Marine plunger matching part

A plunger coupling and marine technology, applied in the field of marine plunger couplings, can solve problems affecting the service life of the plunger coupling, lubricating oil pollution in the camshaft system, easy seizure of the plunger, etc., to avoid heavy oil pollution, Improve production efficiency and prevent seizures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

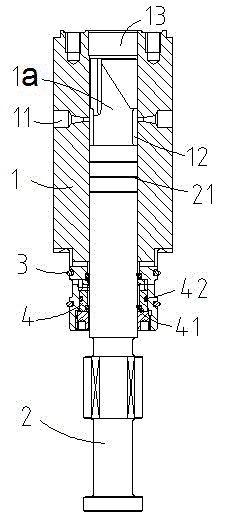

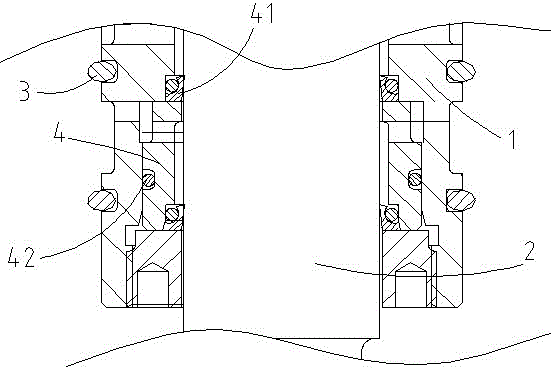

[0023] figure 1 and figure 2 Shown is a schematic cross-sectional structure of the present invention.

[0024] one of them figure 1 and figure 2 The reference signs in are: sleeve 1, axial middle hole 1a, oil inlet hole 11, sealing ring 12, sealing block 13, plunger 2, annular groove 21, first sealing ring 3, oil scraping device 4, mechanical A sealing ring 41 and a second sealing ring 42 .

[0025] A marine plunger couple, including a plunger 2 and a sleeve 1, the sleeve 1 is formed with an axial middle hole 1a, the plunger 2 is movably fitted in the axial middle hole 1a, and the two can be relatively rotated and Sliding up and down, the sleeve 1 is provided with an oil inlet hole 11, and the upper part of the axial middle hole 1a is connected with an oil outlet device, wherein a sealing ring 12 is arranged in the axial middle hole 1a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com