Lotus seedpod electrospinning spray head

An electrospinning and nozzle technology, which is used in spinneret assemblies, textiles and papermaking, fiber processing, etc. and other problems, to achieve the effect of weakening the interference and inhibition of the electric field, improving the uniformity and stability, and promoting rapid jetting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

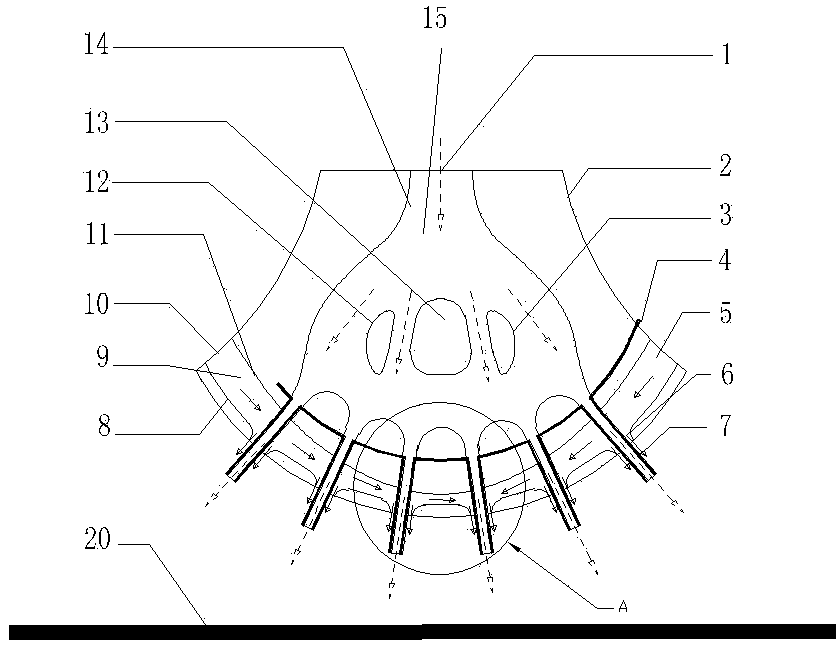

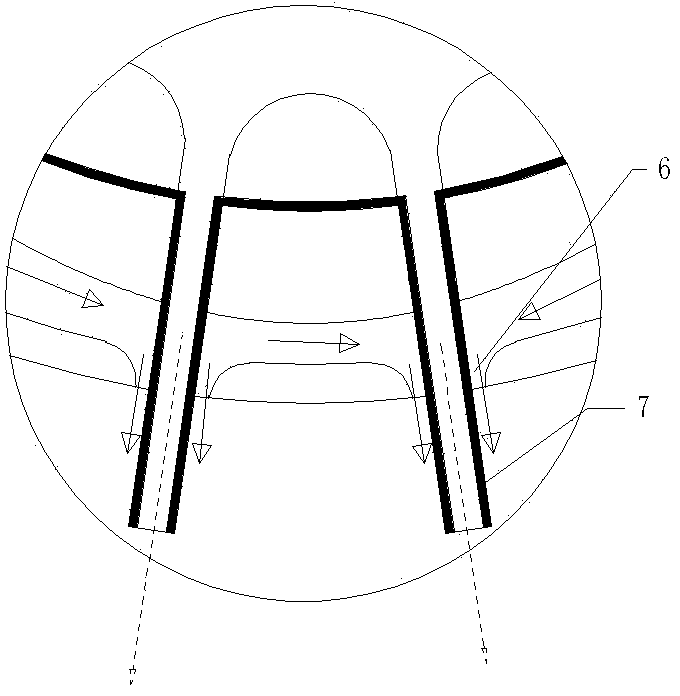

[0028] As a specific example, such as figure 1 As shown, a kind of showerhead electrospinning nozzle of the present invention comprises outer shell 2, and the cross section of described outer shell 2 is fan-shaped up and down, and the top surface of described outer shell 2 is a plane, and the bottom surface of described outer shell 2 is An arc surface, the top surface of the outer casing 2 is provided with a solution inlet 1, and the solution inlet 1 is connected to an external solution supply device, and the inside of the outer casing 2 is provided with a solution channel 15 whose shape matches the outer casing 2. The bottom surface of the solution channel 15 is an arc surface, and the bottom arc surface of the solution channel 15 is provided with a high-voltage electrode 4. The high-voltage electrode 4 is laid on the arc surface in the form of a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com