Method for extracting pure calcium fluoride from calcium fluoride sludge

A technology for producing calcium fluoride and calcium fluoride, which is applied in the field of calcium fluoride sludge treatment, can solve problems such as shortage of fluorine resources, achieve simple process, easy batch continuous production, and solve the effect of secondary fluorine pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

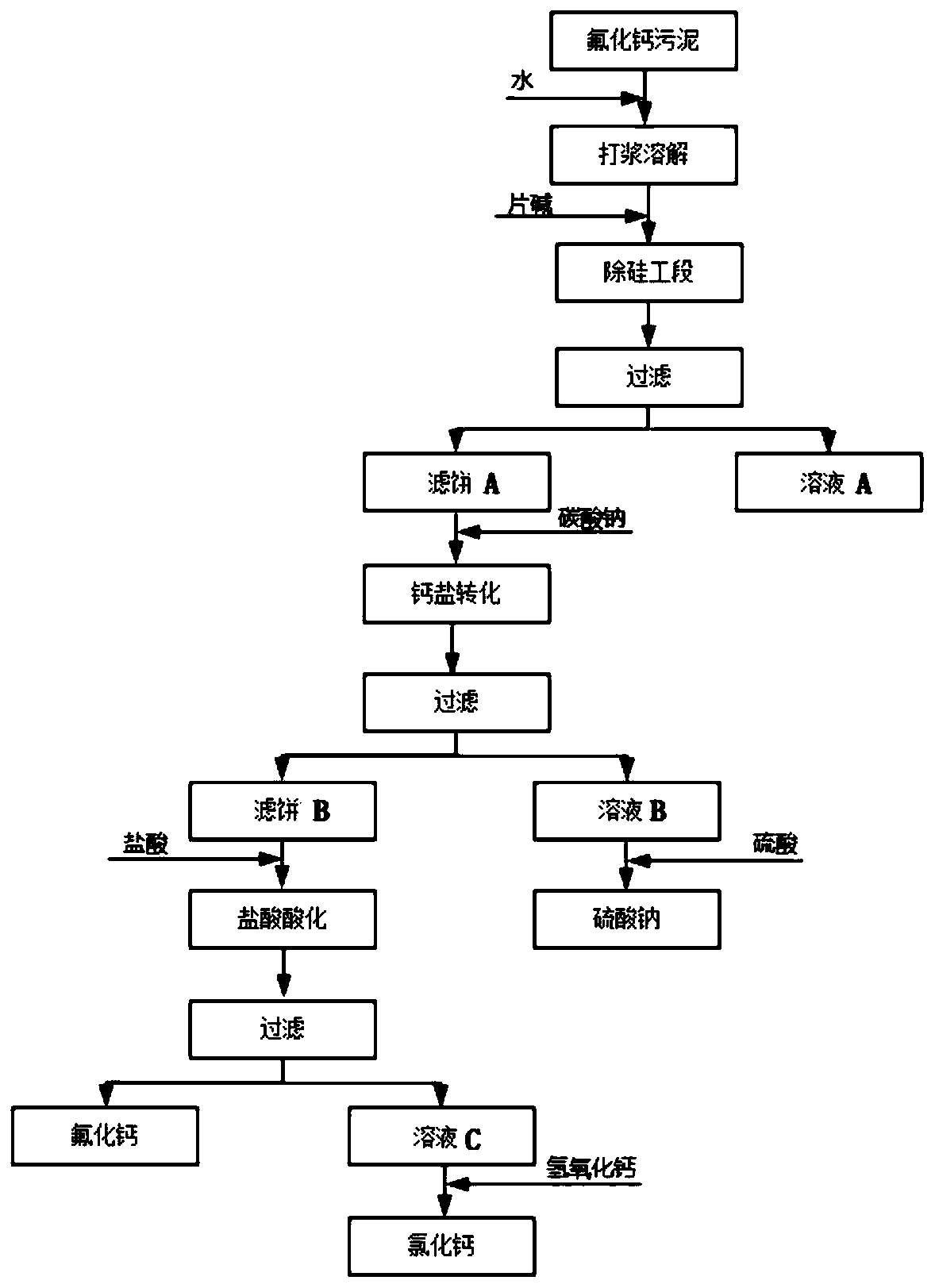

Image

Examples

Embodiment 1

[0028] In this implementation case, calcium fluoride sludge produced in the photovoltaic industry is used as raw material, and the purity of calcium fluoride in the raw sludge is 37.03%. The treatment is carried out according to the experimental method of the present invention, and the specific steps are as follows.

[0029] Beating and dissolving: Weigh 100g of calcium fluoride sludge into a beaker, add 100ml of water, heat and stir at 50°C for 30min to obtain a uniformly dispersed solid-liquid mixture.

[0030] Caustic soda desiliconization: add 8g sodium hydroxide to the solid-liquid mixture, stir for 2 hours to completely convert the silicon dioxide in the sludge into sodium silicate, filter to obtain filter cake 1 and sodium silicate solution; add in 2 times Add 100ml of water to the filter cake 1 to clean the residual sodium salt in the filter cake.

[0031] Calcium salt conversion: add 100ml of water to the filter cake 1 and stir it evenly, add 2g of sodium carbonate to...

Embodiment 2

[0035] In this implementation case, calcium fluoride sludge produced in the photovoltaic industry is used as raw material, and the purity of calcium fluoride in the raw sludge is 37.03%. The treatment is carried out according to the experimental method of the present invention, and the specific steps are as follows.

[0036] Beating and dissolving: Weigh 100g of calcium fluoride sludge into a beaker, add 150ml of water, heat and stir at 55°C for 30min to obtain a uniformly dispersed solid-liquid mixture.

[0037] Caustic soda desiliconization: add 8g sodium hydroxide to the solid-liquid mixture, stir for 2 hours to completely convert the silicon dioxide in the sludge into sodium silicate, filter to obtain filter cake 1 and sodium silicate solution; add in 2 times Add 150ml of water to the filter cake 1 to clean the residual sodium salt in the filter cake.

[0038] Calcium salt conversion: add 150ml of water to the filter cake 1 and stir it evenly, add 2g of sodium carbonate to...

Embodiment 3

[0042] In this implementation case, calcium fluoride sludge produced in the photovoltaic industry is used as raw material, and the purity of calcium fluoride in the raw sludge is 37.03%. The treatment is carried out according to the experimental method of the present invention, and the specific steps are as follows.

[0043] Beating and dissolving: Weigh 100g of calcium fluoride sludge into a beaker, add 200ml of water, heat and stir at 60°C for 30min to obtain a uniformly dispersed solid-liquid mixture.

[0044]Caustic soda desiliconization: add 8g sodium hydroxide to the solid-liquid mixture, stir for 2 hours to completely convert the silicon dioxide in the sludge into sodium silicate, filter to obtain filter cake 1 and sodium silicate solution; add in 2 times Add 200ml of water to the filter cake 1 to clean the residual sodium salt in the filter cake.

[0045] Calcium salt conversion: add 200ml of water to filter cake 1 and stir it evenly, add 2g of sodium carbonate to conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com