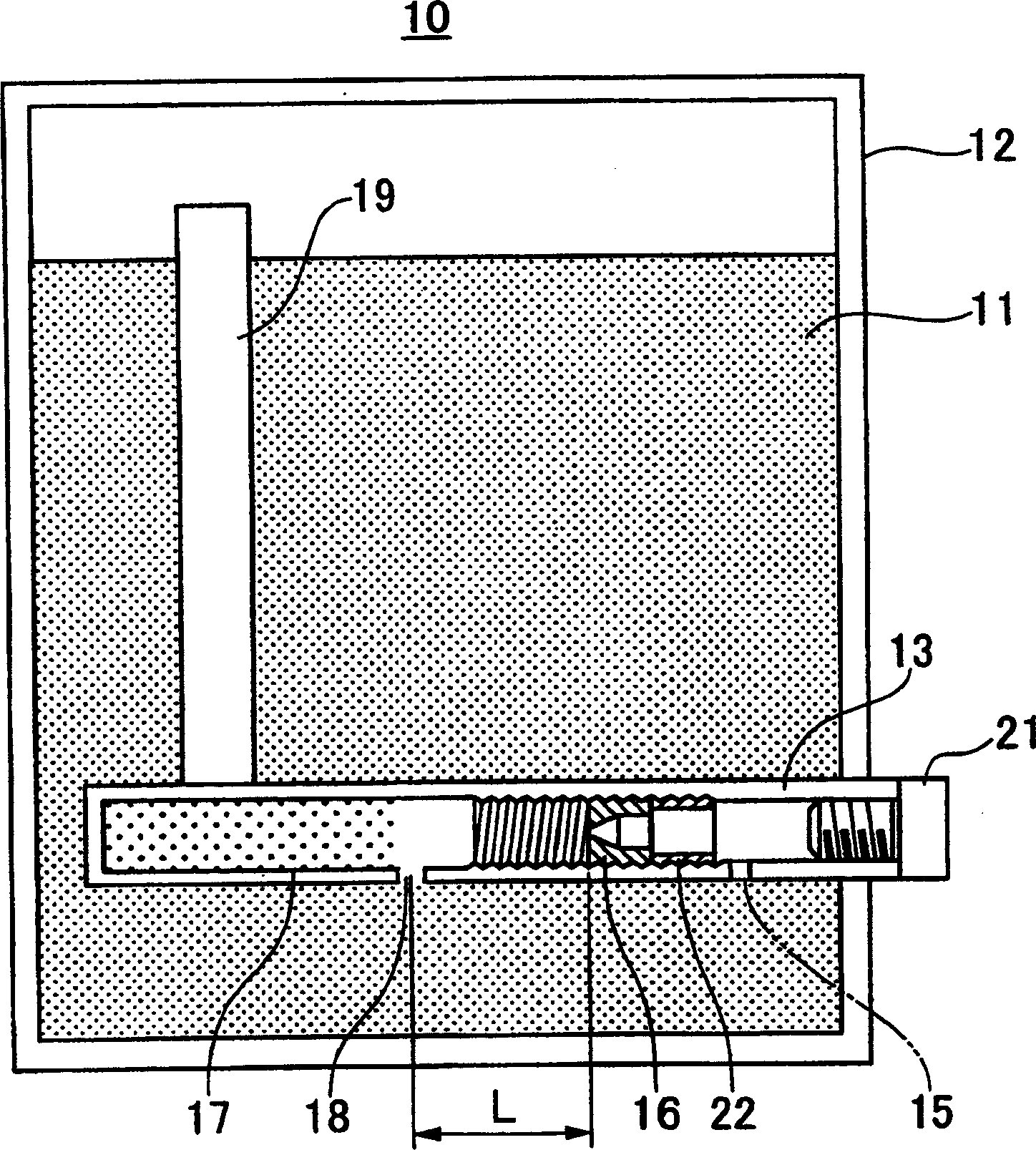

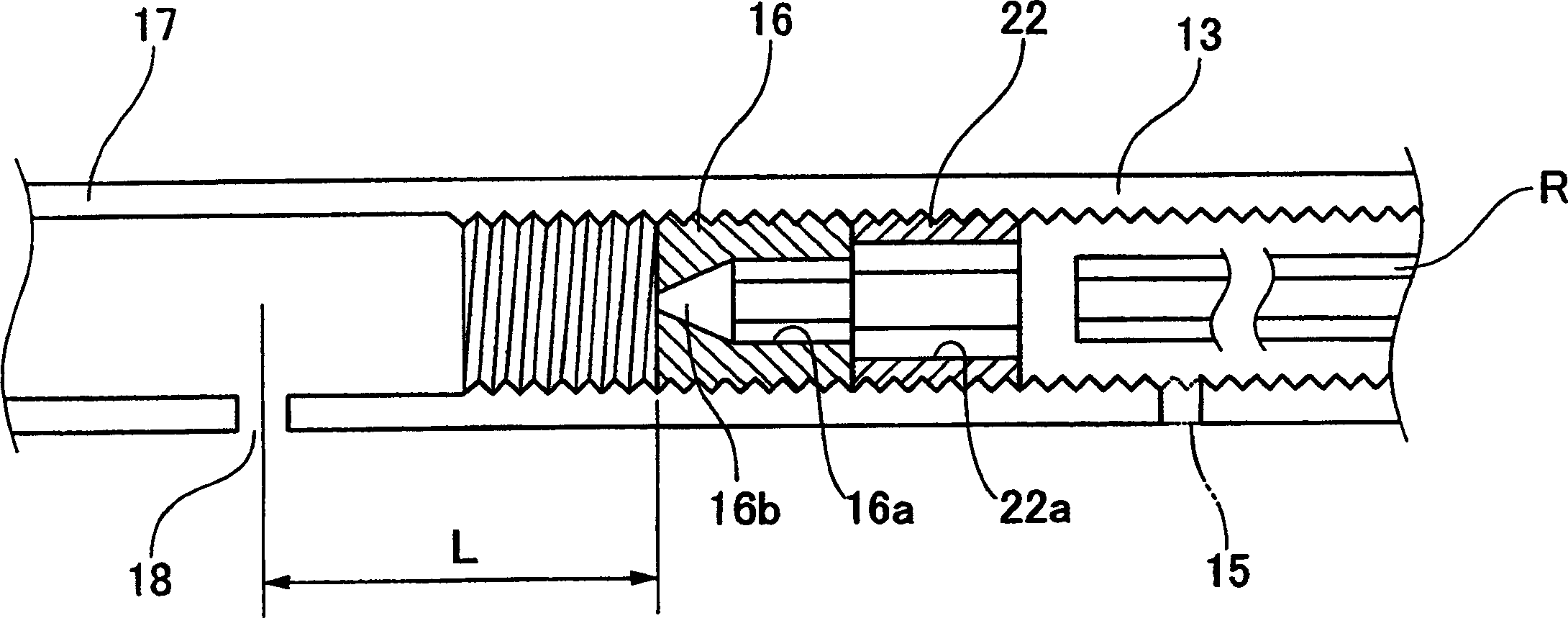

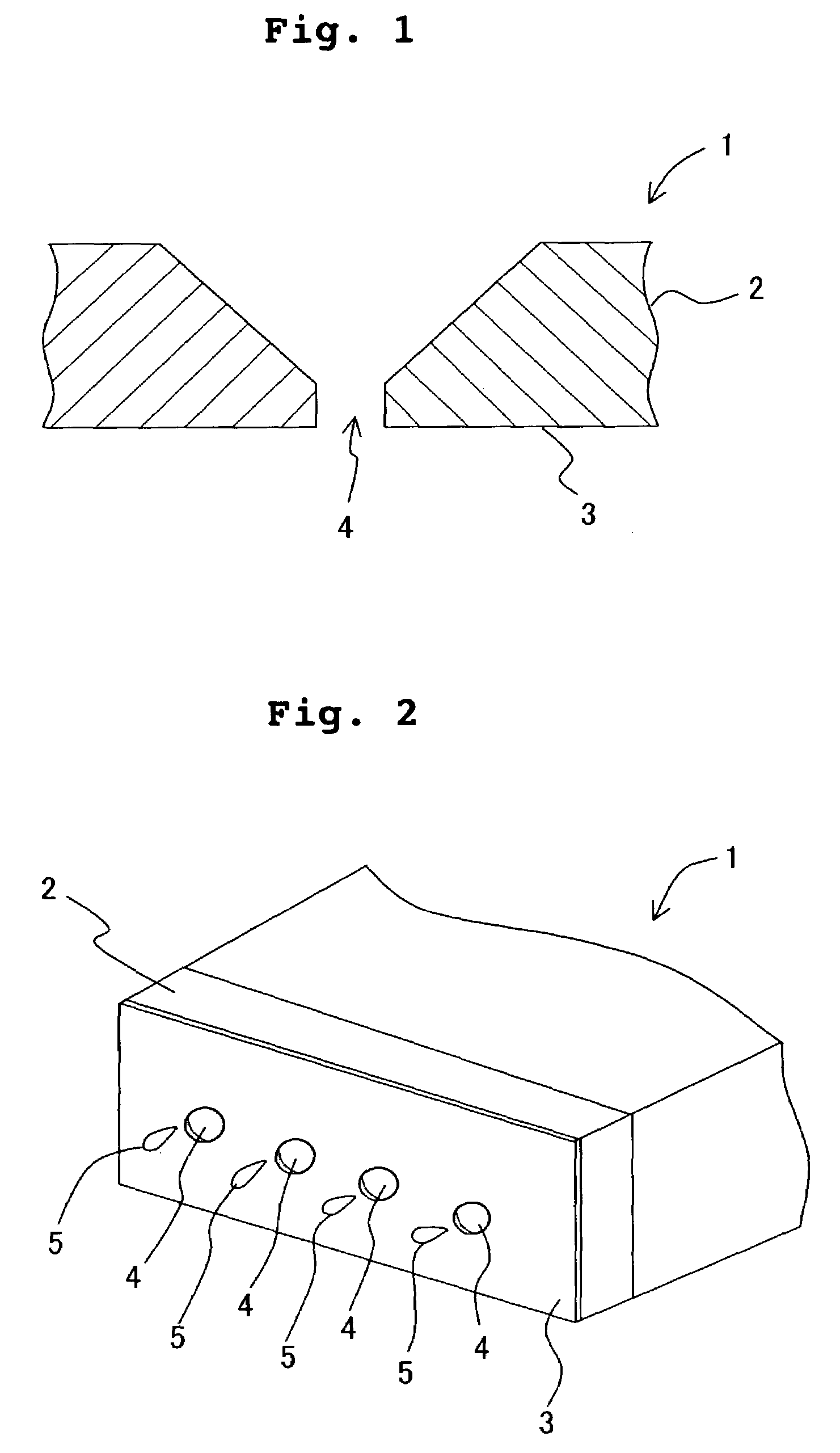

Antiskid material sprinkling apparatus

InactiveCN1488540AJet stabilityDoes not reduce injection volumeWheel adhesionRailway transportEngineeringMaterial storage

This slip preventive material spraying device is provided with a slip preventive material storage container 12 storing the slip preventive material, an air introduction pipe 13 provided in the slip preventive material storage container, a compressed air supply pipe 14 supplying compressed air to the air introduction pipe, a blowout hole 15 formed in the air introduction pipe and spraying the compressed air in the slip preventive material storage container, a nozzle part 16 disposed in the air introduction pipe, a mixing tube 17 connected with the air introduction pipe and mixing the slip preventive material and air, a slip preventive material suction hole 18 formed in the mixing tube, a communicating pipe 19 with its one end communicated with the mixing tube and the other end opened in the slip preventive material storage container, a spraying pipe connected with the mixing tube and spraying the slip preventive material with the compressed air, and sprays the slip preventive material.

Owner:RAILWAY TECH RES INST +1

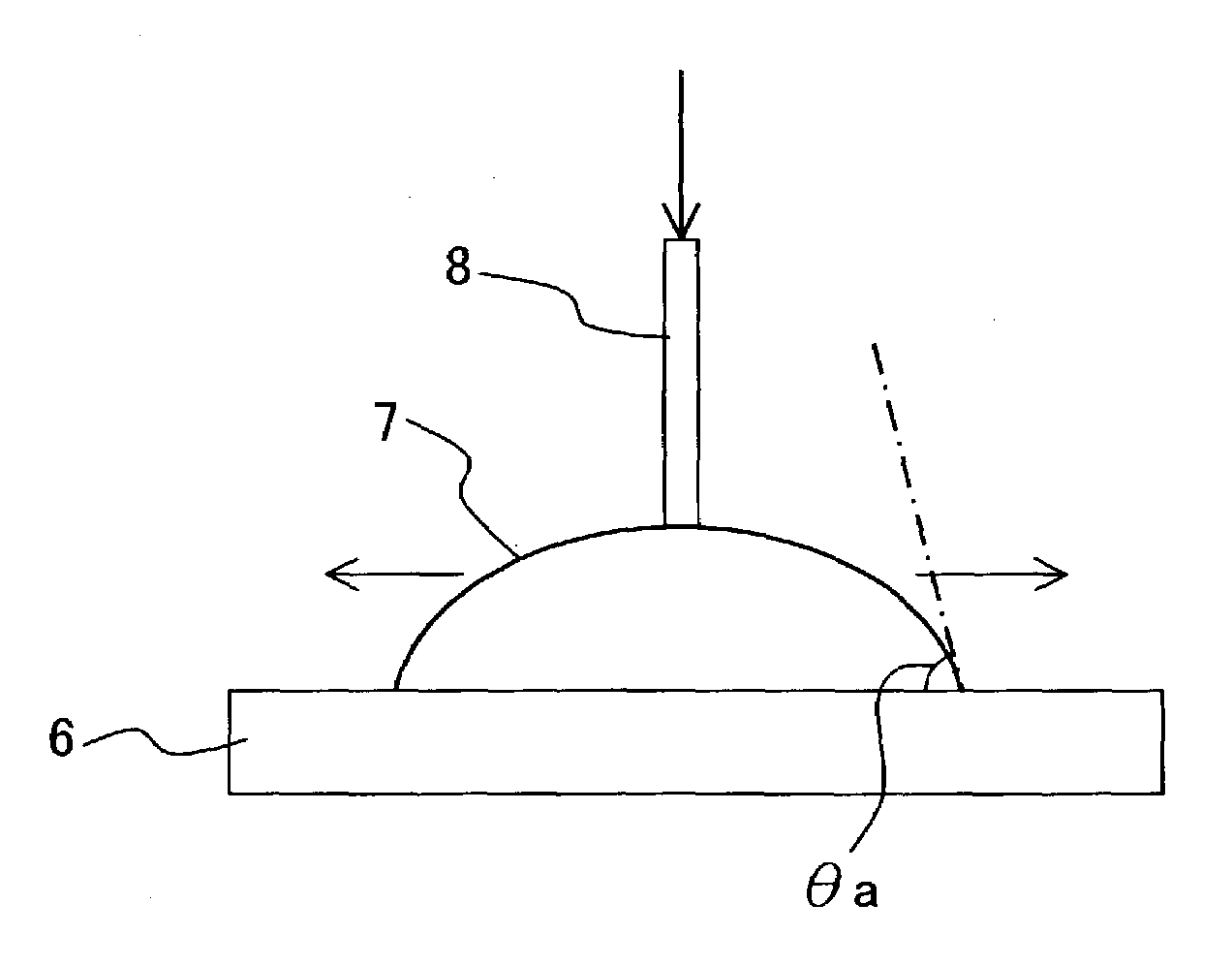

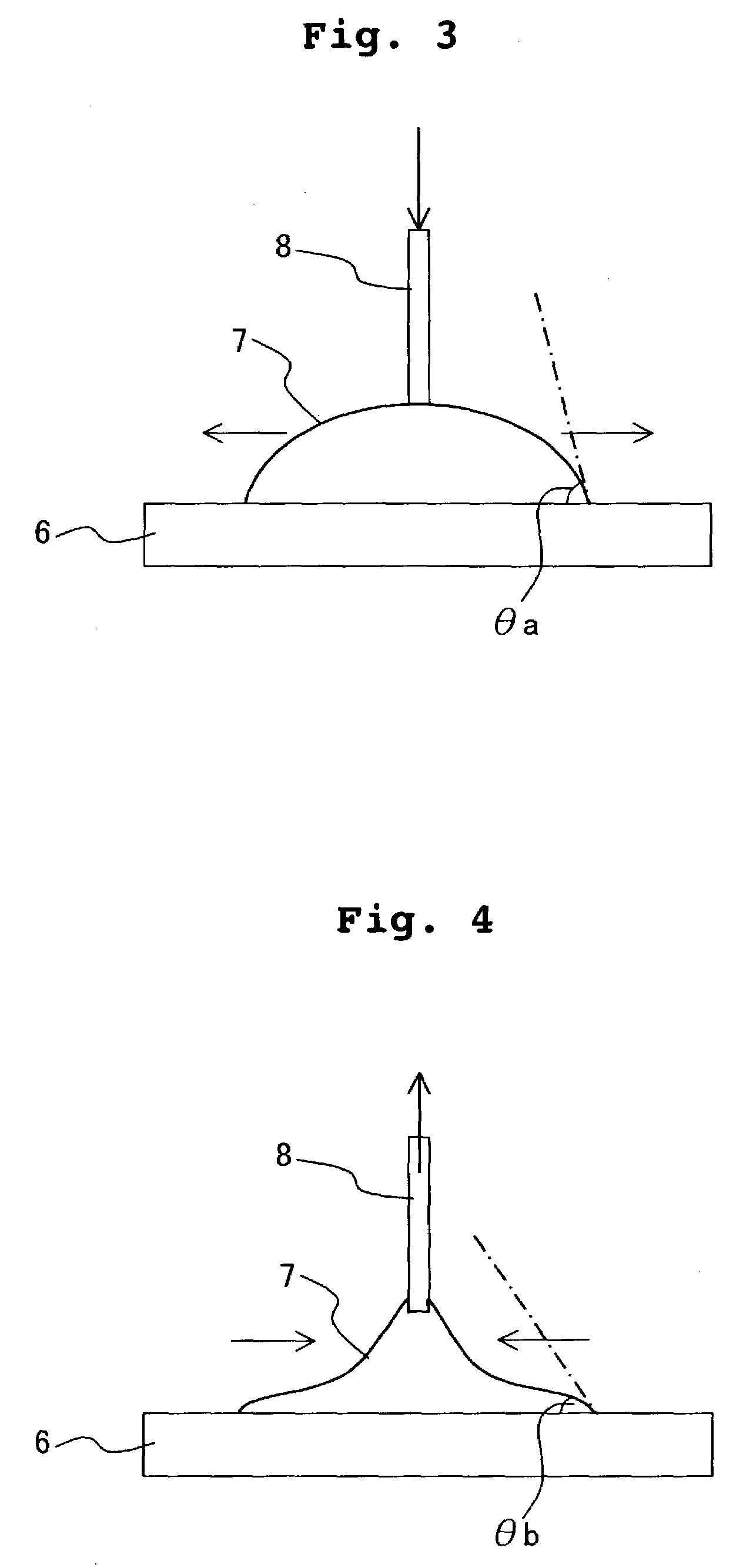

Water base for ink-jet recording and ink-jet recording method

InactiveUS7247198B2Improve waterproof performanceJet stabilityPigmenting treatmentMeasurement apparatus componentsWater basedOrganic solvent

A water base ink for ink-jet recording to be used for an ink-jet recording apparatus having an ink-jet head comprises a self-dispersing type coloring agent, water, and a water-soluble organic solvent. The surface tension of the ink is 30 to 50 mN / M, the advancing contact angle with respect to the jetting surface of the ink-jet head is not less than 65°, the receding contact angle is not less than 55°, and the difference between the advancing contact angle and the receding contact angle is not more than 20°. It is possible to jet the ink stably, it is possible to form a sharp recorded image with less blur, and it is possible to obtain the recorded image excellent in water resistance.

Owner:BROTHER KOGYO KK

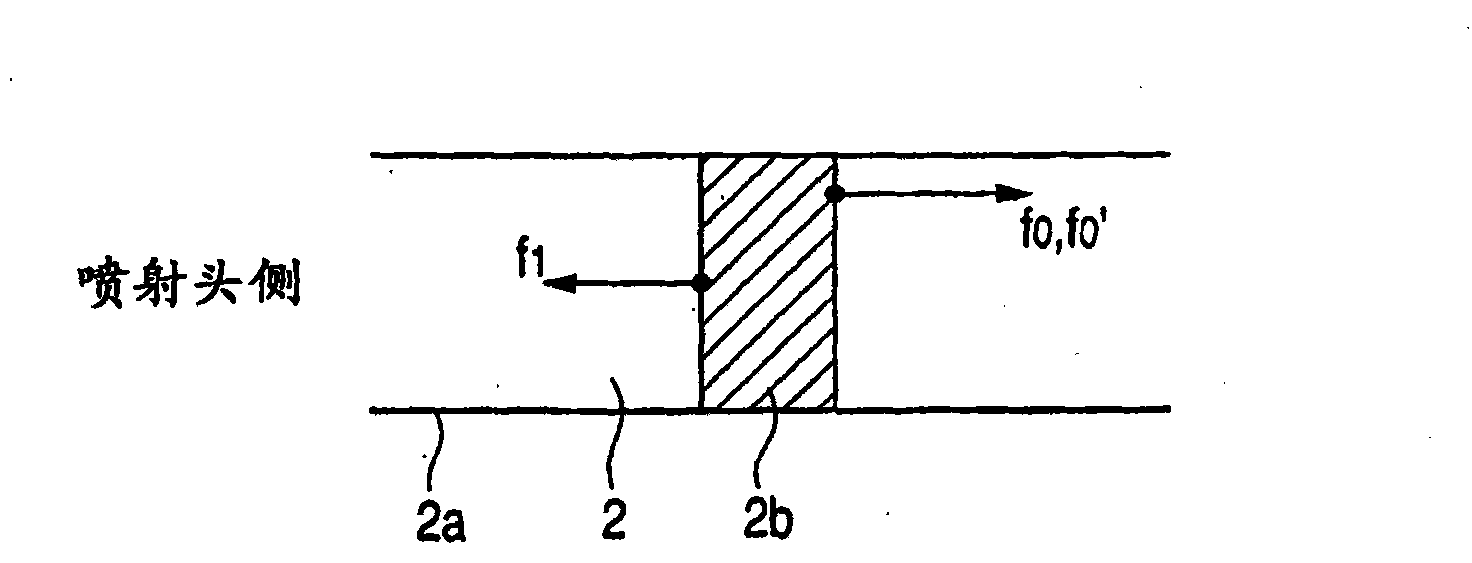

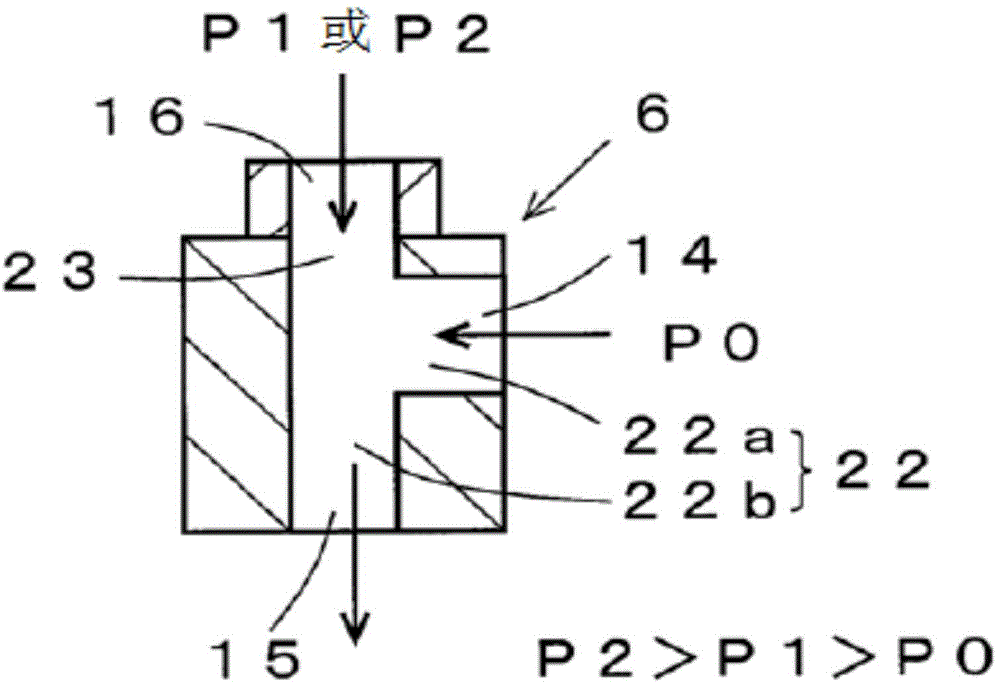

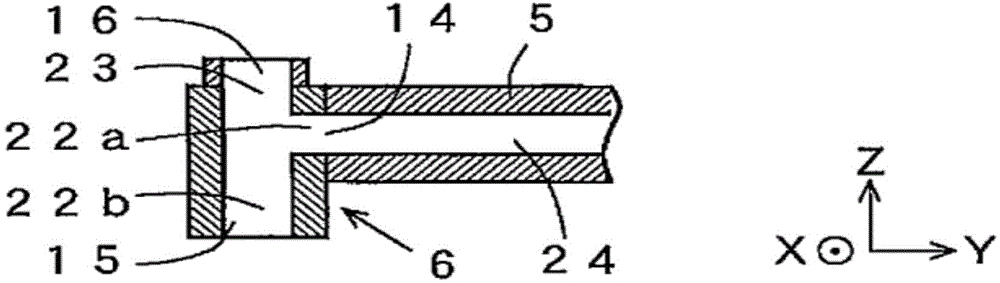

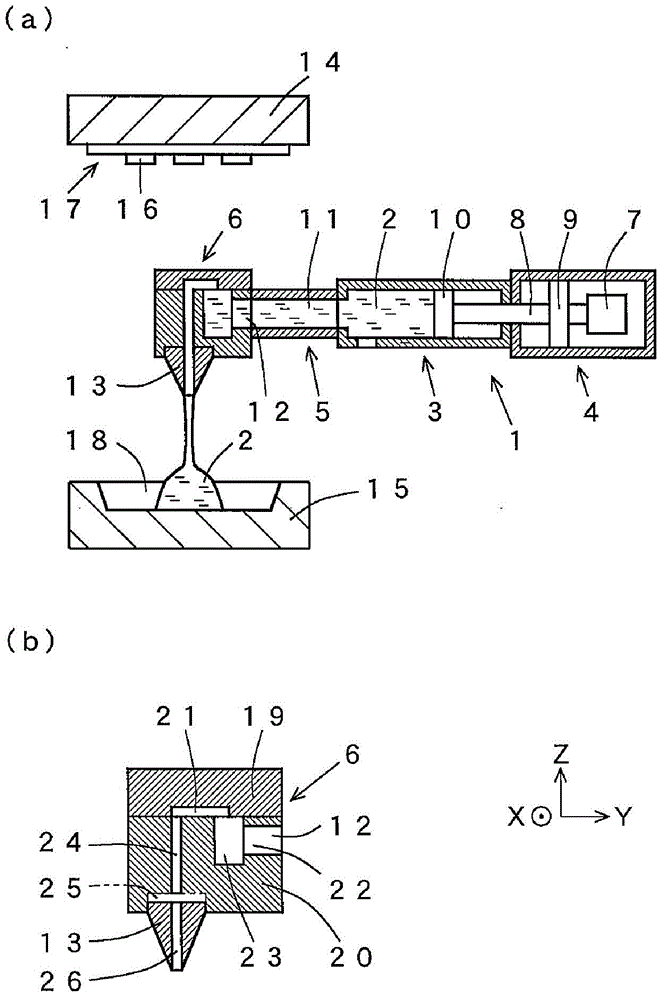

Resin forming device and resin forming method

The invention provides a resin forming device and a resin forming method. In the resin forming device, liquid resin is ejected out through supplying compressed air to a nozzle. A nozzle (6) mounted on the front end of a distributor (1) is provided with a resin supply port (14), a resin ejecting port (15) and an air supply port (16). The resin feed port (14) is connected with the resin ejecting port (15) through a resin channel (22a) extending along the horizontal direction and a resin channel (22b) vertically extending perpendicular to the resin channel (22a). Compressed air in a compressor (7) is supplied to the air supply port (16) through pressure P1 lager than resin pushing pressure P0, to prevent liquid resin (2) from entering into the air supply port (16). The compressed air is ejected to the liquid resin (2) stored in the resin channel (22b) through pressure P2 larger than P1, and the residual liquid resin (2) in the resin channel (22b) can be extruded from the resin ejecting port, so that a certain amount of liquid resin (2) can be supplied to a die cavity (21).

Owner:TOWA

Inkjet ink set, inkjet recording device, and inkjet recording method

InactiveUS20130202862A1Simple processHigh-resolution imageMeasurement apparatus componentsDecorative surface effectsEmulsionAcrylic resin

An inkjet ink set containing a first pigment ink and a second pigment ink. The first pigment ink includes an anionic self-emulsification ether polyurethane, and the second pigment ink includes a styrene acrylic resin emulsion.

Owner:RICOH KK

Three-dimensional printing machine with multi-dimensional motion workbench

The invention provides a three-dimensional printing machine with a multi-dimensional motion workbench. The three-dimensional printing machine comprises a base, first rails, a first supporting frame, second rails, a second supporting frame, a telescopic rod, a workbench, a spraying head bracket, one or multiple printing spraying heads, one or multiple material boxes and the like, wherein the first rails are mounted on the base; the first supporting frame is mounted on the first rails and can move along the length direction of the first rails; the second rails are mounted on the first supporting frame and are perpendicular to the first rails; the second supporting frame is mounted on the second rails and can move along the length direction of the second rails; the workbench is mounted on the second supporting frame through the telescopic rod and can move in the height direction; the spraying head bracket is mounted on the base; the printing spraying heads are mounted on the spraying head bracket and are positioned above the workbench; the material boxes are mounted on the base; the printing spraying heads are connected with the material boxes in a one-to-one correspondence manner. The printing spraying heads of the three-dimensional printing machine are fixedly mounted, so that the continuity of printing material outputting is kept, and the printing effect can be enhanced.

Owner:HEFEI SKE INTELLIGENT TECH

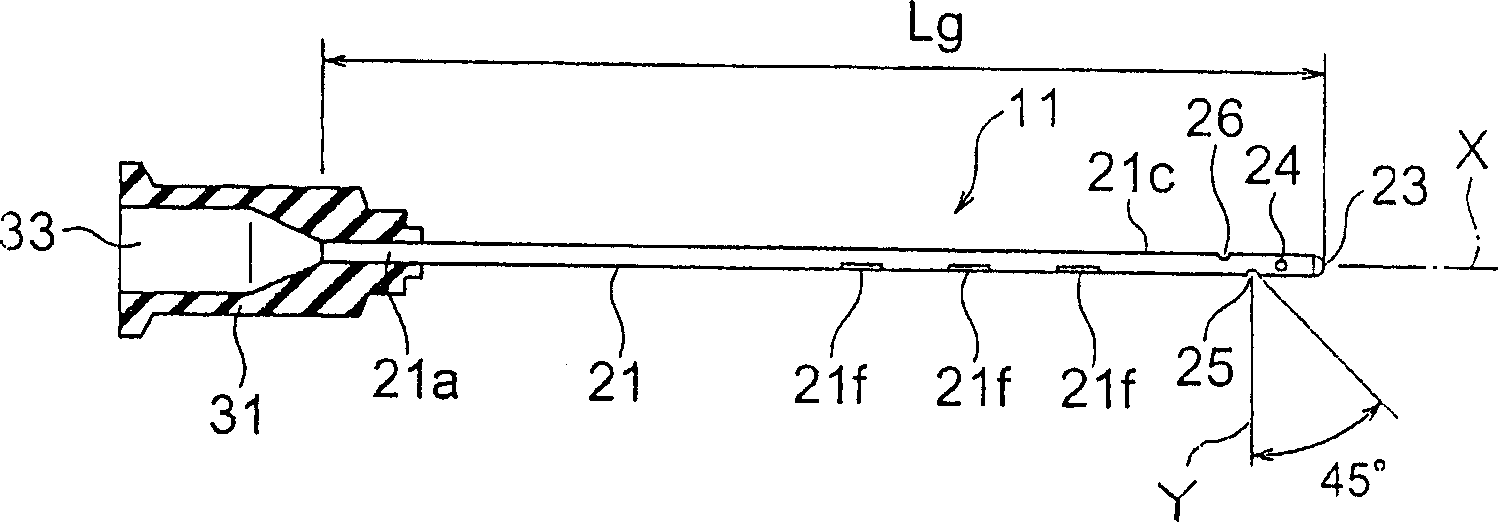

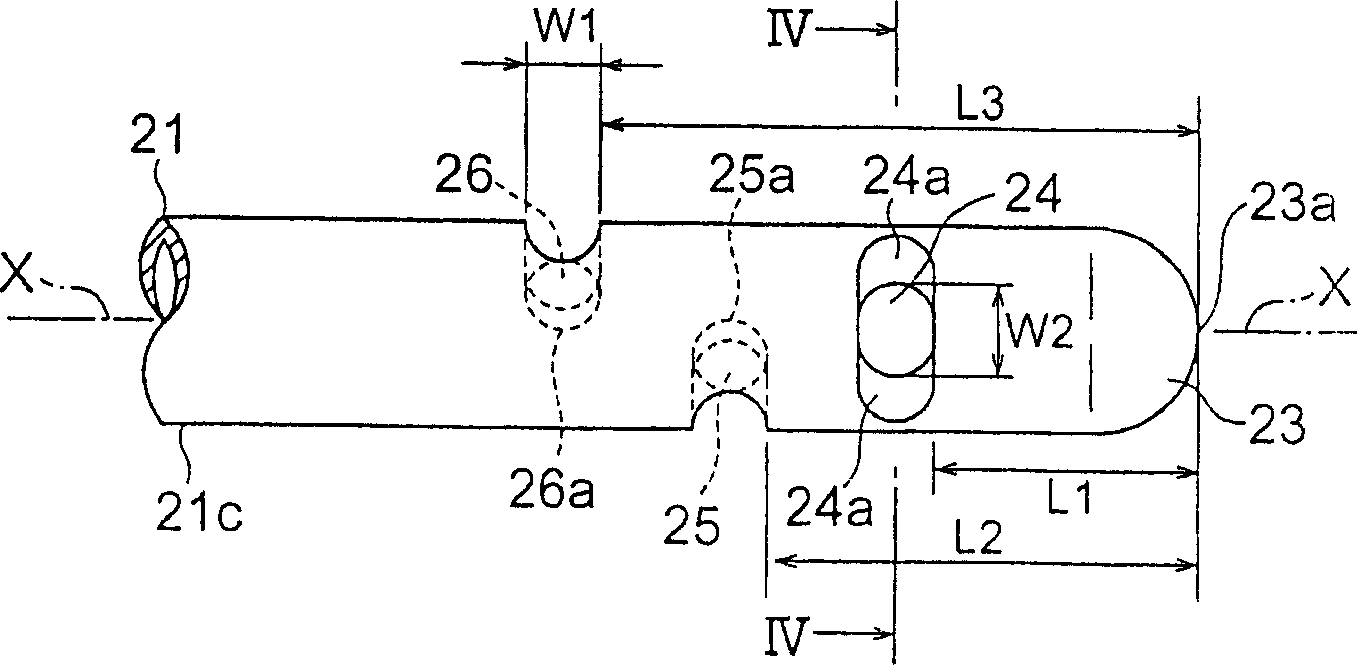

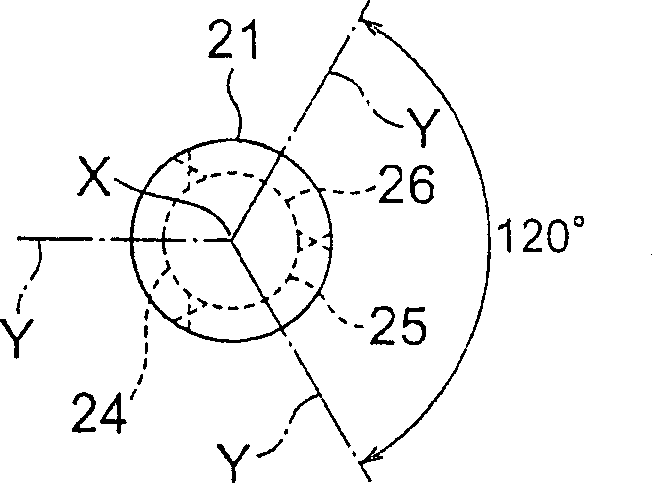

Liquid injection needle for jetting a liquid in a predetermined angle range and method of producing the same

InactiveCN1839772APrecise and Efficient JettingPrevent dripLiquid surface applicatorsGum massageMedicineEngineering

A cannula (21) has a front part (21 c) in a direction of a center axis X with its forward end portion (23) closed. The front part has a plurality of nozzle orifices (24, 25, 26) each of which has an orifice axis Y intersecting the center axis X. Each of the nozzle orifices has a first diameter in a first direction parallel to the center axis X and a second diameter in a second direction perpendicular to the first direction. The first diameter ranges between 0.1 mm and 0.5 mm while the second diameter ranges between 0.1 mm and 0.3 mm so that a liquid in the cannula is jetted from the nozzle orifices in an angle range of 45 degrees towards the forward end portion with respect to the orifice axis.

Owner:MATSUMOTO DENTAL UNIVERSITY

Recording ink for ink-jet recording apparatus, and, ink cartridge, ink-jet recording apparatus, ink-jet recording process,and recorded matter

ActiveCN1871315AJet stabilityReduce printing reliabilityDuplicating/marking methodsInksColoring agentsRecording media

Disclosed is a recording ink for ink-jet recording comprising a colorant, water, a humectant, a surfactant, and a wetting agent, wherein the recoding ink is applied to ink-jet recording apparatuses capable of recording on a second recording side of a recording medium following recording on a first recording side of the recording medium, and the infiltrating period of the recording ink into the first recording side of the recording medium is 5 seconds or less. Also, an ink cartridge, an ink-jet recording apparatus, an ink-jet recording process, and a recorded matter are disclosed that utilize the recording ink respectively.

Owner:RICOH KK

Ink-droplet jetting apparatus

ActiveUS20070195117A1Suppress residual vibrationHigh speed recordingOther printing apparatusElectrical and Electronics engineering

For forming one dot by jetting a plurality of ink droplets, a drive pulse signal in an ink-droplet jetting apparatus includes a first main pulse for jetting, a first regulating signal which is inserted at a first interval from the first main pulse, and a second regulating pulse which is inserted at a second interval from the first main pulse. The first interval is almost the same as or more than the second interval. Accordingly, the ink-droplet jetting apparatus is capable of jetting the ink droplets stably, and printing at a high speed.

Owner:BROTHER KOGYO KK

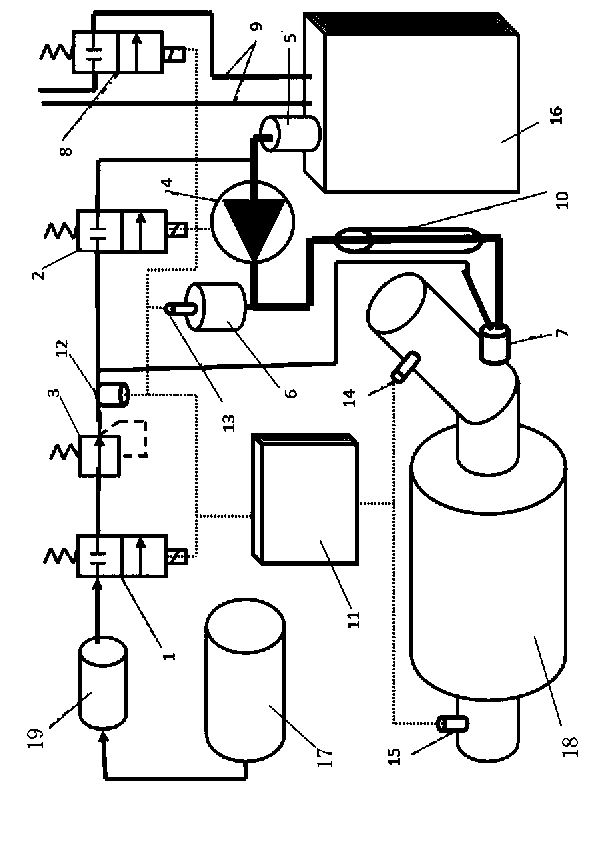

Selective catalytic reduction system of solid reductant

ActiveCN104100337AStable deliveryJet stabilityInternal combustion piston enginesExhaust apparatusEnvironmental engineeringAmmonia

The invention discloses a selective catalytic reduction system of a solid reductant. The system comprises an exhaust gas treatment device, a controller, a solid ammonia storing device, a gasometer, a first switch and a second switch; the solid ammonia storing device is communicated with the exhaust gas treatment device through a first pipeline and communicated with the gasometer through a second pipeline; the gasometer is communicated with an exhaust gas conveying pipe through a third pipeline; the exhaust gas conveying pipe conveys the exhaust gas to the exhaust gas treatment device; the first switch is arranged on the first pipeline; the second switch is arranged on the third pipeline; the controller is connected with the first switch and the second switch. With the adoption of the selective catalytic reduction system of the solid reductant, the ammonia can be provided smoothly.

Owner:科林蓝泰环境科技(长春)有限公司

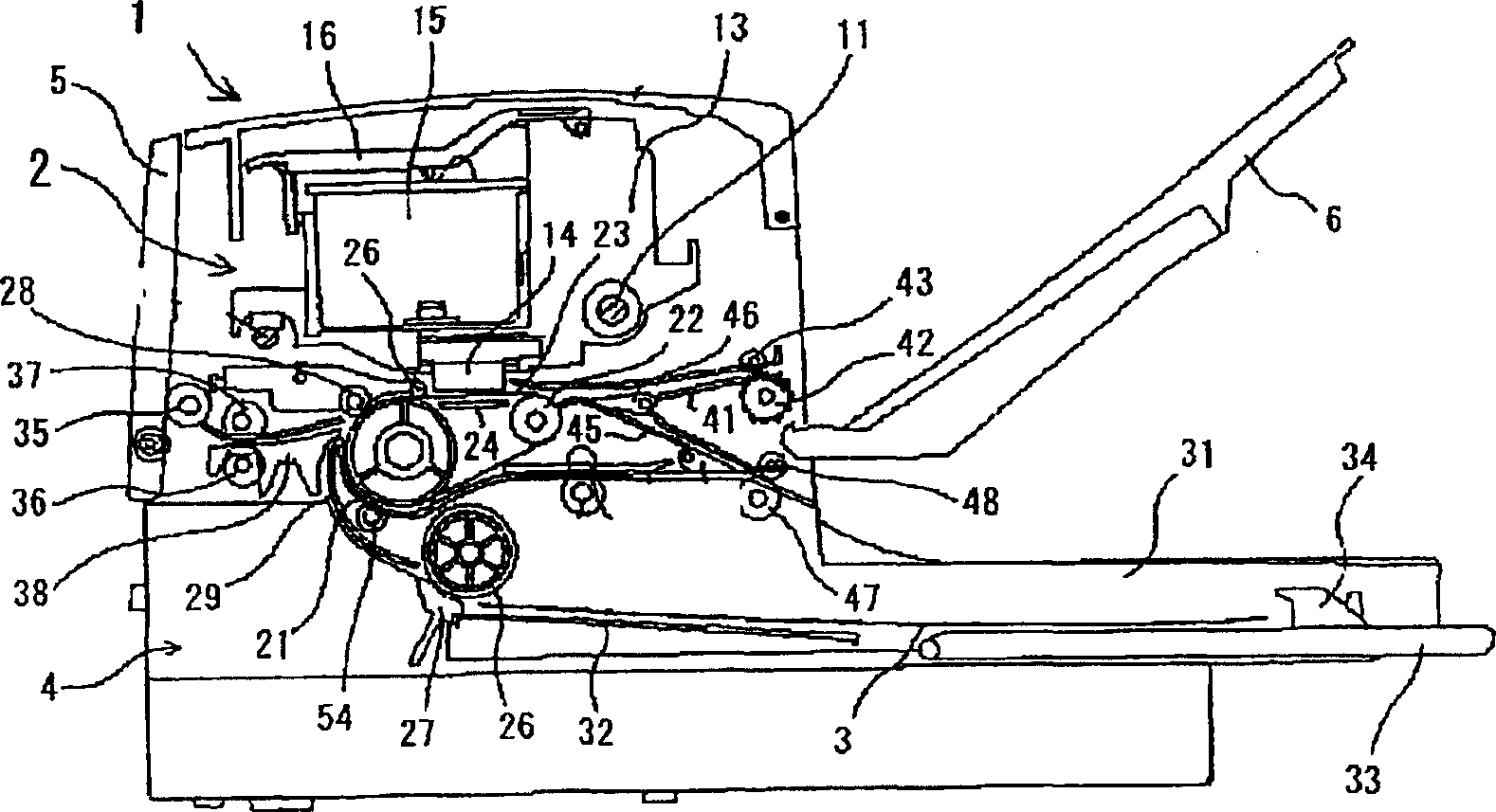

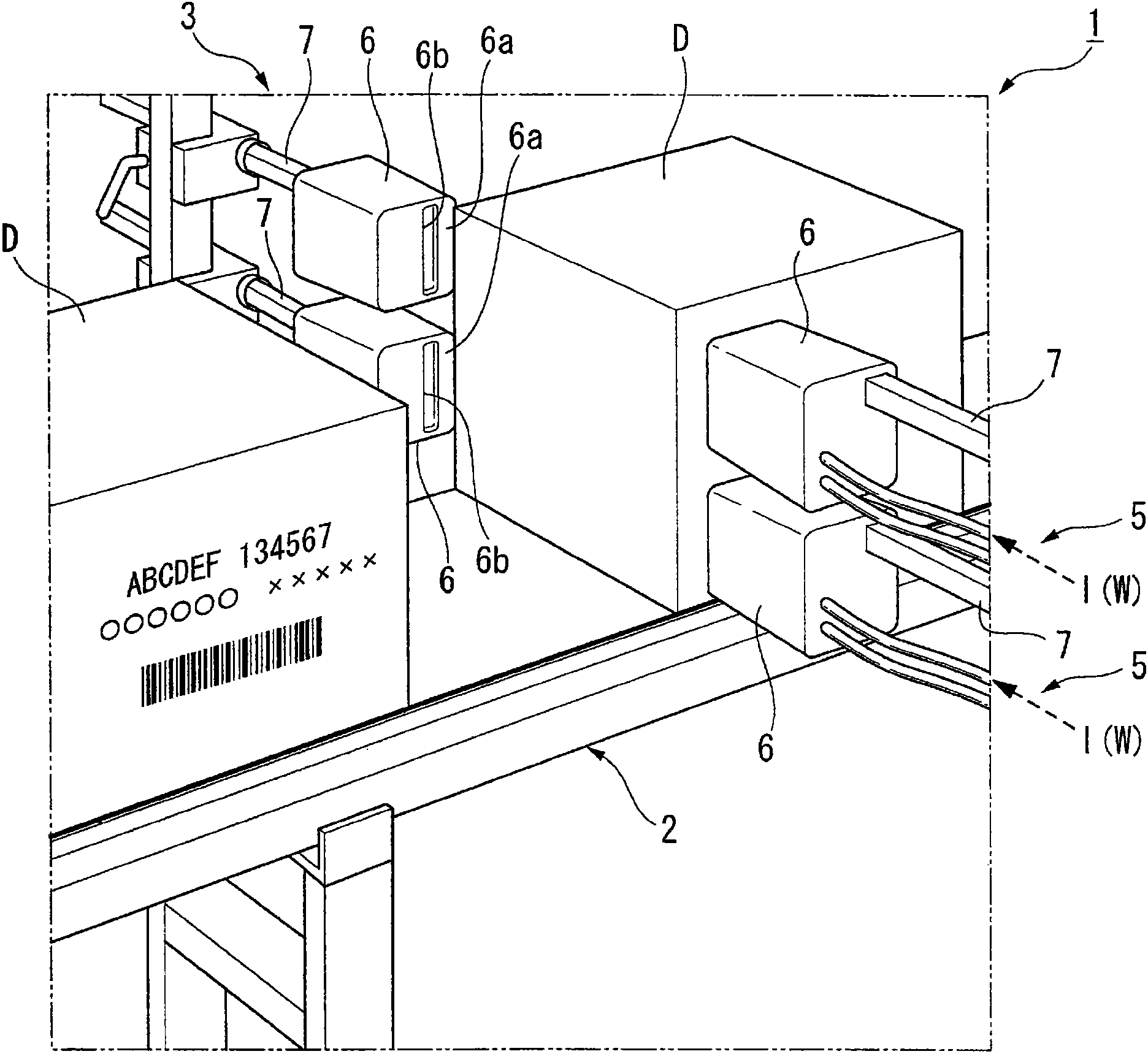

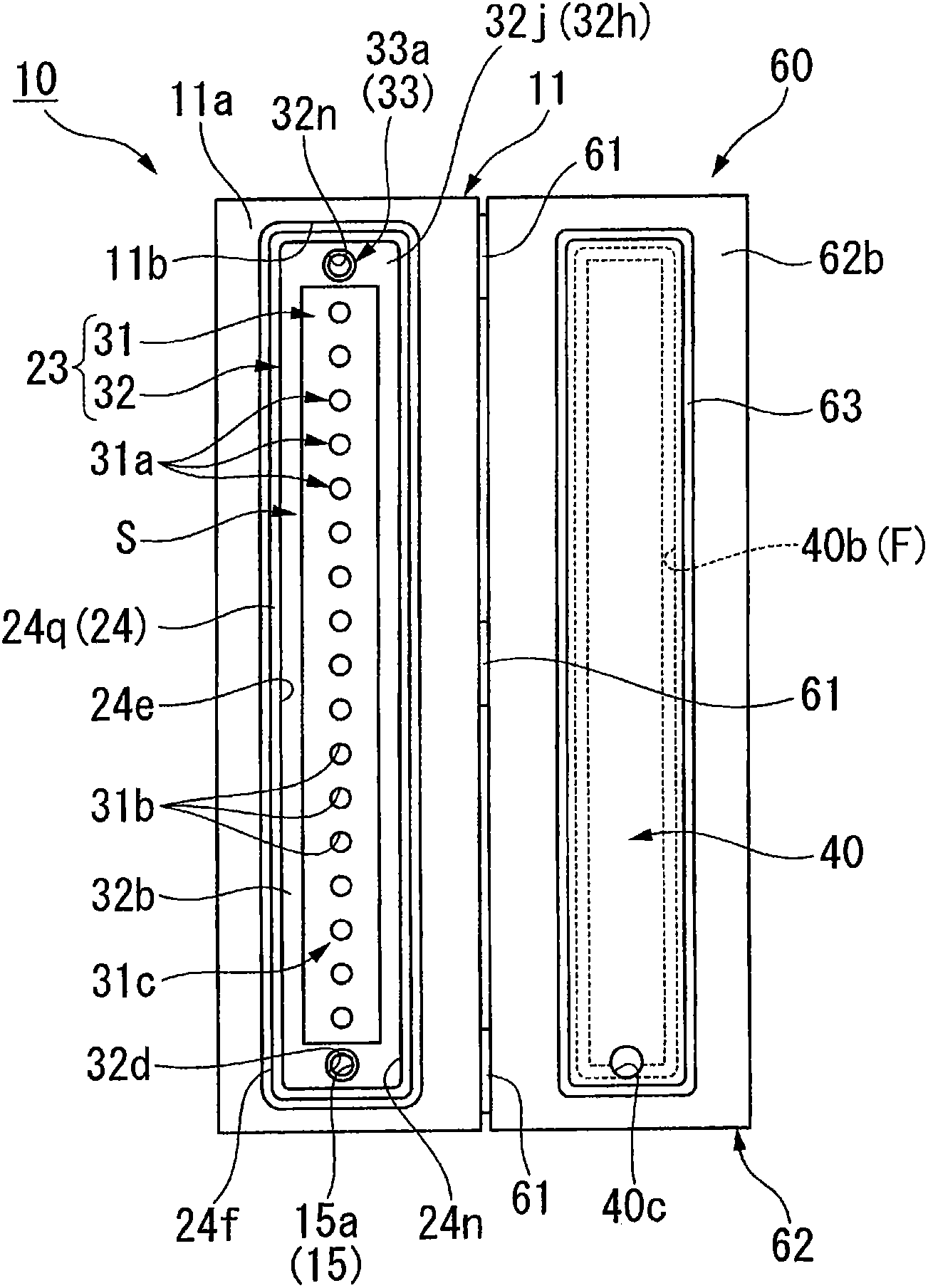

Liquid jetting head, liquid jetting recording apparatus, and method for filling liquid jetting head with liquid

The space factor of a liquid jetting head is improved, and the degree of freedom in designing a liquid jetting recording apparatus is improved. Performance of recovering a surplus liquid is improved with a simple configuration, contamination due to the surplus liquid is eliminated, the liquid jetting recording apparatus is initially filled, and liquid jetting after the liquid filling is stabilized. The liquid jetting head is provided with: a wall section (24), which surrounds the periphery of a jetting port row and protrudes in the same direction as the opening direction of a jetting port; an opening / closing mechanism (60), which has a cover member (62) that can open / close an opening section (24n) formed by the wall section (24), configures a closed space between the wall section (24) and the jetting body (23) in the closed state, and exposes the jetting port to the outside in the opened state; an absorber (40), which is provided on a rear surface (62b) of the cover member (62) and absorbs the liquid spilled out from the jetting port; a suction channel (15), which has a suction port (15a) opened to the closed space and is connected to an external suction apparatus (8); and a section (33) opened to atmosphere, which can perform switching between opening and blocking of the closed space to and from the outside.

Owner:SII PRINTEK

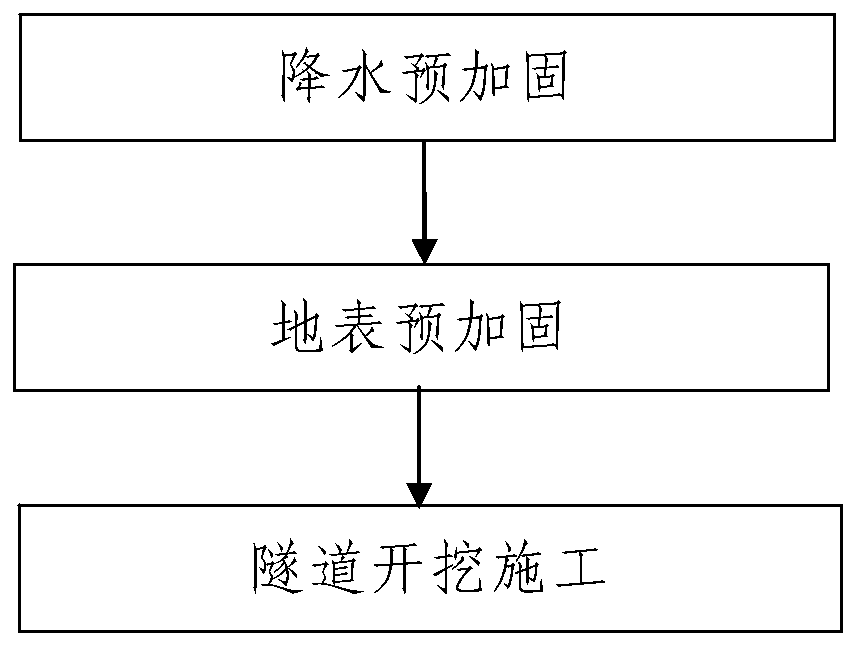

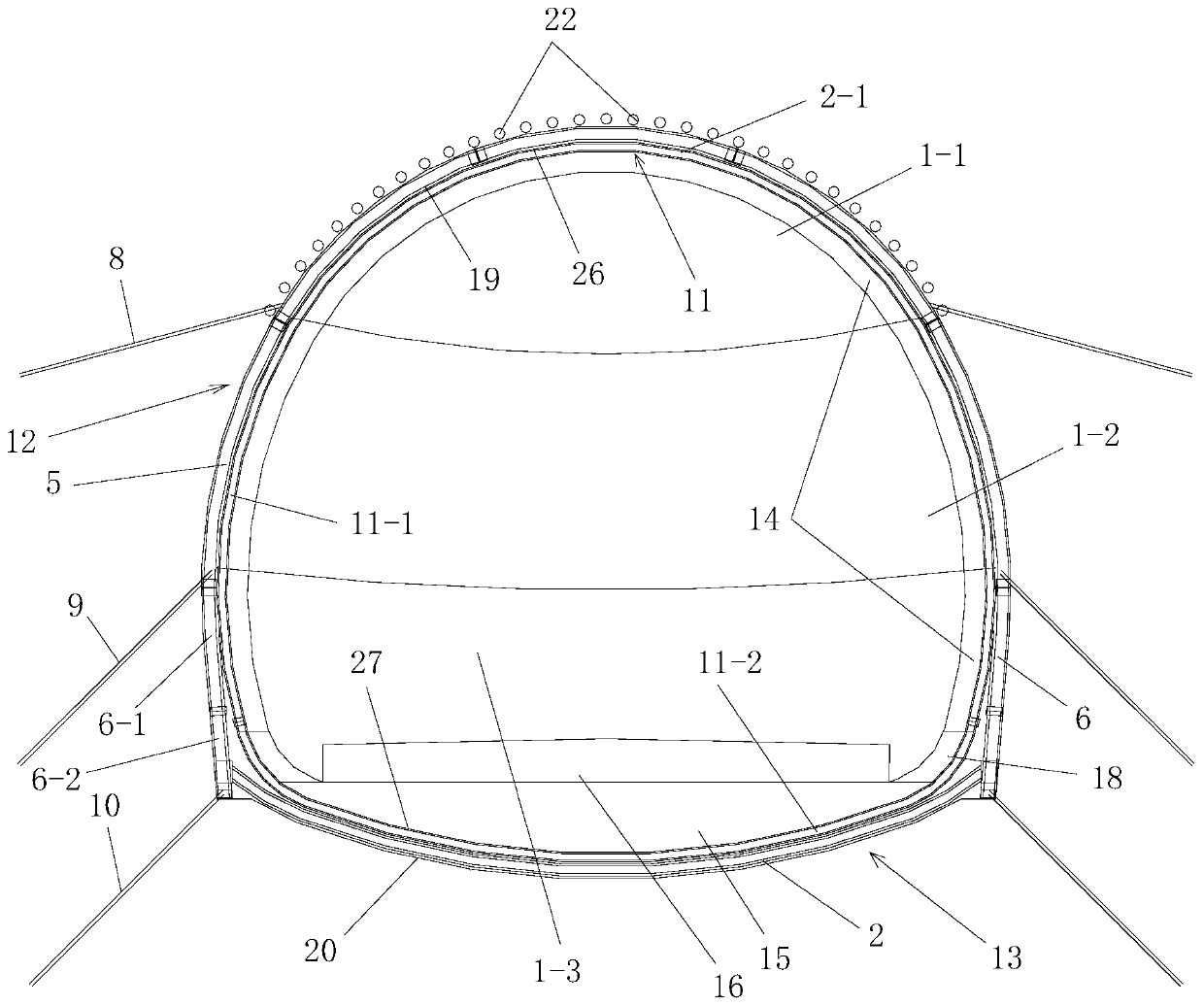

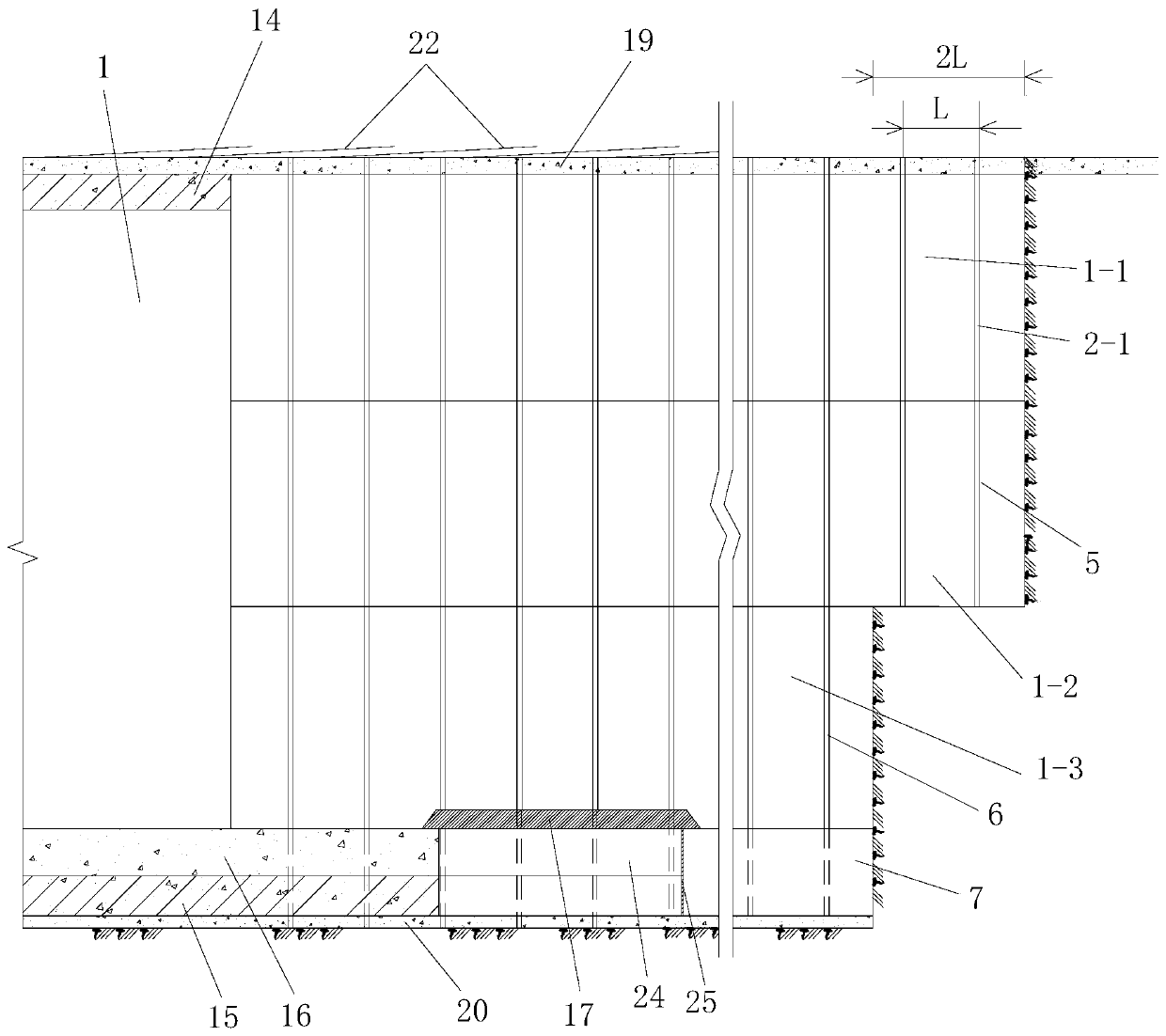

Tunnel portal section pre-reinforcement and excavation construction method based on partition blasting

ActiveCN110847929AConstruction safetyStable structureUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel portal section pre-reinforcement and excavation construction method based on partition blasting. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, earth surface pre-reinforcement, and specifically, reinforcing the surface of a backfill section in a construction tunnel portal section through adopting a cement soil stirring pile; and 3, tunnel excavation construction, and specifically, carrying out excavation construction from rear to front in a plurality of excavation sections, wherein the process comprises the following steps of surveying and setting out, performing drilling and blasting construction, excavating an upper portal body, excavating a middle portal body and excavating a lower portal body. The construction method is reasonable in design, simple and convenient in construction and good in use effect; the underground water level is reduced through precipitation pre-reinforcement, and then surroundingrock is effectively reinforced; after the backfill section is subjected to surface pre-reinforcement through using the cement soil stirring pile, a three-step synchronous excavation mode is used forcarrying out partition blasting excavation, so that it is ensured that the tunnel excavation process is safe and reliable and a tunnel structure is stable.

Owner:CHINA RAILWAY 20 BUREAU GRP

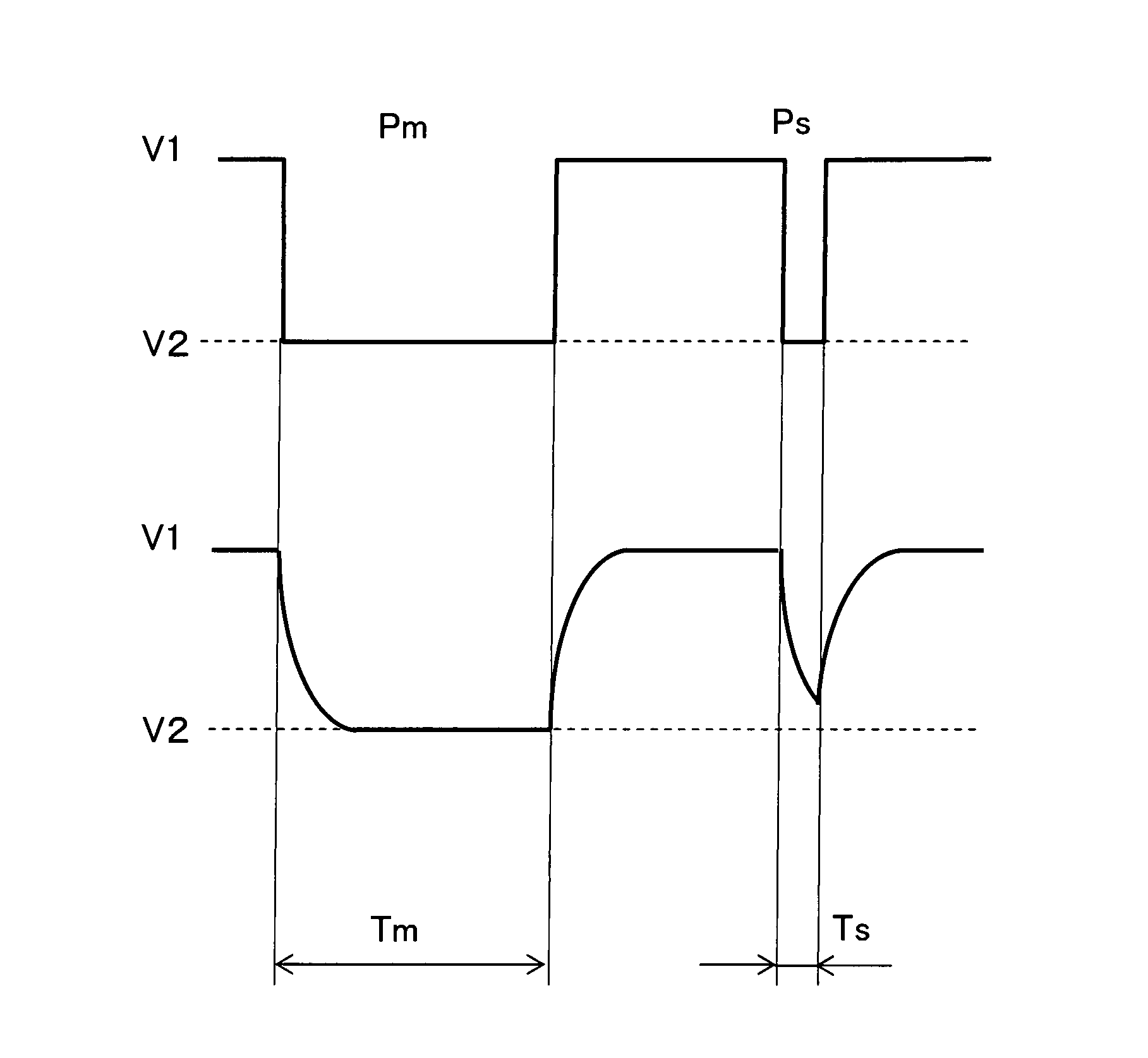

Ink-droplet jetting apparatus

ActiveUS7600838B2Jet stabilityIncrease speedOther printing apparatusEngineeringElectrical and Electronics engineering

For forming one dot by jetting a plurality of ink droplets, a drive pulse signal in an ink-droplet jetting apparatus includes a first main pulse for jetting, a first regulating signal which is inserted at a first interval from the first main pulse, and a second regulating pulse which is inserted at a second interval from the first main pulse. The first interval is almost the same as or more than the second interval. Accordingly, the ink-droplet jetting apparatus is capable of jetting the ink droplets stably, and printing at a high speed.

Owner:BROTHER KOGYO KK

Marine plunger matching part

ActiveCN102979652AGuaranteed tightnessAvoid killingMachines/enginesFuel injecting pumpsHigh pressurePlunger

The invention relates to a marine plunger matching part, which comprises a plunger and a sleeve, wherein an axial center hole is formed in the sleeve; the plunger is movably inserted into the axial center hole, and the plunger and the center hole can slide up and down relatively to fit with each other; an oil filling hole is formed in the sleeve; the upper part of the axial center hole is connected and fitted with an oil-out device; a seal ring is arranged in the axial center hole and pasted on the oil filling hole in a sealing manner; the outer circumference of the sleeve is fitted with at least one first sealing ring which is used for ensuring the sealing property of a low-pressure oil chamber; and the lower part of the sleeve is provided with an oil scraping device in the position fitted with the plunger. According to the invention, the lubricating property of the plunger and the sleeve is improved by forming an additional circular groove in the plunger; the sleeve adopts the axial center hole for sealing and oil discharging; and the machining property is improved, the machining efficiency is increased, while meeting the requirements of high-pressure sealing. The marine plunger matching part has the advantages of novel structure, excellent property, good sealing effect, small volume, precise oil supply, simple structure, easiness in manufacturing, and reliability in spraying.

Owner:YUYAO SHUCHUN MACHINERY

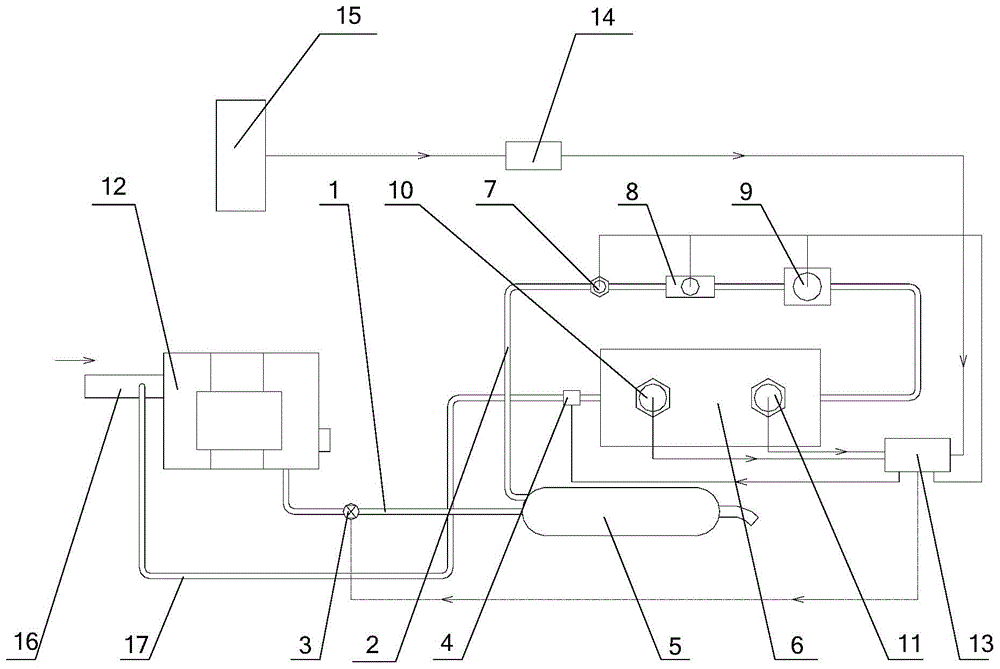

Air-assisted urea supply device used for diesel engine

InactiveCN103899392AHighlight substantiveSignificant progressExhaust apparatusSilencing apparatusAir filterPulp and paper industry

The invention provides an air-assisted urea supply device used for a diesel engine. The air-assisted urea supply device used for the diesel engine comprises a urea storage box, an engine air storage cylinder and an engine exhaust silencer. The urea storage box is connected with an ejector through a urea pump, the ejector is communicated with the engine exhaust silencer, a filter is arranged between the urea storage box and the urea pump, an energy accumulator is further arranged at the output end of the urea pump, the engine air storage cylinder is communicated with the ejector through an air filter, a pressure reducing and stabilizing valve is further arranged between the air filter and the ejector, and the output end of the pressure reducing and stabilizing valve is further communicated with the input end of the urea pump. According to the scheme, the ejector of the device is simple in structure, good in the ejection effect and high in the accuracy and stability, urea crystals will not be generated in the ejecting process, and stable ejection can be achieved.

Owner:SINO TRUK JINAN POWER

Inkjet recording method and inkjet recording device

Owner:RICOH KK

Lotus seedpod electrospinning spray head

ActiveCN104060333AEnsure consistencyEasy to control speedSpinnerette packsFilament/thread formingFiberElectrical conductor

The invention relates to the technical field of electrospinning. A lotus seedpod electrospinning spray head comprises a casing, the bottom surface of the casing is an arc face, a solution inlet is formed in the top surface of the casing, a solution channel is formed in the casing, the bottom surface of the solution channel is an arc face, a plurality of conductor nozzles are evenly arranged on the bottom surface of the solution channel, the conductor nozzles extend out of the casing to form injection channels, a high-voltage electrode is further arranged on the bottom surface of the solution channel, the high-voltage electrode is electrically connected with the conductor nozzles, an air guide pipe is arranged in the casing and at the position under the solution channel, the air guide pipe is communicated with an external auxiliary air flow generator, upper through holes and lower through holes are formed in the upper surface and the lower surface of the air guide pipe, the conductor nozzles penetrate through the upper through holes and the lower through holes, the bore diameter of the lower through holes of the air guide pipe is larger than the outer diameter of the conductor nozzles, flow guide barrels are arranged at the edges of the lower through holes and at the peripheries of the conductor nozzles, and openings matched with the bottoms of the flow guide barrels are formed in the bottom surface of the casing. The method obviously improves electrospinning jet flow density and nano-fiber injection efficiency.

Owner:中科贝思达(厦门)环保科技股份有限公司 +1

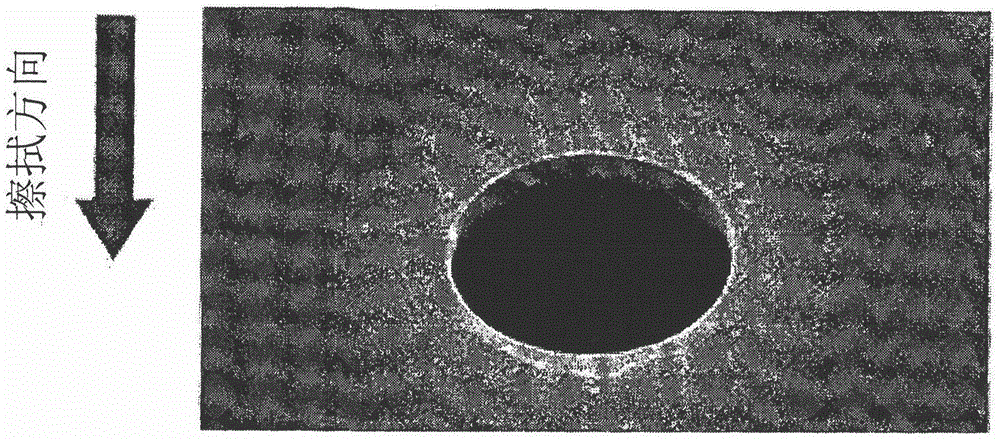

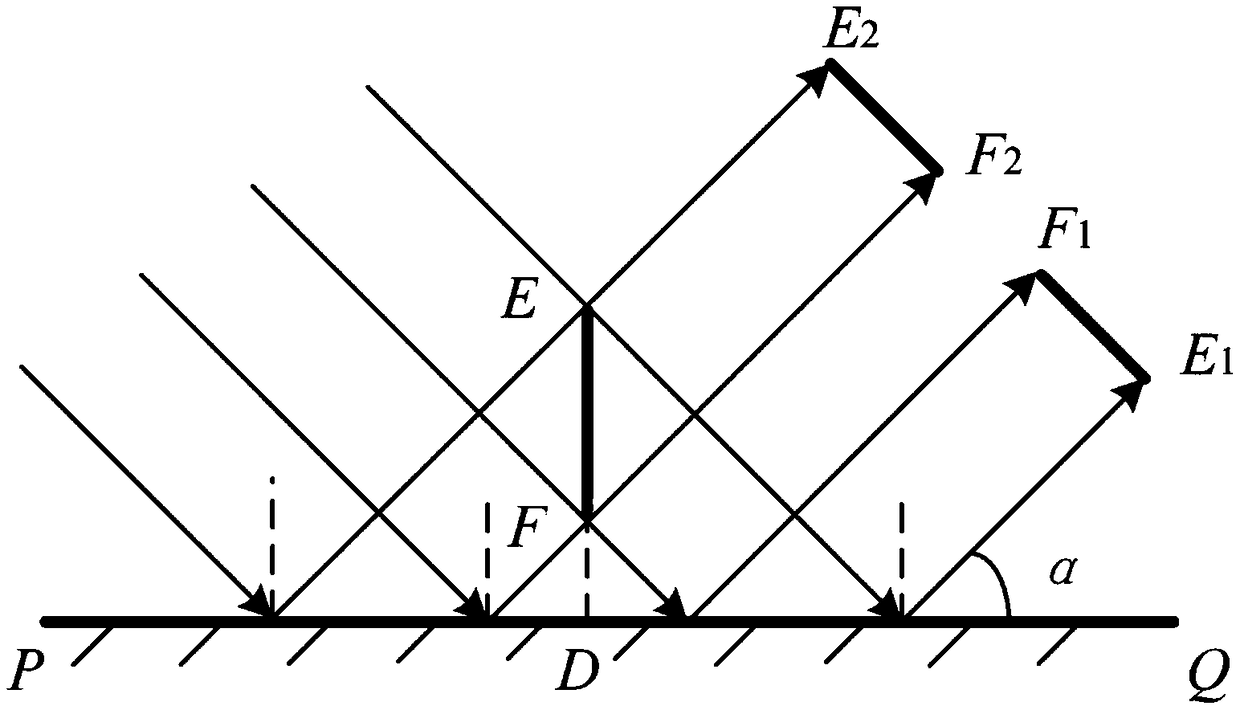

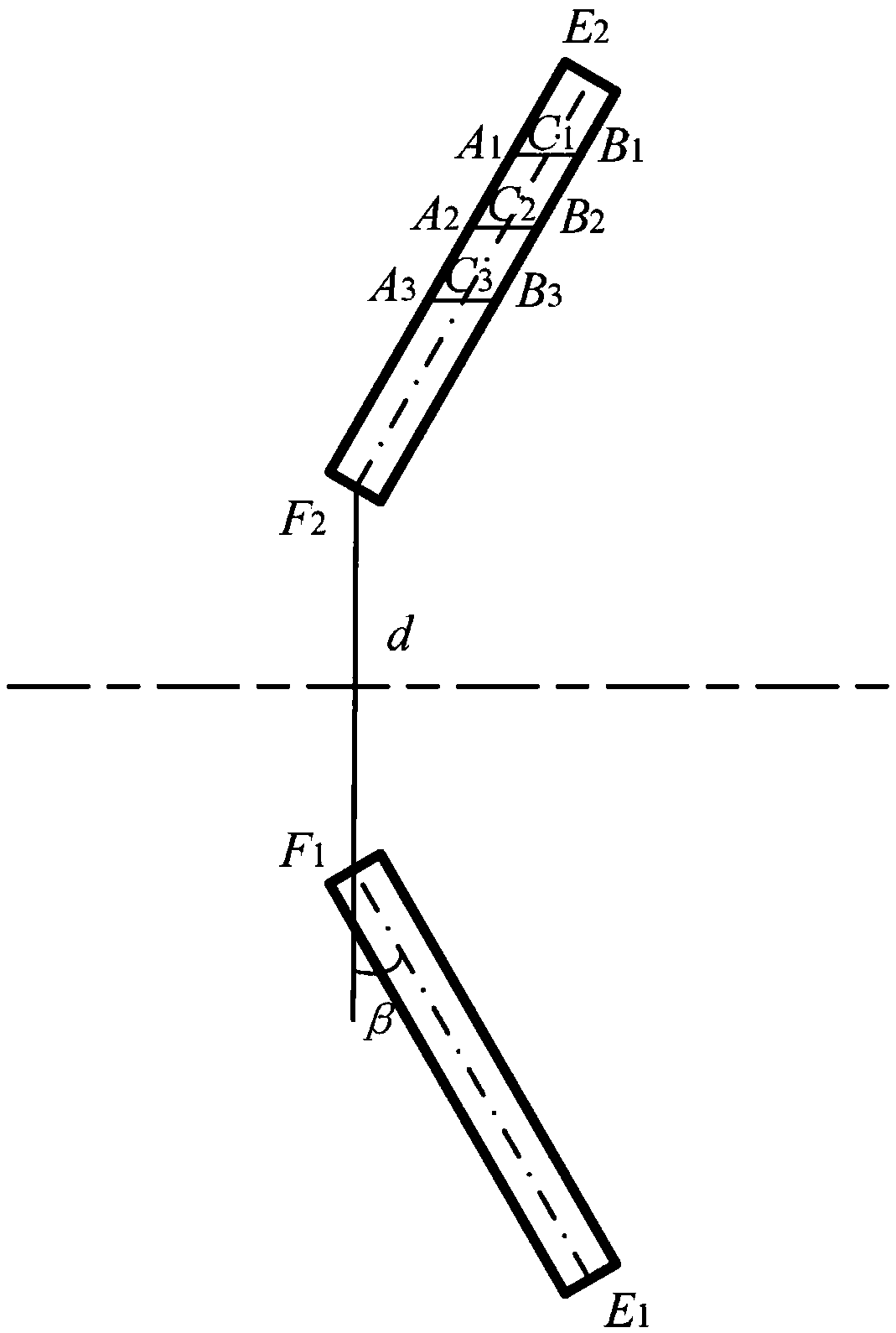

Ink-liquid cone detection device and method suitable for ink-jet printing

The invention belongs to the technical field of ink-jet printing visual detection, and discloses an ink-liquid cone detection device suitable for ink-jet printing. The ink-liquid cone detection devicecomprises a jet module, a motion module, a mechanical auxiliary module and a vision observation module, wherein the mechanical auxiliary module comprises a machine frame, a vertical fine adjustment mechanism and an inclined fine adjustment mechanism; and the visual observation module comprises a camera and a light source which are obliquely arranged, and a mirror symmetry image is acquired through reflection of a substrate. The invention further discloses a corresponding detection method. The detection method is used for achieving optimization schemes which comprise the nozzle position, inclination angle, nozzle and substrate distance detection, the ink liquid cone size and the contour change detection, the jet flow appearance and spraying angle detection, the lag time and duration detection of the jet flow relative to the injection signal, the spraying process parameter feedback control and the drop point position deviation of the jet flow on the moving substrate. According to the device and the method, an ink-liquid cone body and a nozzle for ink-jet printing are executed in a high-efficiency and high-precision mode, and on-line detection is carried out on the jet flow.

Owner:武汉国创科光电装备有限公司

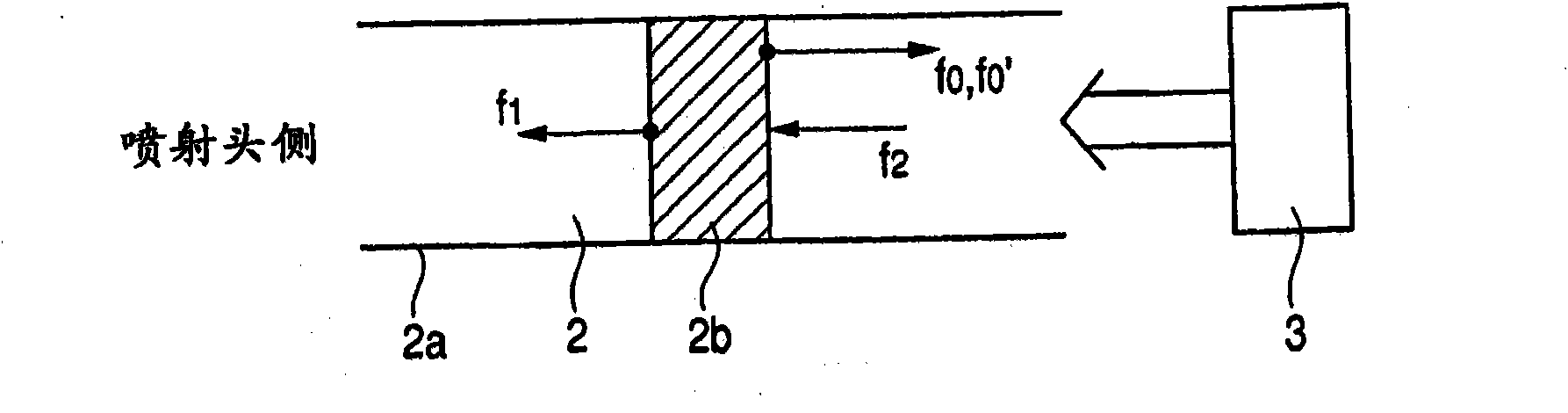

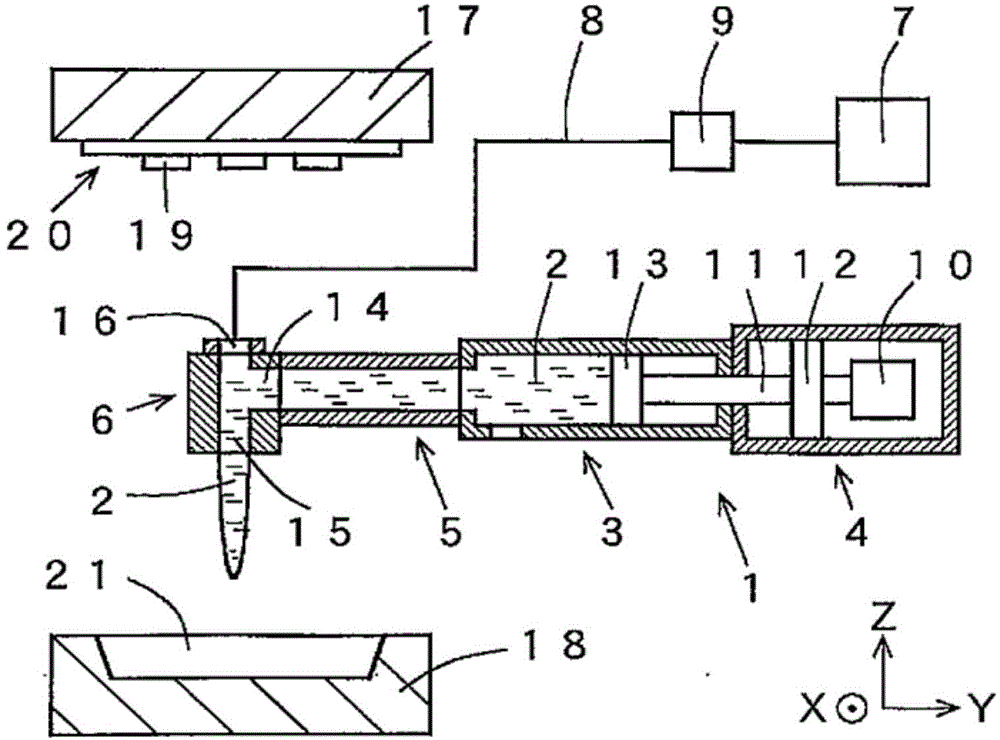

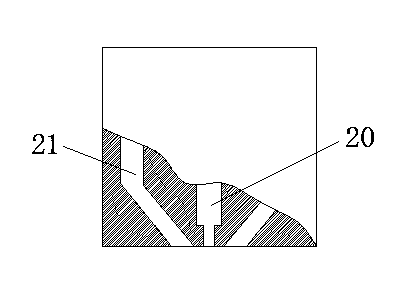

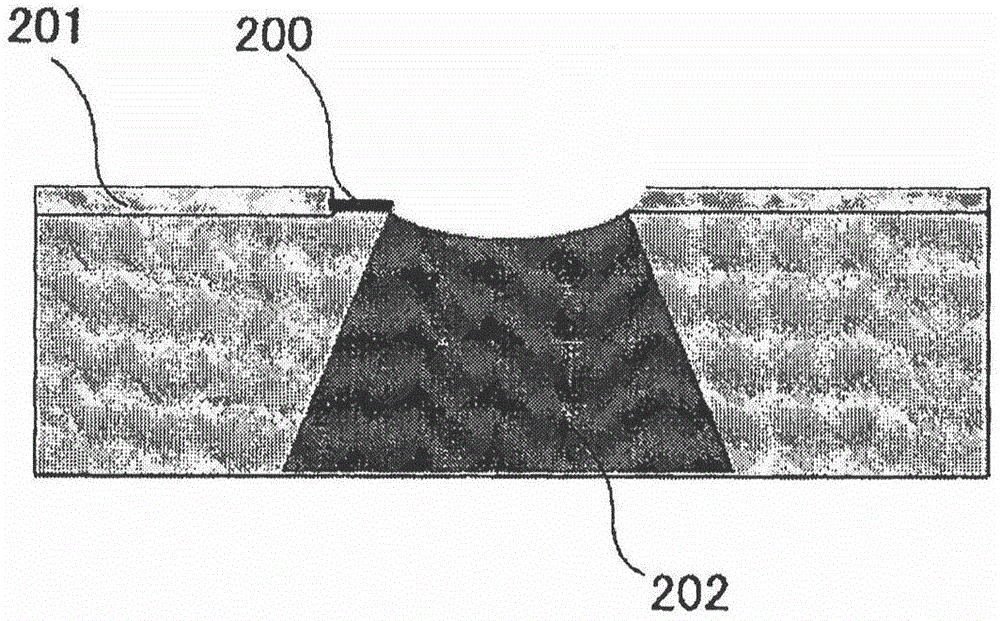

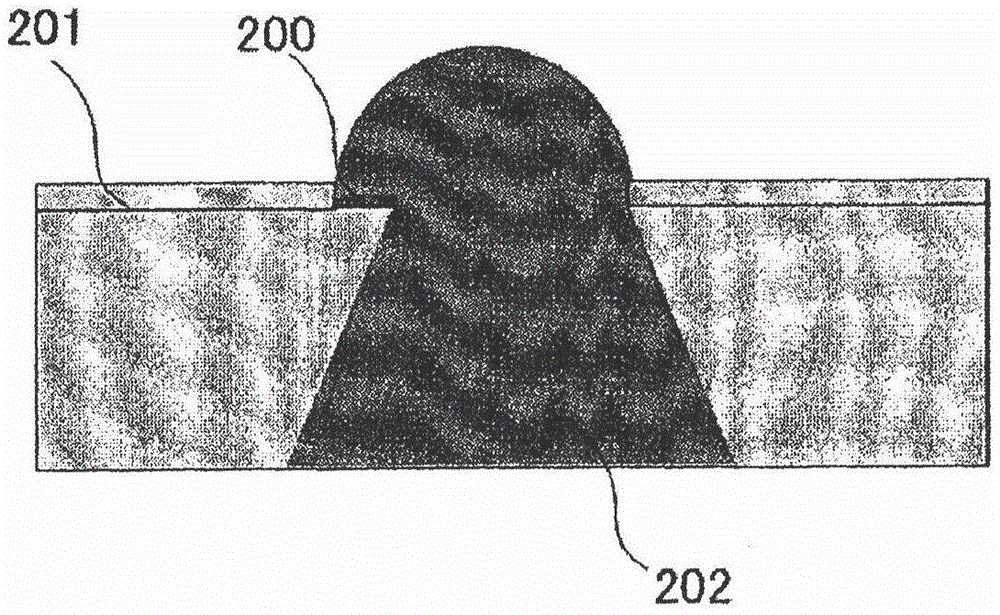

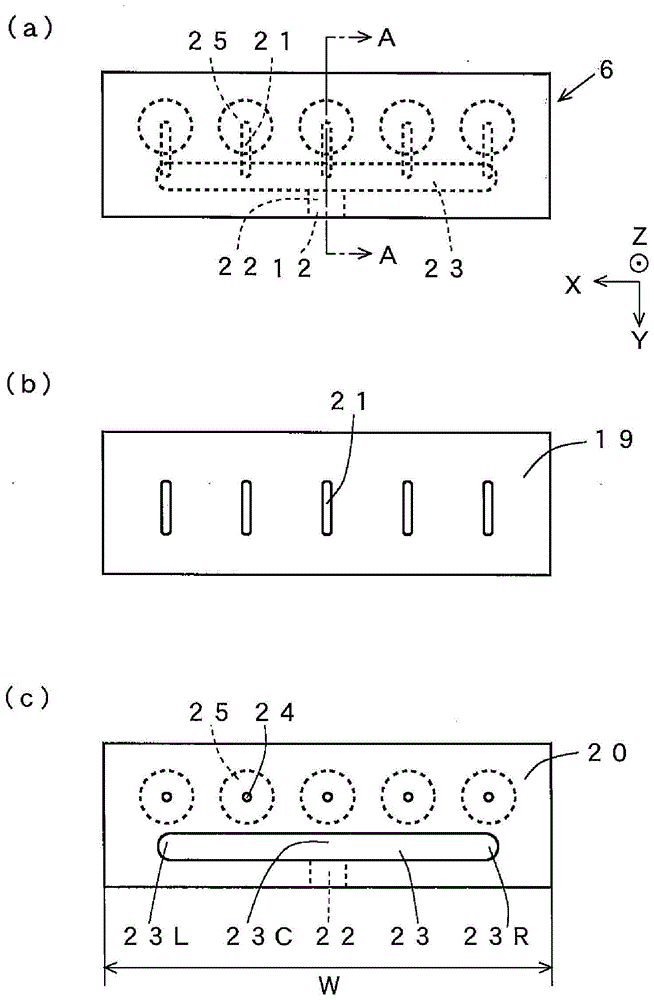

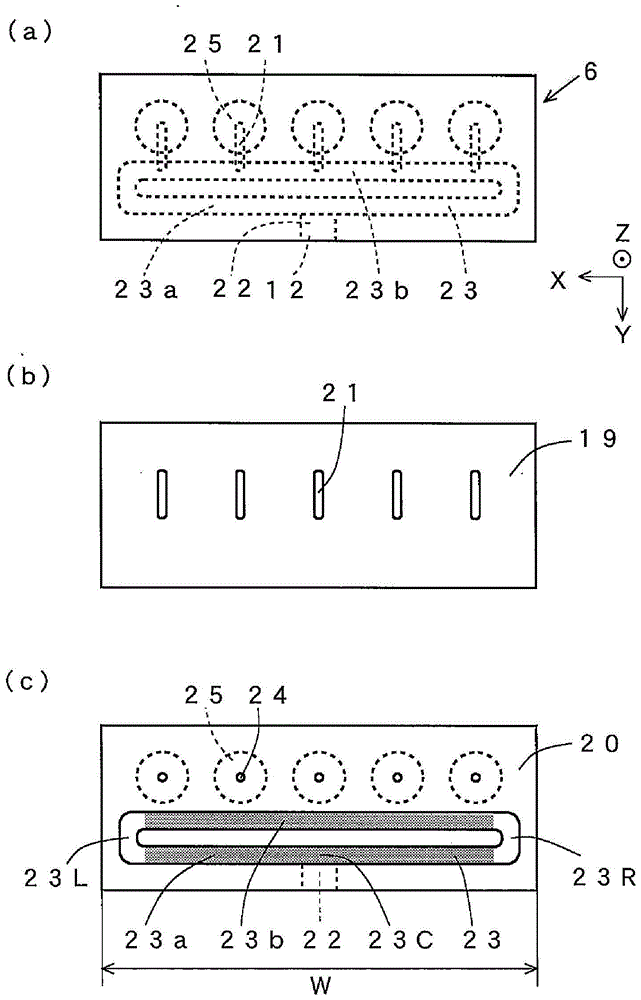

Resin molding apparatus and resin molding method

The invention provides a resin molding apparatus and a resin molding method. In the resin molding apparatus, liquid resin is equably injected at a specified amount from a plurality of nozzles. A resin injection mechanism (6) mounted at the front end of a distributor (1) comprises: a resin storage part (23) for storing the liquid resin (2); a plurality of resin channels (21), which are connected to the resin storage part (23) and extend along a horizontal direction; a plurality of resin channels (24) communicating with the resin channels (21) and extending along a vertical direction; and the plurality of nozzles (13) connected to the resin channels (24), respectively. The liquid resin (2) is supplied to and flows in the resin storage part (23), so that the liquid resin (2) can fill the resin storage part (23). The liquid resin (2) passes through the resin channels (21) extending along a horizontal direction from the top of the resin storage part (23), and through the resin channels (24) extending along a vertical direction from the resin channels (21) in sequence, and is injected towards each mold cavity (18) from the nozzles (13).

Owner:TOWA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com