Irregular-shaped radiating fin automatic assembling device

An assembly device and heat sink technology, applied in other manufacturing equipment/tools, metal processing machinery parts, metal processing, etc., can solve the problems of complex structure of special-shaped heat sinks, affecting productivity, affecting the quality of workpiece assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

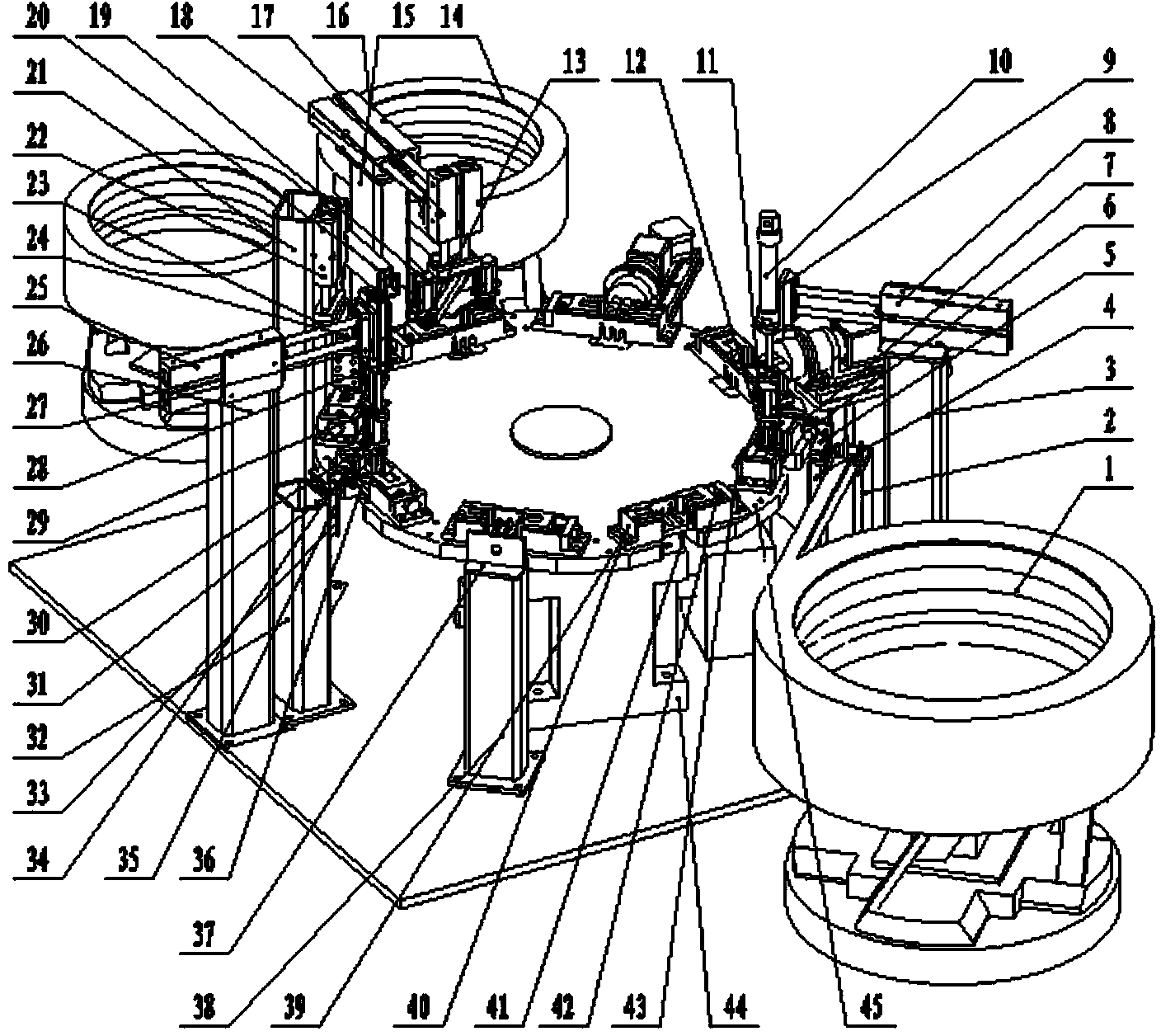

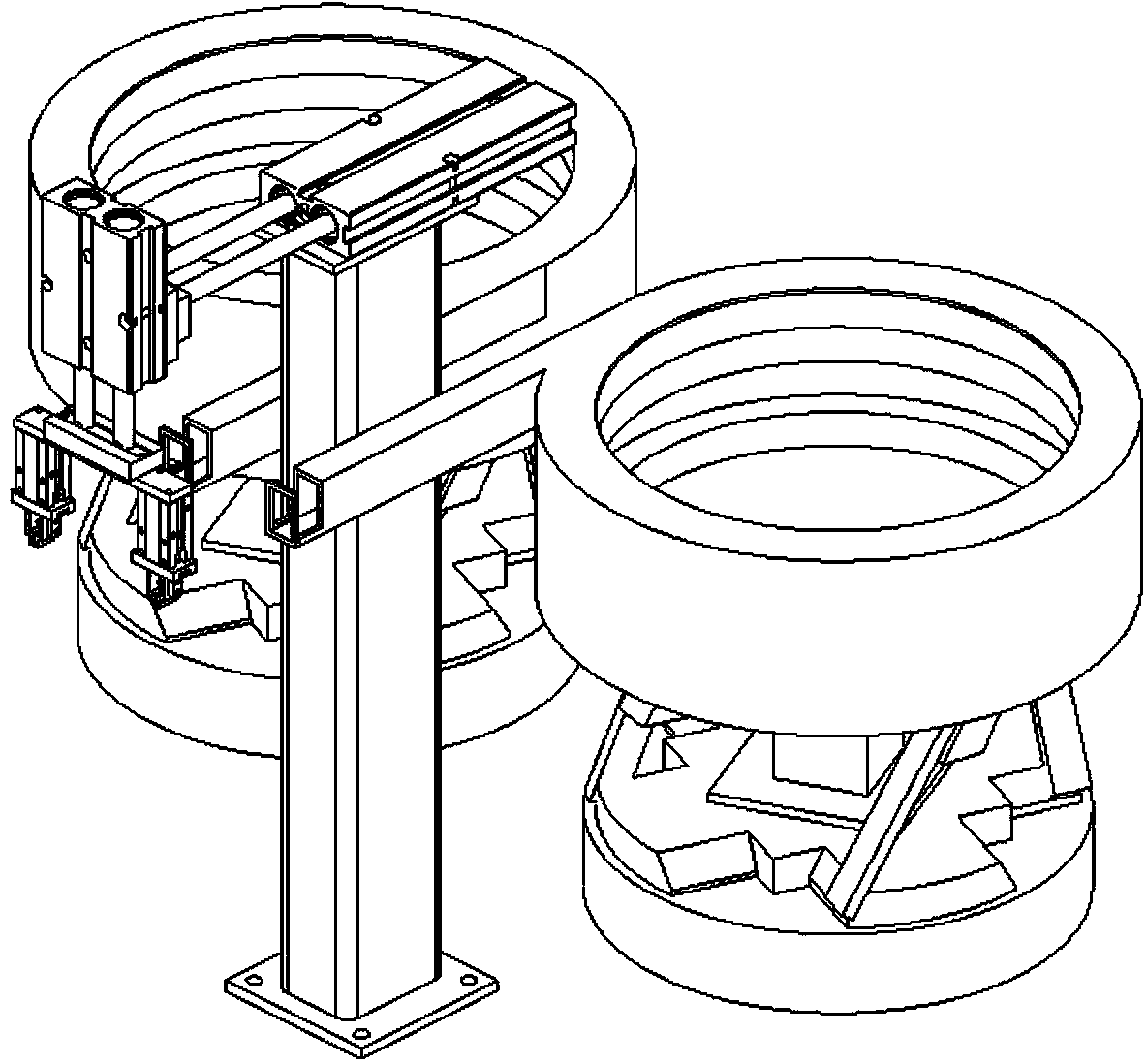

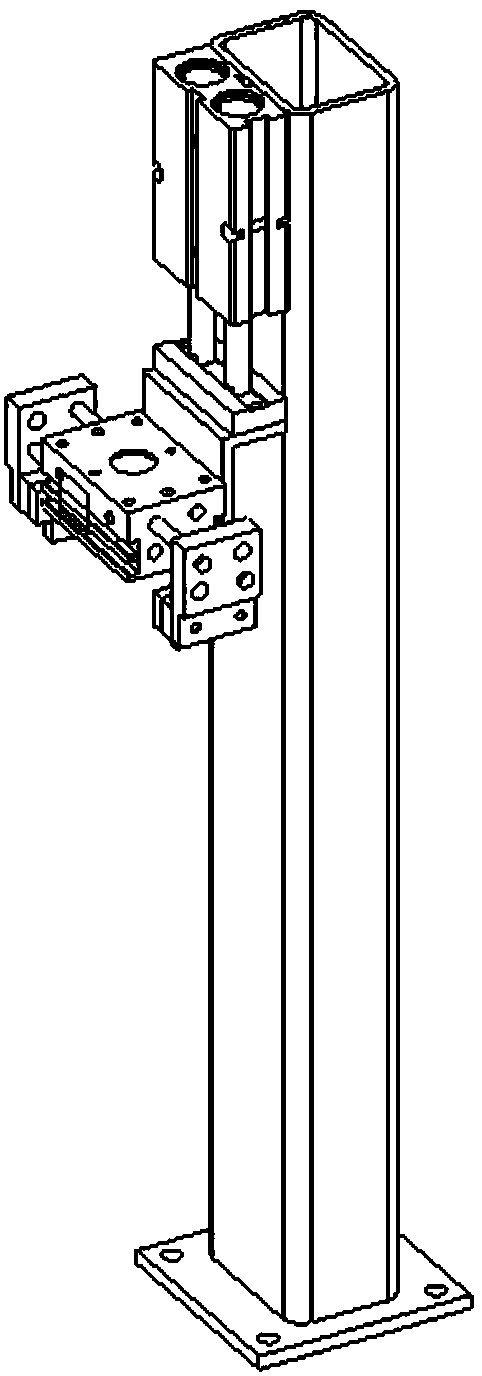

[0012] An automatic assembly device for special-shaped heat sinks is composed of a fixed base plate 48, a divider 44, a turntable 45, a feeding mechanical mechanism, a drilling mechanism 46, a tapping mechanism 47, a welding needle feeding mechanism, a welding needle clamping mechanism, an outlet The feeding mechanism consists of a feeding mechanism, a chip removal mechanism and a fixture. The feeding mechanism consists of a large vibrating plate 1, a feeding top manipulator support 2, a feeding manipulator support 3, a feeding jacking cylinder 4, a feeding top connecting block 5, and a Material top cylinder 6, feed top cylinder rod 7, feed forward cylinder 8, feed connection block 9, feed vertical cylinder 10, feed small air claw 11, feed fixture 12; welding needle feeding mechanism consists of welding needle Feed air claw 13, welding needle vibrating plate 14, welding needle manipulator support 15, welding needle forward cylinder 16, welding needle vertical cylinder 17, weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com