Liquid crystal display device, and frame unit and liquid crystal panel alignment method thereof

A technology of a liquid crystal display device and a liquid crystal panel, which is applied in the field of liquid crystals, can solve the problems of increasing the thickness of the frame of the liquid crystal display device, the inability to realize the design of the ultra-narrow frame, and the unfavorable automatic assembly of the liquid crystal display device, etc., so as to realize the ultra-narrow frame and realize automation Assembly, thickness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

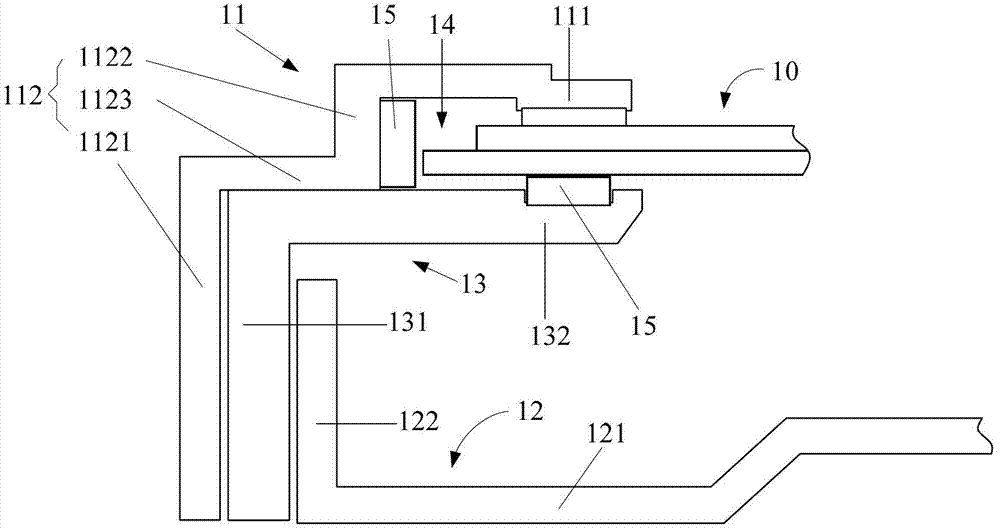

[0022] Example 1, please refer to figure 1 , figure 1 It is a partial structural schematic diagram of a liquid crystal display device using a frame unit according to an embodiment of the present invention.

[0023] In this embodiment, the liquid crystal display device includes a liquid crystal panel 10 and a frame unit, and the frame unit includes but not limited to a front frame 11 and a back panel assembly 12 .

[0024] Specifically, there may be one or more front frames 11 , which include a connected cover plate 111 and a retaining wall 112 . The cover plate 111 abuts against the upper surface of the liquid crystal panel 10 , and its bottom surface can be arranged parallel to the upper surface of the liquid crystal panel 10 to achieve a better fixing effect. The retaining wall 112 may be perpendicular to the cover plate 111, and the retaining wall 112 elastically abuts against the side of the liquid crystal panel 10. Further, the retaining wall 112 may include a first ret...

Embodiment 2

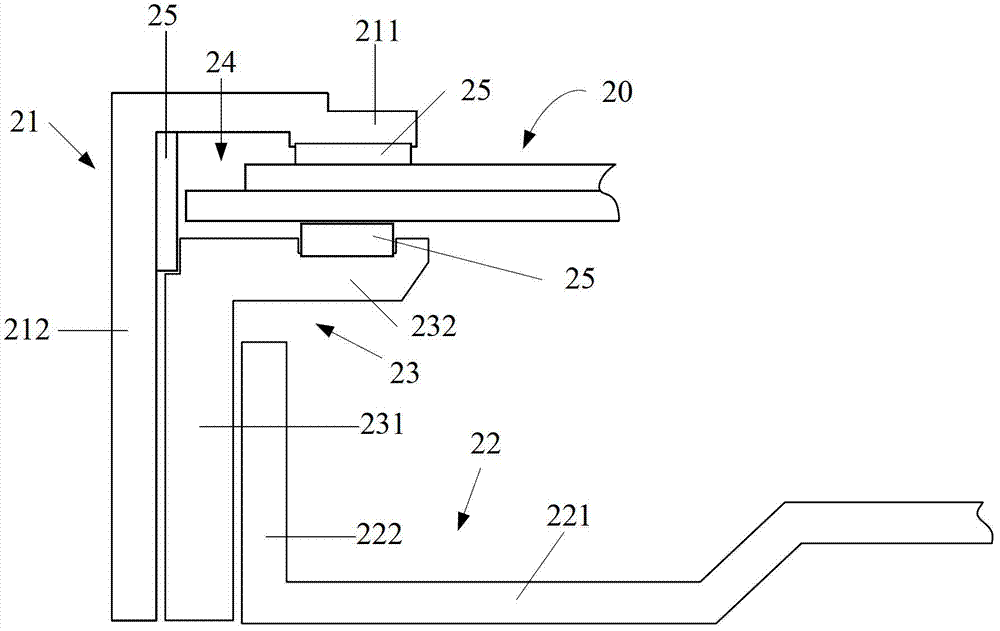

[0030] Example 2, please refer to figure 2 , figure 2 It is a partial structural schematic diagram of a liquid crystal display device adopting another embodiment of the frame unit of the present invention.

[0031] In this embodiment, the liquid crystal display device includes a liquid crystal panel 20 and a frame unit, and the frame unit includes but not limited to a front frame 21 and a back panel assembly 22 .

[0032] The front frame 21 includes a cover plate 211 and a retaining wall 212 which can be vertically arranged, and the back plate assembly 22 includes a bottom plate 221 and a side plate 222 which are connected. It should be pointed out that: the difference between the second embodiment and the first embodiment is that the retaining wall 212 in the second embodiment is arranged parallel to the vertical part 231 and the side plate 222, and does not form a ladder shape as in the first embodiment, that is to say, the retaining wall 212 The wall 212 is not configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com