Patents

Literature

34results about How to "Realize batch continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

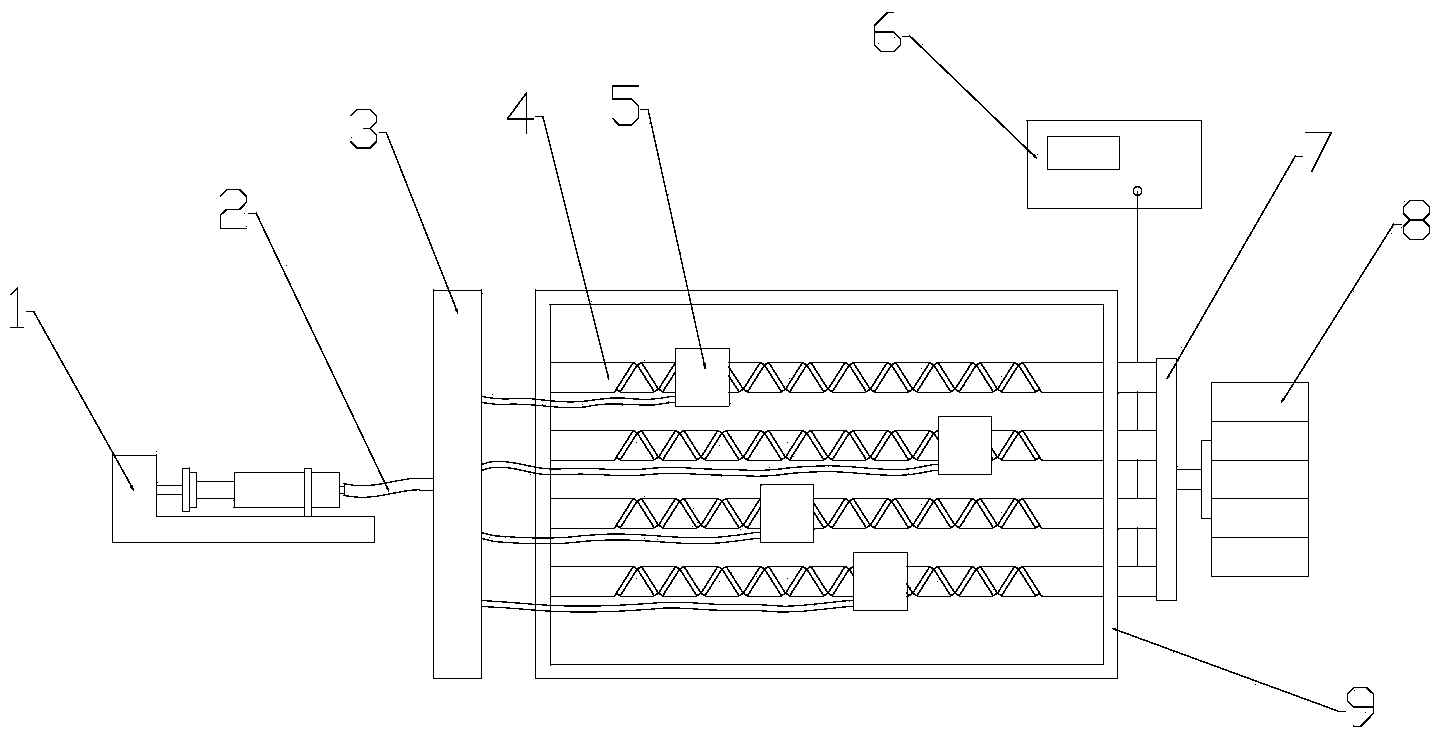

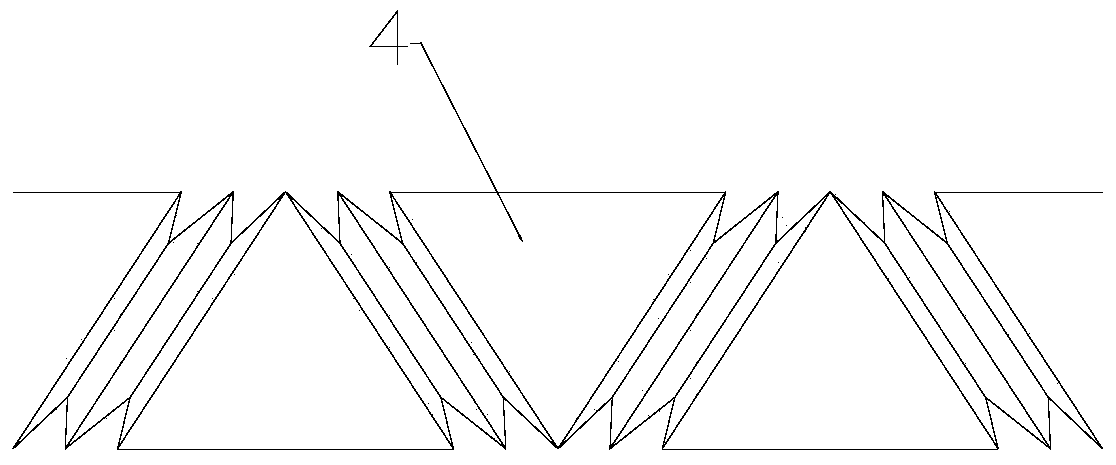

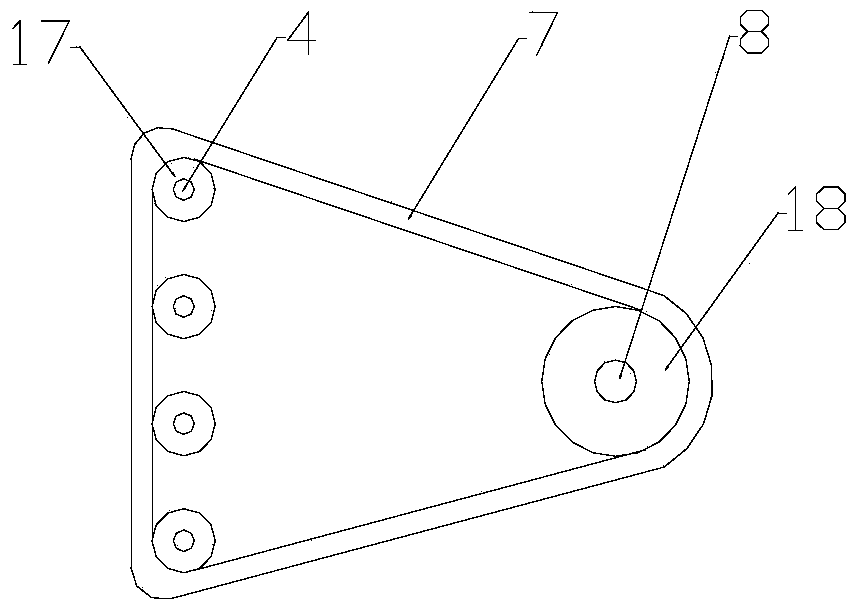

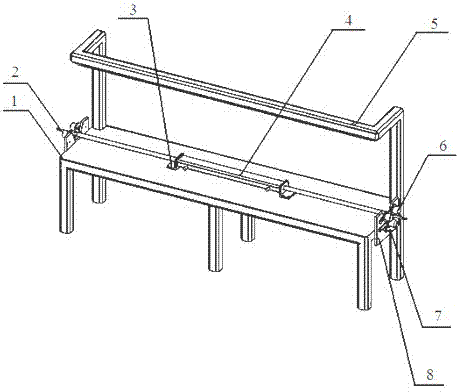

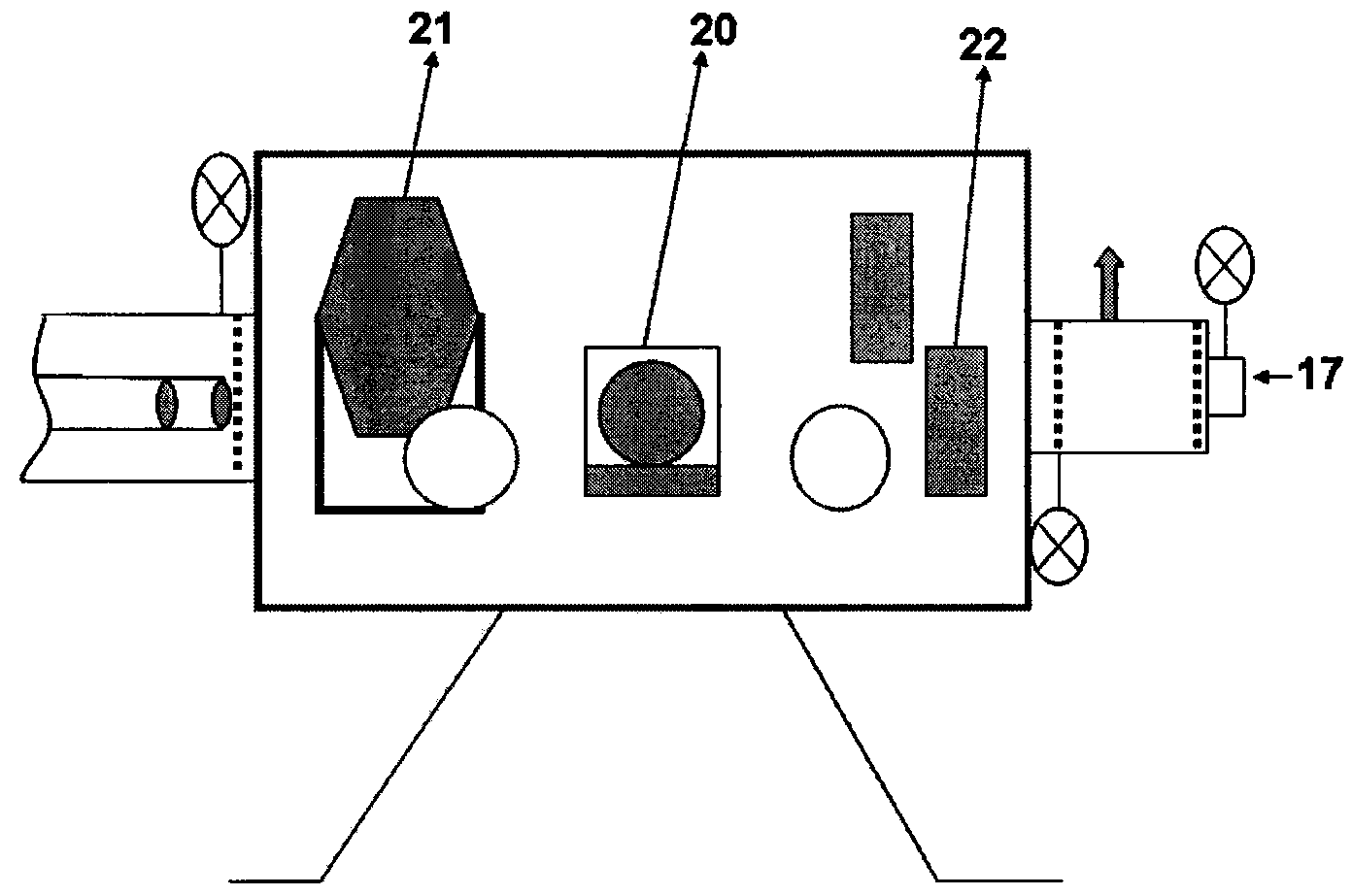

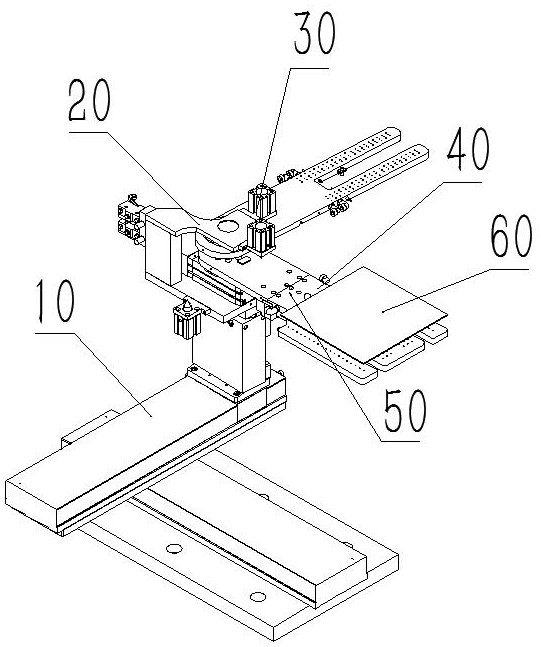

Bidirectional spiral electrostatic spinning device

ActiveCN104032383AJet stabilityImprove thickness uniformitySpinning head liquid feederFilament/thread formingFiberElectrospinning

The invention discloses a bidirectional spiral electrostatic spinning device, and relates to an electrostatic spinning device. The bidirectional spiral electrostatic spinning device is provided with bidirectional threaded guide rods, liquid storage sliders, vertical slide bars, guide rails, a framework, a controllable injection device, a liquid guide pipe, a liquid distributing device, a high-voltage power source, air pumps, pressure regulating valves, air guide pipes, partition plates, motors, driven belt pulleys, driving belt pulleys, V-shaped belts, air hole arrays and collecting devices. The bidirectional spiral electrostatic spinning device has the advantages that large-area and multi-jet injection effects can be realized by the aid of the bidirectional threaded guide rods, so that the electrostatic spinning efficiency further can be improved, phenomena of electrostatic interference among spinning jets and electric field concentration can be reduced, uniform distribution of nano-fibers on collecting plates can be promoted, the thickness uniformity of collected nano-fiber membranes can be improved, the quality of the nano-fiber membranes can be enhanced, the multiple jets can be assuredly stably and quickly injected, and large-area uniform nano-membranes can be collected; the bidirectional spiral electrostatic spinning device is applicable to injection devices with different bidirectional threaded guide rods and different thread shapes, and the lengths, the quantities and the shapes of the bidirectional threaded guide rods of the injection devices can be different from one another.

Owner:XIAMEN UNIV

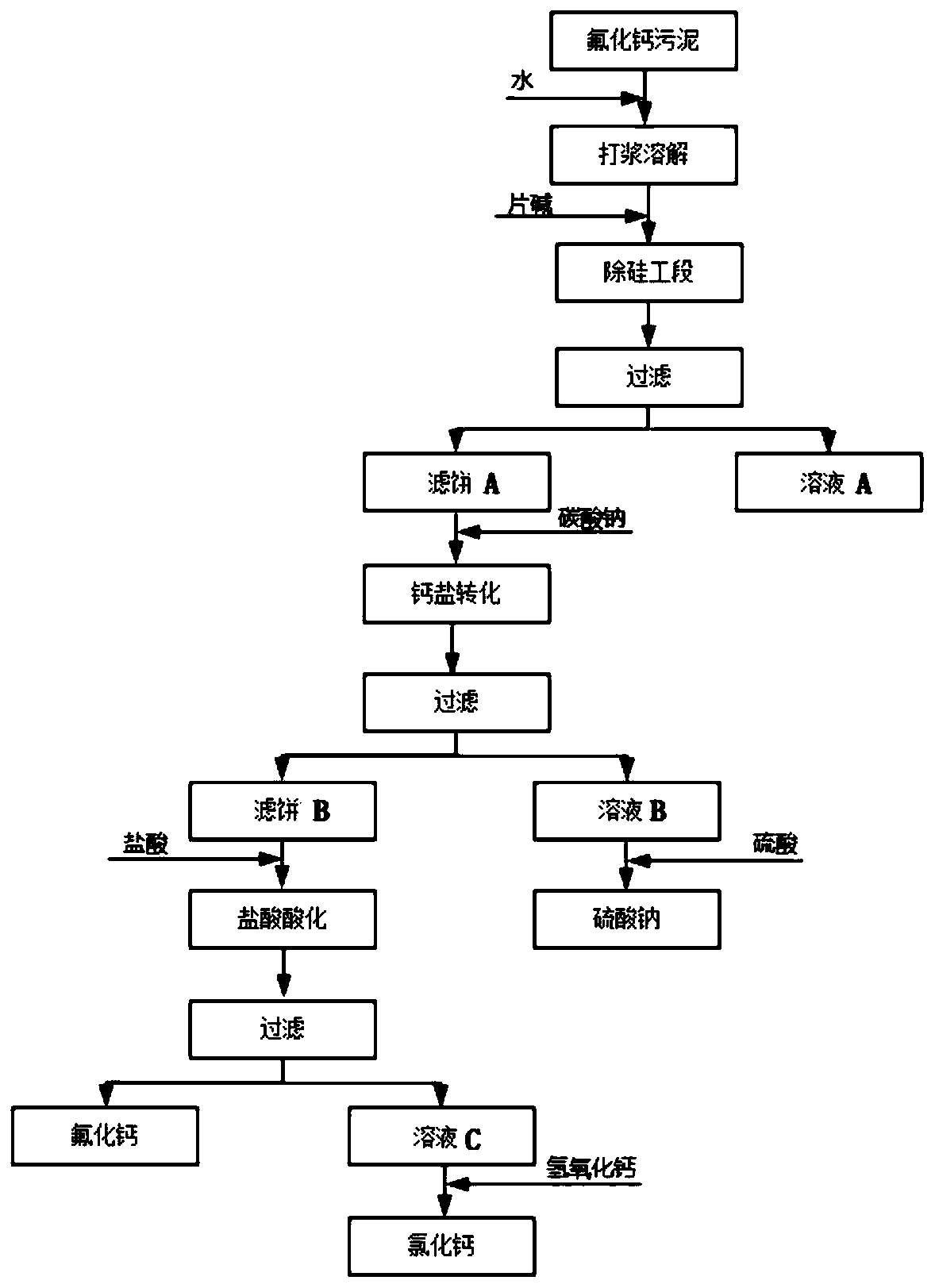

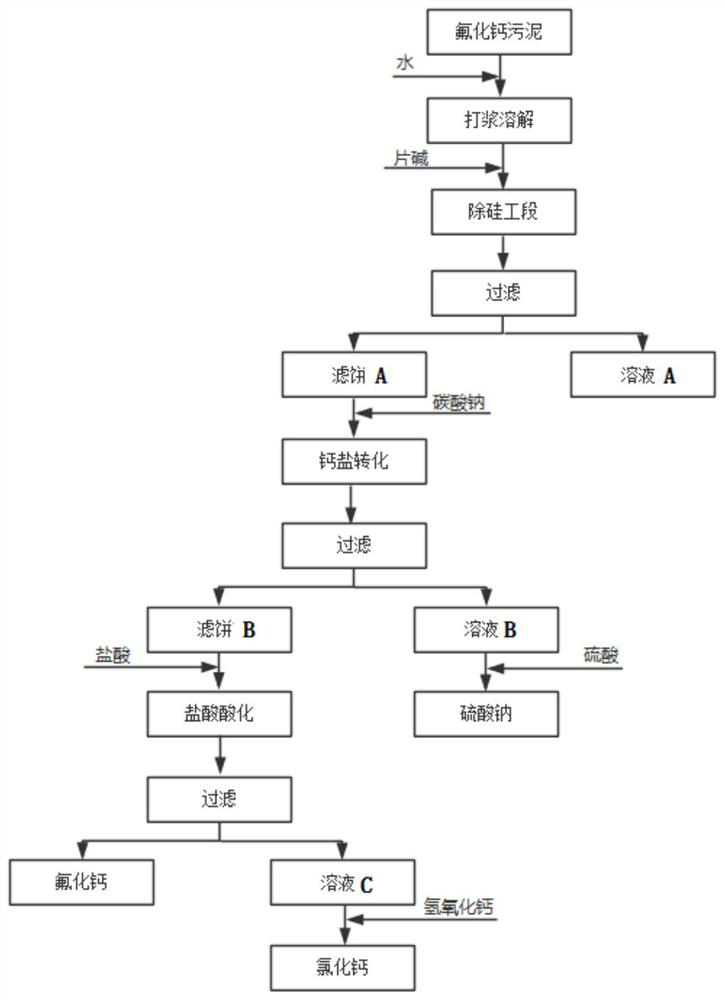

Method for extracting pure calcium fluoride from calcium fluoride sludge

ActiveCN109775743AHigh puritySimple processSludge treatmentCalcium/strontium/barium fluoridesSludgeSilicon

The invention discloses a method for extracting pure calcium fluoride from calcium fluoride sludge. The method includes the following steps of 1, beating and dissolving; 2, silicon removal with caustic soda to obtain a filter cake A and a solution A; 3, calcium salt conversion; 4, acidification with hydrochloric acid to obtain calcium fluoride and a solution C; 5, drying and smashing, wherein theacidified calcium fluoride is dried in an oven at 105 DEG C and smashed by a smasher to obtain the powdery pure calcium fluoride. By means of the method, the calcium fluoride sludge can be effectivelytreated to avoid secondary pollution, and meanwhile the calcium fluoride in the sludge can be recovered to solve the problem of fluorine resource shortage.

Owner:盛隆资源再生(无锡)有限公司

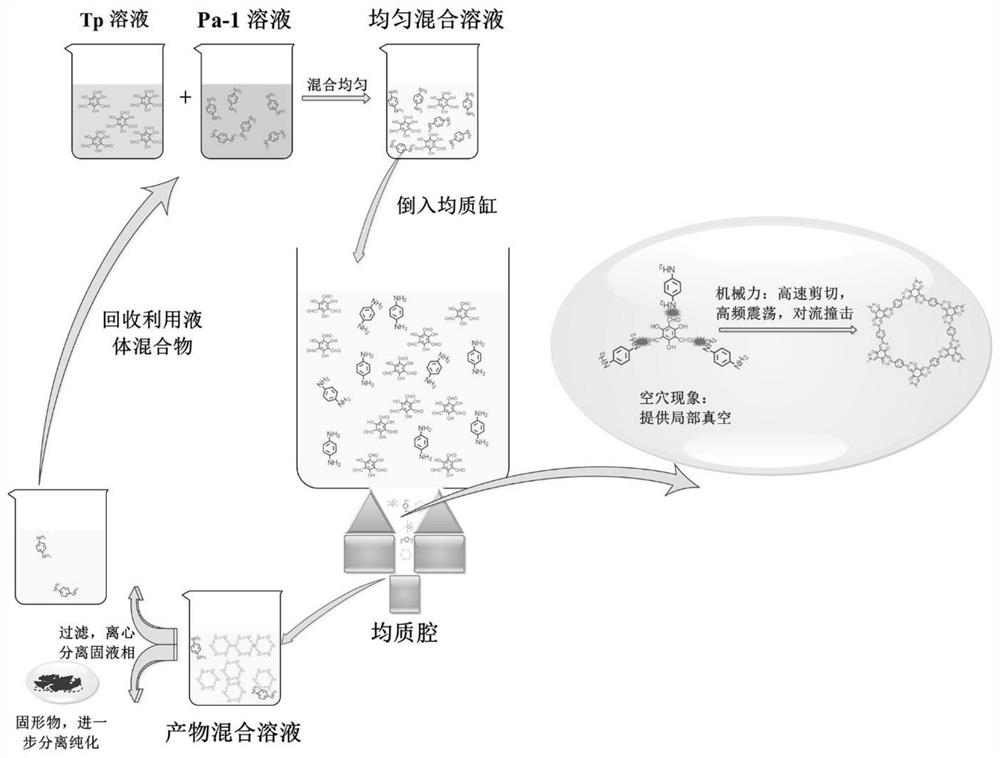

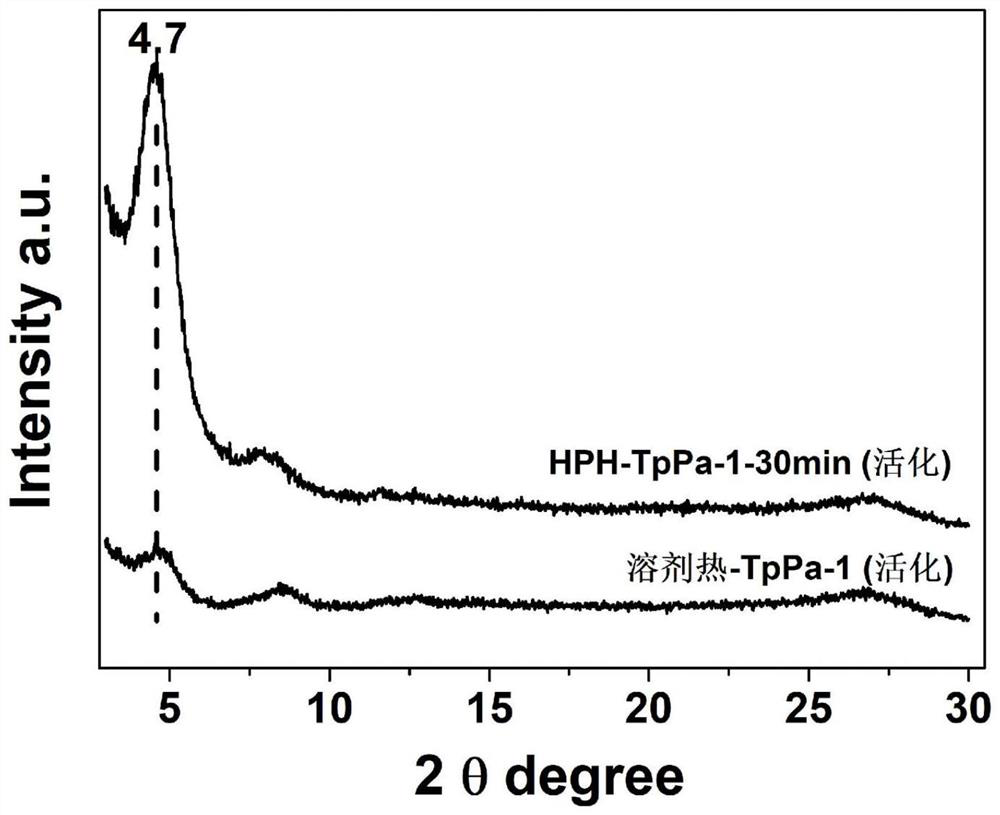

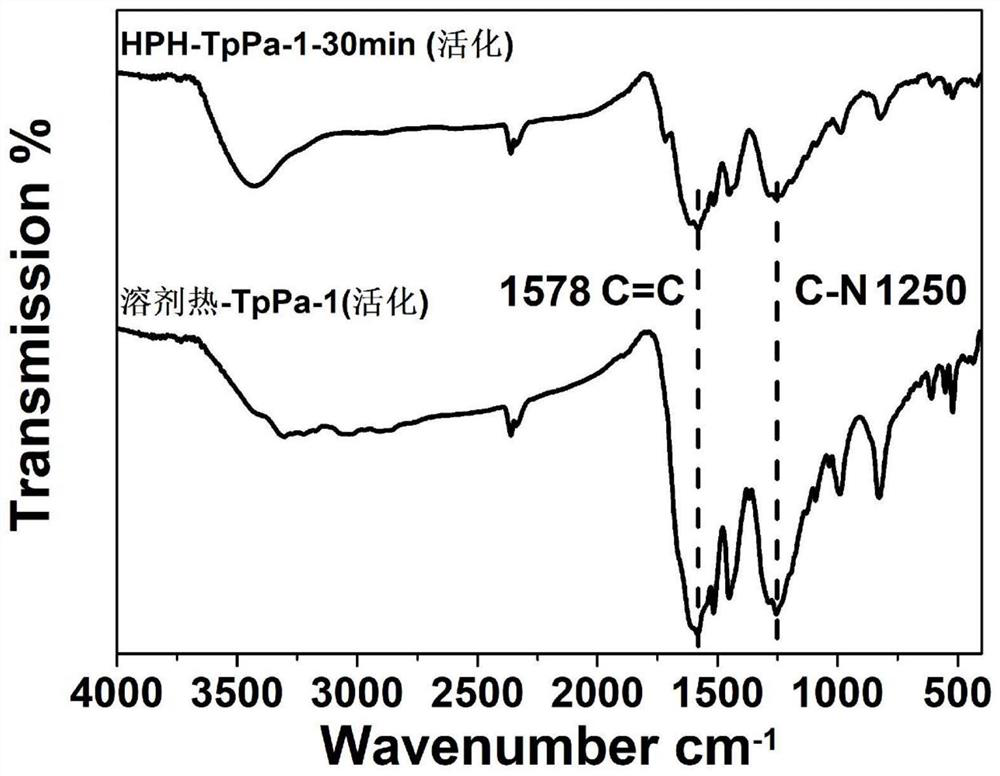

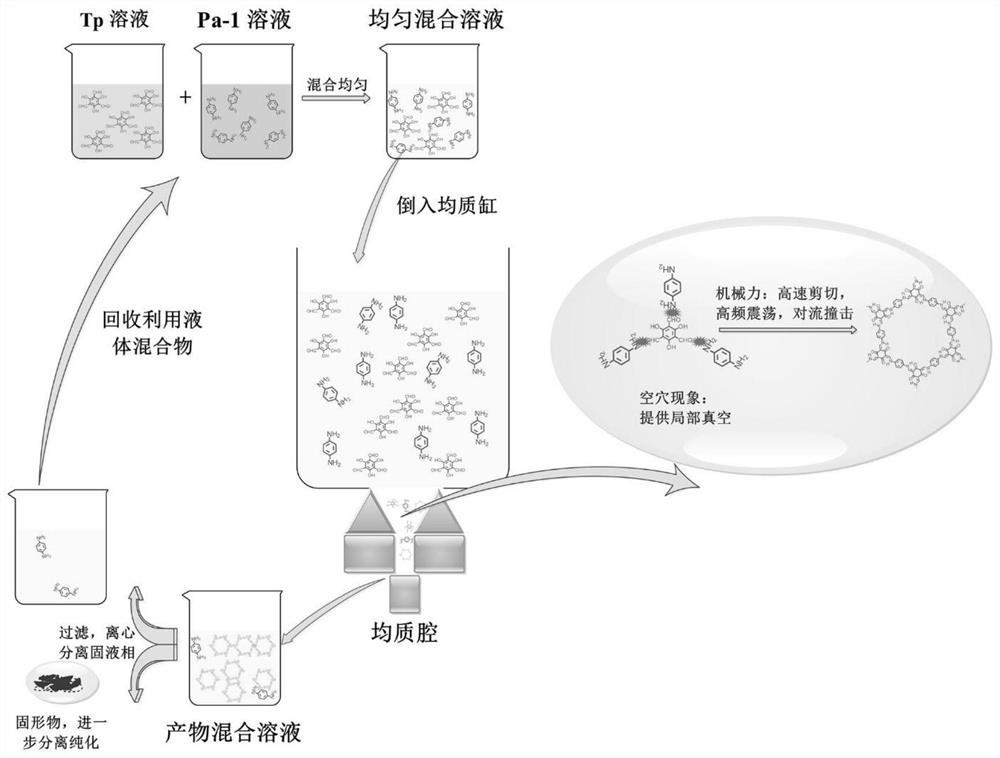

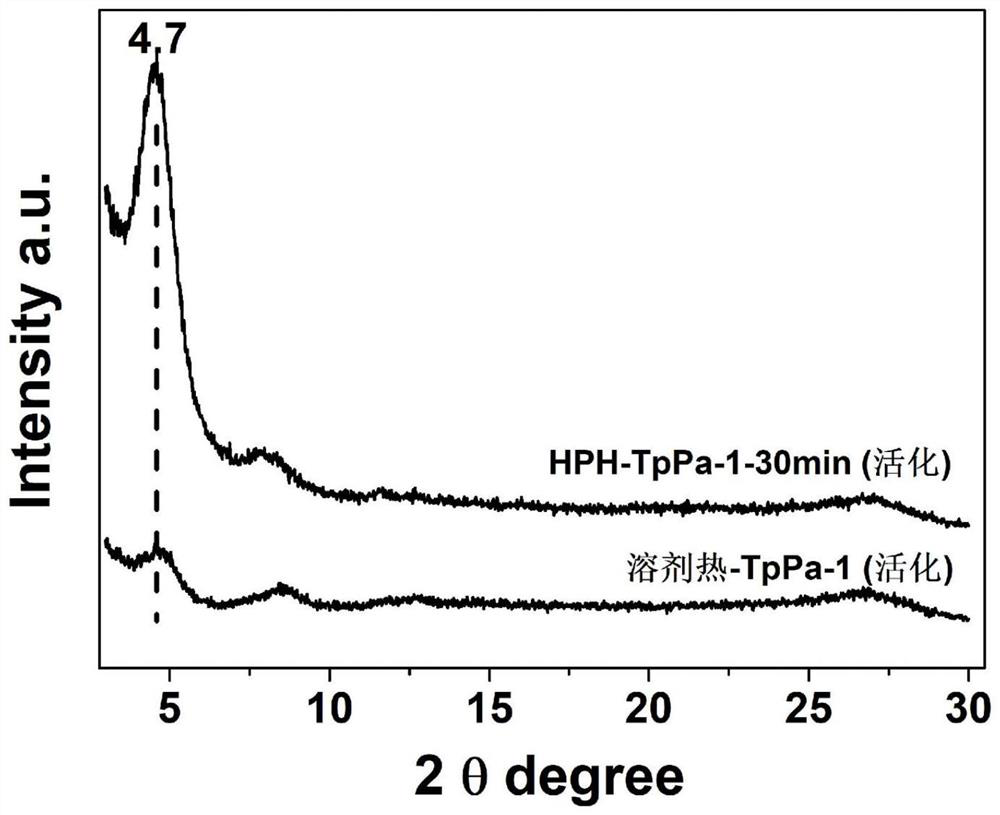

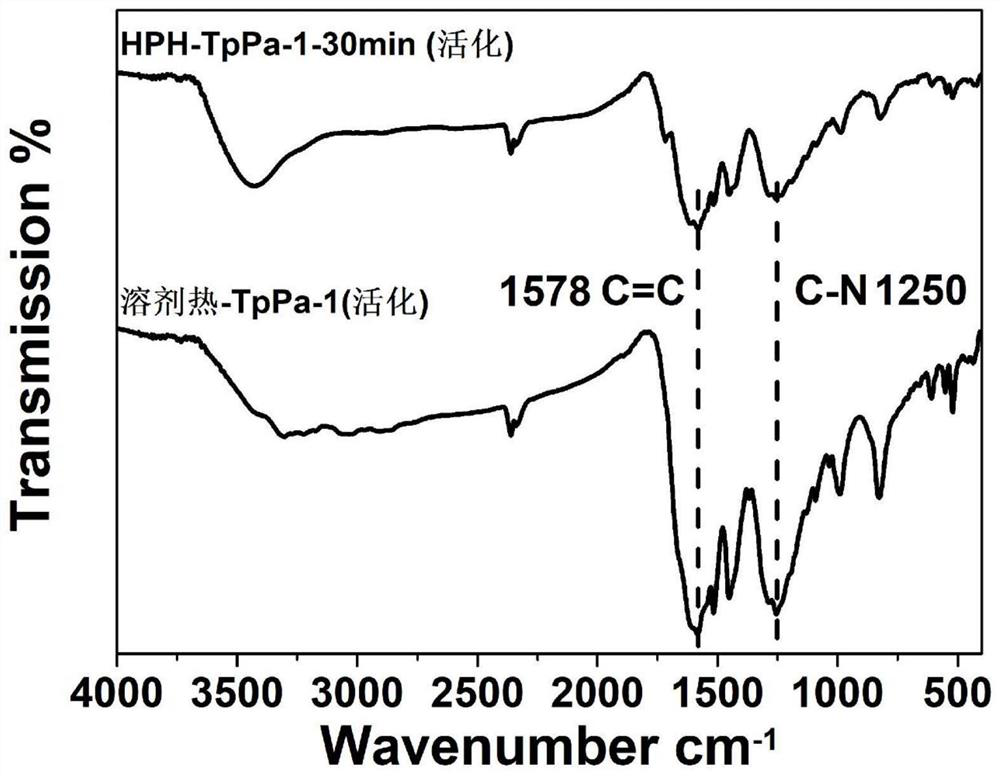

Method for preparing covalent organic framework material by high-pressure homogenization

ActiveCN113024828AShort reaction timeEasy to operateOther chemical processesPtru catalystEthylic acid

The invention relates to a method for preparing a covalent organic framework material by high-pressure homogenization. According to the synthesis method, at normal temperature and normal pressure, a common organic ligand is used as a raw material, water or an organic reagent is used as a solvent and a template agent, organic acid and inorganic acid are used as catalysts, and the corresponding COFs are obtained by homogenizing for a certain time through a high-pressure homogenizer. The method comprises the following steps of: adding 2, 4, 6-trihydroxy-1, 3, 5-benzenetricarboxaldehyde and p-phenylenediamine into a beaker, adding a proper amount of water and acetic acid, uniformly mixing, adding the mixture into a high-pressure homogenizer, and homogenizing for a certain time; and carrying out suction filtration on the product powder after the homogenizing reaction, recycling the filtrate, washing the product powder, and carrying out vacuum drying to obtain the covalent organic framework material HPH-Tp-Pa-1. Compared with other COFs preparation methods, the method provided by the invention has the advantages of continuous reaction, simple operation, low cost, high yield, environmental protection, energy saving, short reaction time and the like, has the potential of large-scale production, and can greatly promote the industrial production process of the COFs material.

Owner:NANKAI UNIV

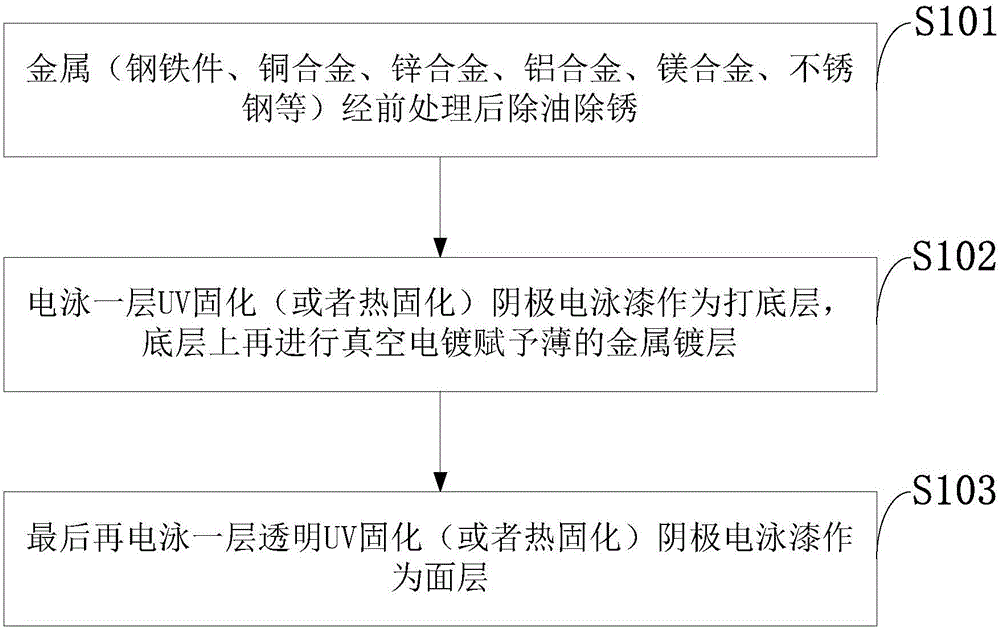

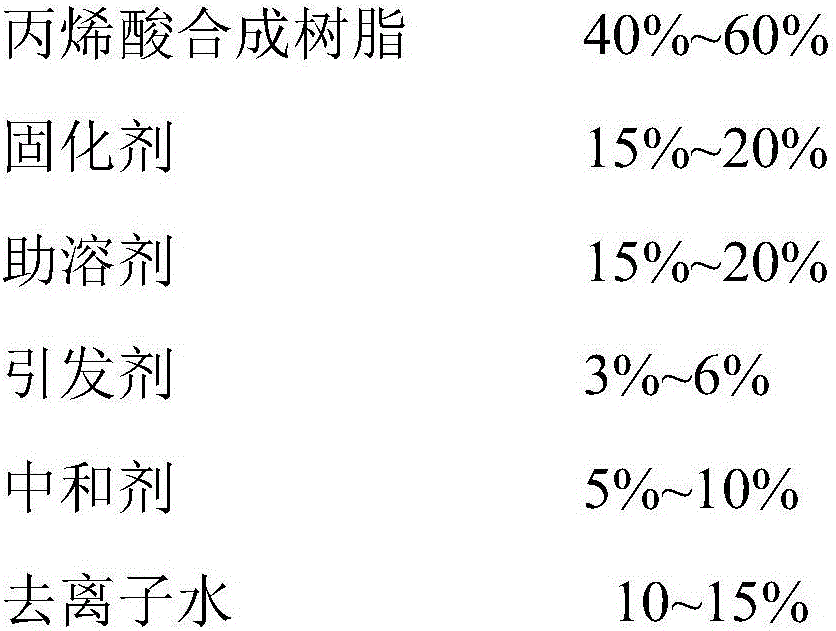

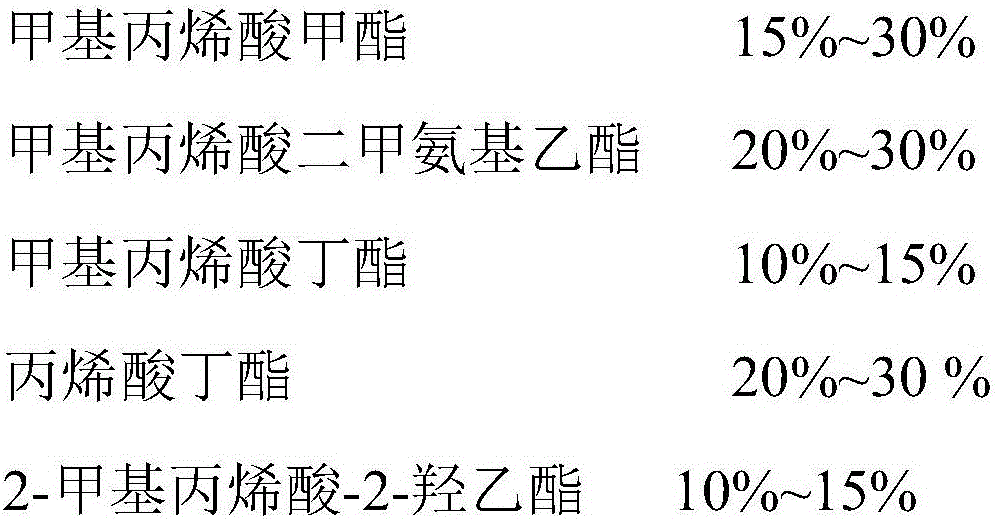

Acrylic acid cathode electrophoretic paint for producing composite coating and application thereof

InactiveCN106497372AStrong metal textureGood metal textureElectrophoretic coatingsPolyurea/polyurethane coatingsSolventBinding force

The invention discloses acrylic acid cathode electrophoretic paint for producing a composite coating and an application thereof. The acrylic acid cathode electrophoretic paint consists of the following components in percentage by mass: 40-60% of acrylic acid synthetic resin, 15-20% of curing agent, 15-20% of cosolvent, 3-6% of initiator, 5-10% of neutralizer and 10-15% of deionized water, wherein the curing agent is closed polyisocyanate; the cosolvent is an alcohol ether organic solvent; the initiator is azodiisobutyronitrile; the neutralizer comprises lactic acid and glacial acetic acid. The electrophoretic paint disclosed by the invention has the advantages of good leveling property, high throwing power, strong covering power against a base material and good binding force with the base material while the obtained film layer has good flexibility; a pulse magnetron sputtering vacuum coating method is adopted for vacuum plating; the adopted target materials include aluminum, titanium, zinc, chromium or alloy thereof, and the deposition speed is high; the film layer is silver white, can reach mirror plane brightness and has strong metal texture; the film layer is 1-2mum thick, the thickness is uniform and the phenomenon of skip plating is avoided; and moreover, the electrical conductivity is good, and a good foundation is laid for follow-up secondary electrophoresis.

Owner:东莞市霖辉金属表面处理材料有限公司 +1

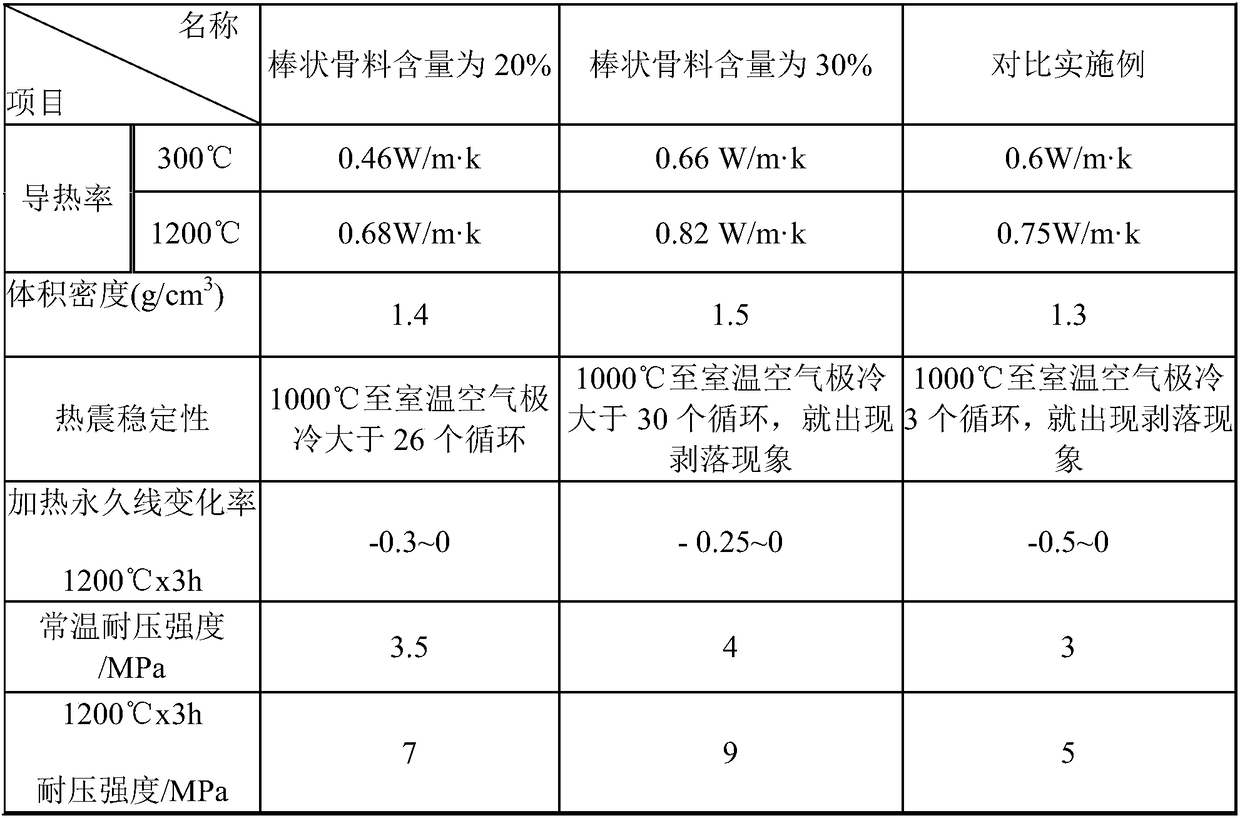

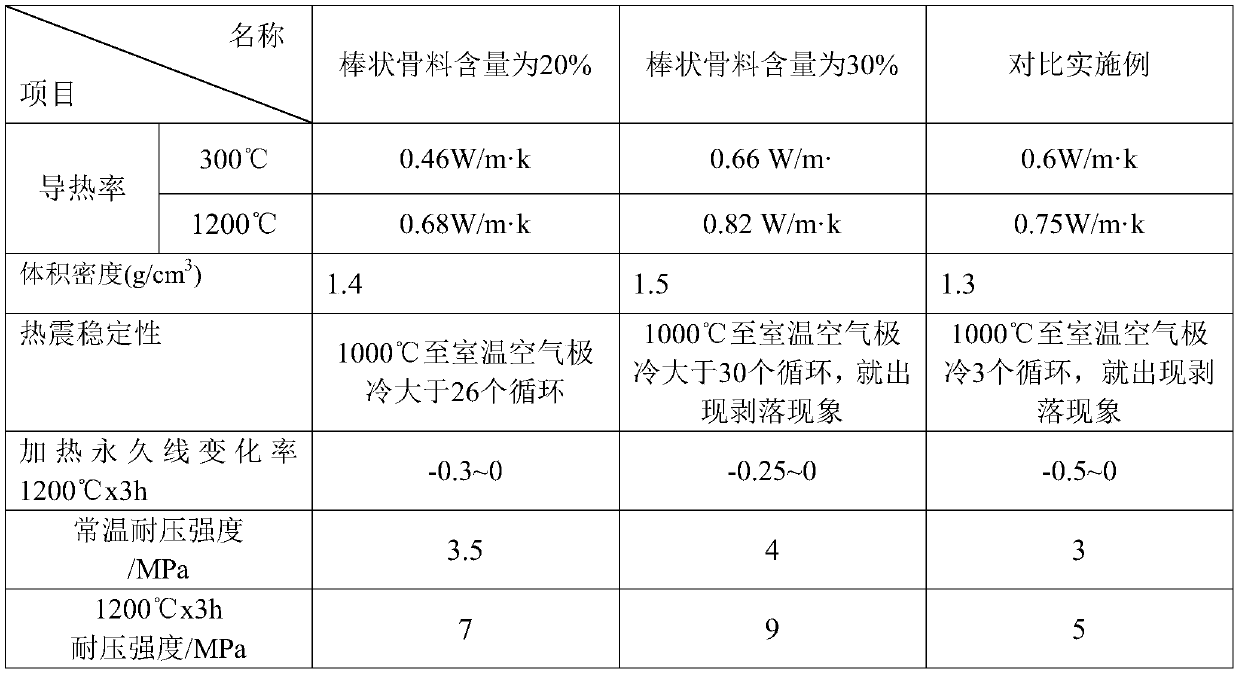

Light-weight casting material

ActiveCN108249934AReduce replacementRealize continuous automatic productionFloating microspheresThermal shock

The invention provides a light-weight casting material. The light-weight casting material is prepared by mixing raw materials including 10 to 50 percent of rod-shaped aggregate, 0 to 45 percent of light-weight aggregate, 4 to 10 percent of silicon ash with the granularity less than or equal to 0.2mu m, 17 to 30 percent of bauxite cement, 8 to 20 percent of floating microspheres, 5 to 10 percent ofclosed-pore pearlite, 0 to 10 percent of high alumina bauxite powder and a water reducing agent. According to the light-weight casting material provided by the invention, the small-size rod-shaped aggregate is uniformly dispersed so that the firing after-shrinkage of a product is reduced, the thermal shock resistance of the casting material is remarkably improved and the service life is greatly prolonged; different amounts of the light-weight aggregate which is continuously graded are added, so that the casting material has high strength and good flowability and casting materials with different thermal conductivity coefficients can be prepared, and furthermore, an application range of the casting material is expanded.

Owner:郑州市裕丰耐火材料有限公司

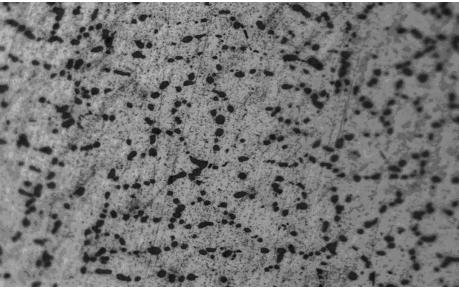

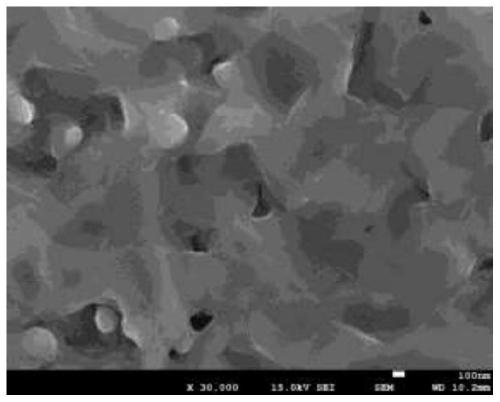

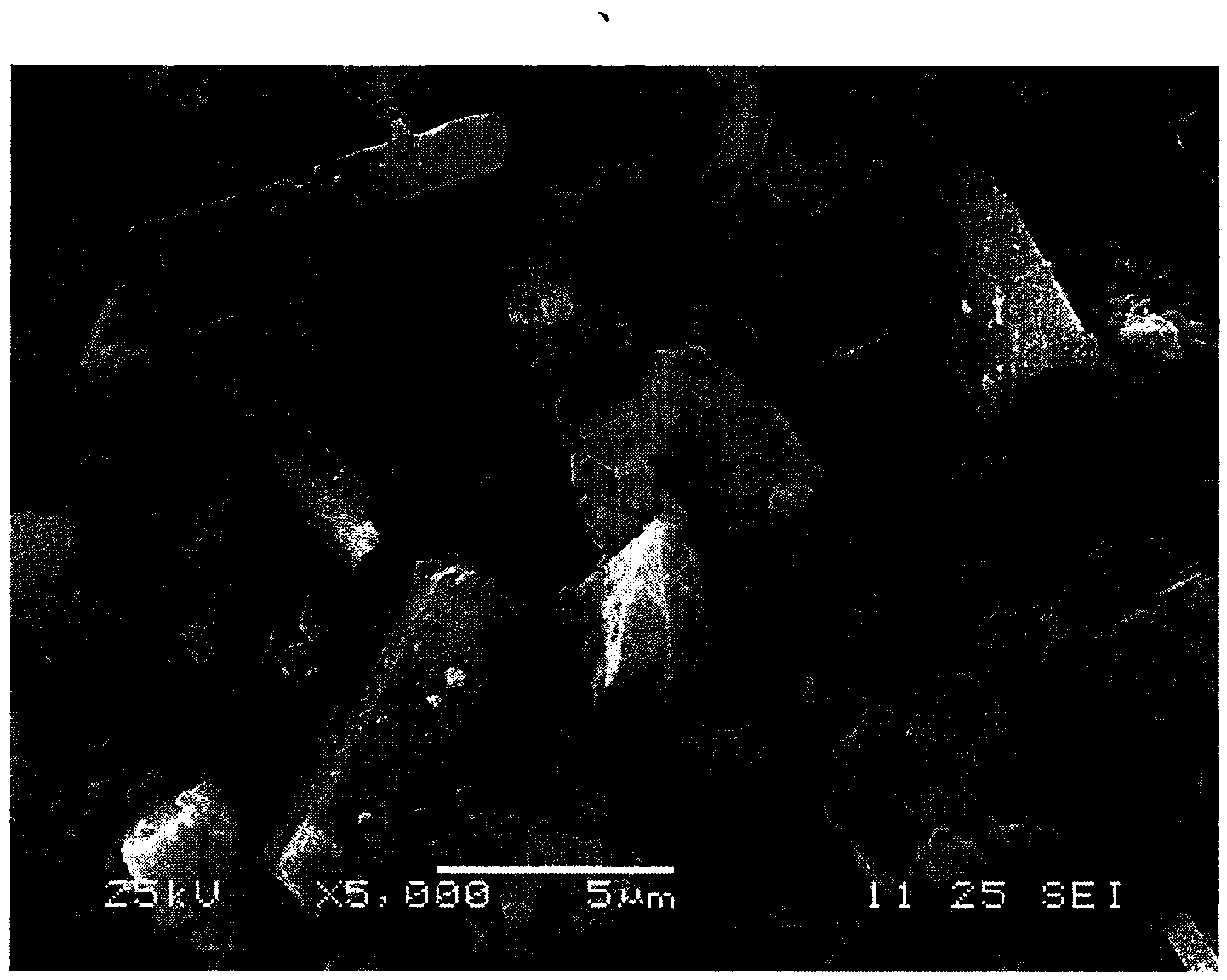

Gasoline engine exhaust valve seat and preparing method thereof

The invention provides a gasoline engine exhaust valve seat and a preparing method thereof and belongs to the technical field of powder metallurgy. The preparing method improves the high-temperature performance and the stability of the gasoline engine exhaust valve seat by adding alloy elements such as chromium, molybdenum and vanadium, the wearing resistance of the exhaust valve seat by adding WC and TiC which serve as the hard phase and the heat dissipation performance of the exhaust valve seat by adding Cu and comprises the steps of powder mixing, pressing, sintering and thermal treatment to prepare the gasoline engine exhaust valve. The preparing method of the gasoline engine exhaust valve seat is low in energy source consumption and cost; the gasoline engine exhaust valve seat is fine and uniform in microstructure and can be added with various high-melting-point alloy elements and hard phase granules conveniently to achieve excellent wearing-resistant, high-temperature and stability performance; besides, the preparation method of the gasoline engine exhaust valve seat is high in operating stability, strong in repeatability and capable of achieving continuous batch production of high-performance gasoline engine exhaust valve seats.

Owner:JIANGDU LEADER POWDER METALLURGY

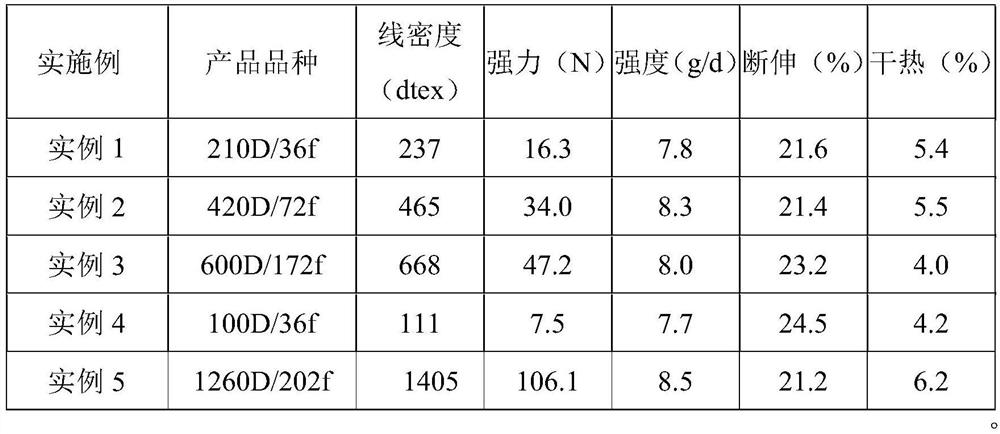

Preparation method of high-strength regenerated polyamide 66 fibers

PendingCN112899796AHigh strengthHigh filtration precisionSpinning solution de-aeratingNew-spun product collectionFiberPolymer science

The invention discloses a preparation method of high-strength regenerated polyamide 66 fibers. The method comprises the following steps of by taking polyamide 66 waste silk as a raw material, performing two-stage melting to obtain a polymer mixture; then performing filtering through a filter screen, extruding, cooling, curing and cutting to obtain regenerated polyamide 66 slices; sequentially performing drying, humidifying-tackifying, vibration screening and re-heating melting on the obtained slices to obtain a molten regenerated polyamide 66 polymer; and then performing mixing, filtering by a spinning assembly, spinning by a spinneret plate and cooling, oiling cooled tows, homogenizing tow oil films, performing drafting and setting, and finally performing winding and forming to obtain the high-strength regenerated polyamide 66 fibers. Through the improvement of multiple technical characteristics, the strength of the prepared regenerated polyamide 66 fibers reaches 7.5-9.5 g / d. According to the invention, the batch continuous production of the high-strength regenerated polyamide 66 fibers is realized, the batch performance of the fibers is uniform and stable, and the blank of a production technology of the high-strength regenerated polyamide 66 fibers in China is filled.

Owner:PINGDINGSHAN SHENMA TIRE CORD FABRIC DEV CO LTD

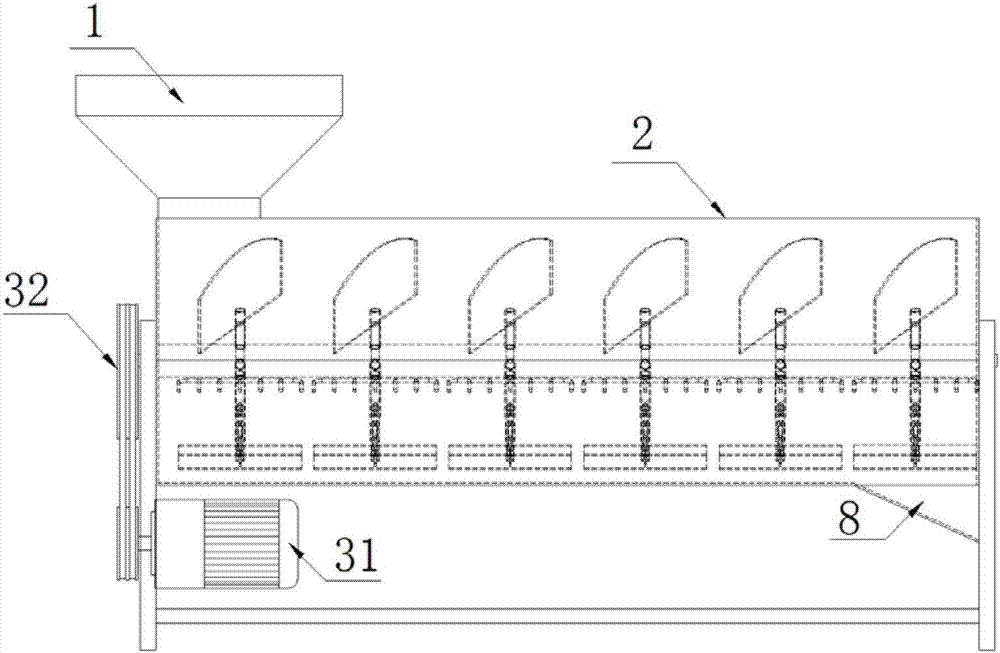

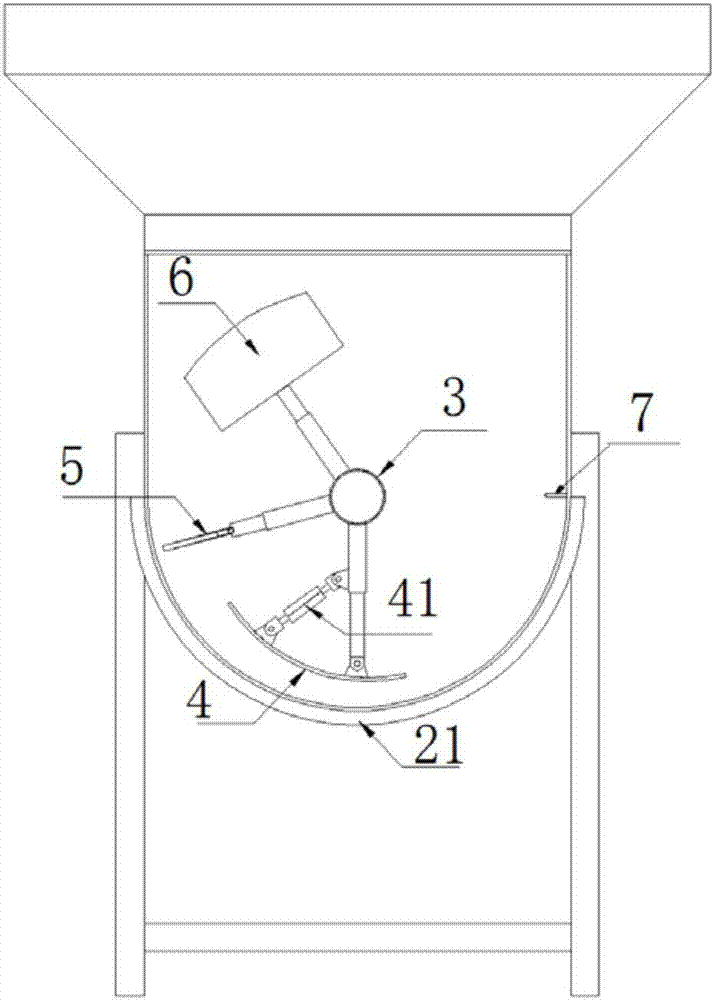

Berry tea frying machine

The invention relates to a berry tea frying machine. The berry tea frying machine comprises a feeding hopper, a pot, a heating element and a tea discharging port, wherein the feeding port is arranged above the head portion of the pot, the tea discharging port is formed under the tail portion of the pot, and the heating element is arranged at the bottom of the pot; the inside of the pot is provided with a spindle and a rubbing and scattering mechanism, and the scattering mechanism is composed of a rubbing plate, a scattering rod, a sweeping plate and stirring nails; the spindle is driven by a spindle driving motor and a belt mechanism, the rubbing plate, the scattering rod and the sweeping plate are sequentially arranged on the spindle, the stirring nails are vertically arranged onto the inner wall of the pot, the rubbing plate is in an arc shape, the scattering rod is provided with scattering nails, and the scattering nails and the stirring nails are arranged in a staggered mode. The invention also discloses a new production process. The new production process is composed of the steps of washing, airing, frying, pile fermentation, stirring, drying, flavoring and the like, obtains continuity and achieves mass continuous production, and due to the fact of being close to manual production processes, can obtain high-quality berry tea and high economic value after technical parameters are set.

Owner:佛山市高明区艾尚科技有限公司

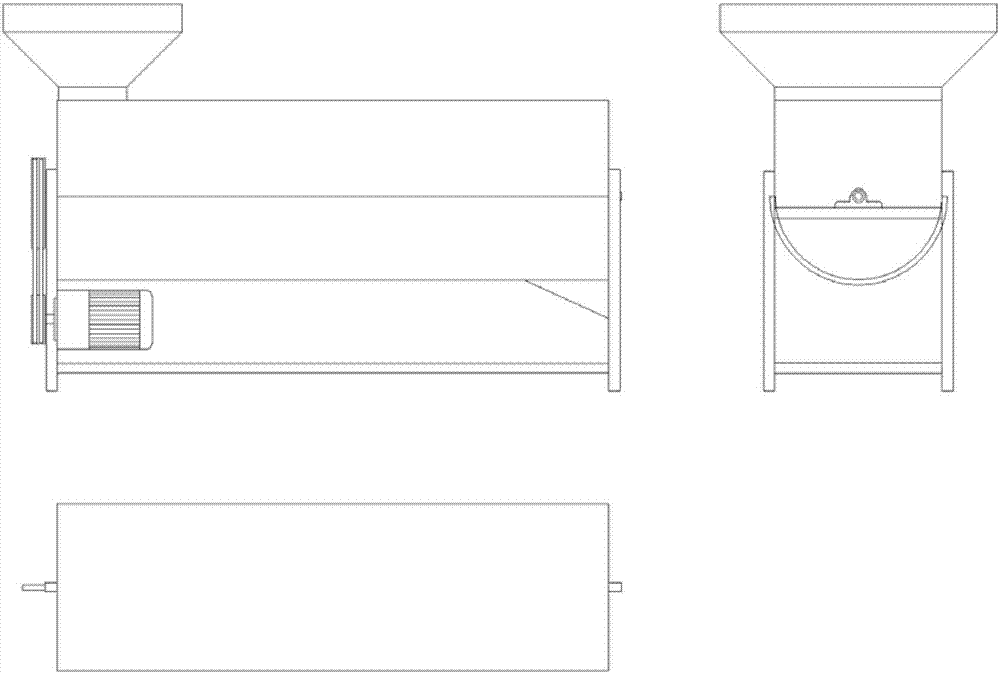

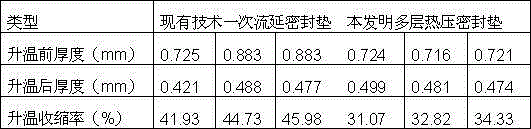

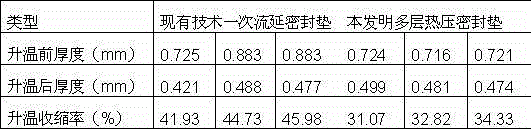

Method for preparing sealing pad of solid oxide fuel cell and waste material recovery process

ActiveCN102945974ARealize batch continuous productionHigh yieldFuel cell detailsPolyethylene terephthalate glycolWaste material

The invention provides a method for preparing a sealing pad of a solid oxide fuel cell and a recovery and utilization method of waste materials generated in the method. Powder of sealing materials are subjected to ball grinding and mixing after being matched with dispersing agents, bonding agents, plasticizing agents and solvents, casting and drying are carried out after the screen net filtering and the vacuum defoamation, blanks are cut according to the overall dimension requirement of the sealing pad, multiple layers are stacked and aligned, then, PET (polyethylene terephthalate) films and stainless steel plates are sequentially padded at two sides, the materials are filled into a plastic package bag for vacuum pumping and plastic package and are then placed on a hot pressing machine for hot pressing, and the materials are taken out to be cut into the sealing pad in specified sizes. Waste materials after cutting are collected, are subjected to ball grinding and mixing after being matched with the solvents and can be continuously used for preparing the sealing pad.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

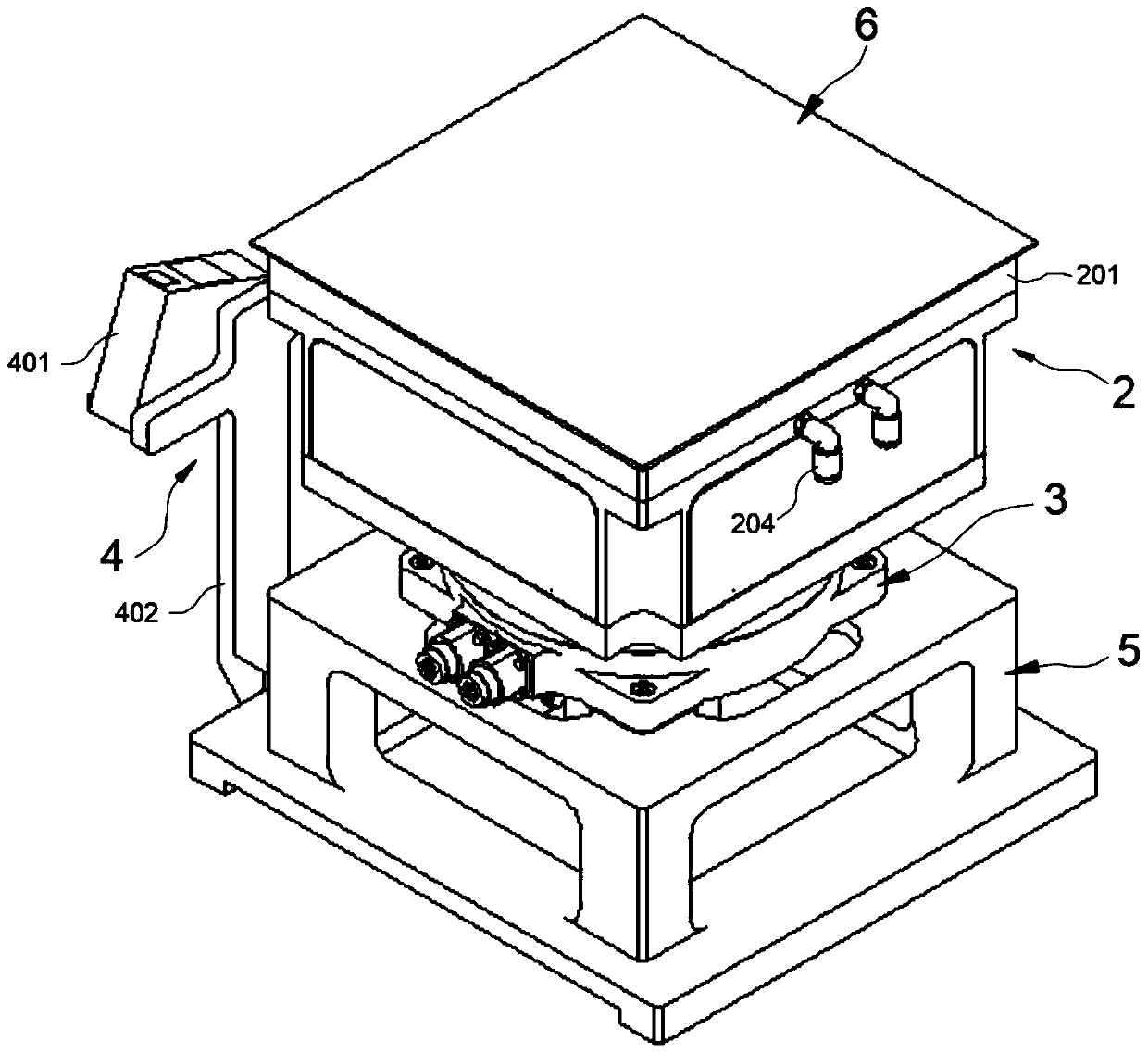

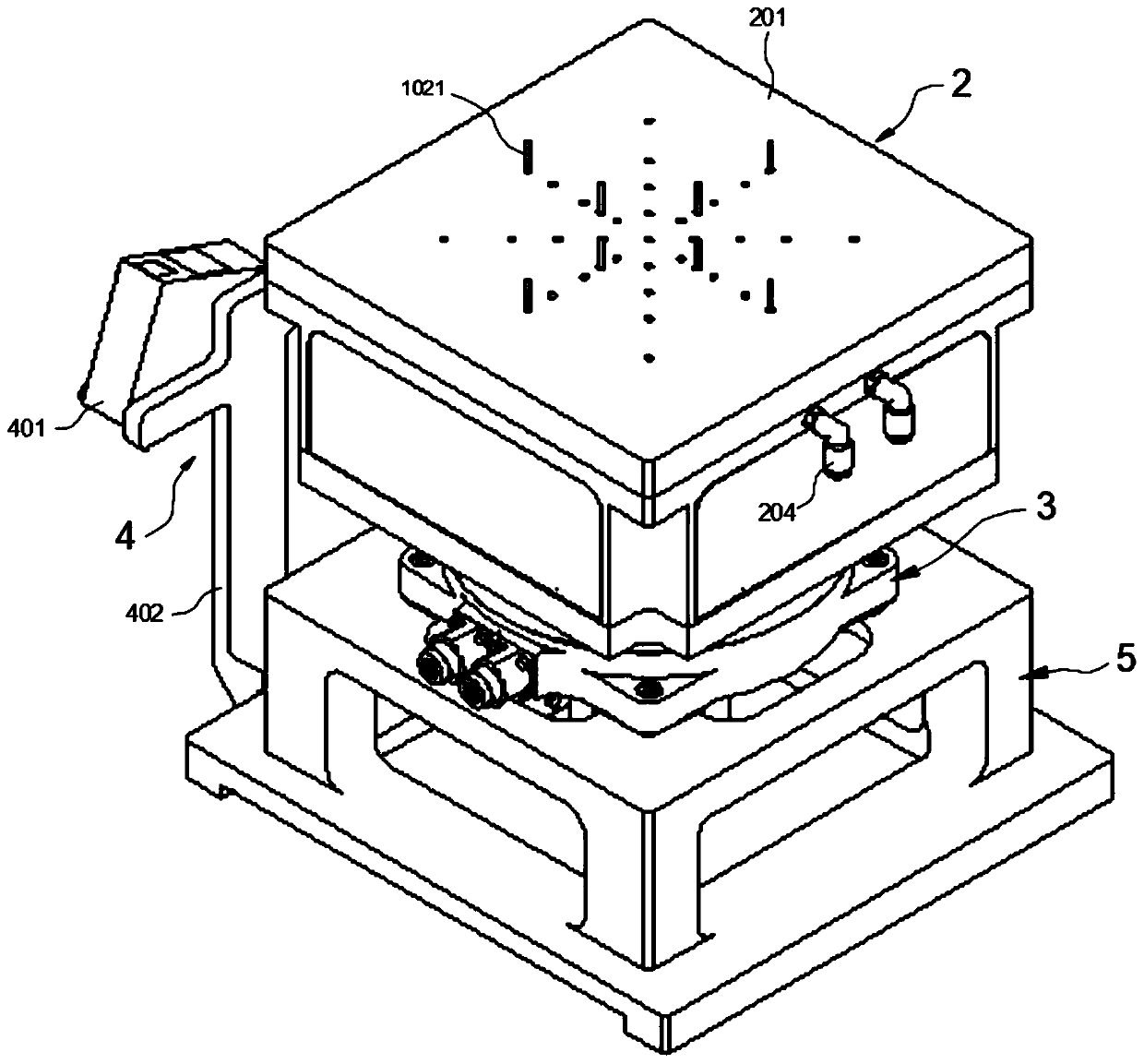

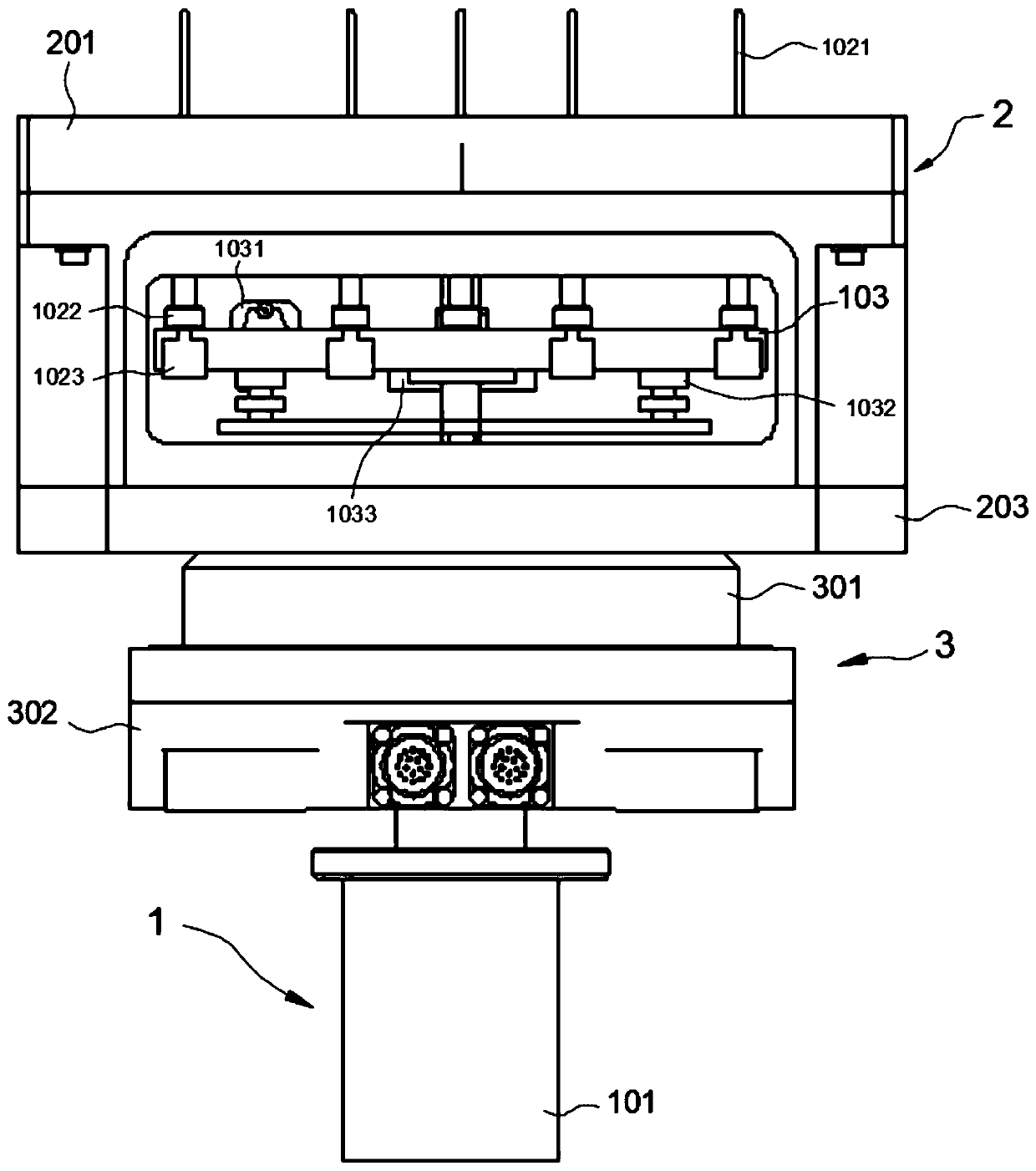

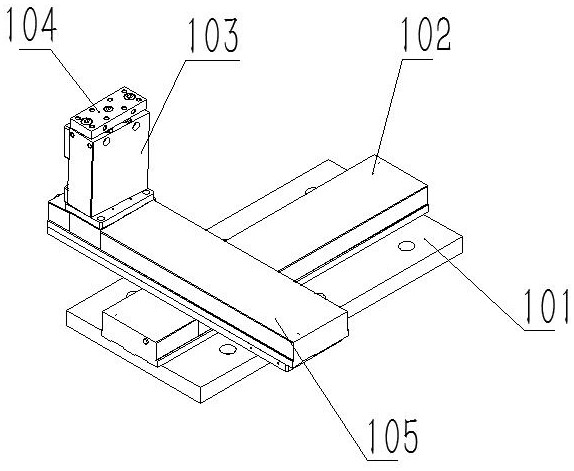

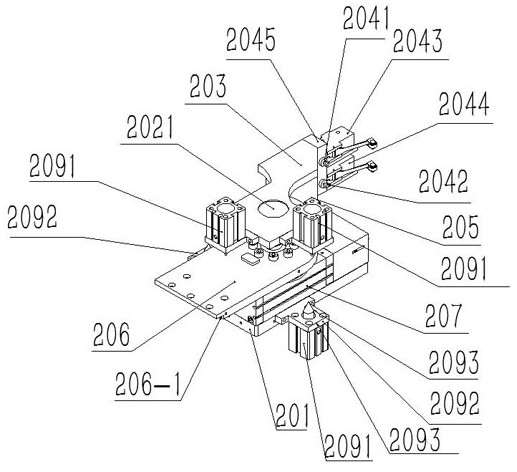

Transfer device for jet printing of film substrate, electronic printing system and electronic printing method

ActiveCN110572940AGuaranteed placement accuracyImprove finished product qualityConveyorsCircuit board tools positioningEnvironmental resistanceEngineering

The invention discloses a transfer device for jet printing of a film substrate, an electronic printing system and an electronic printing method, which belong to the technical field of printing. A lifting assembly, an adsorption assembly and a rotating assembly are correspondingly arranged on the base. The transfer device comprises a lifting motor, a support plate, a thimble mechanism, a rotating motor and the like, and by using mutual matching work of the components, stable feeding, adsorption and angle adjustment of the film substrate on the top surface of the adsorption plate can be accurately realized, and the placement accuracy of the film substrate in the electronic printing process is ensured. The transfer device for jet printing of the film substrate has the advantages that the structure is simple, the control is simple and convenient, the accuracy and the automatic degree are high, the positioning accuracy of the film substrate before printing can be greatly enhanced, the rejection rate in the preparation process of the printed circuit board is reduced, the cost is saved and the device is economical and environment-friendly. Besides, according to the electronic printing system arranged based on the transfer device, the printing method has simple steps, the control is simple and convenient, the substrate electronic printing efficiency can be further enhanced, and the substrate preparation cost is reduced.

Owner:武汉国创科光电装备有限公司

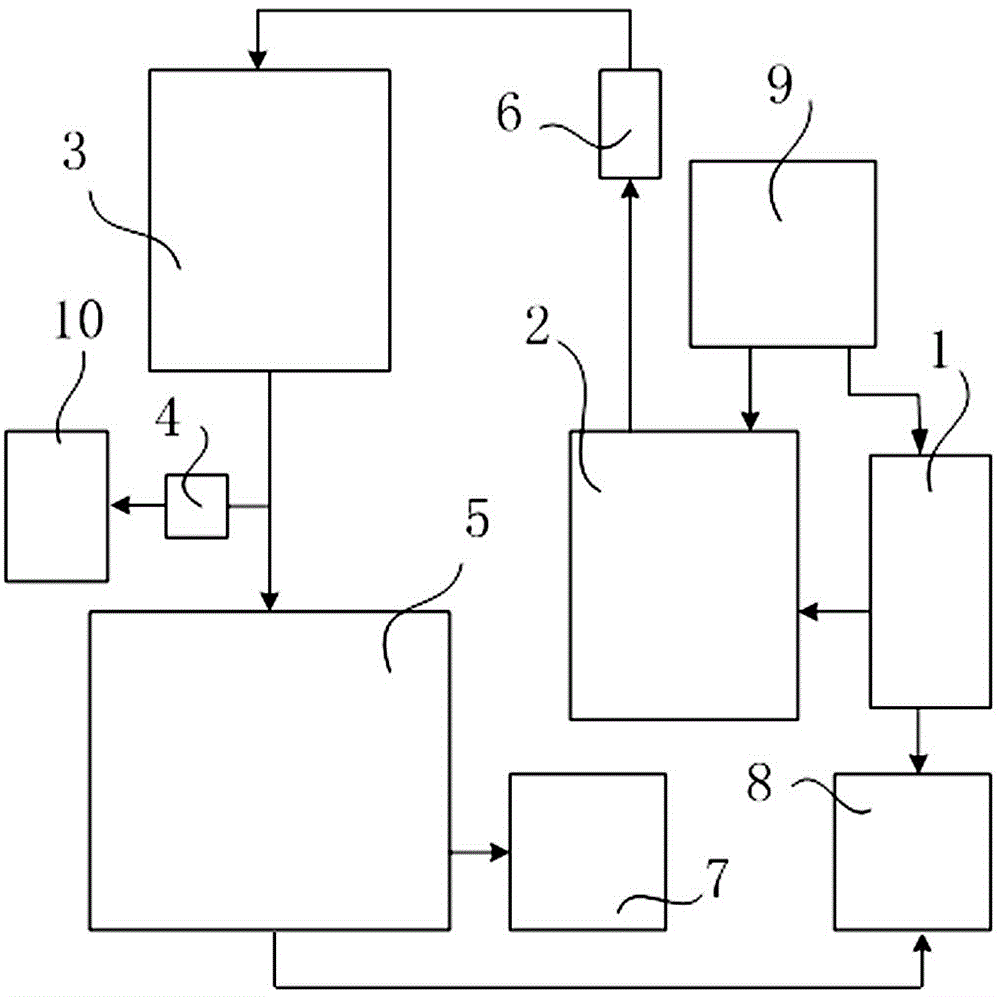

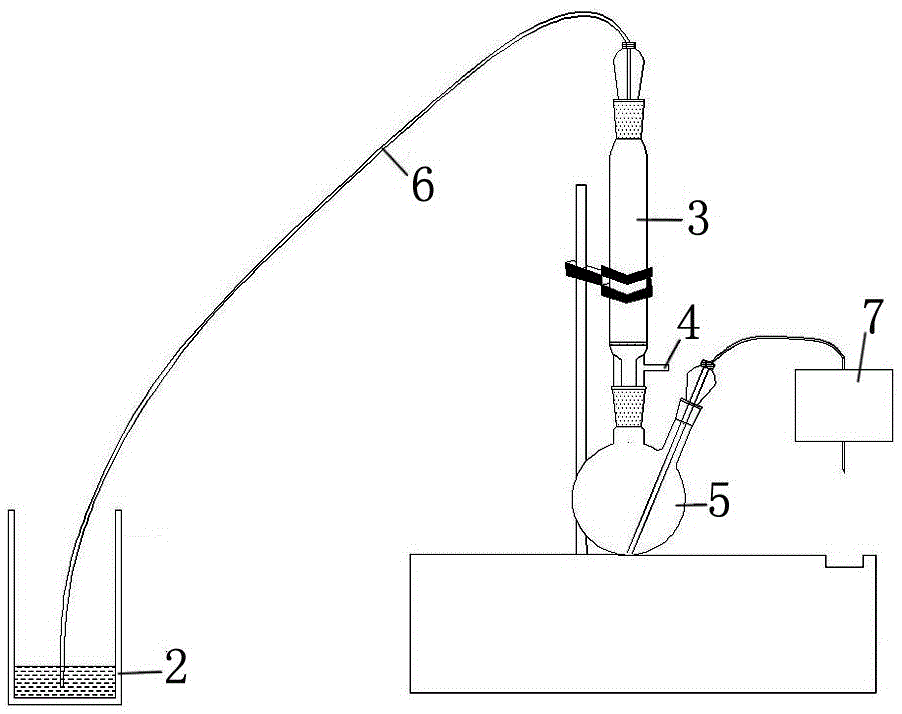

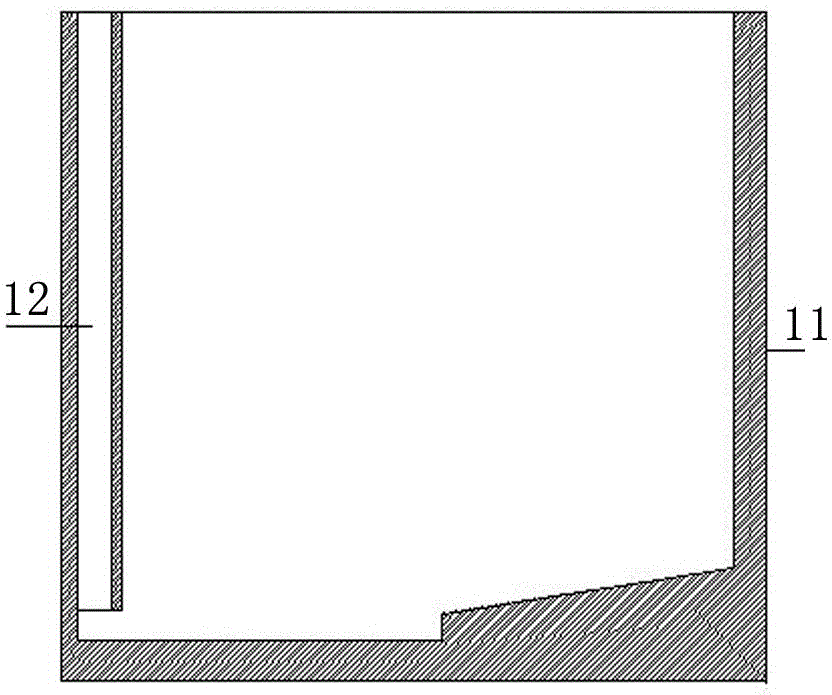

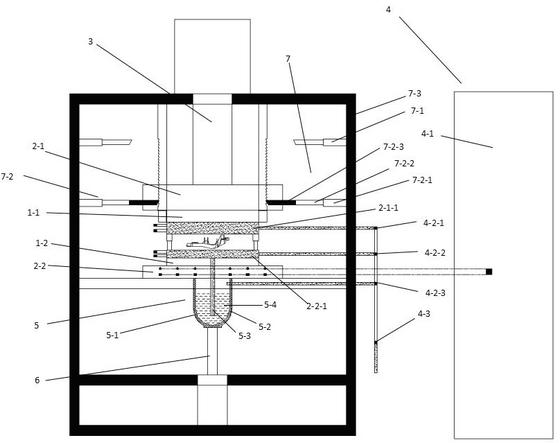

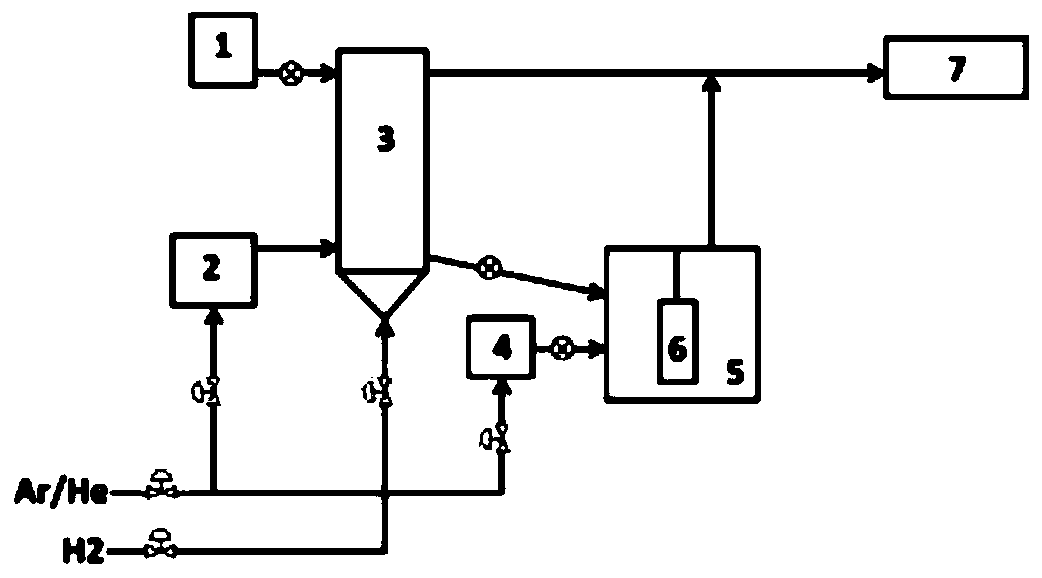

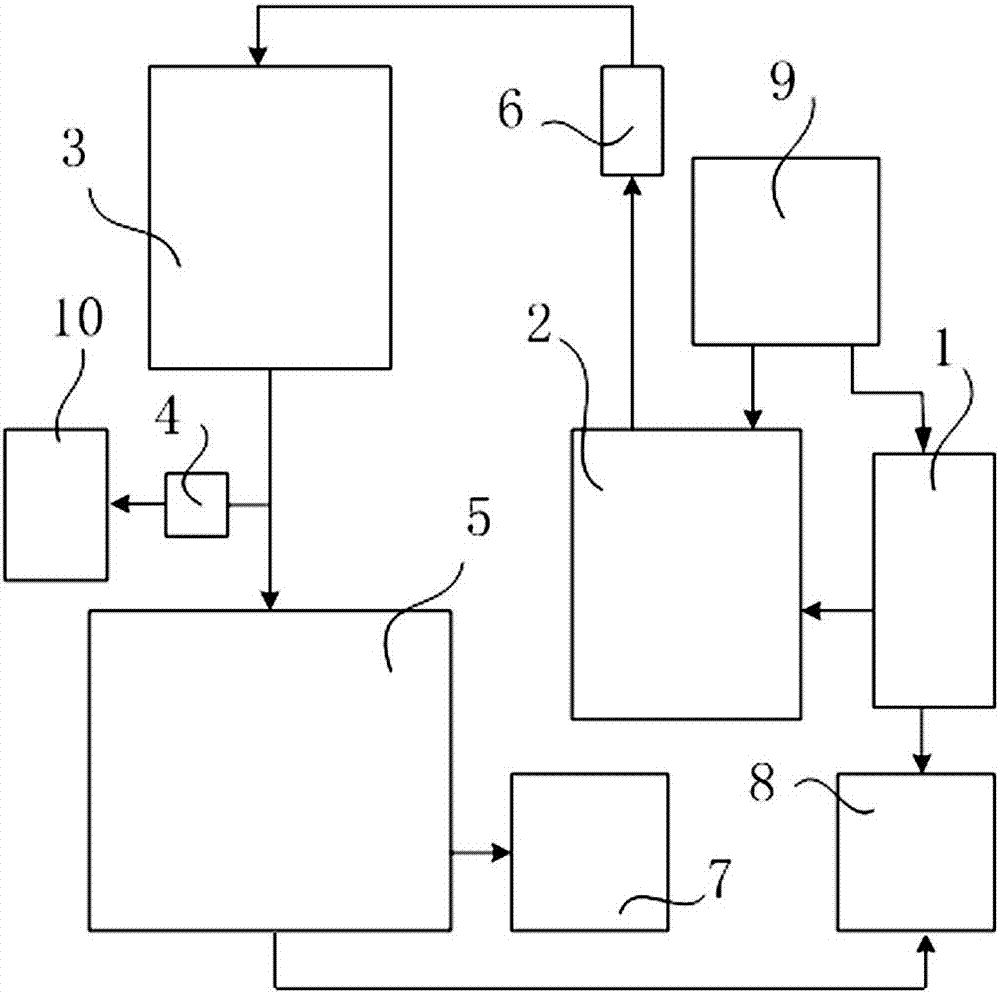

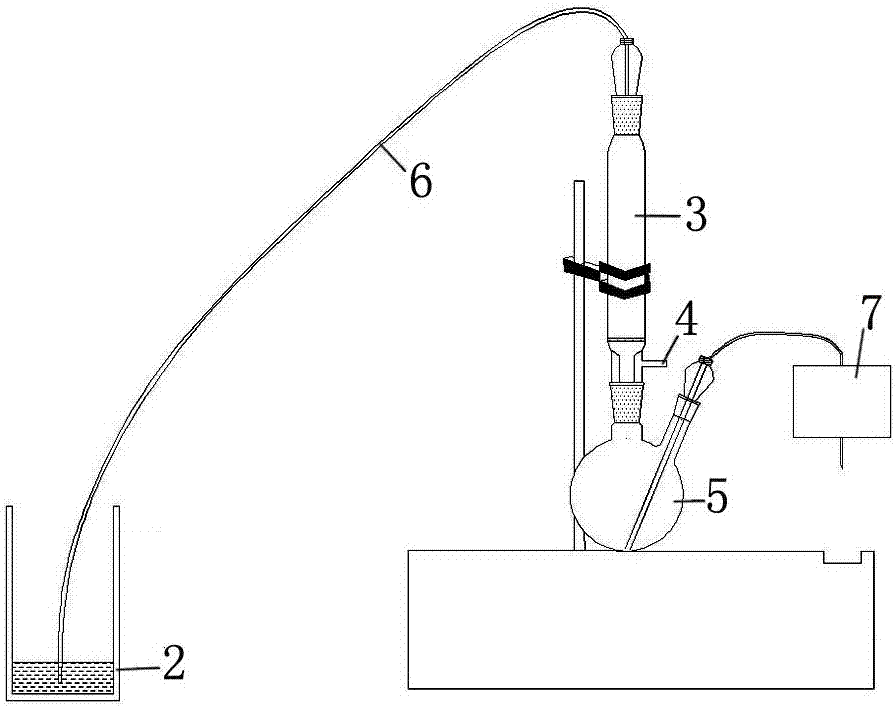

<89>SrCl2 solution production device

ActiveCN106409373ATo achieveEffective inhalationConversion in nuclear reactorLiquid wasteStrontium carbonate

The invention provides a <89>SrCl2 solution production device, and solves the problem that strontium carbonate powders obtained after irradiation are obtained, dissolved, filtered and separated in a target tube, and thus the specific process of the obtained strontium chloride solution cannot realize efficient and simple batch production. The production device comprises a target tube breaking and dissolving device (2) for target breaking and in-target powder dissolving, a filter device (3) for filtering dissolved liquid, a separation bottle (5) connected with the filter device (3), an air extraction connector (4) connected with the filter device (3) and the separation bottle (5), and a water pump (10) communicated with the air extraction connector (4). A liquid inlet of the filter device (3) is communicated to the bottom end of the target tube breaking and dissolving device (2) through a transmission pipeline (6). The <89>SrCl2 solution production device has the advantages of being fast to operate, simple and efficient; the production device is convenient to clean after production; liquid waste can be discharged immediately, thereby reducing the risk of radiation pollution; and the device is compact in structure, is simple and efficient, and is suitable for continuous production.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for preparing porous material by use of eggshell and waste glass

The invention discloses a porous material with eggshell as a foaming agent and a preparation method of the porous material. The pretreated eggshell and waste glass are evenly mixed with an appropriate amount of additives in a certain ratio, and as the eggshell can be decomposed to release gas when heated, the porous material can be formed by virtue of sintering. The porous material produced by use of the method has the advantages of light weight, uniform pore diameter, high strength, good thermal insulation property, stable product quality, low cost and the like, and can be widely applied as a thermal insulation material for housing buildings. The porous material is prepared from easily available raw materials, the preparation process is simple and equipment operation is simple; the effective recovery and reutilization of the solid wastes are realized, the waste materials are changed into things of value, and therefore, remarkable economic and social benefits are produced.

Owner:DALIAN JIAOTONG UNIVERSITY

A method for preparing titanium-aluminum intermetallic compound with hydrogenated titanium-aluminum alloy powder in a short process

InactiveCN103639408BReduce processReduce production processDehydrogenationParticle-size distribution

The present invention is a method for preparing titanium-aluminum intermetallic compounds through a short flow process of hydrogenated titanium-aluminum alloy powder, using high-purity aluminum and sponge titanium as raw materials, and melting them into titanium-aluminum alloy castings in a vacuum auto-electrode arc solidification furnace or a vacuum induction furnace. Ingot, then coarsely crushed into powder, after hydrogenation treatment to obtain brittle hydrogenated alloy powder, and then use vortex jet mill to grind into fine titanium aluminum alloy powder; the hydrogenated alloy powder is made into a green body, and the green body is sintered during the heating process The dehydrogenation reaction occurs in the process, and the alloy powder after the dehydrogenation reaction has high surface activity, and is easy to sinter and compact. After sintering, a titanium-aluminum intermetallic compound product with high purity, low oxygen content, and high relative density is finally obtained. The method has short process flow, high operational stability and strong repeatability, and can realize large-scale continuous production; the prepared titanium-aluminum alloy powder has high purity, low oxygen content, fine particle size, narrow particle size distribution, and good uniformity And other advantages, suitable for compression molding, injection molding, gel injection molding.

Owner:UNIV OF SCI & TECH BEIJING

A lightweight castable

ActiveCN108249934BReduce replacementRealize continuous automatic productionPearliteFloating microspheres

The invention provides a light-weight casting material. The light-weight casting material is prepared by mixing raw materials including 10 to 50 percent of rod-shaped aggregate, 0 to 45 percent of light-weight aggregate, 4 to 10 percent of silicon ash with the granularity less than or equal to 0.2mu m, 17 to 30 percent of bauxite cement, 8 to 20 percent of floating microspheres, 5 to 10 percent ofclosed-pore pearlite, 0 to 10 percent of high alumina bauxite powder and a water reducing agent. According to the light-weight casting material provided by the invention, the small-size rod-shaped aggregate is uniformly dispersed so that the firing after-shrinkage of a product is reduced, the thermal shock resistance of the casting material is remarkably improved and the service life is greatly prolonged; different amounts of the light-weight aggregate which is continuously graded are added, so that the casting material has high strength and good flowability and casting materials with different thermal conductivity coefficients can be prepared, and furthermore, an application range of the casting material is expanded.

Owner:郑州市裕丰耐火材料有限公司

Gasoline engine exhaust valve seat and preparation method thereof

Owner:JIANGDU LEADER POWDER METALLURGY

Quick hook lifting device and method for tension spring

PendingCN114346132AGood molding effectRealize batch continuous productionWire springsEngineeringShackle

The invention belongs to the technical field of elastic element manufacturing, and relates to a quick tension spring hooking device and method. The device comprises a base table board and a rotating body, a through groove matched with the rotating body is formed in the table top of the base body. The upper end face of the rotating body is flush with the table face of the base body. An extrusion block with a semicircular groove is arranged on the upper end surface of the rotating body; a first boss and a second boss are arranged along the tangent positions, perpendicular to each other, of the upper end face of the rotating body, the first boss serves as a placing table top of a spring to be machined, and the second boss serves as a limiting structure of the spring to be machined. By means of the device, quick hooking of the tension spring is achieved, the problems of low spring shackle production efficiency and unstable quality caused by an original shackle hooking mode are solved, secondary rework is avoided, and the forming quality stability of the shackle and the production efficiency of parts are improved.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

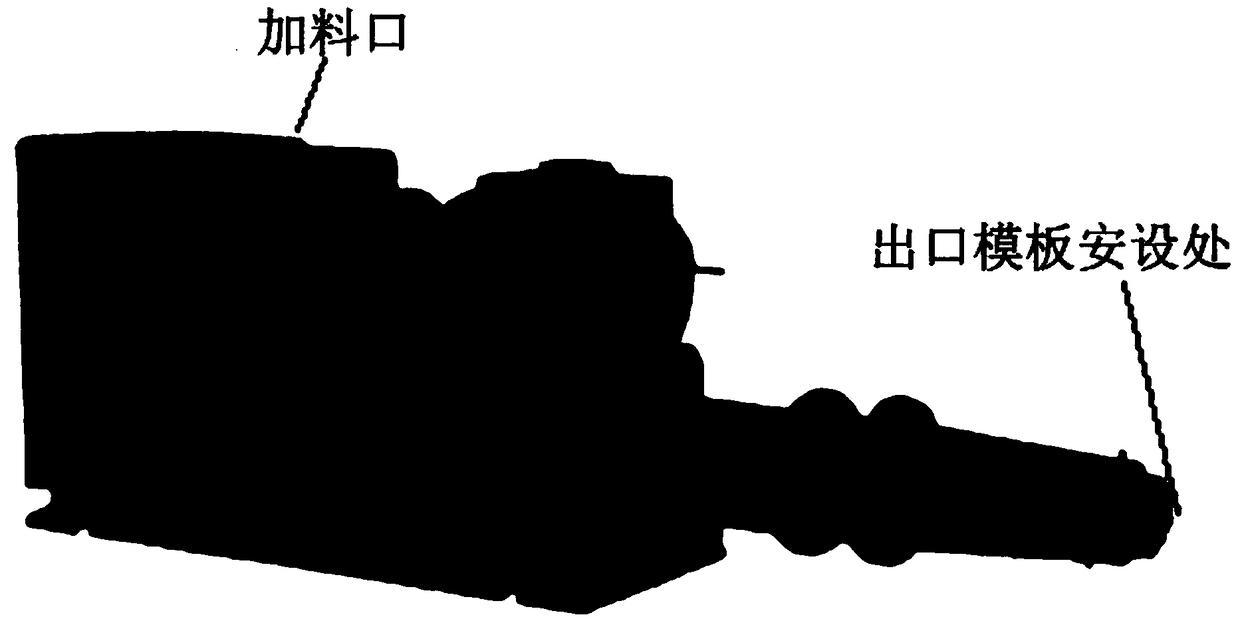

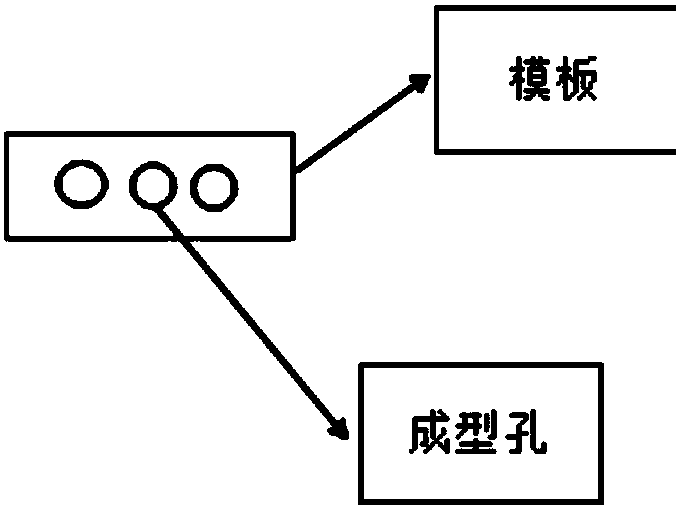

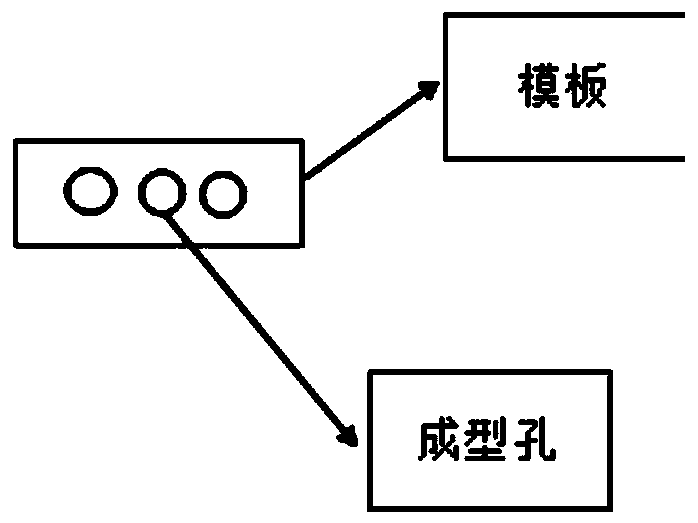

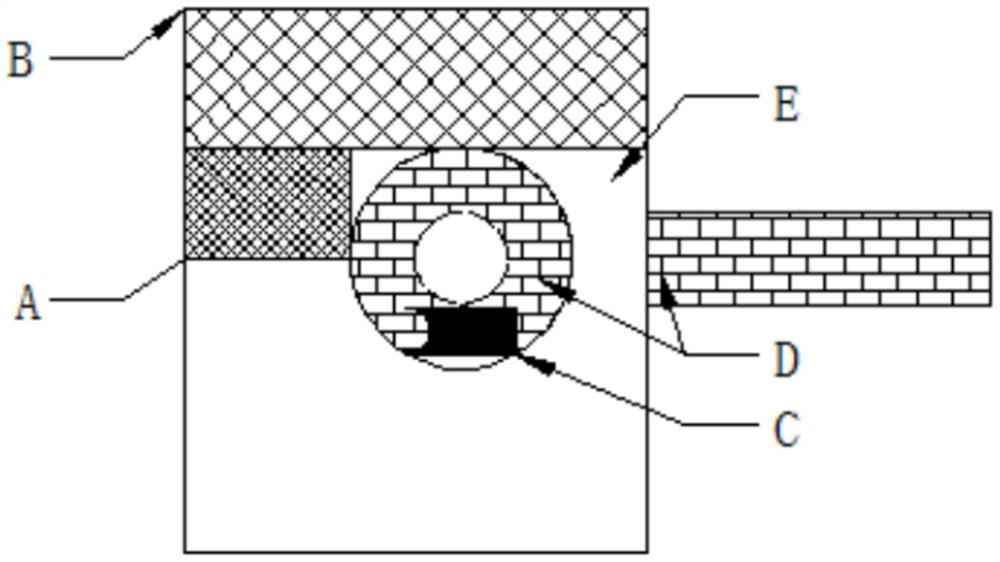

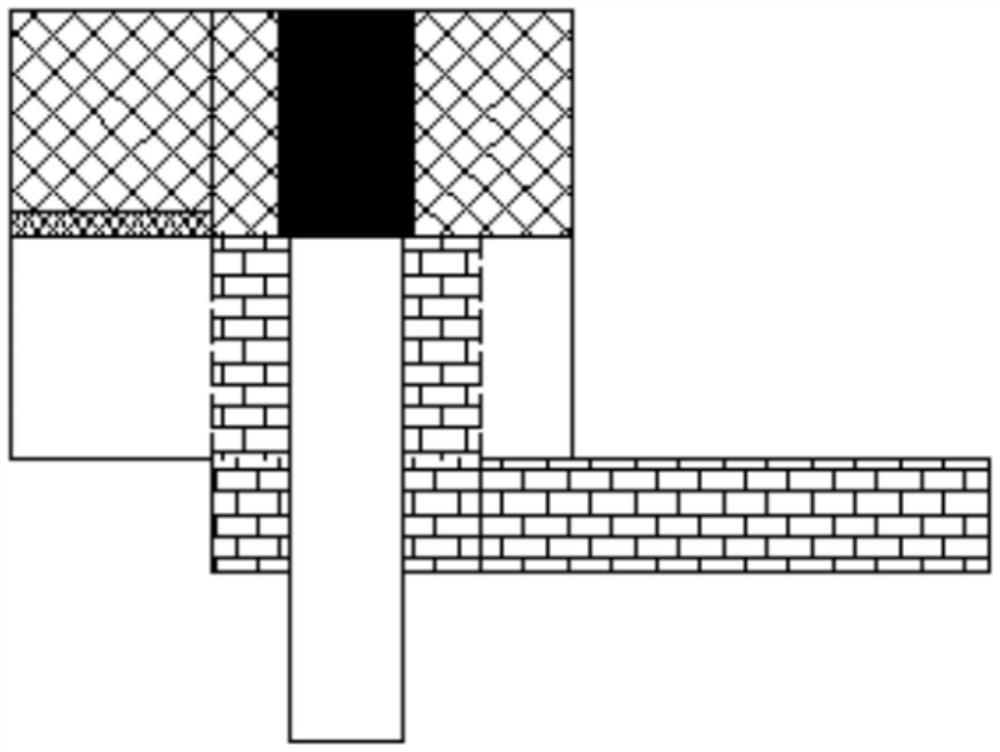

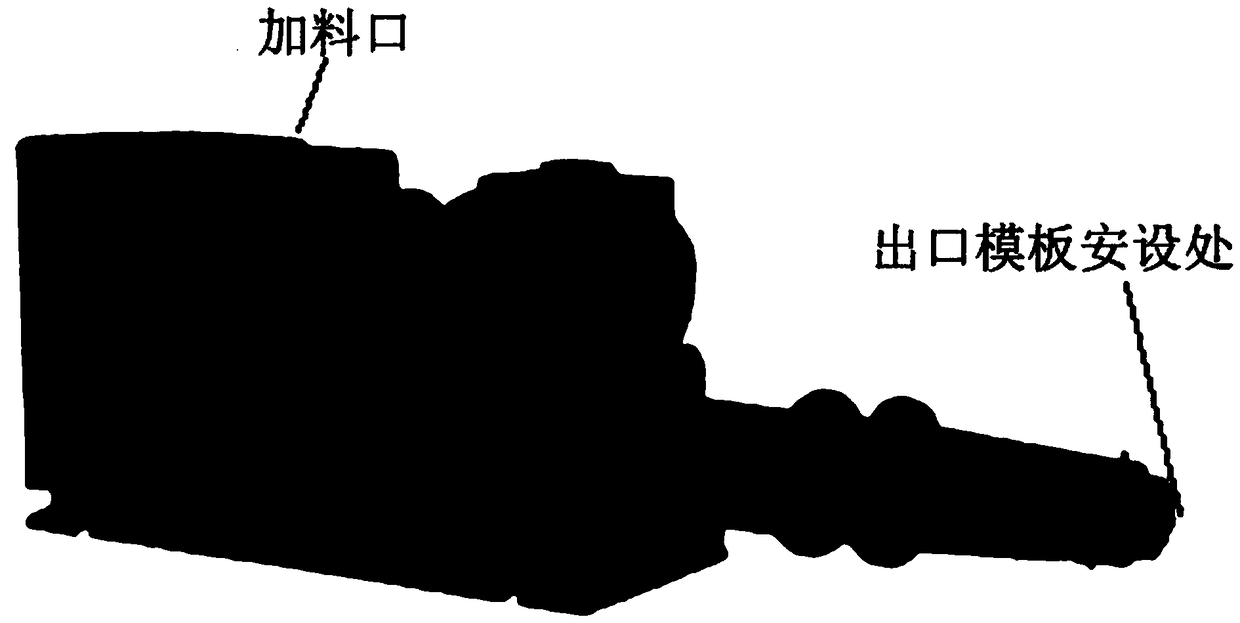

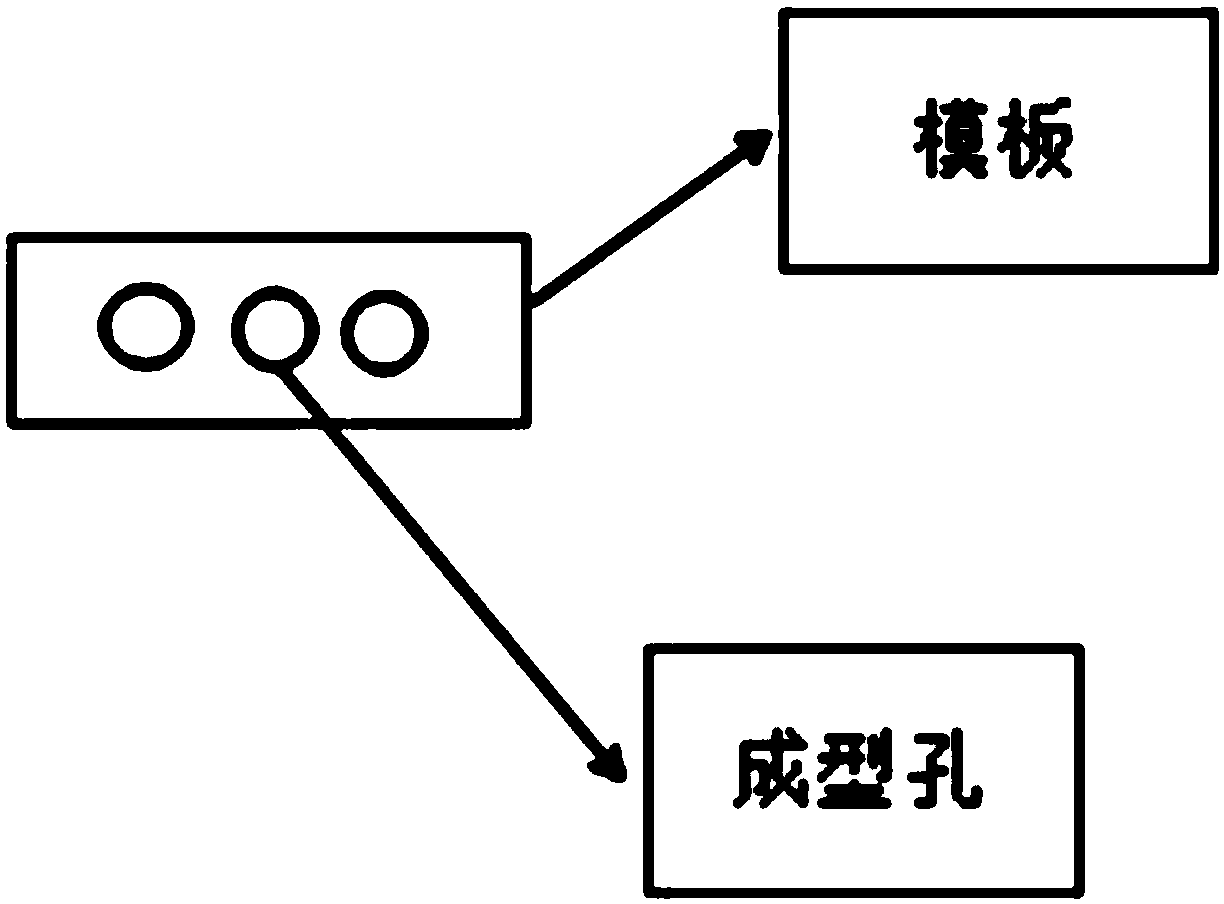

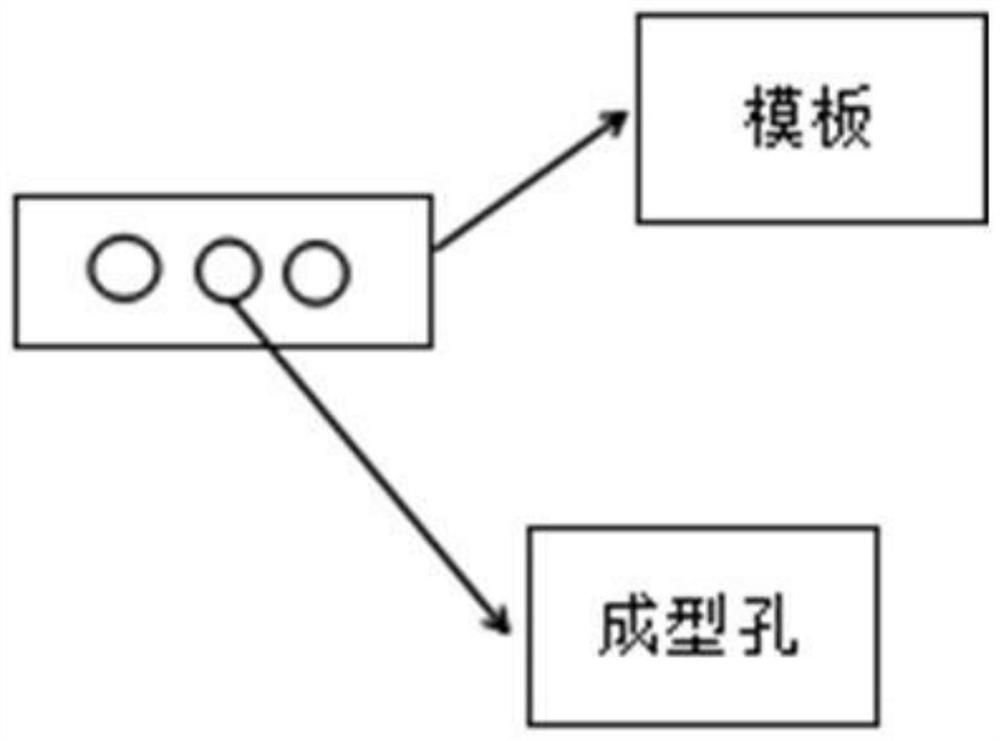

Rodlike aggregate for lightweight castable and preparation method of rodlike aggregate for lightweight castable

ActiveCN108373278AReduce manufacturing costIncrease productivityBuilding reinforcementsBatch productionWater reducer

The invention discloses rodlike aggregate for lightweight castable and a preparation method of the rodlike aggregate for lightweight castable. The preparation method includes: subjecting Guangxi whiteclay, a binding agent and a water reducing agent to dry mixing, then adding water, and mixing to obtain mixed paste; using a vacuum extruder to extrude the obtained mixed paste under conditions thatthe pressure is 1-2MPa, the vacuum degree ranges from -0.085MPa to -0.095MPa, and the temperature during extrusion is 15-25 DEG C so as to obtain a rodlike aggregate blank with the basic diameter being 0.6-3mm; drying and baking to obtain the rodlike aggregate for lightweight castable. By the preparation method, early-stage large-quantity mould preparation and continuous mould replacement processes are avoided, production cost is greatly reduced, production efficiency is increased by 3-5 times as compared with previous production efficiency, continuous automatic production is realized, low cost, low energy consumption and high efficiency are realized, and continuous batch production and high social and economic benefits are realized.

Owner:郑州市裕丰耐火材料有限公司

Method for preparing sealing pad of solid oxide fuel cell and waste material recovery process

ActiveCN102945974BRealize batch continuous productionHigh yieldFuel cell detailsPolyethylene terephthalate glycolWaste material

The invention provides a method for preparing a sealing pad of a solid oxide fuel cell and a recovery and utilization method of waste materials generated in the method. Powder of sealing materials are subjected to ball grinding and mixing after being matched with dispersing agents, bonding agents, plasticizing agents and solvents, casting and drying are carried out after the screen net filtering and the vacuum defoamation, blanks are cut according to the overall dimension requirement of the sealing pad, multiple layers are stacked and aligned, then, PET (polyethylene terephthalate) films and stainless steel plates are sequentially padded at two sides, the materials are filled into a plastic package bag for vacuum pumping and plastic package and are then placed on a hot pressing machine for hot pressing, and the materials are taken out to be cut into the sealing pad in specified sizes. Waste materials after cutting are collected, are subjected to ball grinding and mixing after being matched with the solvents and can be continuously used for preparing the sealing pad.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A method for the homogeneous preparation of covalent organic framework materials using high pressure

ActiveCN113024828BShort reaction timeEasy to operateOther chemical processesPtru catalystEthylic acid

A method for homogeneously preparing covalent organic framework materials under high pressure. The synthesis method is at normal temperature and pressure, using common organic ligands as raw materials, water or organic reagents as solvents and templates, and organic acids and inorganic acids as catalysts. , the method of obtaining the corresponding COFs by homogenizing with a high-pressure homogenizer for a certain period of time. Add 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde and p-phenylenediamine in a beaker, add appropriate amount of water and acetic acid, mix well and add to a high-pressure homogenizer to homogenize for a certain period of time; After the qualitative reaction, the product powder was suction-filtered, and the filtrate was recycled for reuse. The product powder was washed and vacuum-dried to obtain the covalent organic framework material HPH-Tp-Pa-1. Compared with other COFs preparation methods, the present invention has the advantages of continuous reaction, simple operation, low cost, high yield, environmental protection and energy saving, short reaction time, etc., has the potential for large-scale production, and will greatly promote the industrial production process of COFs materials.

Owner:NANKAI UNIV

A method for extracting pure calcium fluoride from calcium fluoride sludge

ActiveCN109775743BHigh puritySimple processSludge treatmentCalcium/strontium/barium fluoridesSludgeSilicon

The invention discloses a method for extracting pure calcium fluoride from calcium fluoride sludge. The method comprises the following steps: 1) beating and dissolving; 2) removing silicon with caustic soda to obtain filter cake A and solution A; 3) calcium fluoride Salt conversion; 4) Acidification with hydrochloric acid to obtain calcium fluoride and solution C; 5) Drying and crushing: put the acidified calcium fluoride in an oven at 105°C for drying, and pulverize with a pulverizer to obtain a powder Pure Calcium Fluoride. The invention can effectively treat the calcium fluoride sludge, avoid causing secondary pollution, and can recycle the calcium fluoride in the sludge to solve the problem of shortage of fluorine resources.

Owner:盛隆资源再生(无锡)有限公司

Gasoline engine piston expansion ring and preparation method thereof

The invention provides a gasoline engine piston expansion ring and a preparation method thereof. In order to keep the expansion ring elastic at high temperature, use iron powder, graphite, ferrosilicon powder, ferromanganese powder, etc. to prepare matrix components, add graphite, MoS2, CaF2 as lubricant, and add WC, TiC, VC, Cr3C2 as hard phase Improve the wear resistance, add V and Mo as alloy elements to improve the high temperature performance of the expansion ring, add Cu powder to improve the heat dissipation performance of the expansion ring, and prepare the expansion ring through powder mixing, pressing, sintering, grinding, and opening. This method can produce expanded rings in near-net shape, and only needs simple grinding and opening treatment after sintering. The process is short and the cost is low; there are no casting defects such as porosity, shrinkage cavity, composition segregation, and coarse lamellar structure. Uniform and fine microstructure, easy to add alloy elements, lubricating components, hard phase particles, excellent performance; in addition, the process has high stability and repeatability, and can realize batch continuous production.

Owner:JIANGDU LEADER POWDER METALLURGY

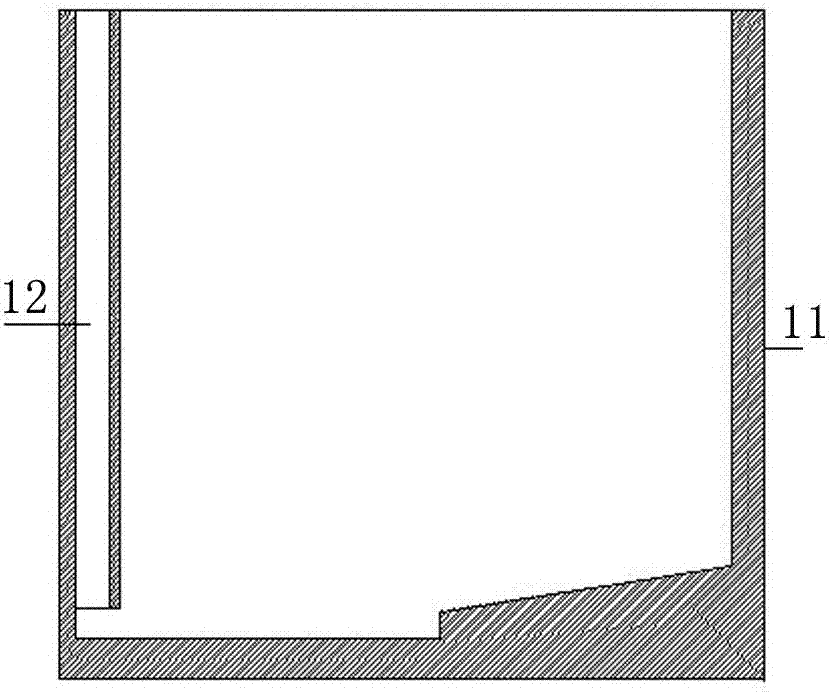

A hollow frame design and differential pressure casting method

The invention discloses a hollow vehicle frame design and differential pressure casting method. The hollow vehicle frame design and differential pressure casting method comprises the following steps that 1, a hollow structure with the wall thickness being 4 mm and meeting 1.5 times of safety of CAE is designed; 2, an aluminum alloy is subjected to dual-phase treatment; 3, a sand core is casted ina sand core mold, then the casted sand core is put into a negative pressure differential pressure casting mold, metamorphic aluminum alloy liquid is molded through a negative pressure differential pressure casting process, the sand core is removed after molding, and a semi-finished product of a hollow vehicle frame is obtained; 4, the semi-finished product is subjected to T6 stage temperature rising heat treatment; and 5, machining is conducted through a large four-axis machining center. According to the hollow frame design and differential pressure casting method, the prepared product is small in weight, high in safety, excellent in tensile strength, yield intensity and extended performance and wide in application range, and batch continuous production can be realized.

Owner:GUANGDONG HONGTAI TECH HLDG

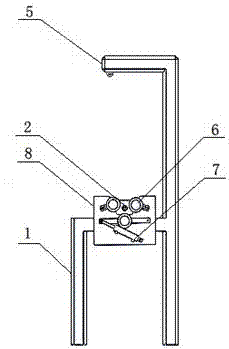

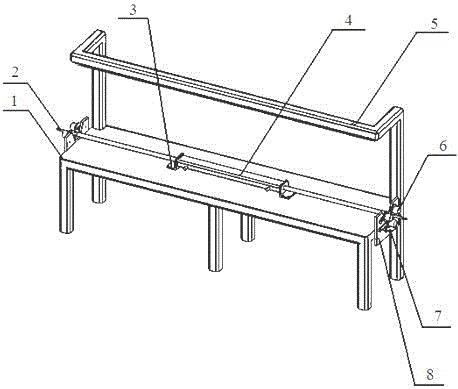

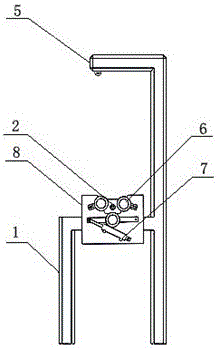

Large-wire-diameter magnetic ring wire hooking device

ActiveCN103903853AHigh strengthReduce replacement frequencyCoils manufactureHookingInverted triangle

The invention discloses a large-wire-diameter magnetic ring wire hooking device. The device comprises a supporting frame (1), a stroke cylinder (4), a cylinder flange (3), wire hooks (2), V-shaped wire hooking baffles (8), fixed cylinders (7) and friction wheels (6), wherein the stroke cylinder is fixed to the middle of the supporting frame through the cylinder flange, the wire hooks are detachably connected to the two ends of the stroke cylinder, the V-shaped wire hooking baffles are fixed to the two ends of the supporting frame respectively, the friction wheels are arrayed on the V-shaped wire hooking baffles in an inverted triangle mode, the fixed cylinders are installed on the V-shaped wire hooking baffles, the two friction wheels located above the V-shaped wire hooking baffles are fixedly connected with the V-shaped wire hooking baffles, and the friction wheels located below the V-shaped wire hooking baffles are connected with piston rods of the fixed cylinders. The large-wire-diameter magnetic ring wire hooking device has the advantages of being capable of being massively and continuously produced and being used for winding large-wire-diameter magnetic ring coils, and high in efficiency.

Owner:XUZHOU GLORIA TECH

A system and method for preparing a zirconium coating

ActiveCN110355360BLow cladding temperatureReduce manufacturing costTransportation and packagingMetal-working apparatusSocial benefitsFluidized bed

The invention discloses a system and method for preparing a zirconium coating. The initial zirconium source material is pretreated in a fluidized bed to obtain a precursor, and then the precursor is produced in a coating reactor to produce a zirconium coating. The preparation of the Zr cladding layer in the present invention has the following outstanding advantages: it can produce zirconium cladding coatings of various shapes and thicknesses in a low-cost, high-efficiency, and large-scale batch at a relatively low temperature, and the morphology, grain The particle size is controllable and has good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

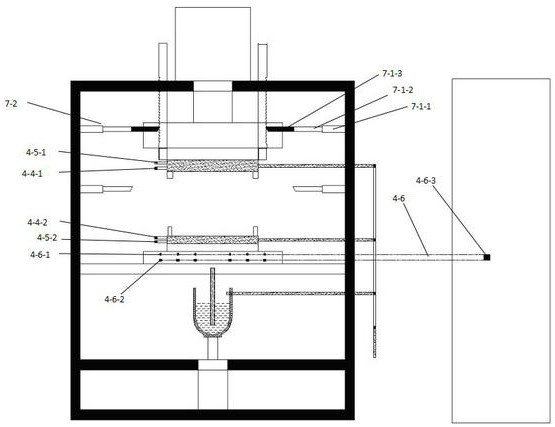

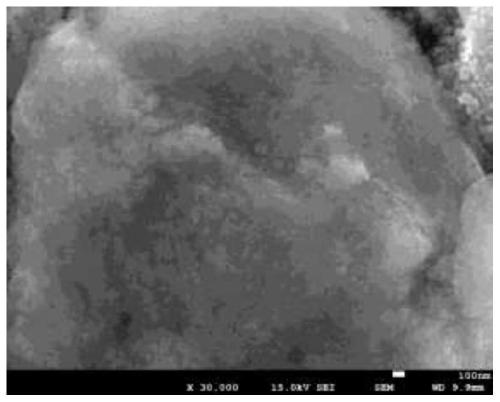

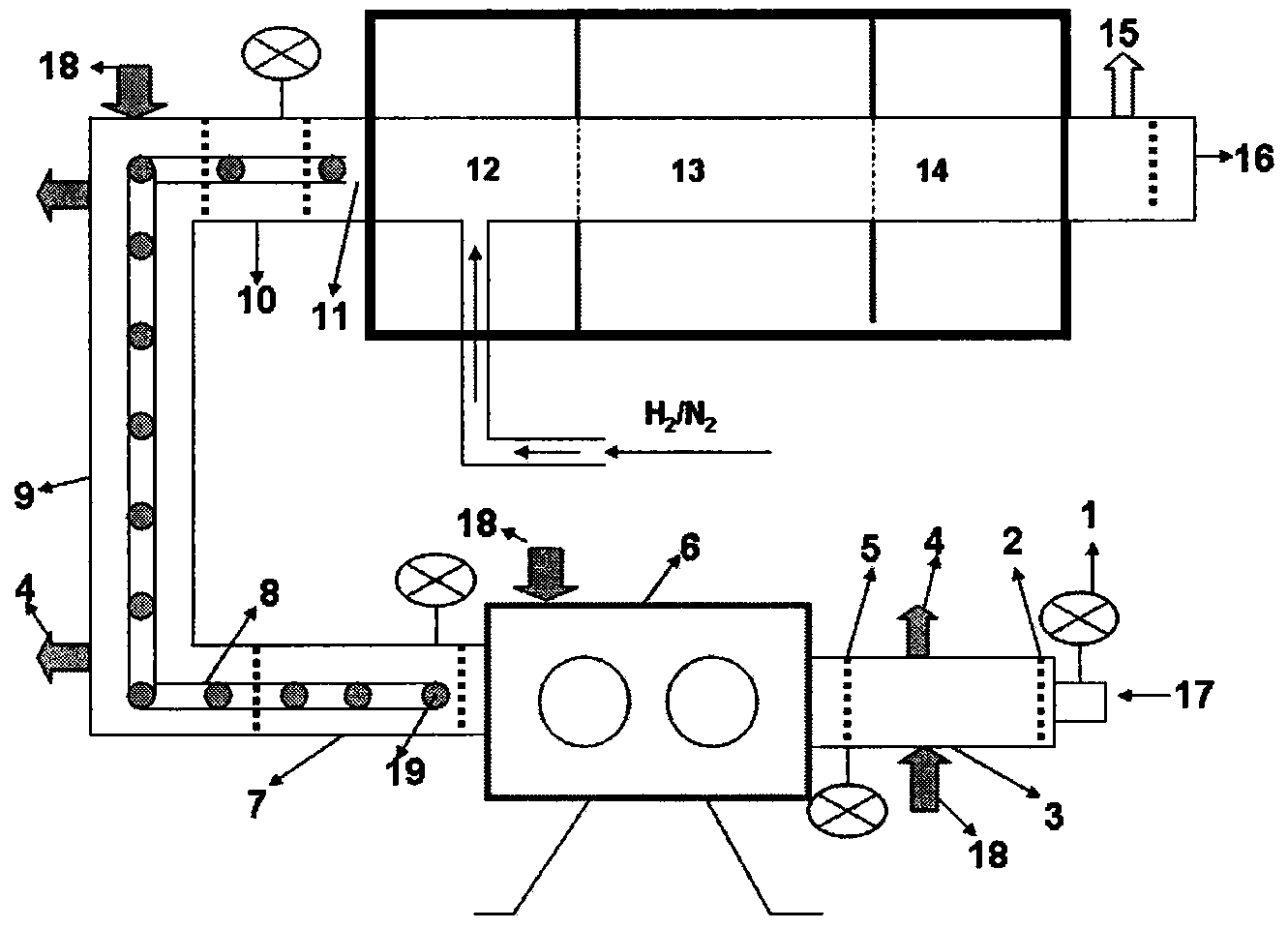

Preparation method for nitride fluorescent powder and equipment for same

InactiveCN103184049BGuaranteed not to be oxidizedGuaranteed oxidationChemical industryLuminescent compositionsTemperature controlHydrogen atmosphere

The invention discloses a method for preparing a nitride fluorescent powder by a high-temperature solid-phase method, and production equipment used for the method. The method comprises the following steps of: (1) detaching raw materials in an oxygen-free and water-free glove box, and mixing the raw materials in a mixing device arranged in the glove box; (2) transferring the mixed raw materials to a reduction furnace via a transition device under nitrogen protection, and solving the problems of other backflows and isolated heat transfer via a transition cabin; (3) calcining at a high temperature in a nitrogen / hydrogen atmosphere by adopting a subsection temperature control method in which three parts, a preheating area, a high-temperature area and a cooling area are formed; and (4) performing aftertreatment on the cooled sample in room-temperature air. By using the method and the equipment, the high-purity nitride fluorescent powder can be manufactured, and the central granularity of the fluorescent powder and the position of an emitting main peak can be controlled by adjusting the calcining temperature and the composition ratio of the raw materials respectively; and with the adoption of three-section calcining, preparation for the nitride fluorescent powder by the method can realize continuous production, thus greatly increasing production efficiency. The method is energy-saving, environment-friendly, and suitable for mass preparation for the nitride fluorescent powder.

Owner:湖南爱德光电新材料有限公司

A kind of 89srcl2 solution production device

ActiveCN106409373BRealize batch continuous productionEfficient batch productionConversion in nuclear reactorStrontium carbonateLiquid waste

The invention provides an 89SrCl2 solution production device, which solves the problem that the specific process of obtaining strontium carbonate powder obtained after irradiation from a target tube, dissolving, filtering and subpackaging to obtain a strontium chloride solution cannot achieve efficient and simple batch production . The target tube crushing and dissolving device (2) used for target crushing and powder dissolution in the target, the filter device (3) used for dissolving liquid filtration, the sub-packaging bottle (5) connected with the filter device (3), The suction joint (4) connected to the filter device (3) and the sub-bottling bottle (5), and the water pump (10) connected to the suction joint (4); the liquid inlet of the filter device (3) is delivered through The pipeline (6) is connected to the bottom end of the target tube crushing and dissolving device (2). The invention has the characteristics of fast operation, simplicity and high efficiency, convenient cleaning after the production is completed, waste liquid can be discharged immediately, and the risk of radioactive pollution is reduced. The invention also has the advantages of compact structure, simplicity and high efficiency, and is suitable for continuous production.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A thick-diameter magnetic ring hooking device

ActiveCN103903853BAvoid thread damageRealize batch continuous productionCoils manufactureEngineeringInverted triangle

The invention discloses a large-wire-diameter magnetic ring wire hooking device. The device comprises a supporting frame (1), a stroke cylinder (4), a cylinder flange (3), wire hooks (2), V-shaped wire hooking baffles (8), fixed cylinders (7) and friction wheels (6), wherein the stroke cylinder is fixed to the middle of the supporting frame through the cylinder flange, the wire hooks are detachably connected to the two ends of the stroke cylinder, the V-shaped wire hooking baffles are fixed to the two ends of the supporting frame respectively, the friction wheels are arrayed on the V-shaped wire hooking baffles in an inverted triangle mode, the fixed cylinders are installed on the V-shaped wire hooking baffles, the two friction wheels located above the V-shaped wire hooking baffles are fixedly connected with the V-shaped wire hooking baffles, and the friction wheels located below the V-shaped wire hooking baffles are connected with piston rods of the fixed cylinders. The large-wire-diameter magnetic ring wire hooking device has the advantages of being capable of being massively and continuously produced and being used for winding large-wire-diameter magnetic ring coils, and high in efficiency.

Owner:XUZHOU GLORIA TECH

Rod-shaped aggregate for lightweight castable and preparation method thereof

ActiveCN108373278BReduce replacementRealize continuous automatic productionBuilding reinforcementsDry mixingEconomic benefits

The invention discloses rodlike aggregate for lightweight castable and a preparation method of the rodlike aggregate for lightweight castable. The preparation method includes: subjecting Guangxi whiteclay, a binding agent and a water reducing agent to dry mixing, then adding water, and mixing to obtain mixed paste; using a vacuum extruder to extrude the obtained mixed paste under conditions thatthe pressure is 1-2MPa, the vacuum degree ranges from -0.085MPa to -0.095MPa, and the temperature during extrusion is 15-25 DEG C so as to obtain a rodlike aggregate blank with the basic diameter being 0.6-3mm; drying and baking to obtain the rodlike aggregate for lightweight castable. By the preparation method, early-stage large-quantity mould preparation and continuous mould replacement processes are avoided, production cost is greatly reduced, production efficiency is increased by 3-5 times as compared with previous production efficiency, continuous automatic production is realized, low cost, low energy consumption and high efficiency are realized, and continuous batch production and high social and economic benefits are realized.

Owner:郑州市裕丰耐火材料有限公司

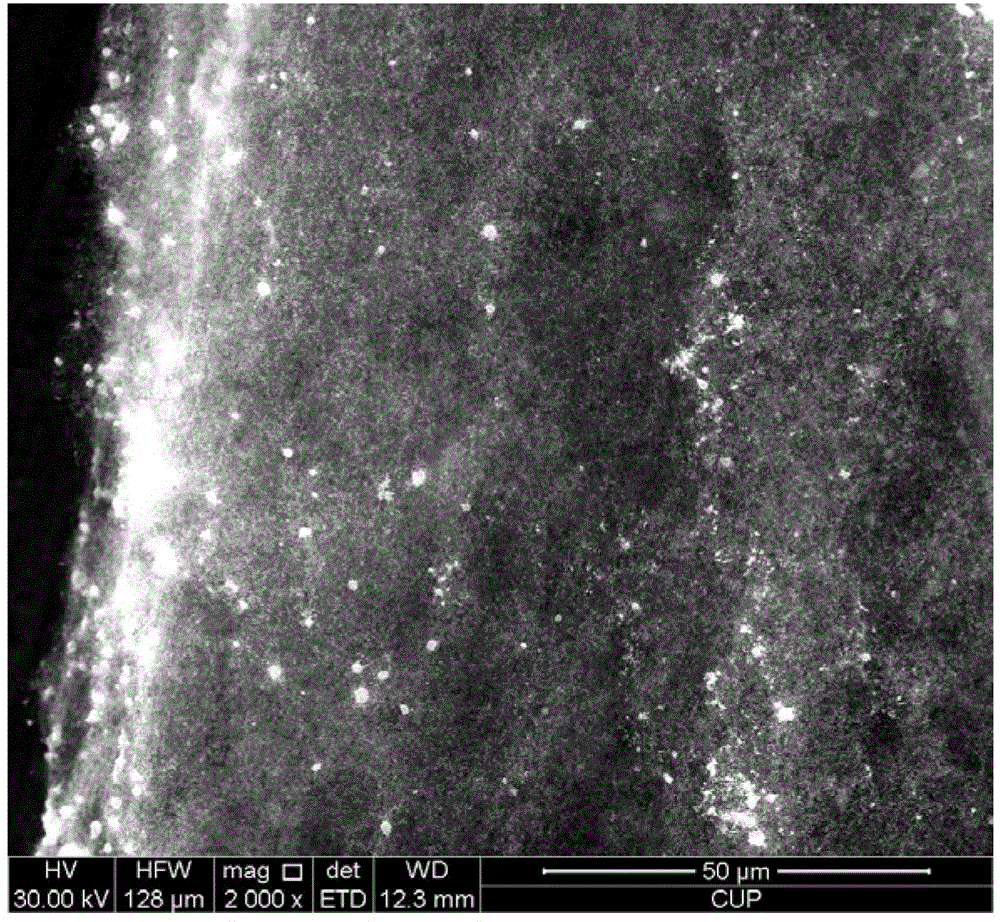

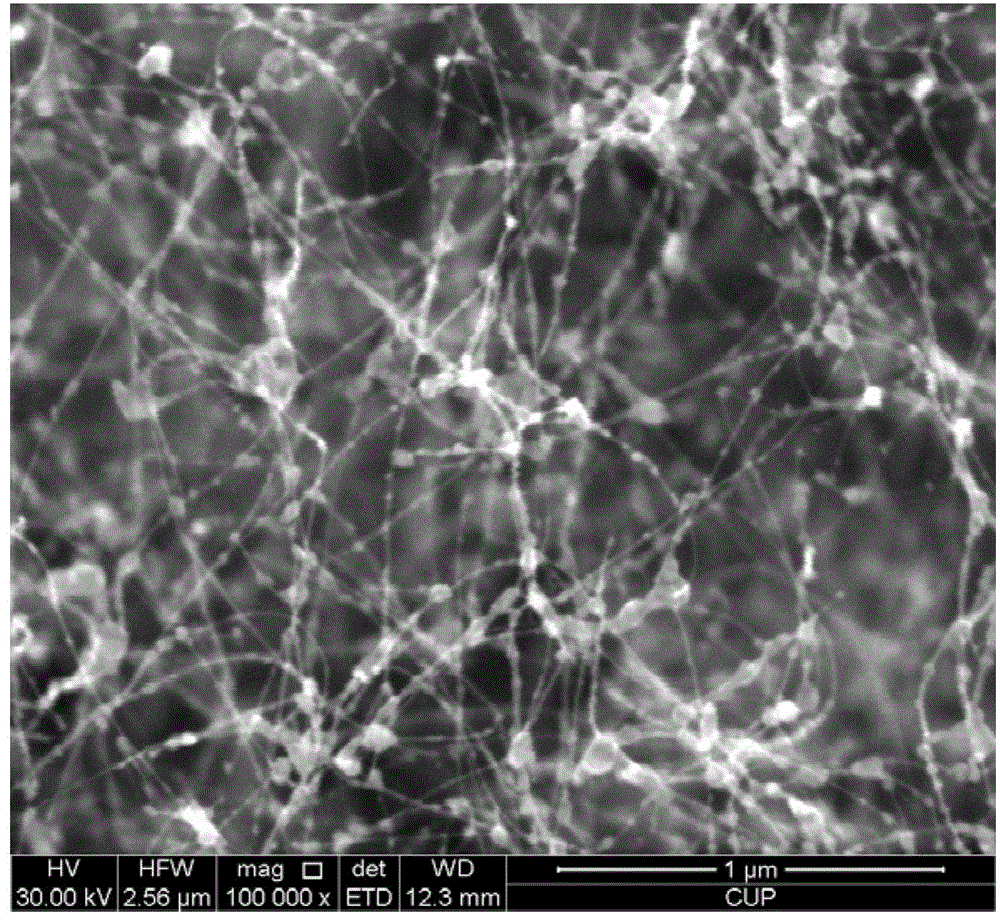

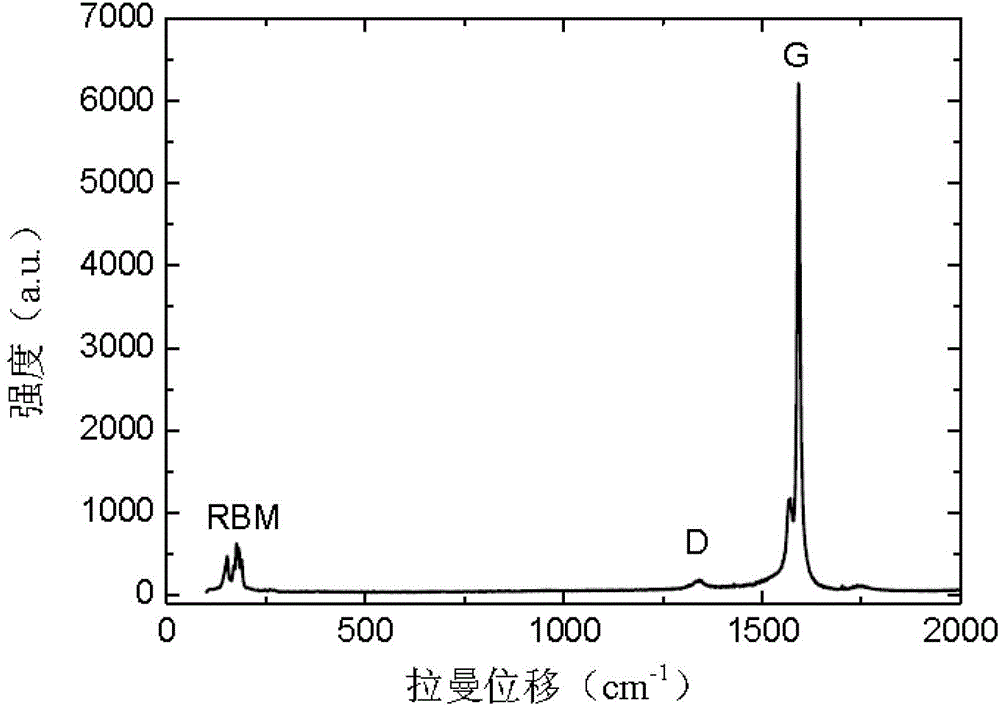

Method for preparing carbon nano tube by taking coke as raw material and prepared carbon nano tube

The invention provides a method for preparing a carbon nano tube by taking coke as a raw material and the prepared carbon nano tube. The method comprises the following steps: preparing a hollow coke rod; carbonizing the hollow coke rod; crushing a part of carbonized hollow coke rod to obtain the carbonized coke powder; mixing a catalyst with the carbonized coke powder to obtain a catalyst mixture; filling the catalyst mixture into the other part of the carbonized hollow coke rod to obtain the carbonized coke rod with the catalyst; and carrying out an arc discharge gasification reaction based on the carbonized coke rod with the catalyst as an anode, thereby obtaining the carbon nano tube. The invention also provides a single-wall carbon nano tube, a double-wall carbon nano tube and a three-wall carbon nano tube prepared by the method. According to the preparation method, the coke serves as the raw material, the positions of the reaction gas and the collected carbon nano tube are controlled, and different types of carbon nano tubes are prepared, so that the prepared carbon nano tube has the advantages of high purity, high yield, high mechanical and electronic performances and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

A substrate conveying device for inkjet printing

ActiveCN111573282BHigh degree of automationRealize batch continuous productionConveyorsCharge manipulationEngineeringMechanical engineering

The invention discloses a substrate conveying device for inkjet printing, comprising a moving assembly, a rotating assembly, a first transfer assembly and a second transferring assembly, the rotating assembly is mounted on the moving assembly and can move along the substrate driven by the moving assembly The X-direction, Y-direction and Z-direction movement of the conveying device, the first transfer assembly and the second transfer assembly are respectively connected with the rotation assembly, and the rotation assembly can respectively drive the first transfer assembly and the second transfer assembly to perform independent rotation. Therefore, the present invention not only has the advantages of high degree of automation, ensuring ink stability in the substrate transfer process after printing, and reducing the reject rate in the printed circuit board preparation process, but also has the advantages of improving the efficiency of substrate electronic printing and reducing substrate preparation costs. , the substrate conveying device of the present invention can quickly realize accurate loading, transfer and unloading of large-format substrates, and realize batch continuous production of printed circuit boards while ensuring the accuracy of electronic printing.

Owner:GUANGDONG SYGOLE INTELLIGENT TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com