Patents

Literature

721results about How to "Realize automated assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

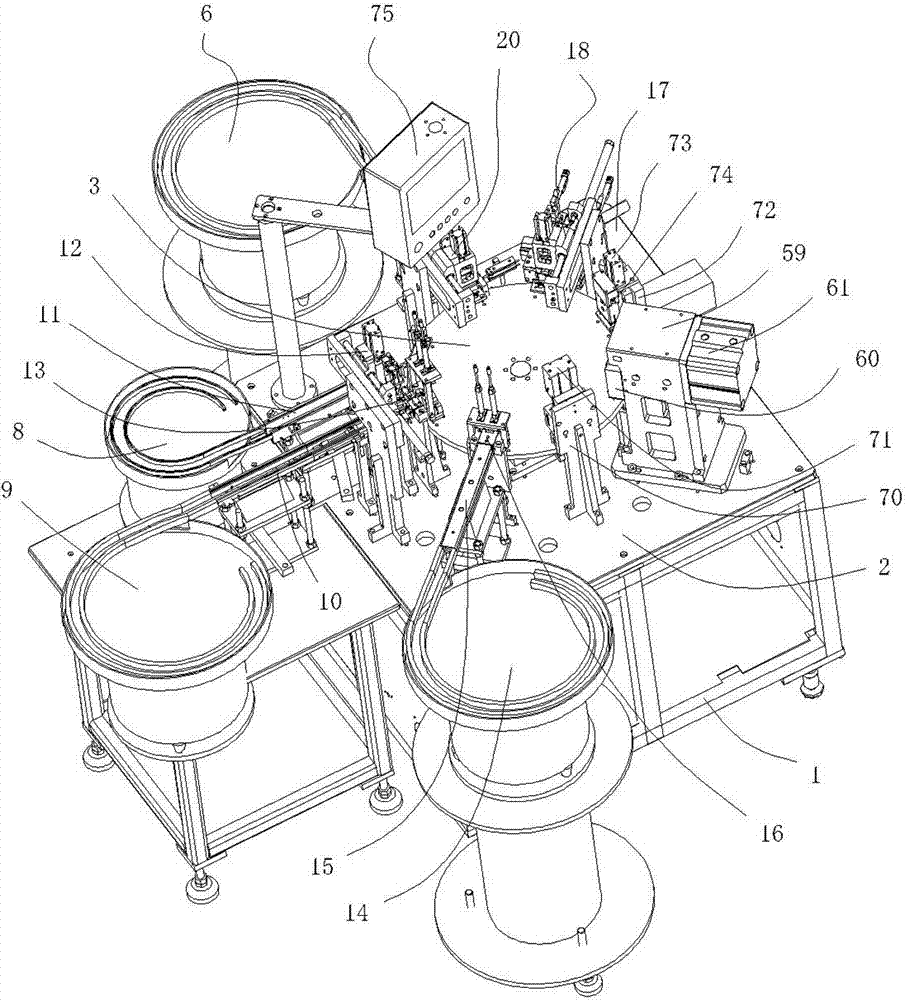

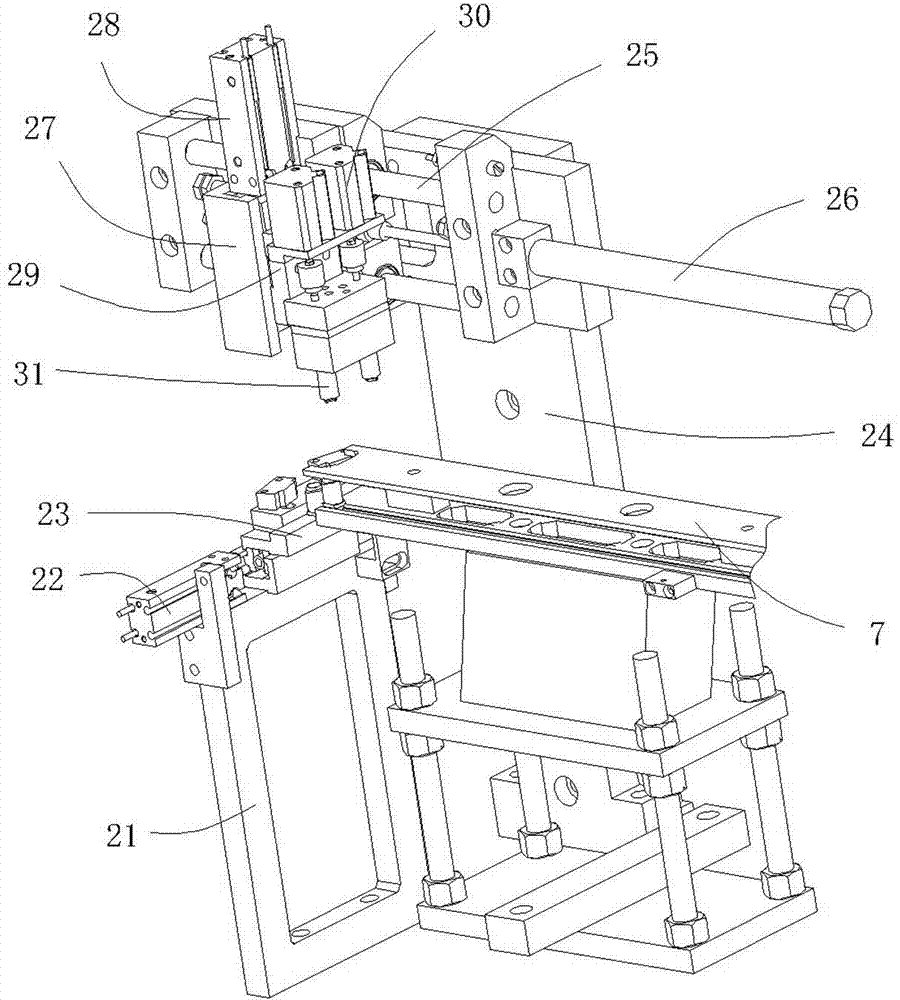

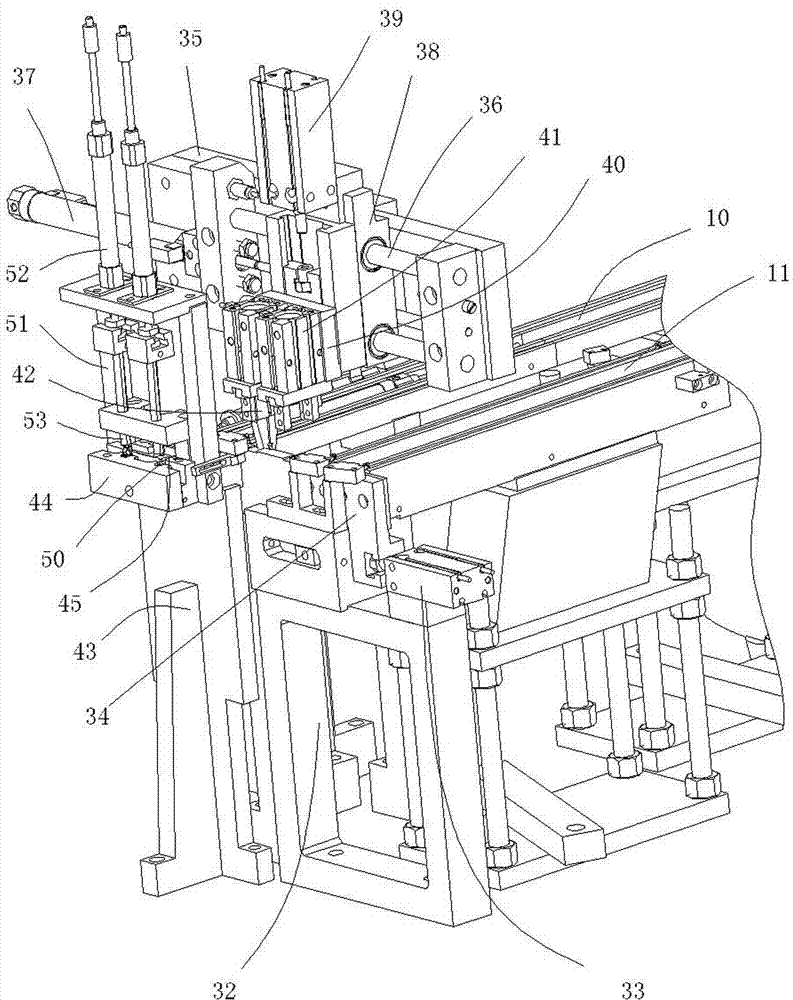

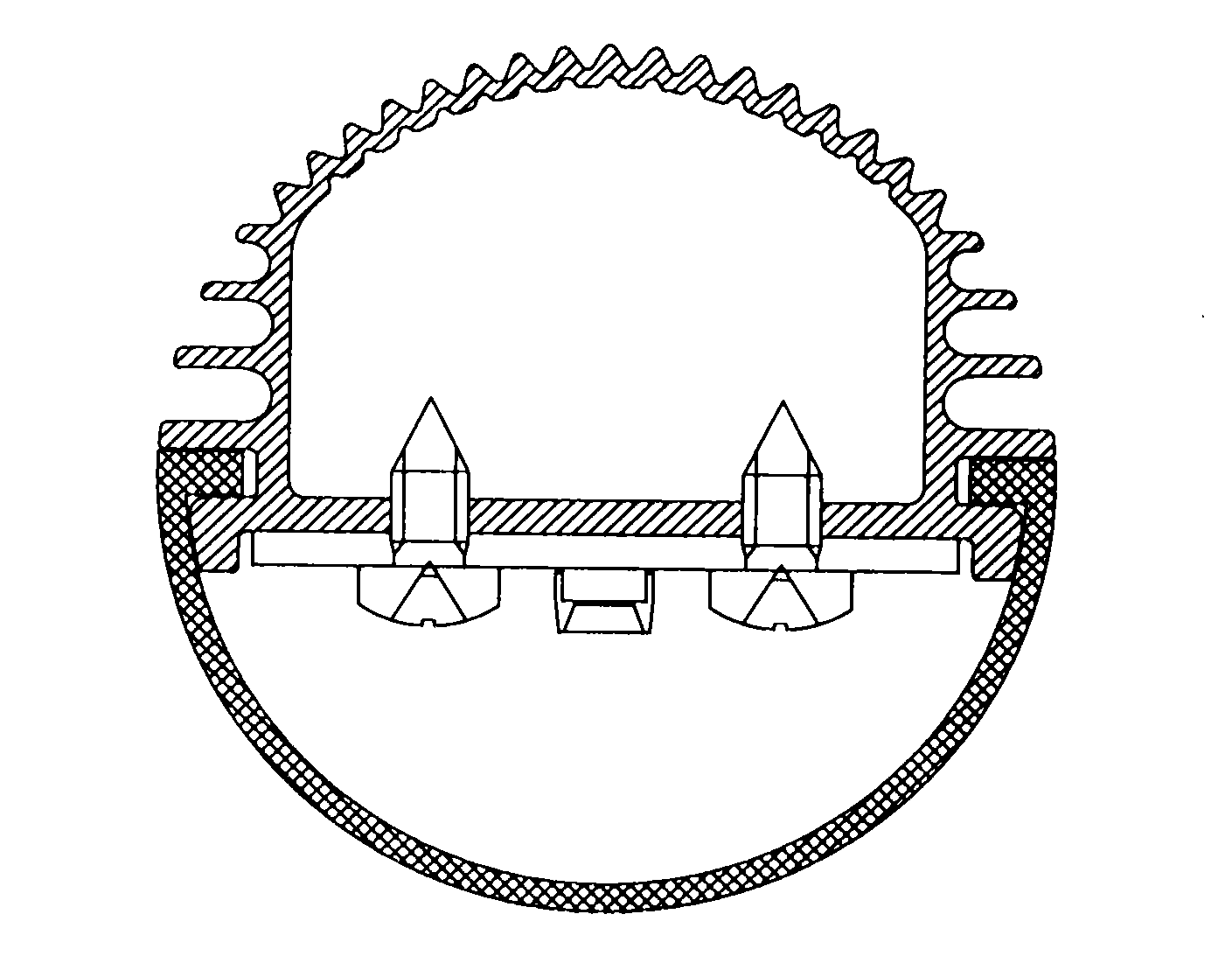

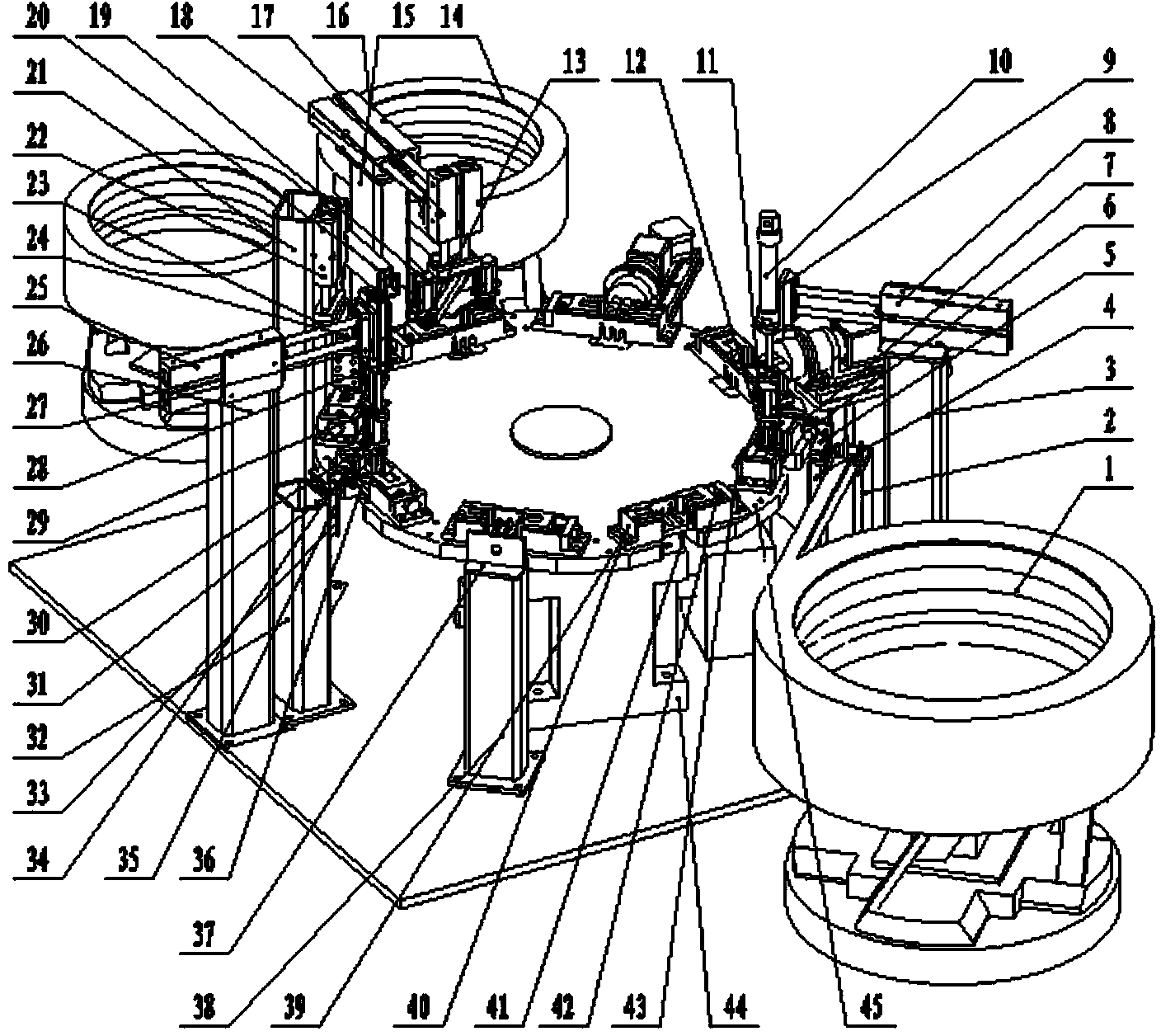

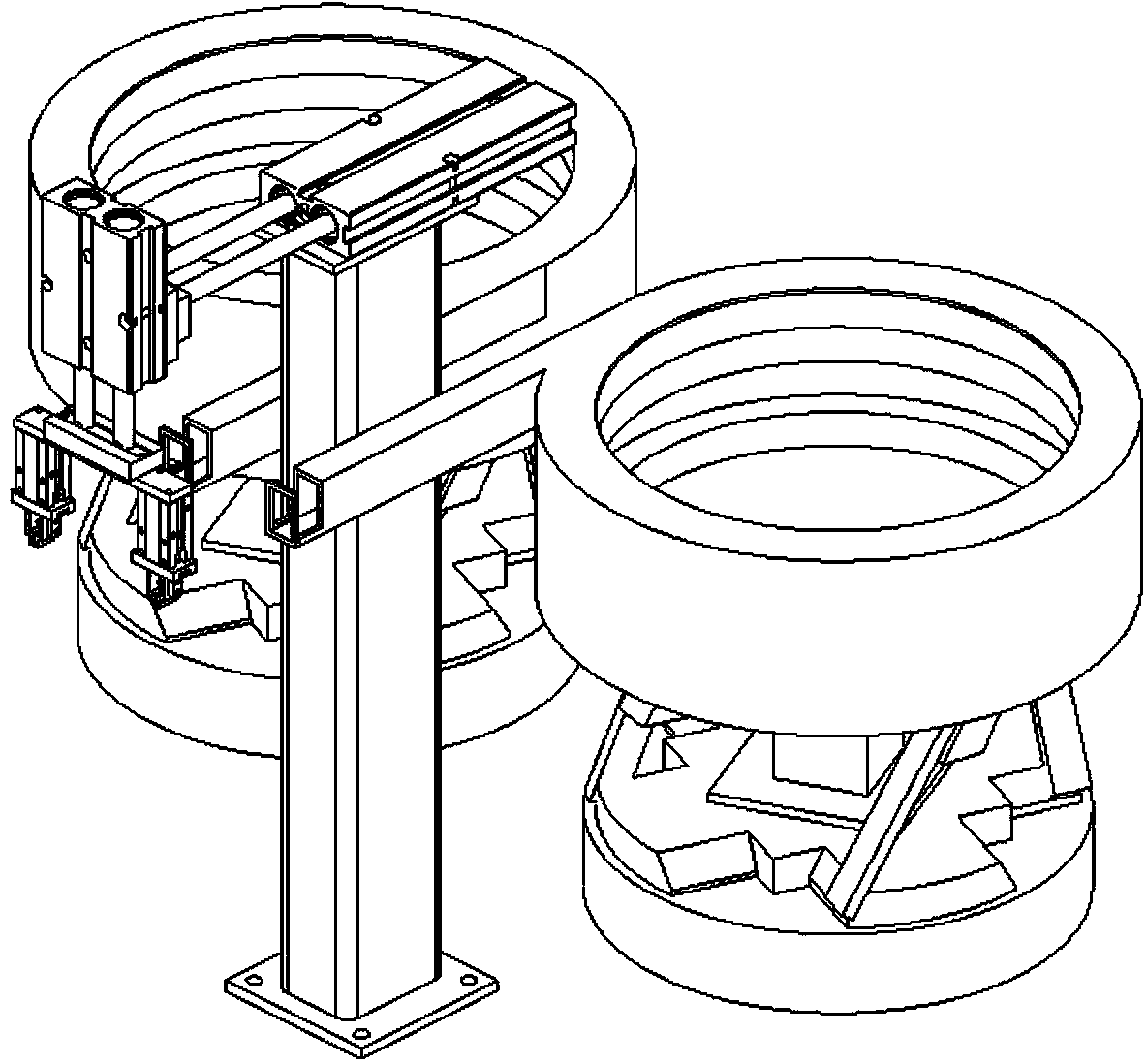

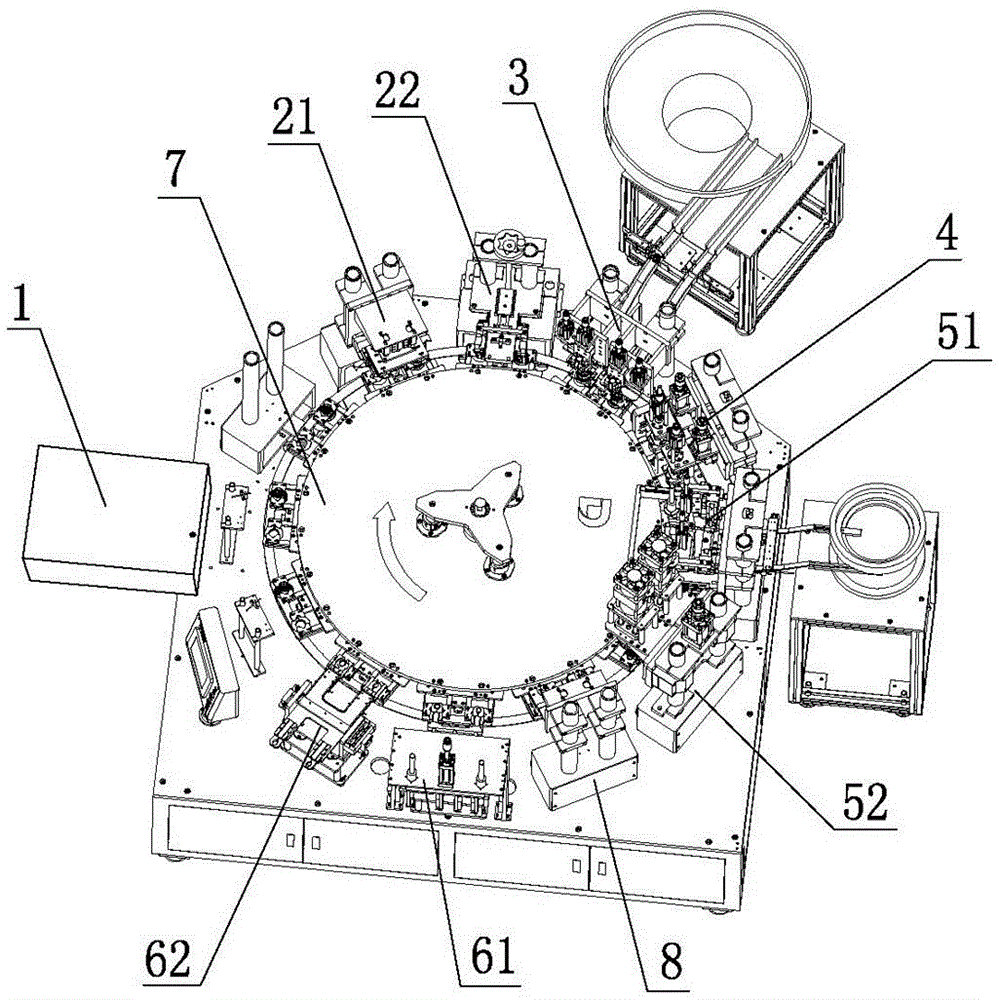

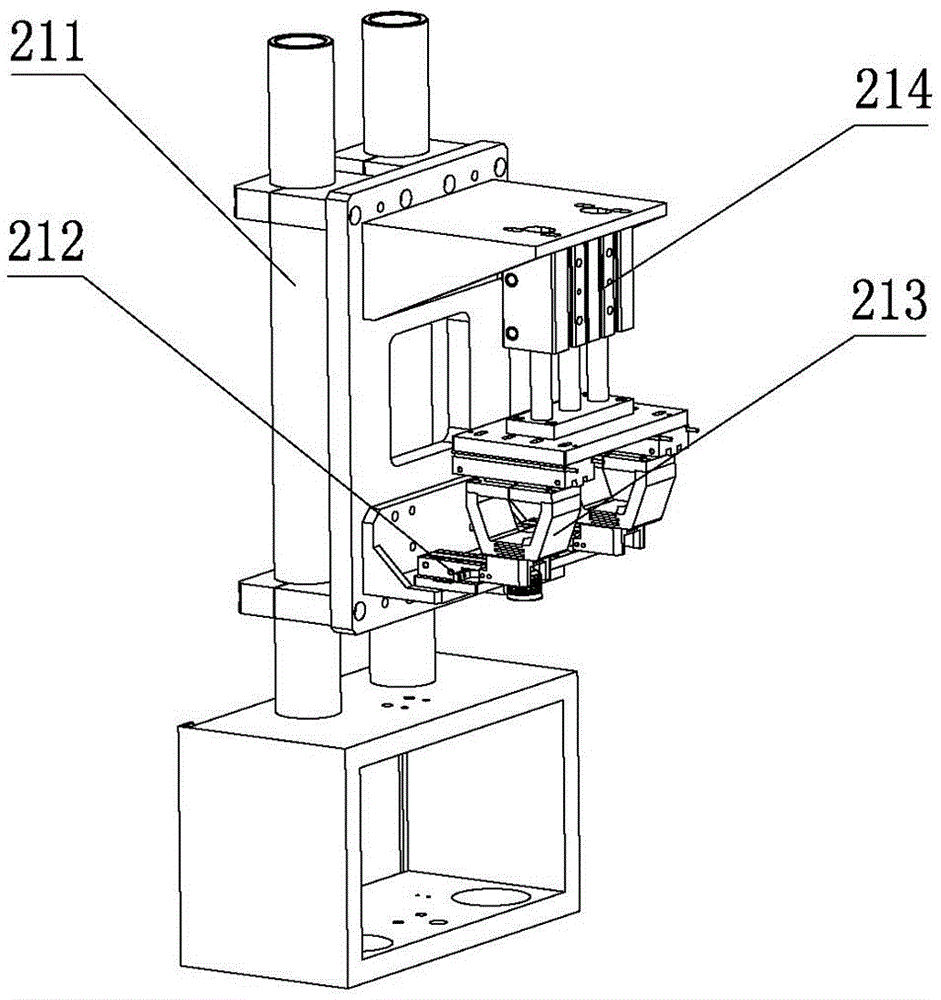

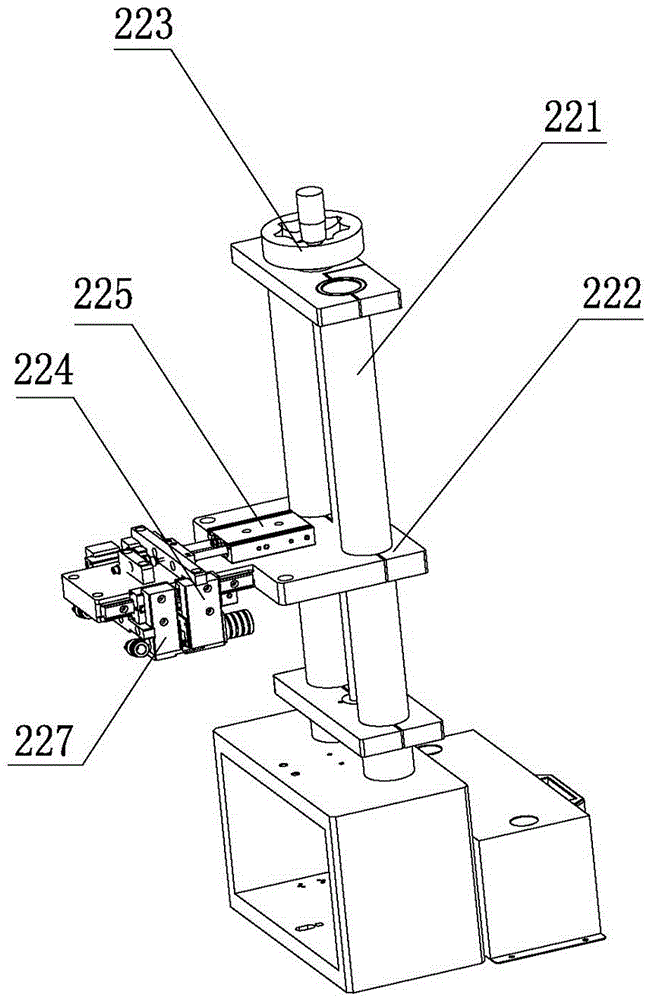

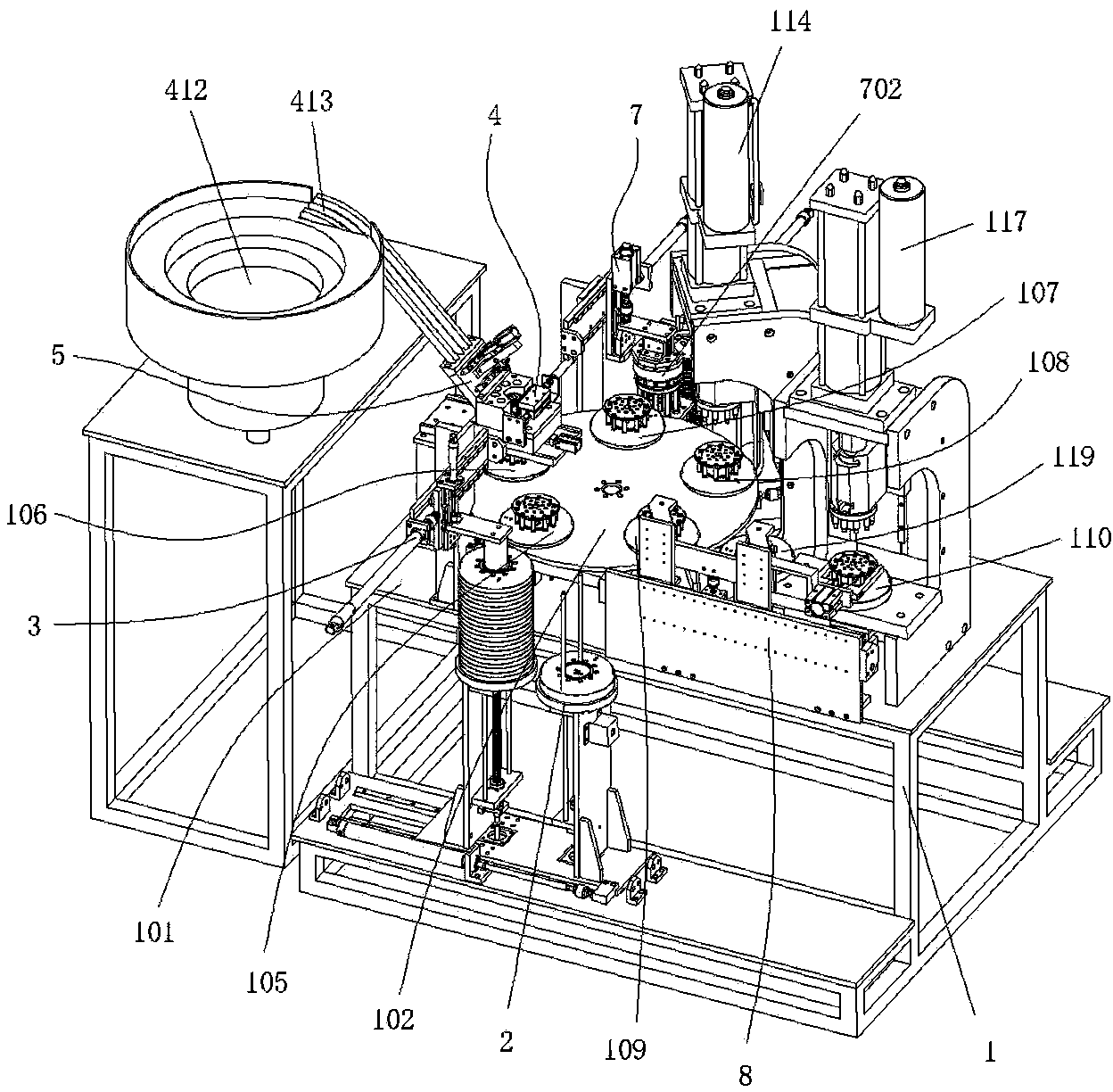

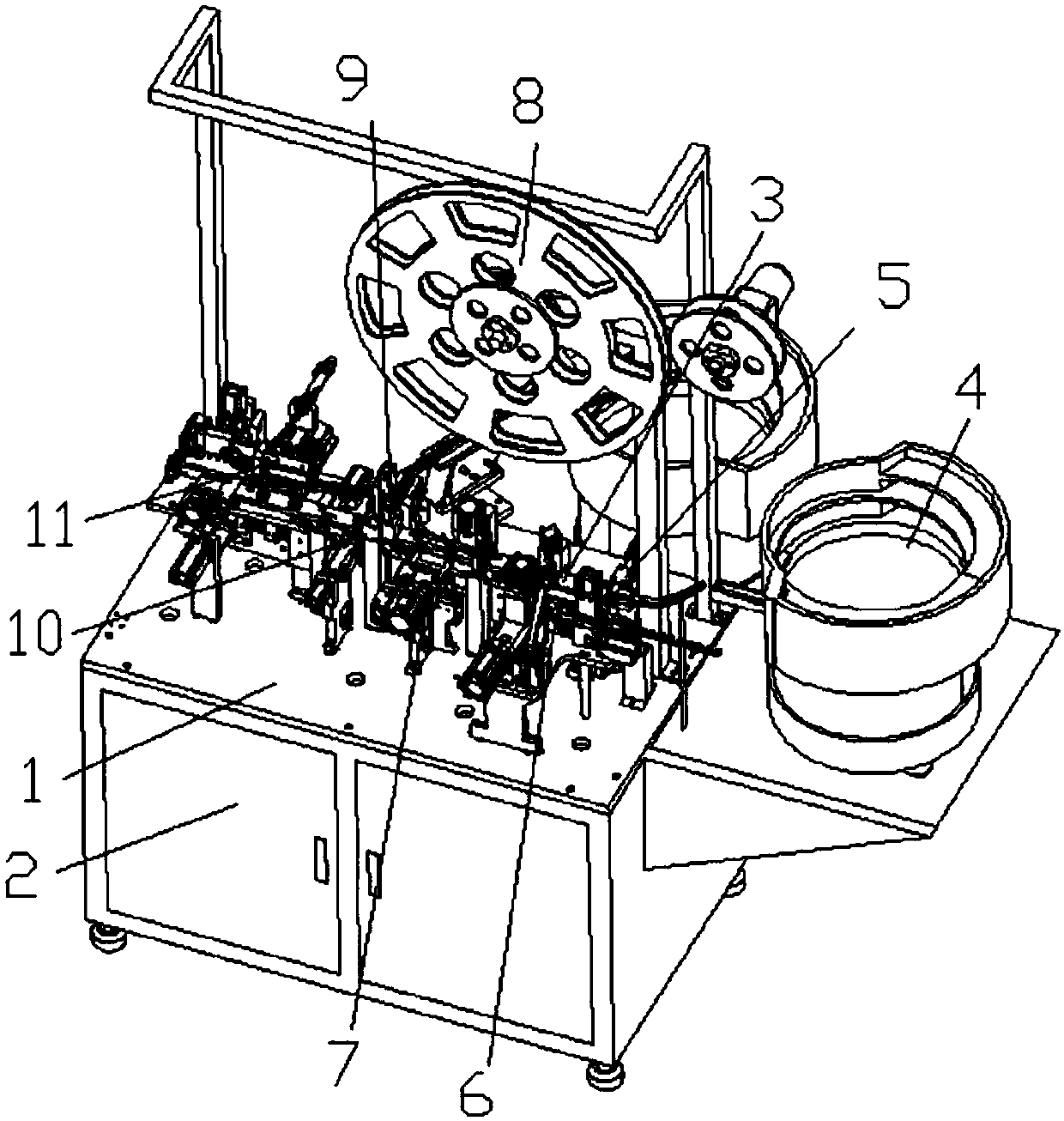

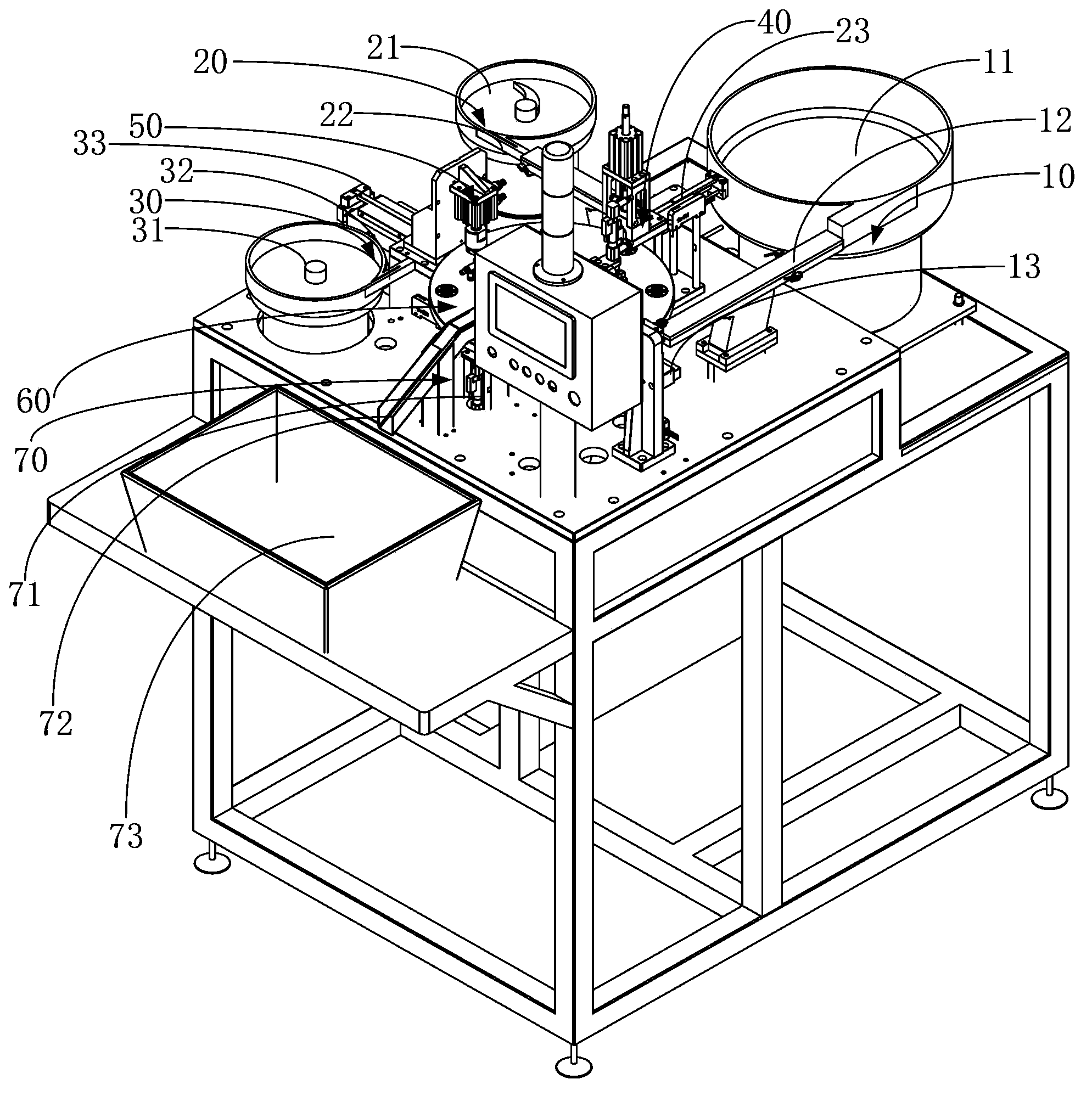

Automatic assembling machine for female joint of television signal line

ActiveCN103481060ARealize automated assemblyIncrease productivityAssembly machinesWork in processEngineering

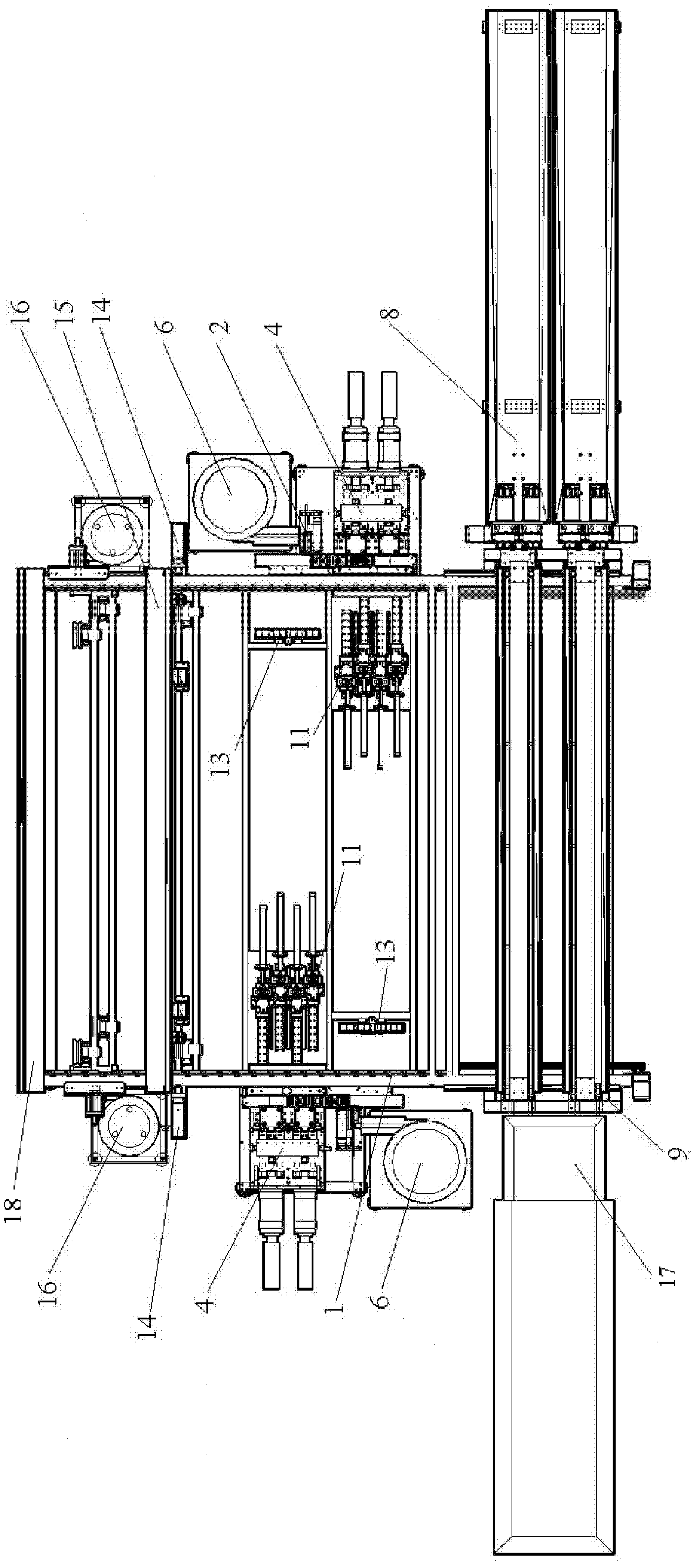

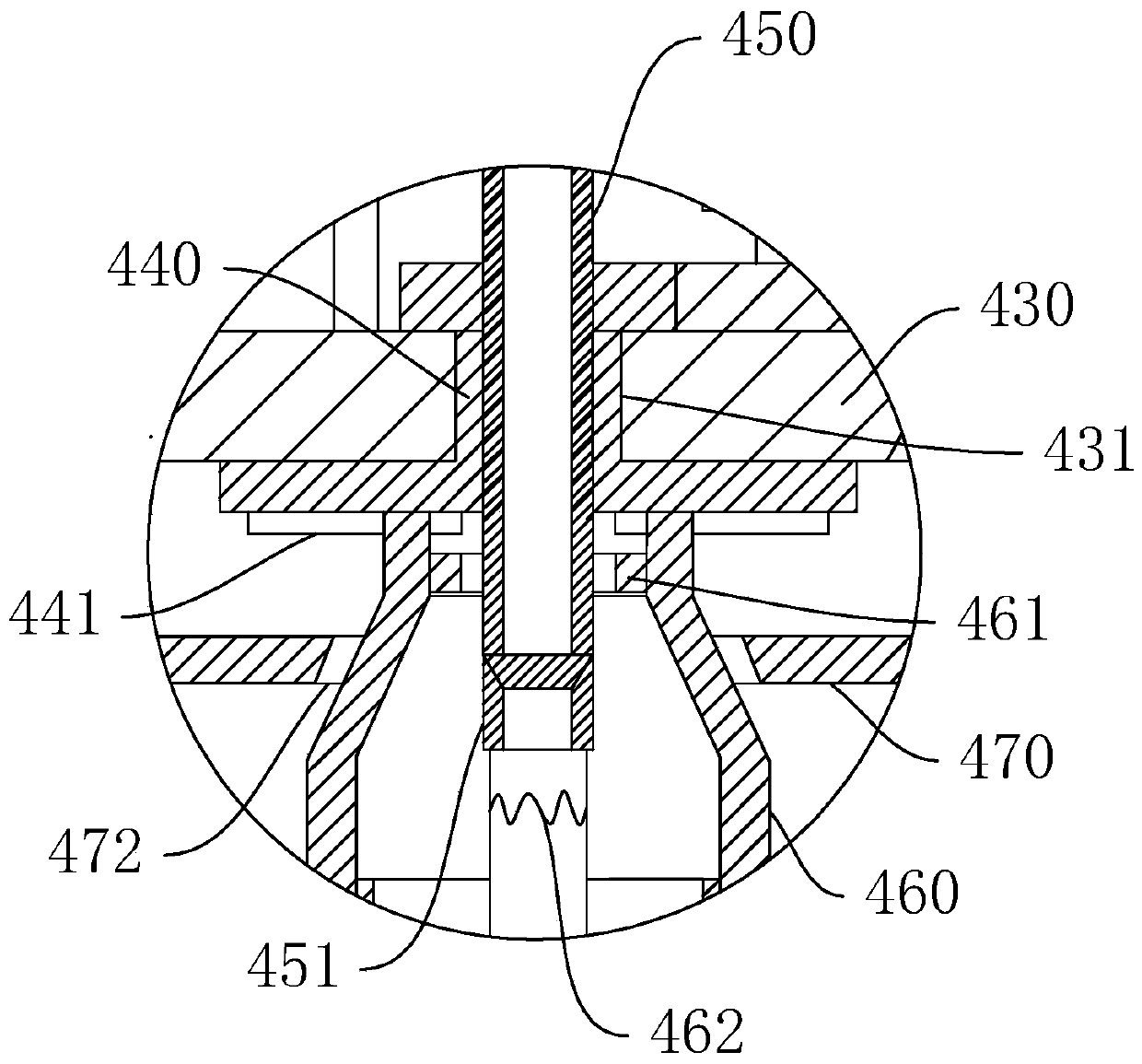

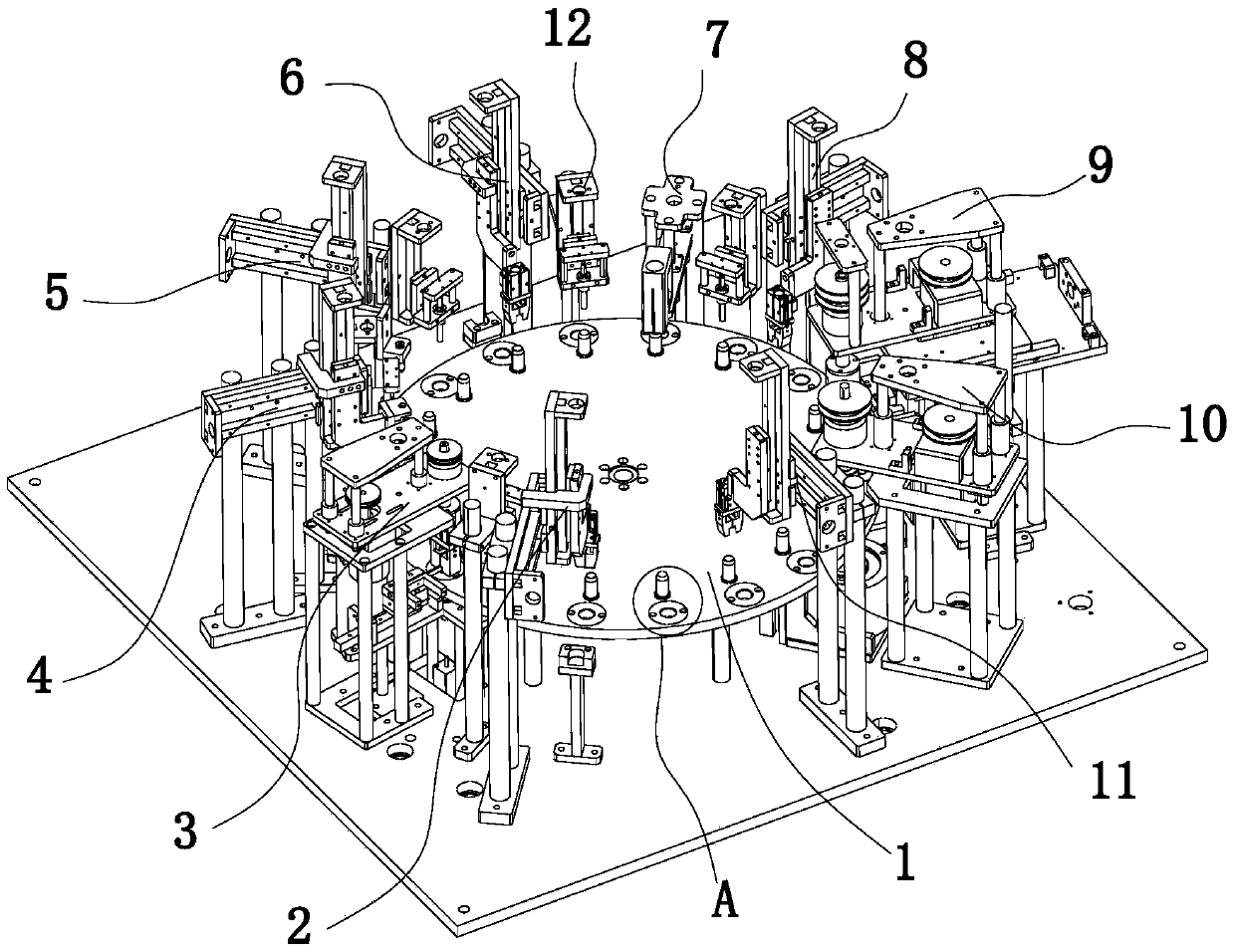

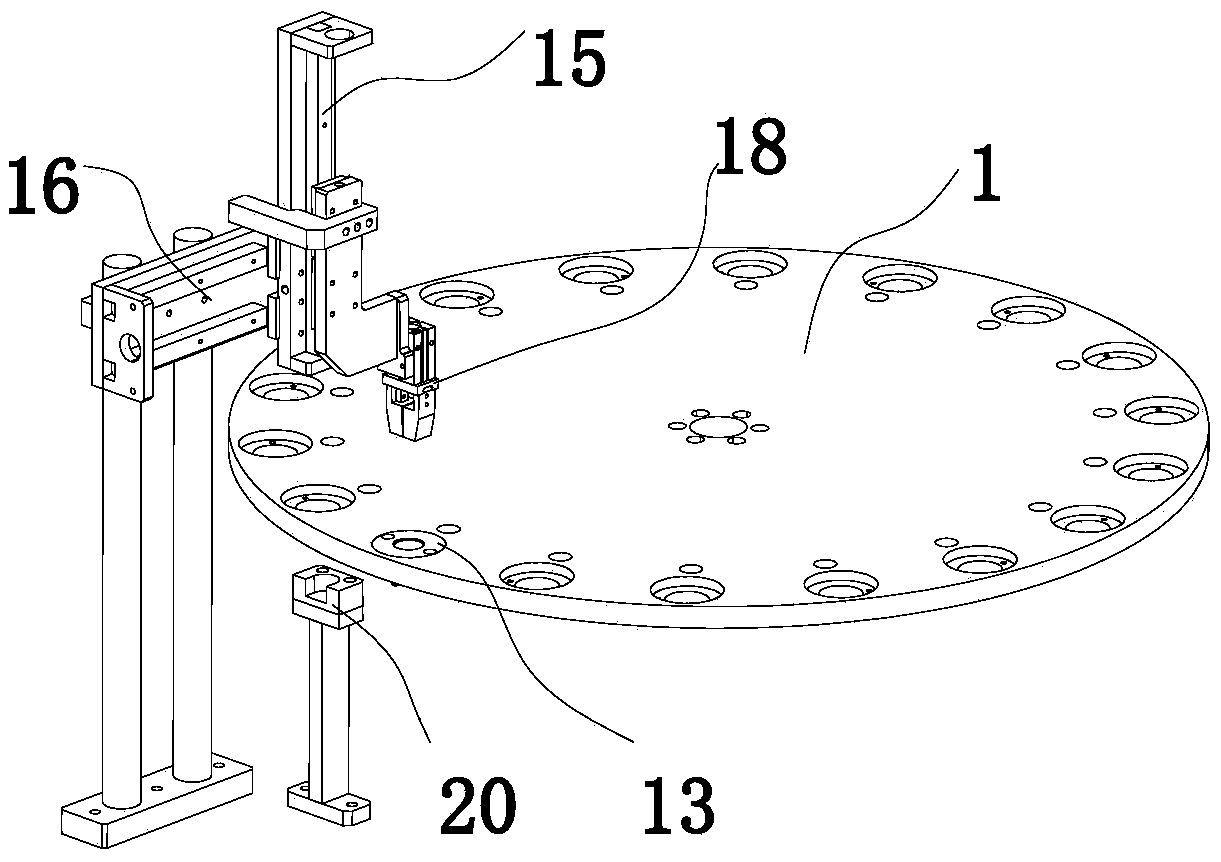

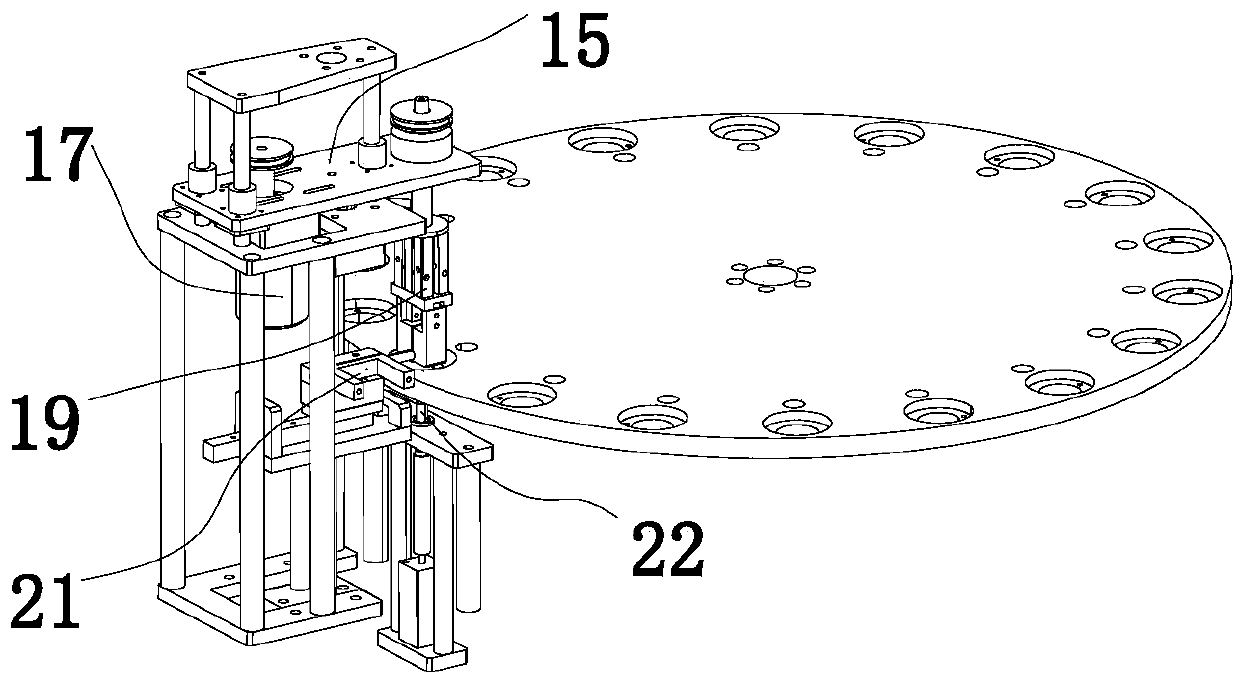

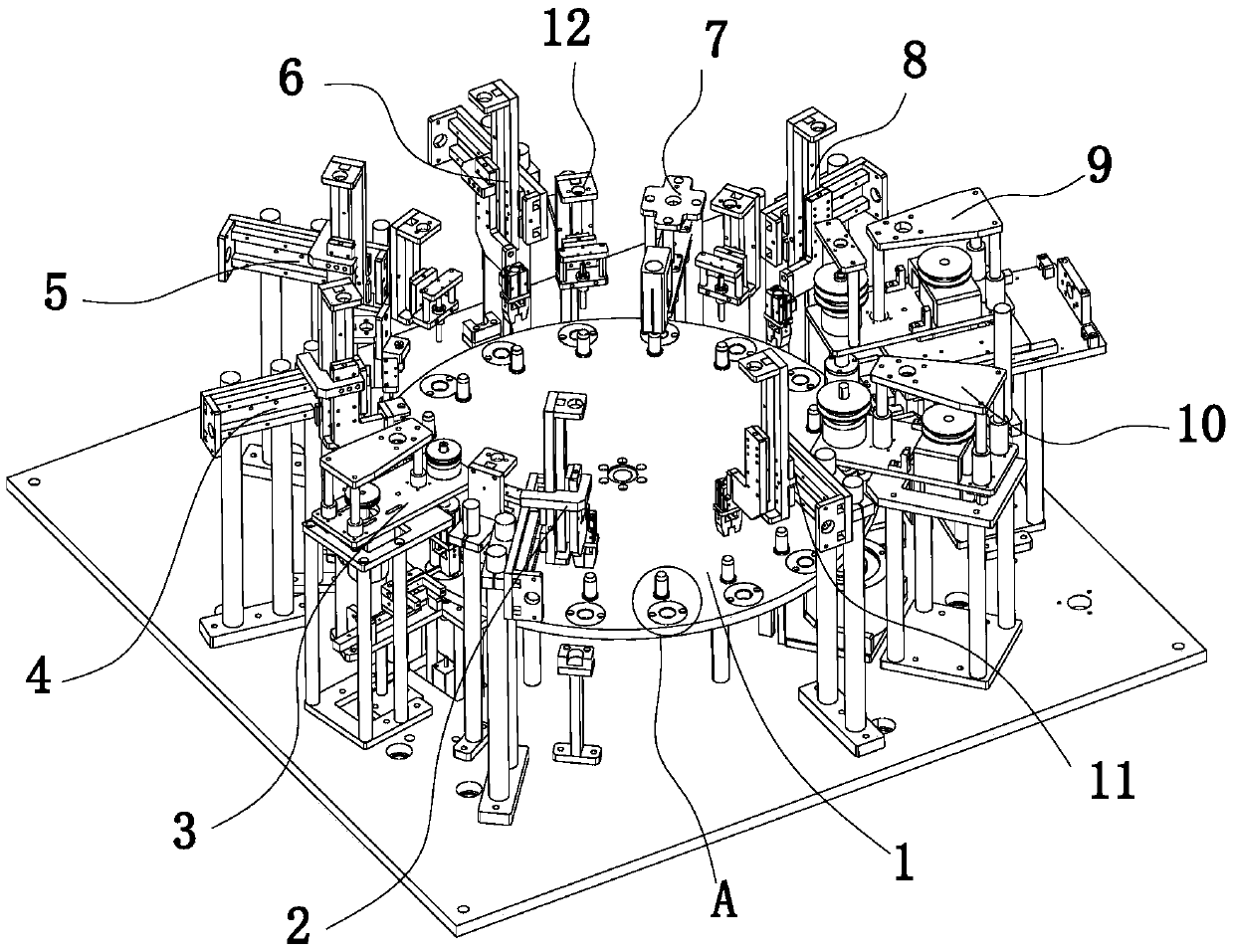

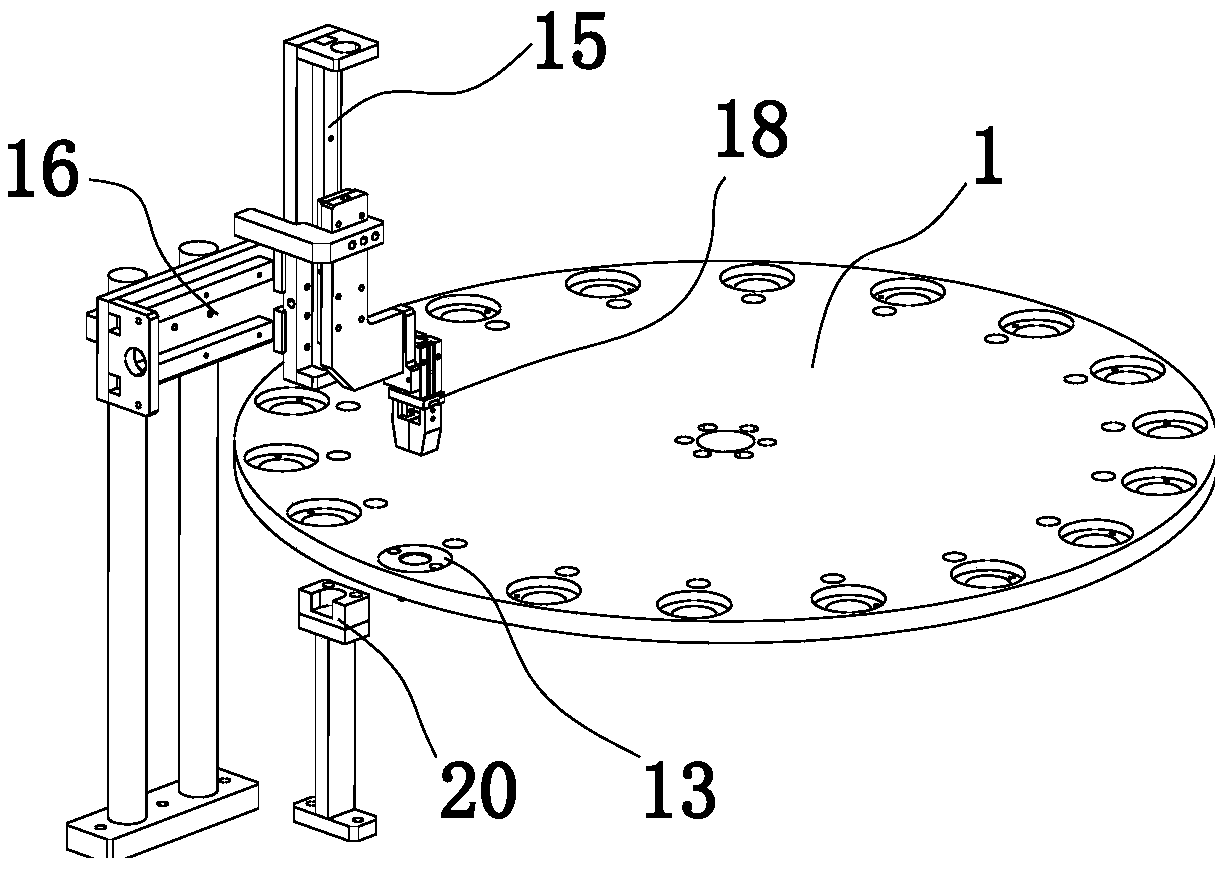

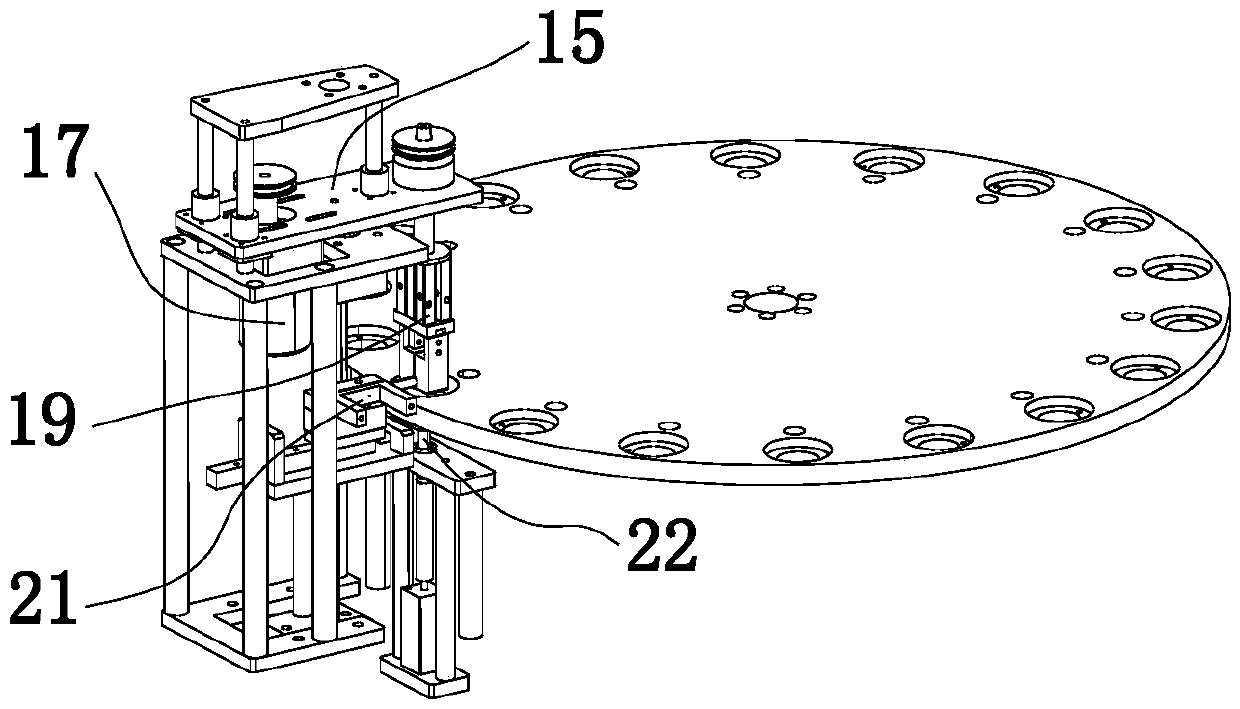

The invention relates to an automatic assembling machine for a female joint of a television signal line. The automatic assembling machine comprises a frame, a working platform and a multi-station turnplate. A plurality of locating modules are uniformly distributed on the multi-station turnplate, and locating slots are concavely arranged on the positioning modules. An upper shell station, an upper semi-finished product station, an upper insulating sleeve station, a riveting station and a discharge station are uniformly and sequentially distributed above the multi-station turnplate. A shell feed vibrating plate and a shell feed mechanism are arranged outside the upper shell station. A socket spring plate feed vibrating plate, an insulating seat feed vibrating plate, a semi-finished product assembling mechanism and a semi-finished product feed mechanism are arranged outside the upper semi-finished product station. An insulating sleeve feed vibrating plate and an insulating sleeve feed mechanism are arranged outside the upper insulating sleeve station. A riveting mechanism is arranged above the riveting station. A discharge channel and a discharge mechanism are arranged outside the discharge station. With the above structure, automatic assembly of the female joint of the television signal line can be achieved, and the assembling machine is high in production efficiency, low in labor intensity and high in qualification rate.

Owner:NINGBO XINGRUI ELECTRONICS TECH

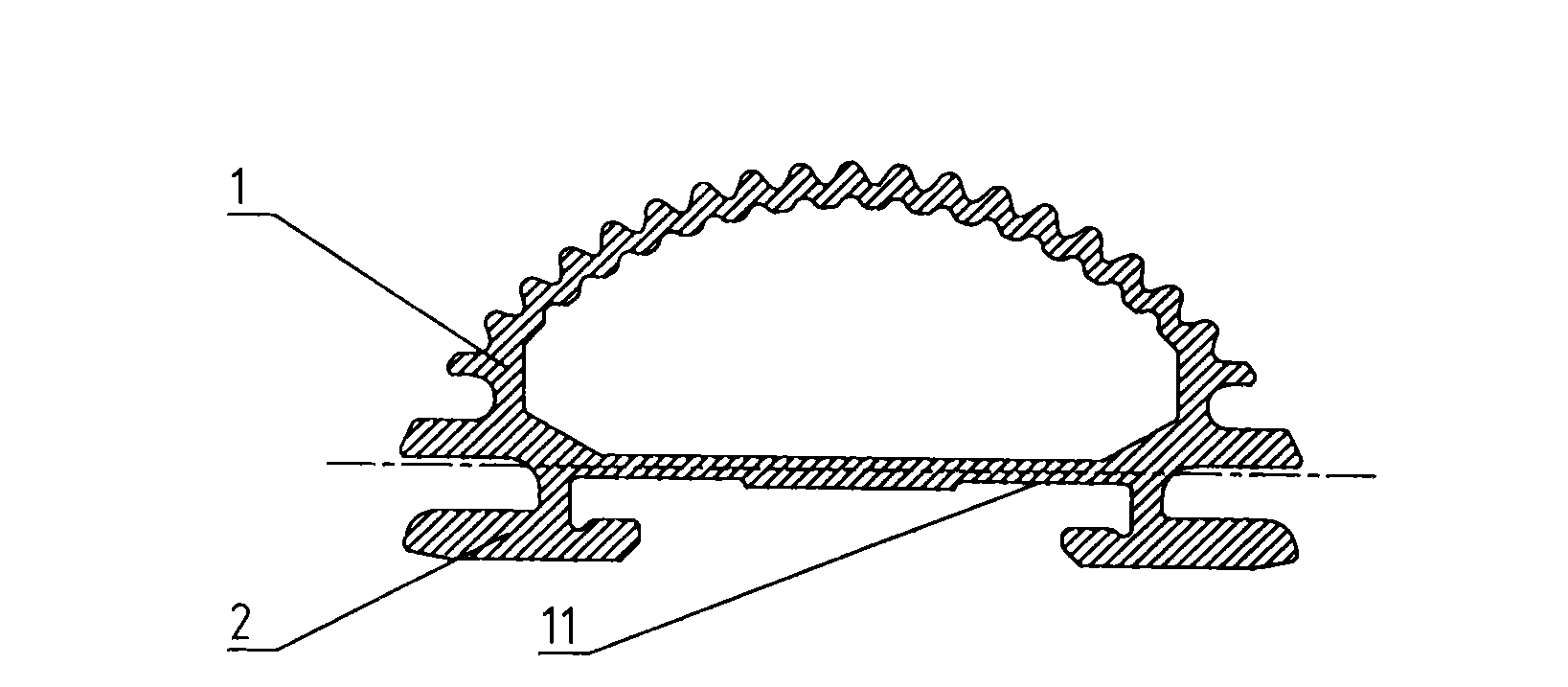

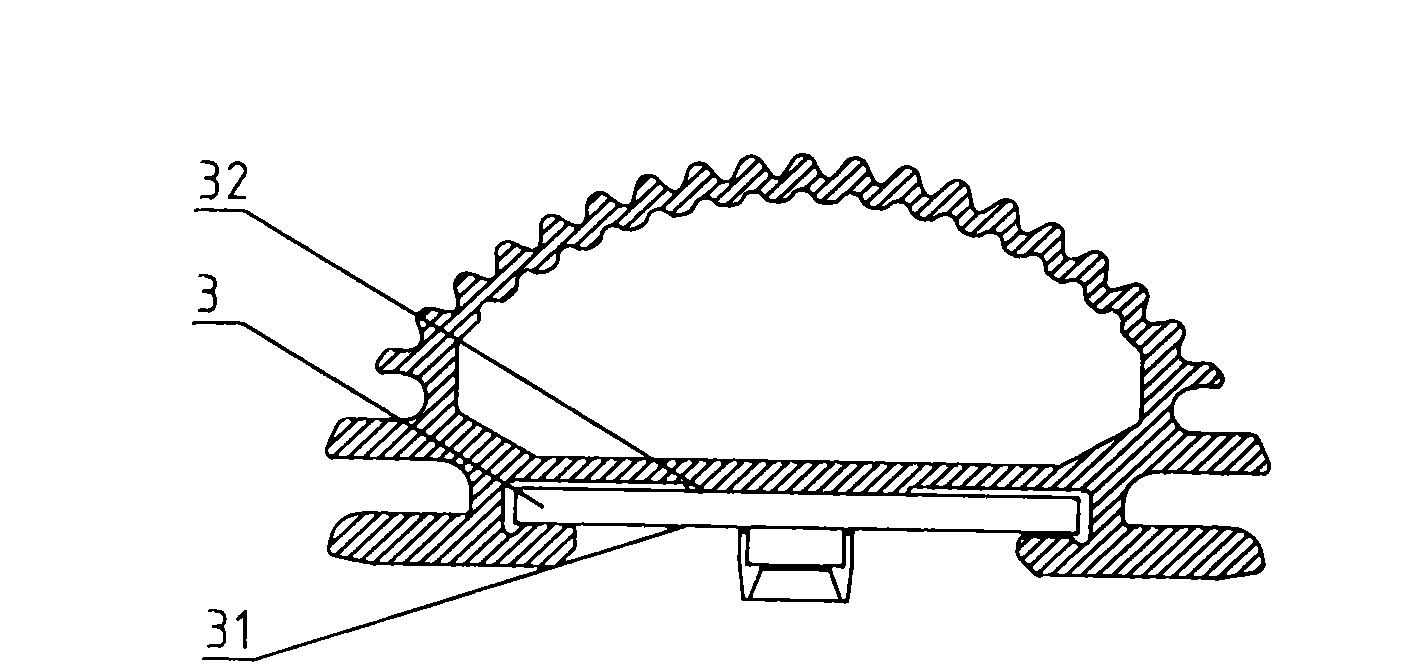

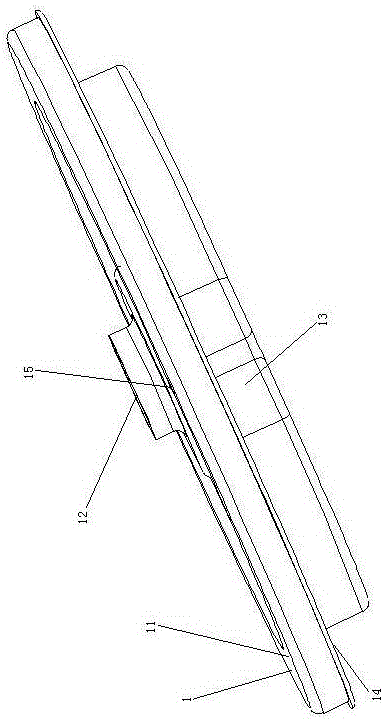

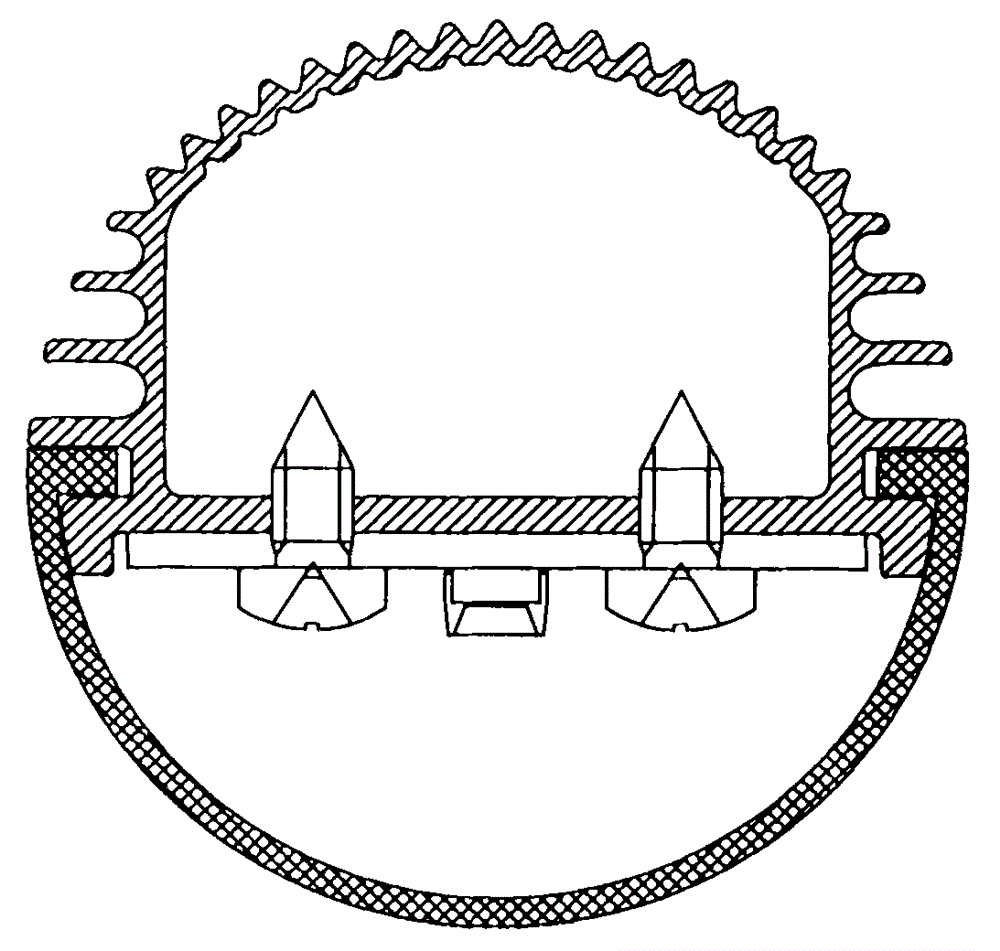

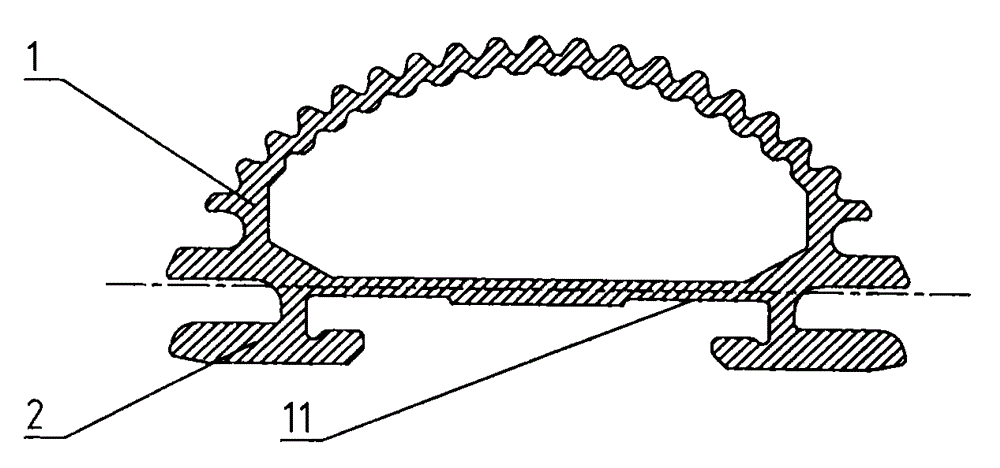

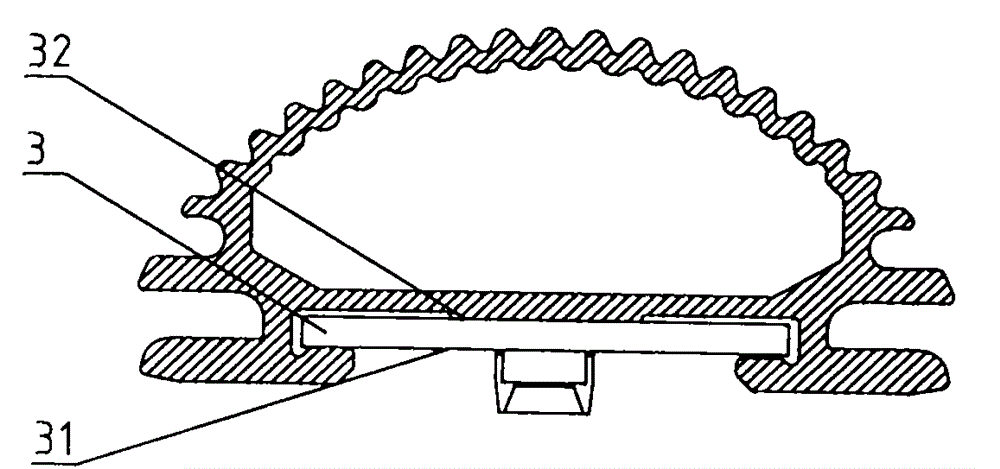

Manufacturing method of lamp-cover-supporting LED tubular lamp with self-clamping heat transmission substrate

InactiveCN103411140AAbsorb moreReduce absorptionPoint-like light sourceLighting heating/cooling arrangementsHeat transmissionEffect light

The invention discloses a manufacturing method of a lamp-cover-supporting LED tubular lamp with a self-clamping heat transmission substrate, and belongs to the technical field of supporting or hanging or connecting of lighting devices. The manufacturing method of the LED tubular lamp includes the steps that S1, the heat transmission substrate is inserted into strip-shaped clamping grooves from side ports of the strip-shaped clamping grooves; S2, after the heat transmission substrate is installed in the strip-shaped clamping grooves, a lamp cover covers a radiator; S3, the lamp cover exerts two acting forces on two T-shaped hooks, and the heat transmission substrate is installed in the strip-shaped clamping grooves in a clamped mode; S4, the radiator, the heat transmission substrate and the lamp cover form a lamp tube of the LED tubular lamp, and two end covers are installed at the two ends of the lamp tube of the LED tubular lamp. According to the lamp-cover-supporting LED tubular lamp with the self-clamping heat transmission substrate, the heat transmission substrate can be arranged in the strip-shaped clamping grooves in the clamped mode because the strip-shaped clamping grooves are formed in an installing part of the heat transmission substrate, heat dissipation efficiency can be improved, and the heat transmission substrate is prevented from thermal deformation.

Owner:辽宁三维传热技术有限公司 +1

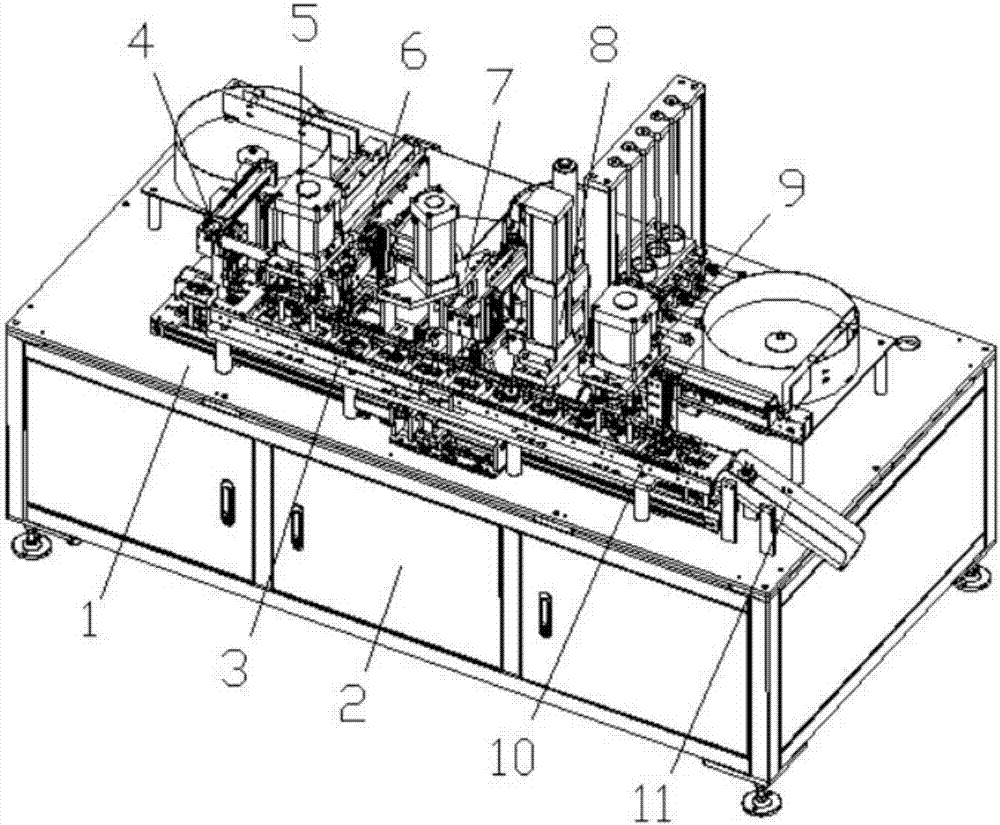

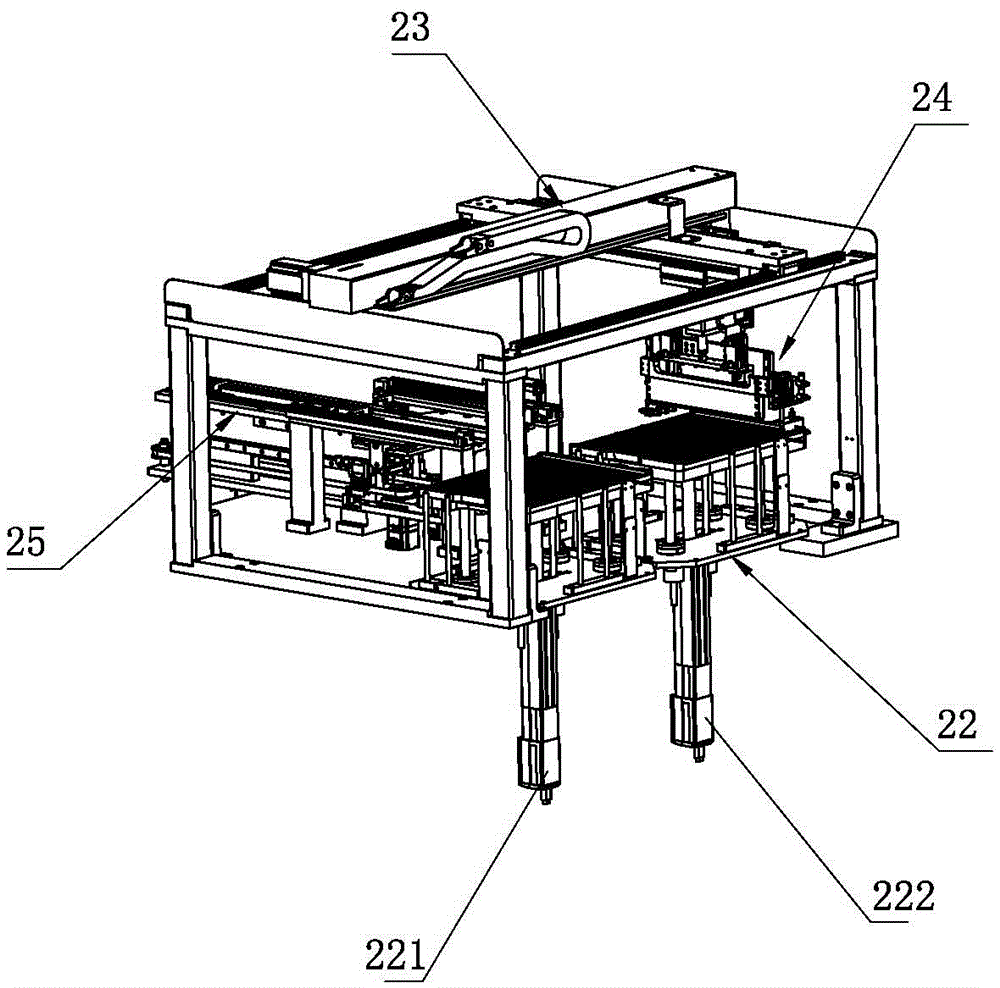

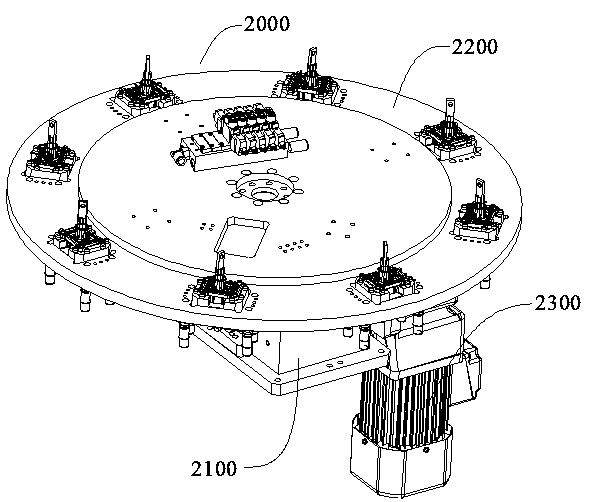

Irregular-shaped radiating fin automatic assembling device

InactiveCN103551849ARealize automated assemblyPrecise positioningPrecision positioning equipmentOther manufacturing equipments/toolsProduction lineEngineering

An irregular-shaped radiating fin automatic assembling device belongs to the automatic assembling field and is composed of a fixed bottom plate, a divider, a turntable, a feeding mechanical mechanism, a drilling mechanism, a tapping mechanism, a welding pin feeding mechanism, a welding pin clamping mechanism, a discharging mechanical mechanism, a slag removing mechanism and clamps. The whole assembling system adopts a rotary production line and is accomplished by using eight working positions; each working position is provided with one clamp for fixing the radiating fin. The irregular-shaped radiating fin automatic assembling device has the beneficial effects of realizing automatic assembling of the irregular-shaped radiating fin, increasing the assembling efficiency, saving labor force and cost, guaranteeing the machining precision as the self-produced clamps clamp the radiating fin automatically and position the radiating fin exactly by utilizing springs, and guaranteeing scale division quality as the divider divides the scale of each working position exactly by utilizing a cam division mechanism.

Owner:杜桂林

Automatic assembly equipment for LED (Light-Emitting Diode) bulb lamp

ActiveCN106425460AProvides productivityImprove product qualityAssembly machinesWaste productEngineering

The invention relates to the technical field of manufacturing of an LED lamp and particularly relates to automatic assembly equipment for an LED bulb lamp. The automatic assembly equipment comprises a lamp holder feeding device, a wire embedding device, a lamp cap mounting device, a wire bending device, a lamp nail mounting device, a blanking device and a conveying device, wherein the wire embedding device is used for settling wires on a lamp holder; the lamp cap mounting device is used for mounting a lamp cap on the lamp holder; the wire bending device is used for bending the wires; the lamp nail mounting device is used for mounting a lamp nail at the upper end of the lamp cap; the conveying device is used for conveying the lamp holder among all devices; the wire embedding device comprises a wire embedding mechanism and a wire shearing mechanism; the lamp nail mounting device comprises a lamp nail feeding mechanism and a riveting mechanism, wherein the riveting mechanism is used for fixedly connecting the lamp nail with the lamp holder. By the structure, the automatic assembly equipment provided by the invention has the advantages of realizing automatic assembly of the lamp cap and the lamp holder of the LED bulb lamp, improving the production efficiency, improving the product quality, reducing generation rate of waste products and realizing automatic large-scale production.

Owner:广东立迪智能科技有限公司

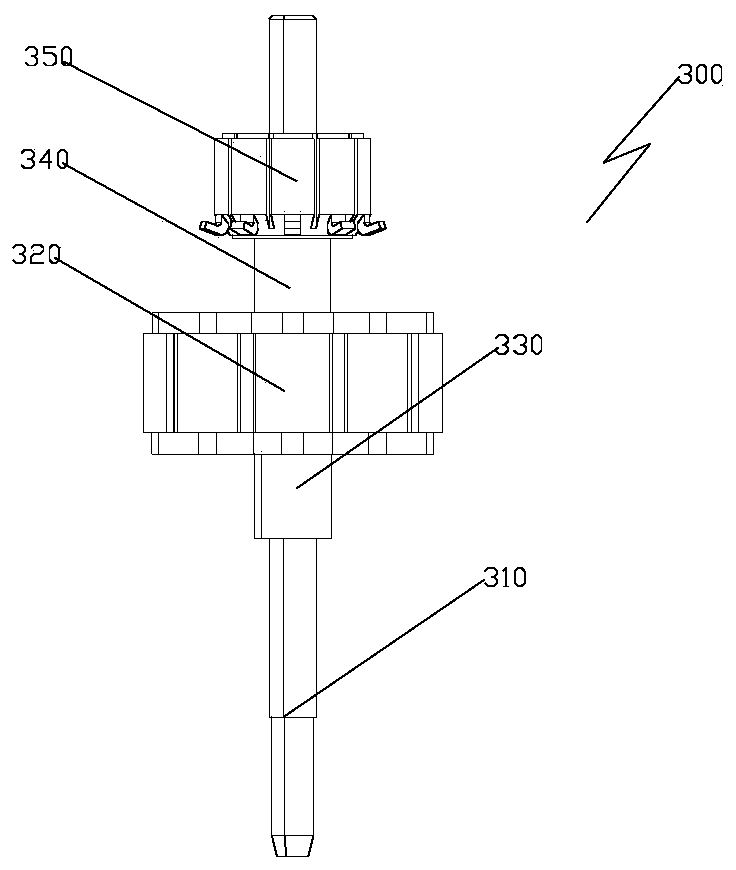

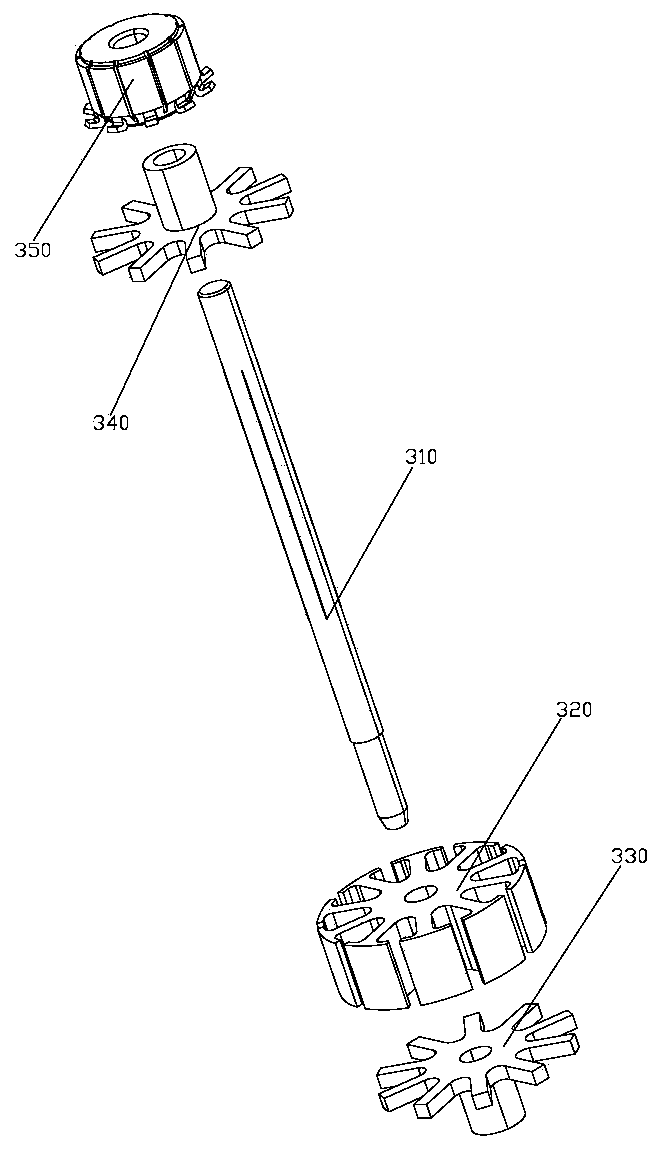

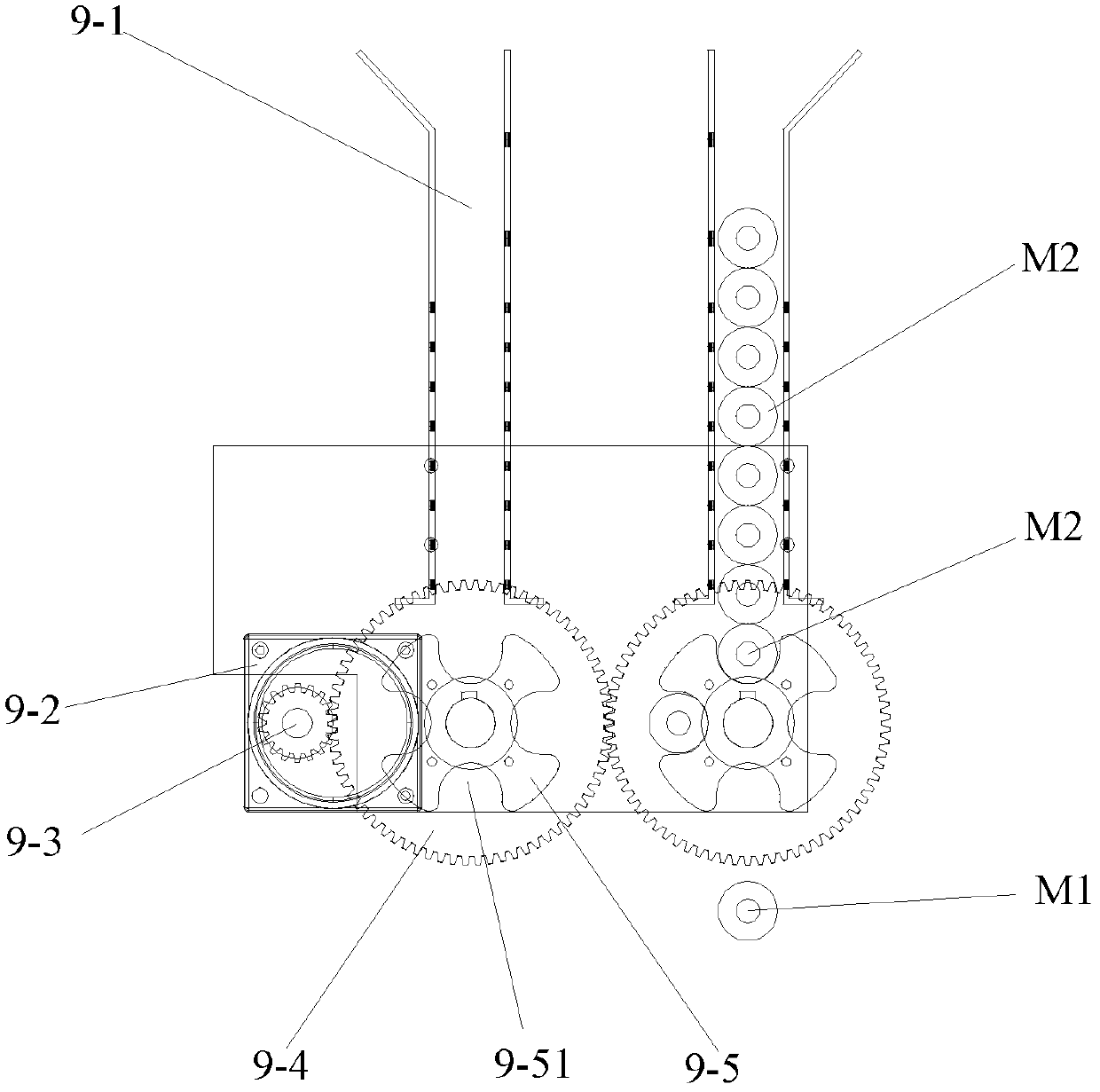

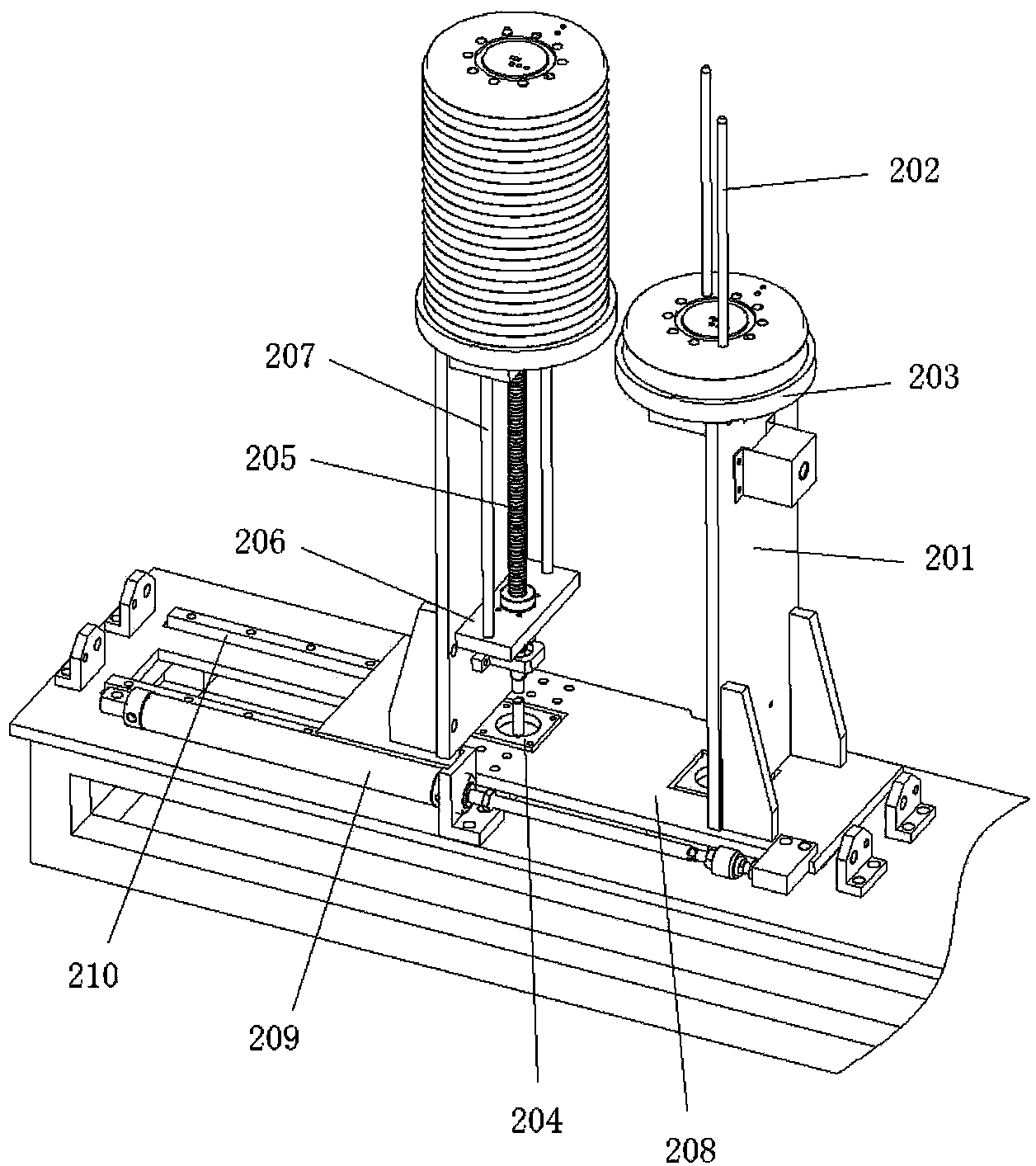

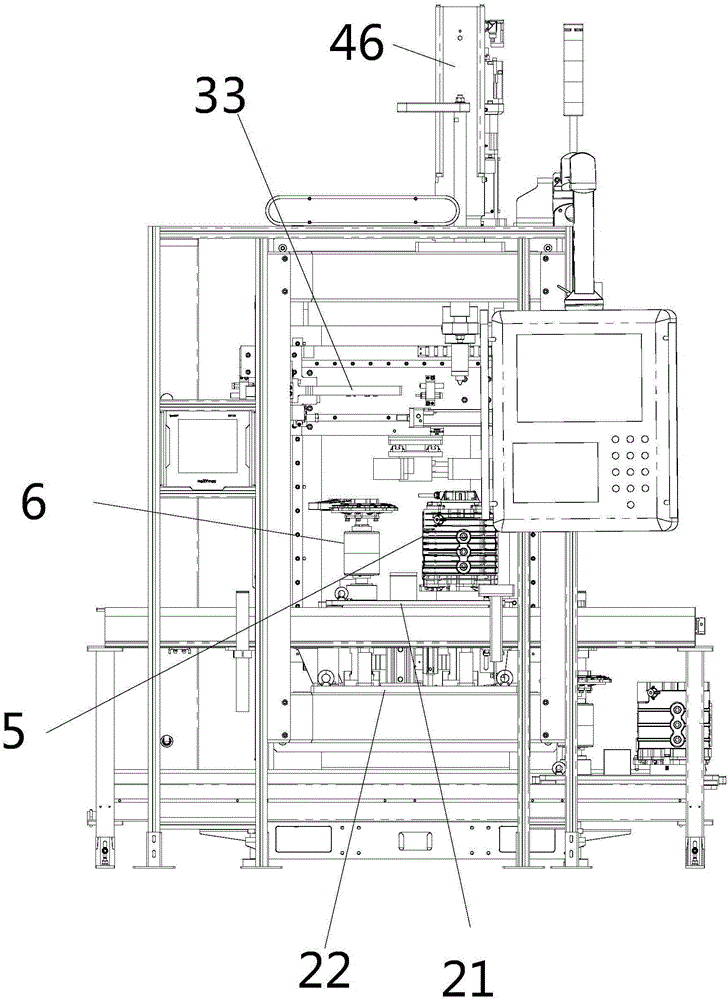

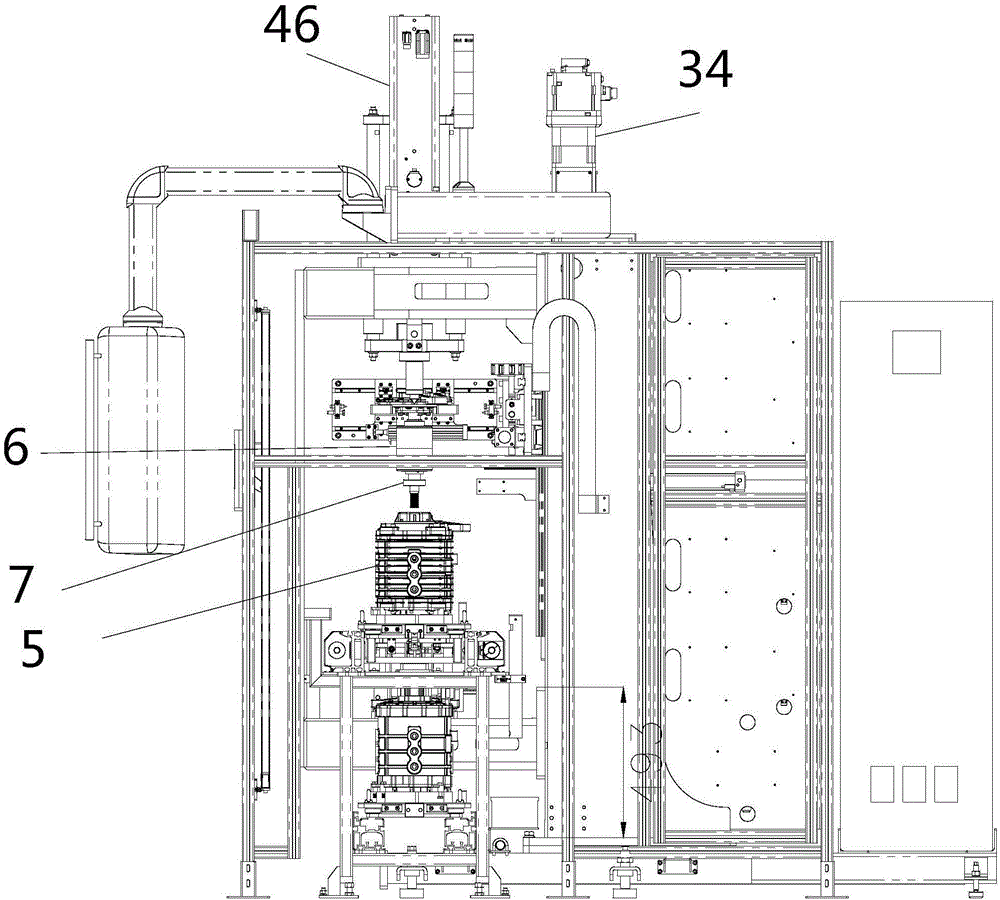

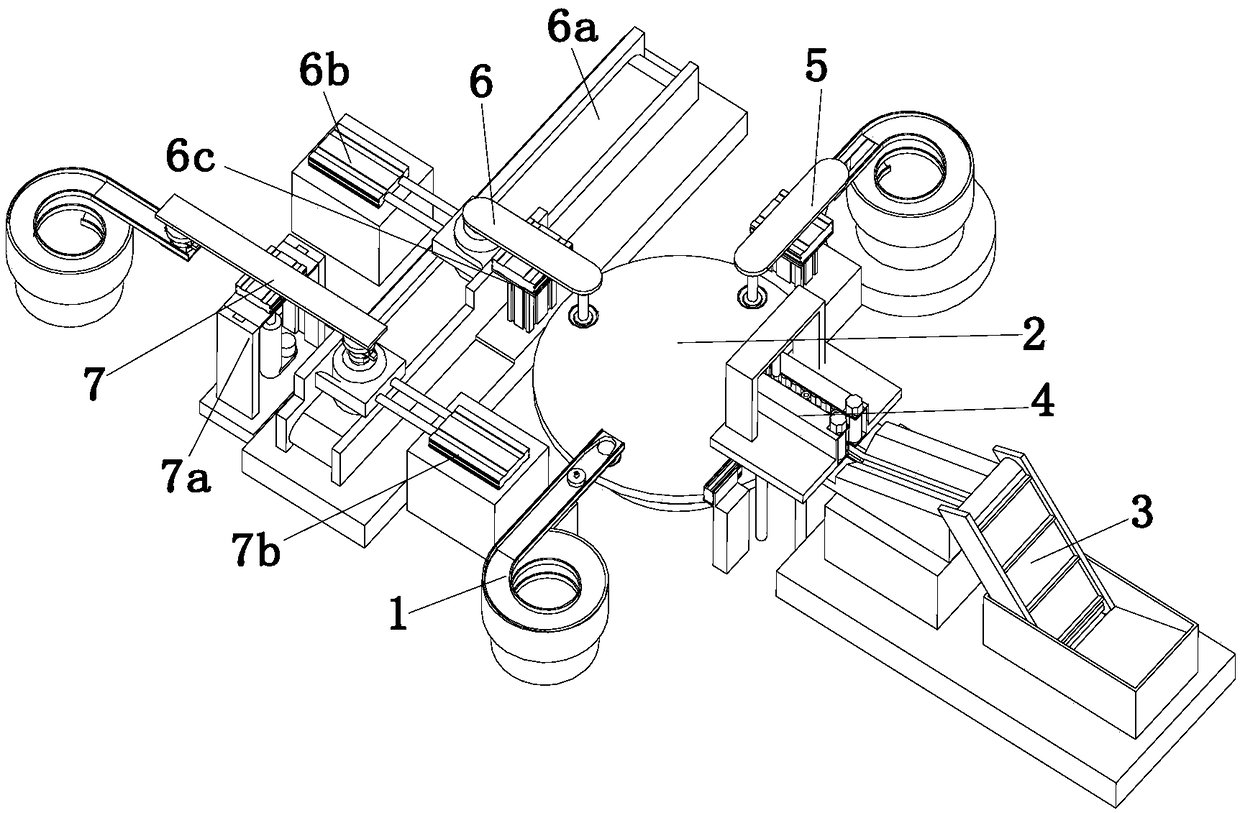

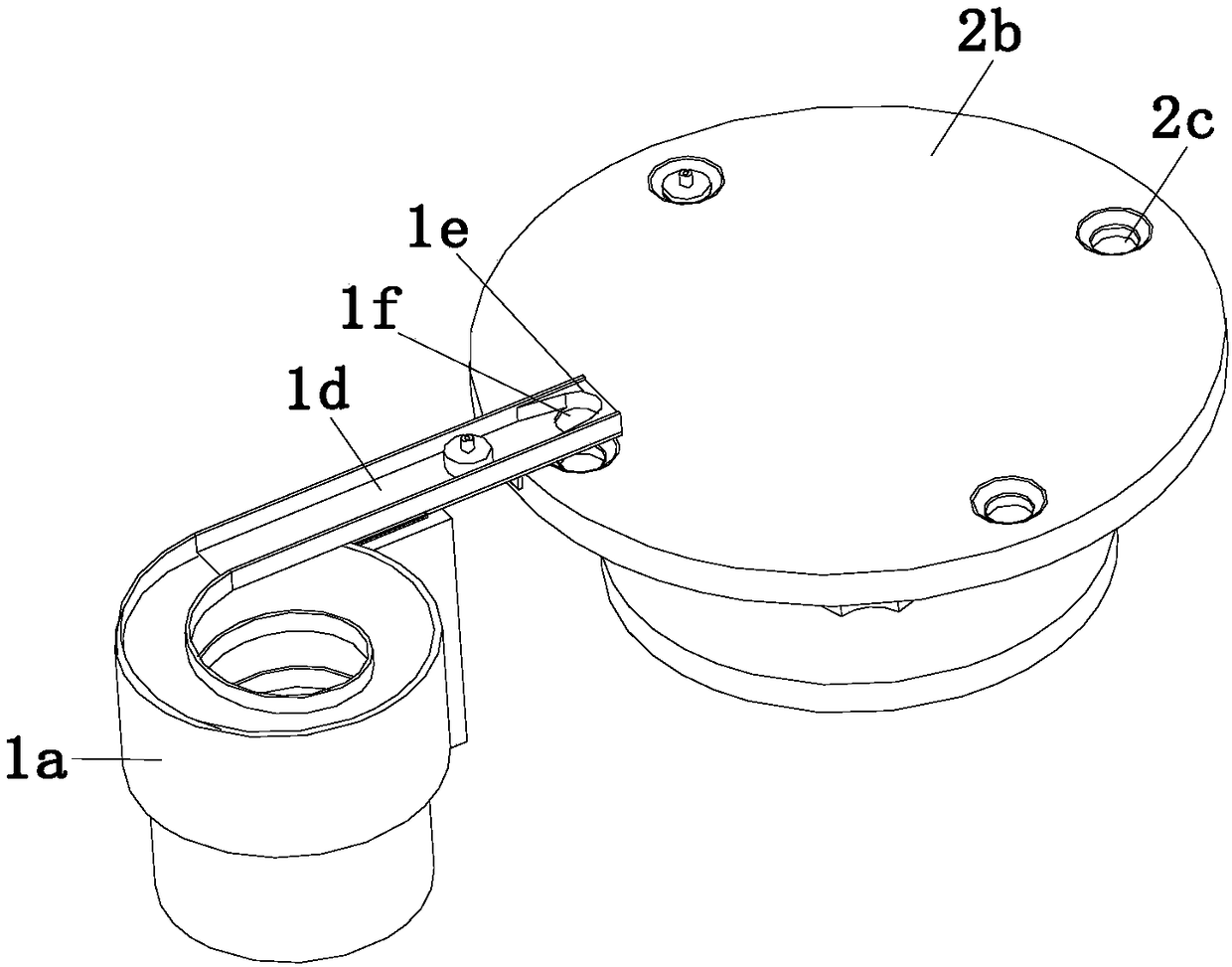

Electric machinery rotor automatic press-fitting machine

ActiveCN110142590ARealize automated assemblyIncrease productivityManufacturing stator/rotor bodiesMetal working apparatusElectric machineryCharging station

The invention discloses an electric machinery rotor automatic press-fitting machine. The electric machinery rotor automatic press-fitting machine comprises a machine frame, an iron core conveying device, a limiting transfer platform, a rotary workbench and a discharging conveying device; an iron core charging device is arranged on one side of the front end of the iron core conveying device; a mandrel charging device and a mandrel press-in device are arranged at the corresponding positions of the two sides of a mandrel insertion station at the front end of the limiting transfer platform; an automatic discharging device corresponding to a limiting transfer channel of the limiting transfer platform is arranged; the mandrel press-in device is arranged on one side of a mandrel press-in stationlimiting transfer channel at the rear end of the limiting transfer platform; a transition conveying device is arranged between the tail end of the limiting transfer platform and the rotary workbench;and a lower end plate charging station, a lower end plate insertion station, an upper end plate insertion station, a commutator insertion station, a commutator correction adjustment station, a commutator press-in station and a rotor discharging station are uniformly arranged on the rotary workbench. Automatic assembly of electronic rotors can be achieved, the production efficiency is high, and theassembly quality is stable.

Owner:深圳市兴特创自动化设备有限公司

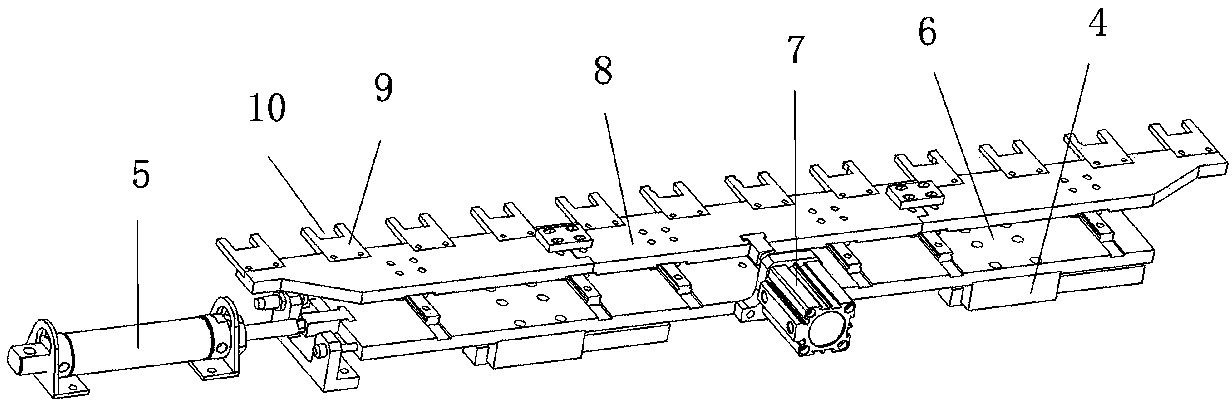

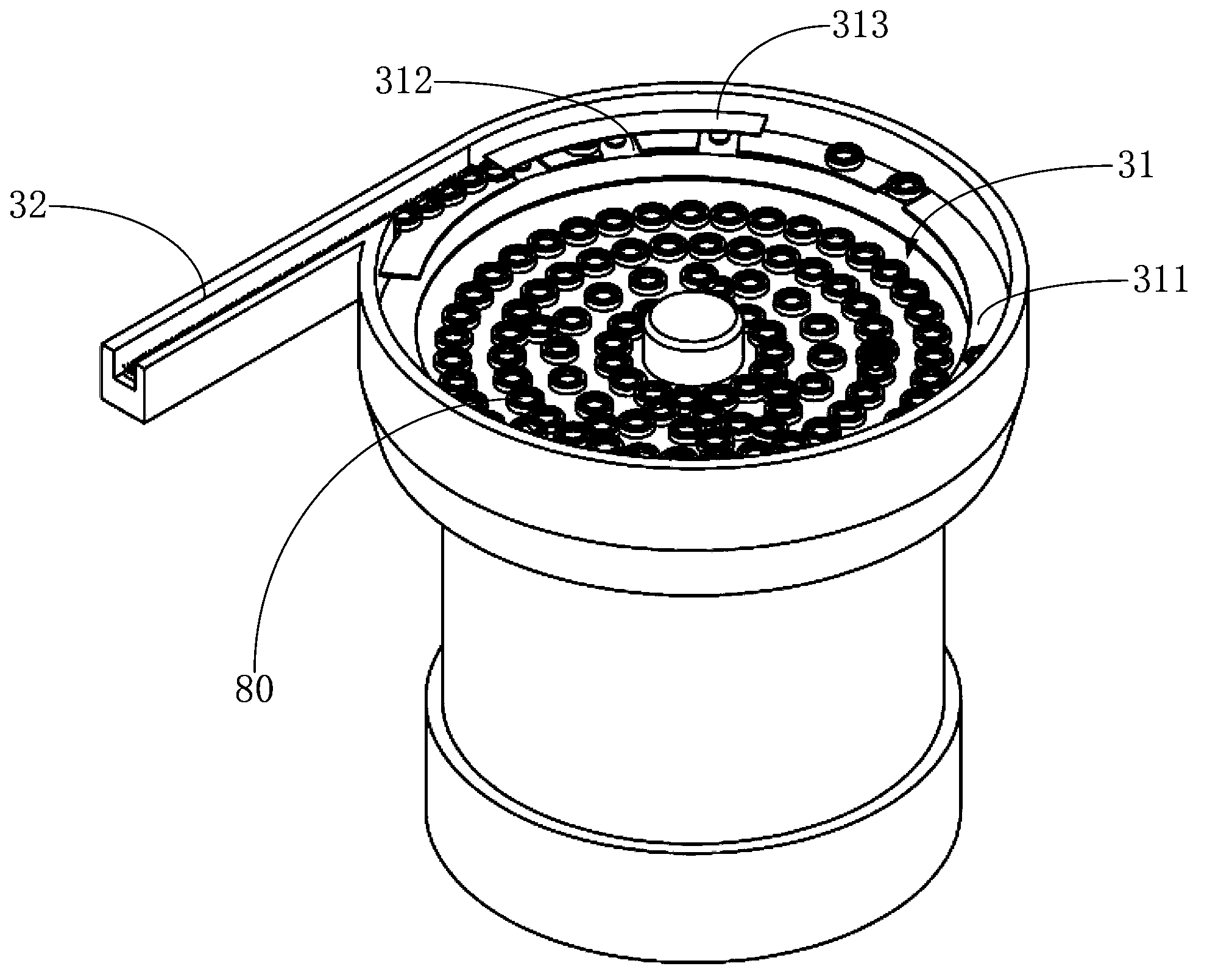

Automatic gear shaft assembling machine

InactiveCN107571008AHigh matching precisionImprove assembly efficiency and yieldAssembly machinesManipulatorBall bearing

The invention relates to an automatic gear shaft assembling machine. The rack is provided with a carrier conveying device. The carrier conveying device comprises a carrier conveying base. Carrier feeding movable air cylinders are arranged on the front side and the rear side of the carrier conveying base and connected with a carrier feeding movable base. The carrier feeding movable base is connected with a carrier feeding movable block. A carrier feeding clamping block matched with a carrier is arranged on the inner side of the carrier feeding movable block. A carrier feeding lifting matched sliding rail is arranged at the upper portion of the carrier feeding movable block and matched with a carrier feeding lifting matched sliding block. The upper portion of the carrier feeding lifting matched sliding block is matched with a carrier feeding lifting air cylinder on the rack. The rack is provided with a ball bearing feeding device, a shaft rod feeding device, an overturning device, a clamping ring feeding device, a gear feeding device, a clamping bearing feeding device and a discharging mechanical arm. According to the automatic gear shaft assembling machine, automatic ball bearing and shaft rod assembling can be achieved, and the assembling efficiency and the yield are greatly improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

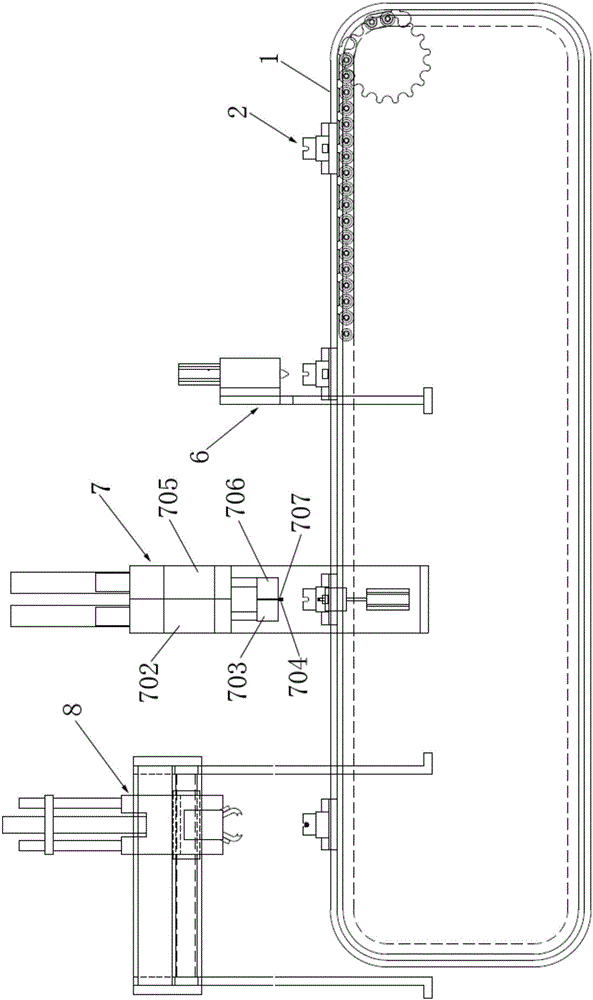

Assembly line for transformers

ActiveCN106586559ARealize automated assemblyIncrease productivityInductances/transformers/magnets manufactureConveyor partsTransformerAdhesive

The invention relates to the technical field of automatic assembly of transformers, in particular to an assembly line for the transformers. The assembly line comprises an assembly line rack. The assembly line rack is provided with a magnetic core feeding device for feeding magnetic cores, a magnetic core adhesive dispensing device for adhesive-dispensing the fed magnetic cores, a wire wrap feeding device for feeding wire wraps and a magnetic core and wire wrap combination mechanism for turning over and combining the fed magnetic cores and the wire wraps. The assembly line rack is provided with a transformer encapsulation device for encapsulation of the combined magnetic cores and the wire wraps. The assembly line rack is provided with an electric detection device for conducting electric property detection on the encapsulated transformers. The assembly line rack is provided with a sorting manipulator for sorting qualified products and defective products of the transformers. By the adoption of the assembly line for the transformers, automatic assembly of the transformers is achieved, the production efficiency is improved, and the labor cost is saved.

Owner:DONGGUAN UGREN AUTOMATION EQUIP

Motor end cover assembly machine

ActiveCN105099105ARealize automated assemblyGood degree of automationManufacturing dynamo-electric machinesEngineeringAssembly machine

The invention relates to a device for motor production. A motor end cover assembly machine comprises a rack, wherein the rack is provided with a motor shell fixing structure, a motor end cover storage mechanism, a separation mechanism and a motor end cover pre-installation mechanism, the motor end cover storage mechanism is provided with a vertically-arranged motor end cover penetrating connection rod, the separation mechanism is used for separating motor end covers sleeved on the motor end cover penetrating connection rod one by one, and the motor end cover pre-installation mechanism is used for transferring and assembling the motor end covers separated by the separation mechanism onto a motor shell arranged in the motor shell fixing structure. The invention provides a motor end cover assembly machine by which the motor end covers can be installed on motor shell, and the problems of labor waste existing in manual assembly of the motor end covers and low automatic degree are solved.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

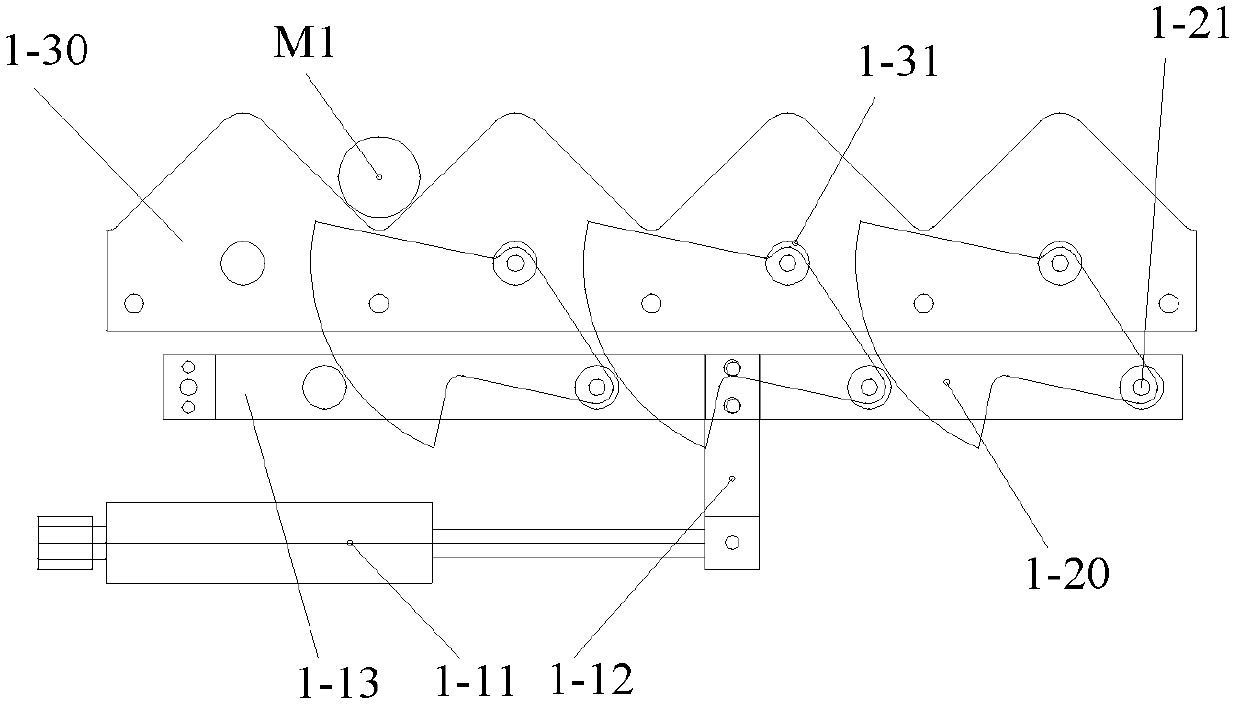

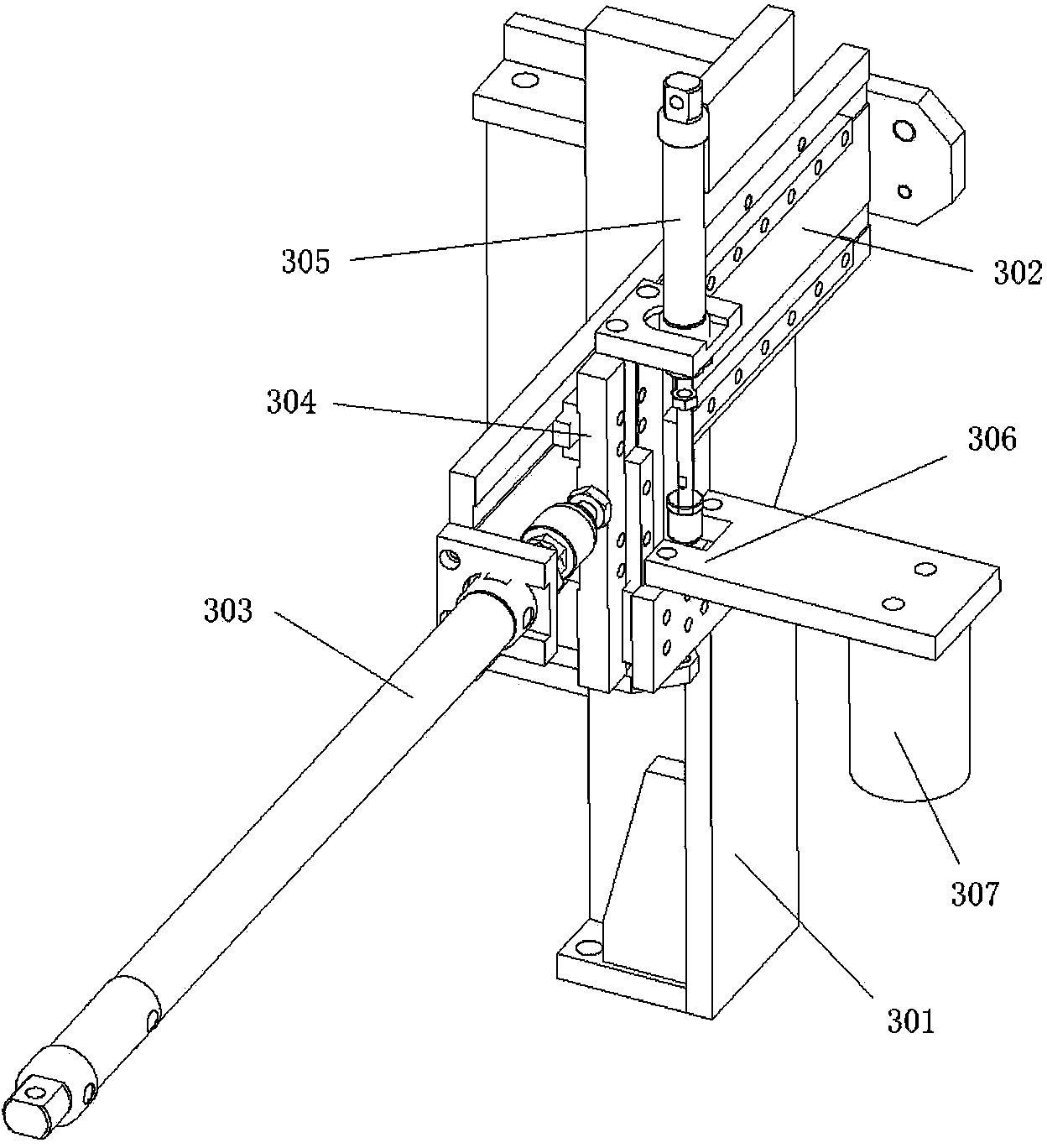

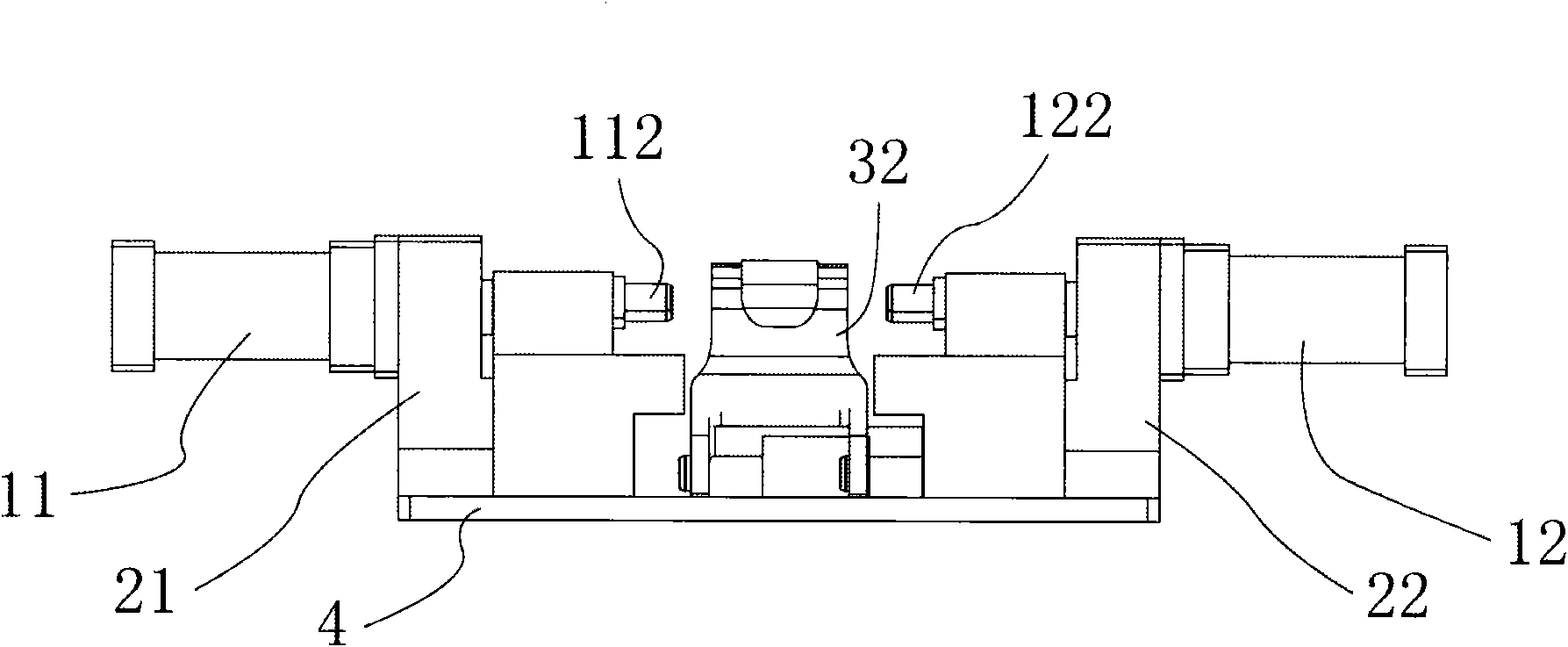

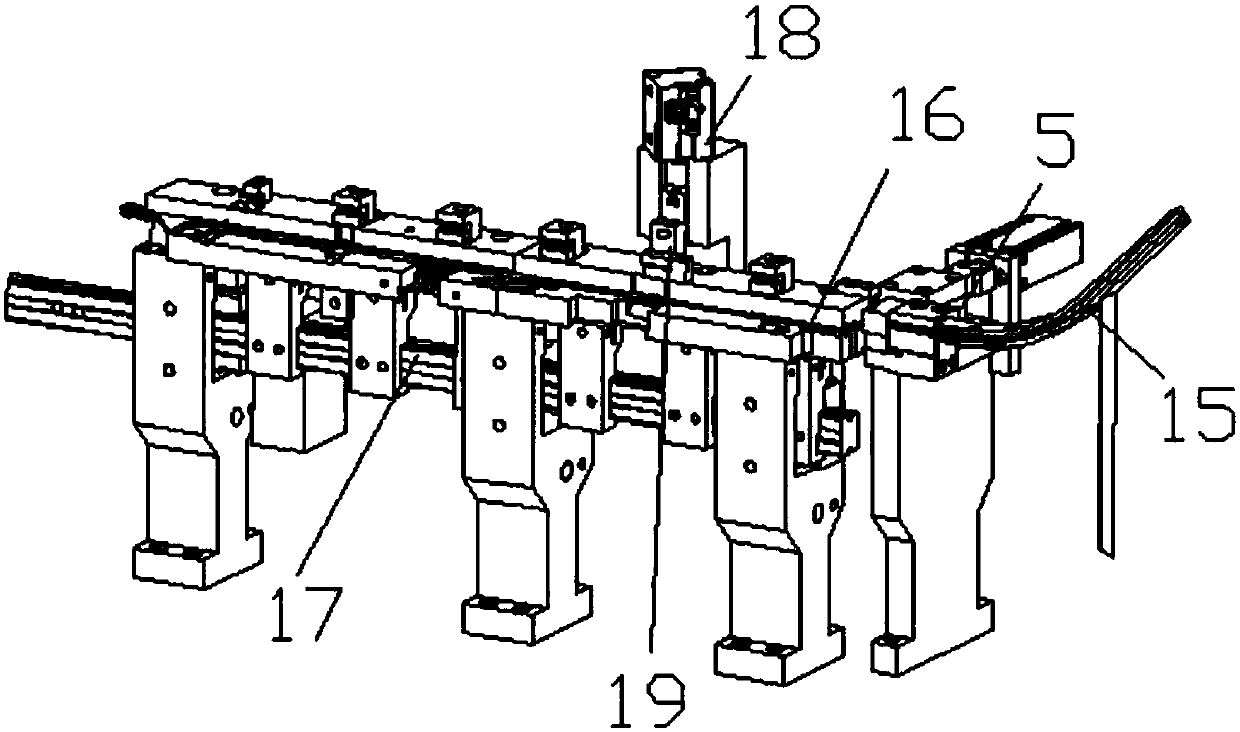

Connecting pipe assembly equipment and connecting pipe assembly method

ActiveCN103372769ARealize industrializationRealize automated assemblyAssembly machinesEngineeringProduction quality

The invention provides connecting pipe assembly equipment and a connecting pipe assembly method. The connecting pipe assembly equipment comprises a conveying device, a pipe penetrating device, a pipe conveying device and a cotton-pipe feeding device. The conveying device is used for conveying a connecting pipe. The connecting pipe comprises a material pipe and a cotton pipe sleeved outside the material pipe. The pipe penetrating device is arranged above the conveying device and used for allowing the material pipe to penetrate the cotton pipe. The pipe conveying device is arranged on one side of the pipe penetrating device along the extending direction of the connecting pipe and is used for conveying the material pipe. The cotton-pipe feeding device is arranged on the other side of the pipe penetrating device along the extending direction of the connecting pipe and is used for conveying the cotton pipe. According to the connecting pipe assembly method, the connecting pipe assembly equipment is used for assembling the connecting pipe. By the equipment and the method, industrialized and automatic assembly of the connecting pipe is realized, production quality of the connecting pipe is effectively guaranteed, and requirements on uniformity, stability and reliability of products are met. Processes are reasonably combined to enable each process step to be performed synchronously.

Owner:GREE ELECTRIC APPLIANCES INC

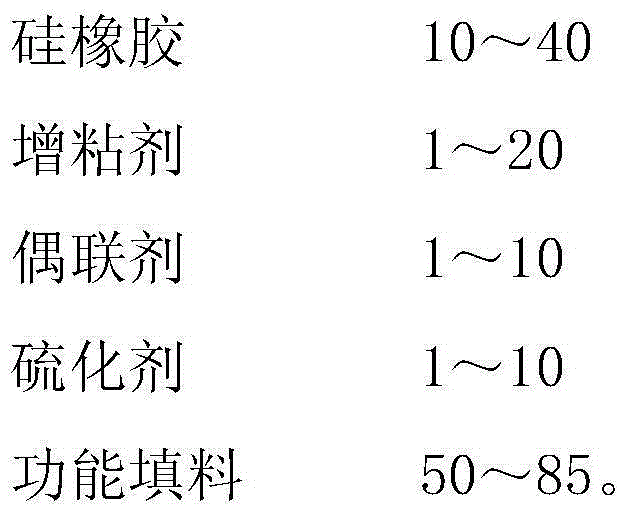

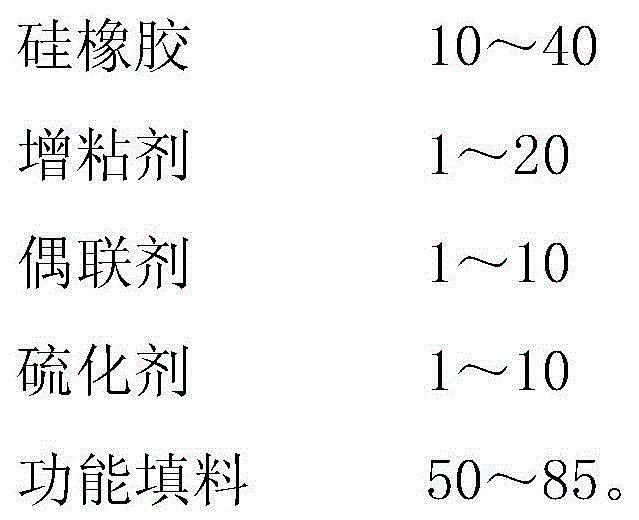

Self-adhesive conductive silicone rubber electromagnetic shielding material

InactiveCN105131612AEliminate poor magnetic sealsImprove electromagnetic shielding performanceNon-macromolecular adhesive additivesMicrometerElectromagnetic shielding

The invention relates to a self-adhesive conductive silicone rubber electromagnetic shielding material. The self-adhesive conductive silicone rubber electromagnetic shielding material is characterized in that the electromagnetic shielding material is prepared from the following components by weight percent: 10 to 40% of silicone rubber, 1 to 20% of tackifier, 1 to 10% of coupling agent, 1 to 10% of curing agent and 50 to 85% of functional filler, wherein the functional filler includes conductive particles of conductive carbon black, nickel coated graphite, nickel coated glass beads, silver coated aluminum powder and silver coated glass beads, the average particle diameter is 0.01 to 500 micrometers, the impurity content is lower than 0.1%, and the moisture content is lower than 0.5%. The self-adhesive conductive silicone rubber electromagnetic shielding material has the functions of conduction and electromagnetic shielding and has a self-adhesive characteristic, poor electromagnetic sealing generated by manual assembly can be eliminated, the electromagnetic shielding effect of a product is good, and automatic assembly can be realized.

Owner:SHENZHEN BORNSUN INDAL

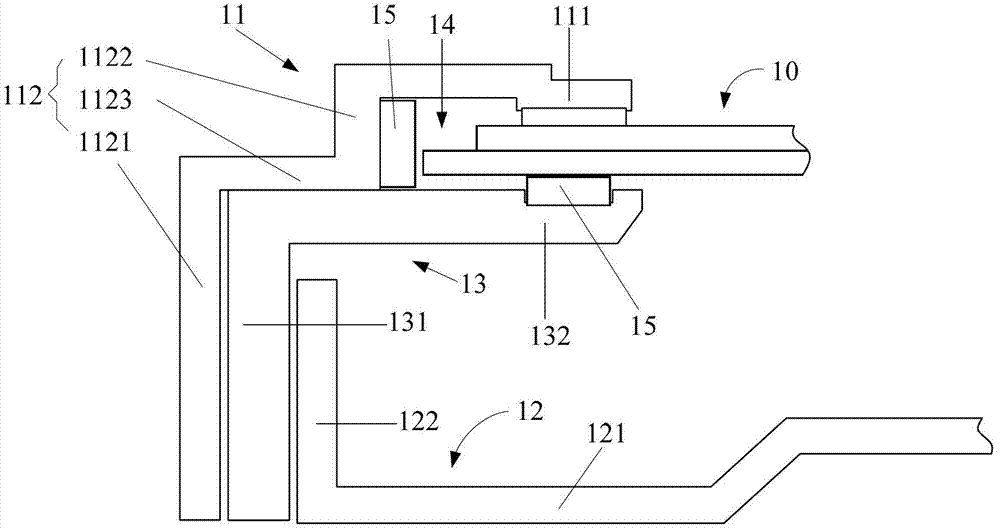

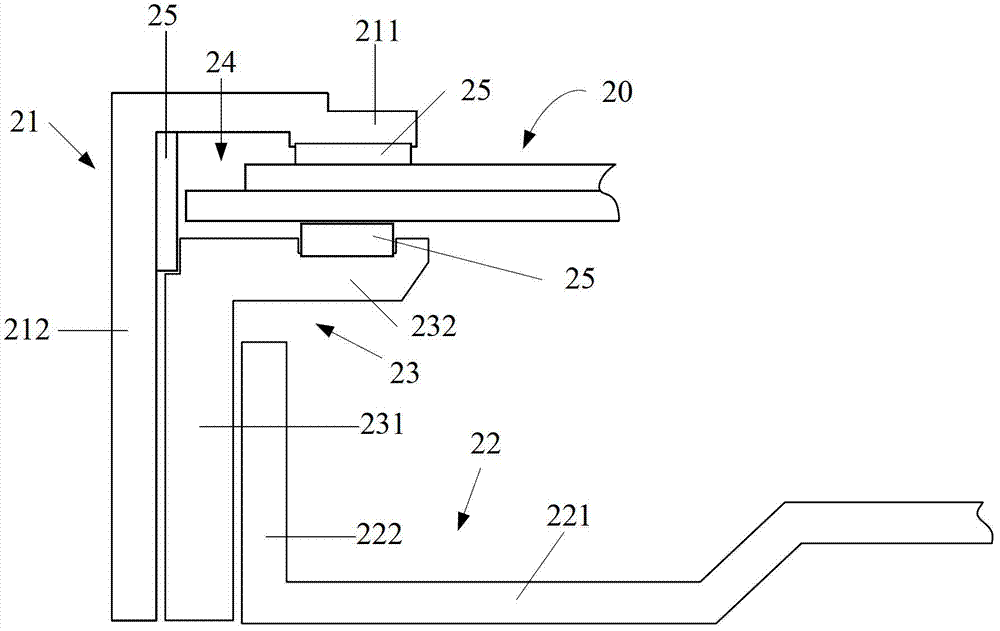

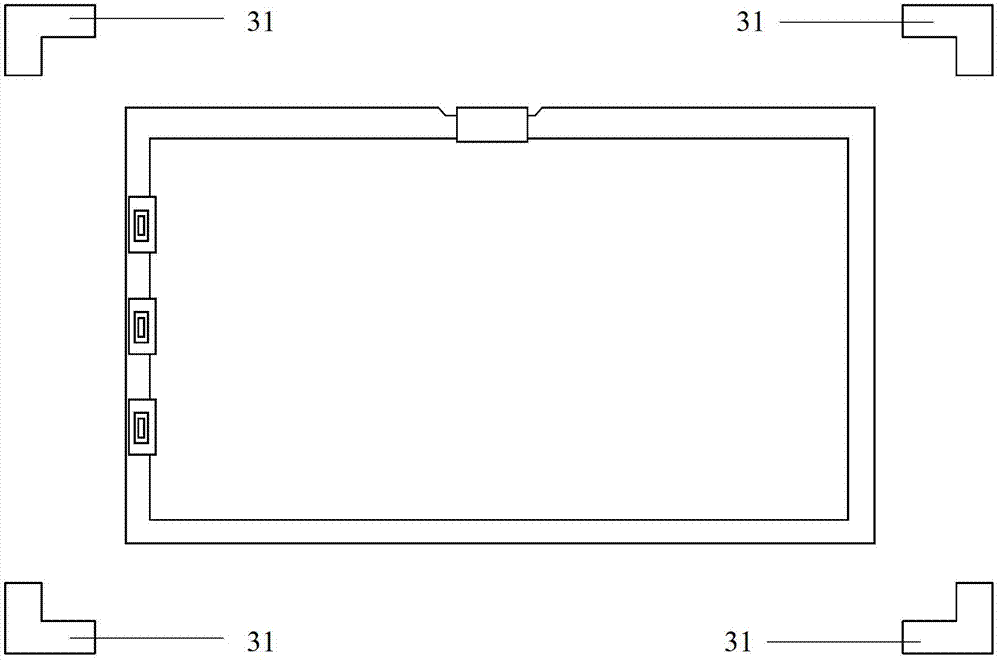

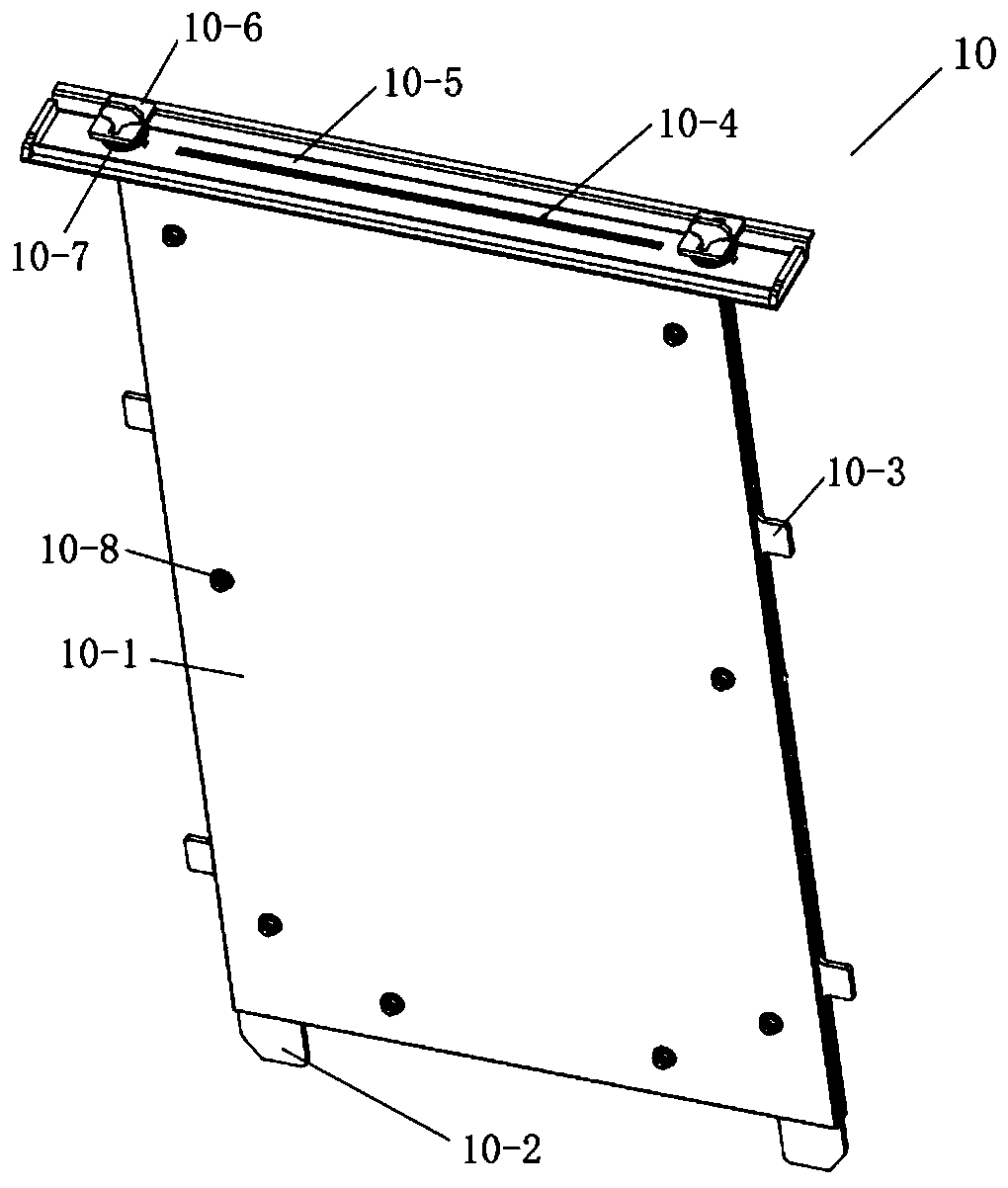

Liquid crystal display device, and frame unit and liquid crystal panel alignment method thereof

ActiveCN102778769ARealize automated assemblyAchieve positioningRack/frame constructionNon-linear opticsLiquid-crystal displayEngineering

The embodiment of the invention discloses a liquid crystal display device and a frame unit thereof. The frame unit comprises a front frame and a backplate assembly, wherein the front frame comprises a cover plate and a retaining wall which are connected; the cover plate is elastically abutted with the upper surface of a liquid crystal panel of the liquid crystal display device; the retaining wall is elastically abutted with the side edge of the liquid crystal panel; the backplate assembly comprises a bottom plate and a side plate which are connected; the bottom plate is used for supporting the optical part of the liquid crystal display device; and the side plate is matched with the retaining wall so as to support the liquid crystal panel. The invention further discloses a liquid crystal panel alignment method of the liquid crystal display device. According to the invention, the frame thickness of the liquid crystal display device can be effectively reduced, the production cost can be lowered, and the automatic assembling of the liquid crystal display device can be realized.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

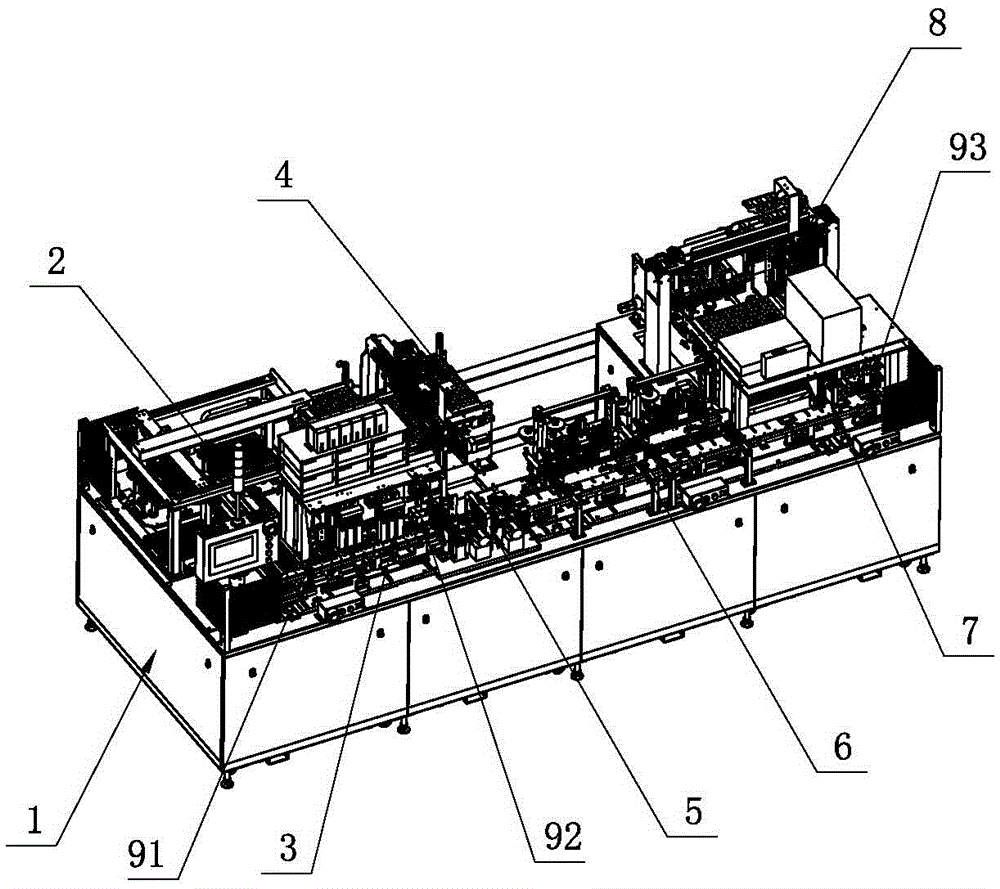

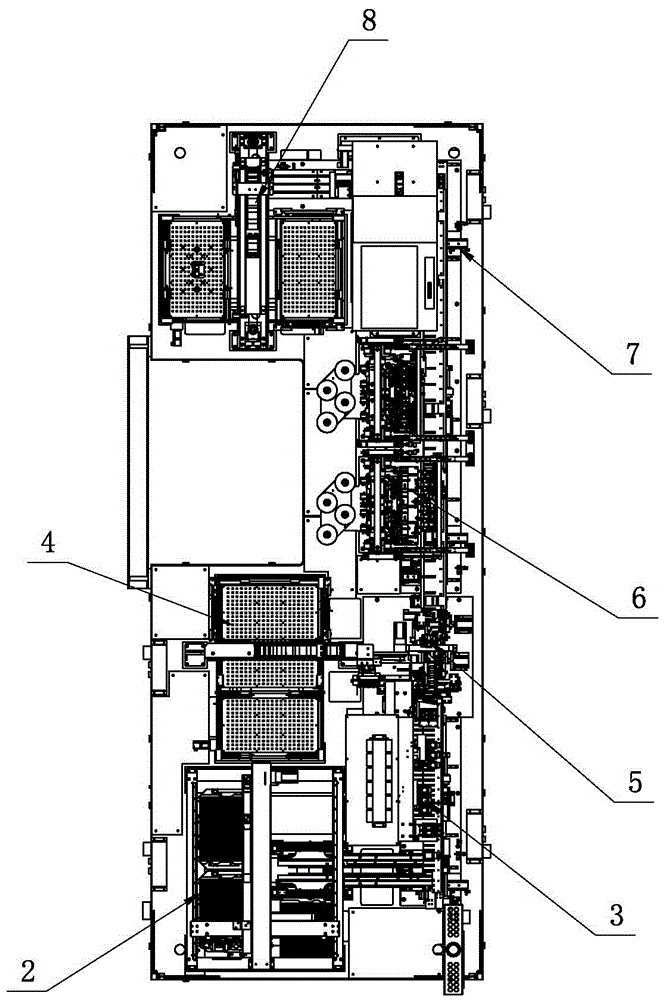

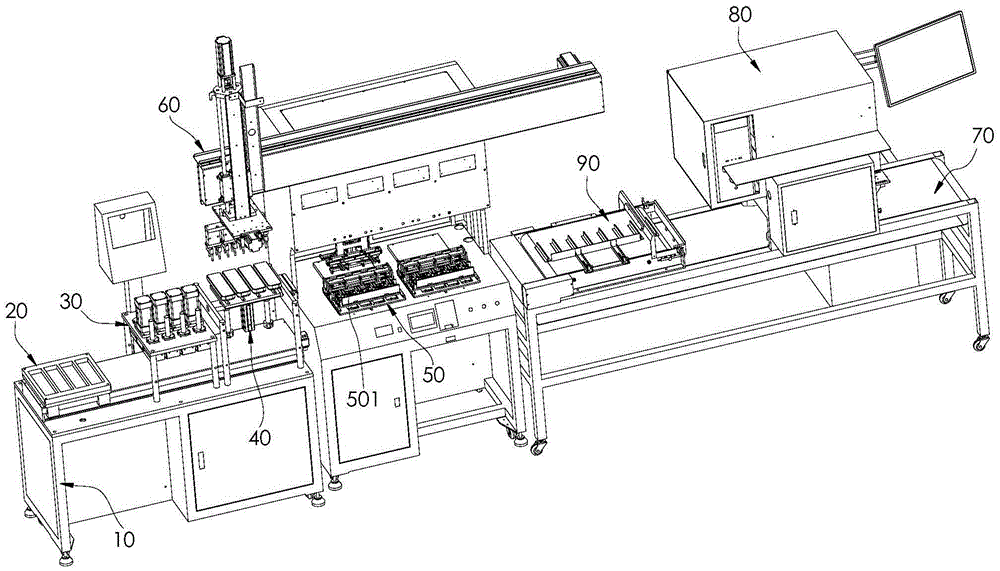

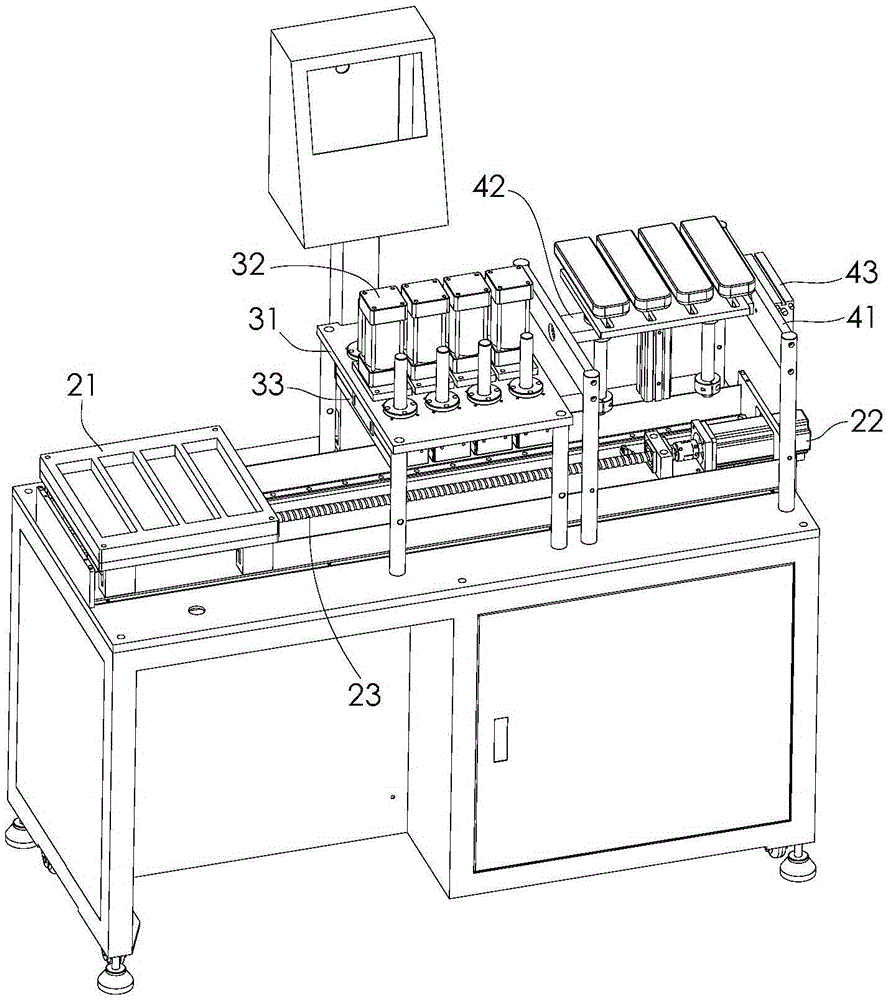

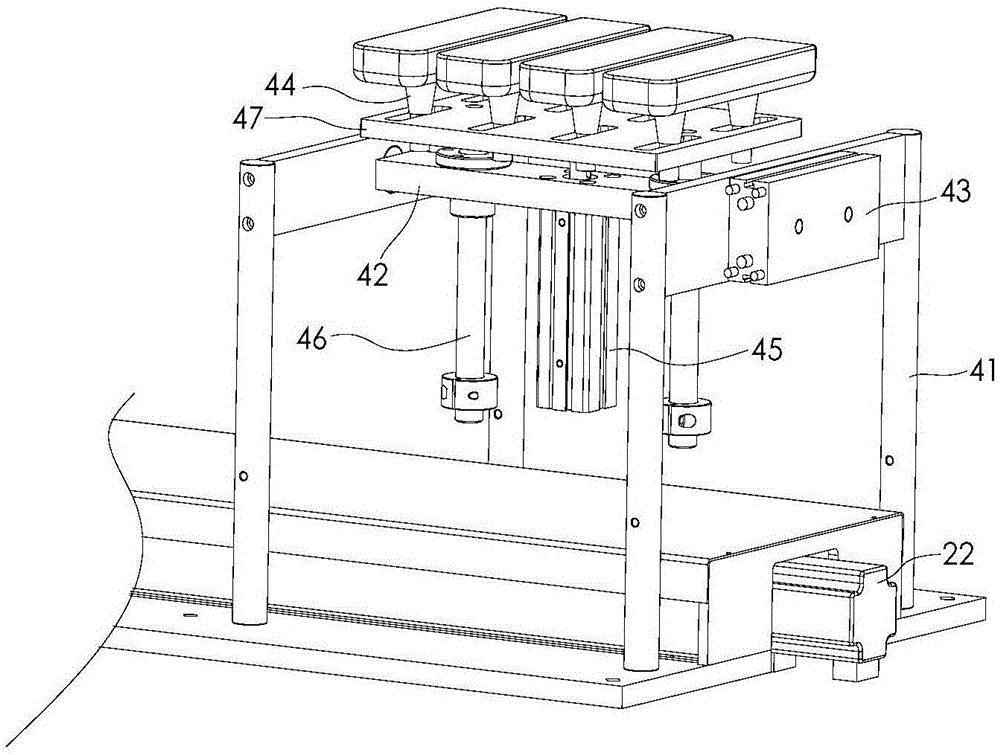

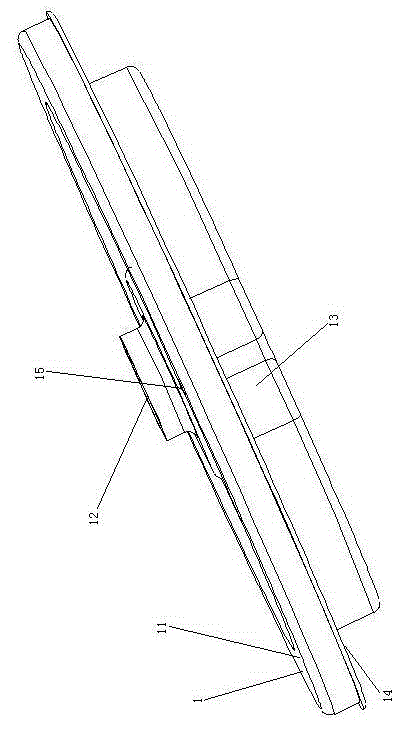

Automatic assembly line of remote controller

InactiveCN105563106ARealize automated assemblyImplement testAssembly machinesAssembly lineEngineering

The invention discloses an automatic assembly line of a remote controller. The automatic assembly line comprises a frame, a first feeding mechanism, a pressing device, a turnover device, an infrared remote controller testing device, a second feeding mechanism, a first manipulator and an appearance detecting device. The pressing device is mounted on the frame, is positioned above the first feeding mechanism, and is used for downwards pressing a remote controller component; the turnover device is mounted on the frame, and is positioned above the first feeding mechanism; the infrared remote controller testing device is mounted on the frame, is positioned on one side, far from the pressing device, of the turnover device, and is provided with a testing station; the second feeding mechanism is mounted on the frame, and is used for conveying the remote controller component; and the appearance detecting device is mounted on the frame, is positioned above the second feeding mechanism, and is used for performing appearance detection for the remote controller component passing through the lower side of the appearance detecting device during detecting. The automatic assembly line can realize automatic assembly and testing of the remote controller, and effectively improves the production efficiency.

Owner:GUANGDONG SENEASY INTELLIGENT TECH CO LTD

Preassembling mechanism for motor end cap

ActiveCN105048734ARealize automated assemblyGood degree of automationManufacturing dynamo-electric machinesEngineeringManipulator

The invention relates to the technical field of motor production equipment. A preassembling mechanism for a motor end cap comprises a frame with a discharging position, a motor housing fixing structure, a second motor end cap supporting block and a motor end cap aligning mechanism with a first motor end cap supporting block, a first manipulator shifting the motor end cap from the discharging position to the first motor end cap supporting block, a second manipulator shifting the motor end cap from the first motor end cap supporting block to the second motor end cap supporting block and a third manipulator shifting the motor end cap from the second motor end cap supporting block and installing onto a motor housing in the motor housing fixing structure. The invention provides a preassembling mechanism for preassembling the motor end cap onto the motor housing, and solves the problem that manual assembling of motor end cap is labor consuming and is low in automation level.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

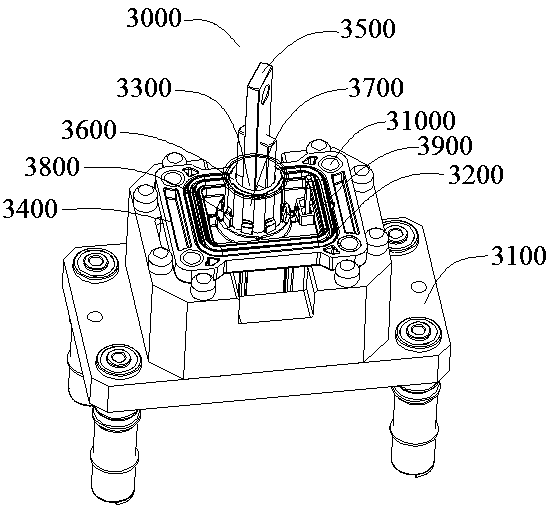

Connector assembling device

ActiveCN110695684ARealize automated assemblyGuaranteed smooth assemblyAssembly machinesMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a connector assembling device. A rotating plate mechanism is arranged on a machine frame and provided with a plurality of stations. A connector tool can be installed at each station and can rotate on the rotating plate mechanism of the machine frame and sequentially pass through a manual feeding station, a PIN press-in station, a lining installing station, a barb piece primary bending station, a lock catch installing station, a barb piece secondary bending station, a seal ring installing station and an unloading station which are circumferentially and sequentially distributed along the rotating plate mechanism to the next process. In this way, the connector assembling device can be used for producing and manufacturing connector products and automatically assemblingthe connector products, the continuity and accuracy of the whole assembling are ensured, the completion of the smooth assembling of the connector products is ensured, and the assembling efficiency isgreatly improved.

Owner:AMPHENOL AUTOMOTIVE CONNECTION SYST CHANGZHOU CO LTD

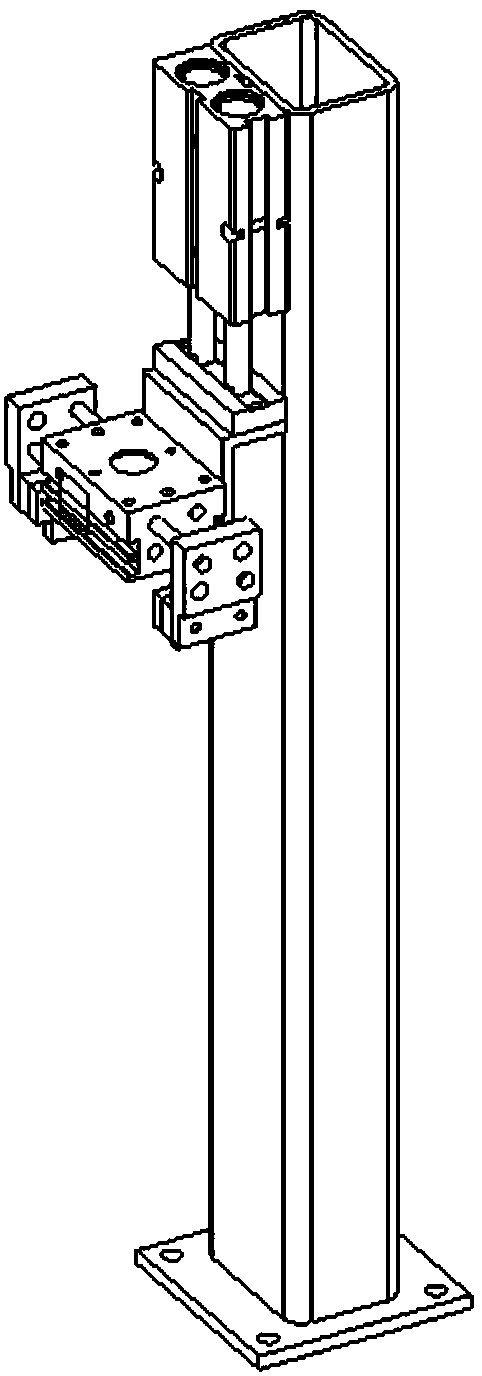

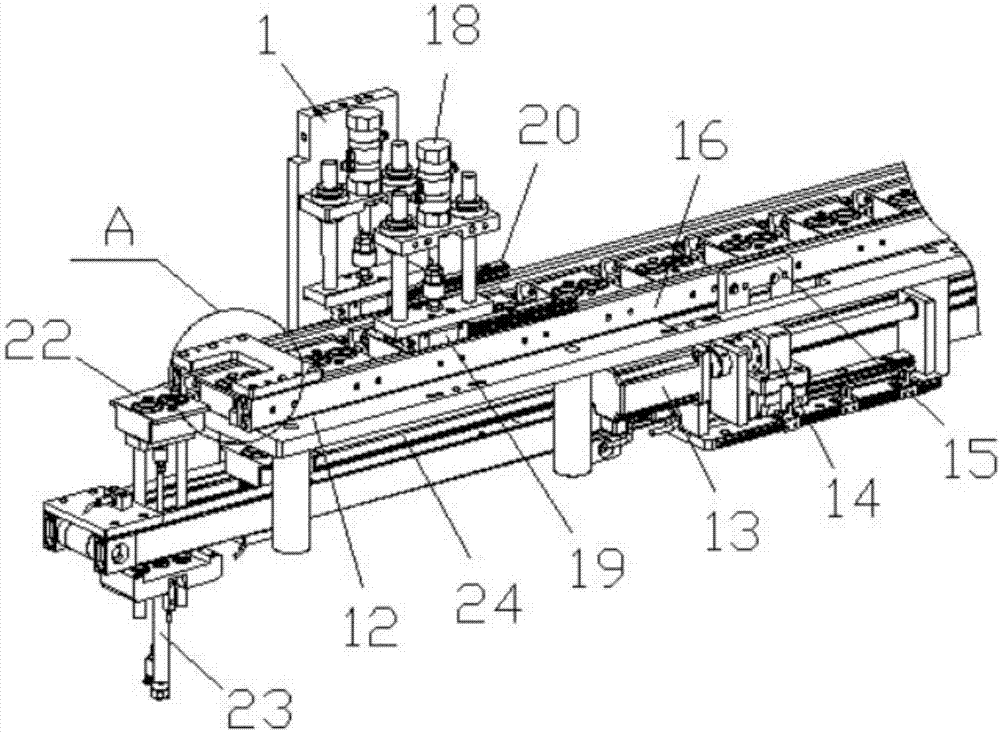

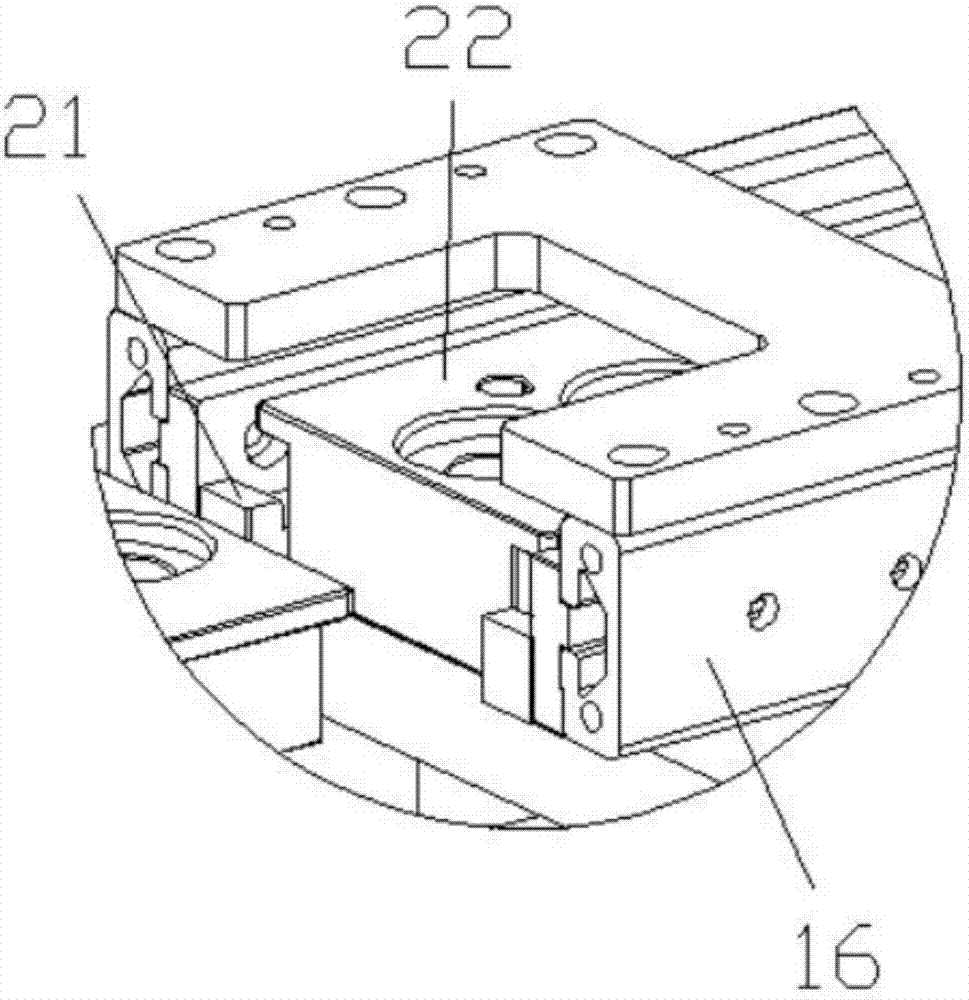

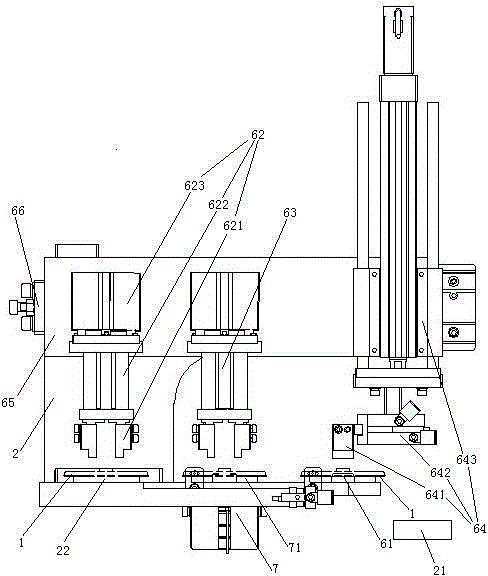

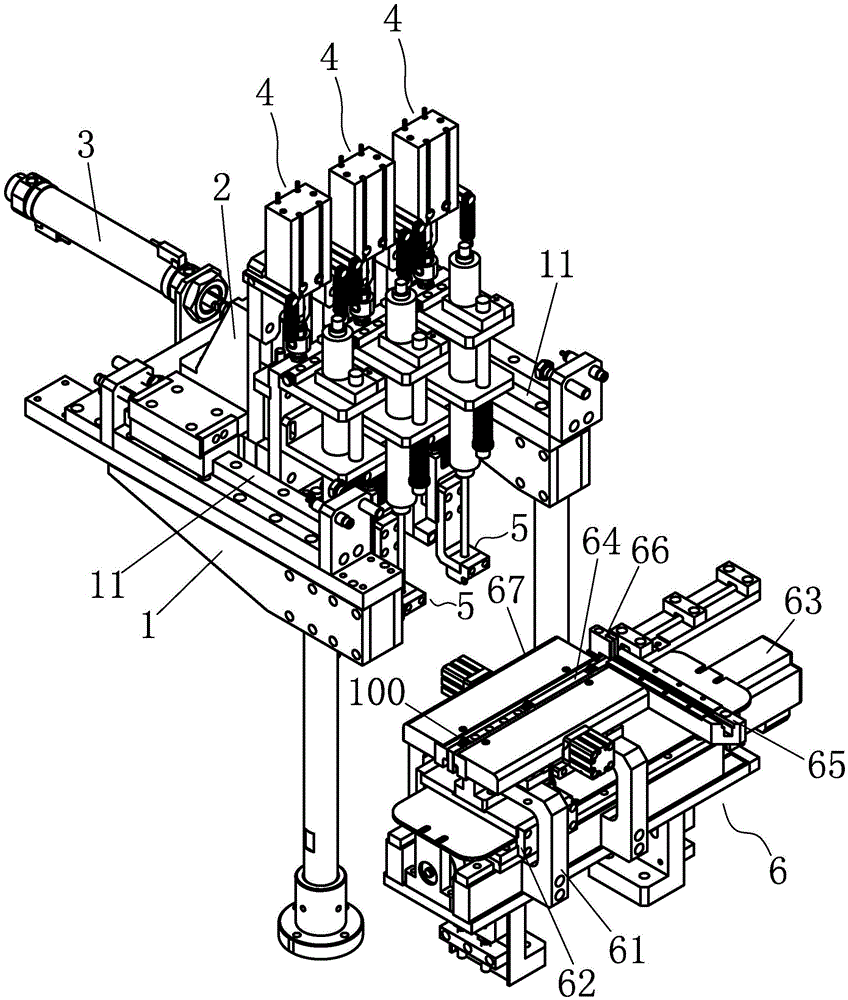

Automatic screw driving machine for wiring terminal

InactiveCN103730803ARealize automated assemblyIncrease productivityContact member assembly/disassemblyEngineeringMechanical engineering

Disclosed is an automatic screw driving machine for a wiring terminal. The automatic screw driving machine for the wiring terminal comprises a machine frame, a workbench and an assembling and feeding rail. The assembling and feeding rail is provided with an upper terminal shell station, a terminal shell correction station, an upper terminal body station, an upper screw station, a plurality of screw turning stations and a finished product detection station. A terminal shell vibration feeding tray, a terminal shell feeding mechanism and a terminal shell detecting mechanism are arranged on the rear portion of the upper terminal shell station. A terminal shell correction mechanism is arranged on the terminal shell correction station. A terminal body vibration feeding tray and a terminal body charging mechanism are arranged on the rear portion of the upper terminal body station. Screw vibration feeding trays, a screw flow dividing device and a screw charging mechanism are arranged on the rear portion of the upper screw station. Electric screw drivers are arranged above the screw turning stations. A finished product detection mechanism is arranged above the finished product detection station. By the adoption of the structure, automatic assembling of the wiring terminal can be achieved, production efficiency is greatly improved, and labor intensity is lowered.

Owner:HONGSHENG MACHINERY EQUIP

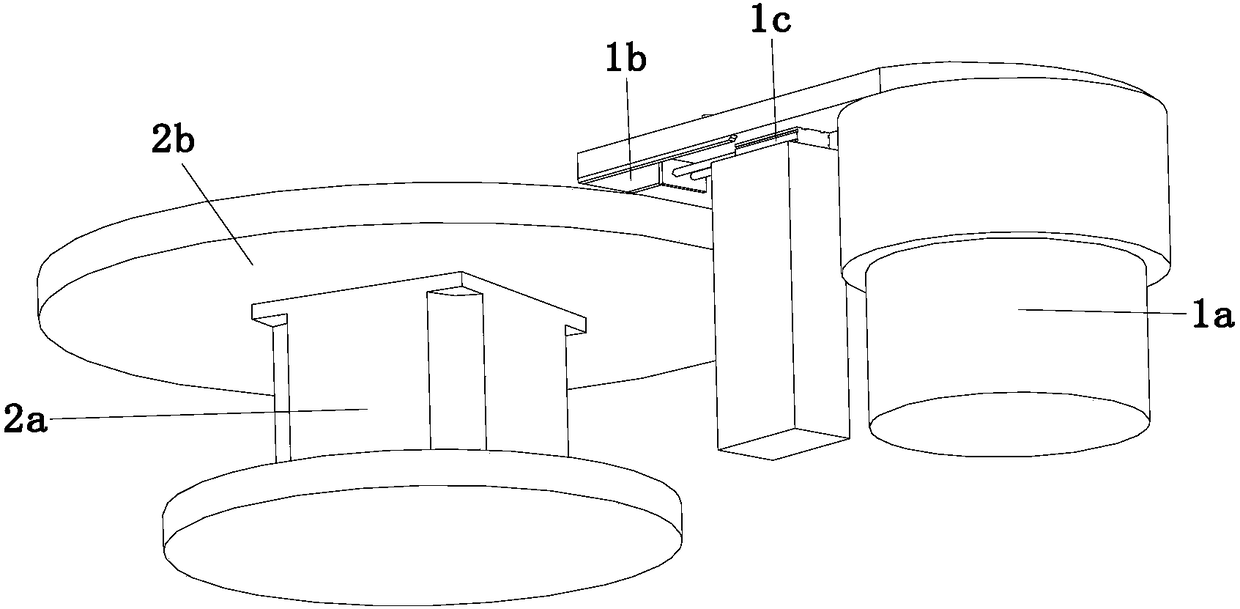

Automatic assembling machine for lamp bracket

InactiveCN103722089ARealize automated assemblyIncrease productivityPunchingElectrical and Electronics engineering

The invention relates to an automatic assembling machine for a lamp bracket. The automatic assembling machine comprises a rack, a workbench and a multi-station rotary disc, an upper chassis station, an upper connecting sleeve station, an upper top disc station, an edge overturning station and a discharging station are sequentially and evenly arranged above the multi-station rotary disc, a riveting pressing station is further arranged on the outer side of the discharging station, a chassis containing mechanism and a chassis feeding mechanism are arranged on the outer side of the upper chassis station, a connecting sleeve feeding mechanism is arranged above the upper connecting sleeve station, a connecting sleeve vibration feeding disc and a flow dividing device are arranged on the outer side of the connecting sleeve feeding mechanism, a top disc containing mechanism and a top disc feeding mechanism are arranged on the outer side of the upper top disc station, an edge overturning upper punching die is arranged right above the edge overturning station, the discharging mechanism is arranged between the discharging station and the riveting pressing station, and a riveting pressing upper punching die is arranged right above the riveting pressing station. The automatic assembling machine has the advantages that the structure is adopted, automatic assembling on the lamp bracket can be achieved, the production efficiency is greatly improved, the labor strength is reduced, manpower is saved, and the production cost is low.

Owner:HONGSHENG MACHINERY EQUIP

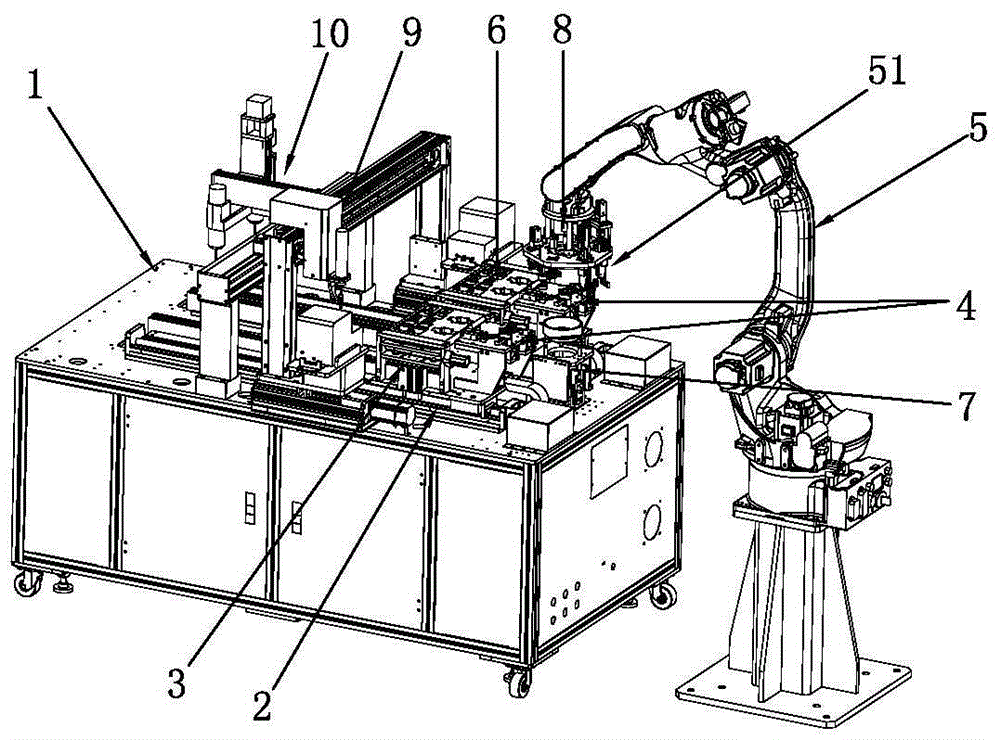

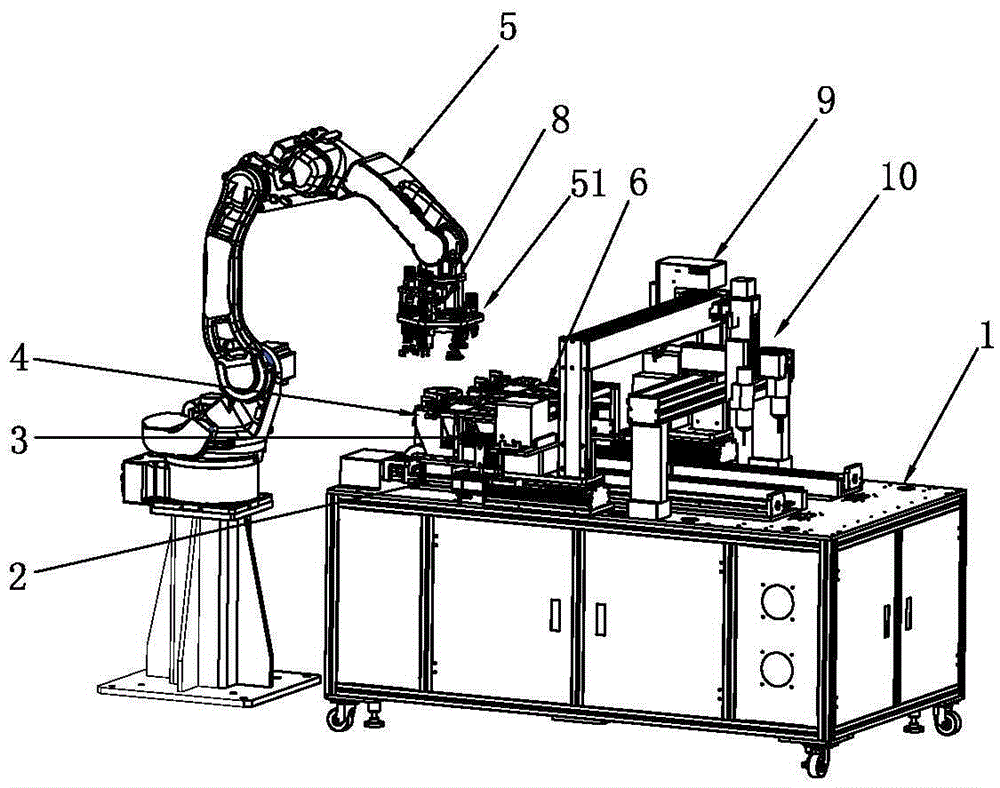

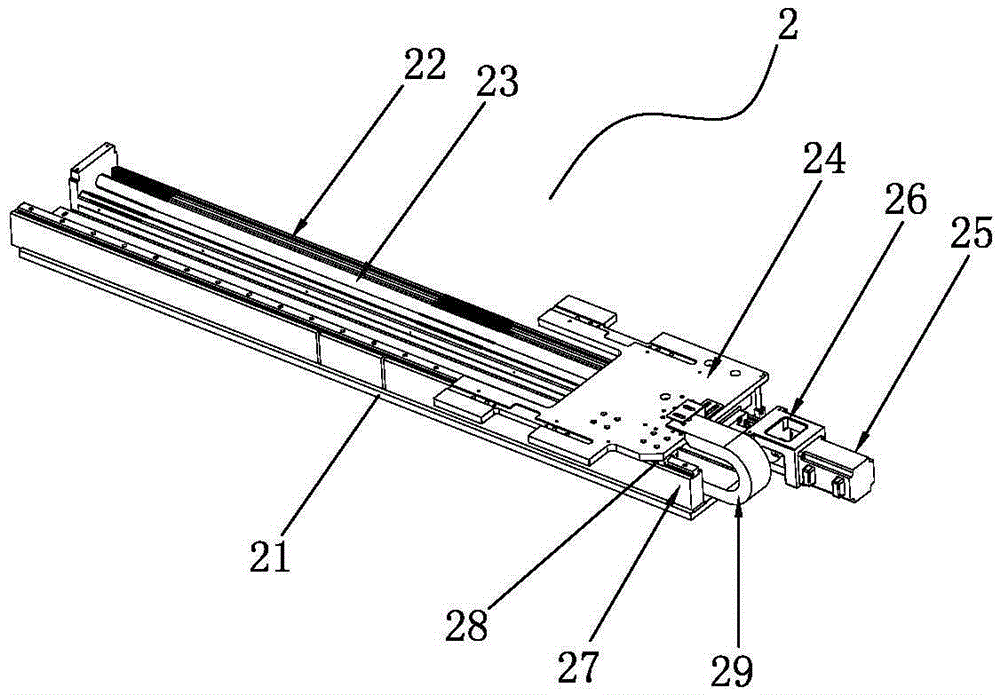

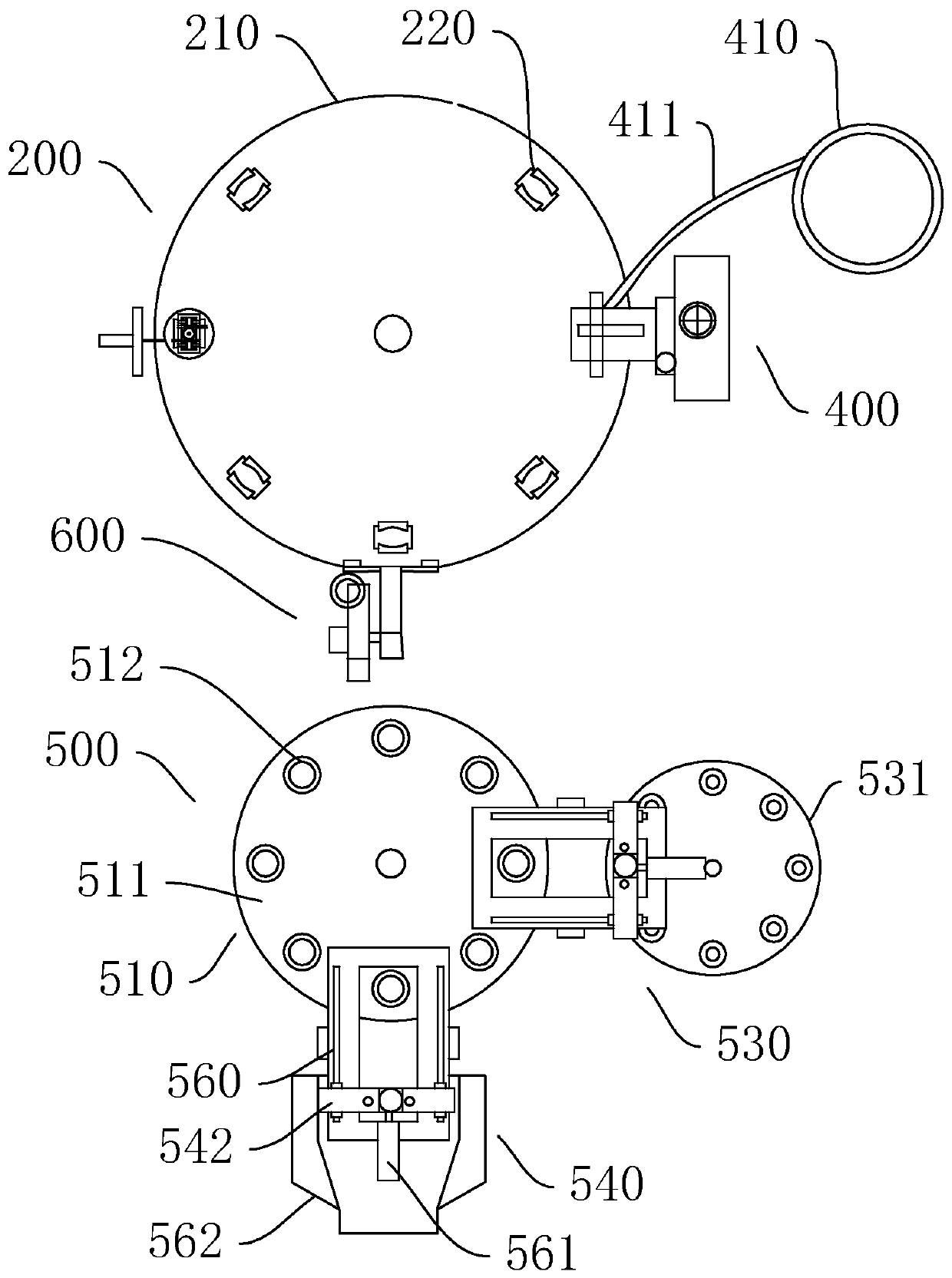

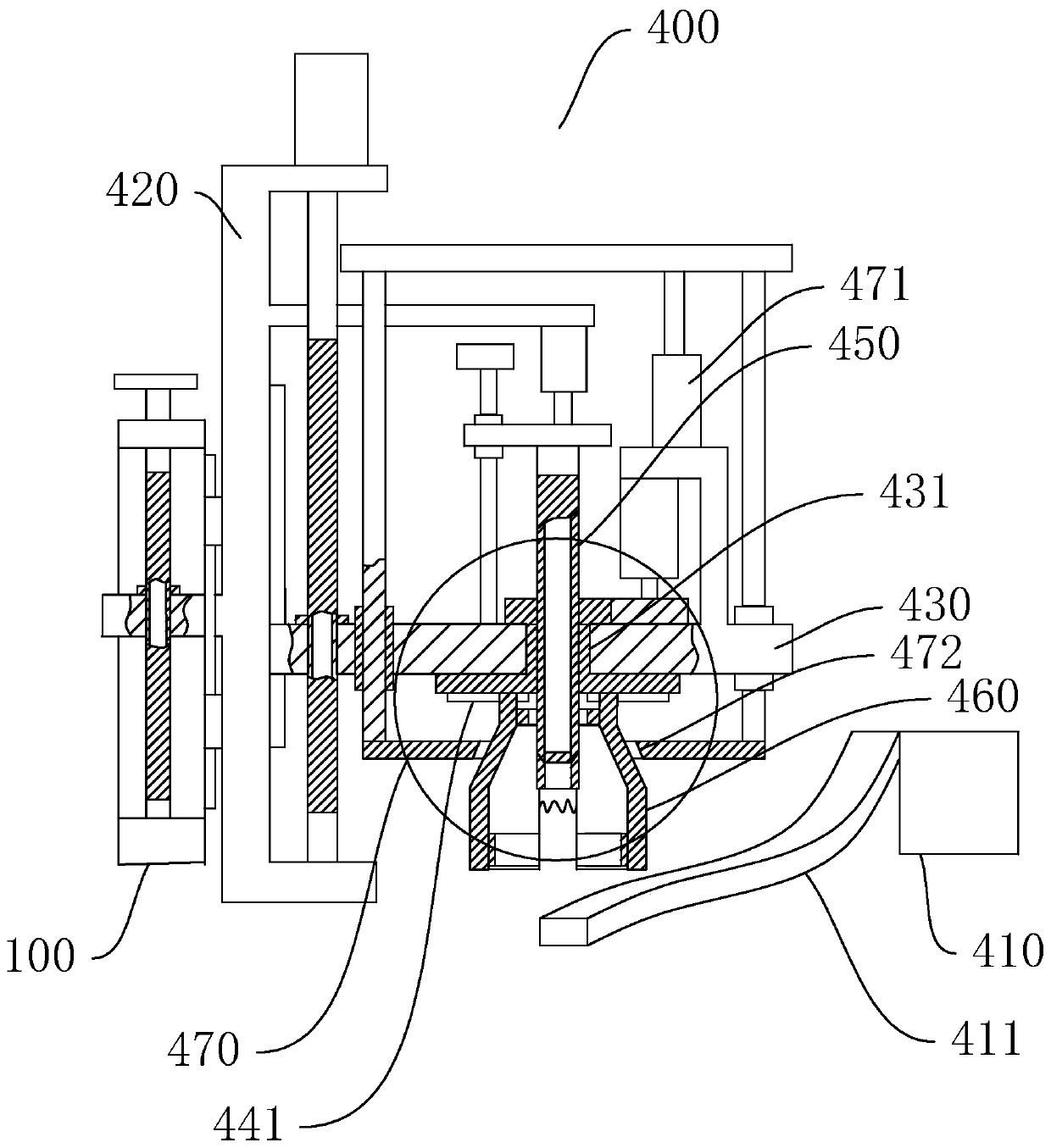

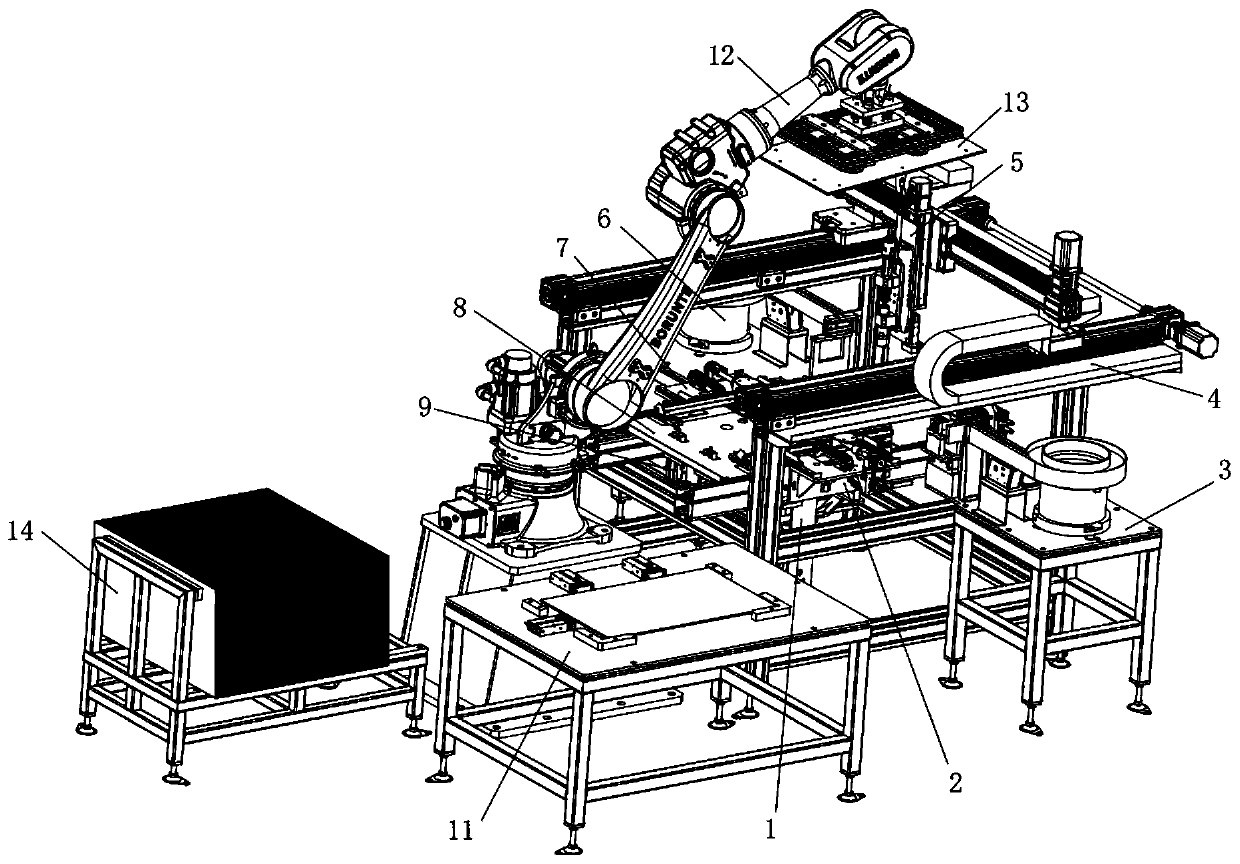

Automatic assembling machine for intelligent watches

ActiveCN105397481AImprove work efficiencyReduce the salary expenditure of enterprise workersAssembly machinesMetal working apparatusEngineeringManufacturing engineering

The invention relates to the technical field of automatic assembling equipment, in particular to an automatic assembling machine for intelligent watches. The automatic assembling machine comprises an assembling rack, an assembling controller, a linear module fixed to the assembling rack, an assembling jig used for automatic assembling and an assembling robot arm; a material carrying mechanism used for bearing a material tray is arranged on the linear module; the assembling jig is fixed to the linear module and located on one side of the material carrying mechanism; the assembling robot arm is used for transferring parts in the material tray into the assembling jig; and the linear module, the assembling jig and the assembling robot arm are all in signal connection with the assembling controller. The automatic assembling machine achieves automatic assembling of intelligent watches, full-automatic operation is achieved in the whole assembling process, manual operation is not needed, and worker wage expenditures of enterprises are reduced while working efficiency is improved; and mechanical assembling is adopted, product precision and quality can be effectively improved, the rejection rate is decreased, and therefore the automatic assembling machine is suitable for large-scale production.

Owner:东莞市新佰人机器人科技有限责任公司

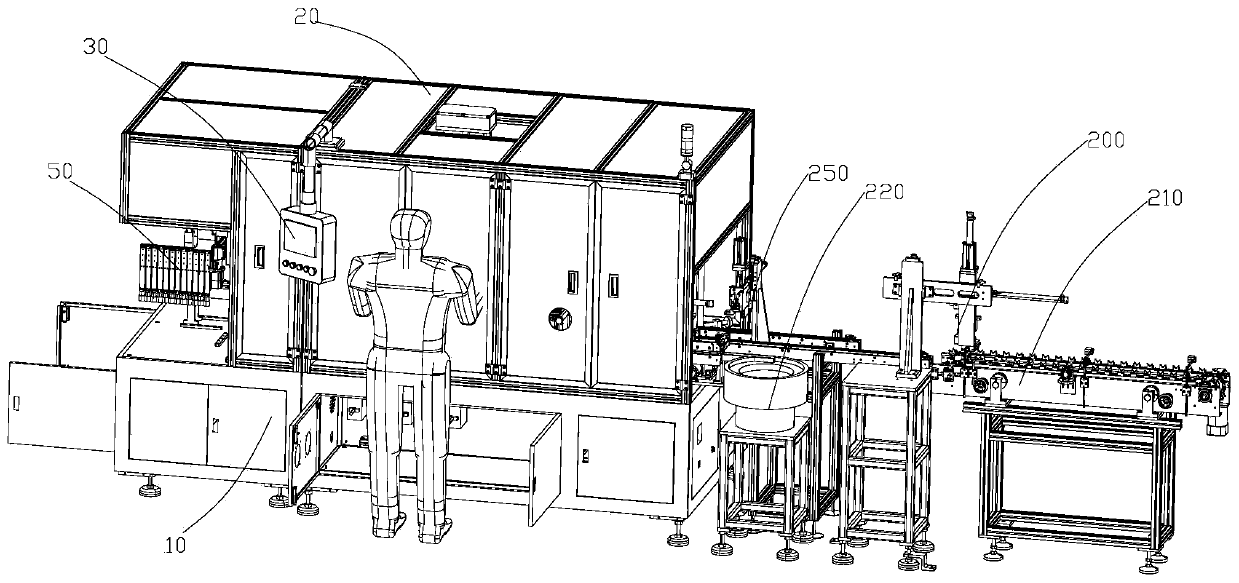

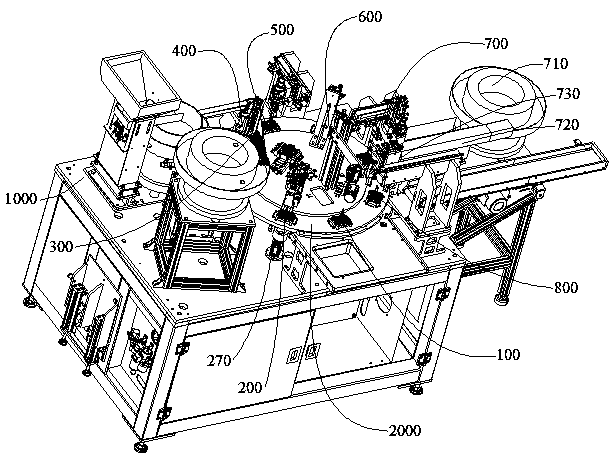

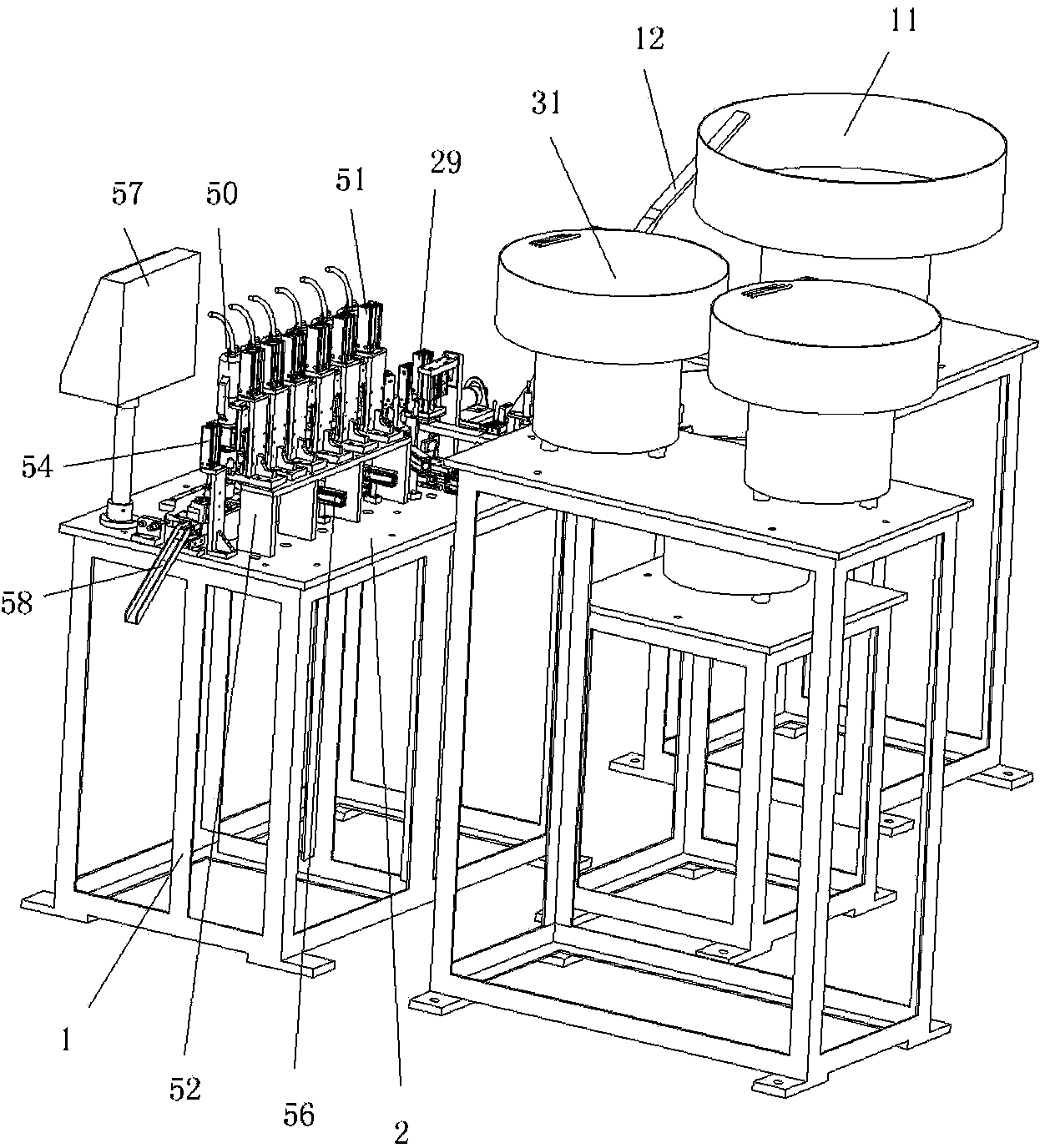

LED lamp automatic assembly system

ActiveCN109759837ARealize automated assemblyIncrease productivityAssembly machinesWork in processEngineering

The invention discloses an LED lamp automatic assembly system. To-be-machined lamp bodies are placed on multiple conveying clamps of a conveying rotary plate one by one. The to-be-machined lamp bodiesare sequentially conveyed to a lamp holder screwing device and a lampshade assembly device through the conveying rotary plate; the lamp holder screwing device automatically conveys lamp holders to aclamping assembly through a lamp holder feeding vibration plate; a lifting assembly drives the clamping assembly to move and place the lamp holders on the lamp bodies; then, the lamp holders are screwed on the lamp bodies through a screwing assembly; the semi-finished lamp bodies are transferred into lamp body sleeves on a lamp body conveying rotary plate through a lamp body transfer device; the semi-finished lamp bodies are sequentially conveyed to a lampshade conveying assembly and a pressing assembly through the lamp body conveying rotary plate; and lampshades are automatically conveyed, the lampshades and the lamp bodies can be automatically and mutually pressed, and therefore automatic assembly of LED lamp bulbs is achieved and the production efficiency is improved. The LED lamp automatic assembly system is used for assembly of the LED lamp bulbs.

Owner:佛山市力美照明科技股份有限公司

Rotating disc type rapid connector assembling machine

ActiveCN105499991ARealize automated assemblyImprove assembly efficiencyAssembly machinesEngineeringAssembly machine

The invention relates to the technical field of rapid connector assembling equipment, in particular to a rotating disc type rapid connector assembling machine. The machine comprises an index plate. A plurality of automatic assembling stations are arranged on the periphery of the index plate. Inner ring workpiece installation stations and outer ring workpiece installation stations are arranged in the circumferential direction of the index plate. The inner ring workpiece installation stations are columnar parts arranged at equal intervals. The outer ring workpiece installation stations are positioning blocks arranged at equal intervals. Each columnar part and the corresponding positioning block which correspond to the same automatic assembling station correspond to each other in the radial direction of the index plate. The automatic assembling stations, the inner ring workpiece installation stations and the outer ring workpiece installation stations are arranged in the circumferential direction of the index plate. Rapid connector assembling comprises three steps of assembling of a center assembly, assembling of an outer sleeve assembly and nut screwing. Automatic assembling of a rapid connector is achieved, the assembling efficiency is high, and the problem that an outer sleeve spring is large in installation difficulty is solved; the phenomenon of missed assembling of components in the automatic assembling process is effectively avoided through the multiple installation detection stations.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

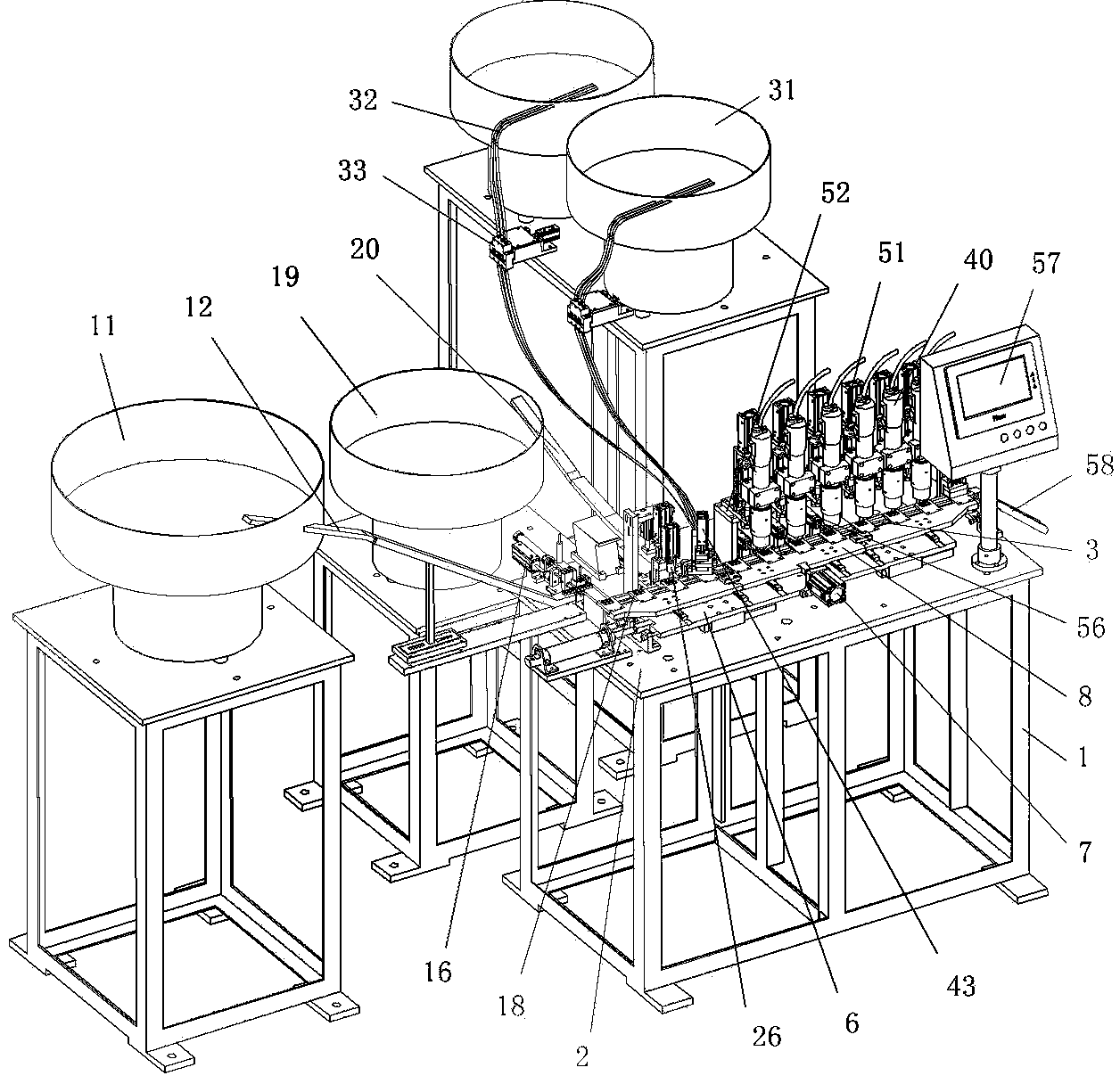

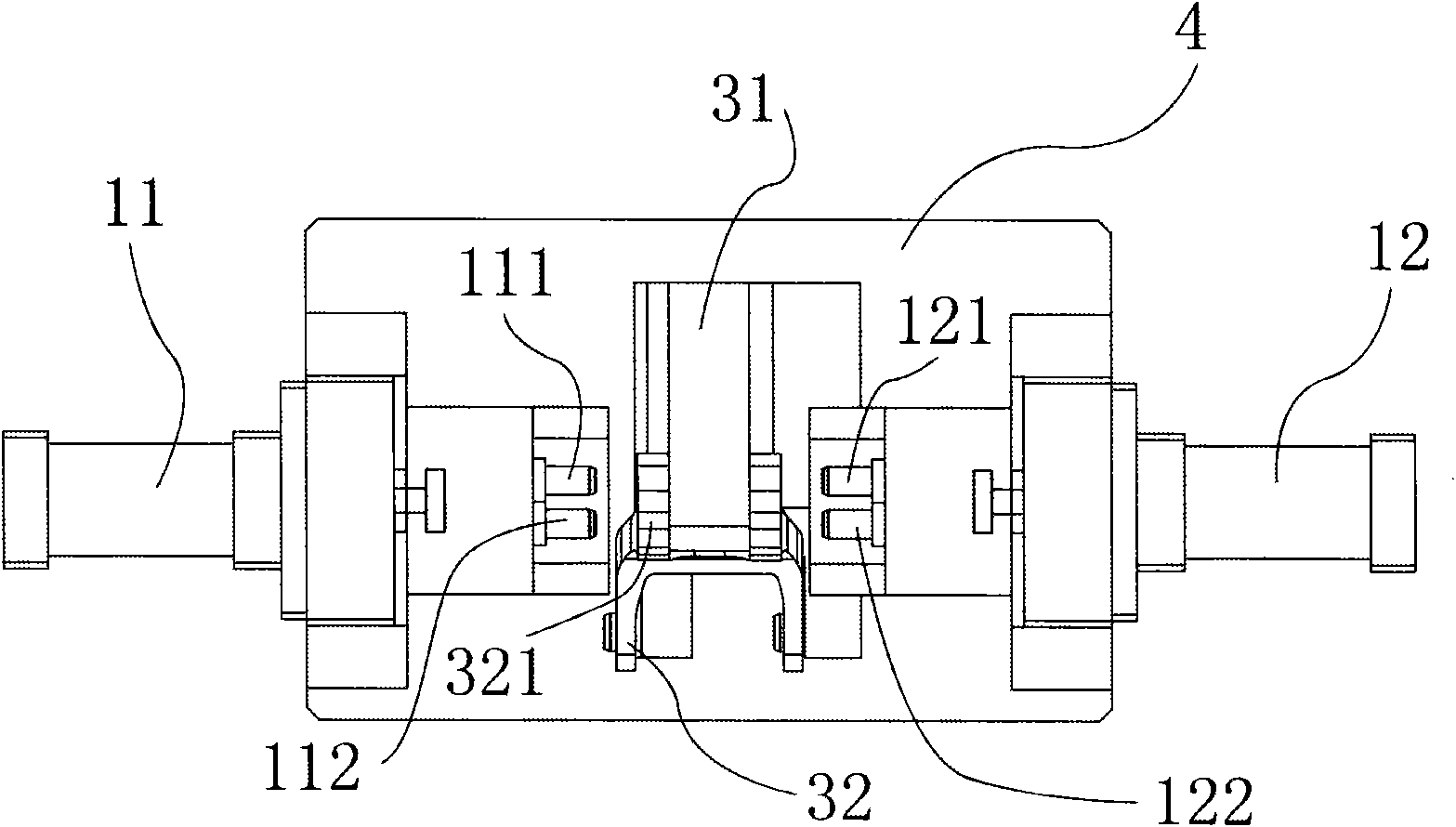

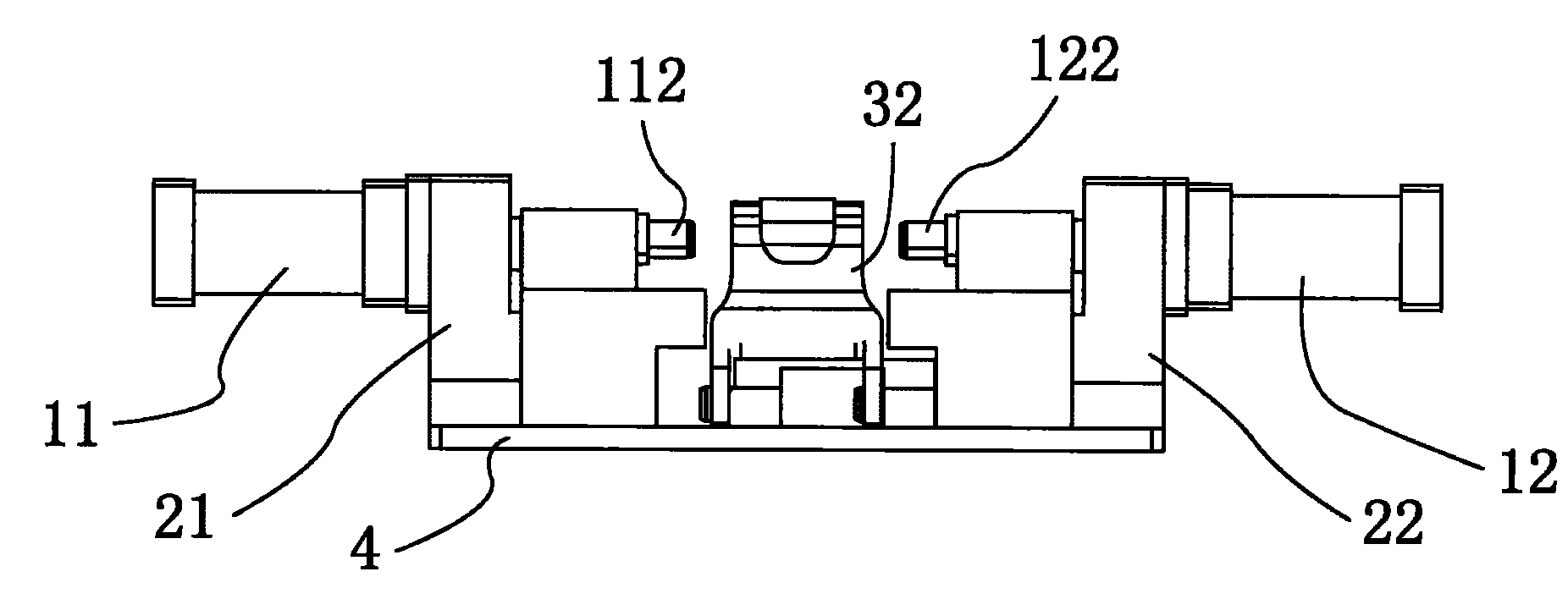

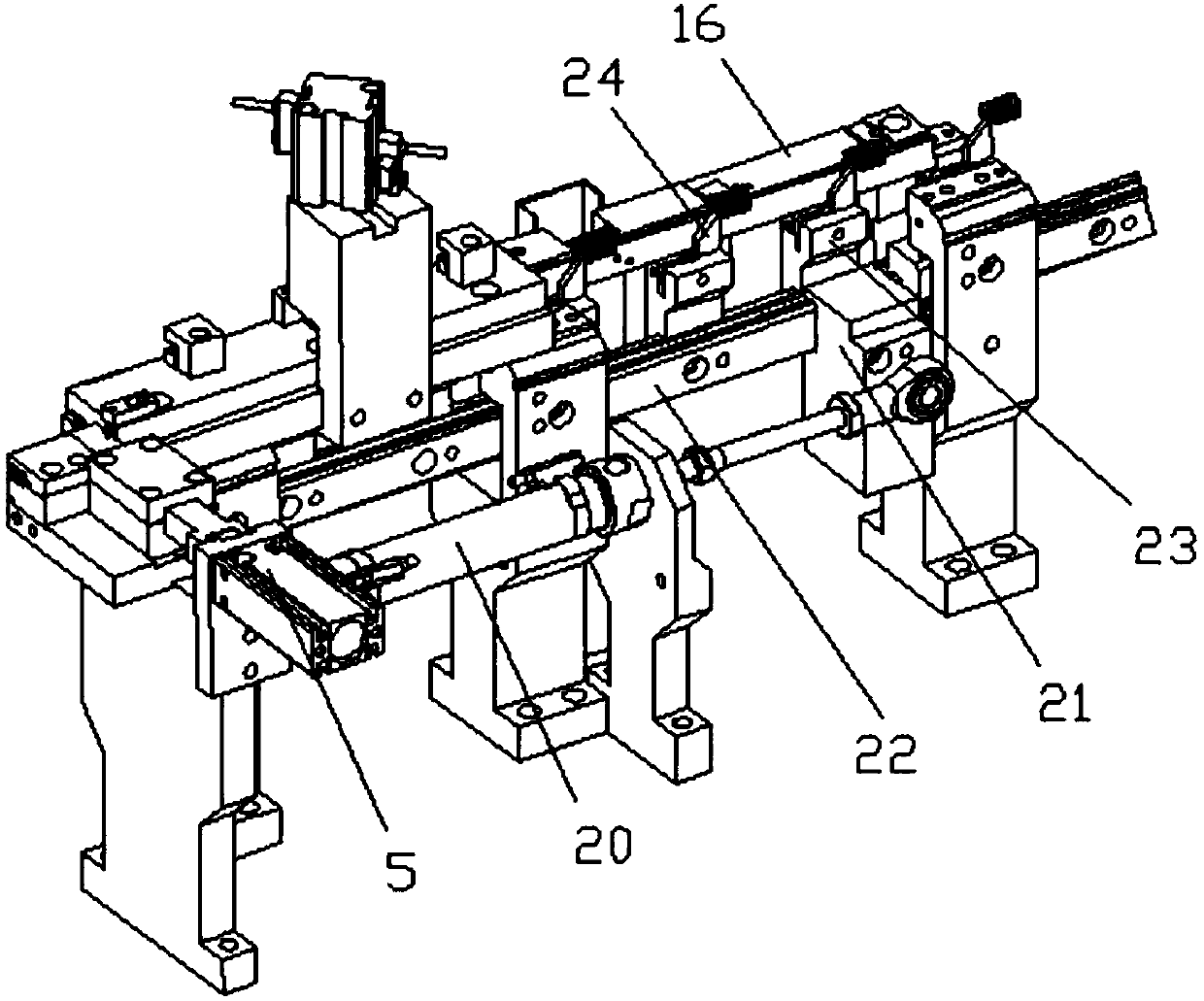

Multi-station quick coupling assembling machine

ActiveCN105499992ARealize automated assemblySolve the difficulty of installationAssembly machinesCouplingEngineering

The invention relates to the technical field of quick coupling assembling equipment, in particular to a multi-station quick coupling assembling machine. The multi-station quick coupling assembling machine comprises a material conveying table capable of moving step by step and multiple automatic assembling stations which are arranged in the moving direction of the material conveying table, the material conveying table is provided with workpiece installation stations corresponding to the all the automatic assembling stations, and each workpiece installation station is provided with a positioning block used for central component assembling and a column-shaped leaning nut used for wrap component assembling. According to the multi-station quick coupling assembling machine, assembling of a quick coupling is divided into central component assembling, wrap component assembling and nut tightening, automatic assembling of the quick coupling is achieved, and the assembling efficiency is high; wrap components and central components are assembled through material shifting stations, and the problem that the wrap springs are difficult to install is solved; the situation that parts are missed in the automated assembly process is effectively avoided by means of multiple installation detection stations.

Owner:JIANGSU GAOJING MECHANICAL & ELECTRICAL EQUIPMENT CO LTD

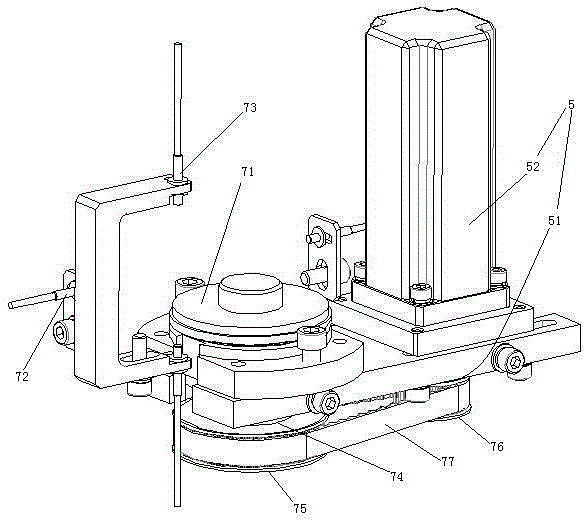

Bush assembling mechanism

InactiveCN102069374ARealize automated assemblyMetal working apparatusEngineeringMechanical engineering

The invention relates to a bush assembling mechanism for inlaying bushes into the bush holes of a part. The mechanism comprises bush placing pin rods, wherein the pin rods are connected with a piston rod of a drive cylinder; the pin rod heads of the pin rods are opposite to the bush holes arranged on the part to be inlaid; and the part to be inlaid is connected or clamped on a stable positioning base seat. The mechanism has the following beneficial effects: the bushes are inlaid into the bush holes by the bush placing pin rods driven by the cylinders, thereby achieving the automatic assembly of the bushes; and further, through arranging multiple bush placing pin rods driven by multiple cylinders, the multiple bushes are inlaid into the bush holes of the same part once, or the multiple bushes are inlaid into multiple bush holes of different parts once.

Owner:SUZHOU NEW DISTRICT KEXING WILL ELECTRONICS

Automatic assembling machine for connector

ActiveCN107553085AAccurate jackingRealize automated assemblyOther manufacturing equipments/toolsMetal working apparatusMechanical engineering

The invention relates to an automatic assembling machine for a connector. A rack is provided with a rubber core conveying device and a shell conveying groove; a shell feeding device is arranged on theupper portion of the shell conveying groove, a shell material feeding device is matched with the right side of the shell conveying groove, and a rubber core ejecting-in port is formed in the front side of the shell conveying groove and is matched with a rubber core ejecting-in device; the shell material feeding device is connected with a shell vibration material feeding disk through a shell material feeding groove; the shell feeding device comprises a shell feeding lifting cylinder which is connected with a shell reciprocating feeding pull rod; the shell reciprocating feeding pull rod is connected with a shell feeding block; and feeding grooves matched with the left and right length of the shell are uniformly formed in the lower portion of the shell feeding block. According to the automatic assembling machine for the connector, by means of the shell feeding device in fixed distance feeding guarantees the fixed distance feeding of a shell, the fixed rubber core ejecting-in port is formed in the shell conveying groove, it is guaranteed that a rubber core is accurately ejected in from the rubber core ejecting-in port, automatic assembling of the connector rubber core and the shell isachieved, meanwhile the positioning and assembling structure is simplified, and the work efficiency is improved.

Owner:TONGXIANG YAORUN ELECTRONICS

Fuel pump production line

ActiveCN105499995ARealize automated assemblyIncrease productivityAssembly machinesWork holdersProduction lineEngineering

A fuel pump production line comprises a precision magnetic shoe assembly machine, a precision oil outlet plate component assembly machine, a precision pump body component assembly machine and a precision pump core comprehensive performance detector. The precision magnetic shoe assembly machine presses a carbon brush holder and a magnetic shoe into an iron shell by cooperation of a carbon brush holder positioning mould, an iron shell positioning mould and a magnetic shoe positioning mould. The precision oil outlet plate component assembly machine realizes press fit of a copper bush and an oil outlet plate by cooperation of a copper bush positioning device and an oil outlet plate positioning device, automatically grabs and puts a rotor into the iron shell by the aid of a grabbing device and realizes press fit of the oil outlet plate and the rotor in the iron shell by the aid of the iron shell positioning device and the oil outlet plate positioning device. The precision pump body component assembly machine supplies power to a pump body by the aid of a probe in a pressure cover to test whether the pump body is capable of rotating or not, tightly presses a head cover and seals edges of the iron shell of the pump body to complete pump body assembly and preliminary testing. The precision pump core comprehensive performance detector automatically detects an assembled pump core. Therefore, automatic production of a production line is realized.

Owner:GUANGZHOU CAMPIU AUTOMOTIVE PARTS

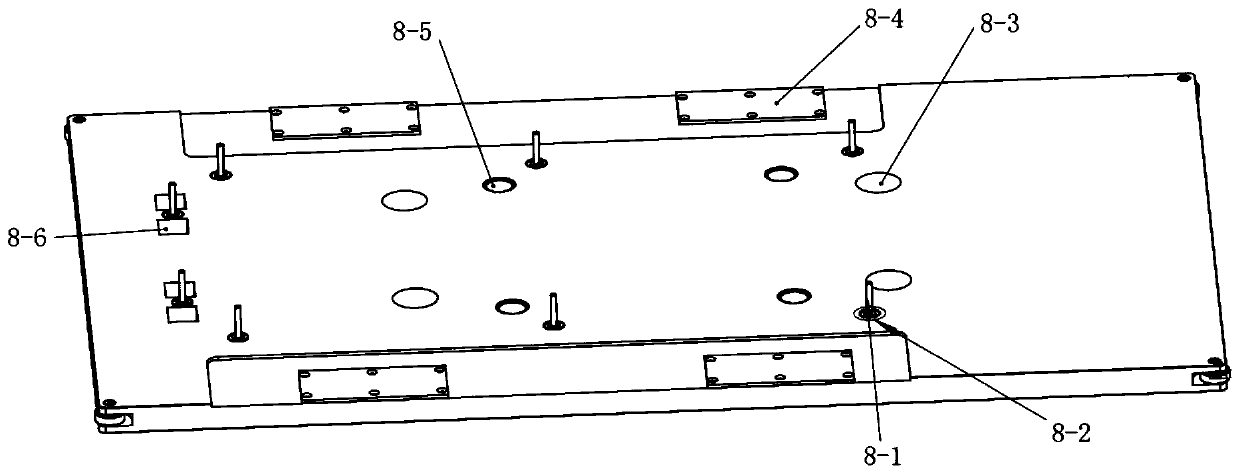

Automatic bolt and nut assembling system for flat cultivation container

PendingCN111299999ARealize automated assemblyImprove throughputMetal working apparatusAgricultural engineeringStructural engineering

The invention relates to an automatic bolt and nut assembling system for a flat cultivation container. The automatic bolt and nut assembling system comprises a carrying plate, a bolt feeding mechanism, a nut feeding mechanism, a bolt and nut grabbing mechanism and a bolt correcting mechanism, wherein the carrying plate is arranged on a conveying line and used for assembling bolts, nuts and other components in the flat cultivation container; the bolt feeding mechanism is used for automatically distributing and feeding the bolts; the nut feeding mechanism is used for automatically distributing and feeding the nuts; the bolt and nut grabbing mechanism is used for clamping the bolts provided by the bolt feeding mechanism, then conveying the bolts to the carrying plate, sucking the nuts provided by the nut feeding mechanism and then conveying the nuts to the carrying plate; and the bolt correcting mechanism is used for adjusting the assembling positions of the to-be-assembled bolts. According to the automatic bolt and nut assembling system for the flat cultivation container, automatic feeding of the bolts is achieved through the bolt feeding mechanism, the assembling positions of the to-be-assembled bolts are adjusted through the bolt correcting mechanism, automatic feeding of the nuts is achieved through the nut feeding mechanism, automatic grabbing of the bolts and the nuts as well as automatic screwing of the bolts and the nuts are achieved through the bolt and nut grabbing mechanism, and therefore high-throughput and automatic assembly of the bolts and the nuts of the flat cultivation container can be realized.

Owner:NANJING PHEYE CROP PHENOMICS RES INST CO LTD +1

Assembling device and method for bearing sealing sleeves

InactiveCN103659259ARealize automated assemblyReduce labor intensityAssembly machinesEngineeringMechanical engineering

The invention relates to an assembling device and method for bearing sealing sleeves. The assembling device comprises a first feeding unit, a second feeding unit, a third feeding unit, a first assembling unit, a second assembling unit, a material bearing unit and a discharging unit. The first feeding unit comprises a vibrating disk and a first linear vibrator and is used for conveying plastic parts to the material bearing unit; the second feeding unit comprises a projecting disk and a second linear vibrator and is used for conveying copper shafts to the first assembling unit; the third feeding unit comprises a multi-section screening vibrating disk and a vibrating disk extending guide groove and is used for conveying the sealing sleeves to the second assembling unit; the first assembling unit is used for pressing the copper shafts to the plastic parts; the second assembling unit is used for pressing the sealing sleeves to the plastic parts where the copper shafts are already installed; the material bearing unit is driven by a driving device to rotate, and the first assembling unit, the second assembling unit and the discharging unit are respectively fixedly installed on the outer side of the material bearing unit. Screening feeding, material arraying, assembling, discharging and other steps are all automatically completed on the device.

Owner:STARYY RESIN PROD KUSN

Manufacturing method of lamp-cover-supporting LED tubular lamp with self-clamping heat transmission substrate

InactiveCN103411140BAbsorb moreReduce absorptionPoint-like light sourceLighting heating/cooling arrangementsHeat transmissionThermal deformation

The invention discloses a manufacturing method of a lamp-cover-supporting LED tubular lamp with a self-clamping heat transmission substrate, and belongs to the technical field of supporting or hanging or connecting of lighting devices. The manufacturing method of the LED tubular lamp includes the steps that S1, the heat transmission substrate is inserted into strip-shaped clamping grooves from side ports of the strip-shaped clamping grooves; S2, after the heat transmission substrate is installed in the strip-shaped clamping grooves, a lamp cover covers a radiator; S3, the lamp cover exerts two acting forces on two T-shaped hooks, and the heat transmission substrate is installed in the strip-shaped clamping grooves in a clamped mode; S4, the radiator, the heat transmission substrate and the lamp cover form a lamp tube of the LED tubular lamp, and two end covers are installed at the two ends of the lamp tube of the LED tubular lamp. According to the lamp-cover-supporting LED tubular lamp with the self-clamping heat transmission substrate, the heat transmission substrate can be arranged in the strip-shaped clamping grooves in the clamped mode because the strip-shaped clamping grooves are formed in an installing part of the heat transmission substrate, heat dissipation efficiency can be improved, and the heat transmission substrate is prevented from thermal deformation.

Owner:辽宁三维传热技术有限公司 +1

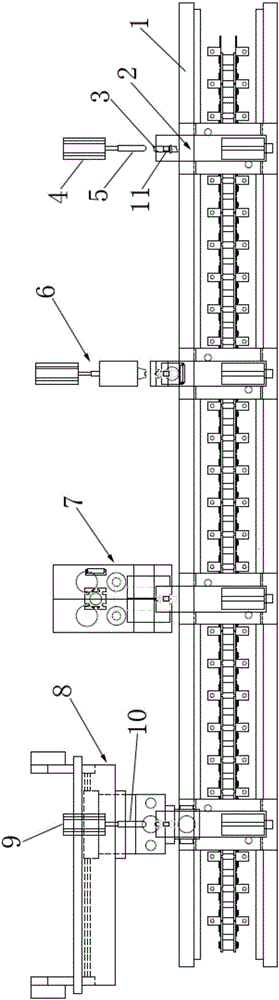

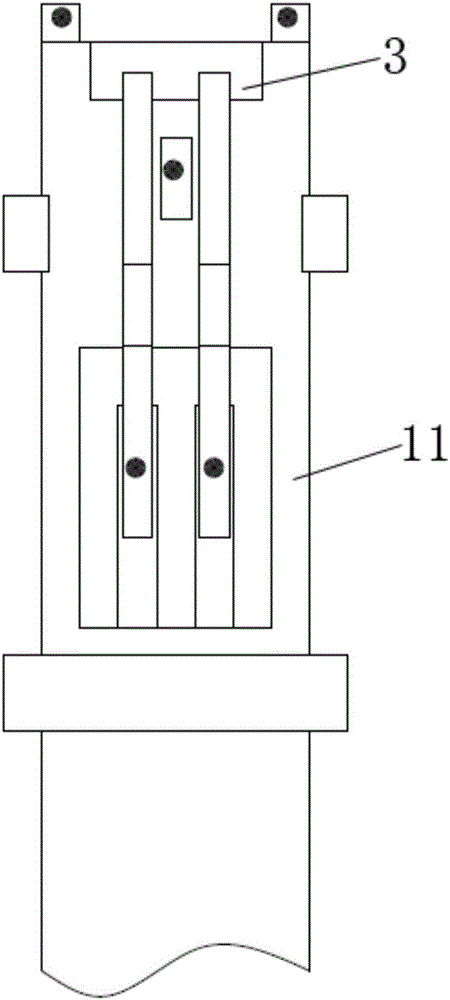

Assembly device for ABS sensor head chips

InactiveCN106181375ARealize automated assemblyImprove assembly efficiencyAssembly machinesOther manufacturing equipments/toolsMaterial resourcesAssembly line

The invention relates to an assembly device for ABS sensor head chips. The assembly device comprises a chain assembly line conveying table. A plurality of fixing clamps are installed on the chain assembly line conveying table; each fixing clamp comprises a clamp body, a workpiece head installing seat, a workpiece cable installing seat, a buckle and a clamping spring; workpieces are locked and fixed by the fixing clamps and conveyed along with the fixing clamps; the chain assembly line conveying table is sequentially provided with an installing work station, a hot riveting work station, a point welding work station and a grabbing work station at intervals; and the complete chip assembling process that the workpieces are installed on an assembly line, the chips are fixed in a hot riveting mode, the chips are connected through point welding and the workpieces are grabbed, transferred and output is achieved through a first unlocking air cylinder, a hot riveting machine, a point welding machine and a workpiece grabbing machine correspondingly. According to the assembly device, the assembly line automatic assembly of the ABS sensor head chips is achieved, all procedures are combined, transferring and storing of ABS sensor skeleton workpieces between the procedures are avoided, the assembly efficiency and the quality of the chips are improved, and the reducing of the cost of manpower and material resources is facilitated.

Owner:SHANGHAI AEROSPACE AUTOMOBILE ELECTROMECHANICAL CO LTD

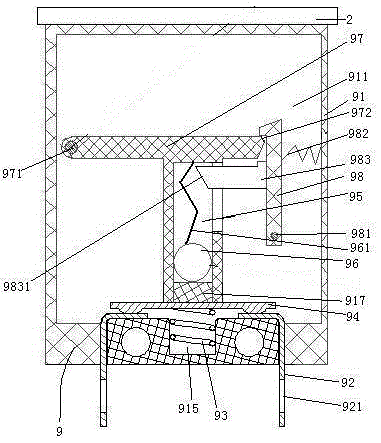

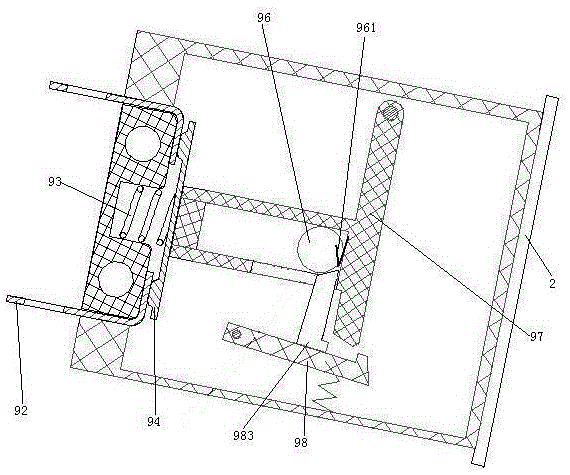

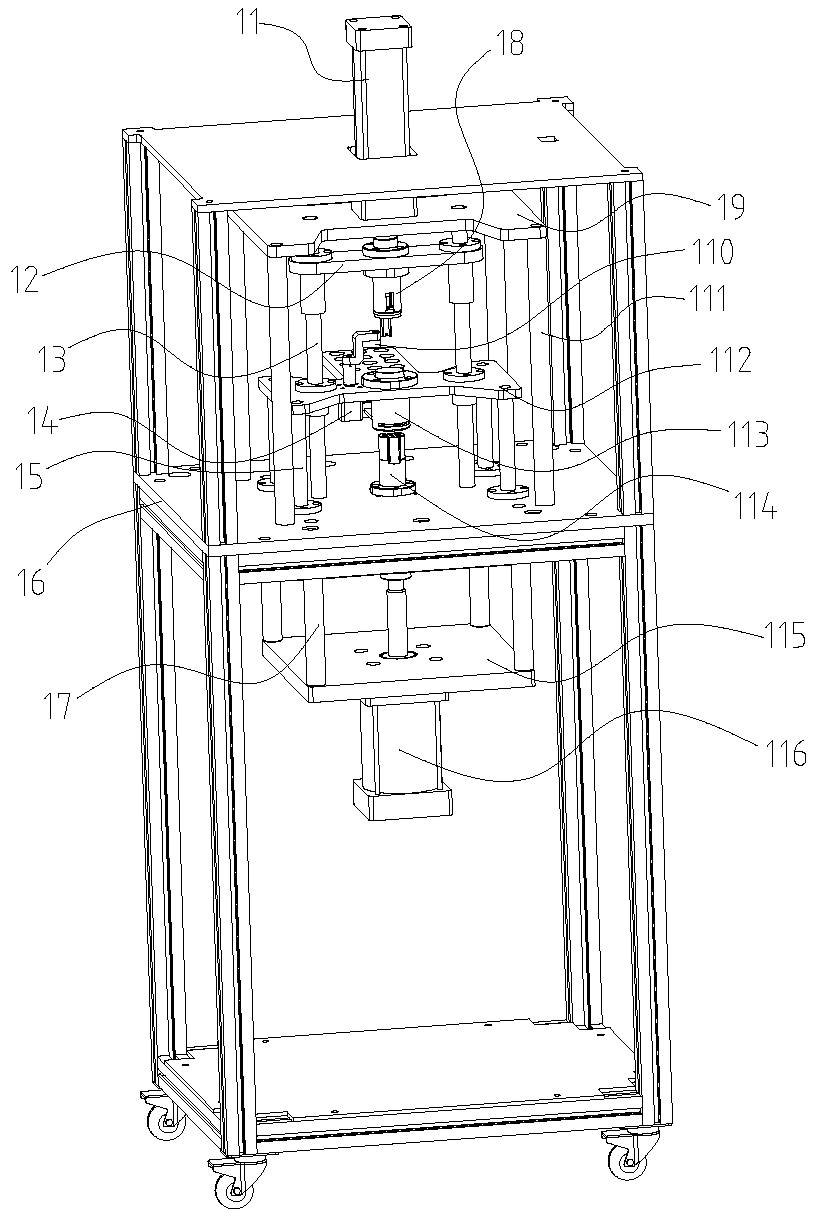

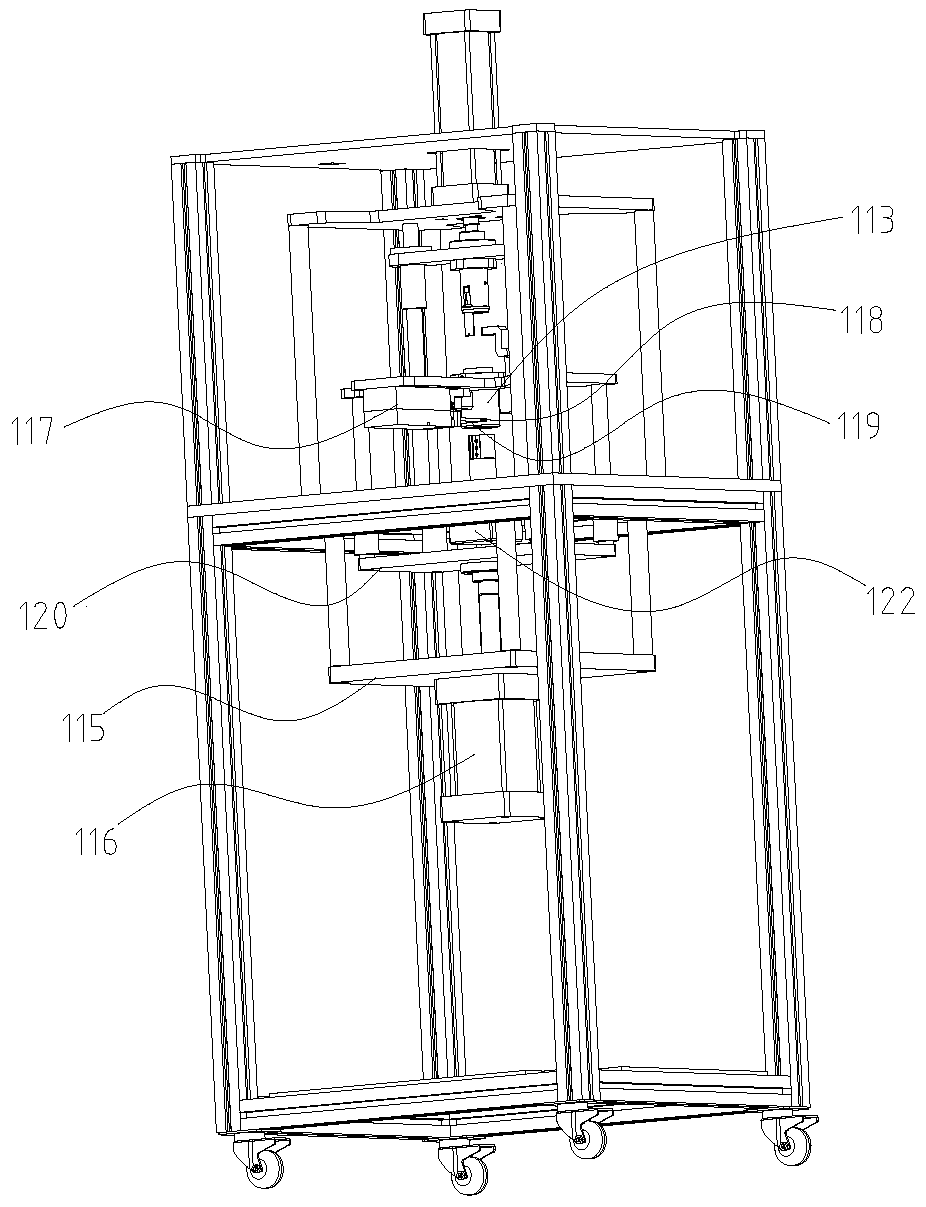

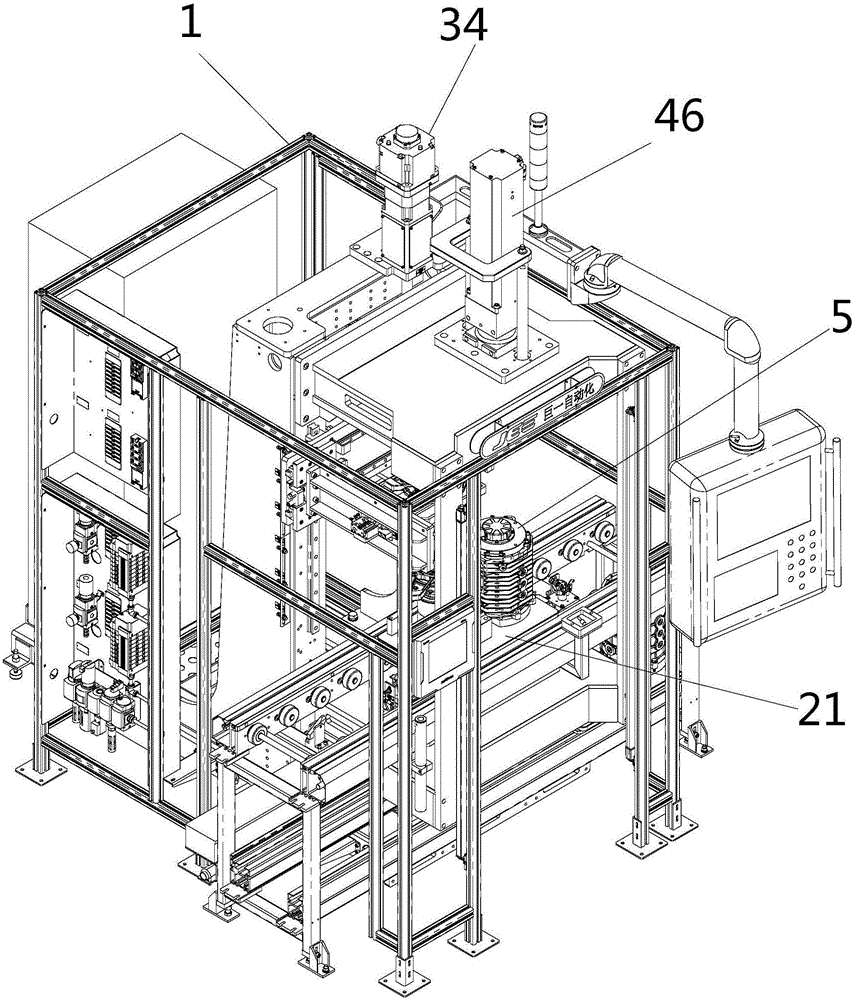

Stator and rotor assembling equipment in new energy motor assembly

The invention discloses stator and rotor assembling equipment in the new energy motor assembly. The stator and rotor assembling equipment comprises a machine body, wherein a double-layer lifting positioning mechanism, a rotor clamping displacement mechanism, a stator tight holding mechanism and a press mounting mechanism are arranged on the machine body; wherein the double-layer lifting positioning mechanism comprises a movable tray and a fixed bottom plate in vertical arrangement; a rotor installing position and a stator installing position are arranged in parallel on the movable tray; the rotor lamping displacement mechanism comprises a vertical sliding installing seat, a transverse sliding installing seat and a holding claw assembly; the press mounting mechanism comprises a press head and an upper center; the upper center is vertically arranged in a cavity of the center of the press head; the upper part of the upper center is provided with an annular position limiting lug boss; the upper end of the upper center is provided with a spring in a sleeving way. The stator and rotor assembling equipment has the advantages that the upper end and the lower end of the rotor are simultaneously jacked by the upper center and the lower center to do synchronous descending along with the press head through being driven by an electric cylinder until the assembly is in place; the stator and rotor assembly concentricity is ensured; the influence of the magnetic force between the stator and the rotor on the assembly is overcome.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Working method of assembling device for medical one-off oxygen humidification bottle

The invention provides a working method of an assembling device for a medical one-off oxygen humidification bottle. The assembling device comprises a humidifying plug charging device, a transferring device, a ventilating pipe charging device, a ventilating pipe assembling device, a first assembling device, a second assembling device and a third assembling device, wherein the ventilating pipe charging device comprises a material box, a first conveyor belt, a charging block and an aligning assembly; the bottom part of the material box is obliquely arranged; a plurality of charging strips are arranged on the first conveyor belt; charging grooves are obliquely formed in the middle part of the charging block; the aligning assembly comprises an aligning motor, an aligning block and four aligningstrips; the cross section of the aligning block is of a rectangular structure, and four aligning grooves which are circumferentially distributed are formed in the aligning block; and the four aligning strips are fixedly connected to the aligning block. The method has the beneficial effects that a humidifying plug, a ventilating pipe, a connecting plug, a bottle body and a bottle cap can be automatically assembled, so that the product production cost is decreased; and the difficulty in production of the one-off oxygen humidification bottle can be increased.

Owner:王槐照

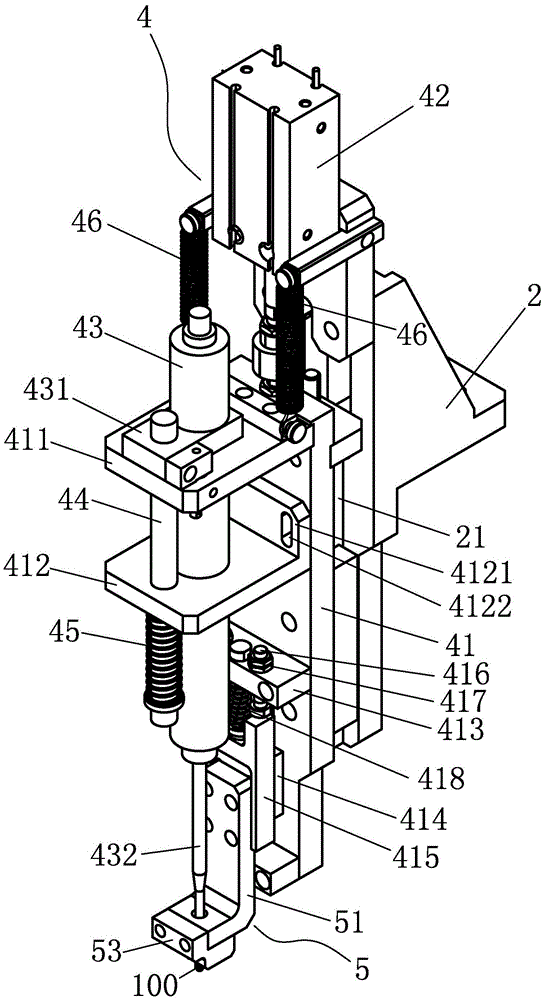

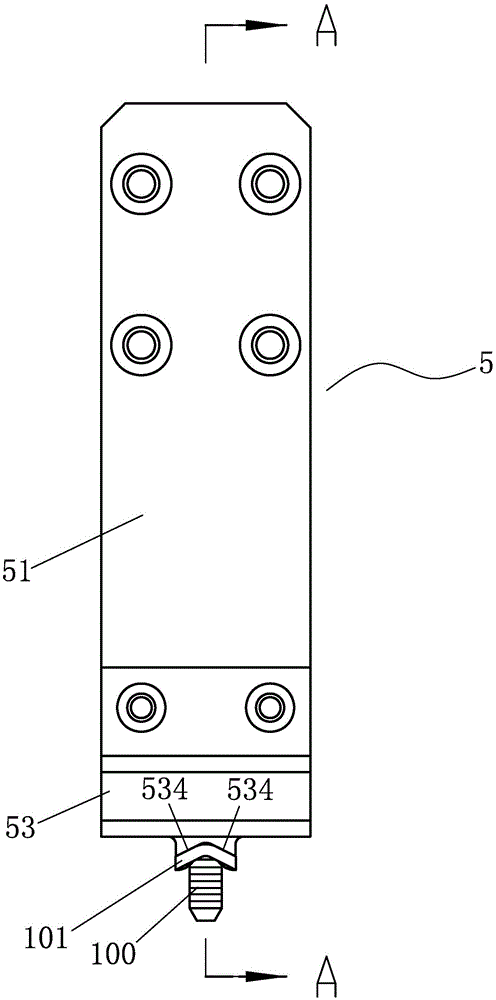

Pickup and locking device for screws

ActiveCN105564987ARealize automatic lockingRealize automated assemblyConveyorsMetal working apparatusEngineeringMechanical engineering

The invention discloses a pickup and locking device for screws. Each pickup and locking device body comprises a vertical sliding block capable of vertically moving. A pneumatic screwdriver is arranged on the upper portion of each vertical sliding block. A screw pickup head is arranged on the lower portion of each vertical sliding block and comprises an L-shaped connecting block, a pickup block and a locating block. The upper ends of the L-shaped connecting blocks are connected with the vertical sliding blocks. The lower portions of the lower ends of the L-shaped connecting blocks are connected with the pickup blocks. The lower portions of the pickup blocks are connected with the locating blocks. The pickup blocks are sleeved with magnetic steel. First vertical through holes are formed in the lower ends of the L-shaped connecting blocks. Second vertical through holes are formed in the pickup blocks. Third vertical through holes are formed in the locating blocks. The first vertical through holes, the second vertical through holes and the third vertical through holes communicate with one another so that the lower ends of rotary shafts of the pneumatic screwdrivers can stretch into the second vertical through holes. The heads of the screws are located by the lower end faces of the pickup blocks and the inner circumferential faces of the third vertical through holes. Automatic pickup and locking of the screws are achieved, automatic assembling of the screws can be achieved, and the assembling efficiency of the screws can be improved.

Owner:XIAMEN HONGFA IND ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com