Clay 3D (Three Dimensional) printer and extruding device thereof

A technology of 3D printers and extrusion devices, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of reducing product strength, low efficiency, and large heat generation, so as to ensure printing quality and fineness, expand the scope of application, and prevent The effect of clay blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

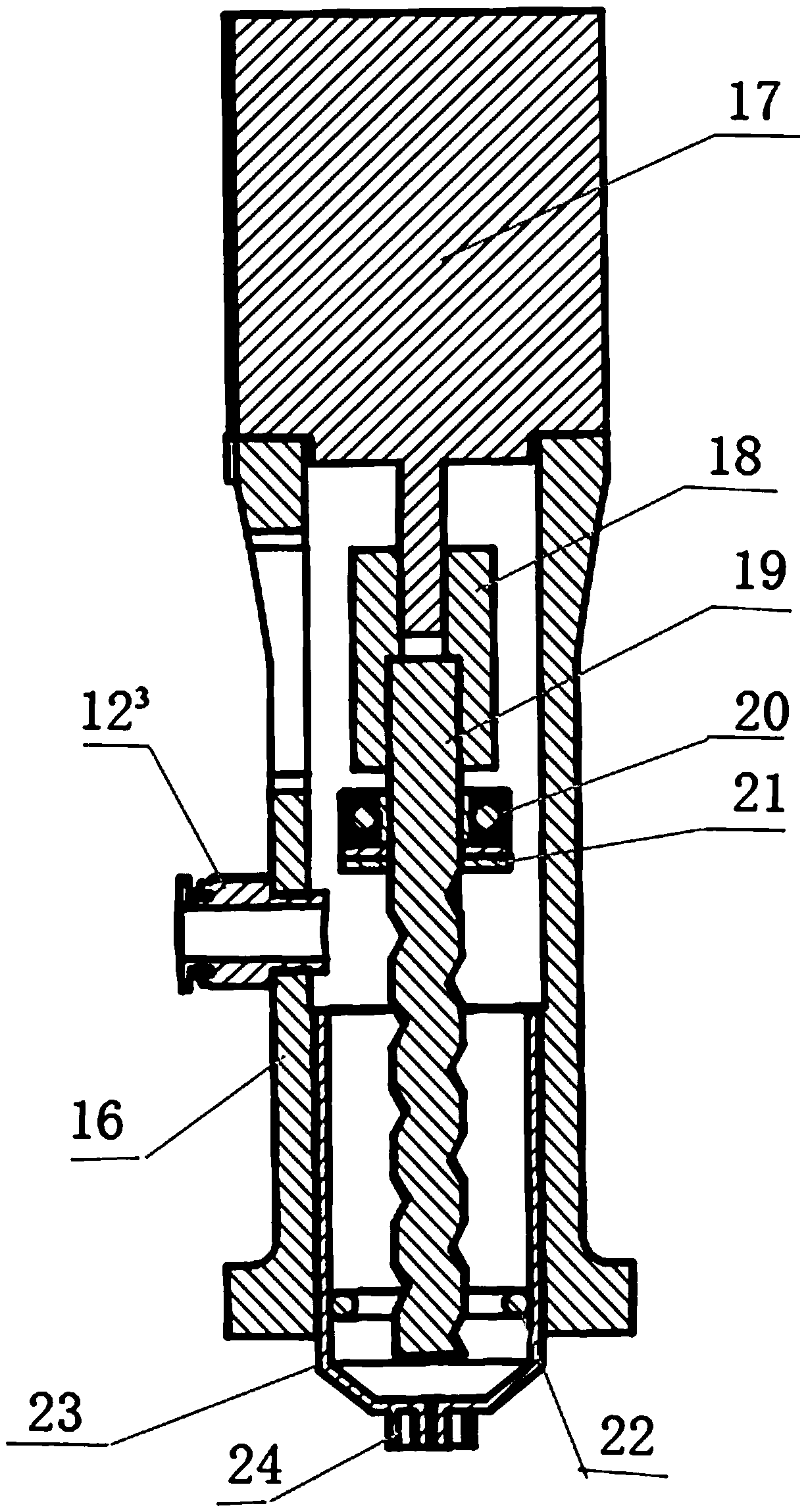

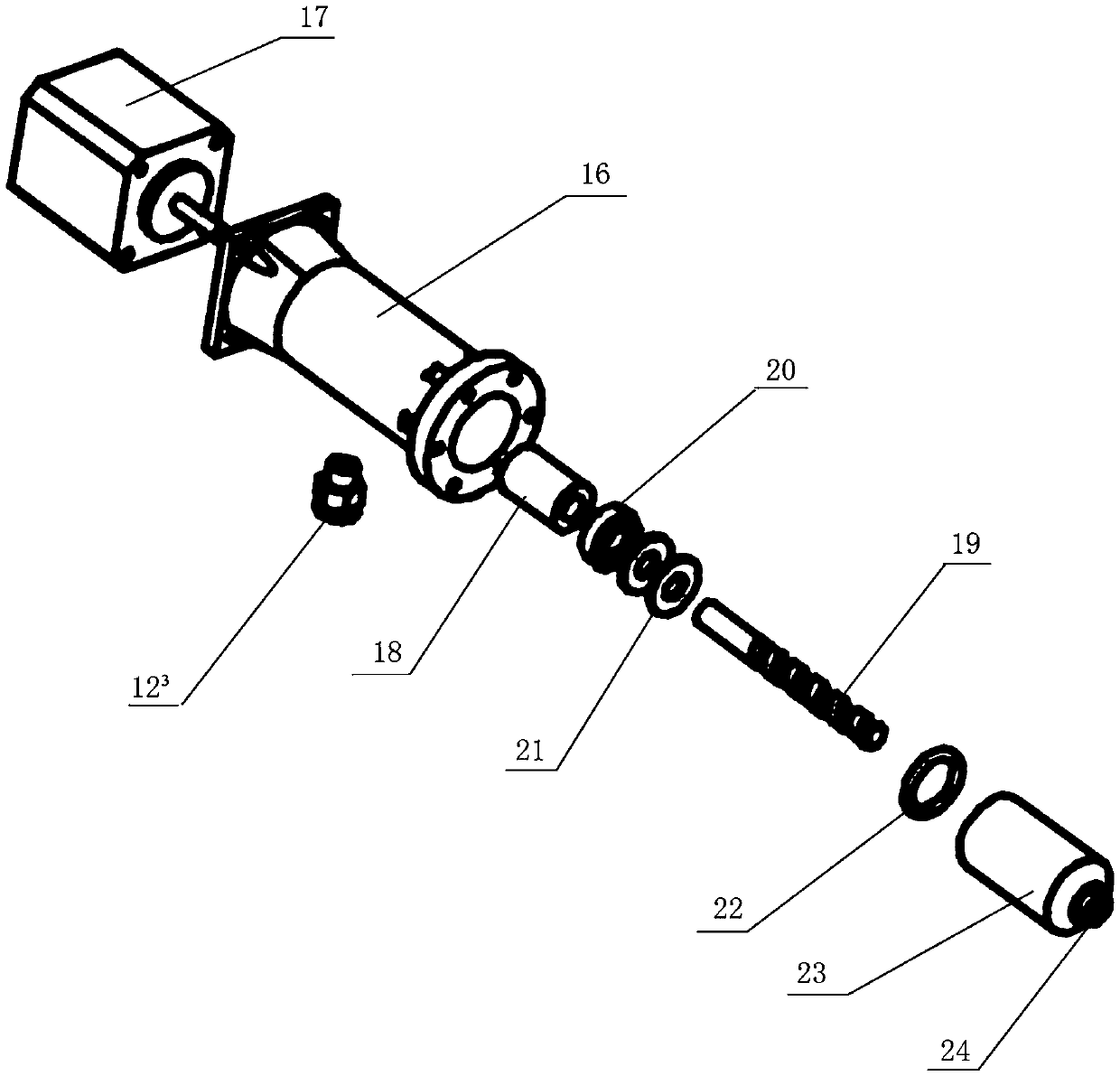

[0028] Embodiment 1: a kind of extrusion device of clay 3D printer, such as figure 1 , figure 2 and image 3 As shown, the extrusion device includes an extruder housing 16, a quick joint 123, a stepping motor 17, a rigid coupling 18, a screw 19, a deep groove ball bearing 20, a sealing rubber pad 21, a U-shaped sealing ring 22, an extrusion Barrel 23 and nozzle 24; quick connector 123 is installed on the extruder housing 16 through threaded connection, stepping motor 17 is installed on the upper end of extruder housing 16 through threaded connection, and the rotating shaft of stepping motor 17 passes through rigid coupling 18 Connected with the screw 19, the deep groove ball bearing 20 and the sealing rubber pad 21 are installed on the upper end of the screw 19, the extrusion barrel 23 is installed on the lower end of the extruder shell 16 through threads, and the nozzle 24 is a fixed size, which is installed on the extrusion material through threads The lower end of the ba...

Embodiment 2

[0029] Embodiment 2: a kind of clay 3D printer, comprises frame, storage device, extruding device and numerical control device;

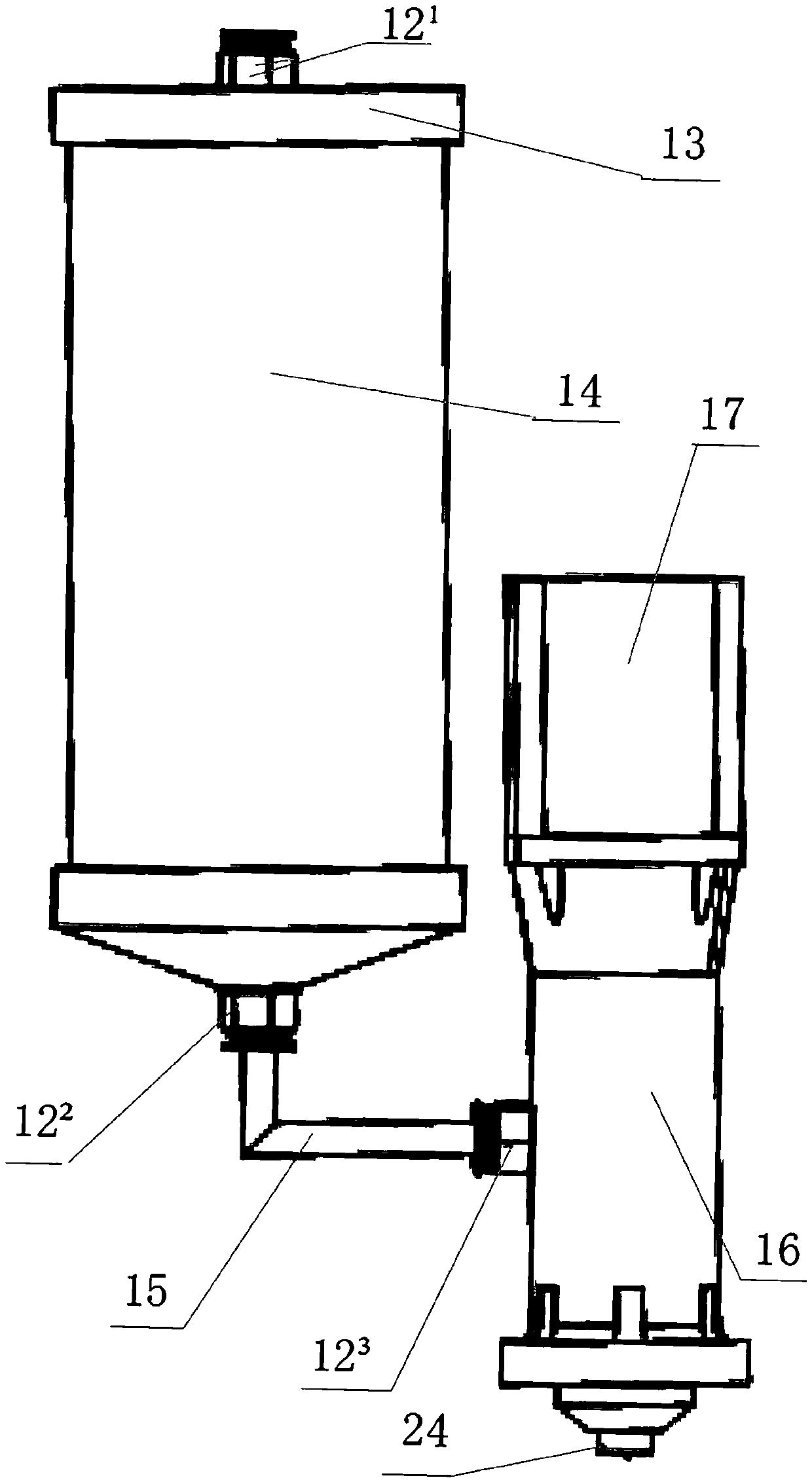

[0030] Such as figure 1 As shown, the storage device includes an air compressor, quick connectors 121 and 122, a storage tank cover 13, a storage tank 14, a piston and a PU hose 15; for the convenience of the clay 3D printer, storage tanks of different sizes are provided. 14. The storage tanks 14 of different sizes can be replaced according to the clay viscosity. The air compressor is connected with the storage tank upper cover 13 through a quick connector 121, the quick connector 121 is installed in the middle of the upper end of the storage tank upper cover 13 through threads, and the storage tank upper cover 13 is installed in the upper end of the storage tank 14 through threads, and the storage tank There is a piston in the material tank 14; the quick joint 122 is installed on the outer center of the bottom end of the material storage tank 14 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com