A lightweight castable

A lightweight castable, lightweight aggregate technology, applied in the field of refractory materials, can solve the problems of difficult to achieve automatic continuous production, time-consuming, reducing strength, etc., achieve excellent volume stability and thermal shock stability, reduce production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

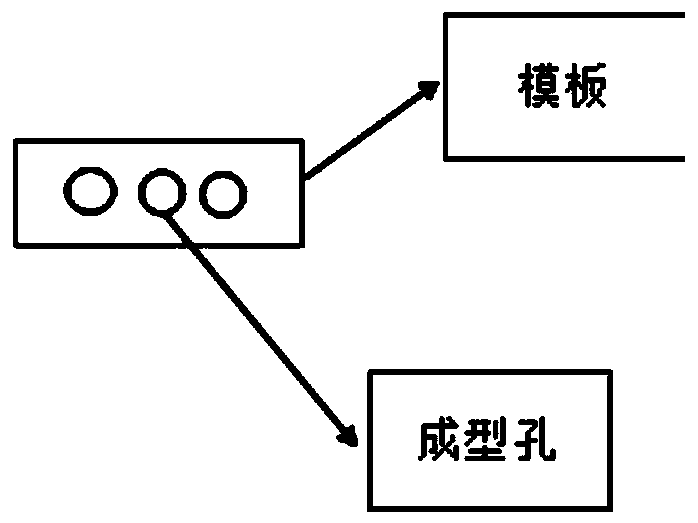

Image

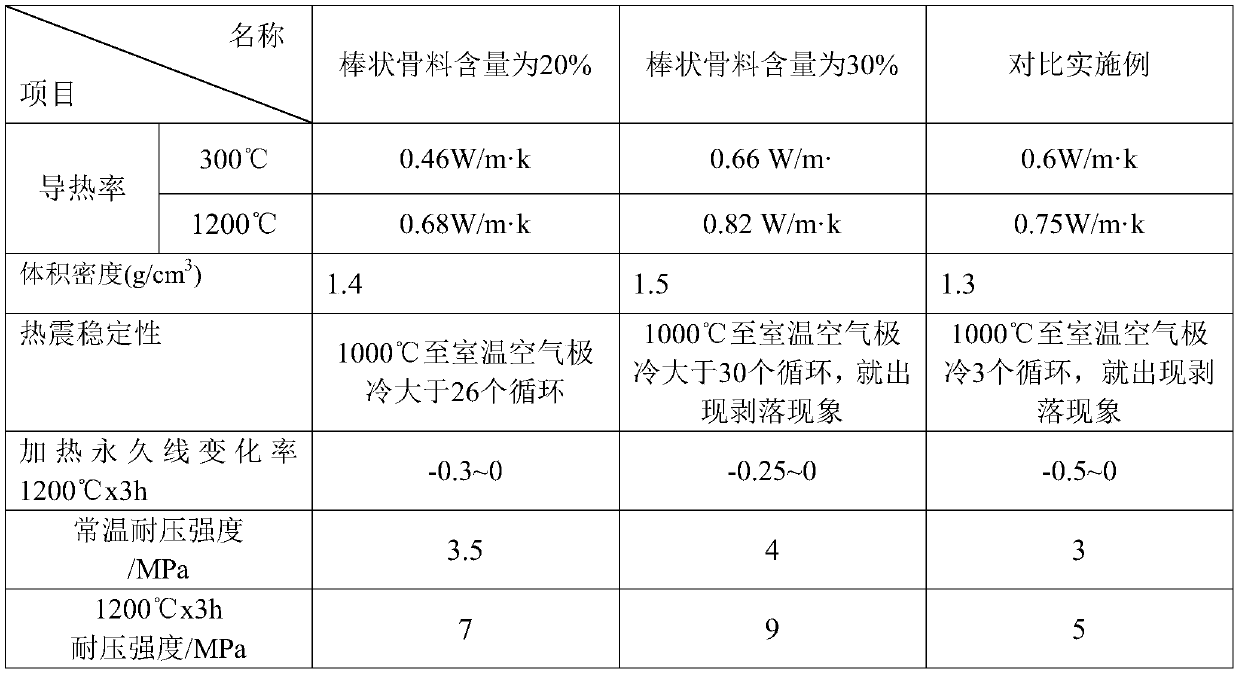

Examples

Embodiment 1

[0054] A rod-shaped aggregate for lightweight castables, which is prepared from the following raw materials in weight percentages:

[0055] Guangxi white clay with particle size ≤45μm: 75%

[0057] Water glass: 10%

[0058] Add 0.2% of hydroxymethyl cellulose accounting for the total weight of the above raw materials and 0.5% of sodium hexametaphosphate accounting for the total weight of the above raw materials.

[0059] The preparation method of the rod-shaped aggregate comprises the following steps:

[0060] (1) Prepare raw materials according to requirements: 75% of Guangxi white mud with particle size ≤ 45 μm, 15% of alumina cement, 10% of water glass; hydroxymethyl cellulose and sodium hexametaphosphate;

[0061] (2) The raw materials prepared in step (1) are added to the planetary mixer according to the required dosage ratio for mixing and stirring, and the stirring is uniform to obtain the mixture;

[0062] (3) adding water accounting fo...

Embodiment 2

[0067] A rod-shaped aggregate for lightweight castables, which is prepared from the following raw materials in weight percentages:

[0068] Guangxi white clay with particle size ≤45μm: 95%

[0069] Water glass: 3%

[0070] Calcium lignosulfonate: 2%

[0071] Add 0.2% sodium tripolyphosphate accounting for the total weight of the above raw materials, 0.4% sodium hexametaphosphate accounting for the total weight of the above raw materials and 0.2% FDN accounting for the above raw materials.

[0072] The preparation method of the rod-shaped aggregate comprises the following steps:

[0073] (1) Prepare raw materials according to requirements: 95% of Guangxi white mud with a particle size of ≤45 μm, 3% of water glass, 2% of calcium lignosulfonate; sodium tripolyphosphate, sodium hexametaphosphate and FDN;

[0074] (2) Add the raw materials prepared in step (1) into the planetary mixer according to the required dosage ratio, mix and stir, and stir evenly to obtain the mixture;

...

Embodiment 3

[0080] A rod-shaped aggregate for lightweight castables, the rod-shaped aggregate is prepared from the following raw materials in weight percentage:

[0081] Guangxi white clay with particle size ≤45μm: 85%

[0082] Water glass: 10%

[0083] Calcium lignosulfonate: 5%

[0084] Add 0.2% hydroxymethyl cellulose that accounts for the total weight of the above-mentioned raw materials.

[0085] The preparation method of the rod-shaped aggregate comprises the following steps:

[0086] (1) Prepare raw materials as required: 85% of Guangxi white mud with a particle size of ≤45 μm, 10% of water glass, 5% of calcium lignosulfonate; hydroxymethyl cellulose;

[0087] (2) The raw materials prepared in step (1) are added to the planetary mixer according to the required dosage ratio for mixing and stirring, and the stirring is uniform to obtain the mixture;

[0088] (3) adding water accounting for 15% of the total weight of the mixture in the mixture obtained in step (2), stirring evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com