Air-assisted urea supply device used for diesel engine

A technology of air-assisted and supplying devices, which is applied in the direction of exhaust devices, noise reduction devices, mechanical equipment, etc., can solve problems such as blocking the mixing chamber, and achieve the effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

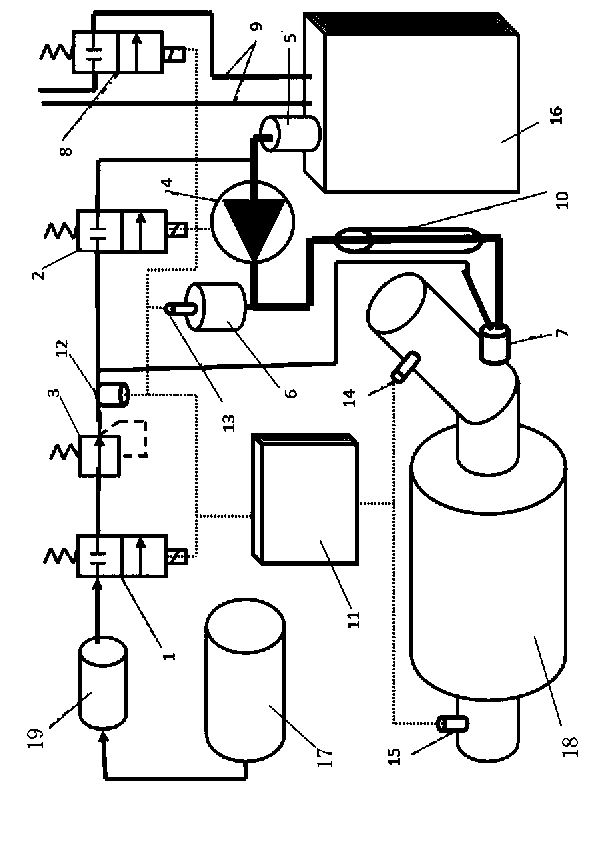

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0023] It can be seen from the accompanying drawings that an air-assisted urea supply device for diesel engines in this scheme includes a urea storage tank 16, an engine air storage tank 17, an engine exhaust muffler 18 (containing an SCR catalyst), and the urea storage tank 16 passes through the urea pump. 4 is connected with the injector 7, and the urea pump 4 is an electromagnetic plunger pump. The injector 7 communicates with the engine exhaust muffler 18, a filter 5 is arranged between the urea storage tank 16 and the urea pump 4, an electric heater 10 is arranged on the pipeline between the urea pump 4 and the injector 7, and The output end of the urea pump 4 is also provided with an accumulator 6, the engine air reservoir 17 communicates with the injector 7 through the air fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com