Guide needle with smooth needle hole for line carving sawtooth line

A technology of zigzag wire and guide needle, applied in the application, surgical instruments and other directions, can solve the problems of cutting the zigzag wire, affecting the routing process and the quality of wire carving surgery, etc., to achieve the effect of convenient operation, quality assurance, and surgical quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

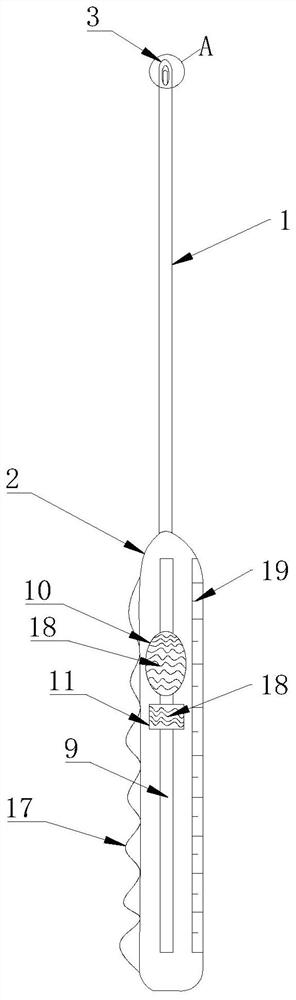

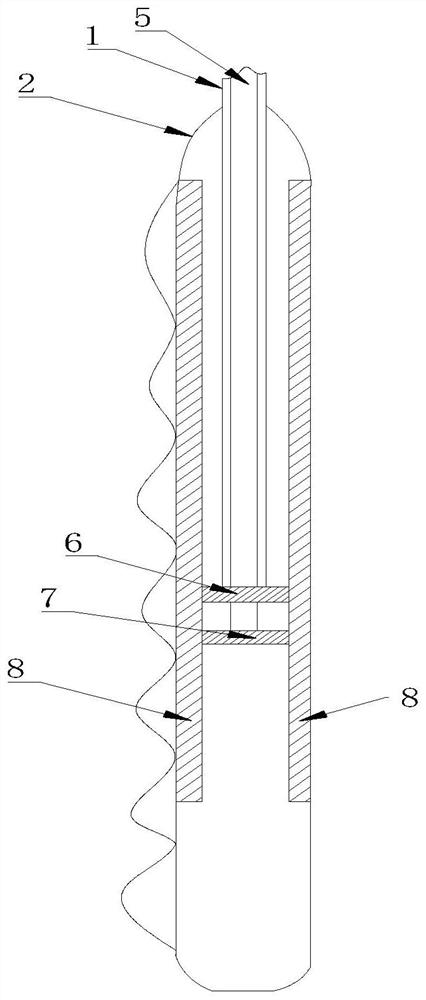

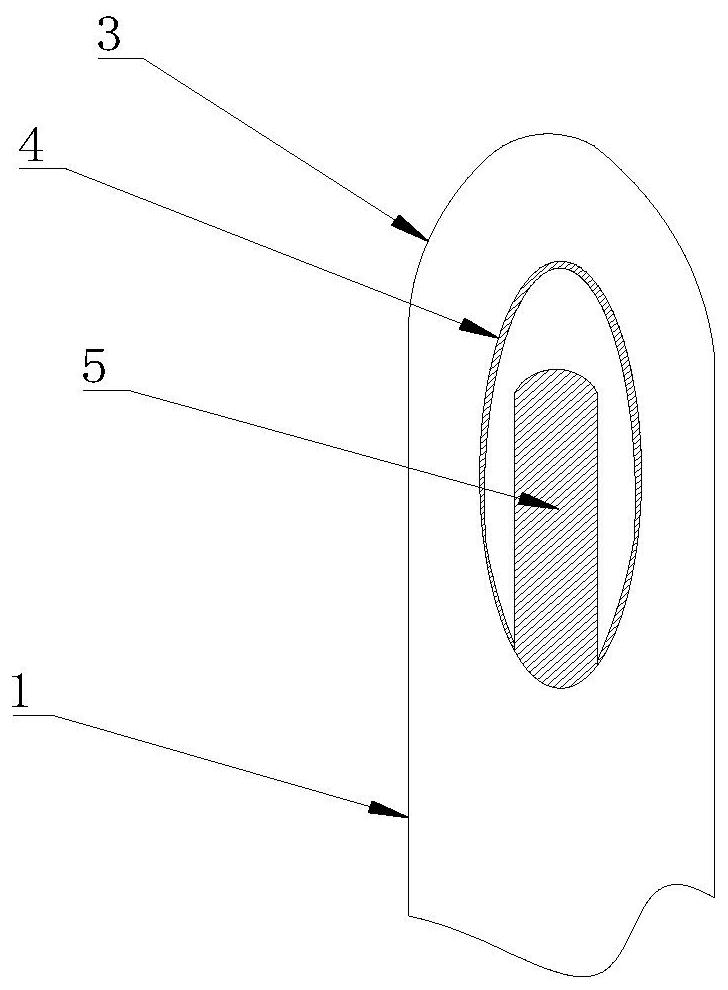

[0025] Embodiment: a kind of guide needle for thread engraving zigzag line with smooth pinhole, such as Figure 1 to Figure 4 As shown, it includes a hollow needle body 1 and a handle 2 connected with the needle body 1 , and one end of the needle body 1 is located inside the handle 2 . The end of the needle body 1 away from the handle 2 is a flat obtuse needle 3 . The 3 flat obtuse needles are processed with oval pinholes 4 , and the edges of the oval pinholes 4 and the outer wall of the flat obtuse needle 3 are polished and smoothly transitioned. A fixed needle core 5 is installed in the needle body 1 , one end of the fixed needle core 5 is close to the oval pinhole 4 , and the other end of the fixed needle core 5 is located inside the handle 2 . The end of the needle body 1 located in the handle 2 is fixedly connected with a hollow connection end 6 . The end of the fixed needle core 5 extending out of the needle body 1 is fixedly connected with a connector 7 . Two symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com