Abrasion proof pipe with ternary composite material as liner and preparing technique thereof

A composite material and preparation process technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problem of tearing, poor quality controllability, inability to meet strength, toughness, wear resistance, corrosion resistance, ease of processing, etc. problems, to achieve the effect of reducing local stress concentration, reducing impact stress, and avoiding external medium corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

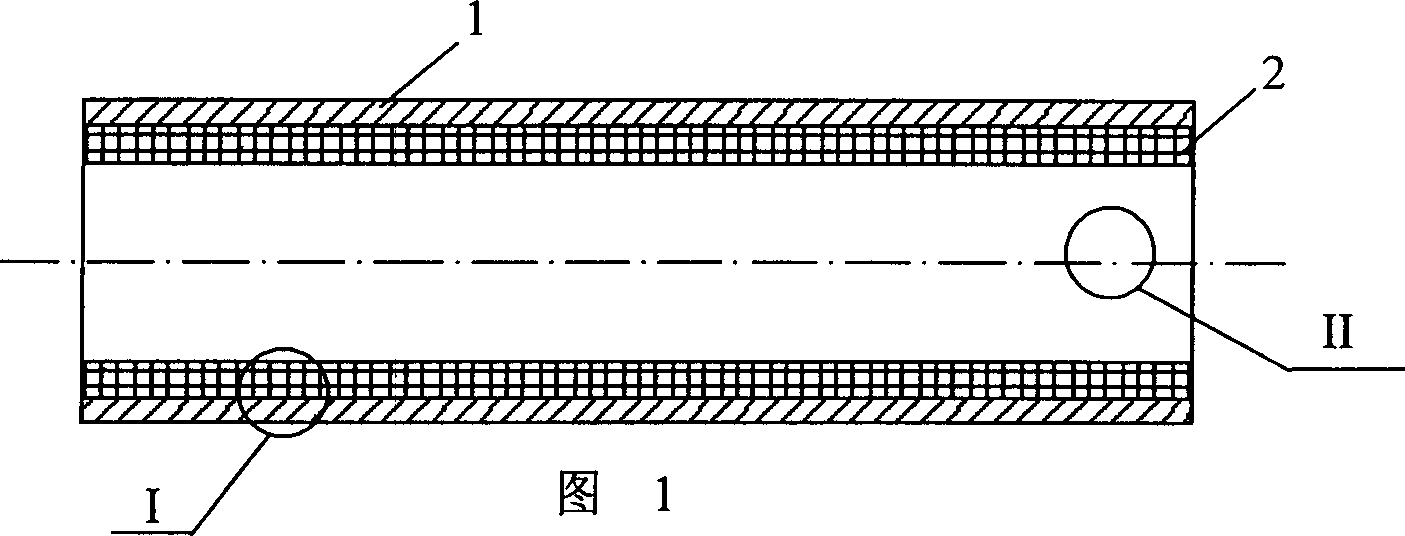

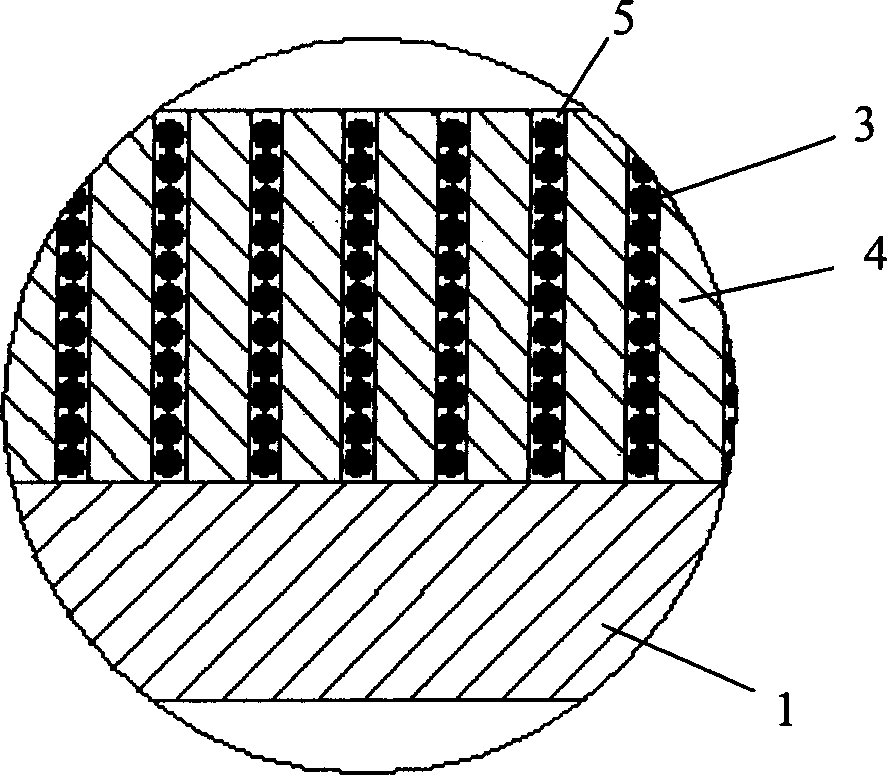

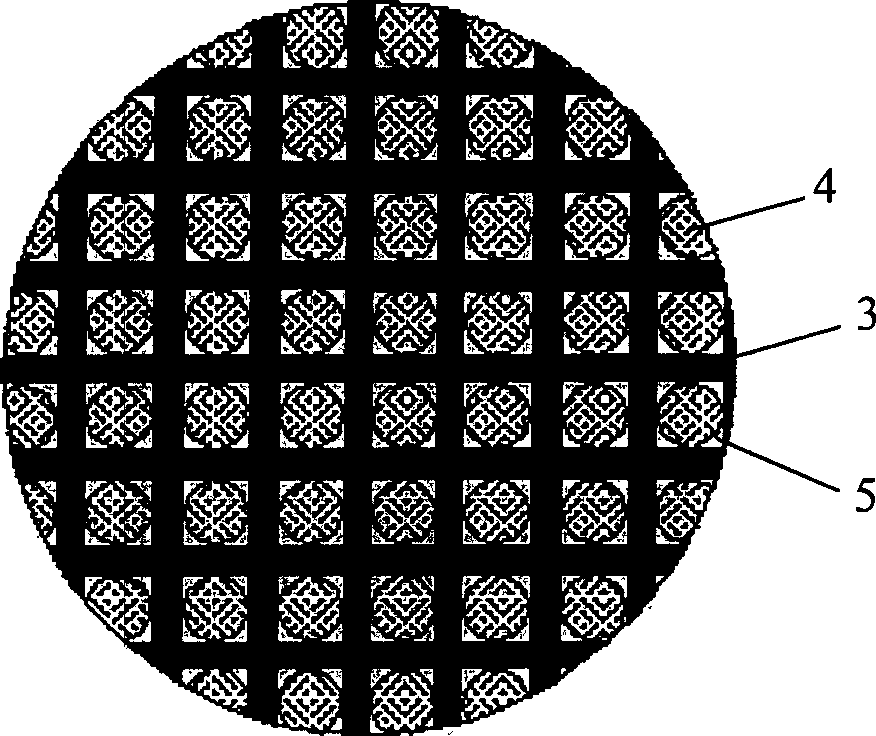

[0050] A wear-resistant straight pipe lined with a ternary composite material with uniform wall thickness, see Figure 1, Figure 2 and Figure 3. It is composed of an outer steel pipe 1 and a wear-resistant inner lining 2, and the wear-resistant inner lining 2 is composed of a wire mesh 3, a ceramic rod 4 and a composite material 5. In this embodiment, the diameter of the outer layer steel pipe 1 is 500 mm, and the thickness of the wear-resistant lining 2 is 10 mm. The wire mesh 3 is braided by Ф0.5mm nano-structured high-carbon steel wire, and the mesh size is 1.5mm; the wire mesh 3 is closely stacked, and it accounts for the volume fraction of the entire ternary composite material-lined wear-resistant pipe 20%; the ceramic rod 4 is made of tungsten carbide, and other hard materials can also be used; the diameter of the ceramic rod 4 is 1.5mm, and its length is equal to the thickness of the metal mesh 3 stack (≤10mm); the ceramic rod 4 is embedded in the metal In the mesh of t...

Embodiment 2

[0058] A wear-resistant three-way pipe lined with ternary composite material, see Figure 4 , Figure 2 and Figure 3. It is composed of an outer steel pipe 1 and a wear-resistant inner lining 2, and the wear-resistant inner lining 2 is composed of a wire mesh 3, a ceramic rod 4 and a composite material 5. In this embodiment, the diameter of the outer steel pipe 1 is 650 mm, and the thickness of the wear-resistant lining 2 is 15 mm. The wire mesh 3 is braided by Ф0.8mm low-carbon alloy steel wire, and the mesh size is 2mm; the wire mesh 3 is tightly stacked; the ceramic rod 4 is made of alumina, and can also be made of tungsten carbide or silicon carbide; ceramic The rod 4 has a diameter of 2mm, and its length is equal to the laminated thickness of the wire mesh 3 (≤15mm); the ceramic rod 4 is embedded in the mesh of the wire mesh 3; the composite material 5 is made of polyethylene.

[0059] The preparation process steps of embodiment 2 are as follows, referring to the process ...

Embodiment 3

[0067] A kind of ternary composite material lined wear-resistant elbow, see Figure 5 , Figure 6 , Figure 2 and Figure 3. It is composed of an outer steel pipe 1 and a wear-resistant inner lining 2, and the wear-resistant inner lining 2 is composed of a wire mesh 3, a ceramic rod 4 and a composite material 5. In this embodiment, the diameter of the outer layer steel pipe 1 is 300 mm, and the thickness of the wear-resistant lining 2 is 10 mm. The wire mesh 3 is braided by Ф0.5mm low-carbon alloy steel wire, and the mesh size is 1.8mm; the wire mesh 3 is tightly stacked; the ceramic rod 4 is made of alumina, and can also be made of tungsten carbide or silicon carbide; The diameter of the ceramic rod 4 is 1.8mm, and its length is equal to the laminated thickness of the wire mesh 3 (≤10mm); the ceramic rod 4 is embedded in the mesh of the wire mesh 3; the composite material 5 is made of polyurethane.

[0068] The preparation process steps of embodiment 3 are as follows, referr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com