Patents

Literature

46results about How to "Prevent push" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

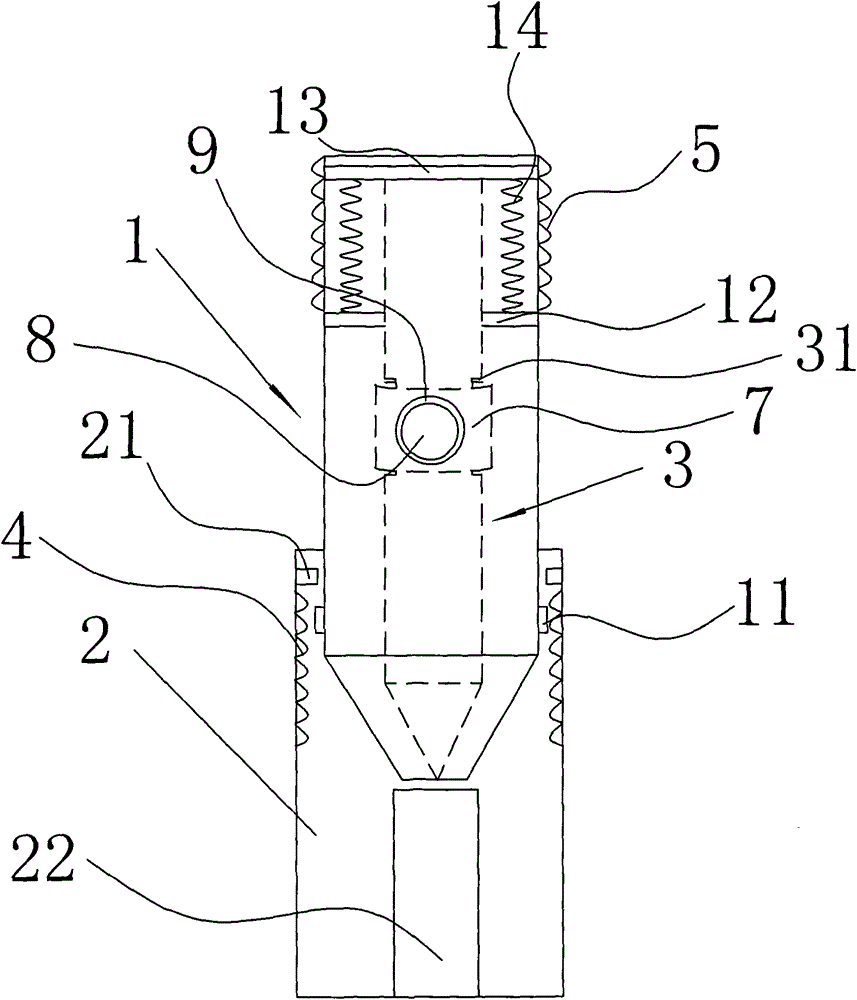

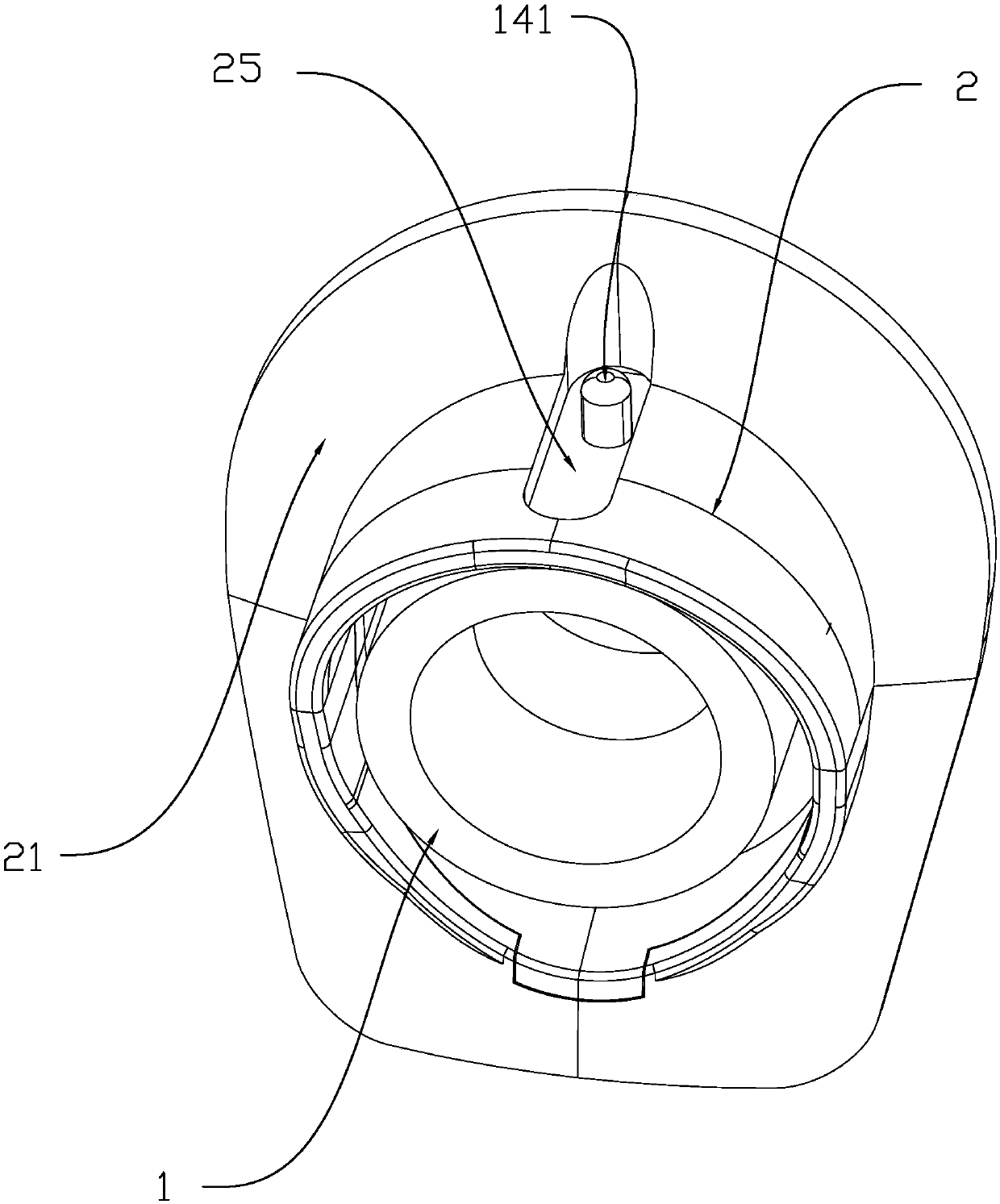

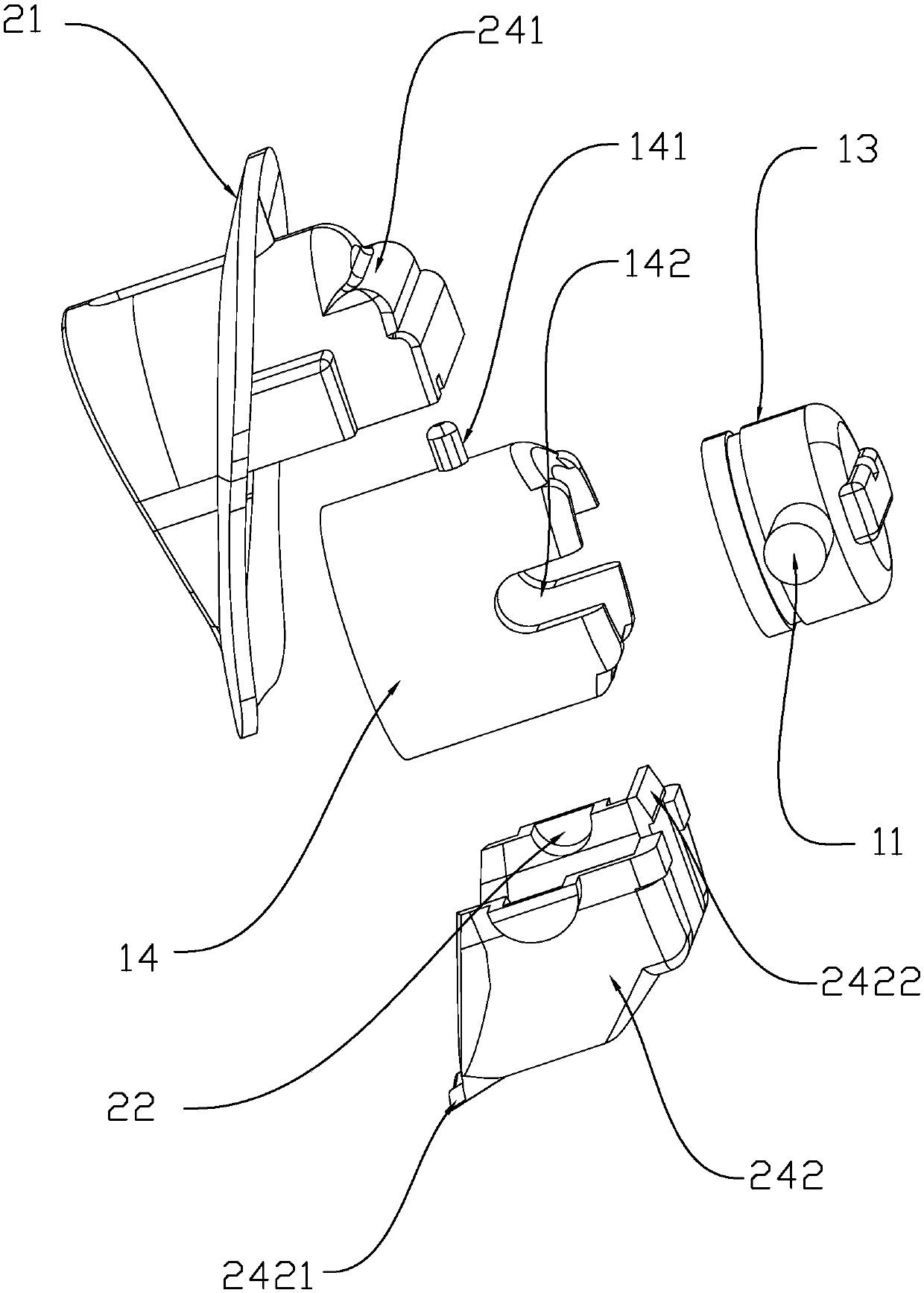

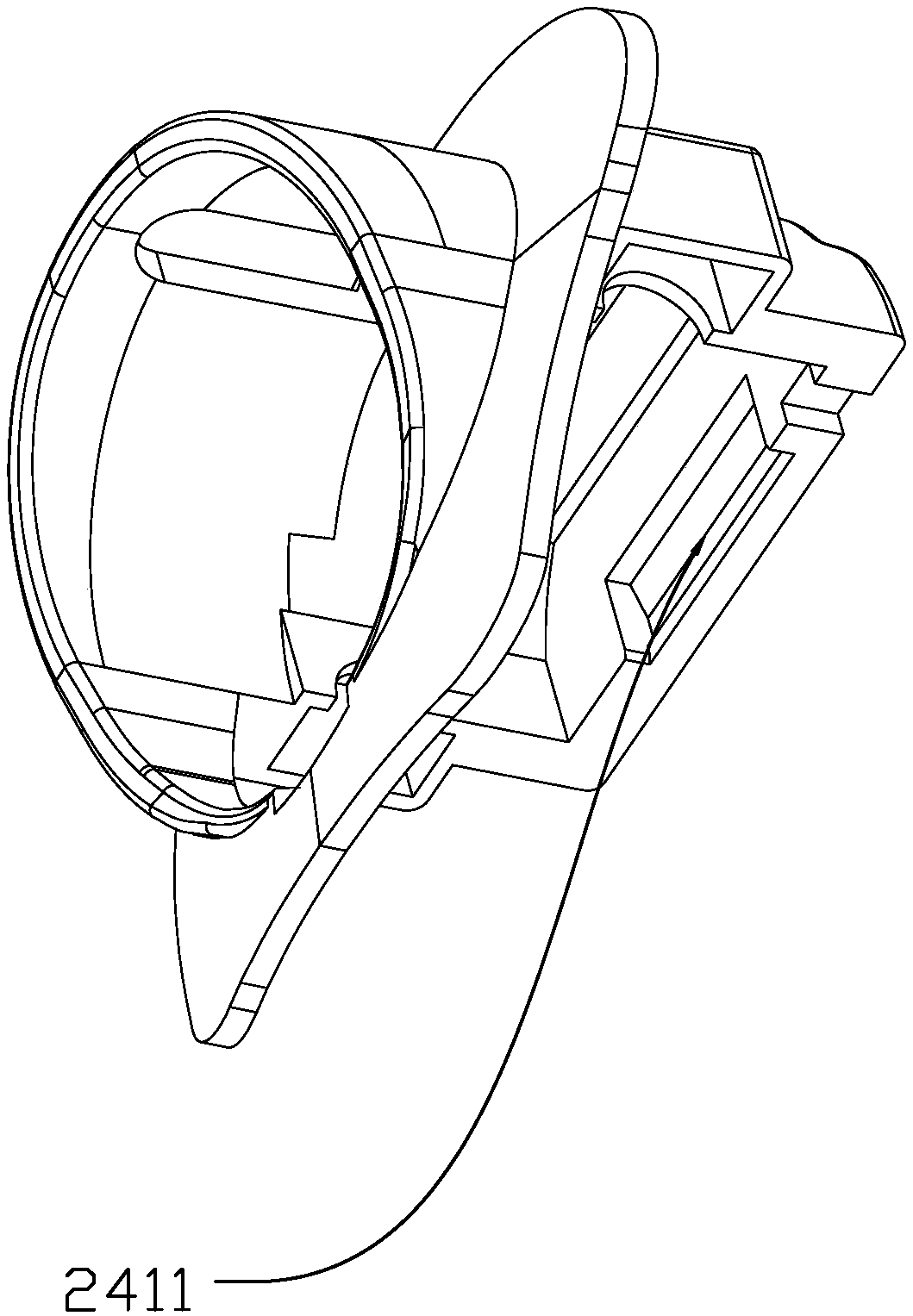

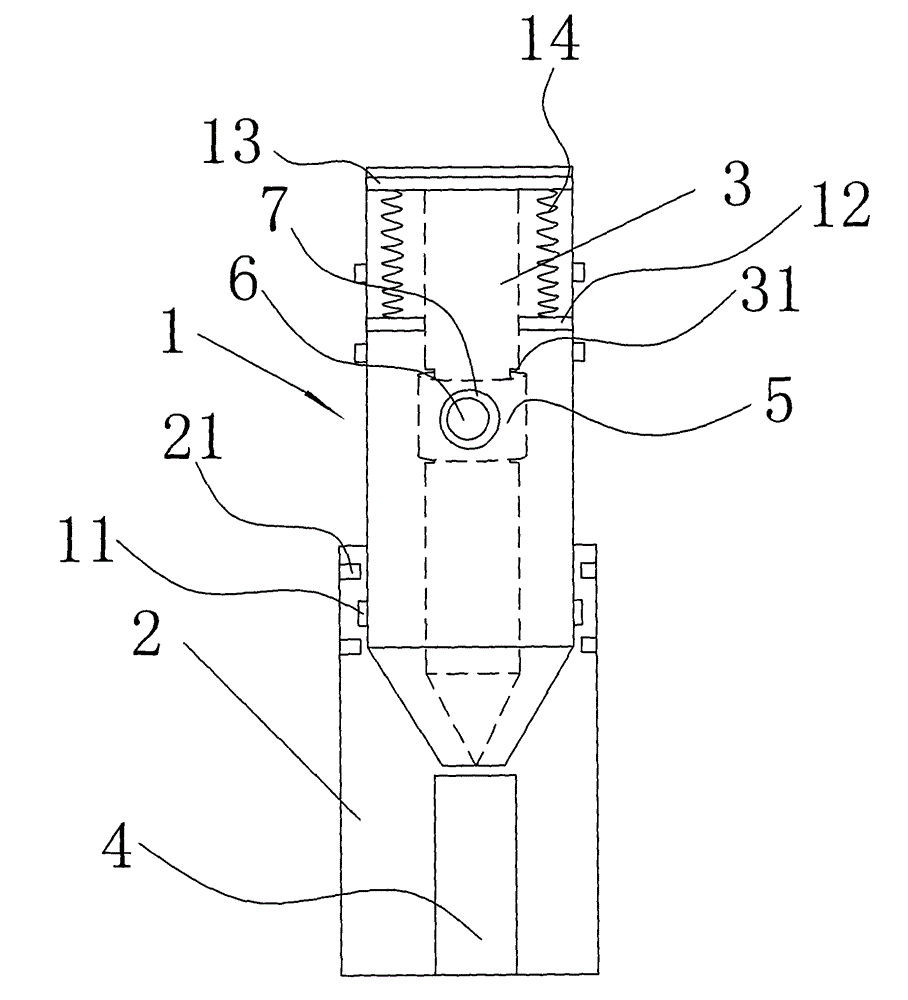

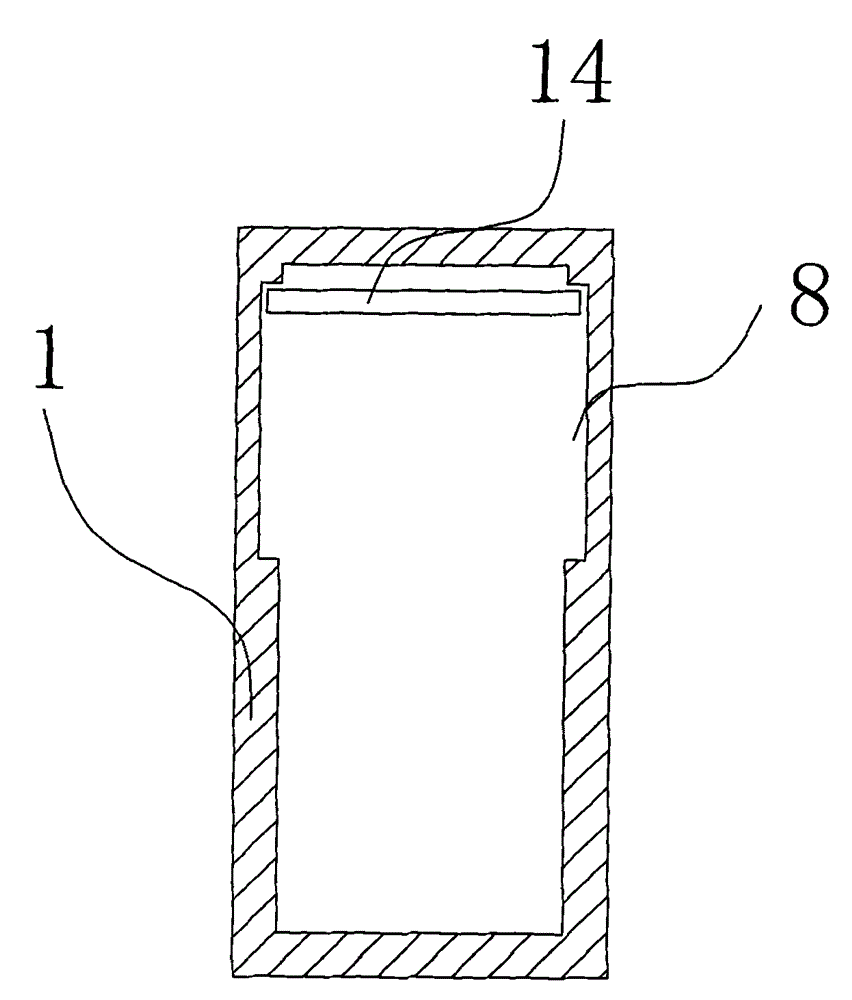

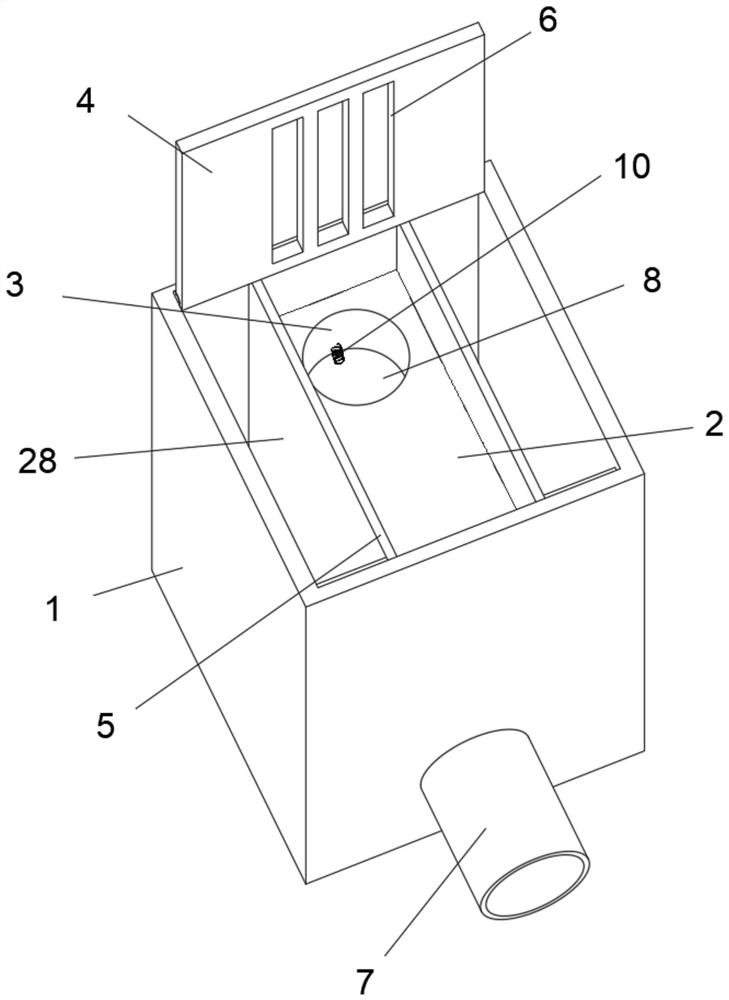

Intelligent air purifier with excellent circulation performance based on Internet of Things

InactiveCN107930286APrevent being pushed toPrevent pushCombination devicesDispersed particle filtrationAir purifierInternet of Things

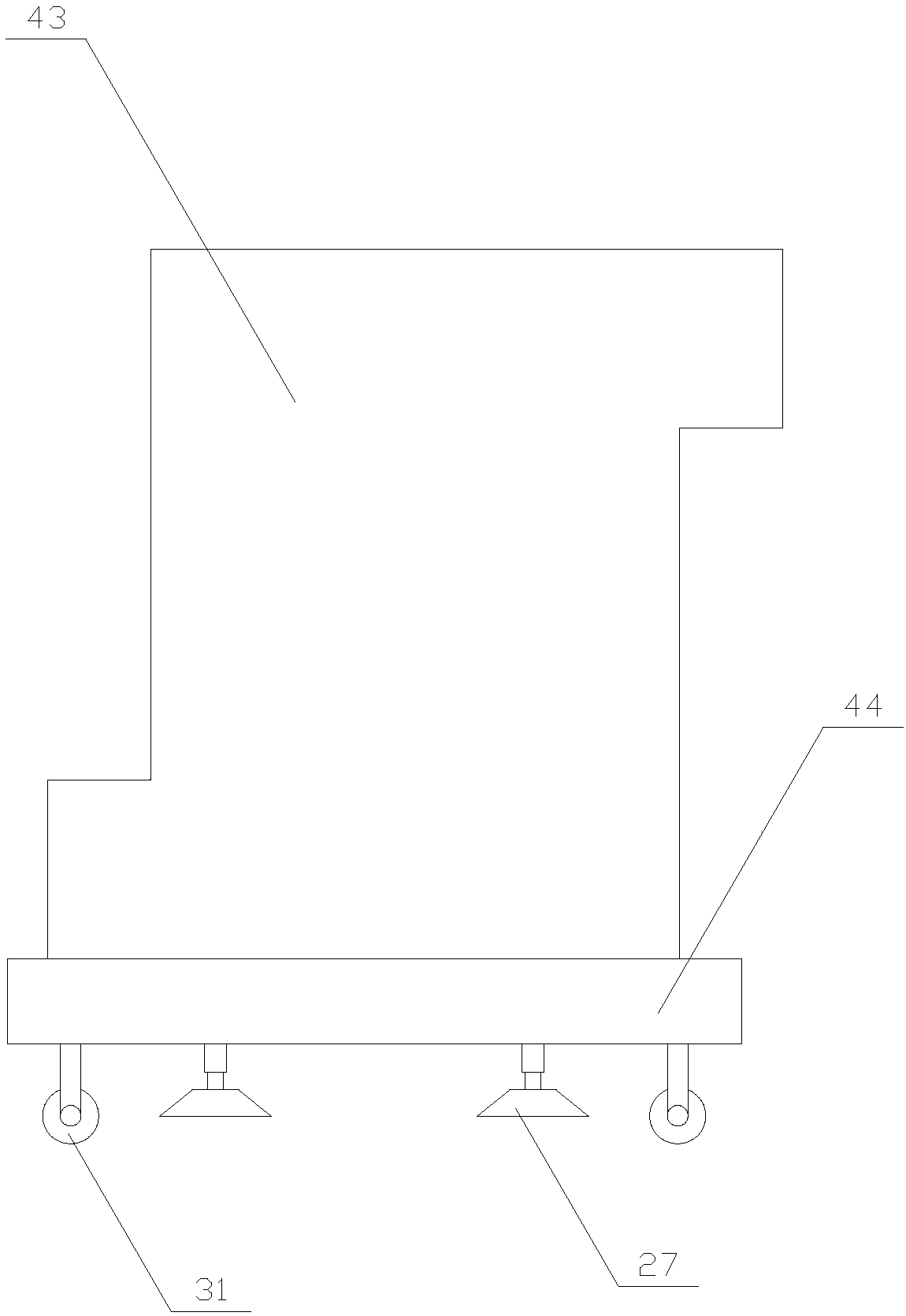

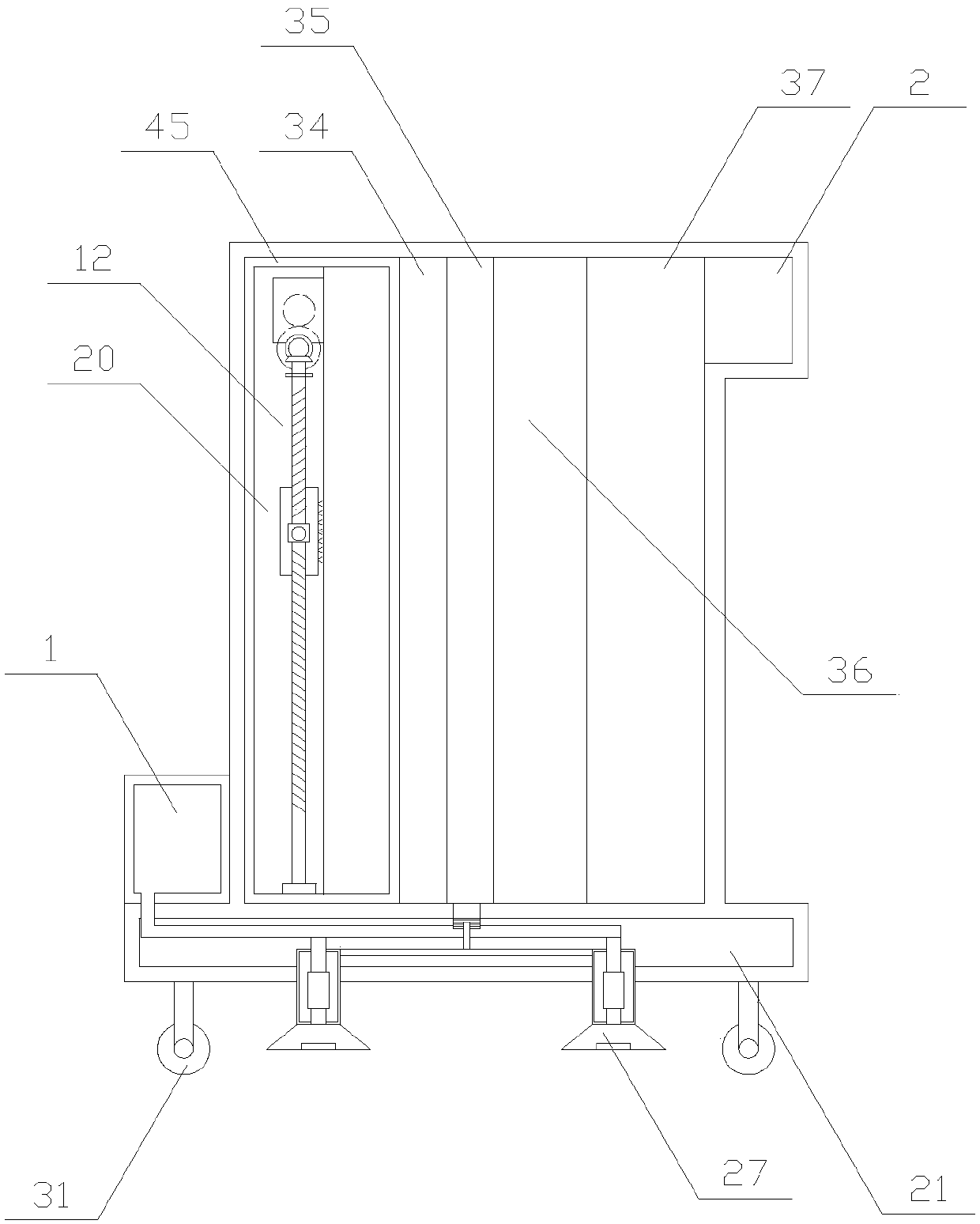

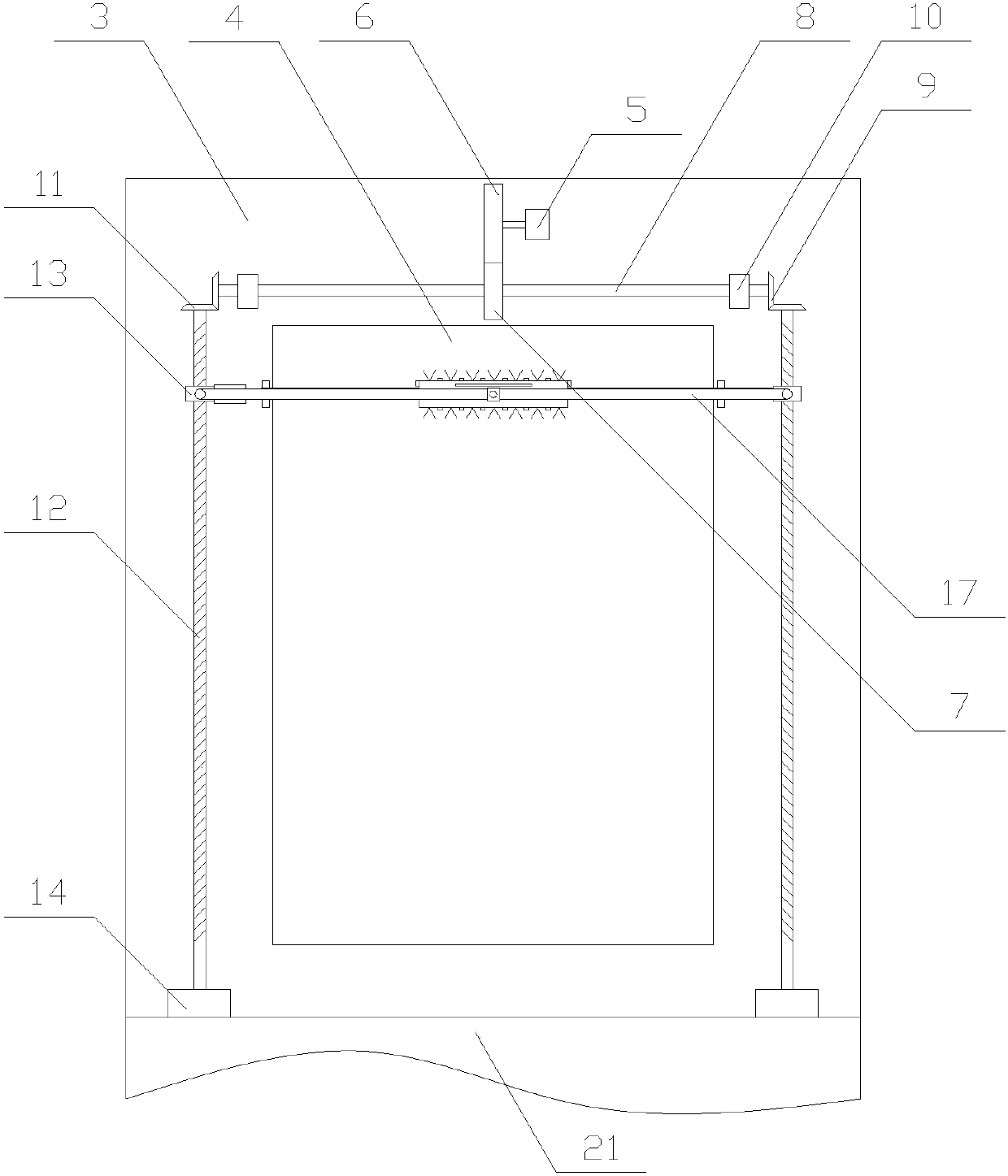

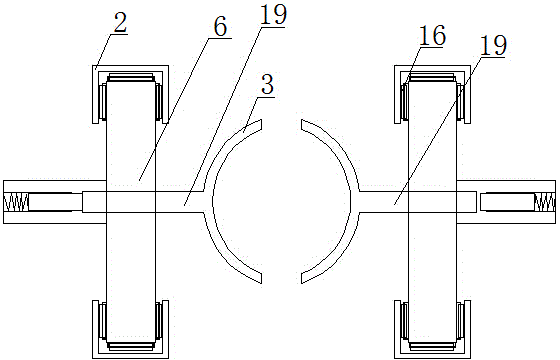

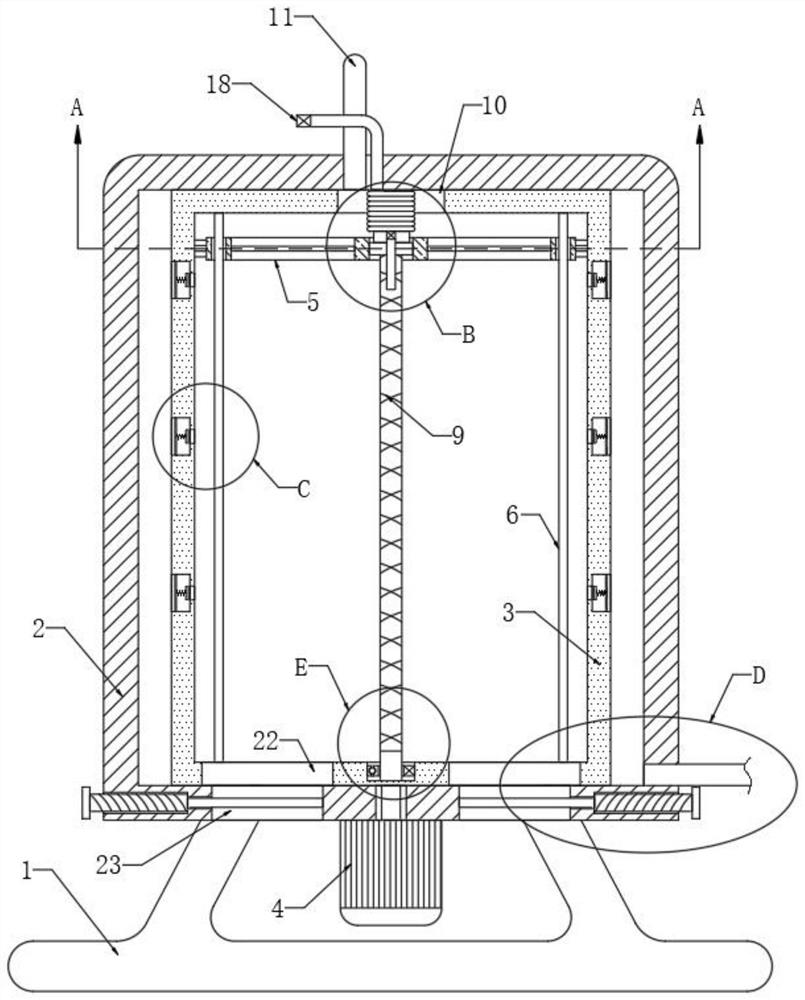

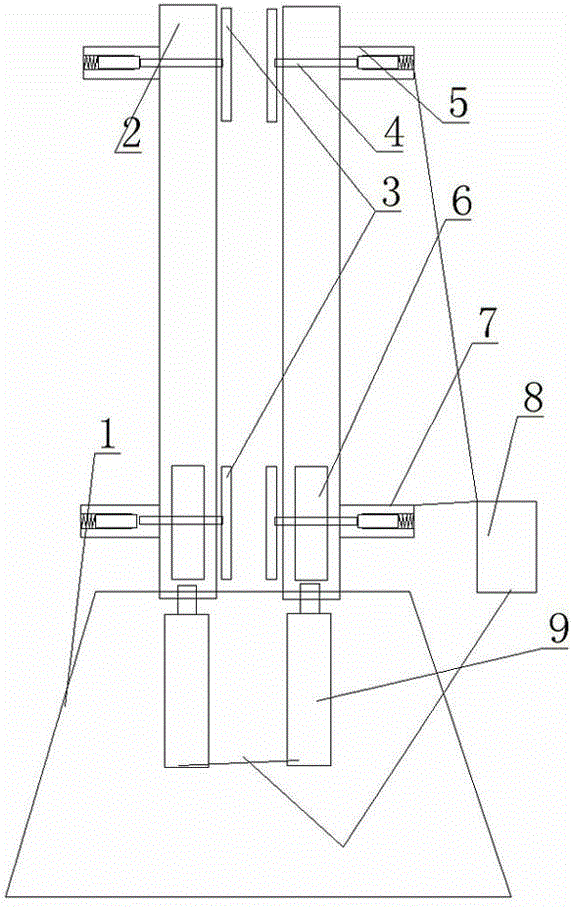

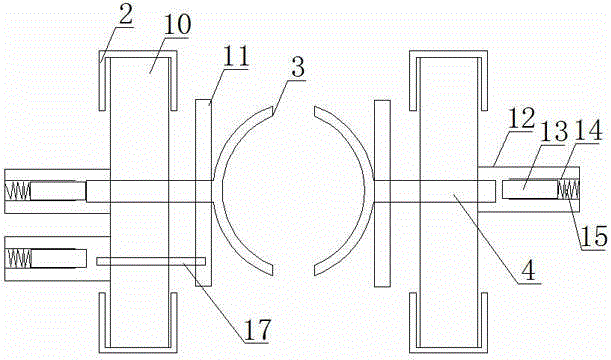

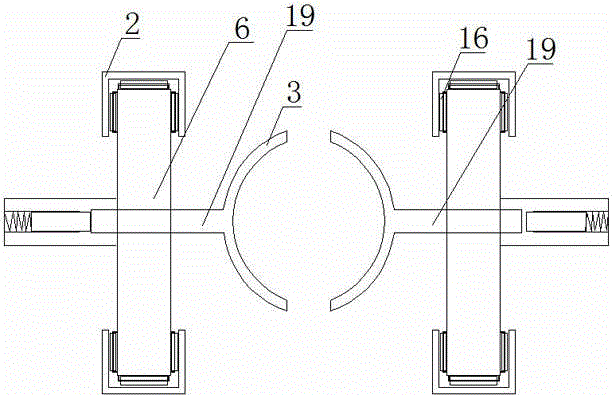

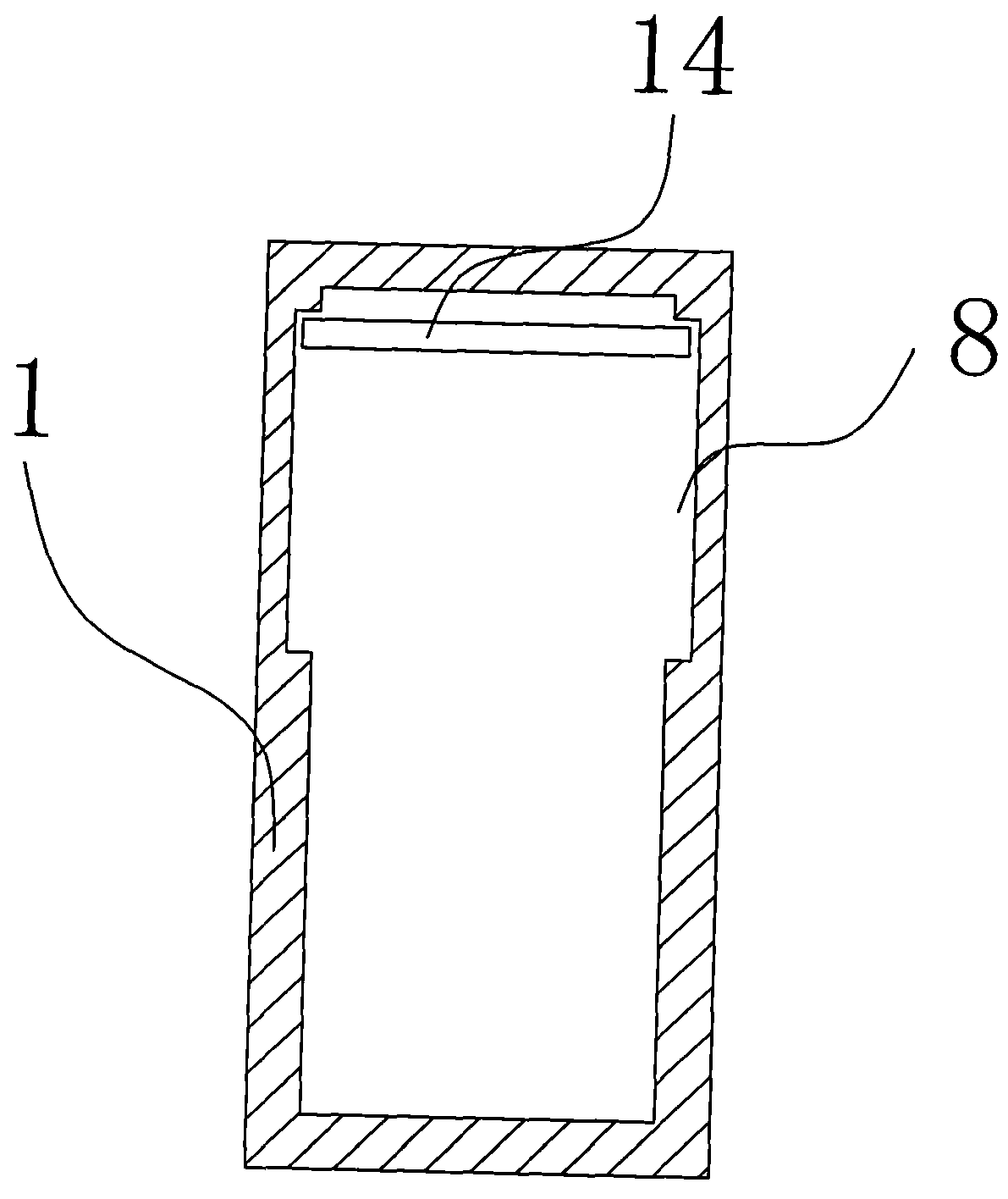

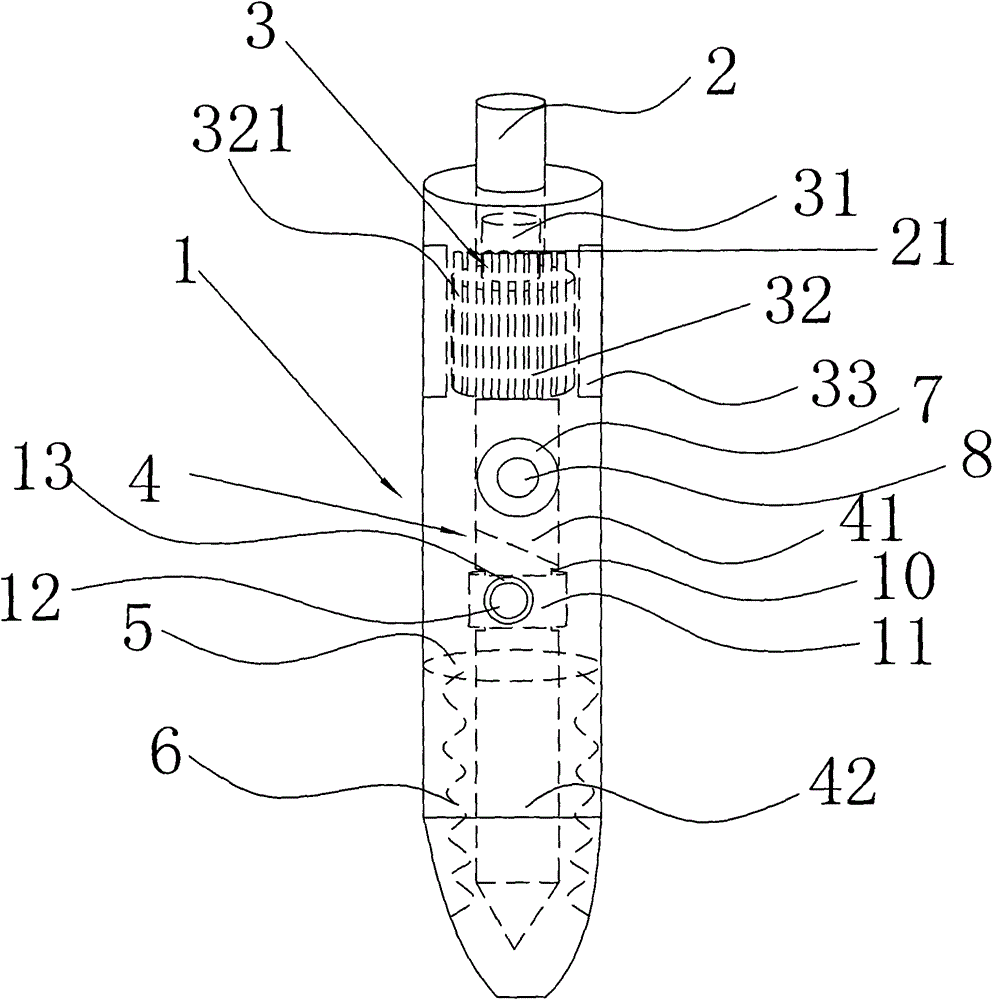

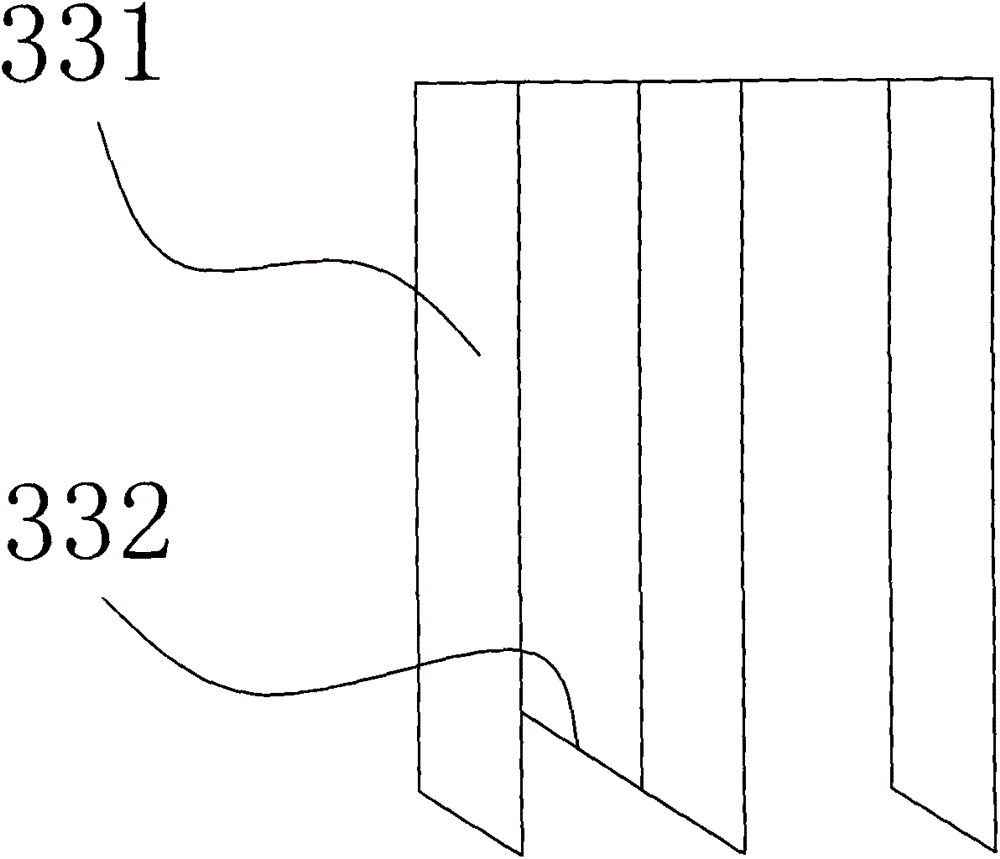

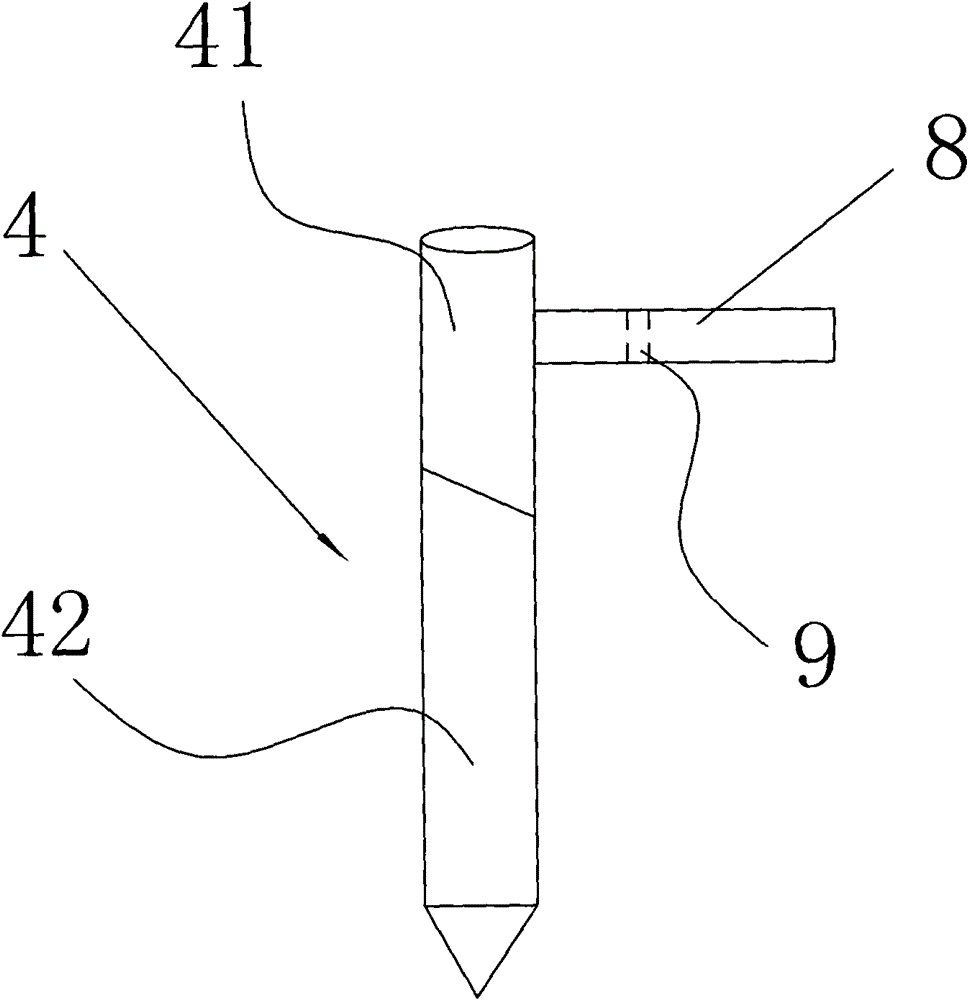

The invention relates to an intelligent air purifier with excellent circulation performance based on Internet of Things. The intelligent air purifier comprises a shell and a chassis, wherein the shellis fixed above the chassis; the shell is internally provided with an air inlet tank, a filtering mechanism, a treatment mechanism and an air outlet tank; the chassis is internally provided with a bottom plate, a power mechanism and two adsorption mechanisms; the filtering mechanism comprises a filtering tank and a cleaning component; the adsorption mechanisms comprise exhaust fans, exhaust tubes,air outlet tubes, lifting tubes, connecting tubes and suckers. According to the intelligent air purifier with excellent circulation performance based on Internet of Things, a filtering net is cleanedthrough the cleaning component, so that the circulation capability of air flowing through the filtering net is improved, the frequency of replacing the filtering net is reduced, and the cost is reduced; compared with a conventional cleaning component, the cleaning component is capable of intelligently changing a working direction and is relatively high in working efficiency, and in addition, theadsorption mechanisms are supported by the power mechanism to be adsorbed to the ground, then the air purifier is prevented from being pushed down, security accidents are avoided, and the stability ofthe air purifier is improved.

Owner:苏州奥柯图葳机电科技有限公司

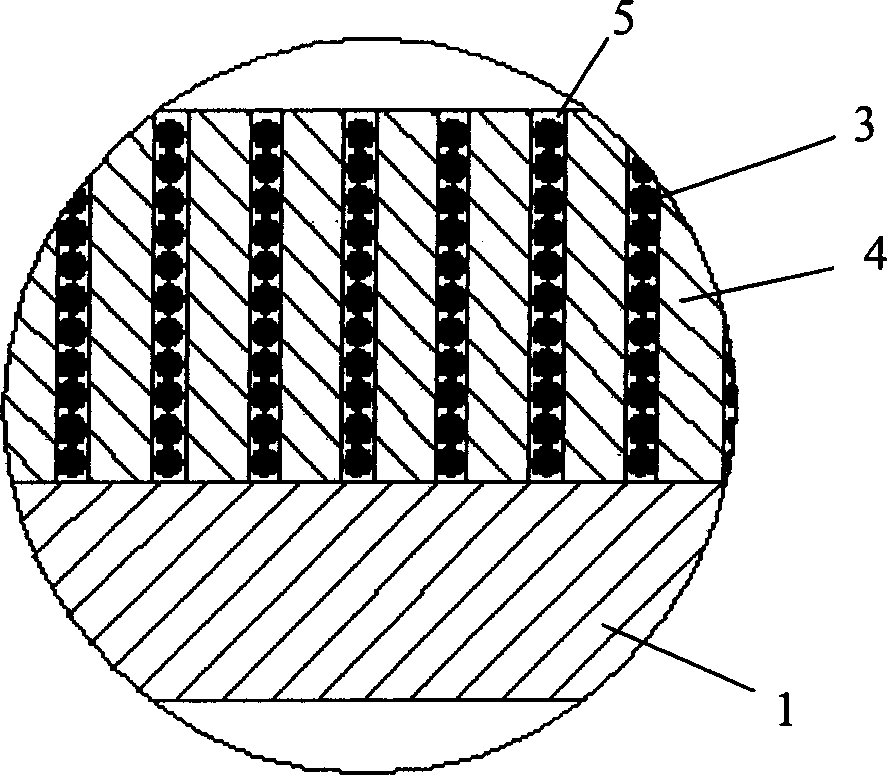

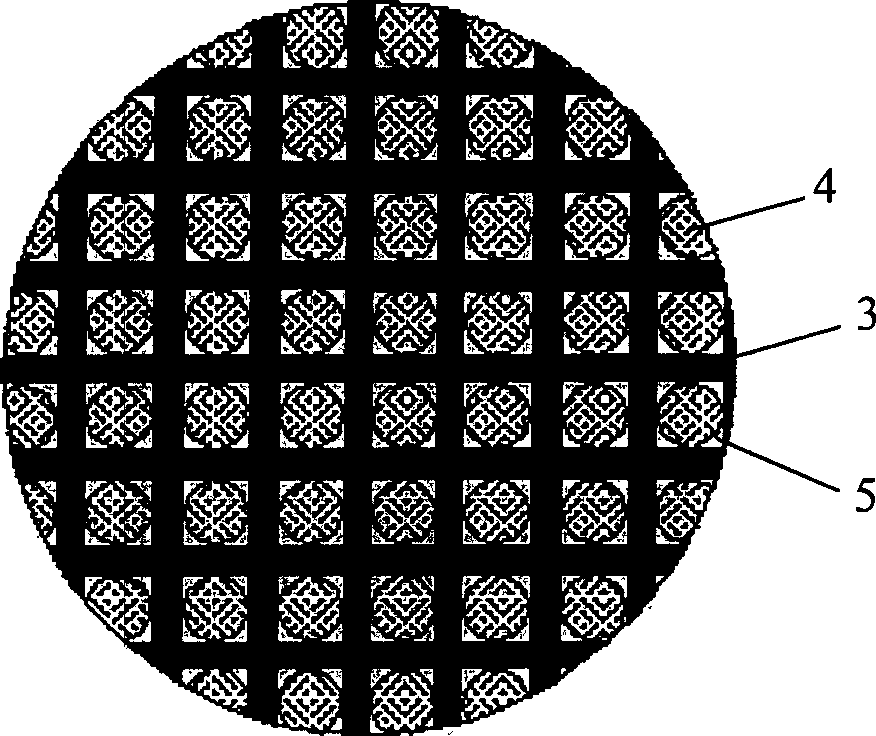

Abrasion proof pipe with ternary composite material as liner and preparing technique thereof

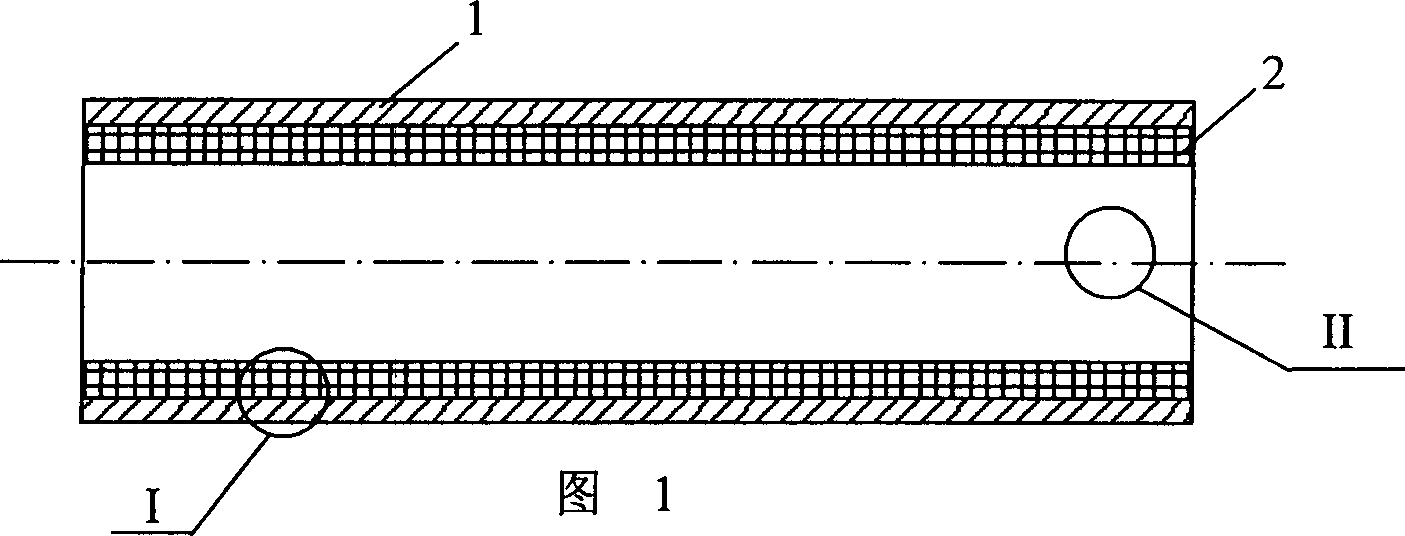

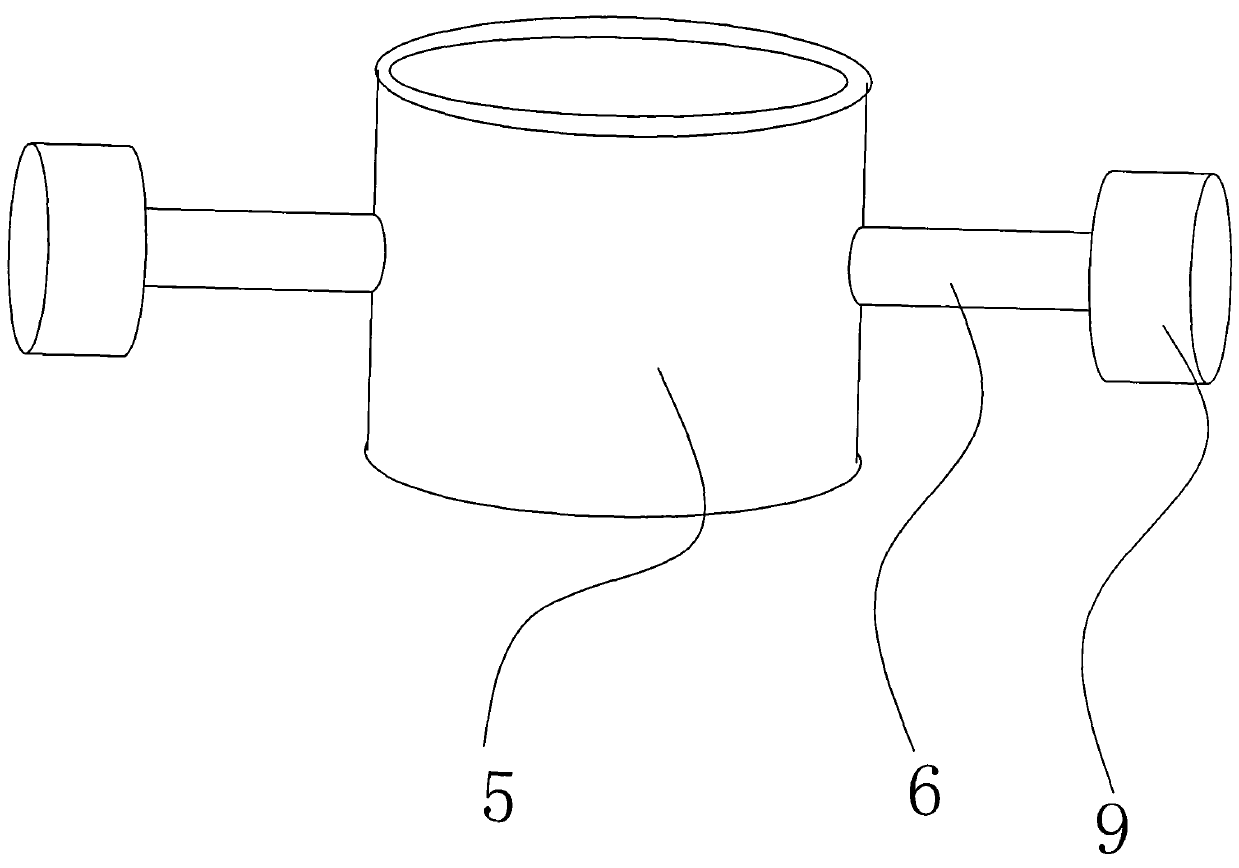

This invention discloses a ternary compound material underlay anti-wearing tube and its process method, which comprises outer steel tube and anti-wearing underlay, wherein, the anti-wearing underlay is composed of metal wire net, ceramics bar and compound materials and the ceramics is imbedded in the metal wire net holes into one part by compound materials. The processed compound materials underlay anti-wearing tube is one of straight tube, bent tube or three-way tube.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Device and method for maintaining and cleaning isolating switches

InactiveCN104409996AReduce resistancePrevent slipping outCleaning using toolsSwitchgearPush pullSelf locking

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

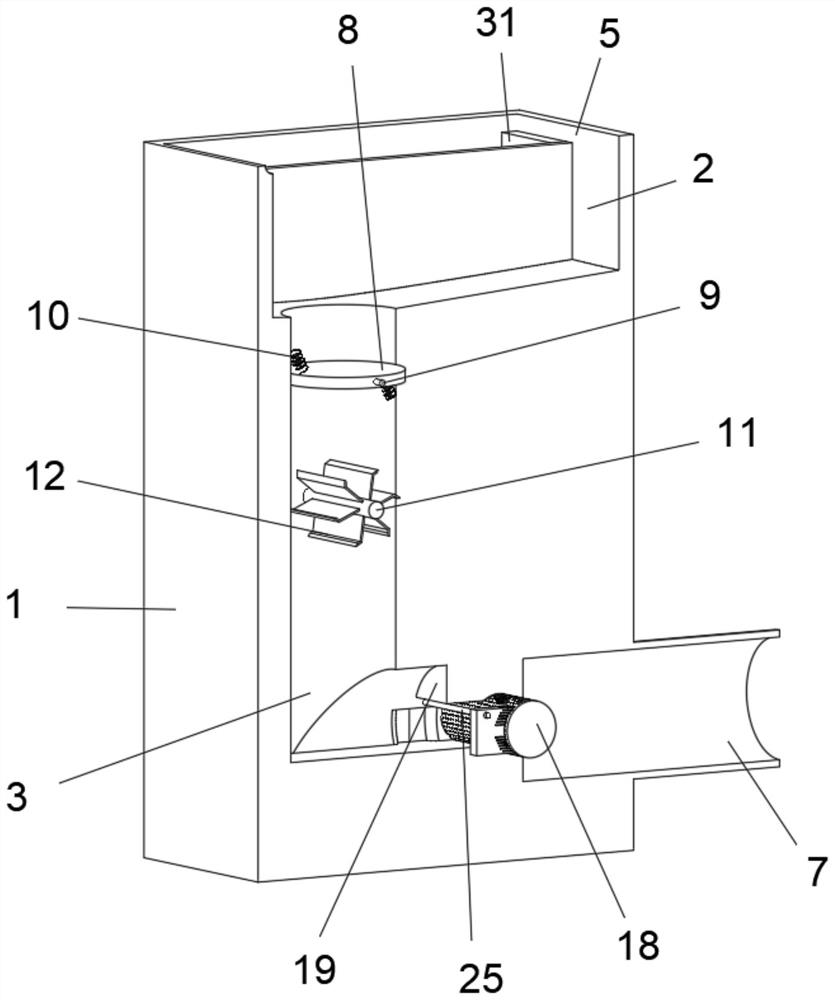

Centrifugal rotary drum type sewage filtering and recycling device

ActiveCN113332784AAvoid cloggingImprove filtration efficiencyWater aerationSustainable biological treatmentSludgeElectric machine

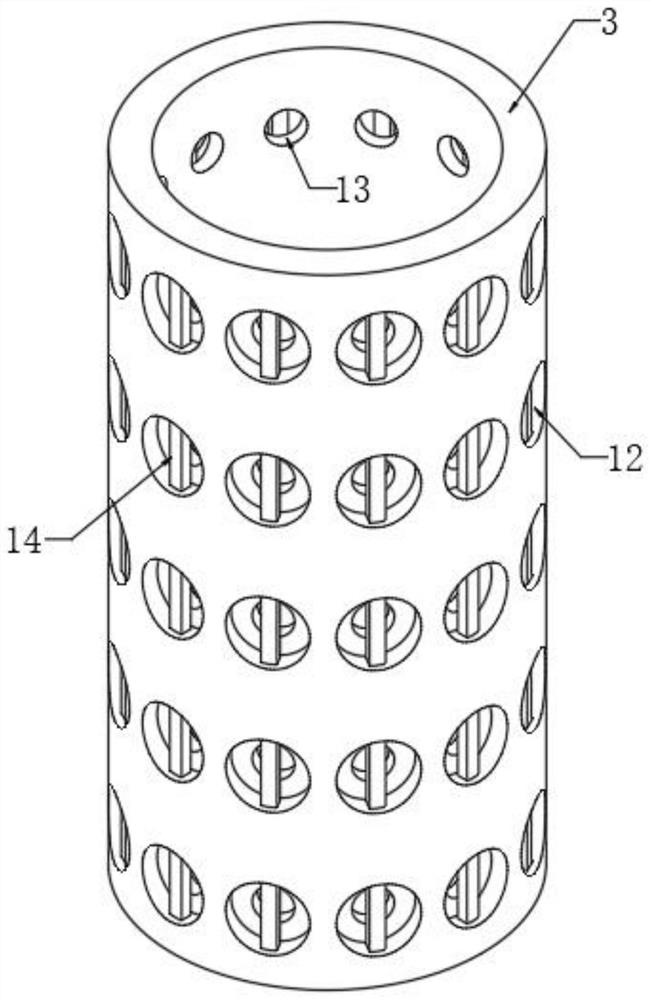

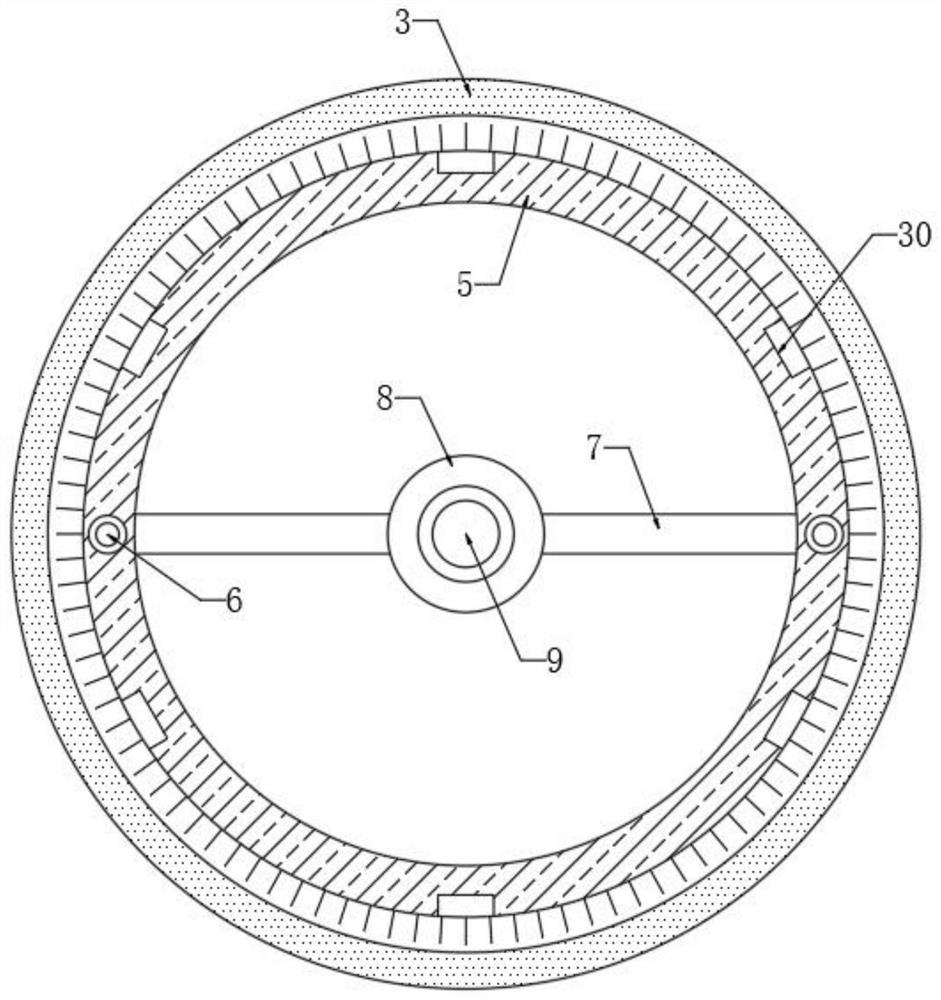

The invention discloses a centrifugal drum type sewage filtering and recycling device. The device comprises a base, wherein the upper end of the base is fixedly connected with an outer box body, the outer box body is internally and rotatably connected with a rotary drum box, the inner wall of the rotary drum box is provided with a plurality of filtering holes, the inner bottom of the outer box body is fixedly connected with a driving motor, an output shaft of the driving motor is fixedly connected to the lower end of the rotary drum box, a mud scraping ring is slidably connected to the interior of the rotary drum box, and a plurality of bristles are fixedly connected to the circumferential outer wall of the mud scraping ring. Kinetic energy generated when the rotary drum box rotates is used for driving the sludge scraping ring to continuously rotate, under the cooperation of a reciprocating lead screw and a lead screw nut, the sludge scraping ring can move up and down in a reciprocating mode, so that sludge thrown to the inner wall of the rotary drum box is scraped off, and the situation that the sludge is accumulated on the inner wall of the rotary drum box and blocks the filtering holes is prevented; in this way, high sewage filtering efficiency can be kept without shutdown cleaning, and compared with a traditional treatment means, water resources are saved, and the overall sewage treatment efficiency is improved.

Owner:XIANGTAN HUIBO CENTRIFUGE

Online detection device for sulfur hexafluoride gas of high-altitude circuit breaker and detection method

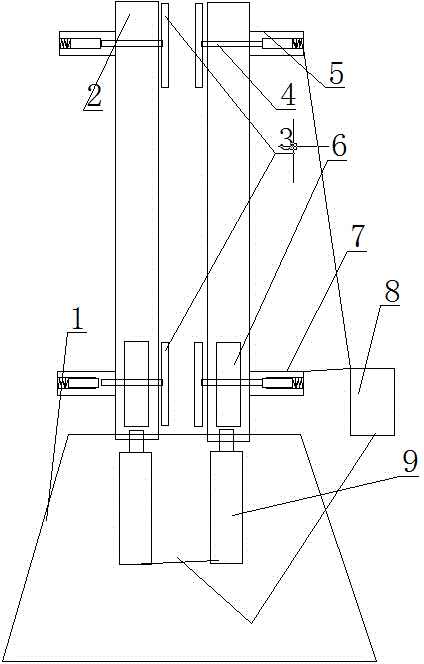

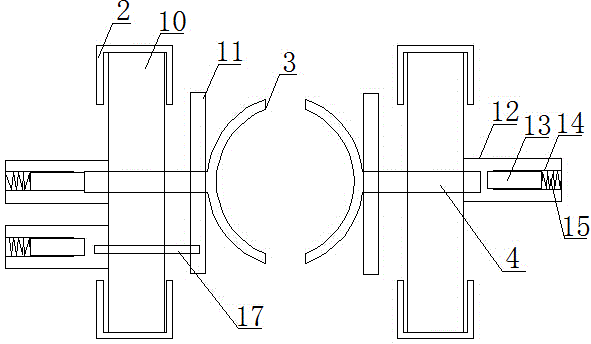

InactiveCN104165973AReduce resistancePrevent slipping outMaterial analysisSulfur hexafluoridePower equipment

The invention discloses an online detection device for sulfur hexafluoride gas of a charged high-altitude circuit breaker and a detection method. The online detection device comprises a frame body with universal self-locking roller wheels at the bottom part and a plurality of operating rods, wherein the frame body is provided with two symmetrical sliding-way mechanisms; each sliding-way mechanism comprises two sliding rails symmetrically arranged on the frame body; a sliding block is arranged between the sliding rails; a limiting block is arranged between the upper parts of the two sliding rails and is provided with an angle and tightness adjusting mechanisms of the operating rods; the sliding block is provided with a tightness adjusting mechanism of the operating rods; the frame body is internally provided with an electric pushing-pulling rod connected with the sliding block; and one end of each operating rod is provided with a detecting mechanism. The online detection device and the detection method disclosed by the invention have advantages that the pointing angles of the operating rods are conveniently adjusted, and convenience is brought for online horizontal-vertical detection of high-altitude power equipment with 360-degree rotation by maintainers.

Owner:STATE GRID HENAN FANGCHENG POWER SUPPLY CO

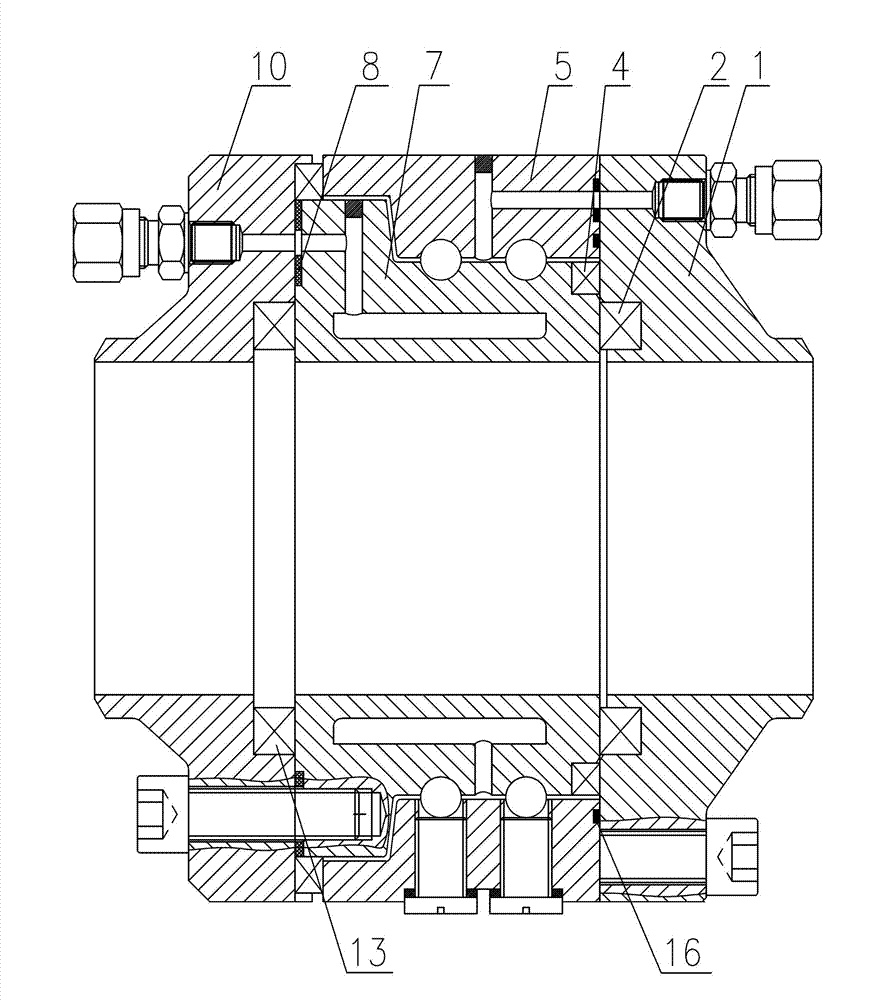

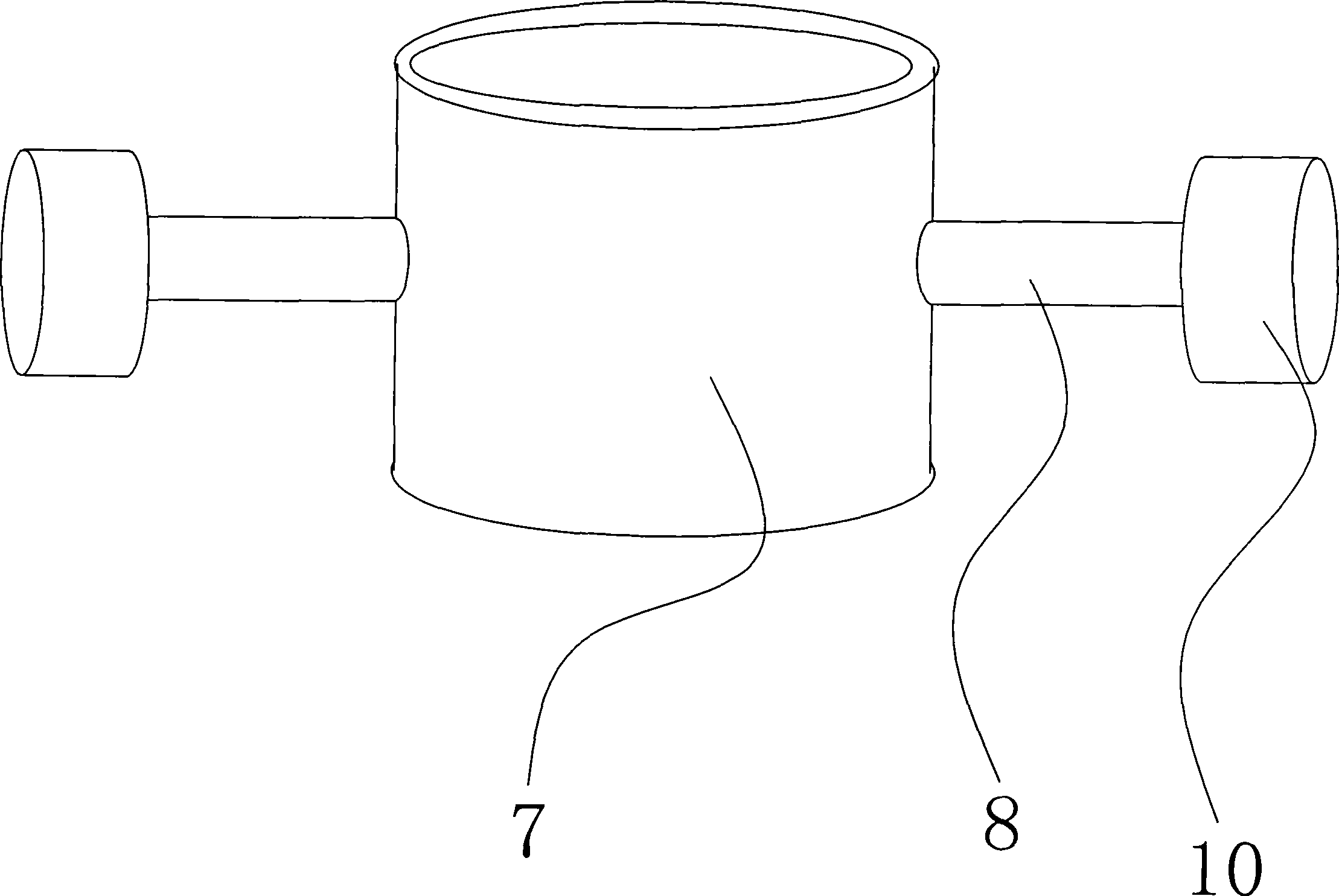

Motive seal swivel joint for entrucking low-temperature LNG (liquefied natural gas)

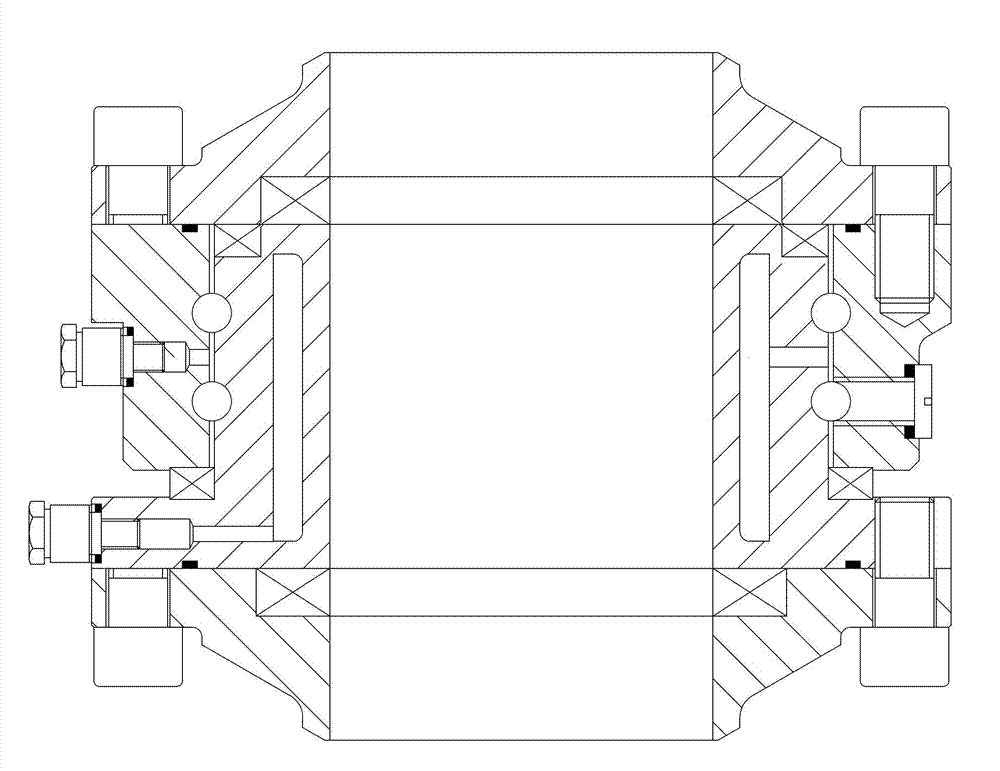

The invention discloses a motive seal swivel joint for entrucking low-temperature LNG (liquefied natural gas), which is not easy to leak the LNG, and comprises a left flange and a right flange, wherein the left flange is connected with an inner ring to form a left rotating member; the right flange is connected with an outer ring to form a right rotating member; the left rotating member and the right rotating member can be relatively rotated; a driving sealing ring is arranged between driving sealing ring grooves arranged at the right side of the inner ring and the left end face of the right flange; and a seam allowance for stopping the slide of the driving sealing ring is arranged on the driving sealing ring groove arranged on the right flange left end face. The seam allowance is added at the driving sealing ring groove to be a semi-open groove so as to prevent that the leaked LNG can push the driving sealing ring to a runner after expansion, thereby avoiding the failure of sealing. The motive seal swivel joint has better sealing performance.

Owner:JIANGSU CHANGLONG PETROCHEM EQUIP

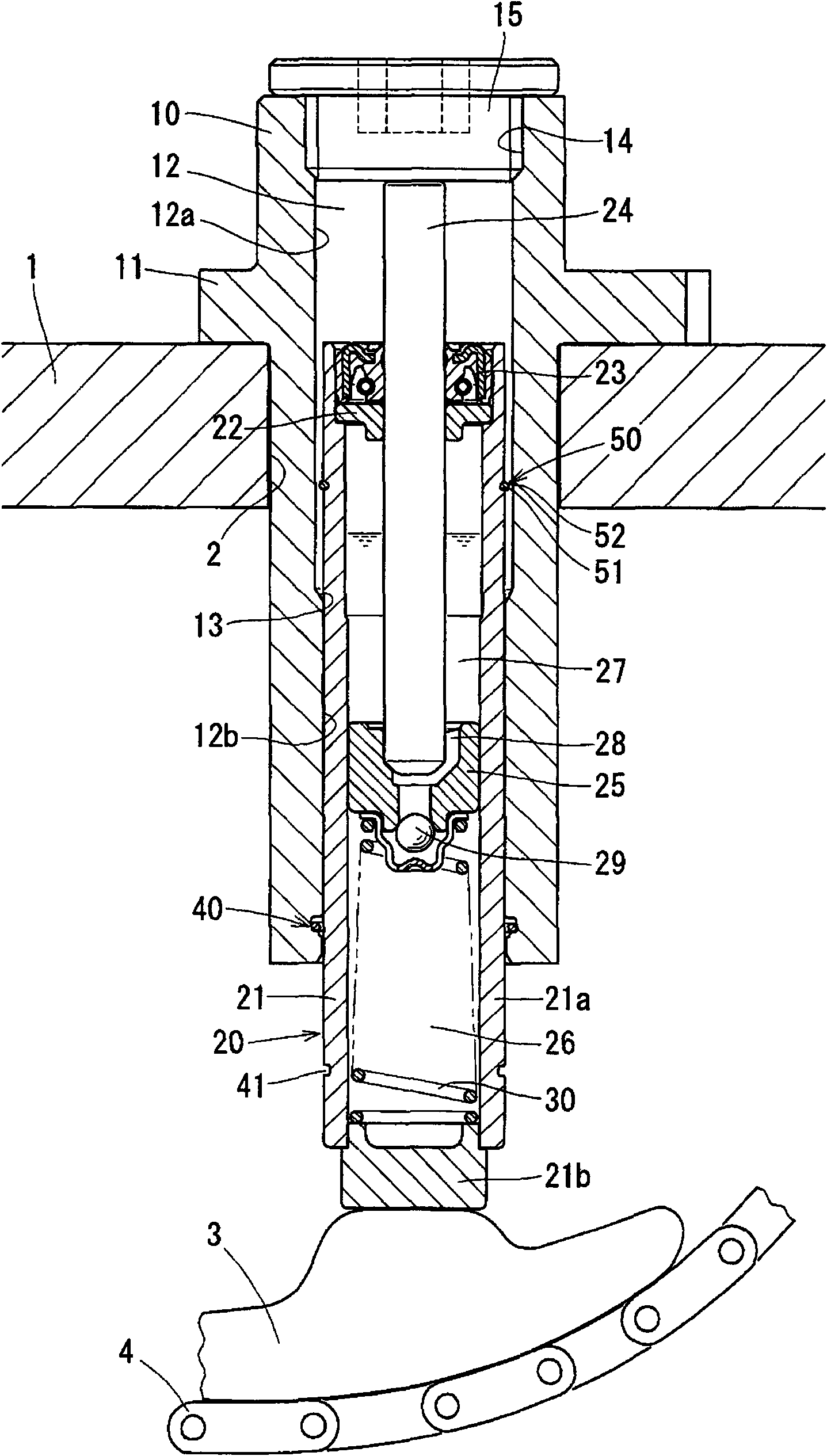

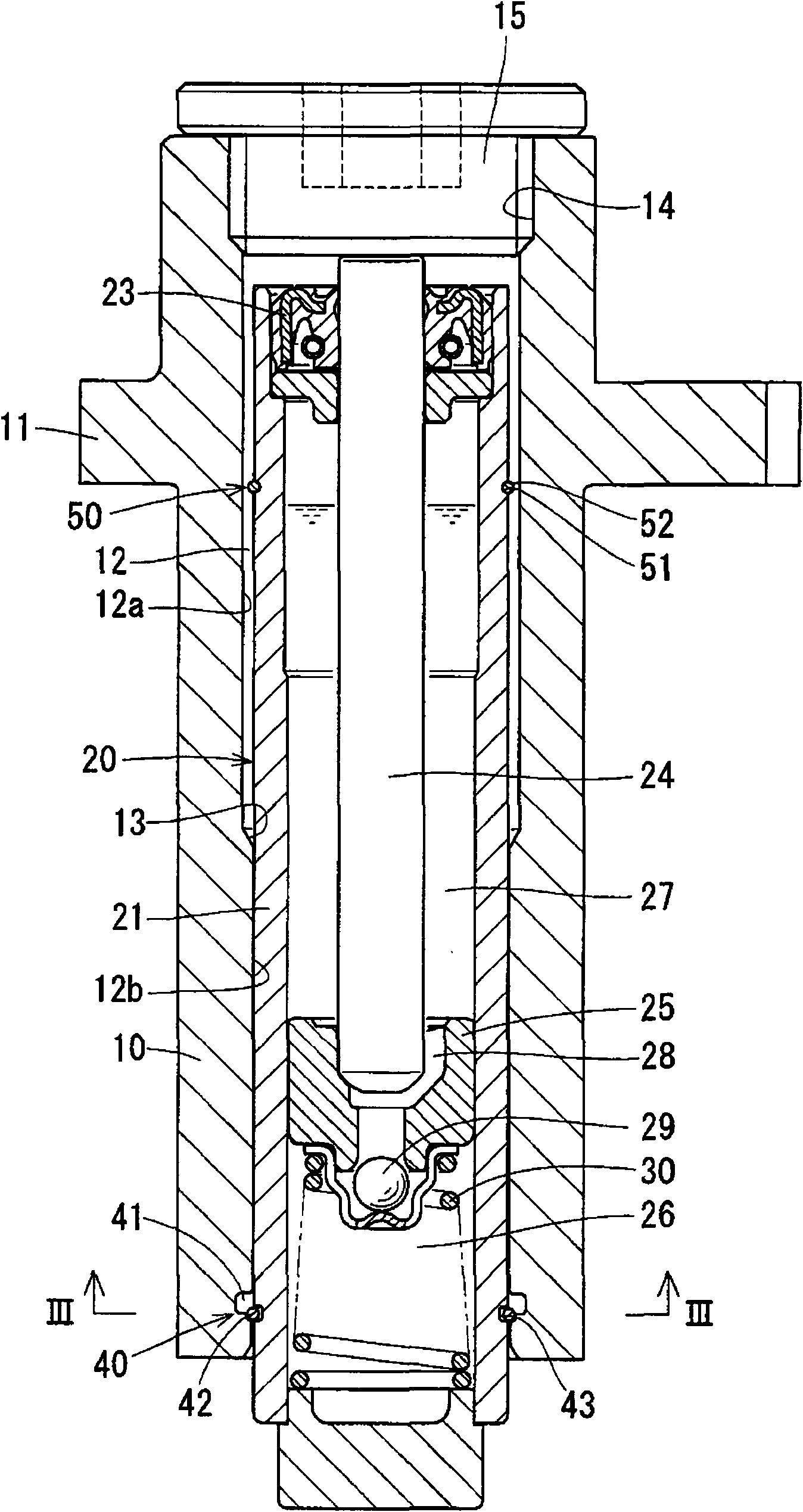

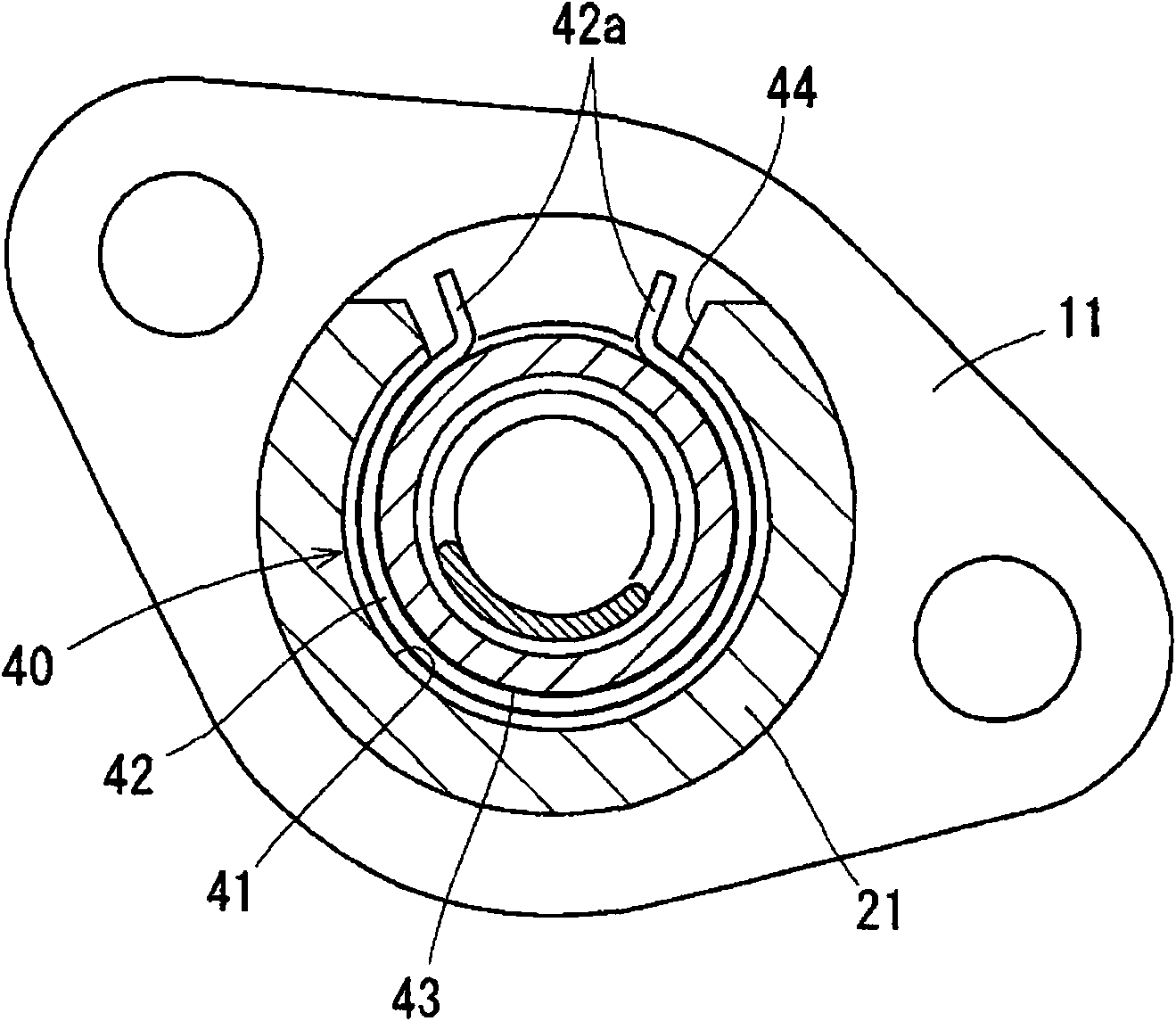

Oil pressure sealing type chain tightener

InactiveCN102128239AAdjust the elasticityPrevent disengagementGearingEngineeringMechanical engineering

The present invention provides an oil pressure sealing type chain tightener which can exert a downward adjusting force to the chain. An oil pressure sealing type tightening unit (20) is slidably mounted in a guiding hole (12) which is provided on a housing (10) of a chain cover (1). The oil pressure sealing type tightening unit (20) keeps a tension of the chain (4) to a constant value through the extension and contraction of a rod (24). The rod (24) slidably passes through a cylinder (21) and a sealing component (23). An upper opening of the cylinder (21) is sealed through mounting the sealing component (23). An upper end of the rod (24) of the tightening unit (20) is propped by a lower surface of a head cover (15) that closes the guiding hole (12). Furthermore a chain guiding part (3) is slidably pressed by the bottom of a cylinder (21) that is supported by the housing (10) for keeping the tension of the chain (4) constant.

Owner:NTN CORP

Coop rack for laying hen breeding

Owner:贵州省黄平县勤坡丰俊生态养殖有限公司

Laser composite manufacturing furnace winding roller high-temperature-oxidation-resistant and press-in nodulation-resistant functional layer alloy material and process method

PendingCN113564587AImprove high temperature red hardnessPrevent pushMetallic material coating processesCarbideOxidation resistant

The invention belongs to the technical field of surface treatment, and particularly relates to a laser composite manufacturing furnace winding roller high-temperature-oxidation-resistant and press-in nodulation-resistant functional layer alloy material and a process method. The laser composite manufacturing furnace winding roller high-temperature-oxidation-resistant and press-in nodulation-resistant functional layer alloy material comprises the following components in percentage by mass: 1.5%-2.5% of C, 20.0%-30.0% of Cr, 5.0%-10.0% of Ta, 5.0%-10.0% of Al, 0.5%-1.0% of Y, 0.5%-1.0% of Si and the balance of Co. According to the laser composite manufacturing furnace winding roller high-temperature-oxidation-resistant and press-in nodulation-resistant functional layer alloy material, cobalt-based alloy serves as a base body, Ta is added, C is added, high-hardness carbide is formed, the high-temperature red hardness of the alloy is improved, meanwhile, Al is added, a high-temperature oxidation film is formed, then a proper amount of Si element is added to improve the oxidation resistance, the Y element can refine the structure, and the Cr element improves the high-temperature corrosion resistance of the surface of a furnace winding roller.

Owner:沈阳大陆激光先进制造技术创新有限公司

child-resistant pen

Owner:扬州华创塑业有限公司

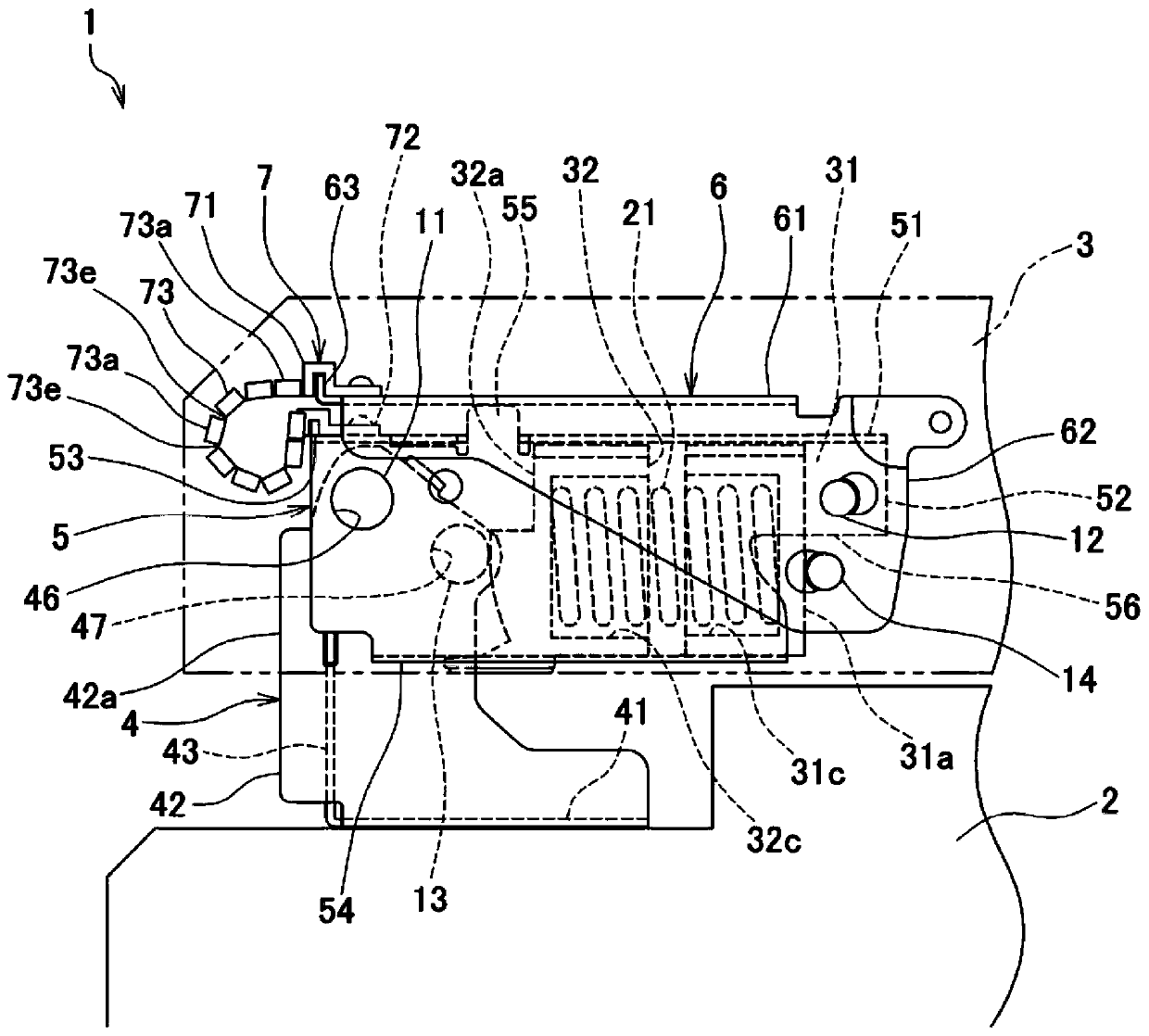

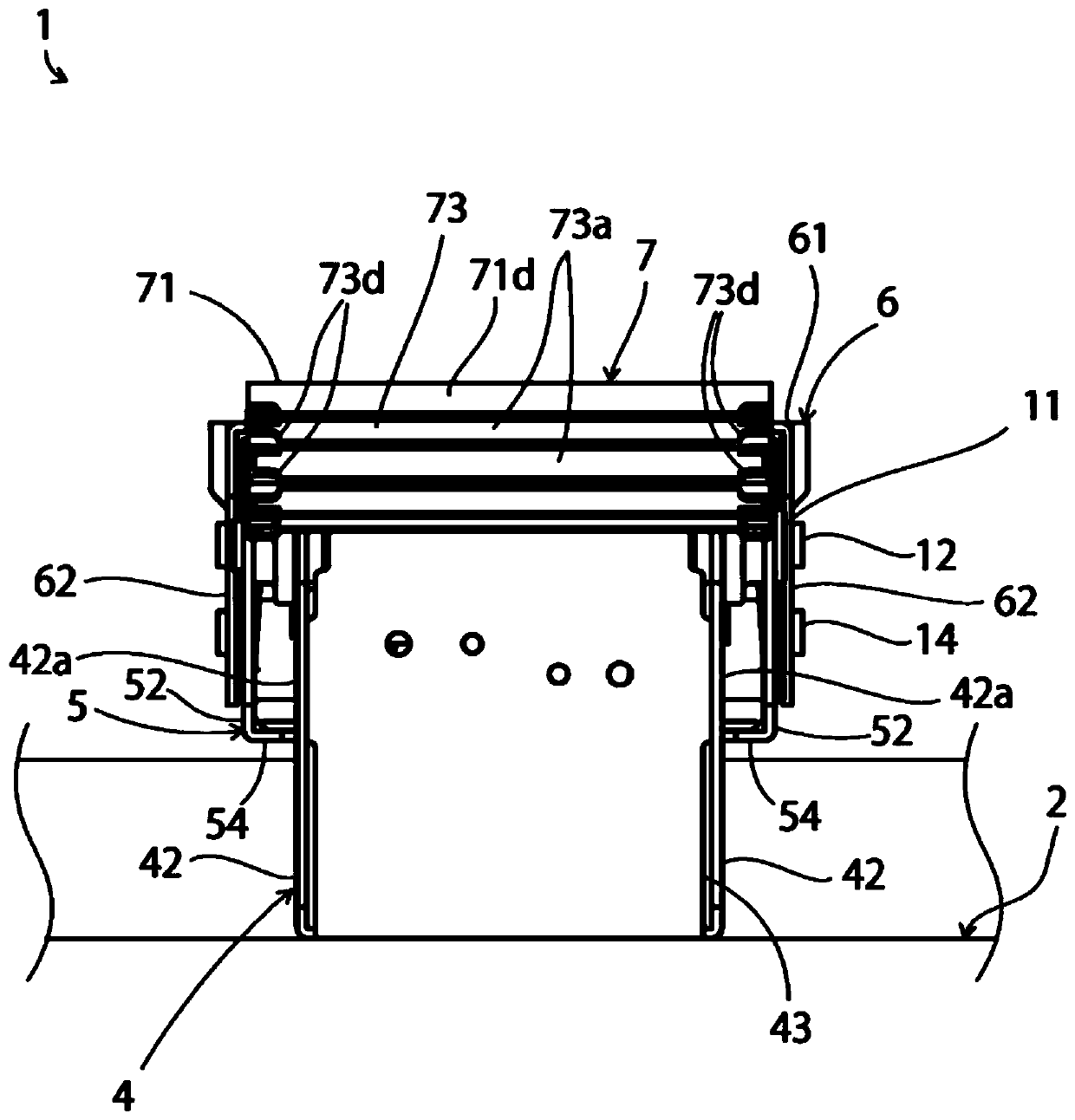

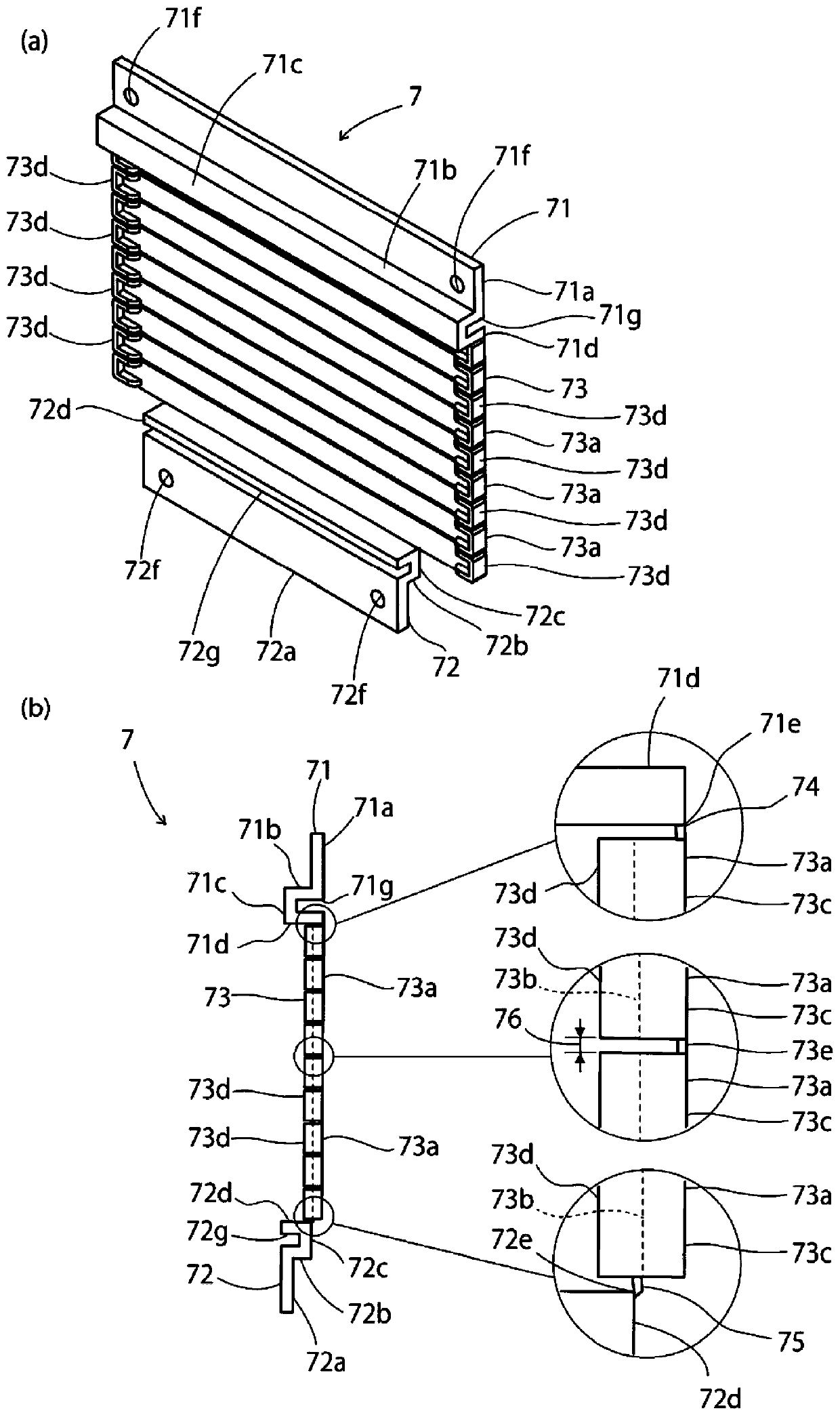

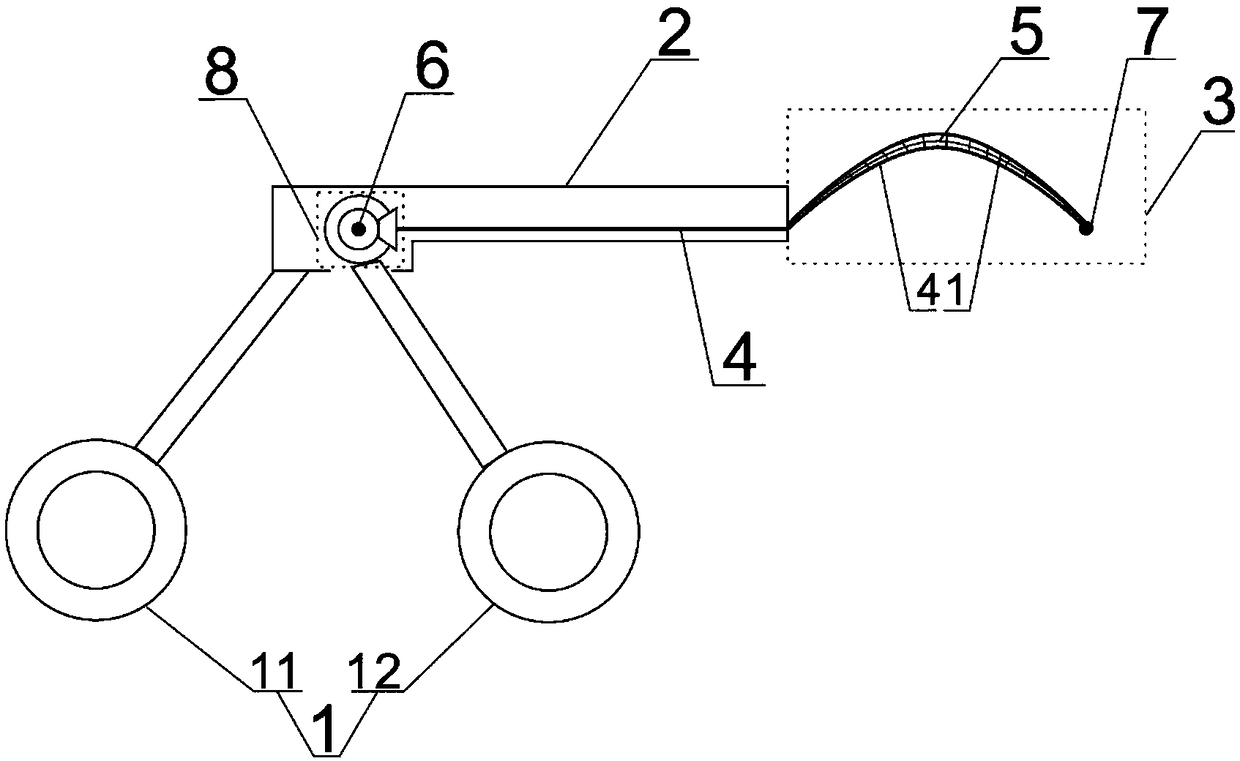

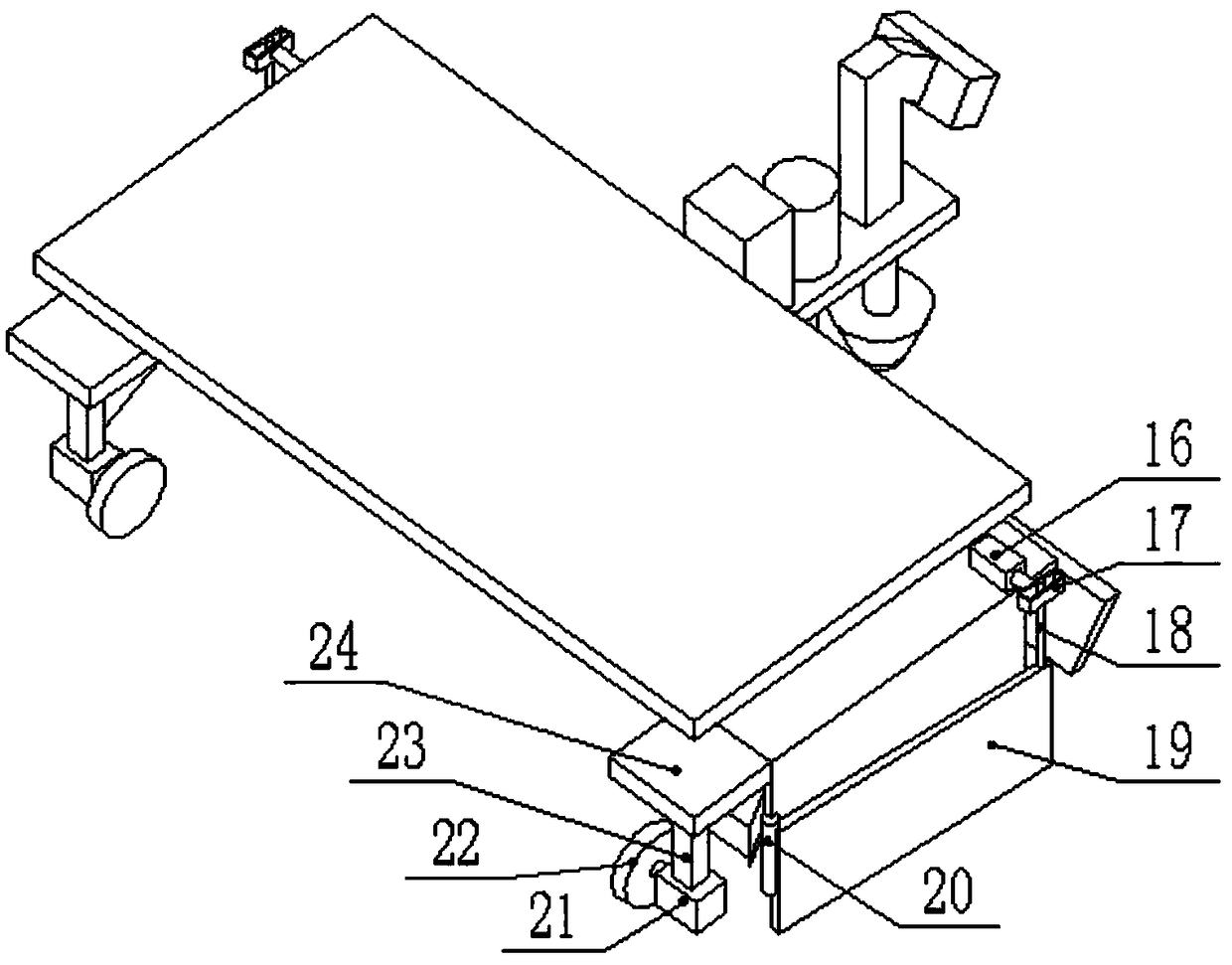

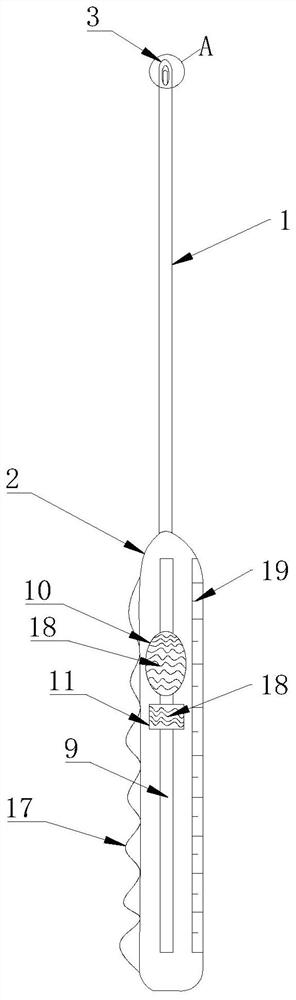

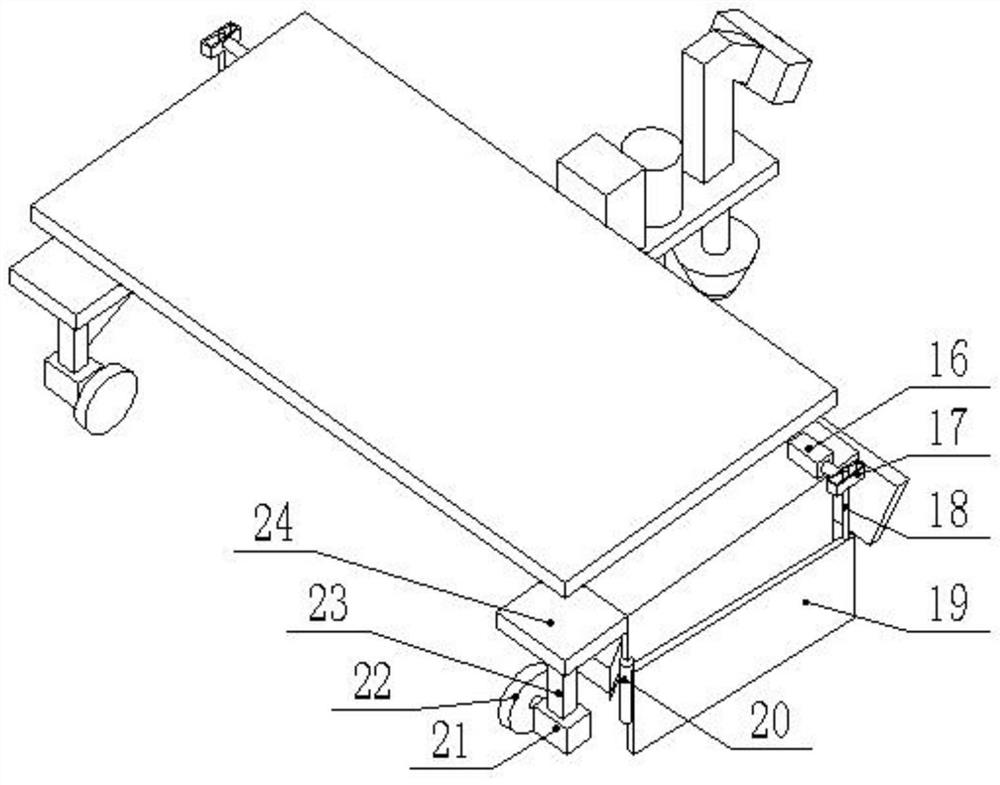

Manuscript pressing plate opening and closing device and office machine including the same

ActiveCN111381473APrevent intrusionAvoid injuryElectrographic process apparatusStructural engineeringMachine

Provided are a manuscript pressing plate opening and closing device and an office machine including the same, which can prevent fingers from being caught in the space between a lifting member and a supporting member and being injured. The manuscript pressing plate opening and closing device 1 includes: a mounting member 4, which is installed on the device body 2 side of the office machine having amanuscript pressing plate 3; a supporting member 5, which is rotatably pivotally supported on the mounting member 4 via a first hinge shaft 11; and a lifting member 6, which overlaps the supporting member 5, is pivotally supported on the free end side of the supporting member 5 via a second hinge shaft 12 in a direction opposite to the supporting member 5, and is installed on the manuscript pressing plate 3, wherein in order to block the space formed between the lifting member 6 and the supporting member 5 when the lifting member 6 rotates in the opposite direction to the supporting member 5,an anti-pinching mechanism 7 is arranged between the lifting member 6 and the supporting member 5 or the mounting member 4 or the first hinge shaft 11.

Owner:KEM HONGKONG

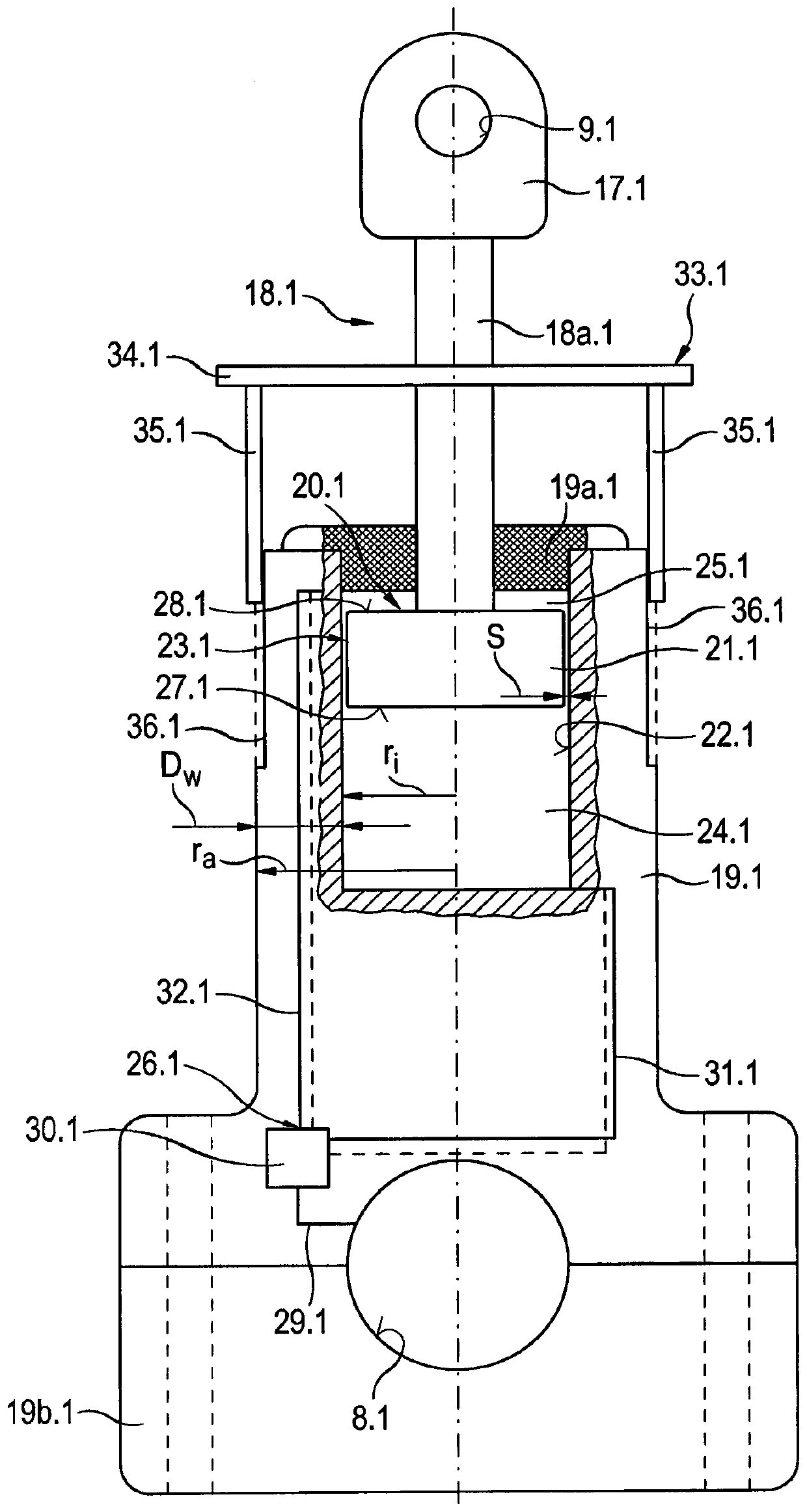

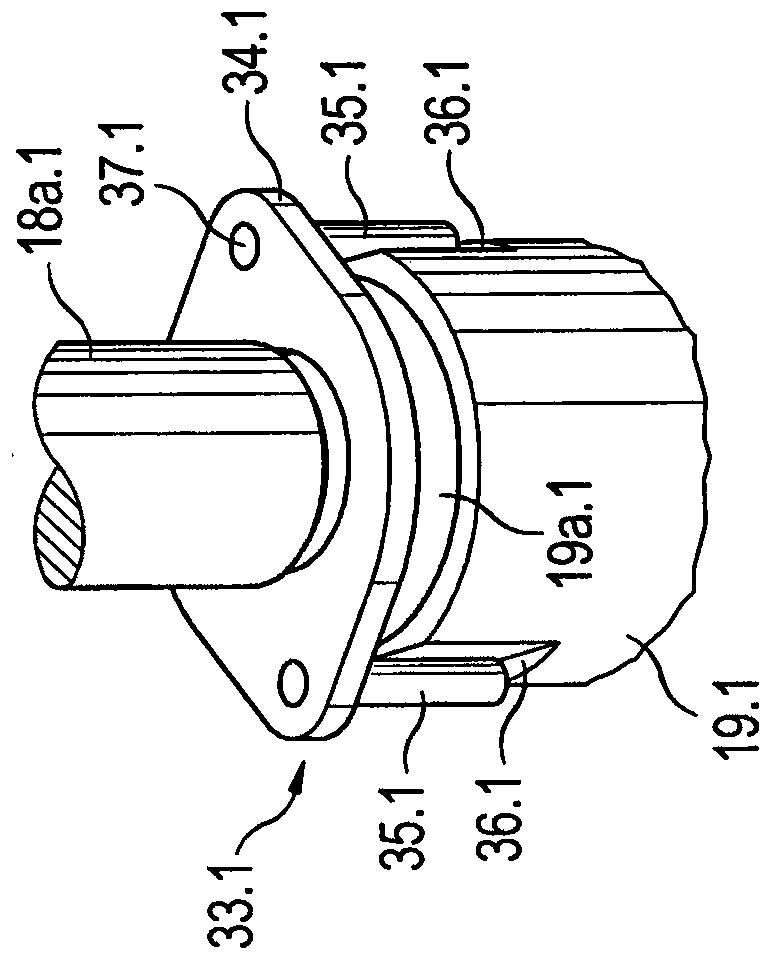

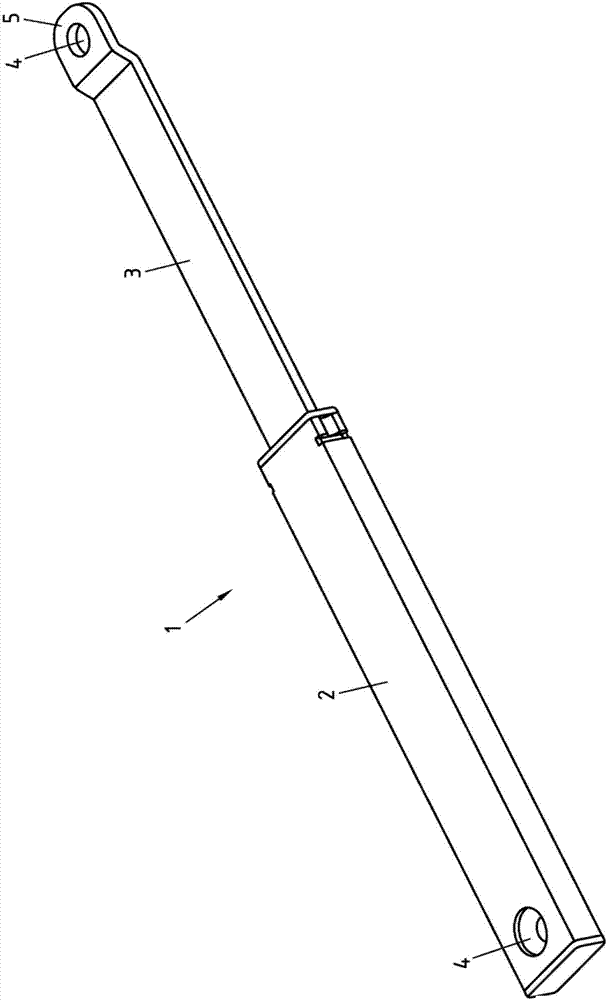

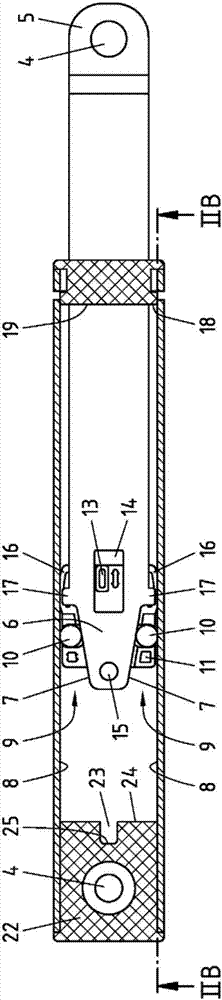

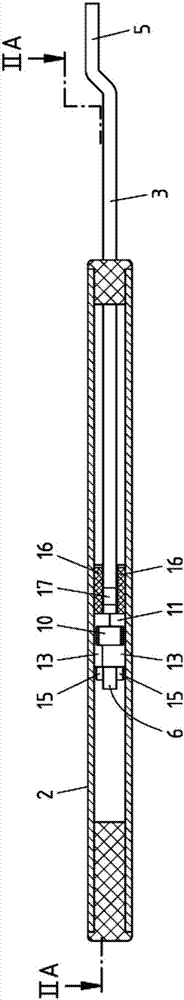

Longitudinally-adjustable connecting rod with cylinder-piston unit with rotational locking

ActiveCN110799739APrevent twistingMinimize residual clearanceConnecting rodsEngine controllersEngineeringInternal combustion engine

The invention relates to a longitudinally-adjustable connecting rod for an internal combustion engine. The rod comprises a first connecting rod part, a second connecting rod part and at least one cylinder-piston unit for controlling the first connecting rod part relative to the second connecting rod part. The cylinder-piston unit comprises a housing with a cylinder bore, an adjusting piston that can be longitudinally moved in the cylinder bore, at least one pressure chamber provided in the cylinder bore, and a rotation-lock device. The rotation-lock device for fixing the angular position of the piston pin to the crankshaft journal is arranged on the first connecting rod part and extends with at least one securing arm in the longitudinal direction along a guide on the second connecting rodpart. The invention also relates to an internal combustion engine comprising said type of longitudinally-adjustable connecting rod and to the use of said type of cylinder-piston unit for a longitudinally-adjustable connecting rod of an internal combustion engine.

Owner:IWIS MOTORSYSTEME GMBH & CO KG +1

Safety pen

The invention relates to a safety pen which comprises a pen holder, a pen case and a pen refill. The pen refill is arranged in the pen holder, a press rod capable of squeezing the pen refill out of the pen holder is arranged in the pen case, a projection is arranged on an inner ring of an opening of the pen case, a flange matched with the projection is arranged at the upper end of the outer side wall of the pen holder, an annular groove is formed in the pen refill, a flexible fixing part is matched with the annular groove and arranged in the groove, a first press rod is fixedly connected onto the flexible fixing part, the pen holder is provided with a first through hole matched with the first press rod, and the first press rod penetrates the first through hole and extends to the outside of the pen holder. A child can be prevented from opening a pen cap or pressing out the pen refill, and safety is high.

Owner:ZHONGSHAN VOCATIONAL & TECHNICAL COLLEGE

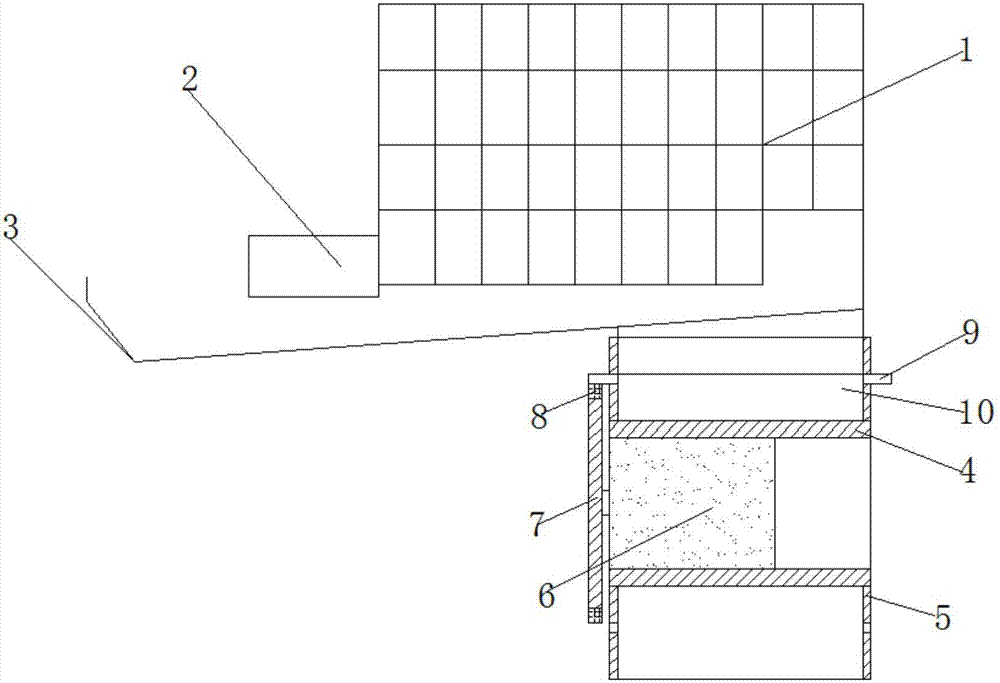

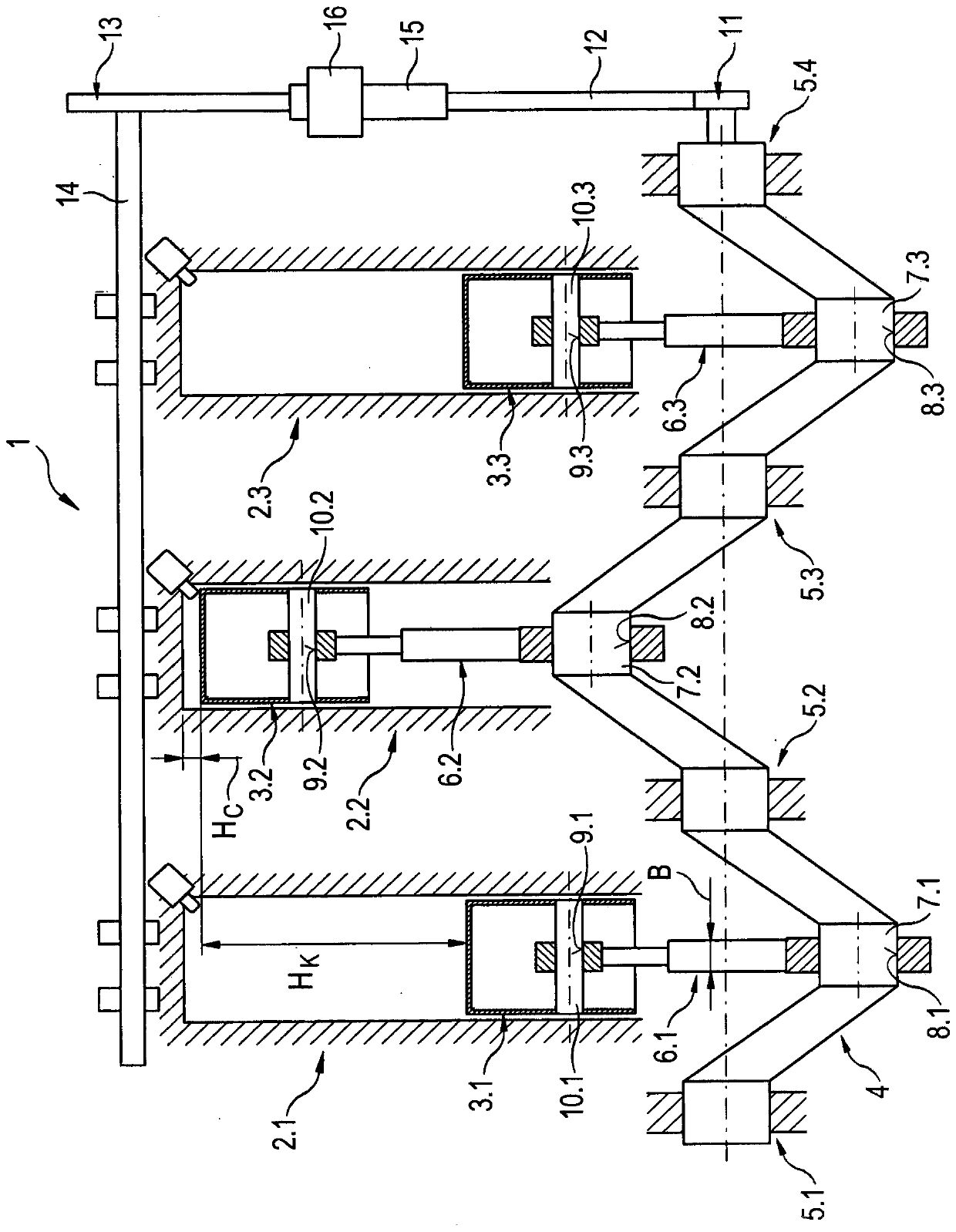

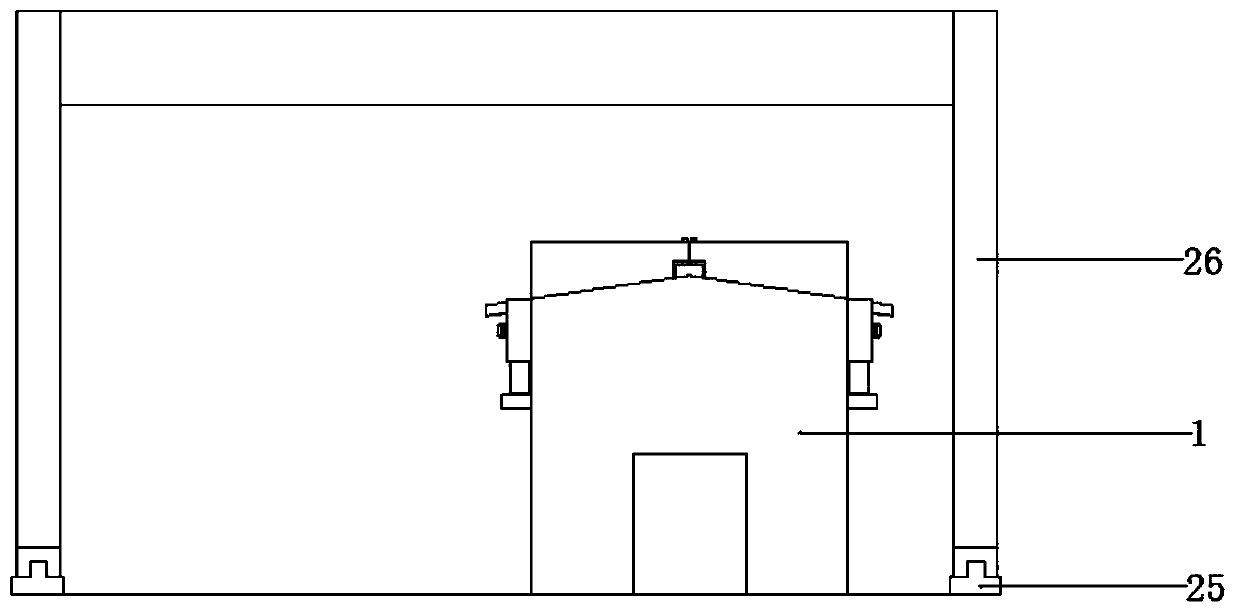

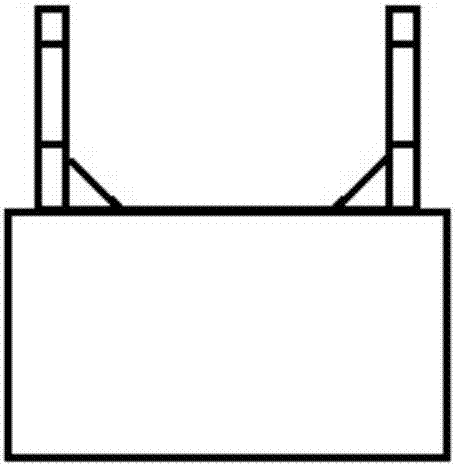

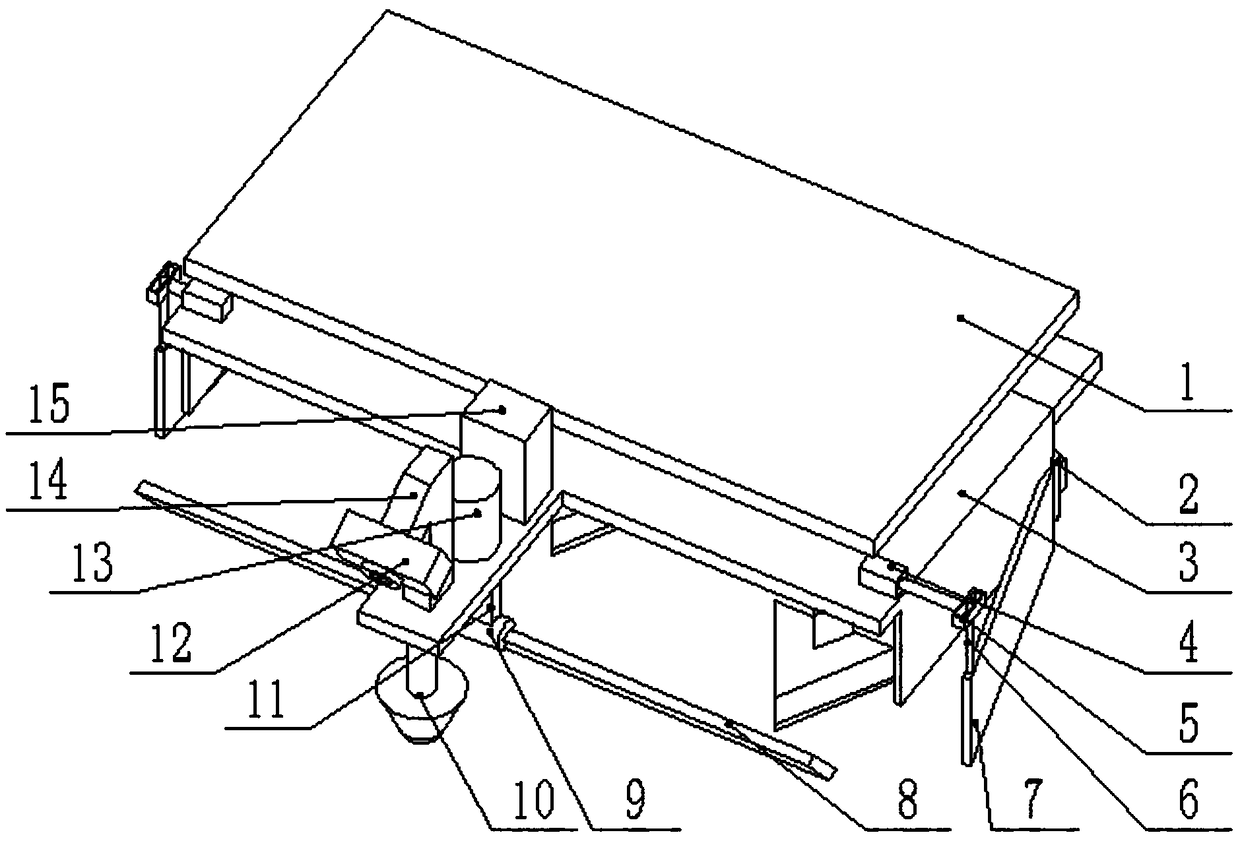

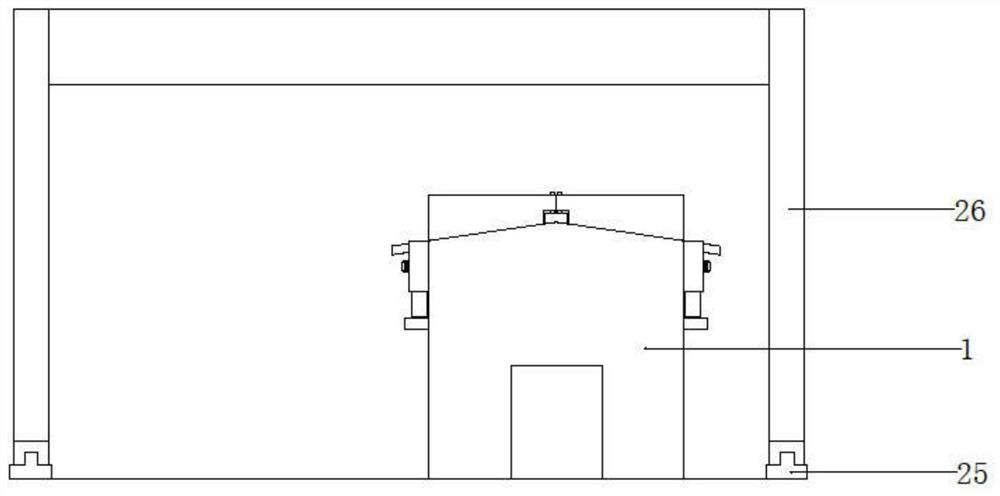

Factory building for industrial production of large components

The invention discloses a factory building for industrial production of large components. The factory building comprises a building body, a snow removing mechanism I and a snow removing mechanism II.The building body comprises a guide rail and a slide cover. A roof is provided with a plurality of hoisting ports that allow the large components to pass through. A fixing block is fixed to the side wall of the room body. Sliding grooves I are formed in the fixing block. Two ends of the guide rail are correspondingly in sliding connection with the two sliding grooves I. A connecting plate is fixedto the bottom of a sliding cover. A walking end beam is fixed to the bottom of the connecting plate and slides on the guide rail. A supporting beam is fixed to the side wall of the building body. A plurality of cylinders are distributed on the supporting beam. Piston rods of the cylinders are connected with the guide rail. A pair of baffles are arranged on two sides of the top of a lifting opening. The sliding cover can ascend, descend and slide. The lifting opening can be completely covered when the sliding cover is closed. The lateral side of the lifting opening is provided with a baffle. The edge of the lifting opening is wrapped with a sealing strip. Rain and snow can be prevented from entering the building body. When the sliding cover is opened, the lifting opening is exposed so thatthe large components can be lifted out by a gantry crane, and the snow removing mechanism I and the snow removing mechanism II can push the accumulated snow on the roof and the sliding cover.

Owner:CCCC SHEC FOURTH ENG

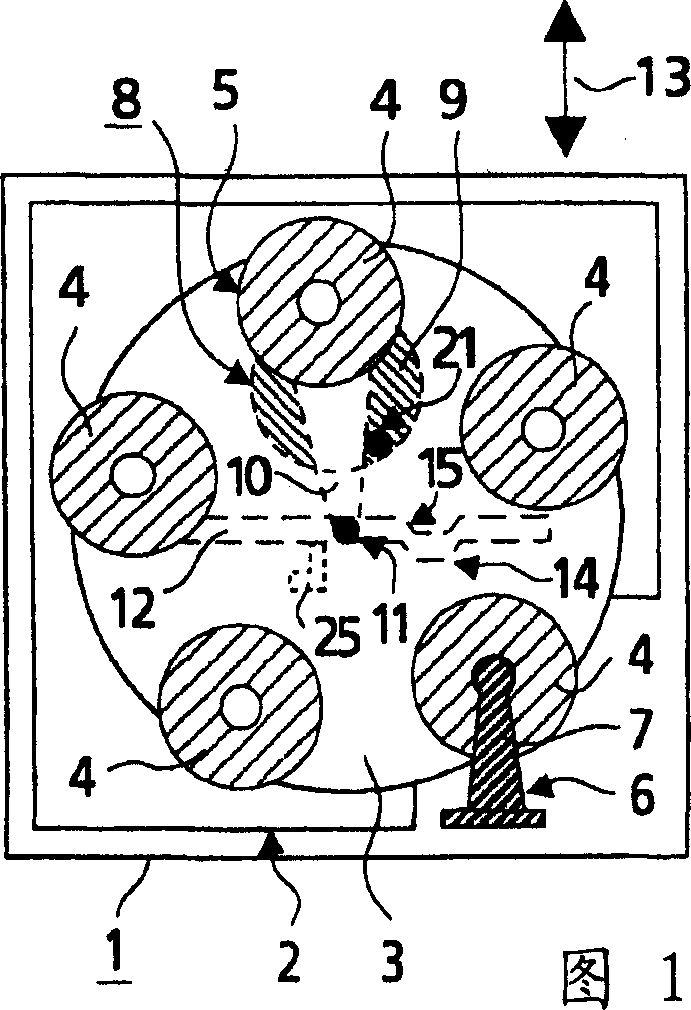

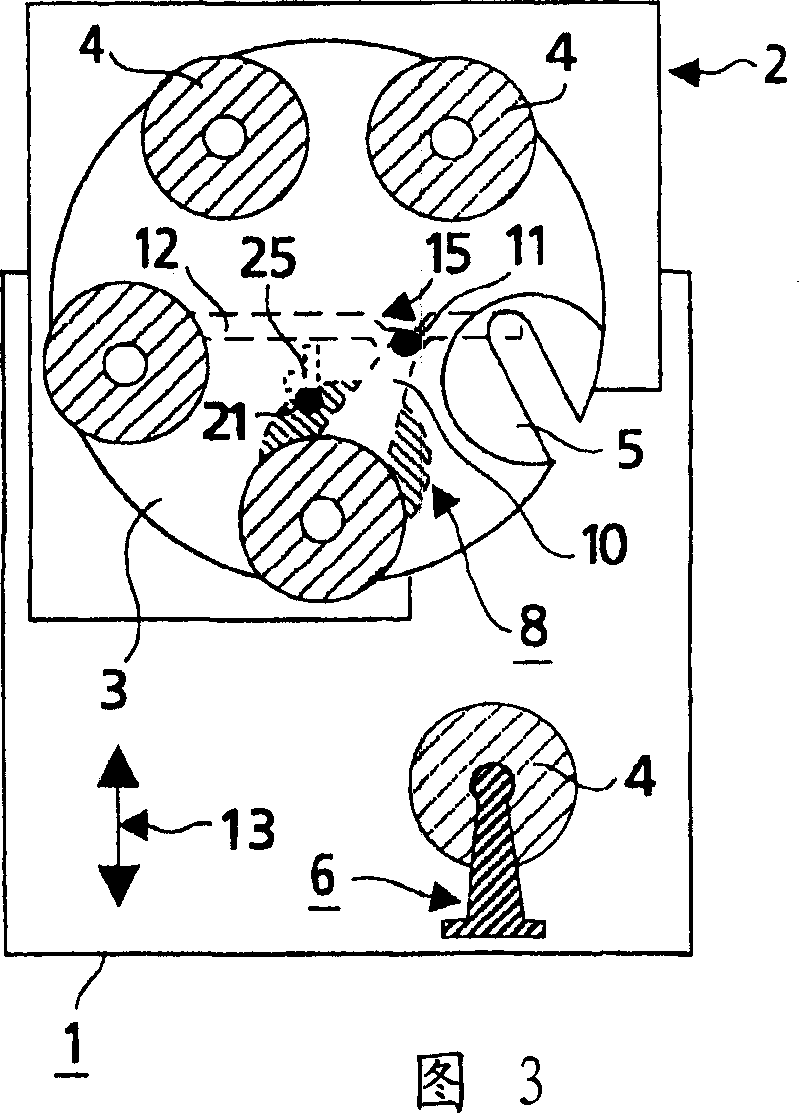

CD changing device

InactiveCN1492419APush to avoidAvoid collisionCarrier constructional parts dispositionRecord information storageEngineeringOptical recording

The present invention relates to a CD changer of the 'carousel type', in which three or five optical recording media, referred to below as disk, are arranged on a rotatable disk holder, the carousel. It has a drawer (2) which can be moved between a retracted and an extended position by a drawer movement mechanism (8). The object of the invention is to propose a solution which improves the functionality of the CD changer. It is proposed in the invention that the drawer has a stop (15, 25) which, in the extended position, bears against a pin (11, 21) of the drawer movement mechanism (8), and which, when force acts on the drawer (2), exerts on the drawer movement mechanism a force which is directed in the radial direction of said mechanism.

Owner:THOMSON LICENSING SA

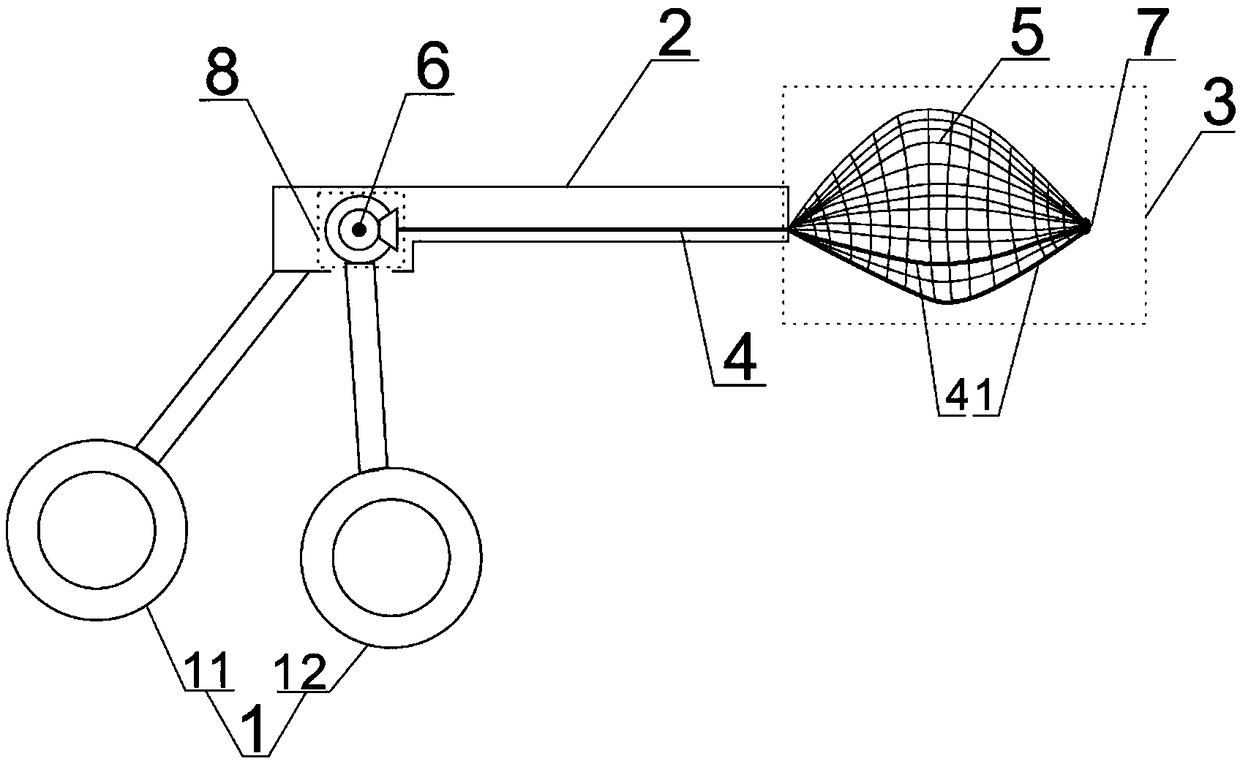

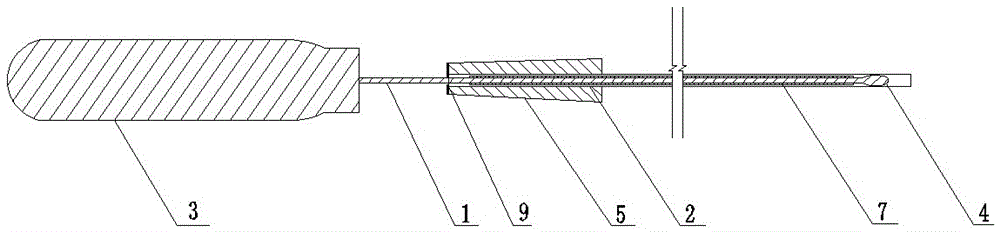

Nasal cavity foreign matter taking-out clamp

The invention relates to a nasal cavity foreign matter taking-out clamp, and belongs to the technical field of medical instruments. The problem that a circular foreign body in the nasal cavity in theprior art is difficult to take out is solved. The nasal cavity foreign matter taking-out clamp comprises a handle, a clamp body and a clamp head. The handle and the clamp body are in shaft connection.The clamp body is capable of allowing a steel wire to pass through. One end of the steel wire is connected with the handle, and the other end of the steel wire extends out of the clamp body and is connected with the clamp head. The clamp head can be opened or closed under the stretching of the handle. When the clamp head is opened, the clamp head is folded to be arc-shaped. When the clamp head isclosed, the clamp head unfolded to form a netty space. In this way, a circular foreign matter in the nasal cavity can be quickly and conveniently taken out, and the nasal cavity is prevented from being damaged. The pain of a patient is relieved. Meanwhile, the structure of the clamp head can be replaced. As result, one clamp is dedicated to one person, so that the clamp is convenient and sanitary.

Owner:PEOPLES HOSPITAL PEKING UNIV

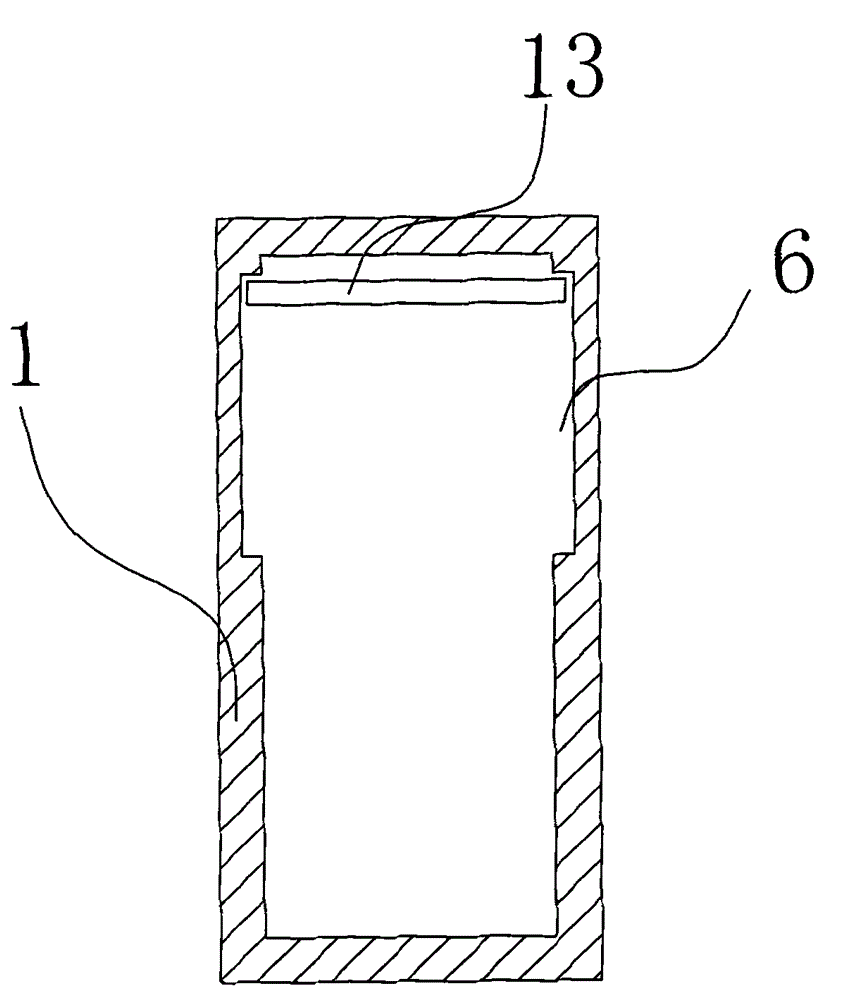

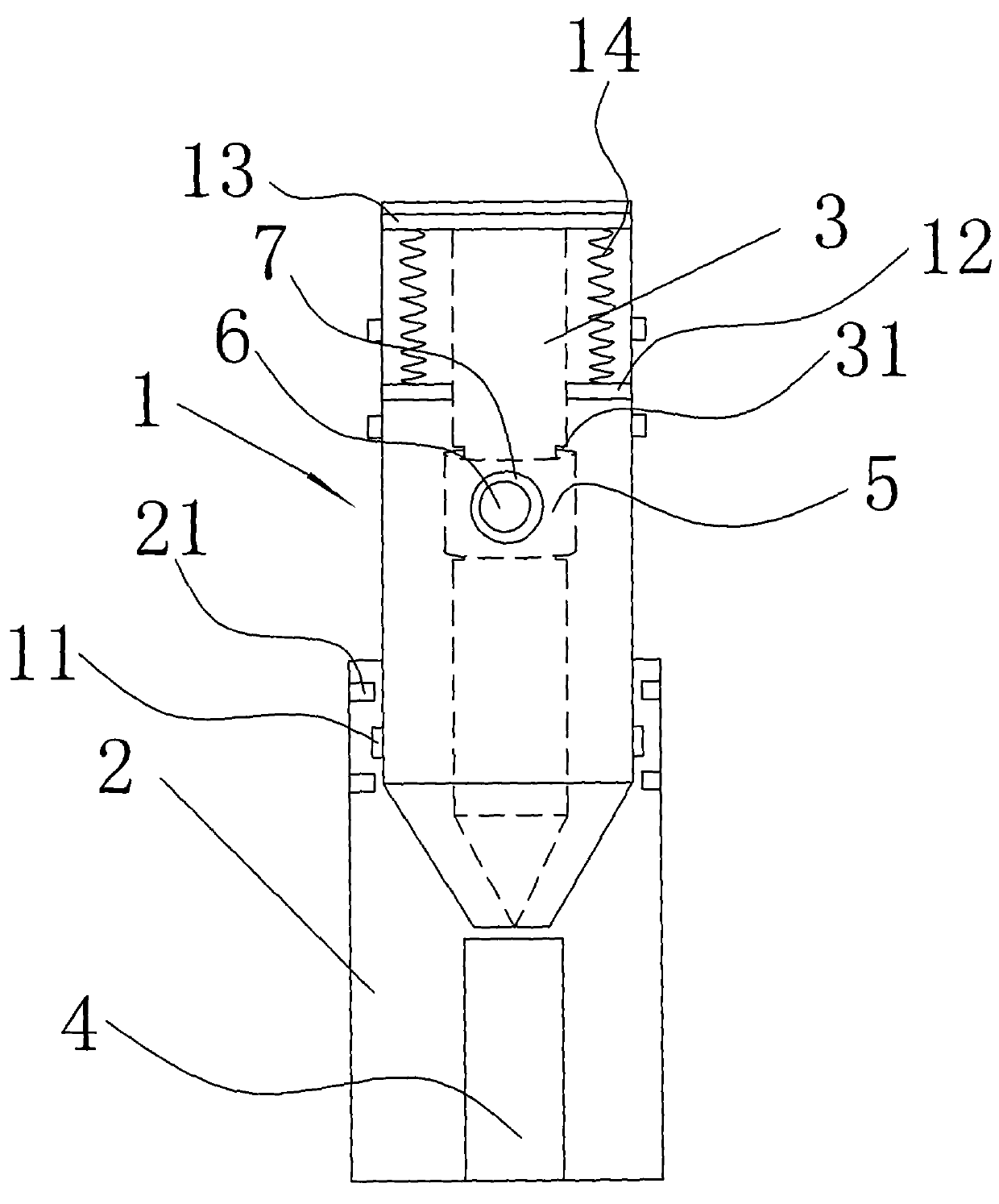

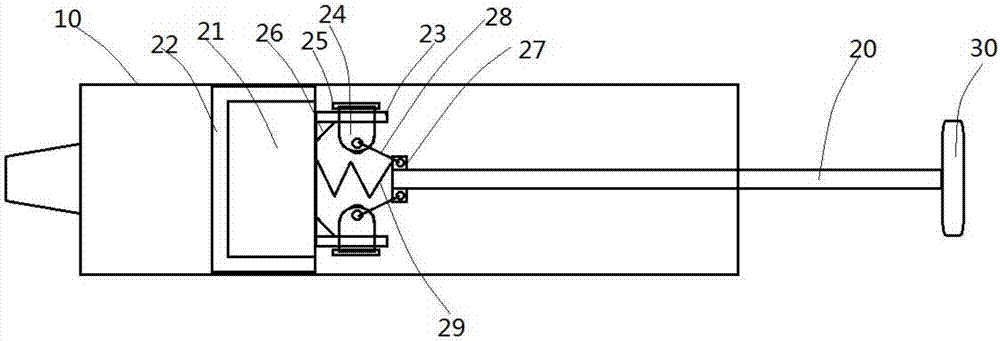

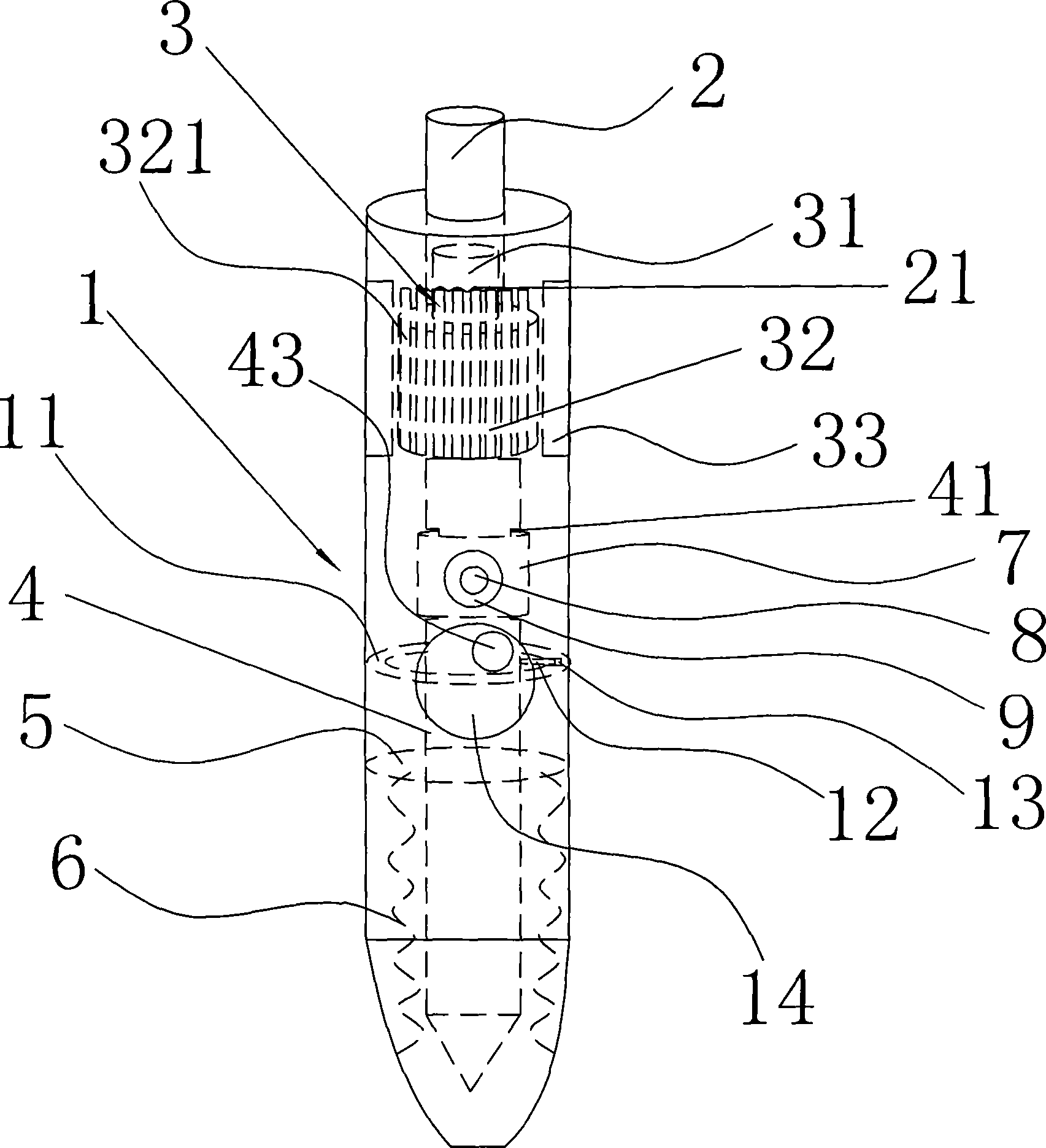

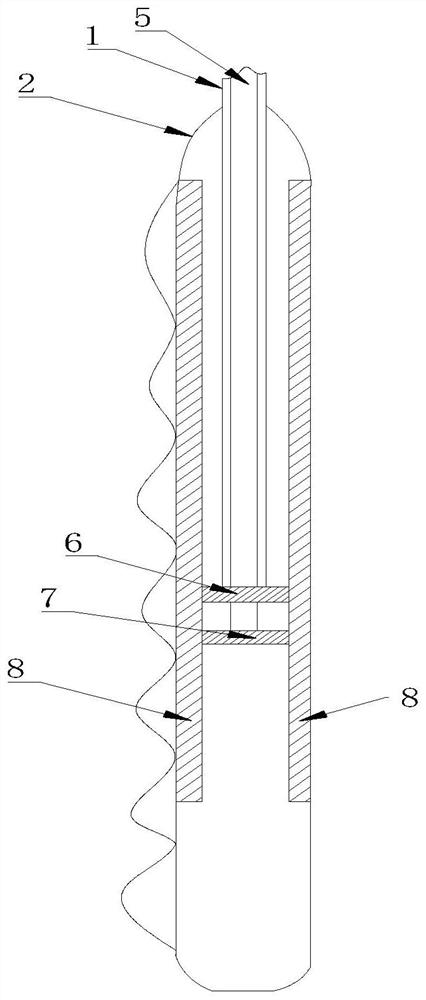

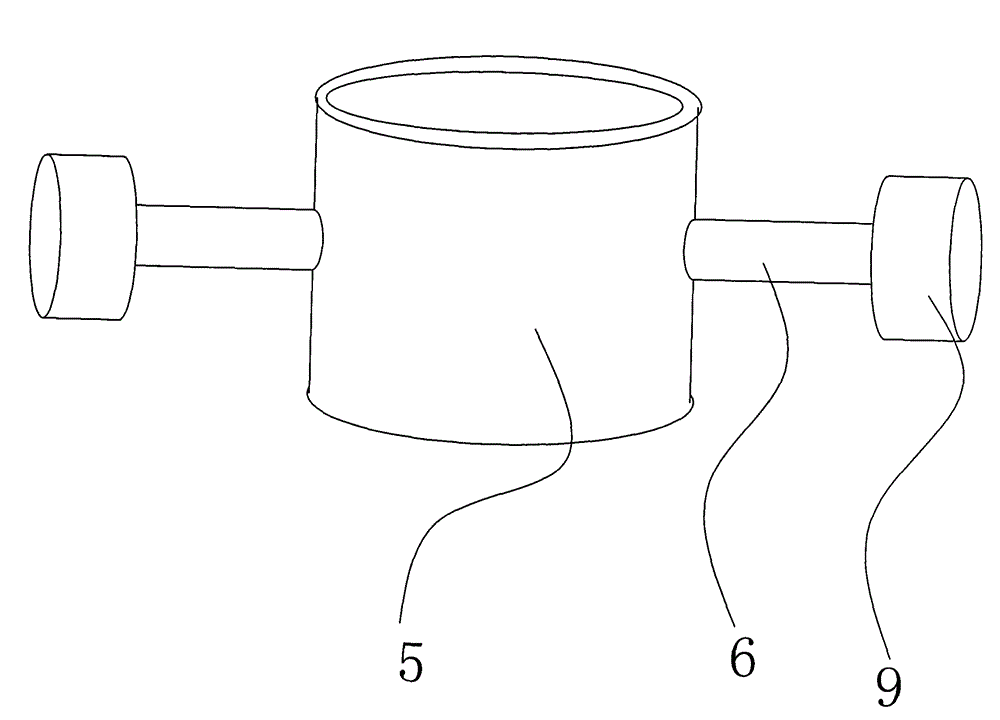

Nutrient solution pushing device

ActiveCN107157779APrevent pushIncrease sliding resistanceAgriculture gas emission reductionFeeding-tubesEngineeringStructural engineering

The invention discloses a nutrient solution pushing device, which comprises a drum body, a push rod, a piston head and sliding blocks, wherein the piston head comprises a seal sleeve and an inner core; the second end of the inner core is provided with at least one pair of supporting arms in a mode of extending outwards; each pair of the supporting arms of the at least one pair of supporting arms are arranged on parts, close to periphery of the inner core, in a mode of directly facing to each other; a guide hole is formed in each supporting arm; each sliding block is inserted into the corresponding guide hole in a sliding mode; friction soft pads are arrange at the first ends of the sliding blocks and first holes are formed in the second holes of the sliding blocks; at least one pair of branched sheets are formed at the first end of the push rod; each pair of the branched sheets of the at least one pair of branched sheets are formed at two opposite sides of the first end of the push rod; a second hole is formed in each branched sheet; one of the first holes is in correspondence to one of the second holes; a rigid connecting rod is connected between one of the first holes and one corresponding second hole; and a spring is further supported between the second end of the inner core and the first end of the push rod.

Owner:GENERAL HOSPITAL OF PLA

Head light component and integral safety hamlet provided with same

ActiveCN107559683ASimple structureEasy to installDomestic lightingElectric circuit arrangementsEngineeringMaterials science

The invention relates to a head light component. The head light component comprises a head light and a head light assembly base, wherein the head light assembly base is a cylindrical component with anopening at a front end; the head light is arranged in the head light assembly base; a baffle wall which extends radially is arranged at the opening of the head light assembly base; and the baffle wall is integrated with the head light assembly base. By adopting the structure, the head light component provided by the invention is higher in safety, adjustable in head light and tidy in appearance; the head light is prevented from sinking inside; the head light is adjustable; the appearance is tidy; and safety is higher.

Owner:董文茂

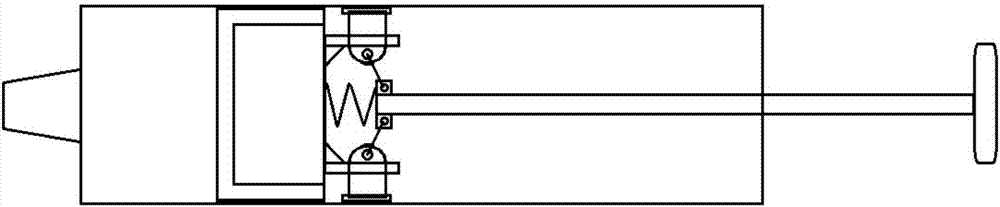

Ovarian tissue section pushing device

ActiveCN106344131ASave porting timeShort exposure timeMedical devicesObstetrical instrumentsEngineeringOvarian tissue

An ovarian tissue section pushing device comprises a pushing core and an outer tube, wherein the outer tube coaxially sleeves the outside of the pushing core; the length of the pushing core is greater than or equal to the length of the outer tube; one end of the pushing core is fixedly connected with a handle; a projection is arranged at the other end of the pushing core and is positioned in the outer tube; and the projection is in sliding fit with the outer tube in a sealed manner. The ovarian tissue section pushing device is simple in structure and convenient to use, and transplanting time of an ovarian tissue section is greatly saved; and because the exposure time of the ovarian tissue section out of the body is short, recovery of an ovarian tissue and fertility of a postoperative patient is facilitated.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

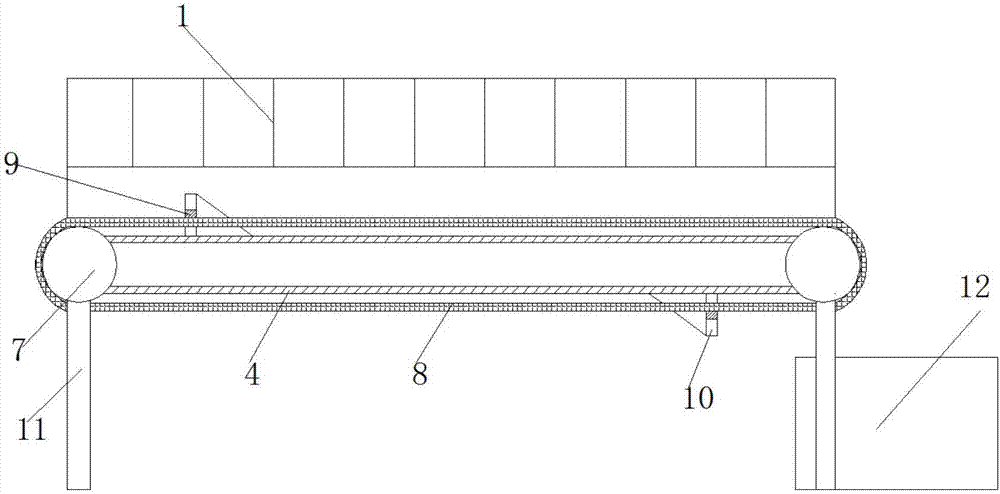

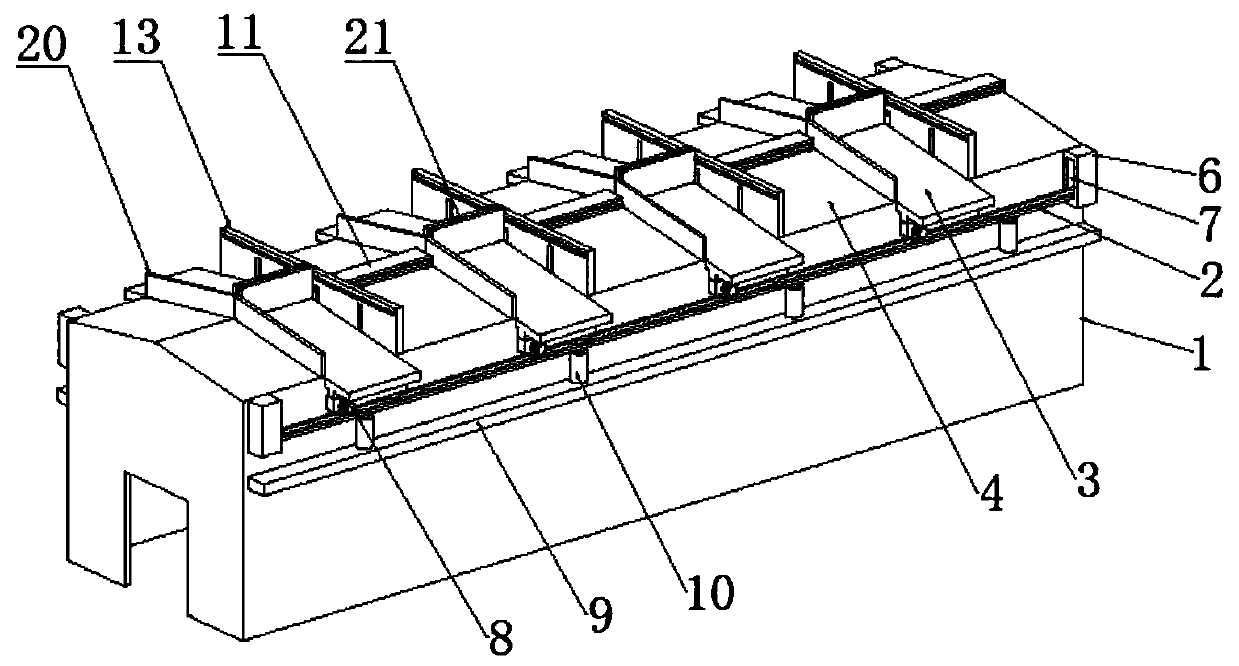

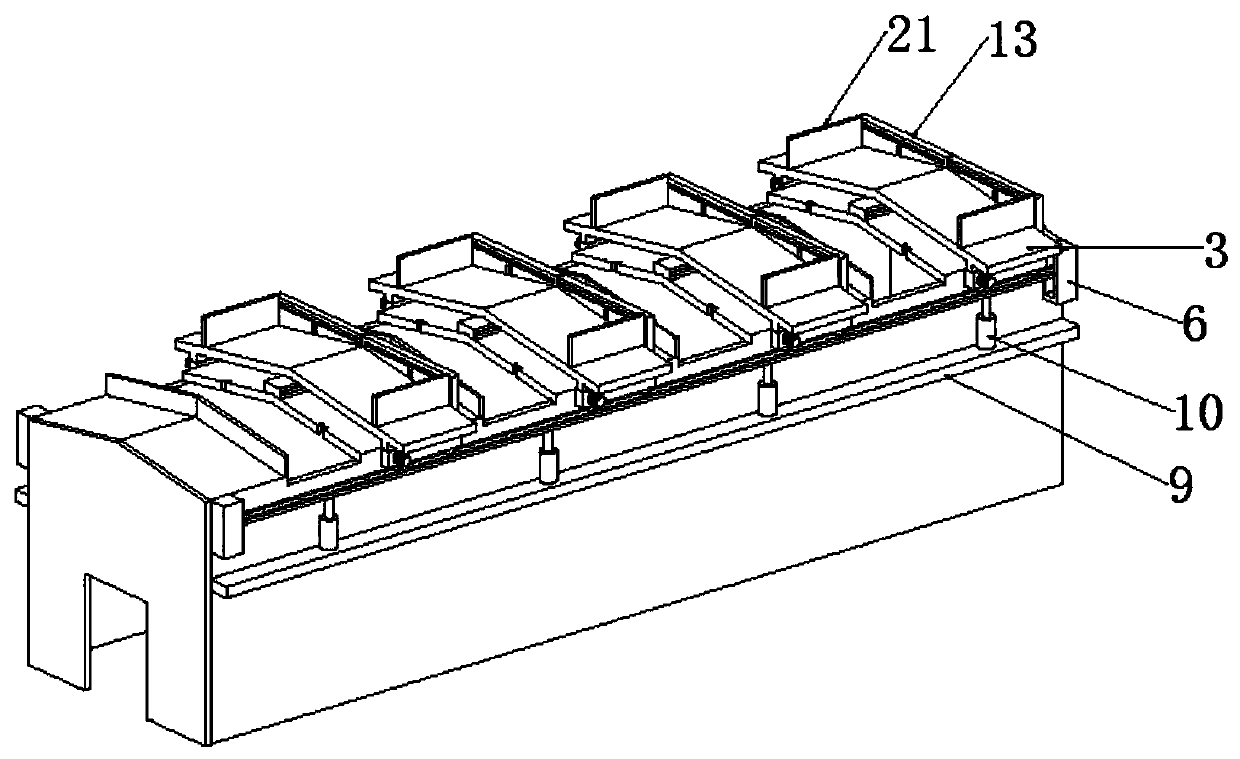

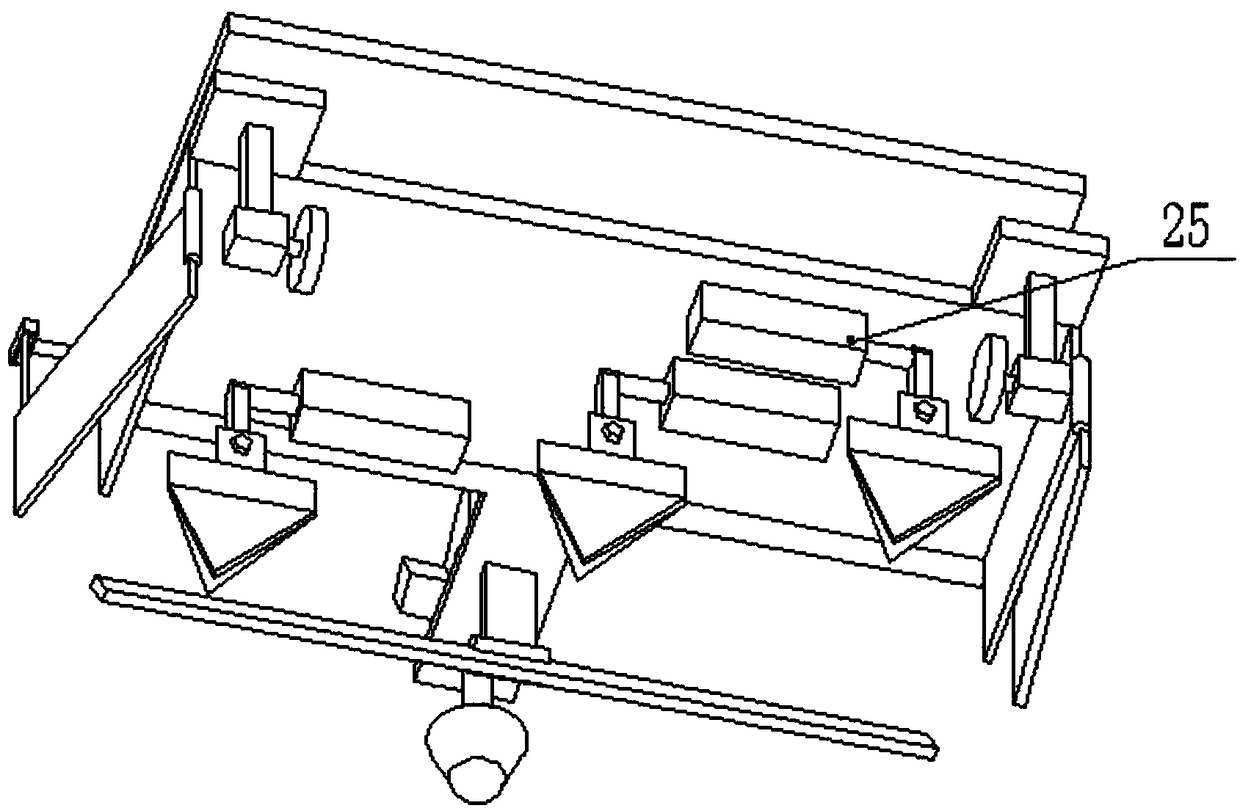

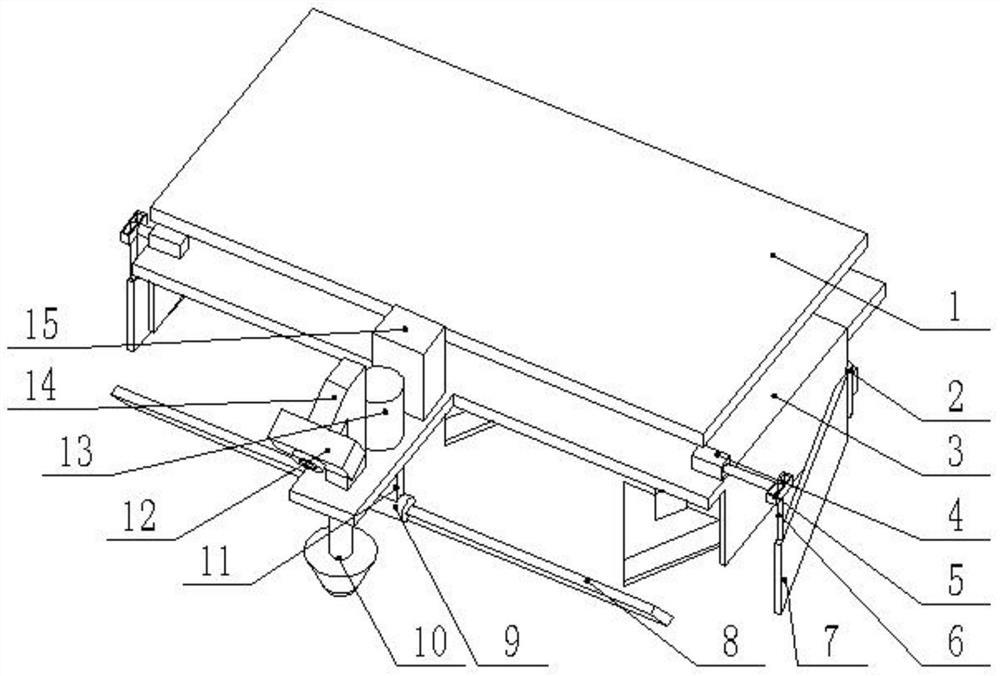

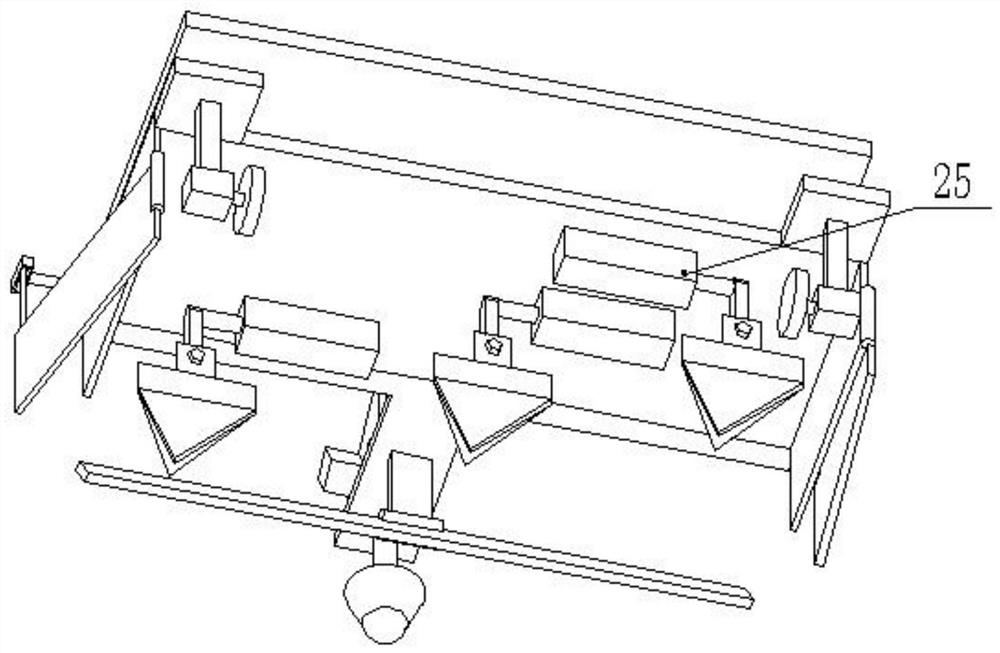

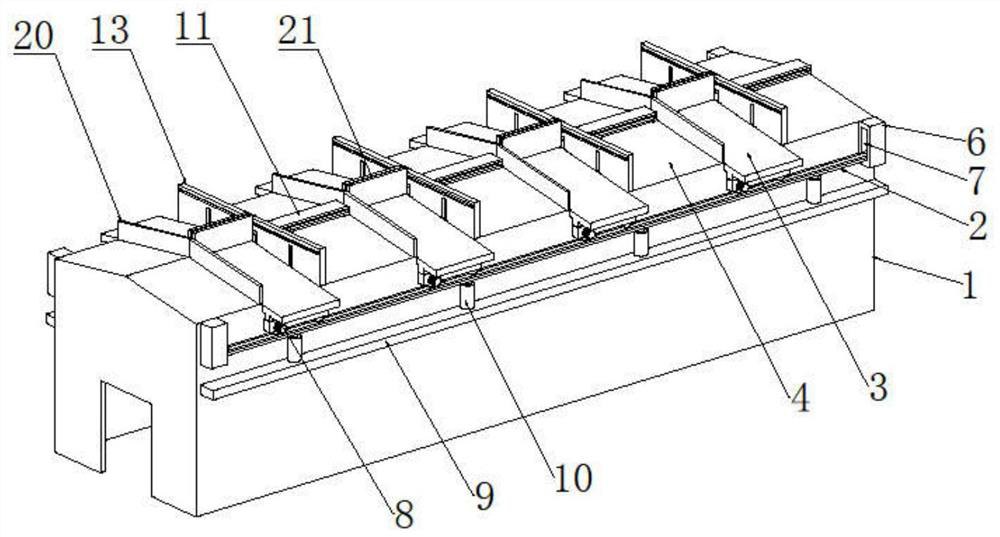

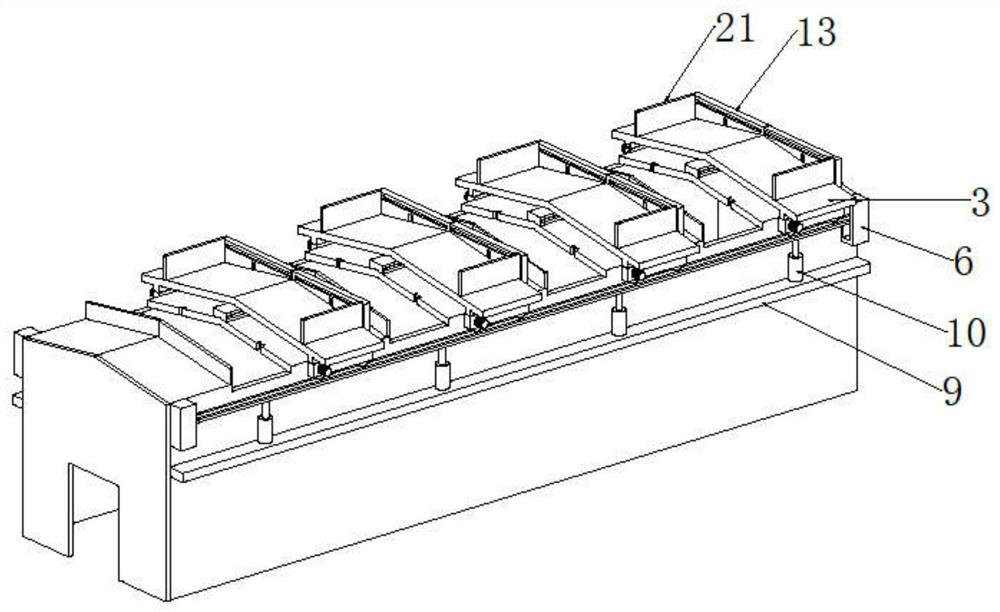

Agricultural cereal grain tedding device

ActiveCN108576214APrevent being pushed toPrevent pushClimate change adaptationSeed preservation by dryingAgricultural engineeringSolar cell

An agricultural cereal grain tedding device belongs to the field of agricultural machinery. A solar cell panel is fixed on a solar cell panel base. The front end of a first baffle is connected to a first stirring bar while the rear end is connected to a first rotary shaft. A flatting plate is fixed in a second rotary shaft. Universal wheels are fixed to the lower side of a long board on the frontend of a cover plate. A camera is installed on a camera seat. A controller is located between the camera seat and a storage battery which is fixed to the cover plate. Two motors are respectively fixedonto two motor bases. Two wheels are relatively installed on the two motors. Three material distributors are fixed to the lower side of the cover plate. The camera is used for recognizing a route, the control plans the route and the solar cell panel serves as a power supply, then the flatting plate uniformly spreads the cereal grains and the material distributors re-heaping the cereal grains. Thetedding device can replace manual tedding operations, reduces manual work and increases work efficiency.

Owner:南昌金进果粮油有限公司

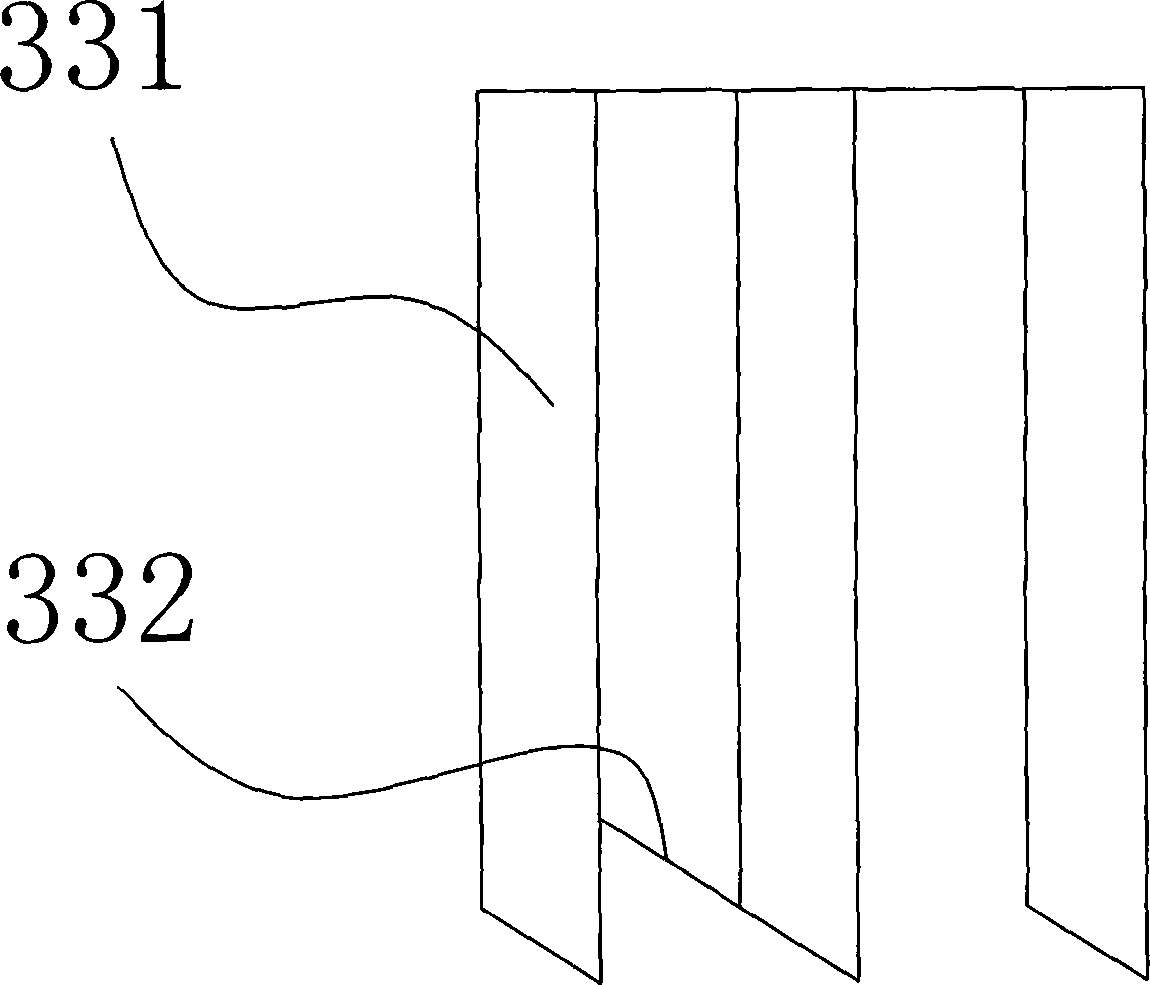

Pen preventing being opened by children

InactiveCN103722939APrevent pressing outPrevent pushWriting connectorsWriting unitsElastic componentEngineering

The invention relates to a pen preventing being opened by children. The pen comprises a pen holder, a pen cap, a driving device and a pen refill. The pen refill is arranged in the pen holder. A protruding ring is arranged on the pen refill. The front end of the pen refill is sleeved with an elastic component. The driving device comprises a connecting rod, a clamp head and a locating device. The connecting rod is sleeved with the pen cap and is fixedly connected with the clamp head. The clamp head is provided with a protruding strip. The pen cap is provided with a groove. The locating device is fixed in the pen holder. The locating device comprises sliding strips, one end of each sliding strip is an oblique plane, and blocking strips are arranged between the sliding strips. The pen refill is provided with a first annular groove, and a soft fixing piece is arranged in the first annular groove. The soft fixing piece is connected with pressure bars, and the pen holder is provided with through holes matched with the pressure bars. The pressure bars penetrate through the through holes and extend out of the pen holder. Fixed plates are arranged on the inner sidewall of the pen holder. The pen refill is provided with stop rods. Each fixed plate is provided with an open slot. A push rod is arranged on the pen refill. The pen holder is provided with a first through hole. The pen can prevent children from opening the pen cap or pressing out the pen refill, so the safety performance of the pen is high.

Owner:梁德政

Lifting adjustment devices and seating and/or reclining furniture with lifting adjustment devices

Owner:FERDINAND LUSCH GMBH & CO KG

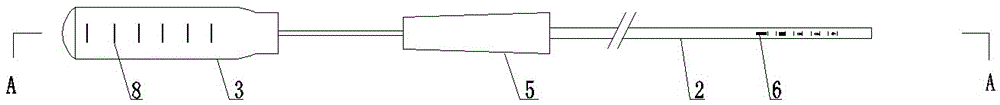

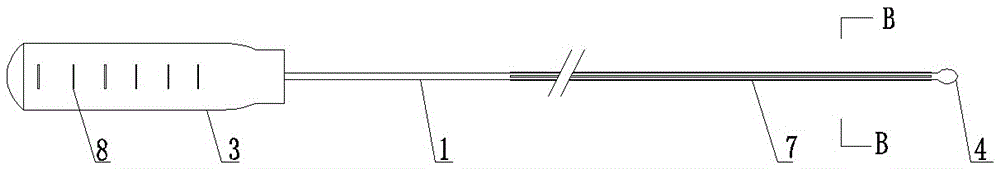

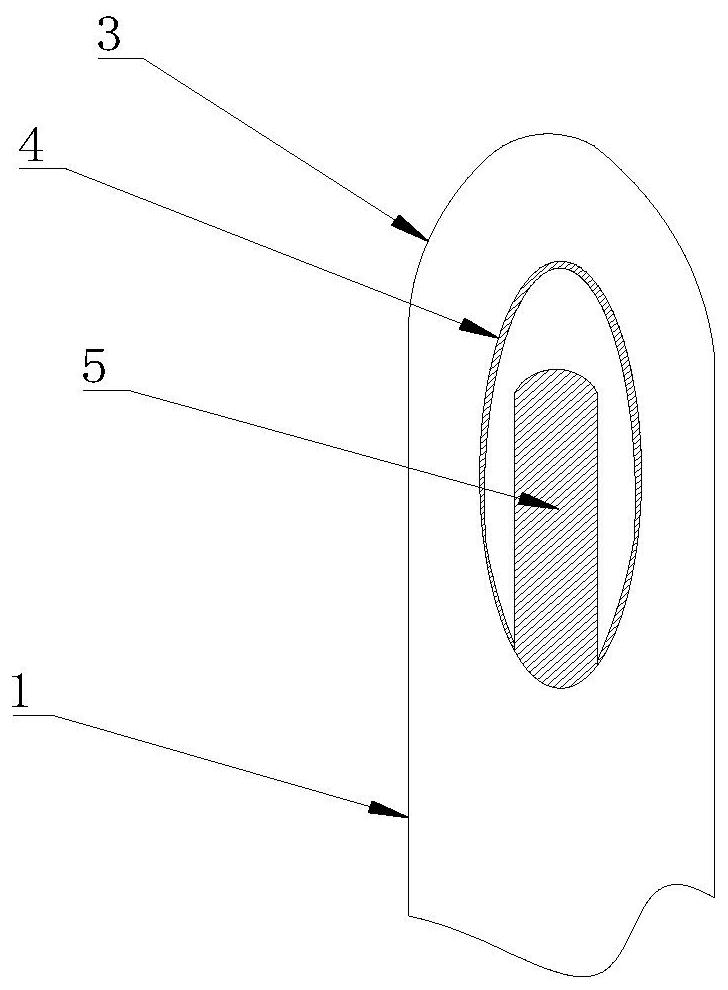

Guide needle with smooth needle hole for line carving sawtooth line

PendingCN111671478AQuality assuranceGuarantee the quality of surgerySuture equipmentsBiomedical engineeringMechanical engineering

The invention discloses a guide needle with a smooth needle hole for a line carving sawtooth line, and relates to the technical field of medical plastic instruments, and the key points of the technical scheme are as follows: the guide needle comprises a needle body with a flat obtuse-angle needle head and a grab handle, the flat obtuse-angle needle head is provided with an oval needle hole, and the edge of the oval needle hole is polished and smoothly transited; a fixed needle core is arranged in the needle body; the end, located in the grab handle, of the needle body is fixedly connected witha hollow connecting end. A connector is arranged at the end part of the fixed needle core; a sliding rail is arranged on the inner wall of the grab handle; and a strip-shaped groove, a first slidingbutton and a second sliding button are arranged on the wall surface of the grab handle. When the guide needle draws a sawtooth line for routing, the sawtooth line is not prone to being cut off by theedge of a needle hole in the needle head of the guide needle, the guide needle draws the sawtooth line conveniently for forward and reverse routing operation, one end of the sawtooth line can be stably fixed to the needle hole, and the line carving operation quality is guaranteed conveniently; meanwhile, the length of the needle body of the guide needle can be adjusted according to needs, operation is convenient, and tedious operation of replacing guide needles of different lengths is avoided.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

An agricultural grain drying device

ActiveCN108576214BPrevent pushImprove the efficiency of tanningClimate change adaptationSeed preservation by dryingAgricultural engineeringFarm machine

The utility model relates to an agricultural grain drying device, which belongs to the field of agricultural machinery equipment. The solar panel is fixed on the base of the solar panel, the front end of the first baffle is connected with the first lever, the rear end is connected with the first rotating shaft, and the pulling plate is fixed in the second rotating shaft, so The universal wheel is fixed under the long plate at the front end of the cover, the camera is installed on the base of the camera, the controller is located between the base of the camera and the battery, the battery is fixed on the cover, and the motor has Two of them are respectively fixed on two motor bases, two of the wheels are oppositely installed on the motors, and three of the distribution devices are fixed under the cover plate. The invention uses the camera to identify the path, the controller to plan the path, and the solar panel to provide energy, so that the flat plate spreads the grain evenly, and the material distribution device re-divides the grain, replacing the steps of manual drying of the grain, reducing manual labor and improving work efficiency.

Owner:南昌金进果粮油有限公司

a security pen

The invention relates to a safety pen which comprises a pen holder, a pen case and a pen refill. The pen refill is arranged in the pen holder, a press rod capable of squeezing the pen refill out of the pen holder is arranged in the pen case, a projection is arranged on an inner ring of an opening of the pen case, a flange matched with the projection is arranged at the upper end of the outer side wall of the pen holder, an annular groove is formed in the pen refill, a flexible fixing part is matched with the annular groove and arranged in the groove, a first press rod is fixedly connected onto the flexible fixing part, the pen holder is provided with a first through hole matched with the first press rod, and the first press rod penetrates the first through hole and extends to the outside of the pen holder. A child can be prevented from opening a pen cap or pressing out the pen refill, and safety is high.

Owner:ZHONGSHAN VOCATIONAL & TECHNICAL COLLEGE

Safety pens that prevent children from opening

The invention relates to a safety pen prevented from being opened by a child. The safety pen comprises a penholder, a pen cap, a drive device and a refill. The refill is arranged in the penholder, a protrusive ring is arranged on the refill, an elastic assembly is arranged at the front end of the refill in a sleeved mode, and the drive device comprises a connecting rod, a clamping head and a positioning device. The connecting rod is fixedly connected with the clamping head which is connected with the refill, protrusive strips are arranged on the side edge of the clamping head, grooves are formed in the lower end of the pen cap, the upper ends of the protrusive strips are matched with the grooves, the positioning device is fixed in the penholder, and the positioning device comprises sliding strips. The ends of the sliding strips are inclined planes, and stopping strips are arranged between the sliding strips at intervals. The refill comprises an upper portion of the refill and a lower portion of the refill. The protrusive ring is arranged on the lower portion of the refill, a first through hole is formed in the penholder, a pull rod is arranged to be fixedly connected with the upper portion of the refill, a first groove is formed in the lower portion of the refill, a flexible fixing part is arranged, pressure rods are arranged on the flexible fixing part, and the pressure rods penetrate through the first through hole to extend to the outside of the penholder. The child can be prevented from opening the pen cap or the pressing the refill out, and therefore safety is high.

Owner:重庆市金尺子课外教育培训学校有限公司

A factory building for factory production of large components

The invention discloses a factory building for industrial production of large-scale components, which includes a room body, a snow removal mechanism 1 and a snow removal mechanism 2, the room body includes guide rails and sliding covers, and a plurality of hoisting openings for allowing large-scale components to pass are arranged on the roof. A fixed block is fixed on the side wall, and a chute is provided on the fixed block. The two ends of the guide rail are slidably connected with the two chutes. The beam slides on the guide rail, and the support beam is fixed on the side wall of the room body. There are multiple cylinders distributed on the support beam. The piston rod of the cylinder is connected to the guide rail. The sliding cover can be raised and lowered and slid, and can completely cover the lifting opening when closed. There is a baffle on the side of the lifting opening and a sealing strip is wrapped around the edge of the lifting opening, which can prevent rain and snow from entering the room. When the sliding cover is opened, the lifting opening is exposed. The gantry crane can hoist large components out, and the snow removal mechanism 1 and snow removal mechanism 2 can push down the snow accumulated on the roof and sliding cover.

Owner:CCCC SHEC FOURTH ENG

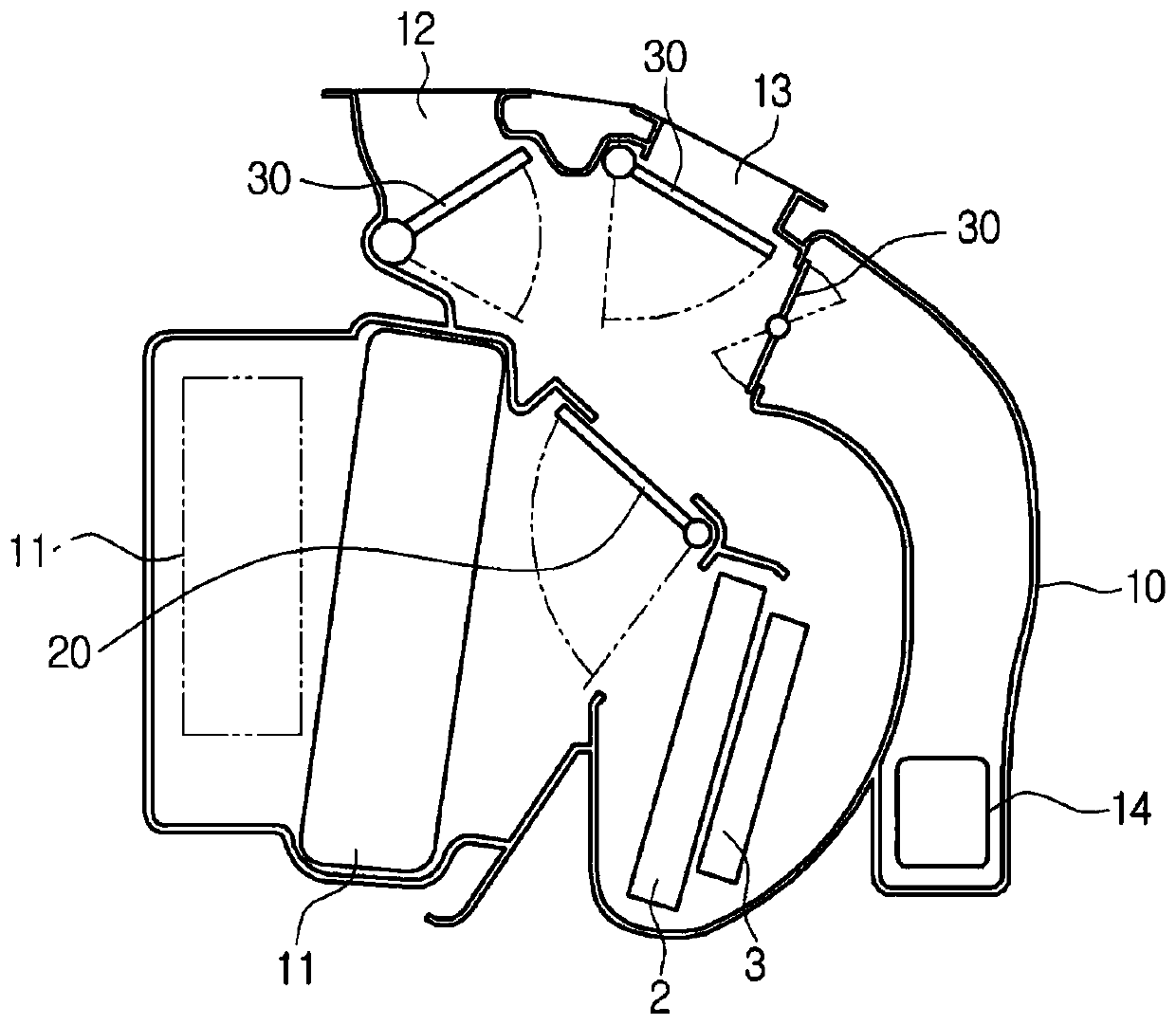

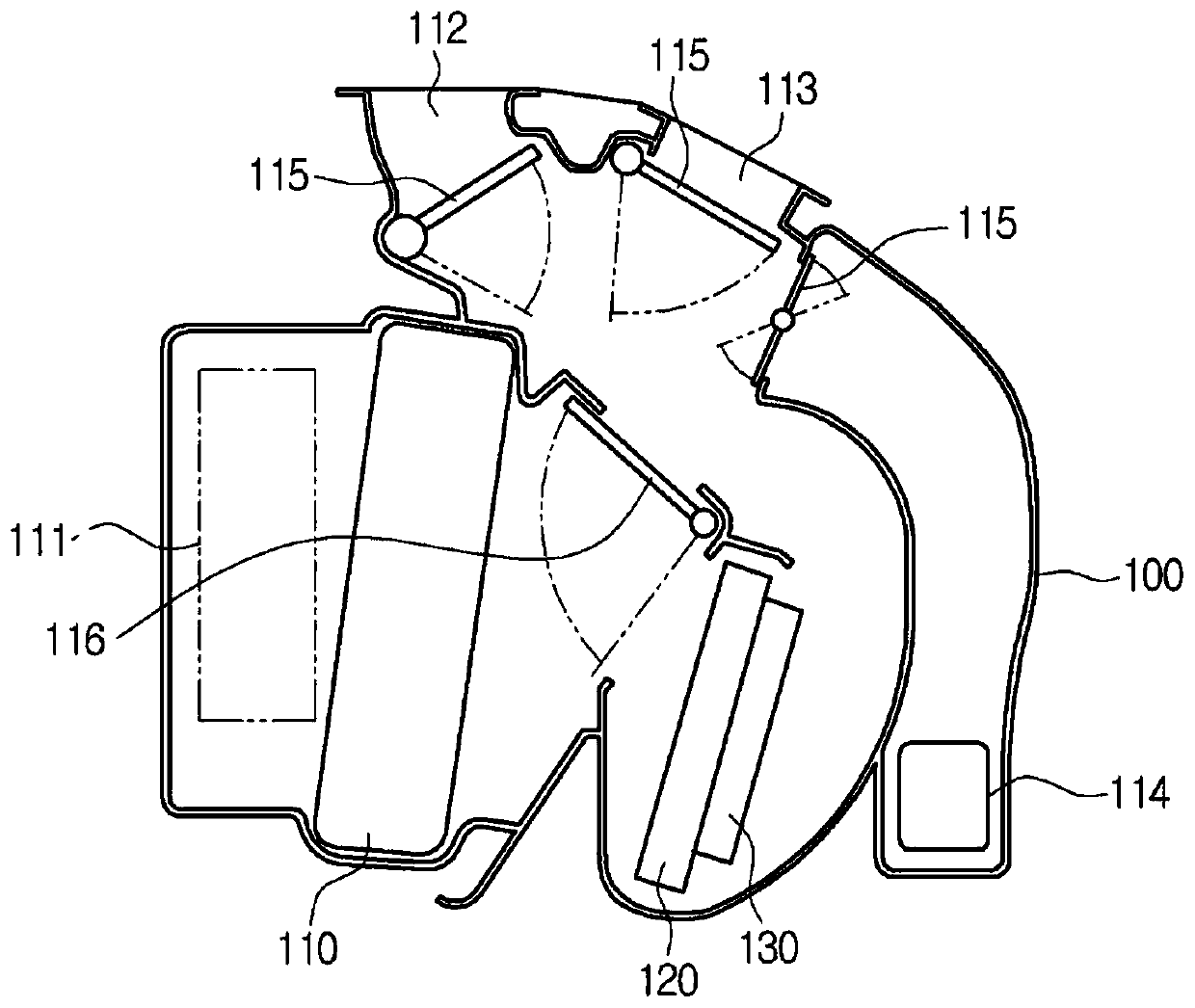

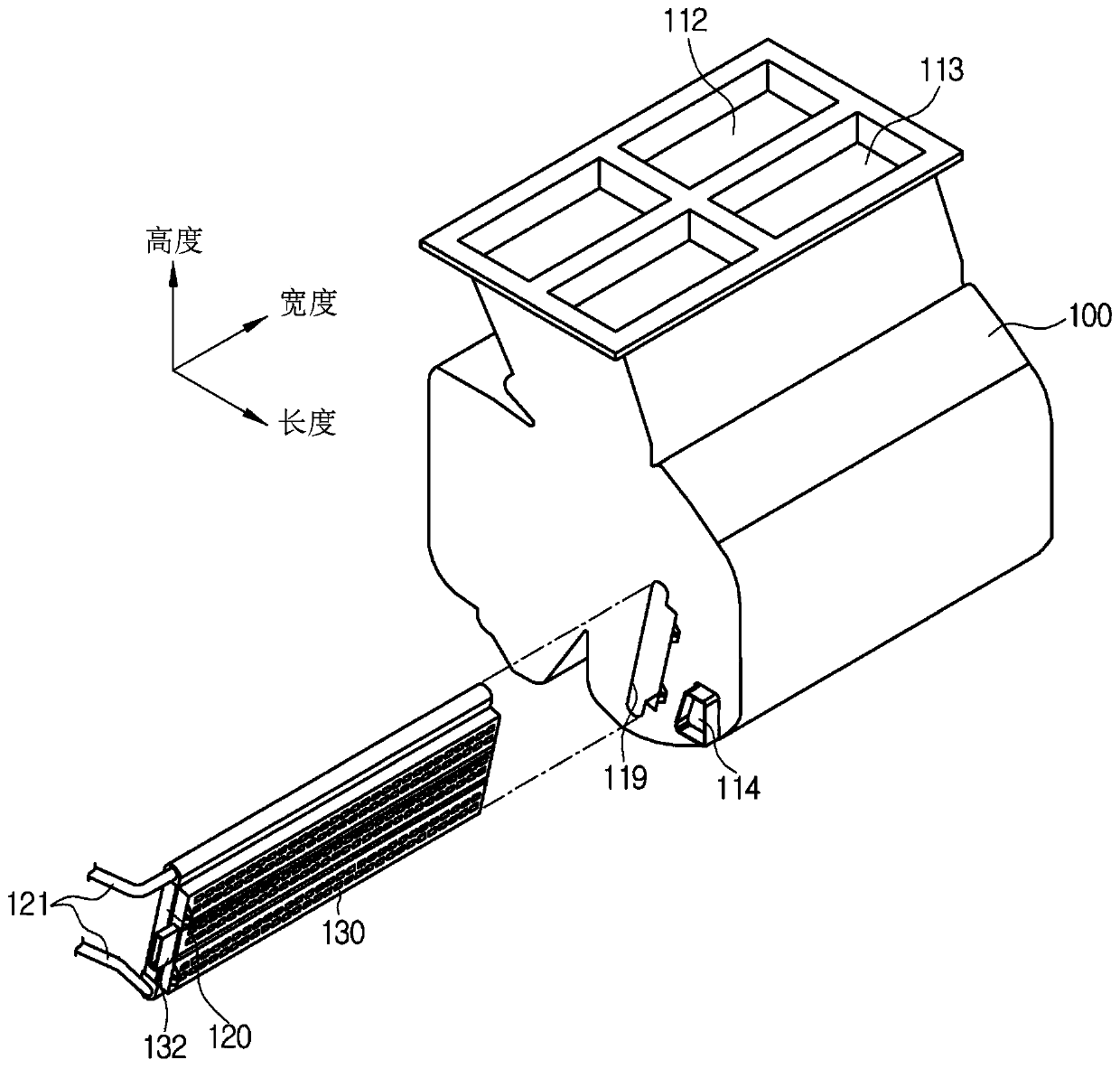

Vehicle air-conditioning device and assembly method thereof

ActiveCN110834513AImprove quality drop problemRealize automated assemblyAir-treating devicesVehicle heating/cooling devicesHeater coreElectrical and Electronics engineering

The invention discloses a vehicle air-conditioning device and an assembly method thereof, wherein the shape of the PTC heater placement section is changed so that the PCT heater placement section canbe guided to the normal position even if the PTC heater is detached or assembled incorrectly. The vehicle air-conditioning device includes: an air-conditioning case; a heater core, which is arranged inside the above-mentioned air-conditioning case and heats air by a cooling water heat source; an electric heater that heats the air by applying heat from a power source; wherein the above-mentioned heater core and electric heater are combined in the vehicle air conditioner. The heater includes an insertion hole formed in the air conditioner case to insert the heater core and the electric heater; acoupling part that couples the electric heater inserted into the air conditioner case; and a guide part formed in the air conditioner Chassis, used to place the connection part. The guide portion isformed to protrude by a certain height in the coupling direction of the coupling portion.

Owner:HANON SYST

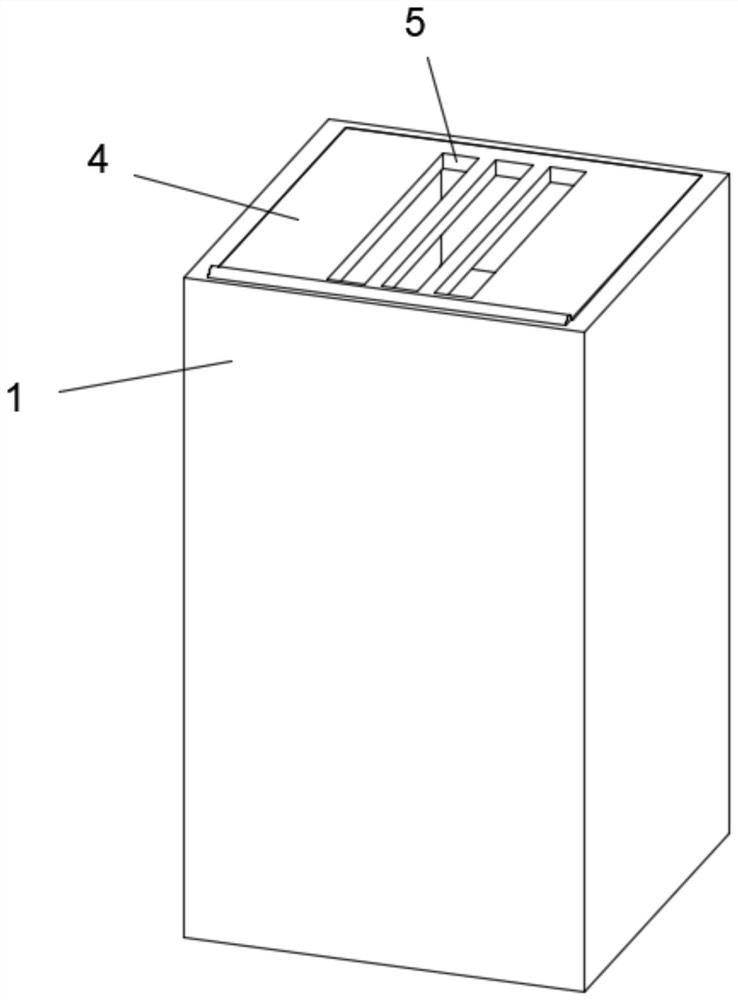

Municipal drainage system

PendingCN113982084AAvoid cloggingImprove emission efficiencySewerage structuresSewer pipelinesSewage outfallWater flow

The invention discloses a municipal drainage system and belongs to the technical field of municipal drainage. The municipal drainage system comprises a shell, wherein a water tank is formed in the middle of a top face of the shell, a guide rod is fixedly arranged at the position, opposite to an upper end of the front side of a movable plate, in a drainage channel, and drain outlets are formed in the positions, opposite to the movable plate, of the inner walls of the two sides of the drainage channel; collecting grooves are formed in the positions, opposite to the outer side end of the sewage draining outlet, of the two sides in the shell, a pressing plate is arranged on a top face of the outer side of a sealing plate, a pulling plate is fixedly arranged at a rear end of a top face of the pressing plate, and a bottom face of the sealing plate and bottom faces of the collecting grooves are each of a front-back symmetrical structure and provided with two round cavities; a compression spring is fixedly arranged between the interiors of the two circular cavities located on the same side. The energy of flowing water can be fully utilized, a phenomenon that impurities are accumulated on the front side of a roller to block water flow loss is avoided through back-and-forth movement of the movable plate, drainage efficiency of the drainage system is greatly improved, and water accumulation and waterlogging are avoided.

Owner:黄珺

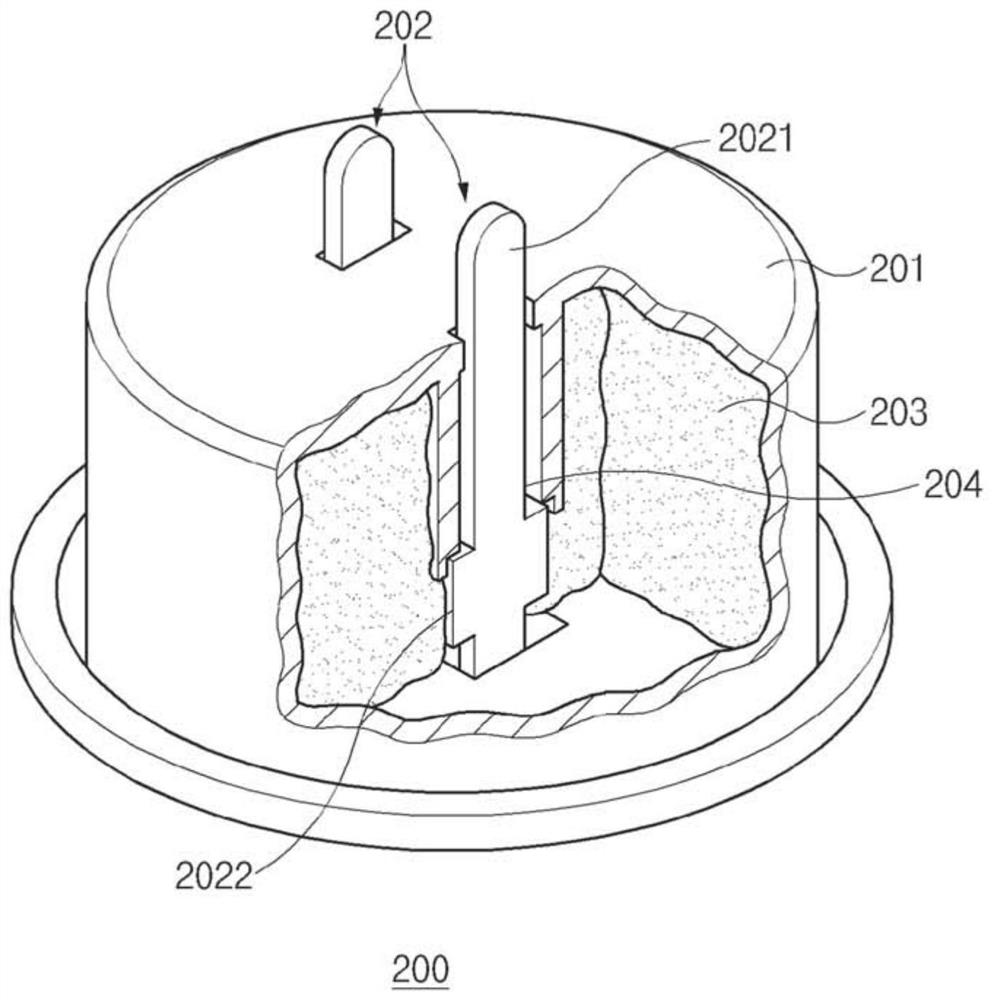

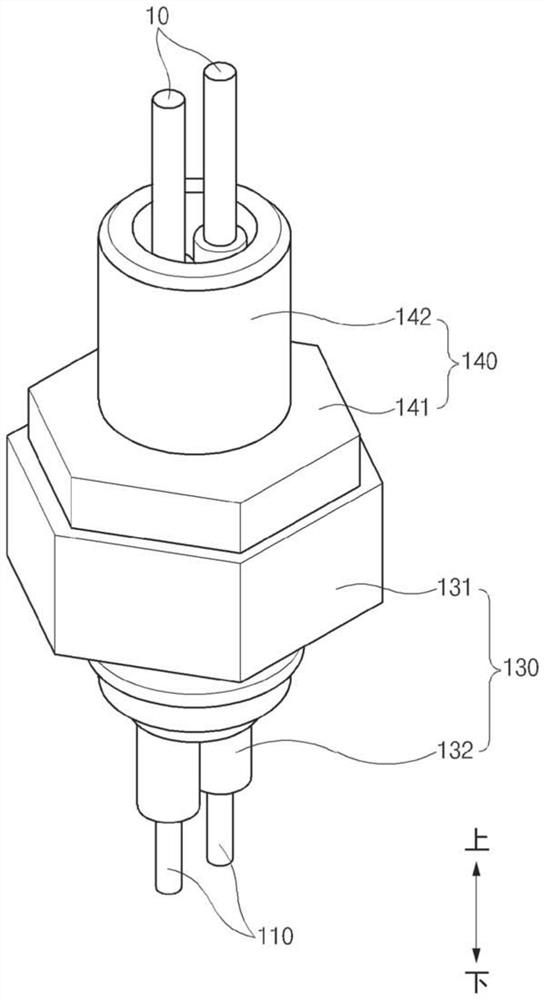

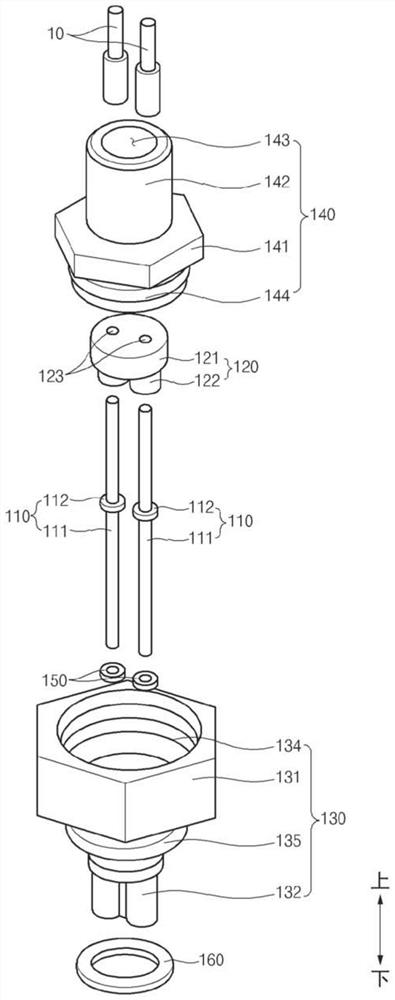

Electrode terminal assembly for liquid quality meter apparatus and liquid quality meter apparatus comprising same

PendingCN113366304APrevent pushPrevent water leakageMaterial resistanceElectrical resistance and conductanceEngineering

According to the present invention, an electrode terminal assembly for a liquid quality meter apparatus for measuring liquid quality on the basis of the electrical resistance of a liquid to be measured comprises: a pair of electrode terminals comprising a body, which contacts the liquid being measured when liquid quality is measured and has an overall rod shape, and a protruding step formed at a predetermined portion between the opposite ends of the body; and a fixing body comprising a pair of electrode through-holes through which the pair of electrode terminals pass. In the electrode terminal assembly having the above-described structure, each of the pair of electrode terminals is arranged such that, when the electrode terminals are inserted into the electrode through-holes of the fixing body by a predetermined length, the protruding step is caught by the fixing body so that the electrode terminals are no longer inserted.

Owner:KYUNGDONG NAVIEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com