Well control method for changing valve under pressure

A technology for changing valves and valves under pressure, which is applied in the valve device of wellbore/well, earthwork drilling, wellbore/well components, etc. The effect of the simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

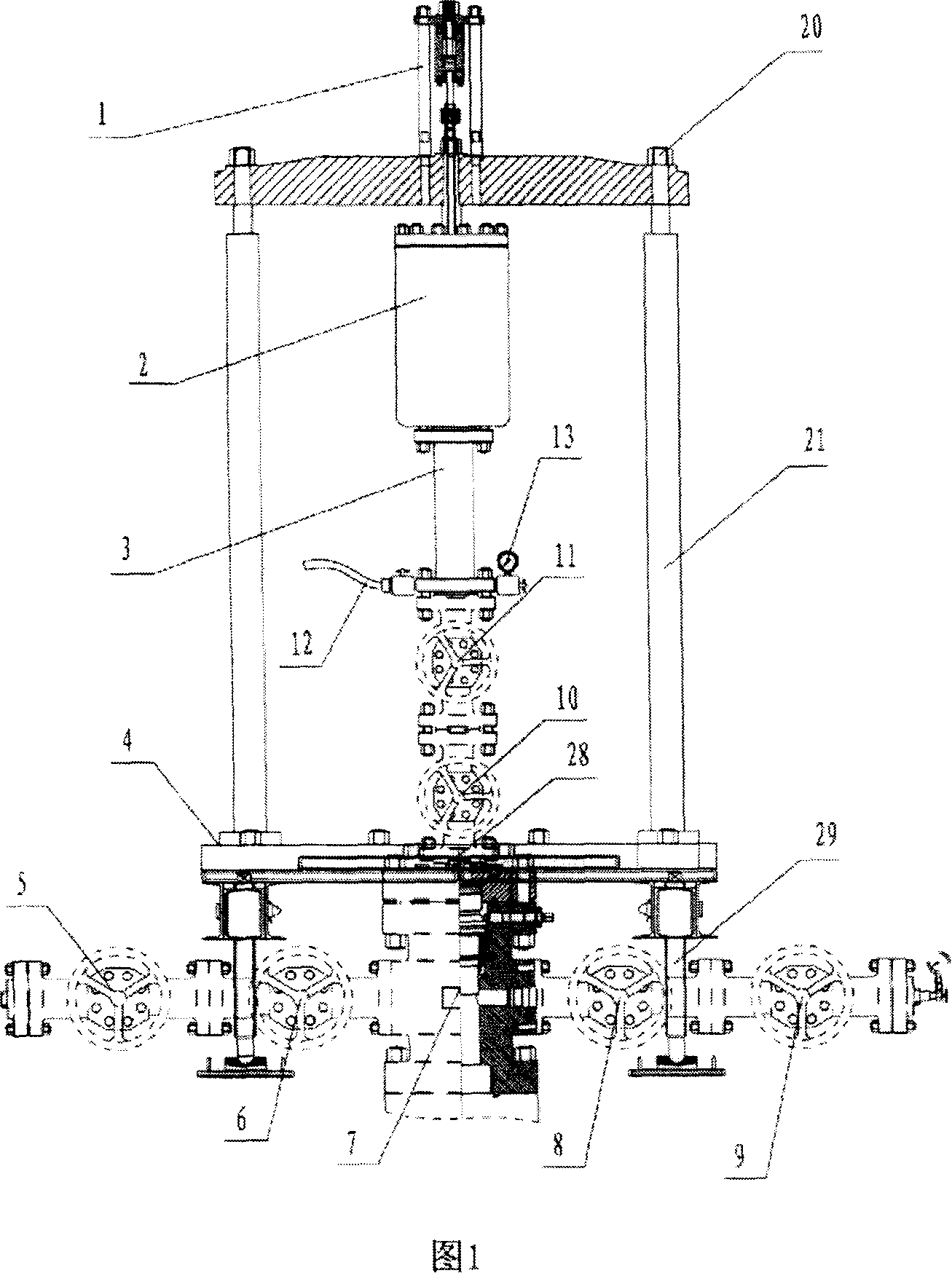

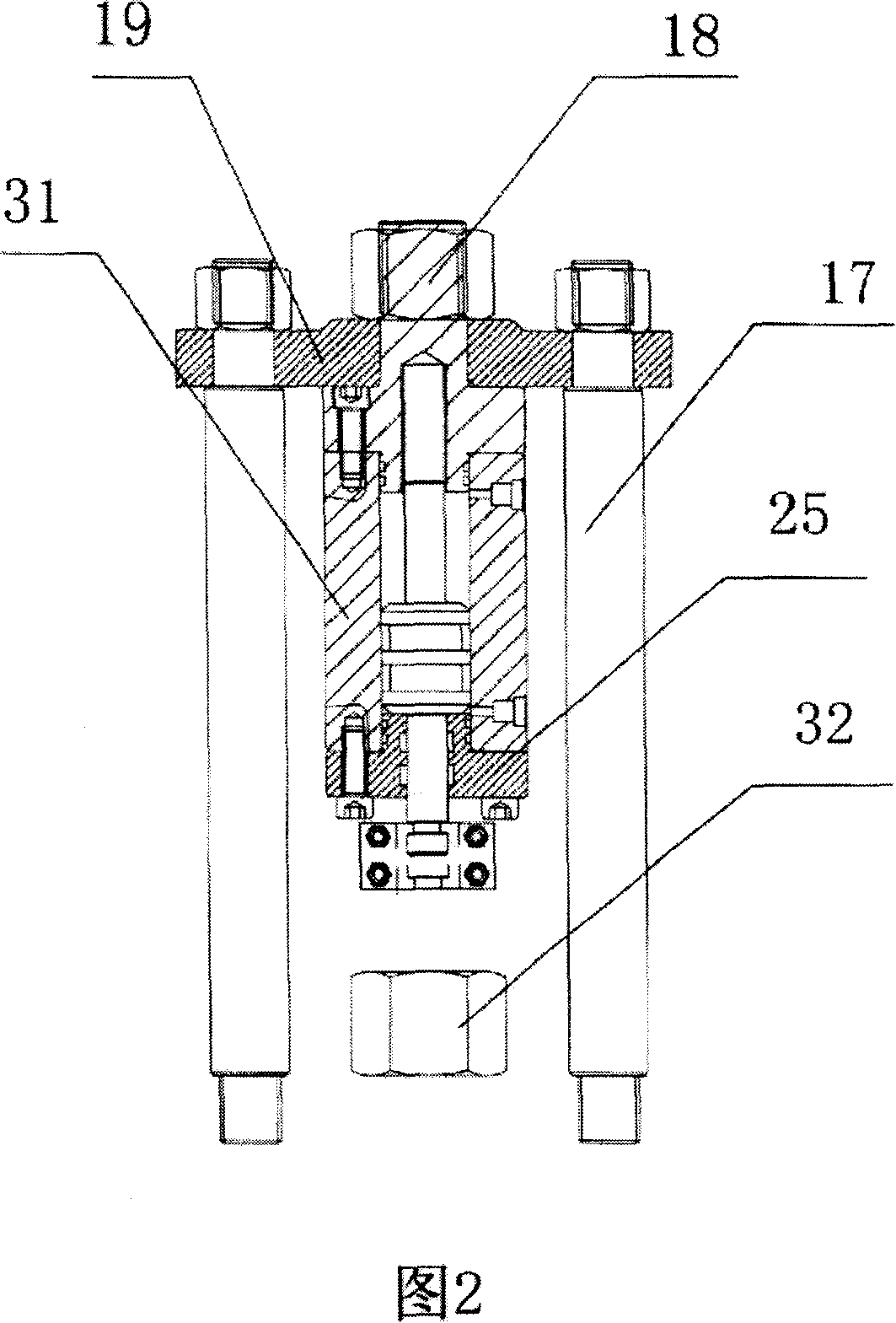

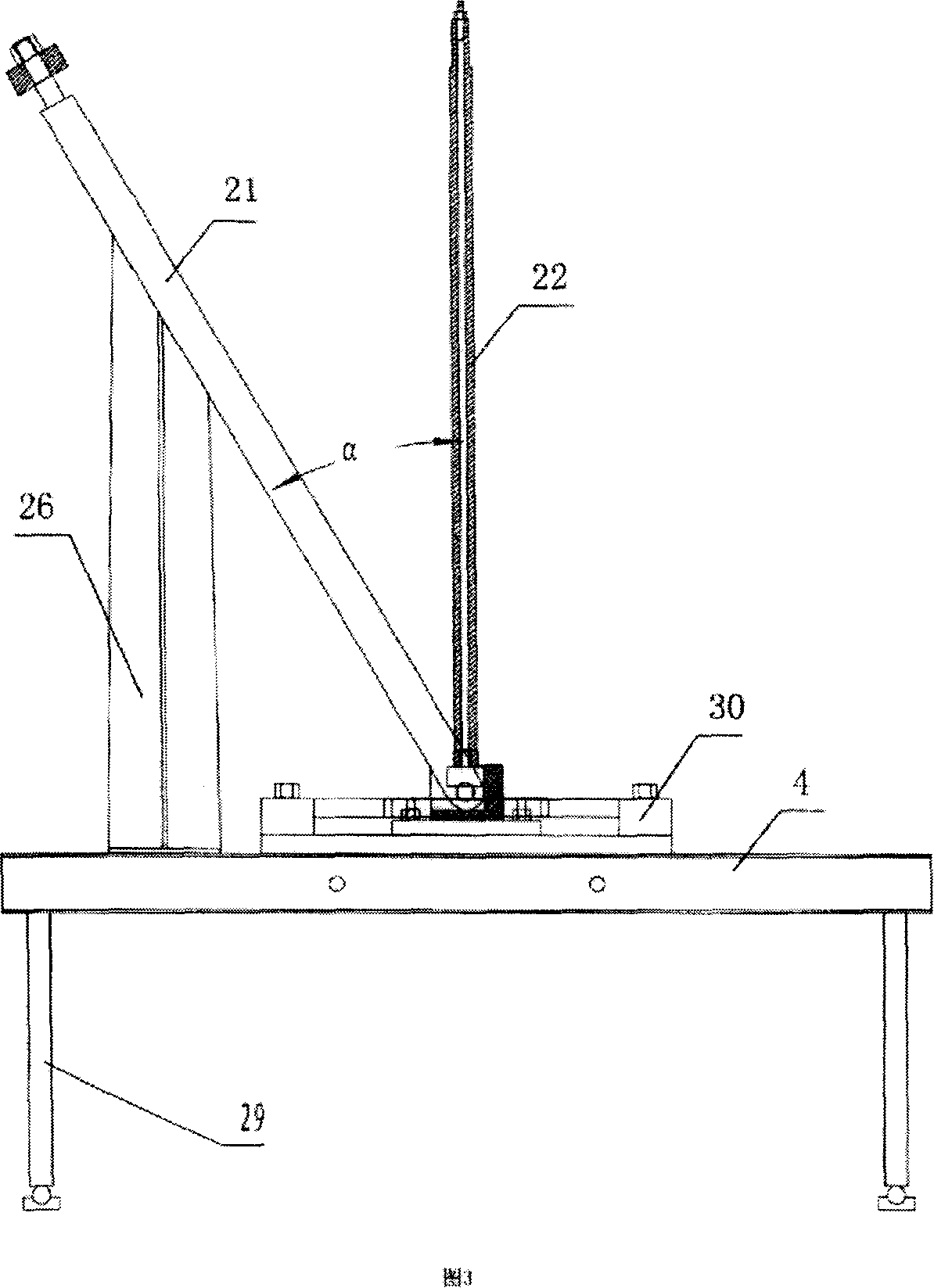

[0059] First of all, the special device structure required by the present invention will be described. As shown in Figure 1, the device includes a plug assembly 1, a lifting hydraulic support 21, a self-sealing head assembly 2, a double flange pup joint assembly 3, an underframe assembly 4 that can be arranged on the tubing jacket 7, and Hydraulic control system.

[0060] The underframe assembly 4 includes several support screw rods 29 arranged around the tubing jacket 7, and a support plate arranged on the upper end of the support screw rod 29 and connected thereto. A small pressure plate 30 is arranged on the top, and the edge of the support plate is provided with an adjusting bolt passing through the small pressure plate 30 , and the middle part of the small pressure plate 30 is provided with a perforation with an adjustable aperture.

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com