Automatic assembly equipment for LED (Light-Emitting Diode) bulb lamp

An LED bulb lamp and automatic assembly technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of inability to automate large-scale production, low production efficiency, and low product quality, and achieve large-scale automation The effect of large-scale production, reduction of waste generation rate, and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Attached below figure 1 to attach Figure 13 , and specific embodiments will further illustrate the present invention.

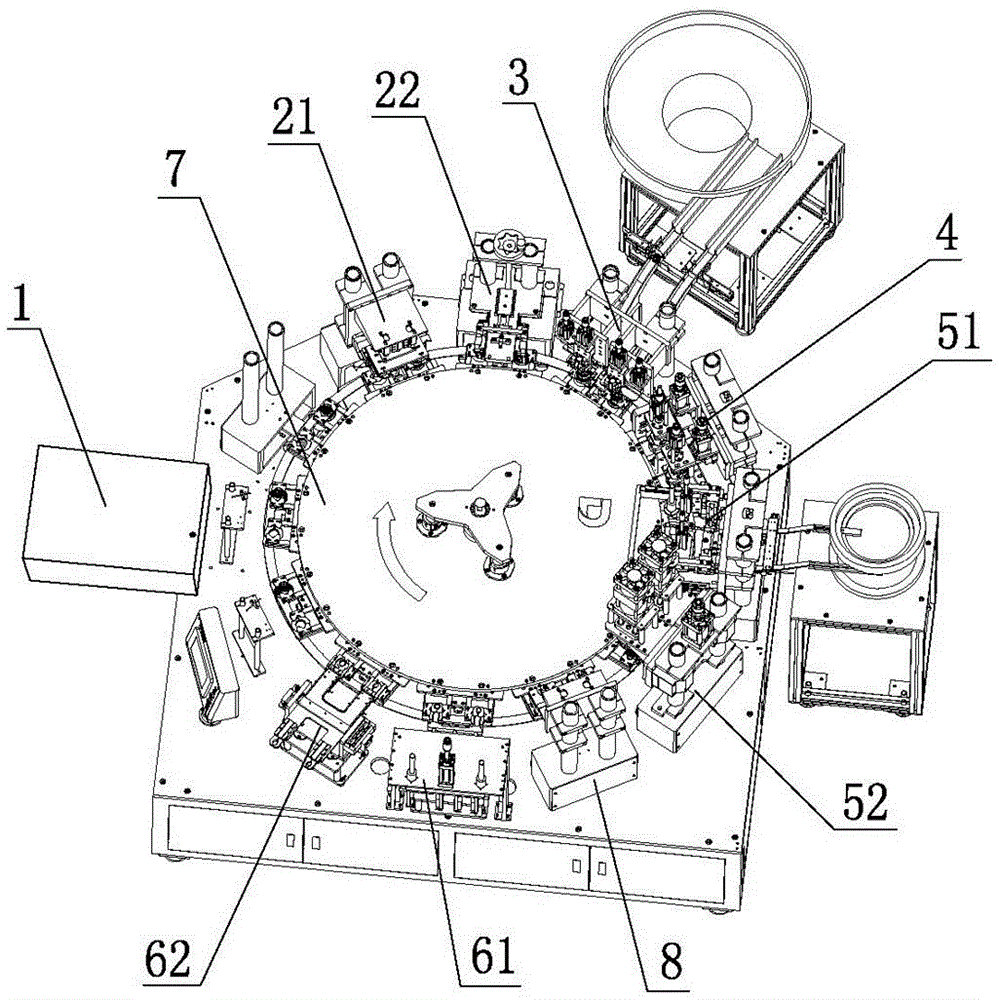

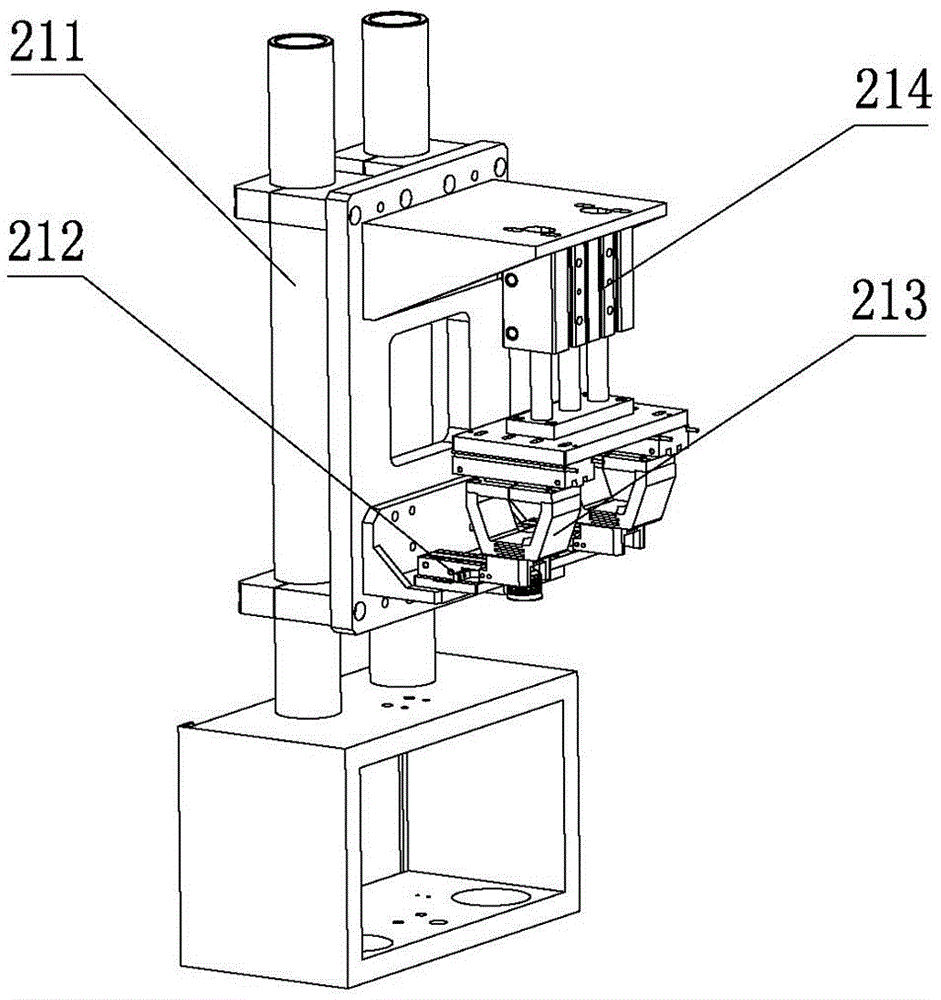

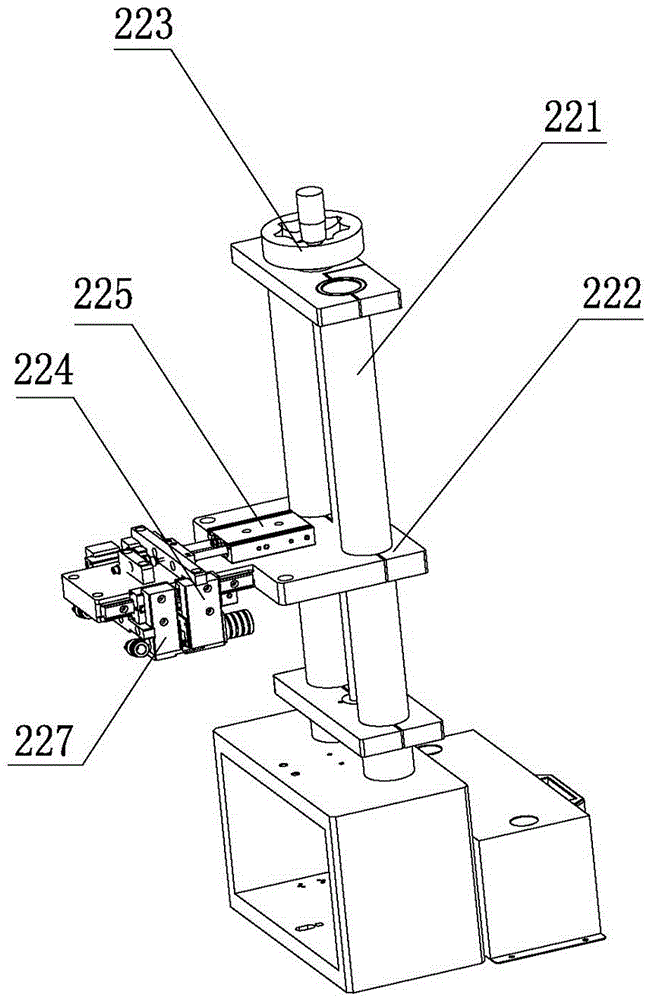

[0030] Such as figure 1 As shown, an automatic assembly equipment for LED bulb lamps, including a lamp holder feeding device 1, a wire management device for arranging the wires on the lamp holder, a lamp holder installation device for installing the lamp holder on the lamp holder 3, folding the wires A curved wire bending device 4, a lamp nail installation device for installing lamp nails at the upper end of the lamp cap, a material unloading device and a transmission device 7 for transferring the lamp holder between each device, and the wire management device includes a wire management mechanism 21 and The thread trimming mechanism 22, the lamp nail installation device includes a lamp nail feeding mechanism 51 and a riveting mechanism 52 for fixedly connecting the lamp nail with the lamp holder.

[0031] After the lamp holder in this embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com