Resin molding apparatus and resin molding method

A technology of resin molding and resin, which is applied in the field of resin molding devices, and can solve problems such as increased device costs and complex device structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

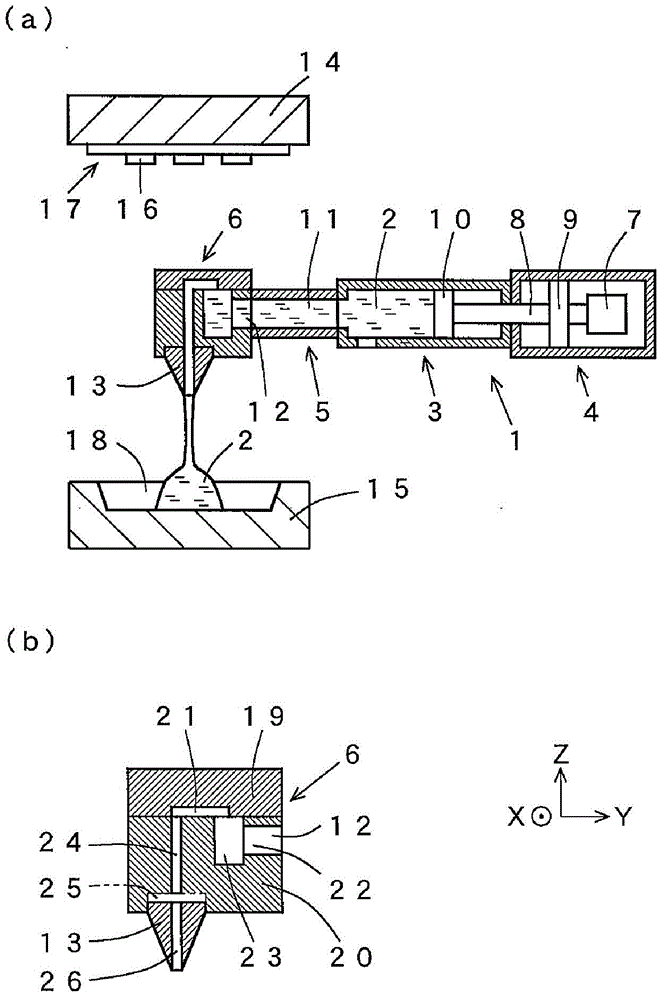

[0087] refer to figure 1 with figure 2 , Embodiment 1 of the resin supply mechanism of the resin molding apparatus according to the present invention will be described. For ease of understanding, any of the drawings in the present application documents are appropriately omitted or exaggerated to be schematically drawn. The same reference numerals are used for the same structural elements, and explanations are appropriately omitted.

[0088] figure 1 The dispenser 1 as a resin supply mechanism shown in (a) is a horizontal dispenser arrange|positioned along the horizontal direction. The dispenser 1 is provided with: a storage part 3 for storing the liquid resin 2; a metering and sending mechanism 4 for measuring and sending out the liquid resin 2 according to a predetermined amount; a resin transfer part 5 for transferring the sent out liquid resin 2; and a resin injection The mechanism 6 ejects the transferred liquid resin 2 .

[0089] The liquid resin 2 transferred from ...

Embodiment 2

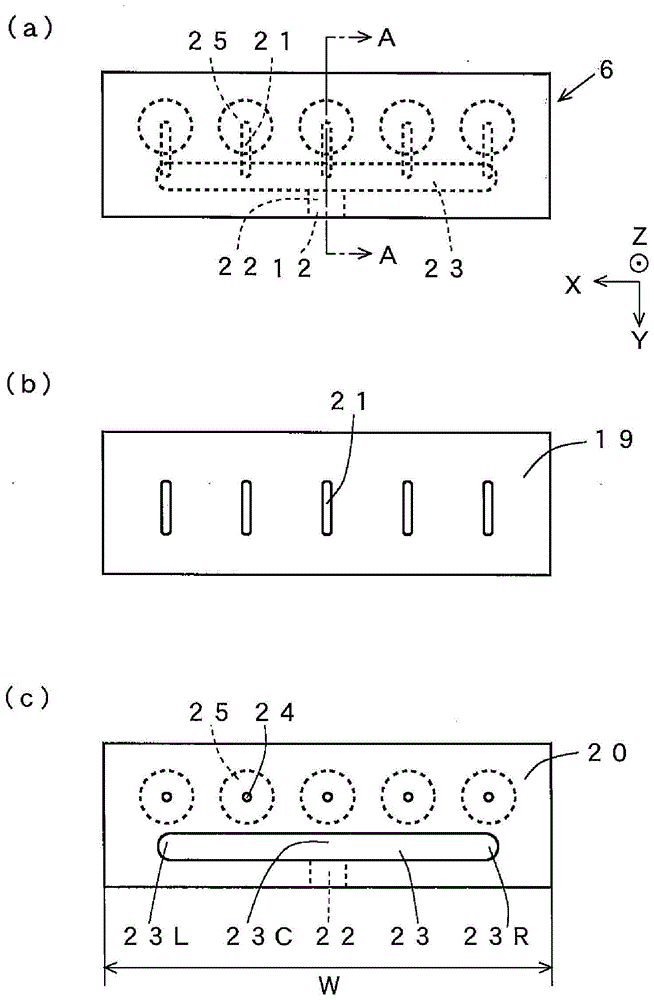

[0113] refer to image 3 , Embodiment 2 of the resin supply mechanism of the resin molding apparatus according to the present invention will be described. The difference from Example 1 is that the resin storage part 23 is formed as an annular groove in plan view. Other than that, it is the same as in Example 1, so description is omitted. Such as image 3 As shown in (c), the lower part 20 is provided with a resin passage 22, an annular resin storage part 23 connected to the resin passage 22 and formed in a horizontal plane (in a plane including the X-axis and Y-axis), along the vertical A plurality of thin resin passages 24 extending in the direction (-Z direction) are connected to the plurality of resin passages 24 and are used for installing nozzles 13 (refer to figure 1 (b)) a plurality of nozzle mounting ports 25. The annular resin storage portion 23 has resin storage portions 23a, 23b constituted by two extensions extending side by side. That is, it has a resin reser...

Embodiment 3

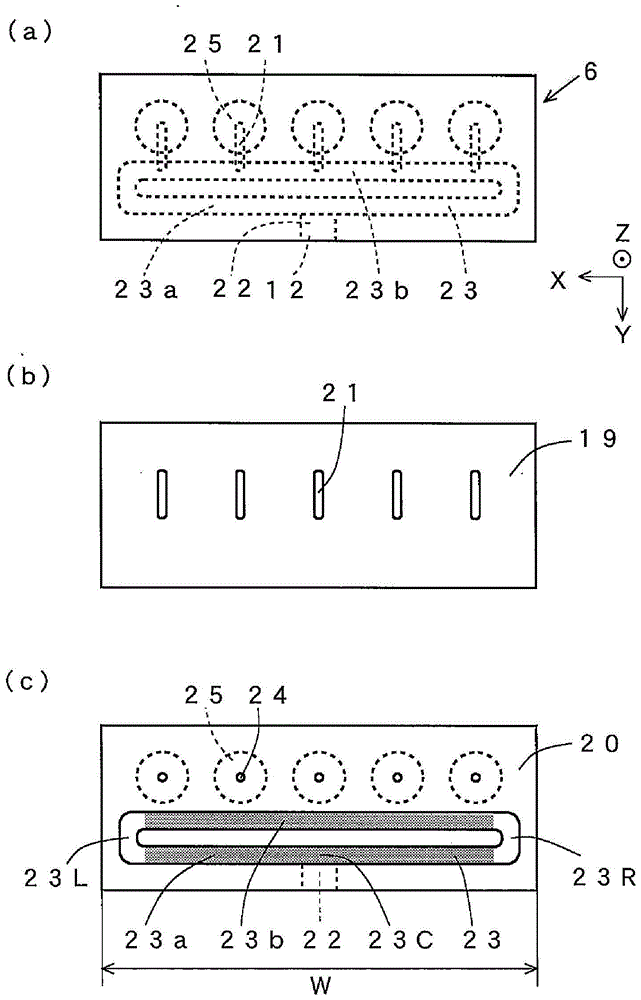

[0119] refer to Figure 4 , Embodiment 3 of the resin supply mechanism of the resin molding apparatus according to the present invention will be described. The difference from Embodiment 2 is that the central part of the resin storage part 23 a and the central part of the resin storage part 23 b are connected through the resin channel 27 in the annular resin storage part 23 . Other than that, it is the same as in Example 2.

[0120] Such as Figure 4 As shown in (c), the lower part 20 is provided with a resin passage 22, an annular resin storage part 23 connected to the resin passage 22, and a central part for connecting the resin storage part 23a and the central part of the resin storage part 23b. The resin passage 27 , the plurality of resin passages 24 extending in the vertical direction (−Z direction), and the plurality of nozzle mounting ports 25 connected to the plurality of resin passages 24 for mounting the nozzles 13 . In a state where the upper member 19 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com